Patents

Literature

81 results about "Bead embroidery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bead embroidery is a type of beadwork that uses a needle and thread to stitch beads to a surface of fabric, suede, or leather. Bead embroidery is an embellishment that does not form an essential part of a textile's structure. In this respect, bead embroidery differs from bead weaving, bead crochet, and bead knitting. Woven, knitted, and crocheted beads may be attached during fabric production, whereas embroidered beads are always added upon finished fabric.

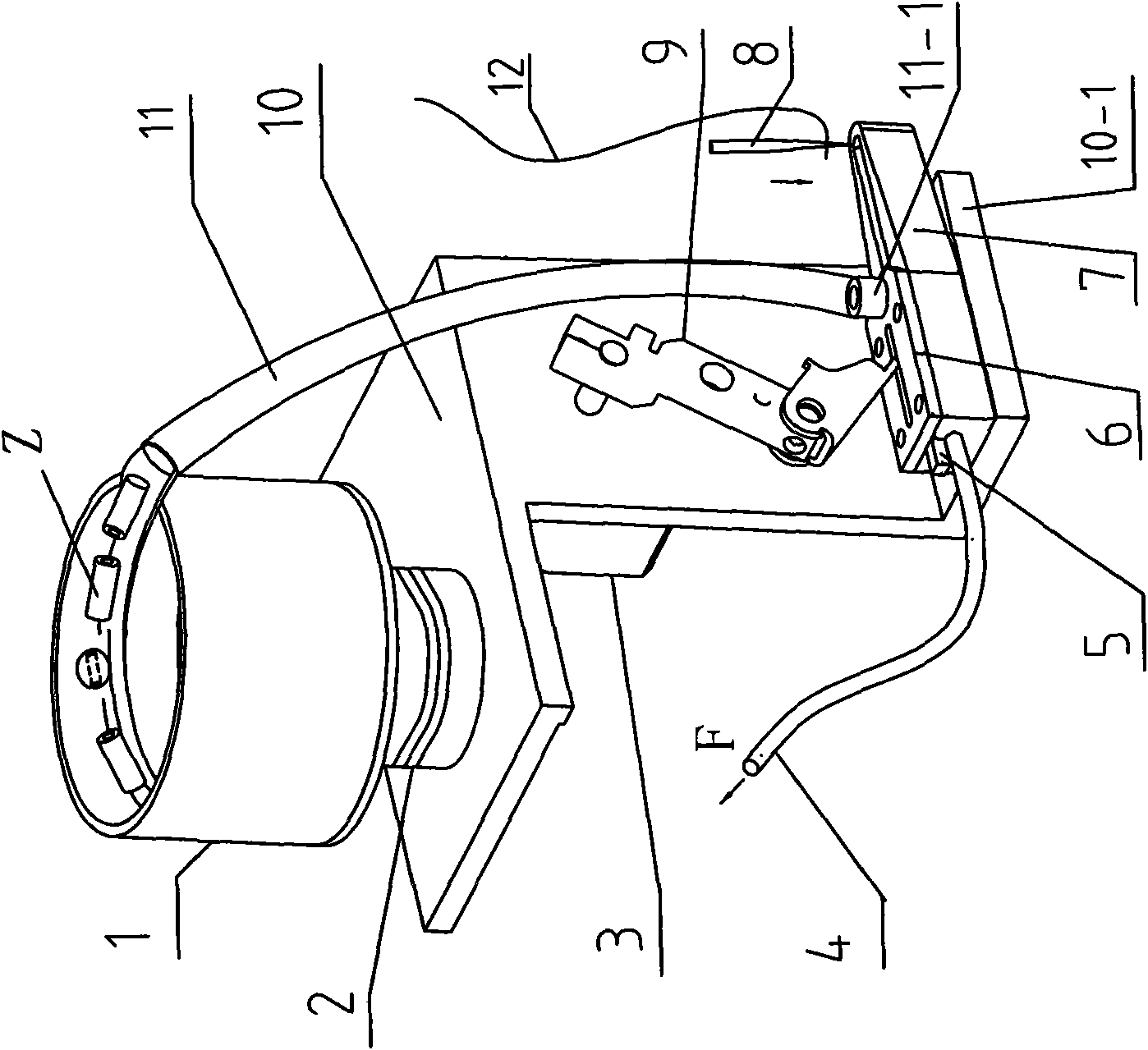

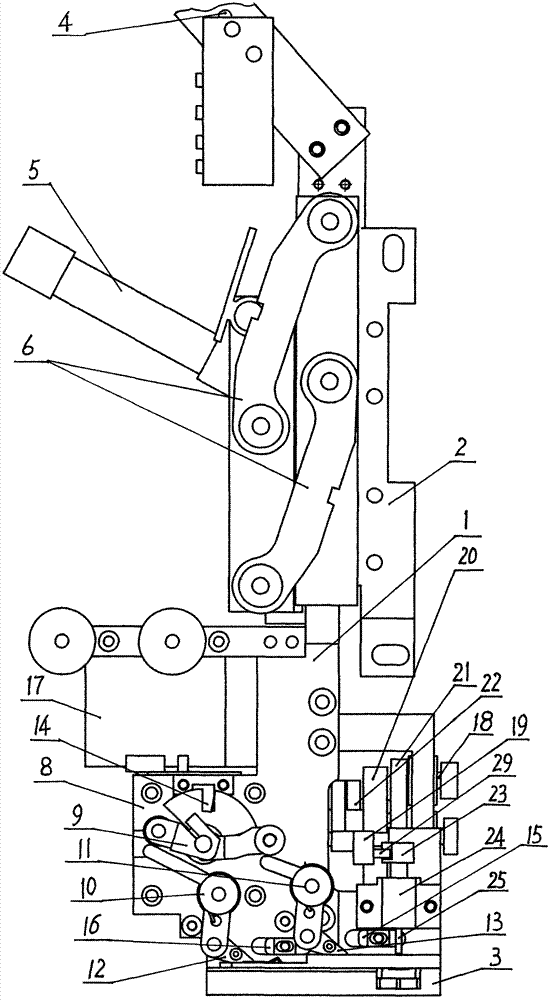

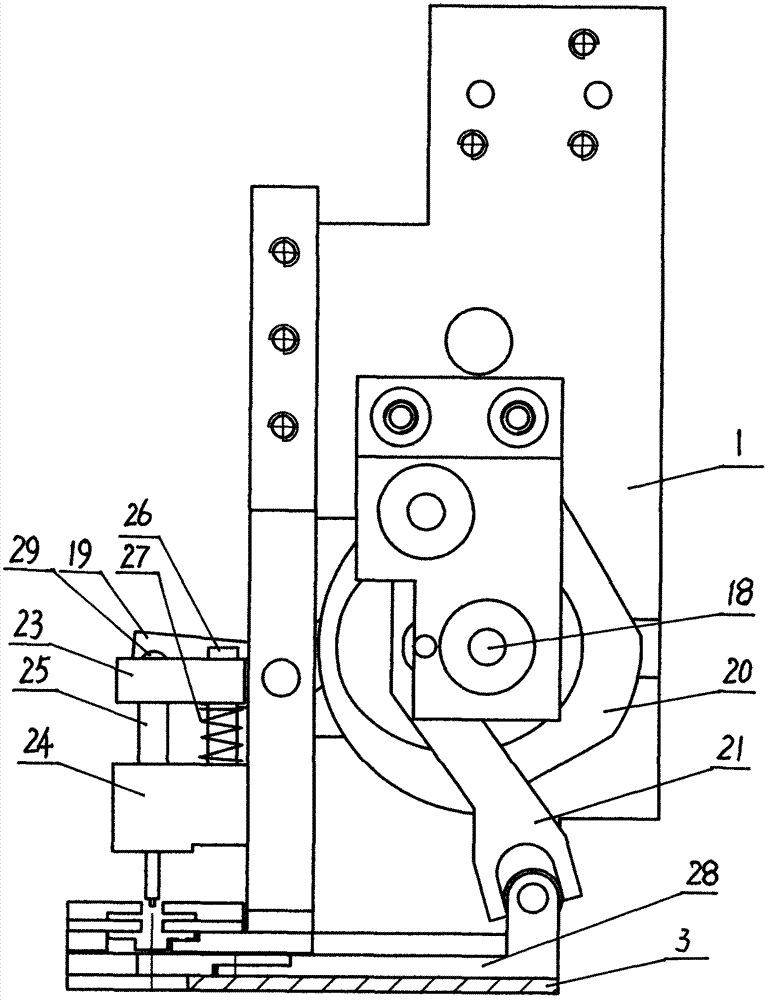

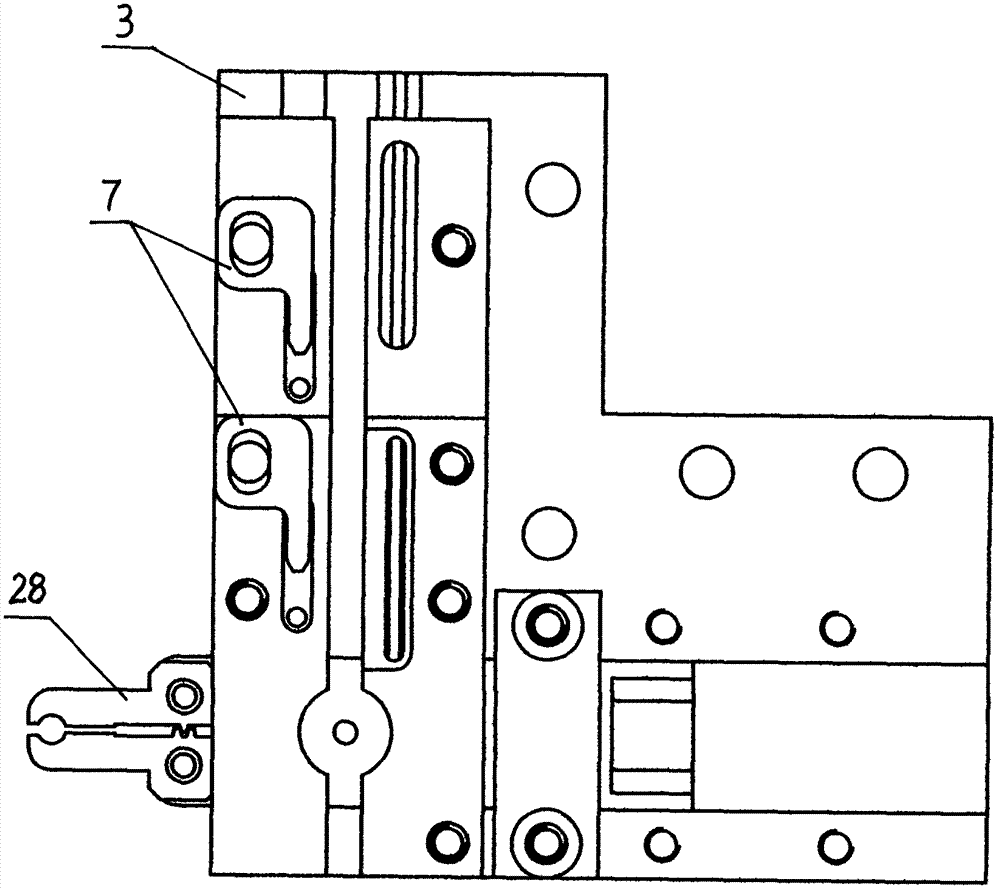

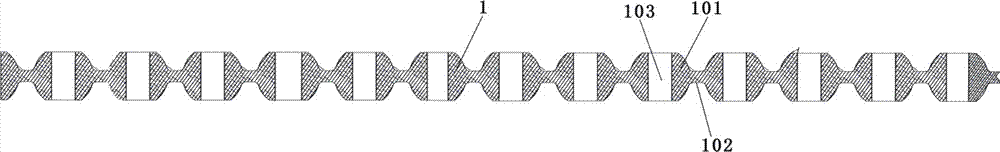

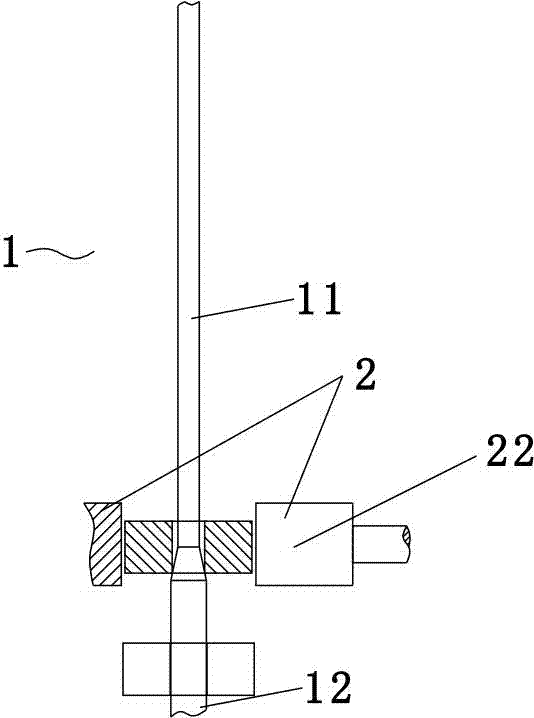

Bead embroidery embroidering machine and bead feeding method

ActiveCN103866501APrecisely throughPrecise positioningAutomatic machinesAuxillary devicesMechanical engineeringBead embroidery

