Lossless clamp of steel wire rope

A steel wire rope and clamp technology, applied in the field of wire rope tensile test clamps, can solve the problems of easy loss, complicated operation, extrusion of steel wire rope cores, etc., and achieve the effect of reducing the number of parts, reducing the number of installations, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

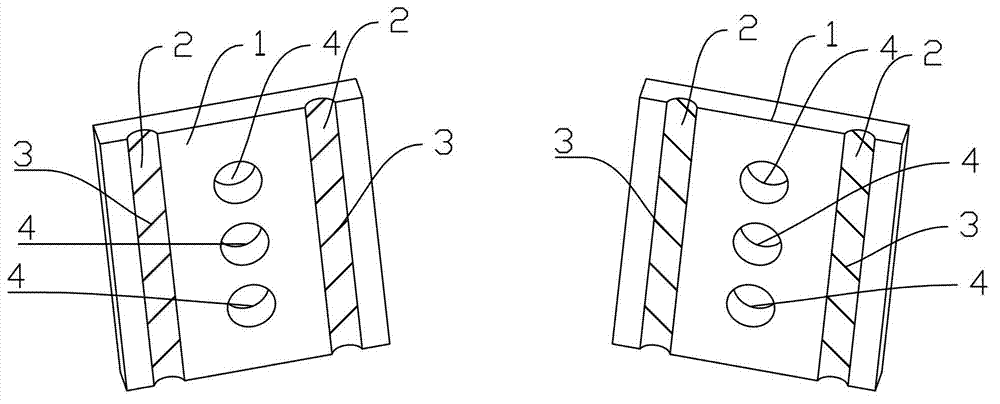

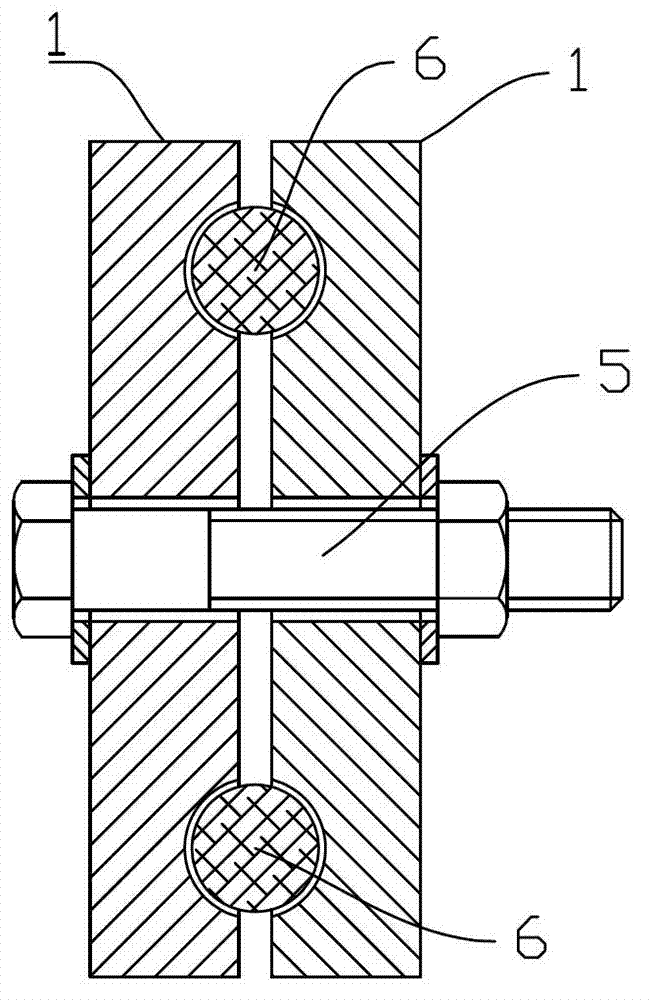

[0018] Embodiment one: if figure 1 As shown, the wire rope non-destructive fixture includes two splints 1 and connecting bolts 5 for connecting the two splints together.

[0019] The two splints 1 are respectively provided with a clamping working surface; the clamping working surfaces of the two splints are respectively provided with two arc-shaped concave linear clamping grooves 2 adapted to the outer surface of the steel wire rope, and the clamping grooves on the same clamping plate 2 are parallel to each other; the spacing between the clamping grooves on one splint is equal to the spacing between the clamping grooves on the other splint; the sum of the depths of the corresponding two clamping grooves 2 on the two splints 1 is less than diameter; the two splints 1 are correspondingly provided with a plurality of connecting holes 4 for matching with connecting bolts 5 .

[0020] In the jig, a plurality of connection holes 4 on each splint 1 are arranged in a row, and are loc...

Embodiment 2

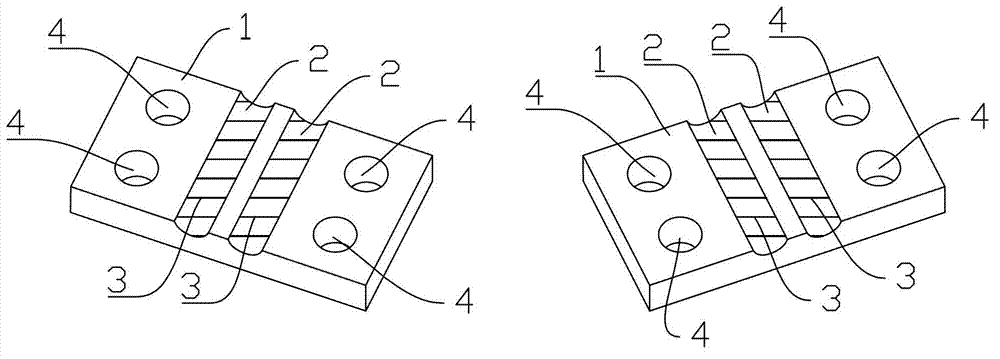

[0026] Embodiment two: if image 3 As shown, the difference from the first embodiment is that the connection holes 4 on each splint 1 in this embodiment are in two rows, and the two clamping grooves 2 are located between the two rows of connection holes 4 .

[0027] In addition, in order to ensure that the test obtains correct comparison data, the size of the splint 1 in this embodiment is 110 mm in length, 120 mm in width, and 15 mm in thickness. The axial direction along the clamping groove is the length direction.

[0028] All the other technologies are the same as in Embodiment 1.

Embodiment 3

[0029] Embodiment three: as Figure 4 As shown, the difference from Embodiment 1 is that in this embodiment, there are three connecting holes 4 on each splint 1, which are respectively located on both sides of the two clamping grooves 2 and between the two clamping grooves 2. .

[0030] During manufacture, the size of each splint 1 of the jig is 110 mm in length, 60 mm in width, and 15 mm in thickness; the axial direction along the clamping groove 2 is the length direction.

[0031] All the other technologies are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com