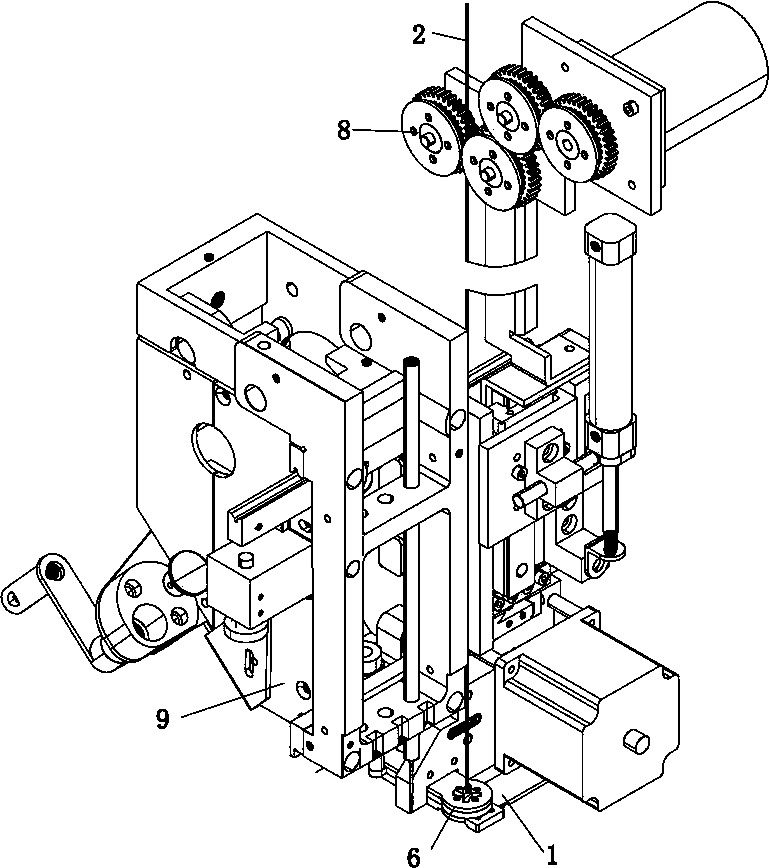

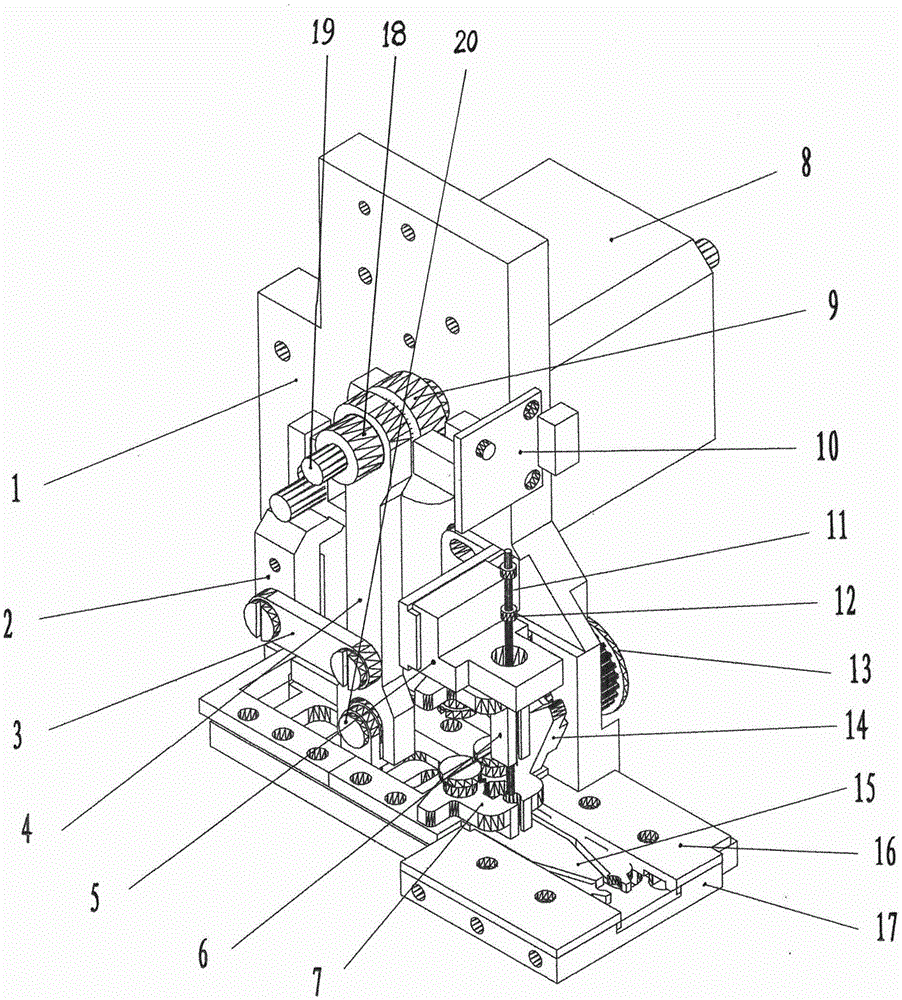

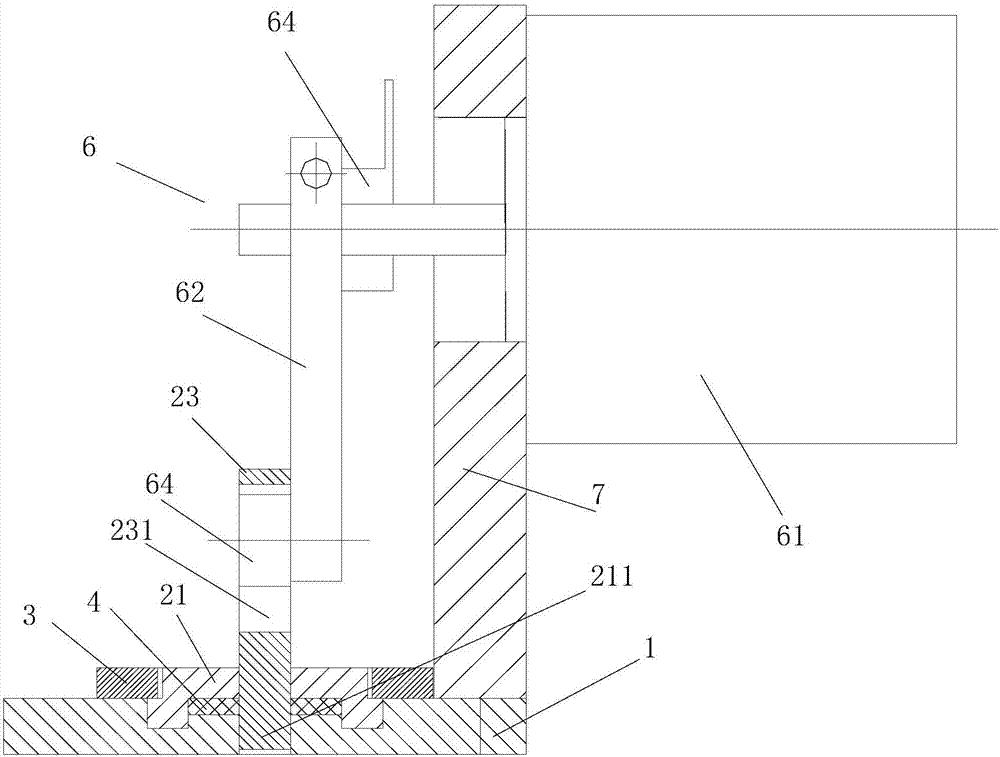

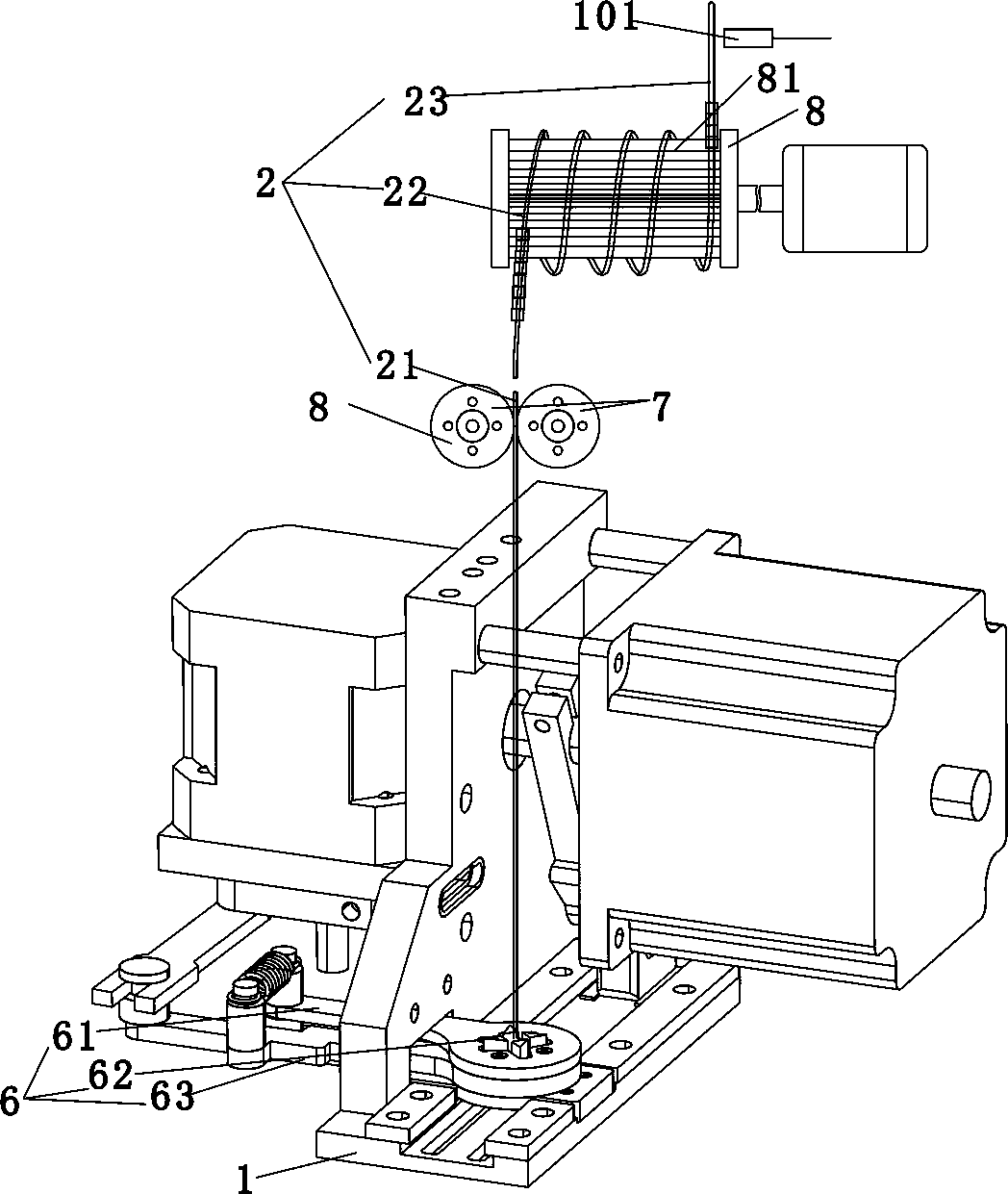

The invention discloses a bead embroidery embroidering machine. The bead embroidery embroidering machine comprises an engine body, wherein the engine body is provided with one or more than one machine head; the machine head is connected with a feeding mechanism for gradually conveying embroidery beads to a position right below an embroidering needle of the embroidering machine one by one; the feeding mechanism is provided with a clamping opening for clamping and positioning the embroidery beads; a bead guide rod for supplying the embroidery beads to the feeding mechanism is suspended above the feeding mechanism; the embroidery beads are threaded on the bead guide rod to form a bead cluster; a positioning structure for positioning the embroidery beads which need to slide to corresponding feeding positions of the feeding mechanism from the bead guide rod is further arranged above the feeding mechanism; the positioning center of the positioning structure and the positioning center of the clamping structure are concentric. The bead guide rod is provided with the bead cluster formed by the embroidery beads and the bead cluster can be continuously fed to the feeding mechanism; the bead guide rod and the positioning structure can be used for accurately positioning the embroidery beads so that the embroidery beads accurately slide into the corresponding parts of the feeding mechanism according to requirements and the embroidery beads are conveniently and accurately positioned and conveyed, and furthermore, the embroidering needle can accurately penetrate through needle holes in the embroidery beads to embroider the embroidery beads on a textile.

Owner:诸暨市化工机械厂

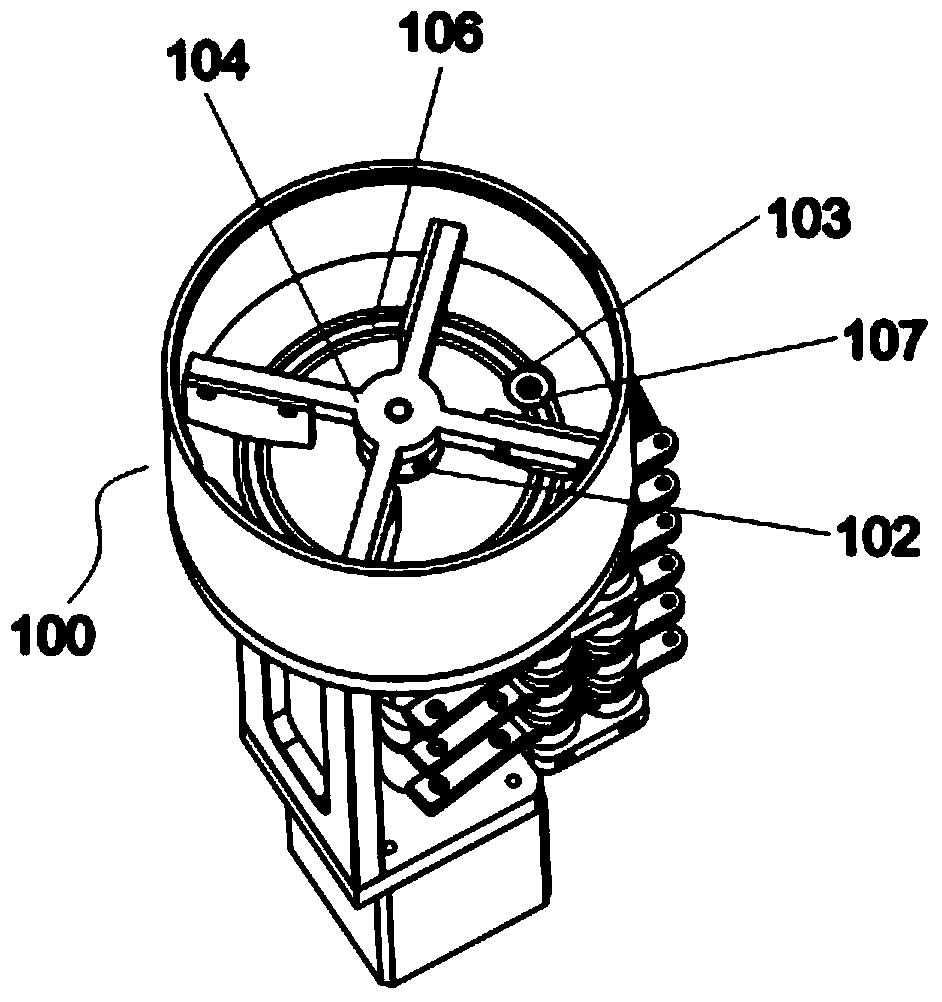

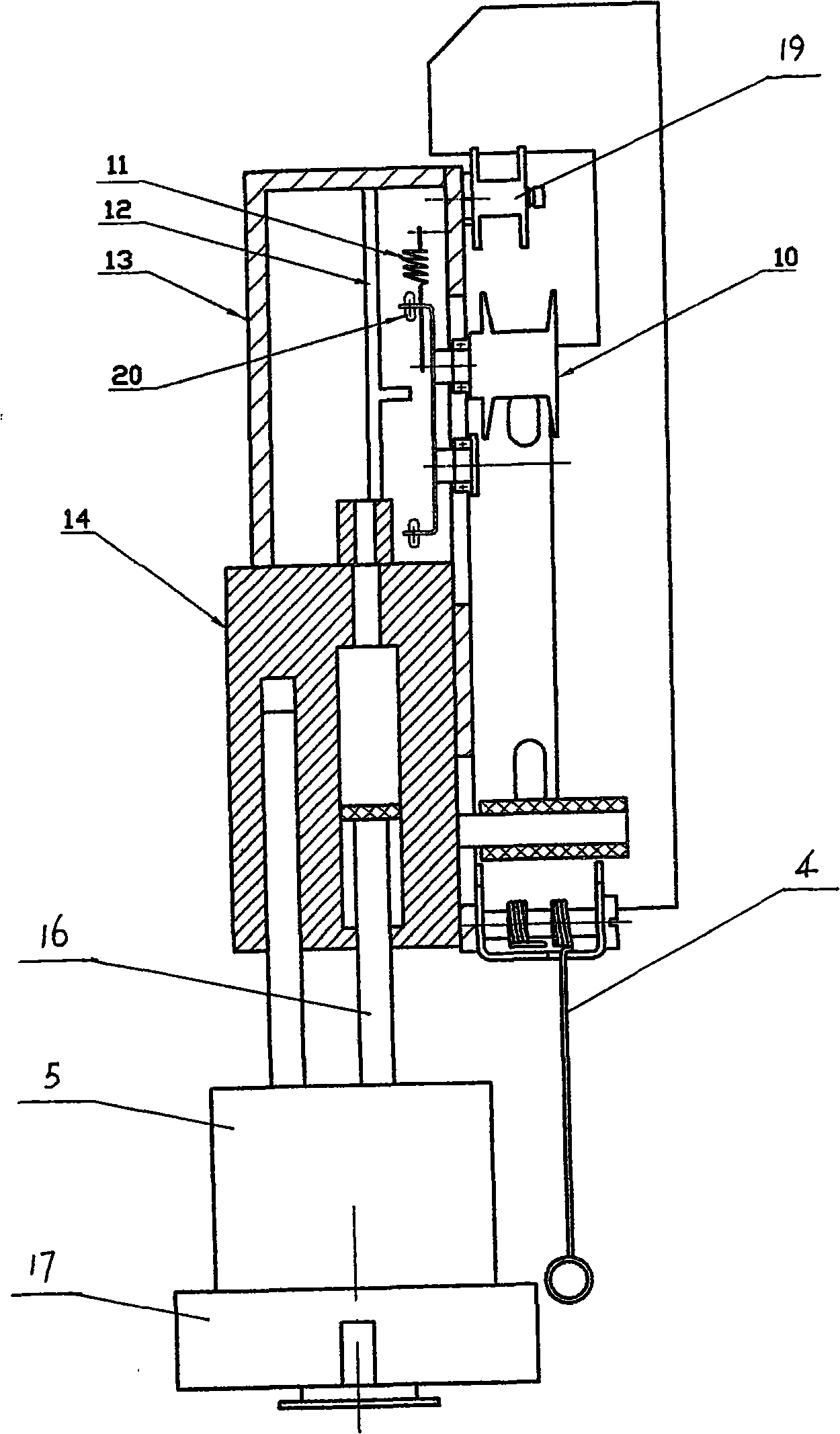

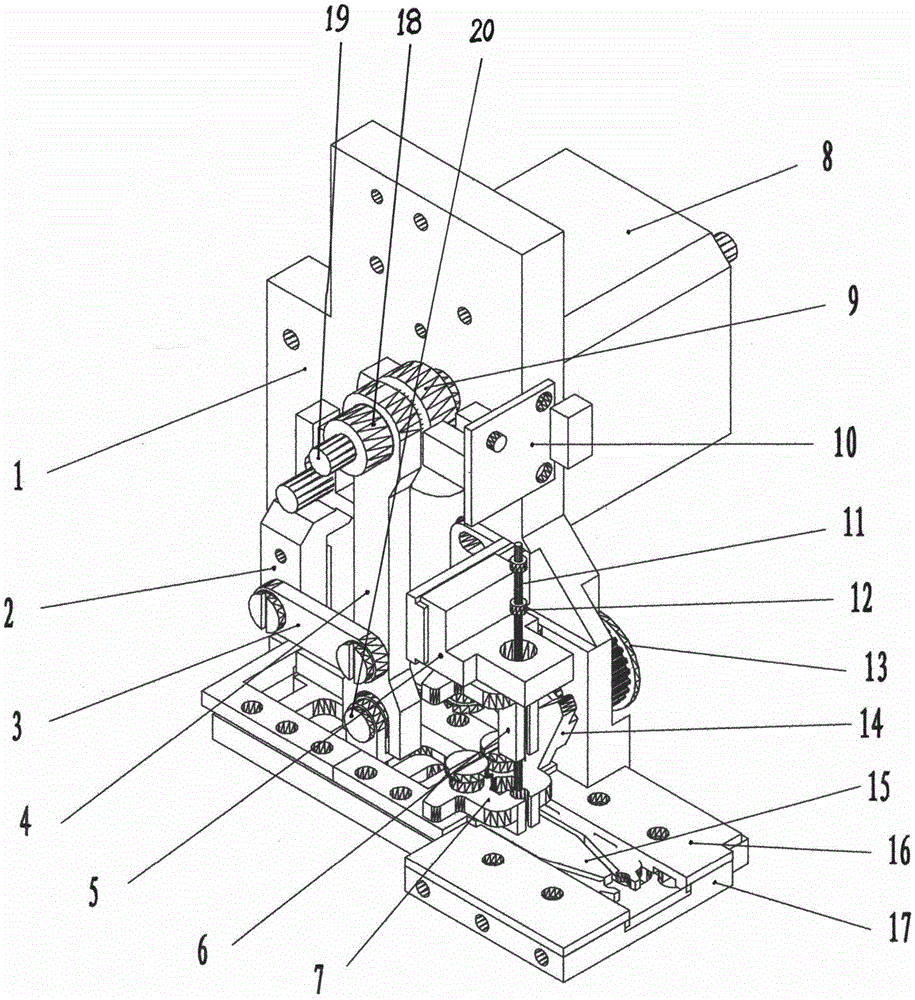

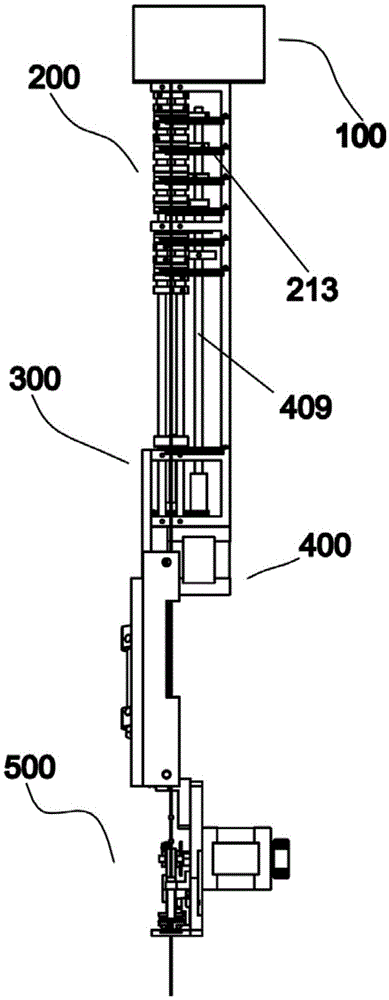

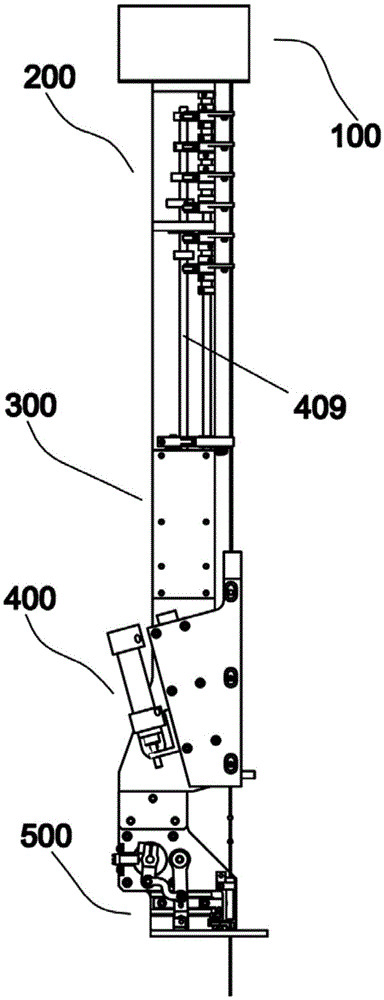

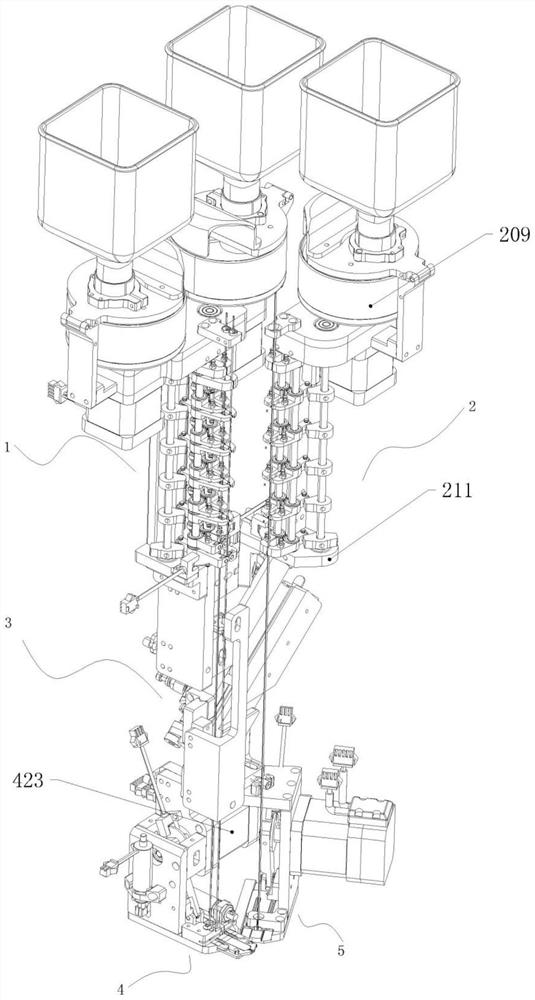

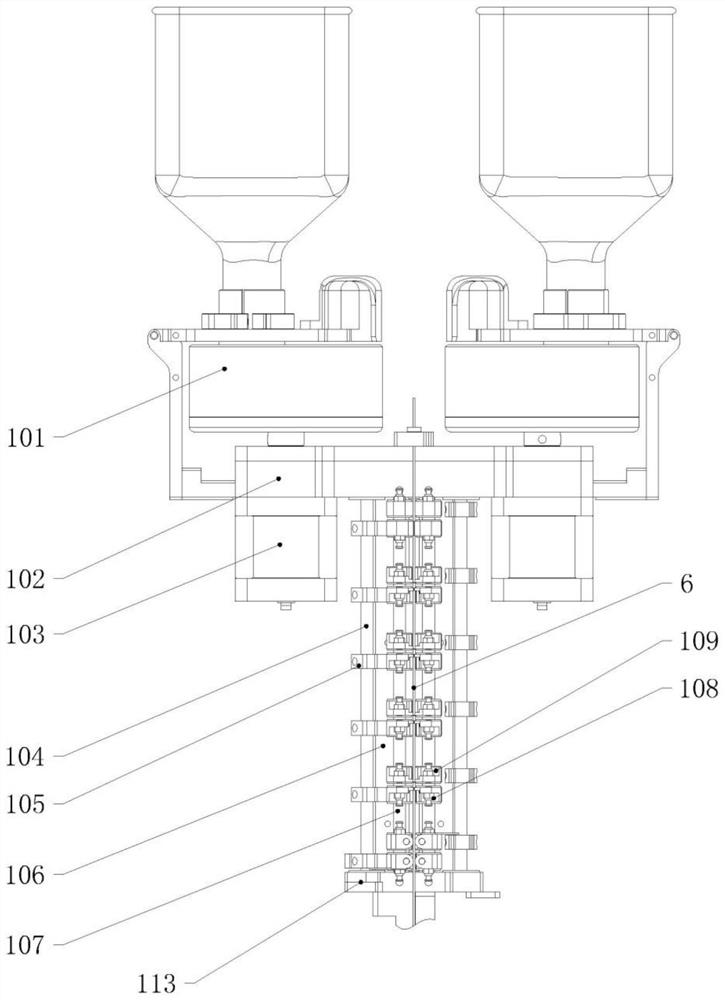

Automatic beading device of pearl embroidery

ActiveCN104213345AImprove the purpose of rowing pearlsArranged in orderAutomatic machinesAuxillary devicesWork performanceDrive shaft

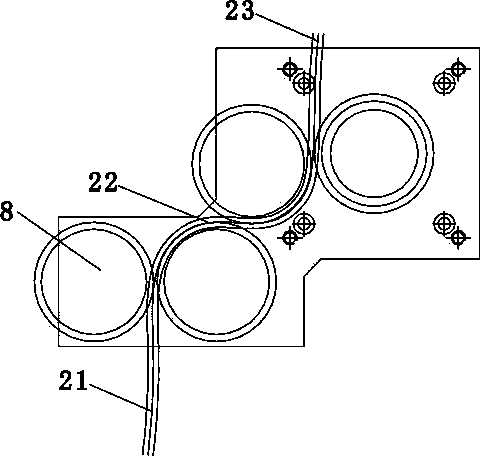

The invention discloses an automatic beading device of pearl embroidery. The automatic beading device comprises a pearl guide pole used for guiding embroidery pearls to fall and a pearl feeding mechanism. The pearl feeding mechanism comprises a frame, a power driving device, a transmission shaft and a clamping device. The power driving device is arranged at the lower end of the frame. A plurality of eccentric blocks are arranged on the transmission shaft. The clamping device comprises a plurality of clamping jaw mechanisms matched with the eccentric blocks in use. One ends of the clamping jaw mechanisms clamp the pearl guide pole, and the other ends of the clamping jaw mechanisms butt against the eccentric blocks. The power driving device drives the transmission shaft to rotate further to drive the eccentric blocks to rotate alternately, thereby opening and closing the corresponding clamping jaw mechanisms to clamp the pearl guide pole alternately so as to achieve downward conveying of the embroidery pearls. The automatic beading device has the advantages of being high in the automation degree, stable in the work performance, high in production efficiency and applicable to embroidery pearls in different size and different shape.

Owner:WENZHOU OULUOHUA INDAL

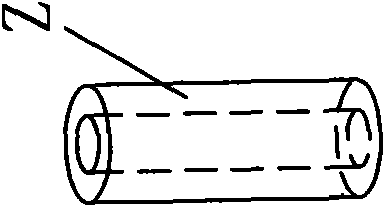

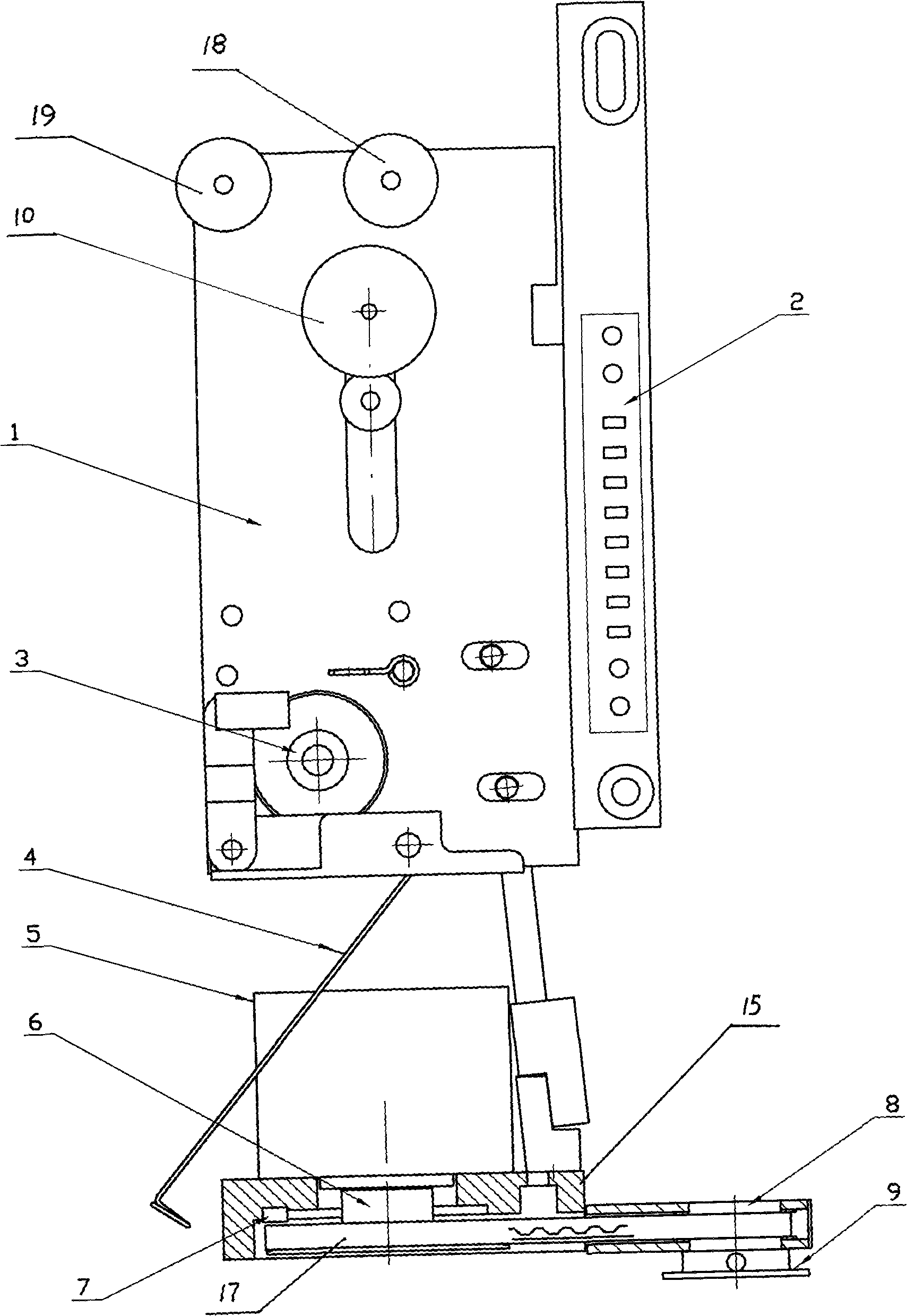

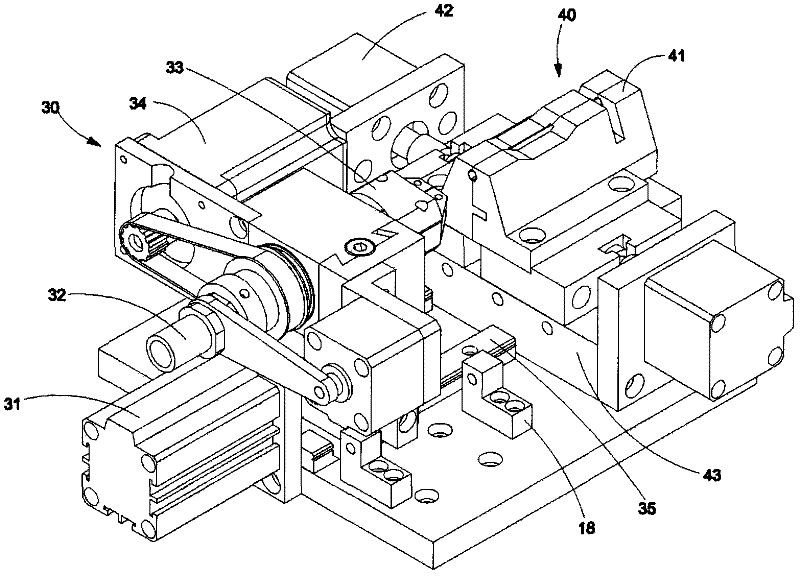

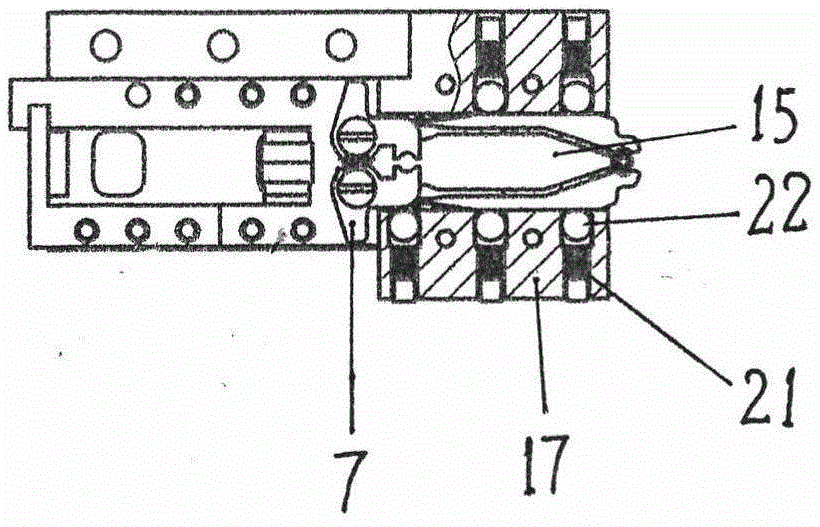

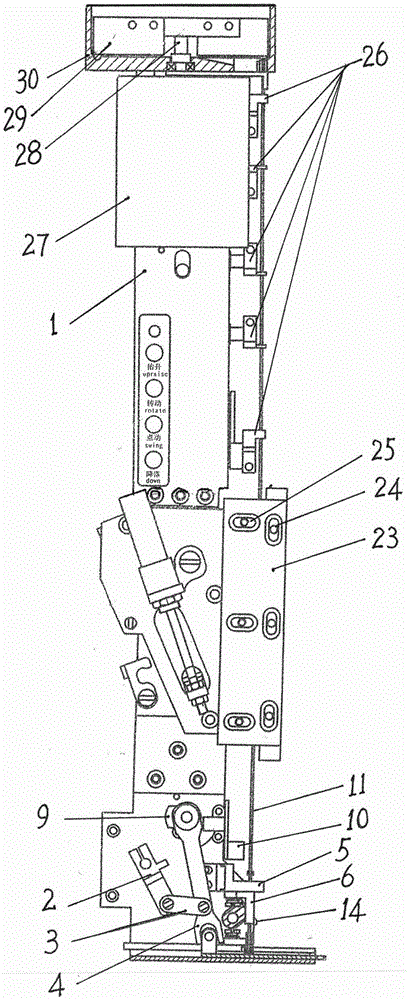

Tube-bead embroidery automatic feeding device

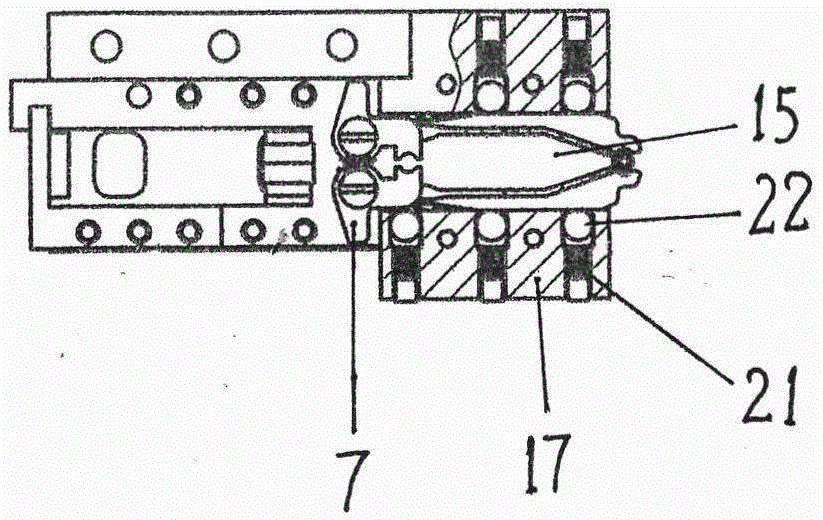

InactiveCN101603254ARealize fully automatic operationImprove sewing qualityAutomatic machinesAuxillary devicesReciprocating motionEngineering

The invention relates to an embroidering machine, and aims to provide a special sewing machine for tubes or beads, which can realize the automatic sewing of tubes or beads, and has the advantages of good sewing quality, high working efficiency and low processing cost. The technical proposal of the invention is characterized in that: the tube-bead embroidery automatic feeding device comprises a feeding device and a pushing device which is matched with the feeding device and is capable of making the straight reciprocating motion, wherein the feeding device is provided with a vibration type feeder, and a bead guide tube of the feeder is an output pipeline of tubes or beads; the pushing device faces the outlet end of the bead guide tube and is provided with a bead guide seat provided with a horizontal track, a bead pushing plate capable of making the reciprocating motion along the track, a swinging mechanism driving the bead pushing plate to move and an air suction device sucking air in a cavity in the bead guide seat through an air suction tube; and the front end of the bead guide seat is provided with a bead guide hole vertically downward, and a space is reserved between the bottom end face of the bead guide hole and the surface of the working table, so that the tubes or beads can be conveniently outputted.

Owner:ZHUJI MAYA ELECTRIC APPLIANCE MACHINERY

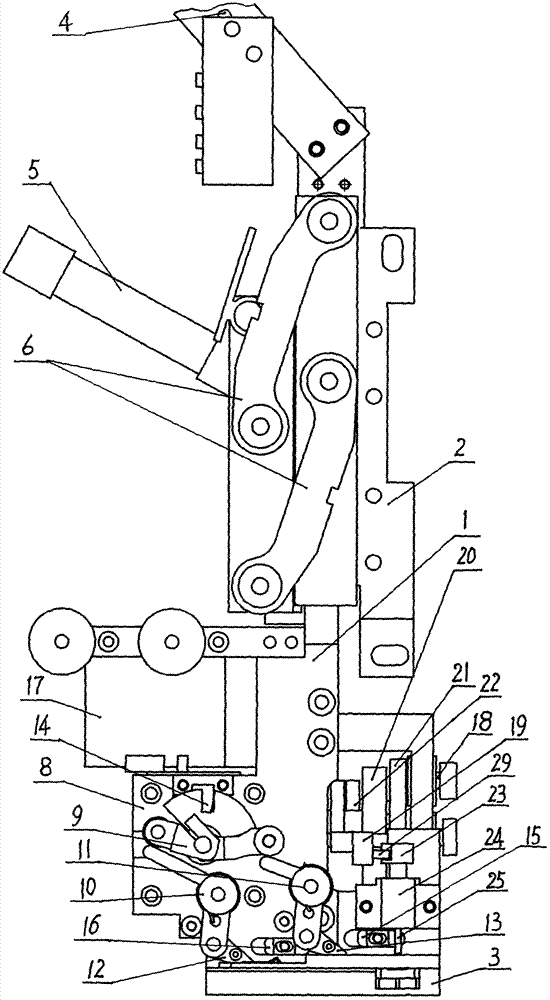

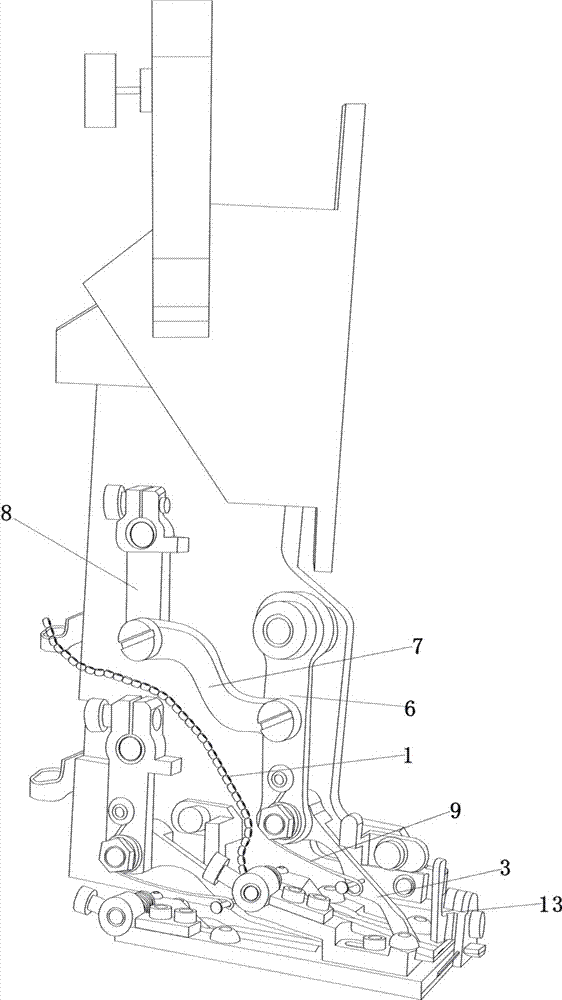

Pearl embroidery device for computerized embroidery machine

ActiveCN104514104ASimple structureEasy maintenanceAutomatic machinesAuxillary devicesRejection rateBead embroidery

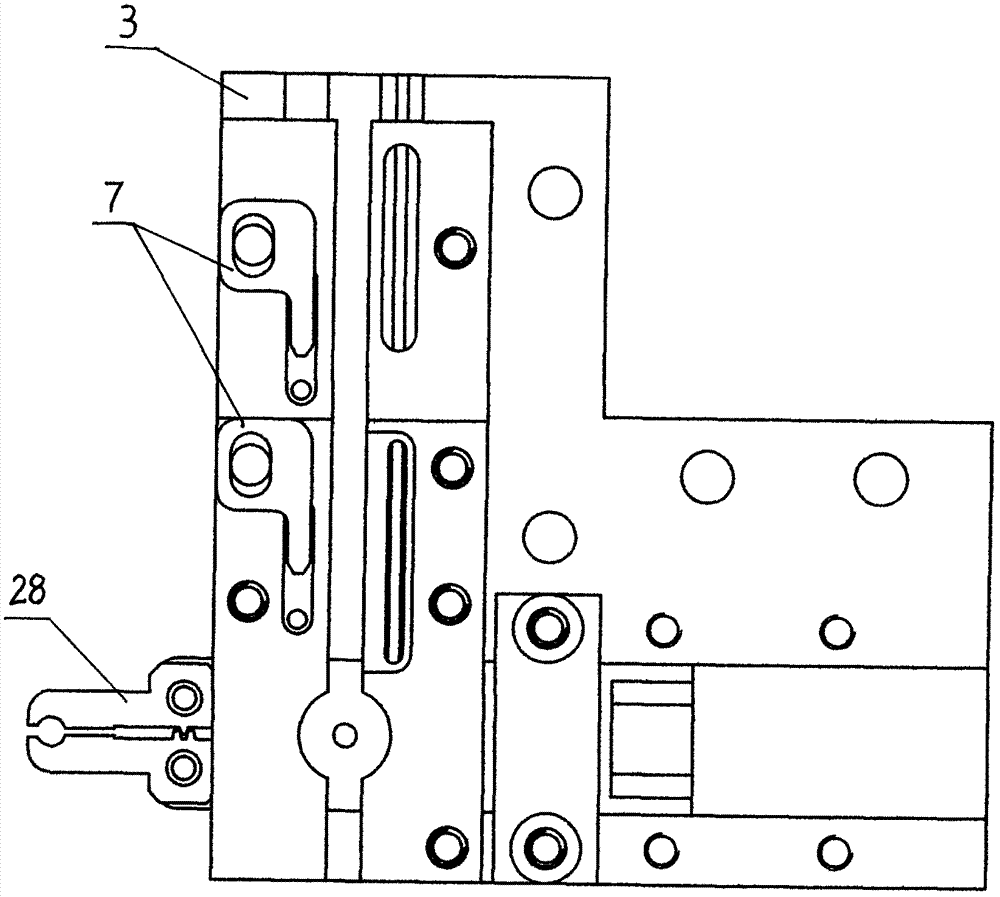

The invention discloses a pearl embroidery device for a computerized embroidery machine. The pearl embroidery device comprises a conveying mechanism, a feeding mechanism and a pearl guiding wire, wherein the conveying mechanism comprises a base and a holder, a chute is arranged on the base, the holder is mounted in the chute in a matched manner, a jaw slideway is arranged on the base, a jaw formed by two parallelly arranged holding arms is arranged at one end of the holder, at least one group of hold-down devices is symmetrically arranged on two sides of the jaw slideway, and the hold-down devices enable the holding arms on the holder, which slides in the jaw slideway, to be always subjected to a force pressing the jaw. The pearl embroidery device is simple in structure; the hold-down devices enable pearls to be always subjected to a force pressing the jaw when sliding in the jaw slideway to ensure that the pearls are always in a pressing state, so that accurate positioning of the pearls is guaranteed, and the embroidery product is improved. The pearl embroidery device is convenient to maintain, safe and reliable in operation and smooth and uninterrupted in pearl supply, improves the working efficiency and lowers the rejection rate.

Owner:WENZHOU OULUOHUA INDAL

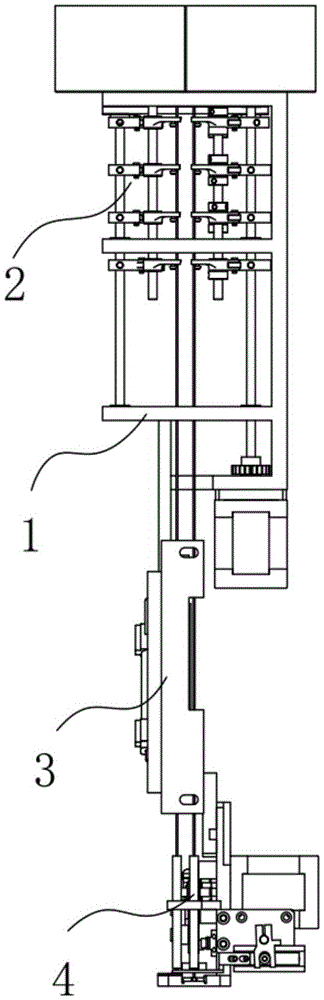

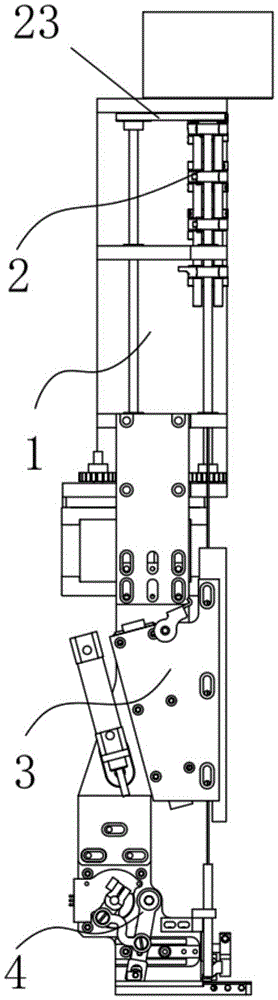

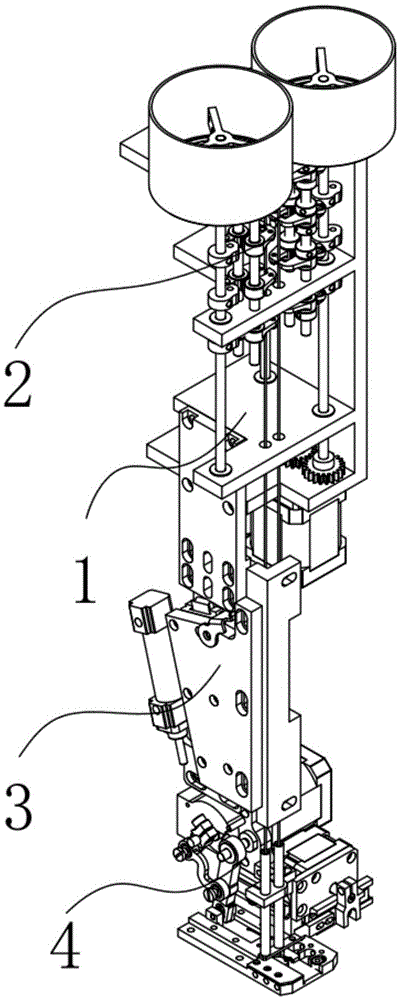

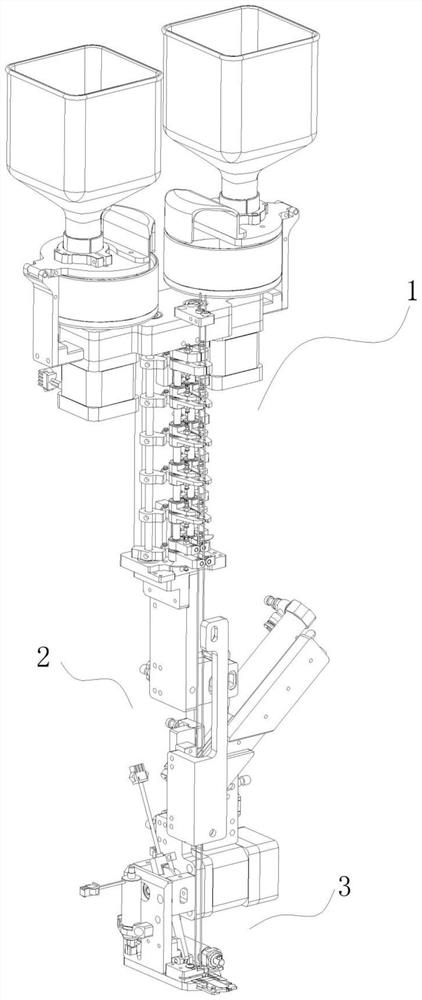

Two-color bead embroidery machine head

ActiveCN105624942AMeet the simultaneous useImprove performanceAutomatic machinesAuxillary devicesEngineeringGuide tube

The invention discloses a two-color bead embroidery machine head. The two-color bead embroidery machine head comprises a frame, a bead stringing device and a feeding device, wherein the bead stringing device comprises a first bead guide tube and a second bead guide tube; the two-color bead embroidery machine head further comprises a sorting device; the sorting device is arranged on the frame and comprises a driving mechanism and a sorting plate arranged on the driving mechanism; a bead sorting hole is formed in the sorting plate and is used for feeding a bead to be embroidered to the jaw of the feeding device. The two-color bead embroidery machine head can meet the requirement on using beads with different specifications at the same time, and is stable in performance and high in efficiency.

Owner:WENZHOU OULUOHUA INDAL

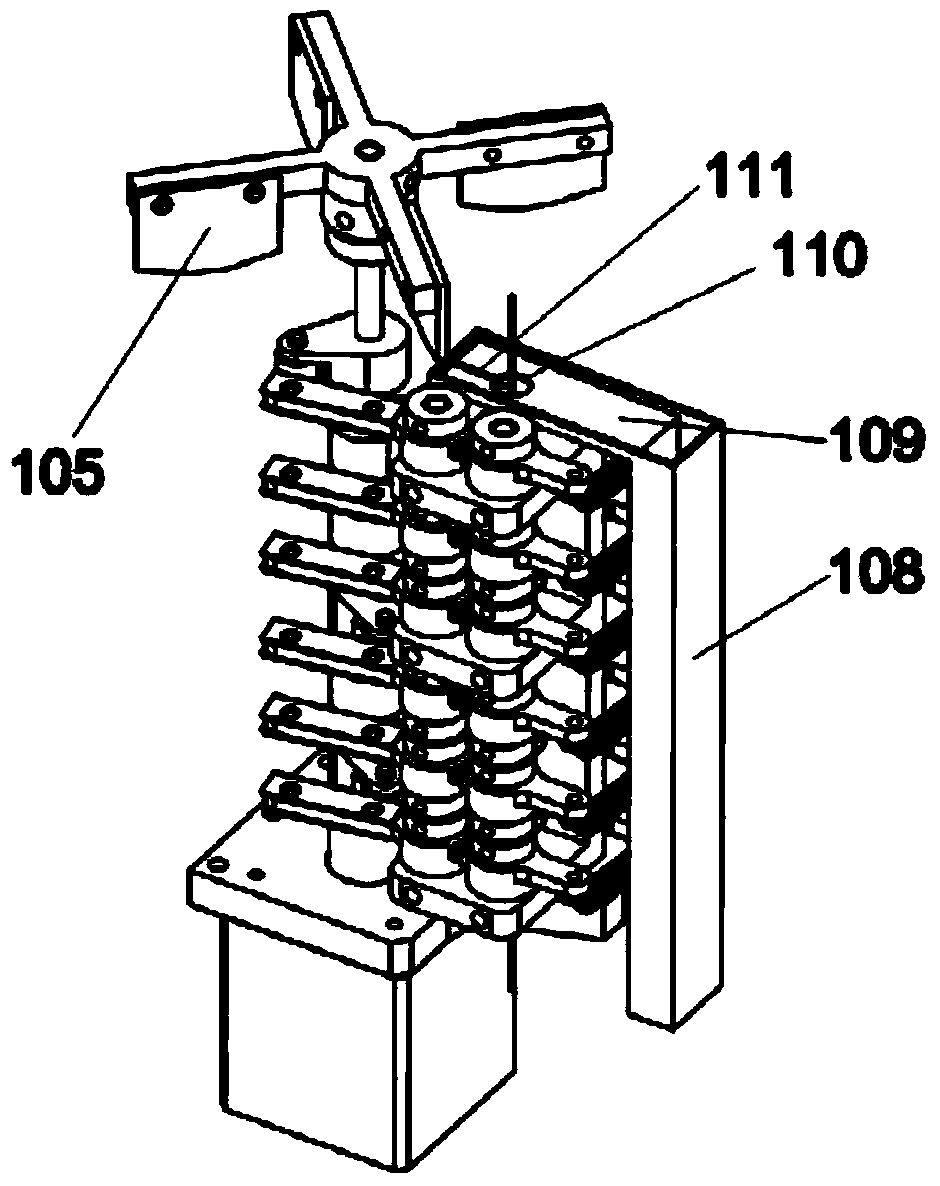

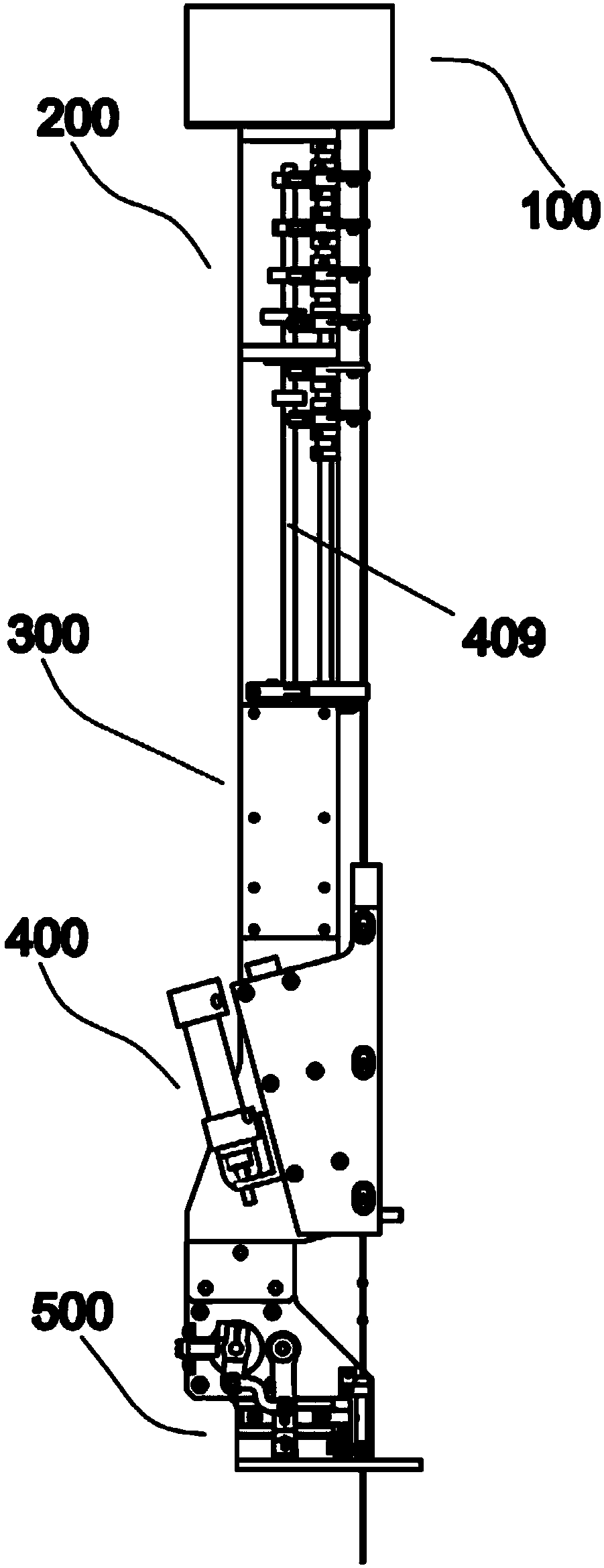

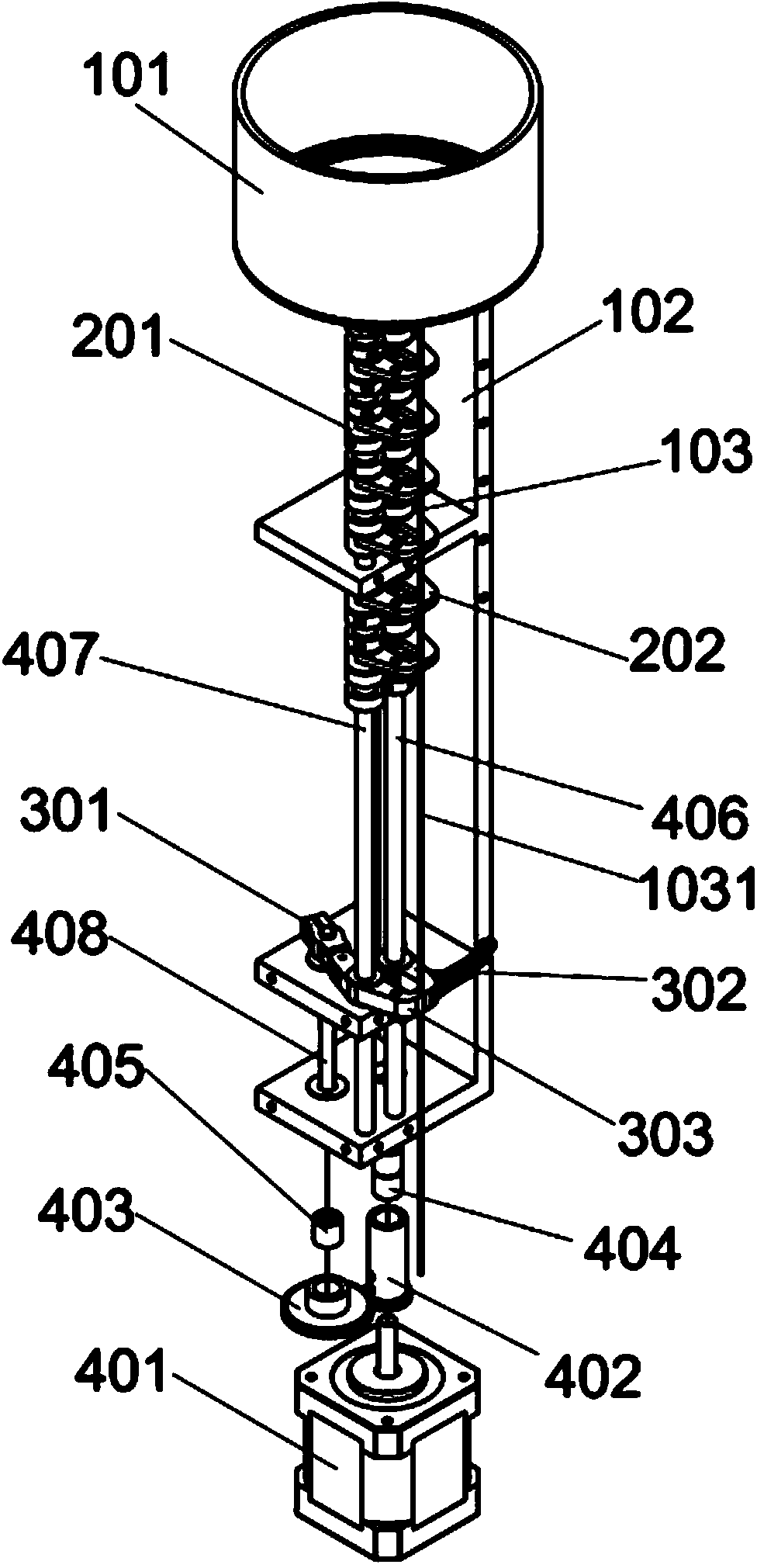

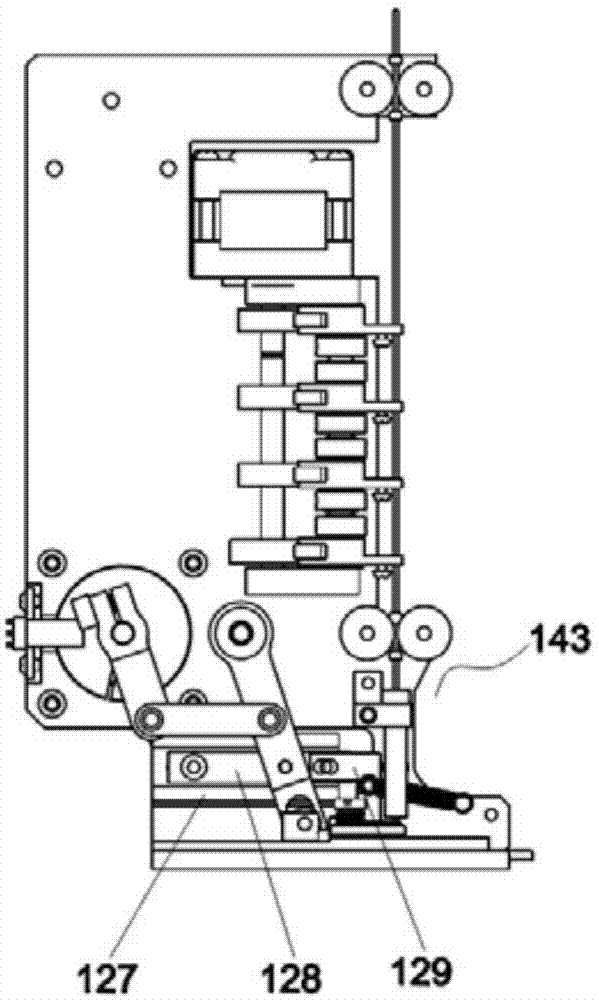

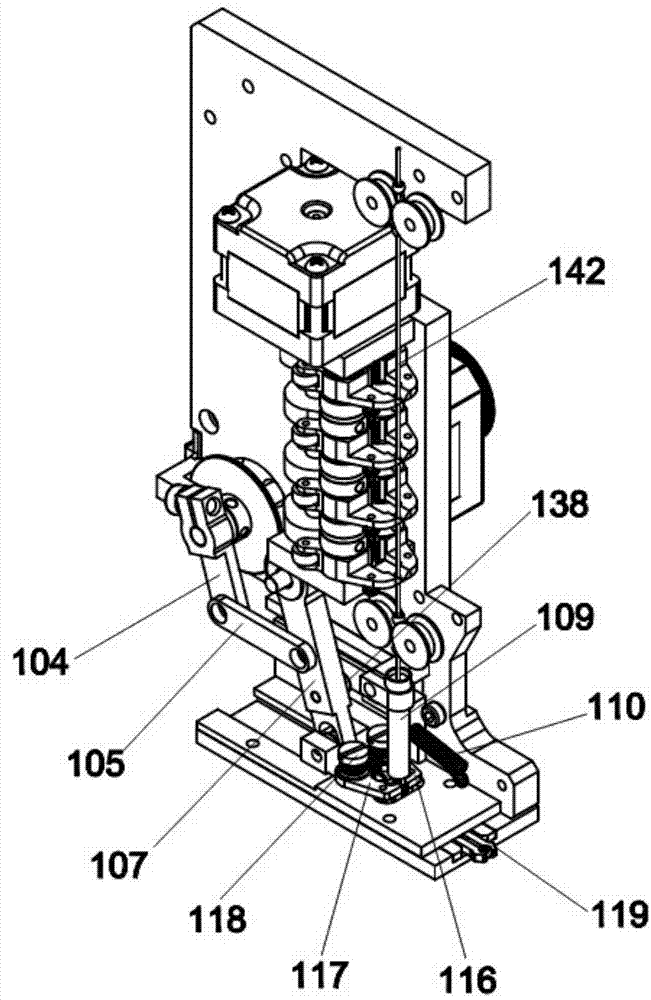

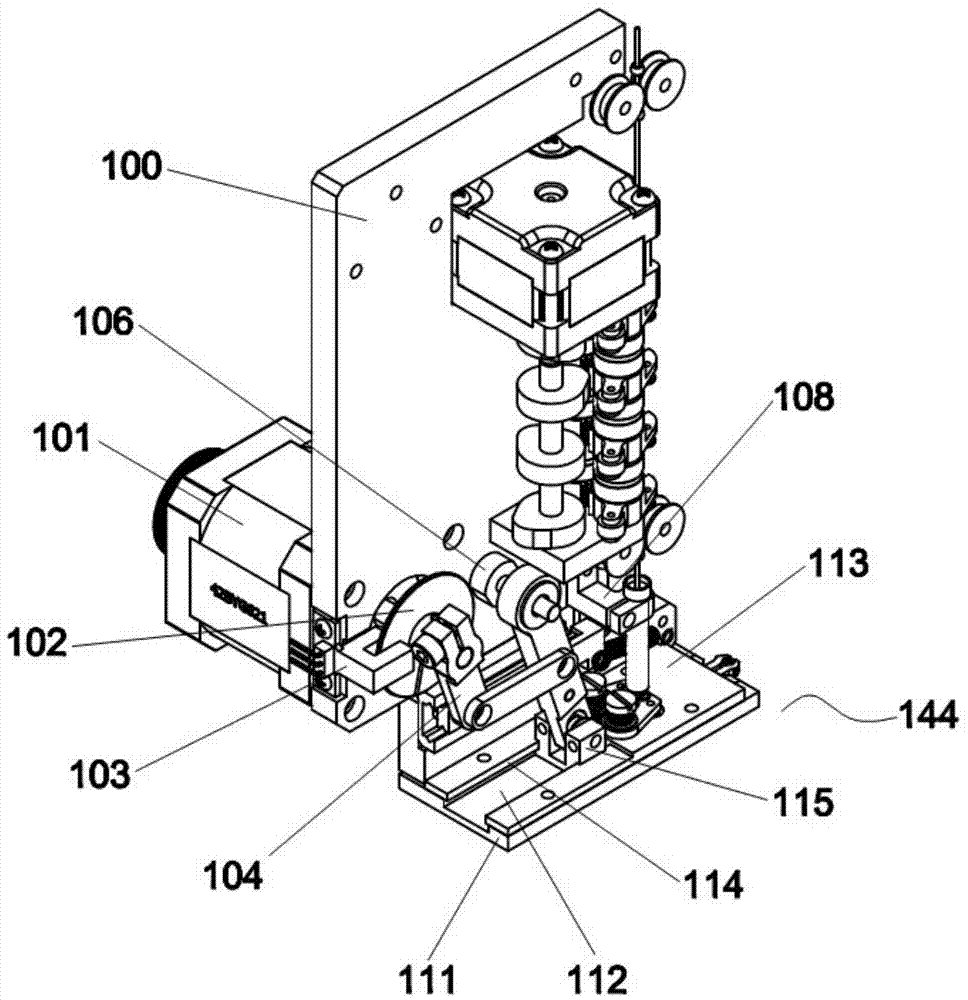

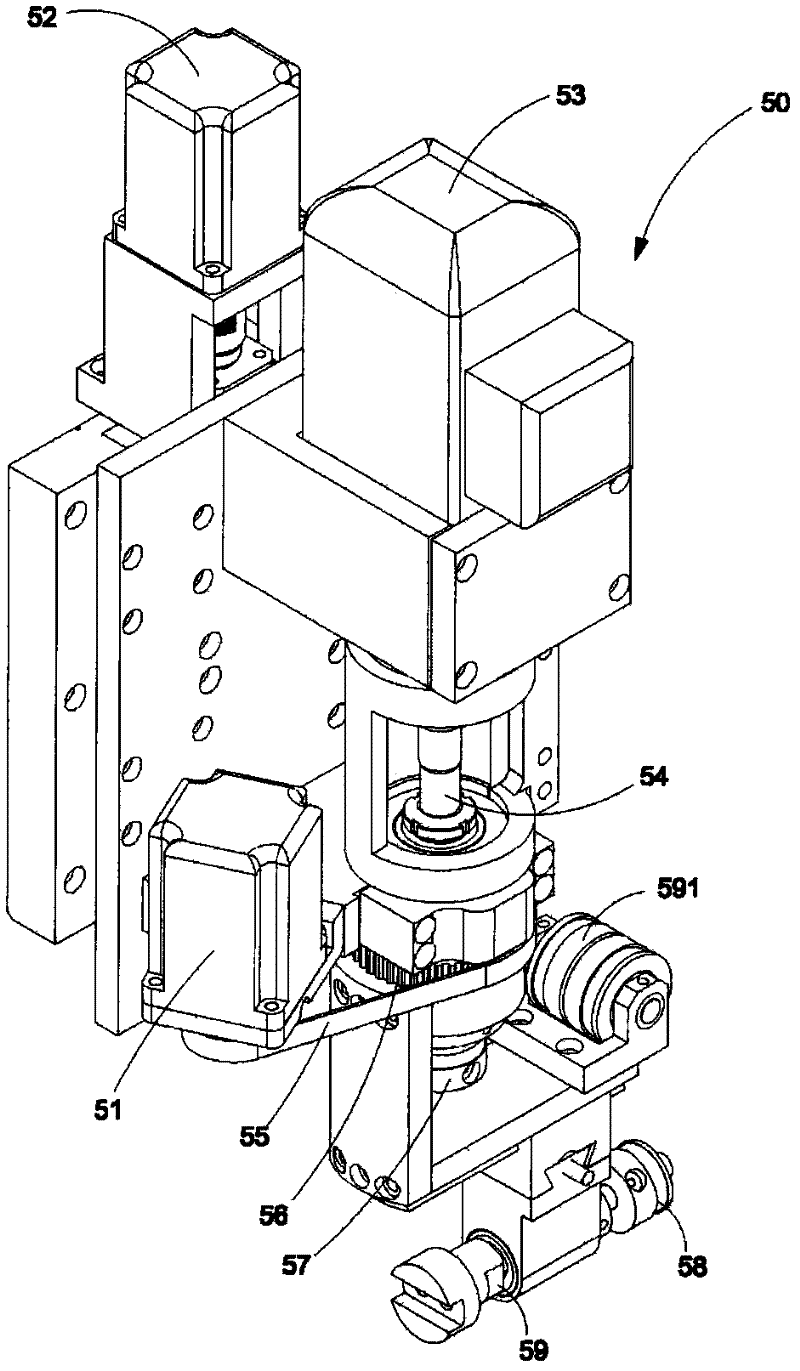

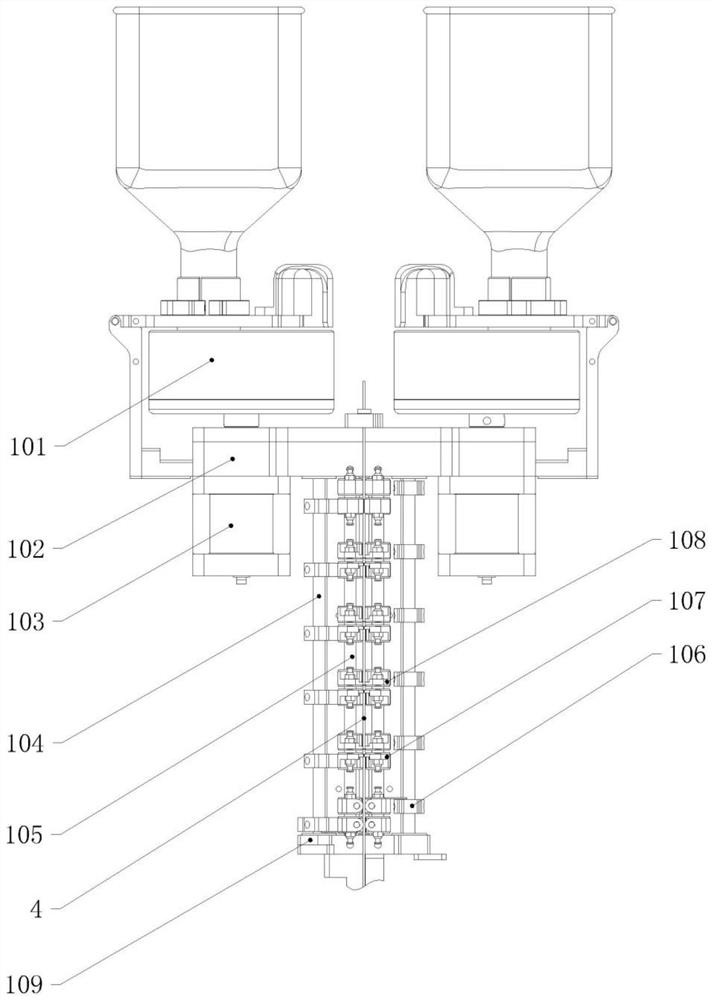

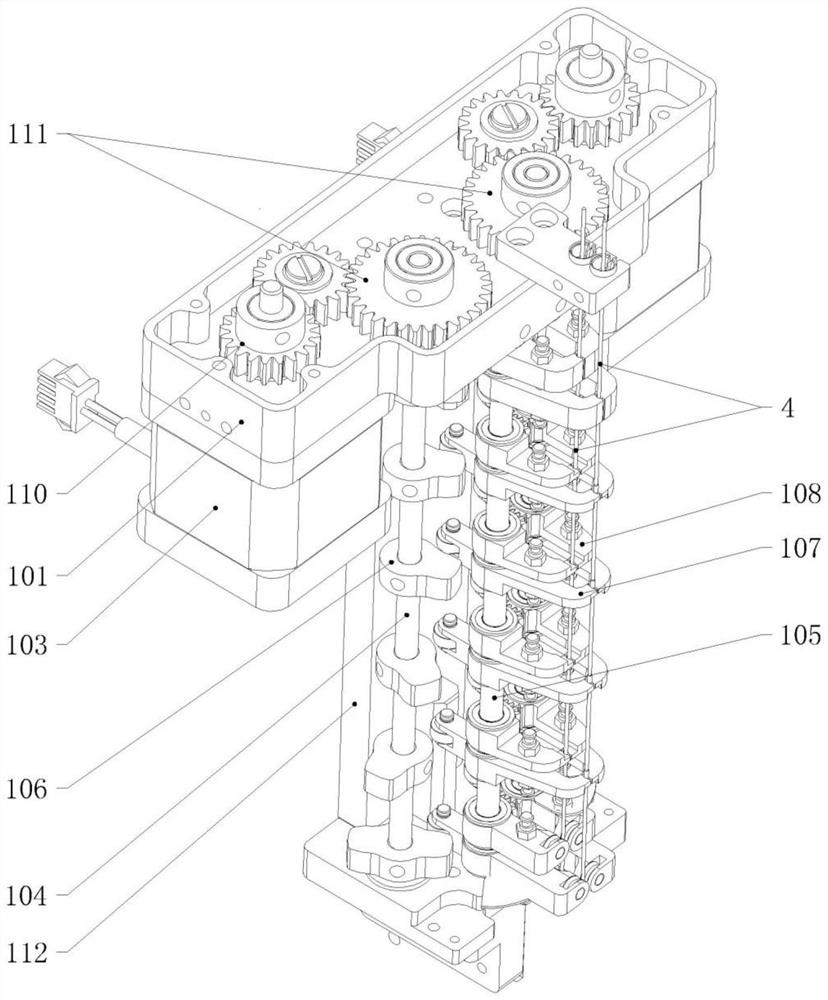

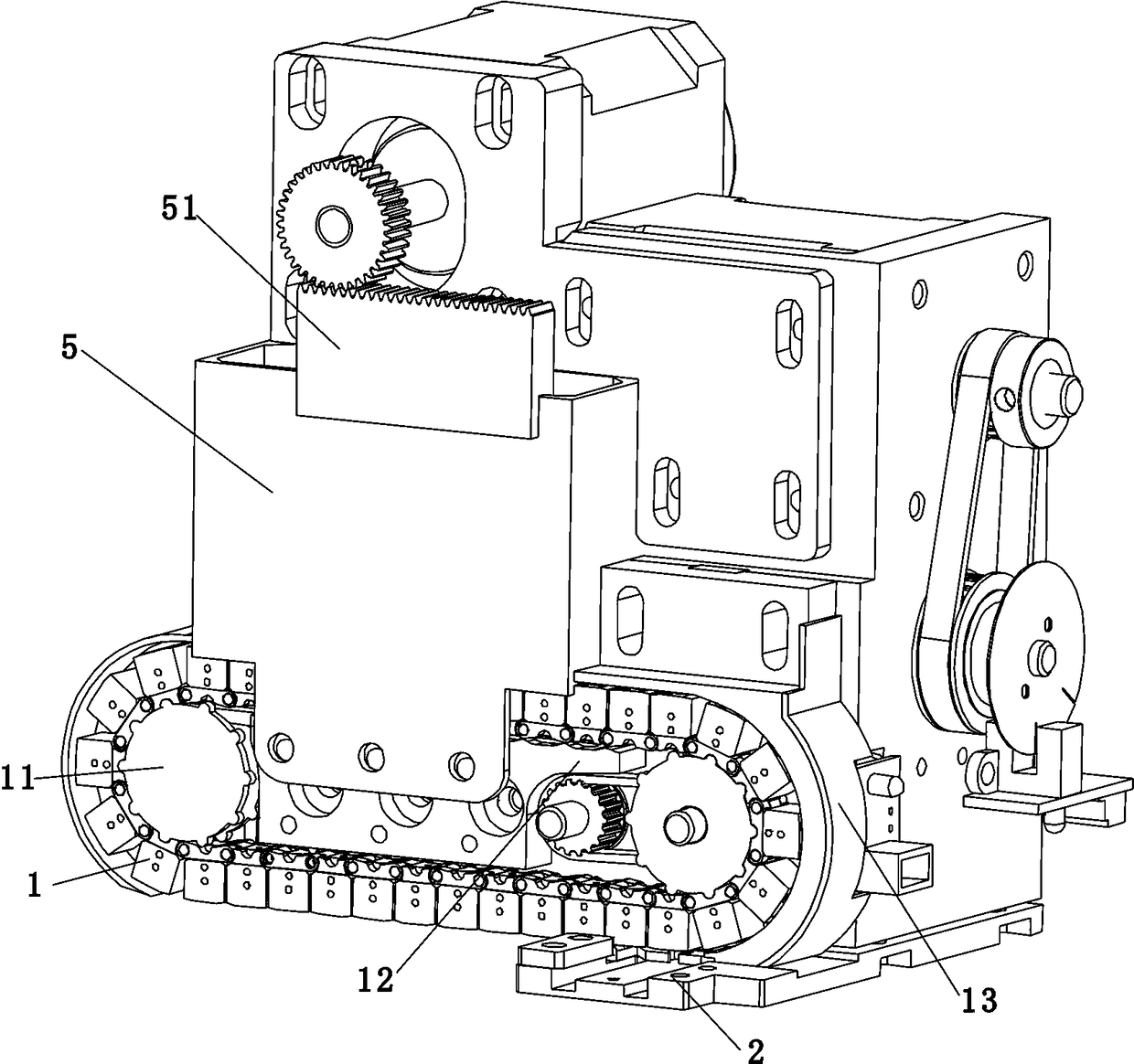

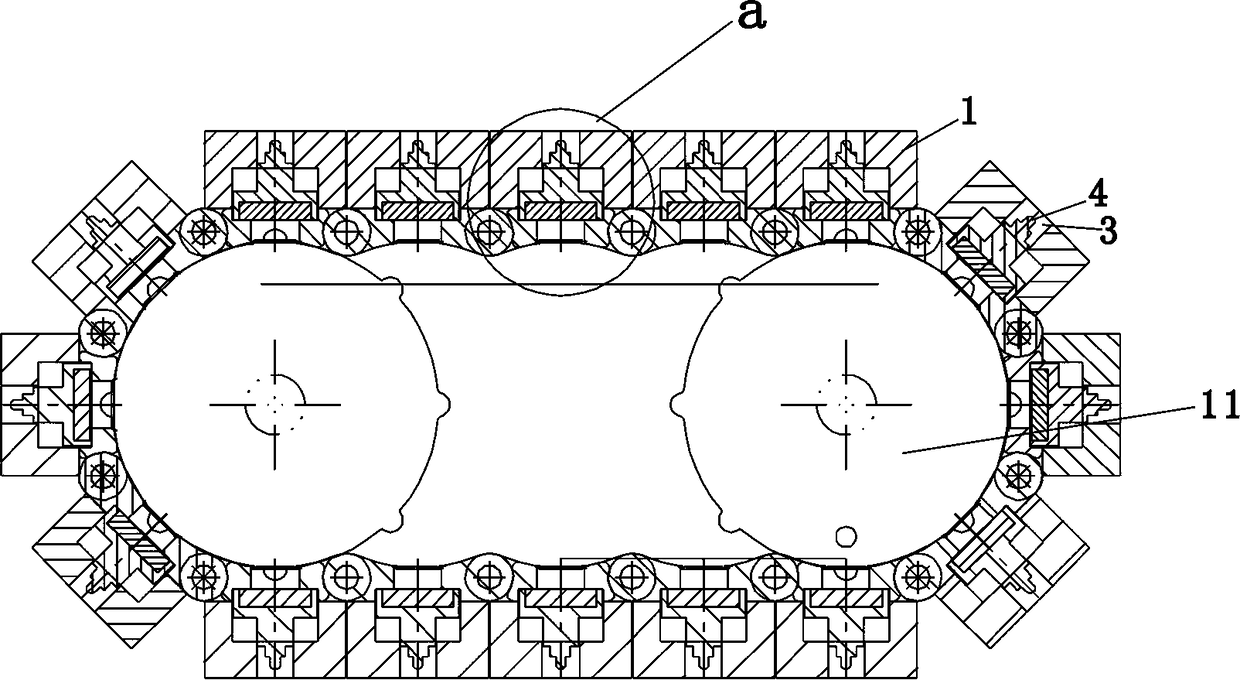

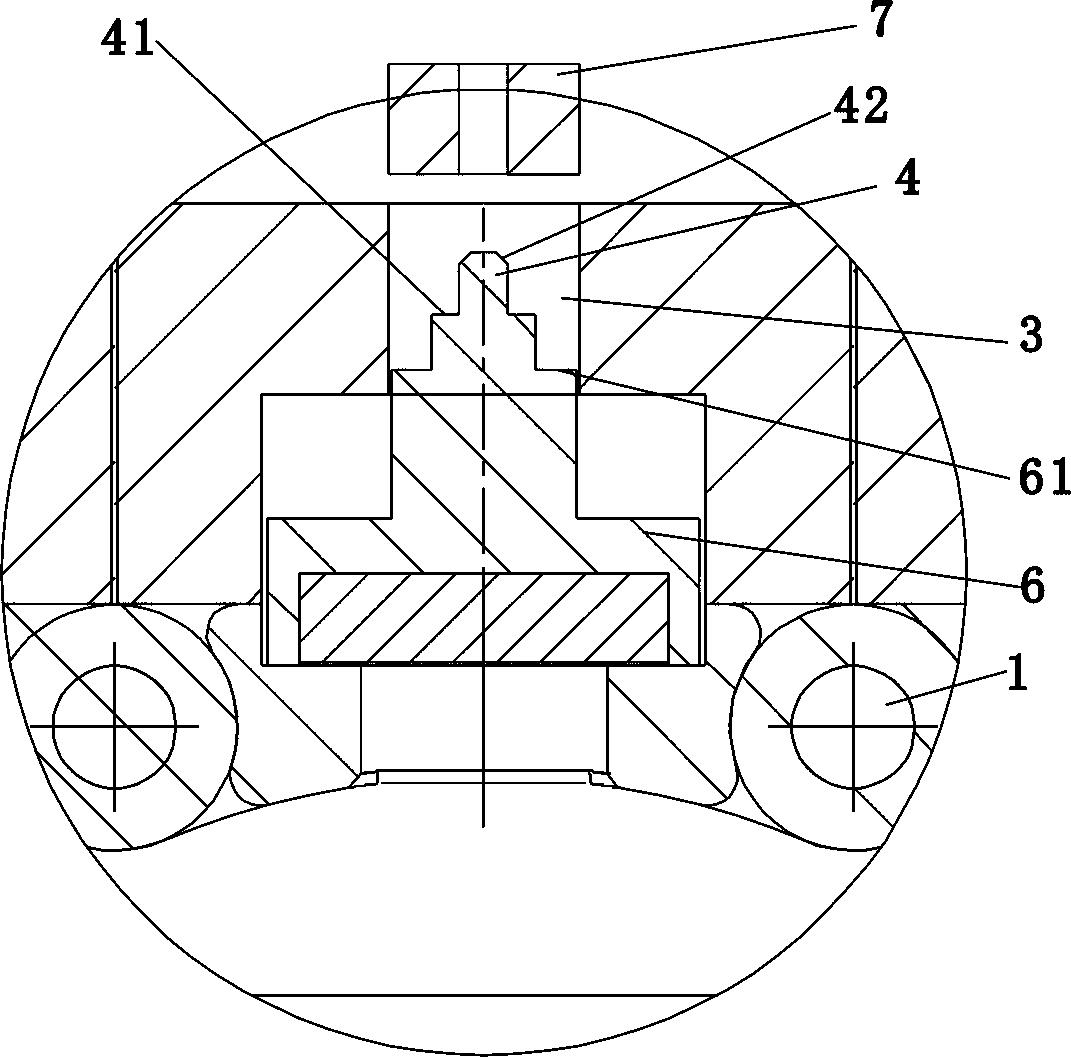

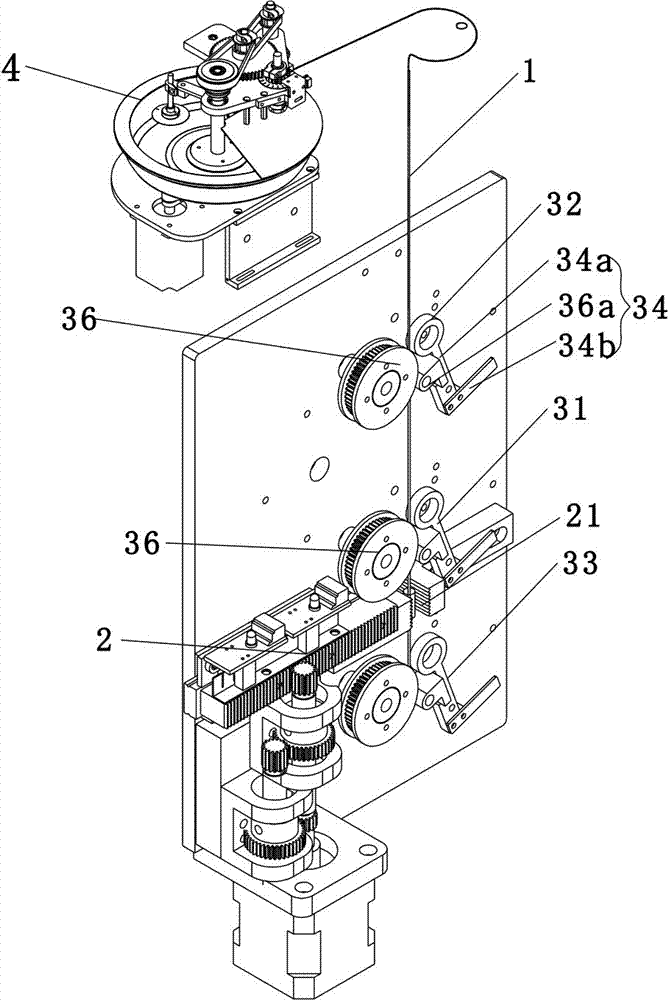

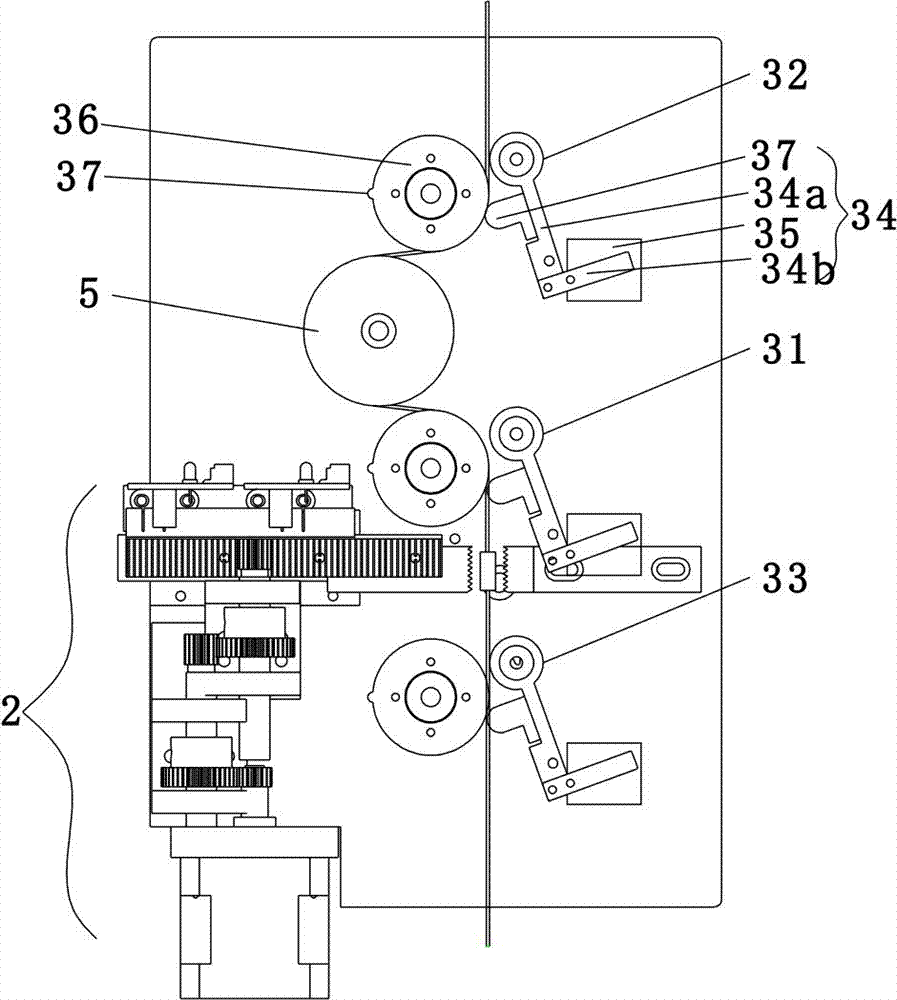

Bead arranging and feeding device of bead embroidery device

ActiveCN104372542AGuaranteed to stay the sameAchieve teleportationAutomatic machinesAuxillary devicesEngineeringMechanical engineering

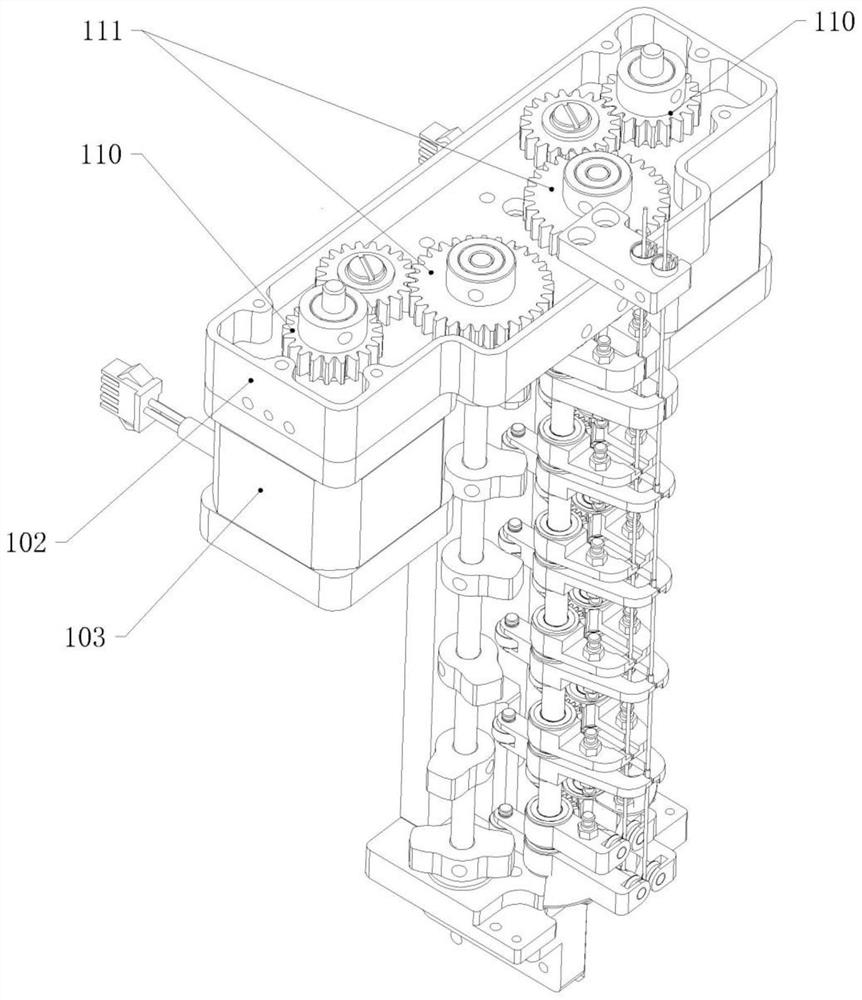

The invention discloses a bead arranging and feeding device of a bead embroidery device. The bead arranging and feeding device comprises a rack, a power driving and distributing device which is fixedly arranged on the rack, a bead guide rod for guiding beads to drop and provided with a bead containing section, an upper bead feeding section movably arranged on the rack, and a lower bead feeding section movably arranged on the rack, wherein a bead arranging device is arranged at the upper part of the rack, the upper bead feeding section comprises a plurality of upper section clamping devices, the power driving an distributing device drives at least one upper section clamping device which is used for clamping the bead guide rod; and the lower bead feeding section comprises a lower section clamping device, the power driving and distributing device drives the lower section clamping device to clamp the bead guide rod, and the lower section clamping device is away from the closest upper section clamping device by a distance, so that the enough beads can penetrate the bead containing section between the lower section clamping device and the closest upper section clamping device. The bead arranging and feeding device has a simple structure, can be used conveniently, has the high production efficiency and can clamp the bead guide rod stably.

Owner:WENZHOU OULUOHUA INDAL

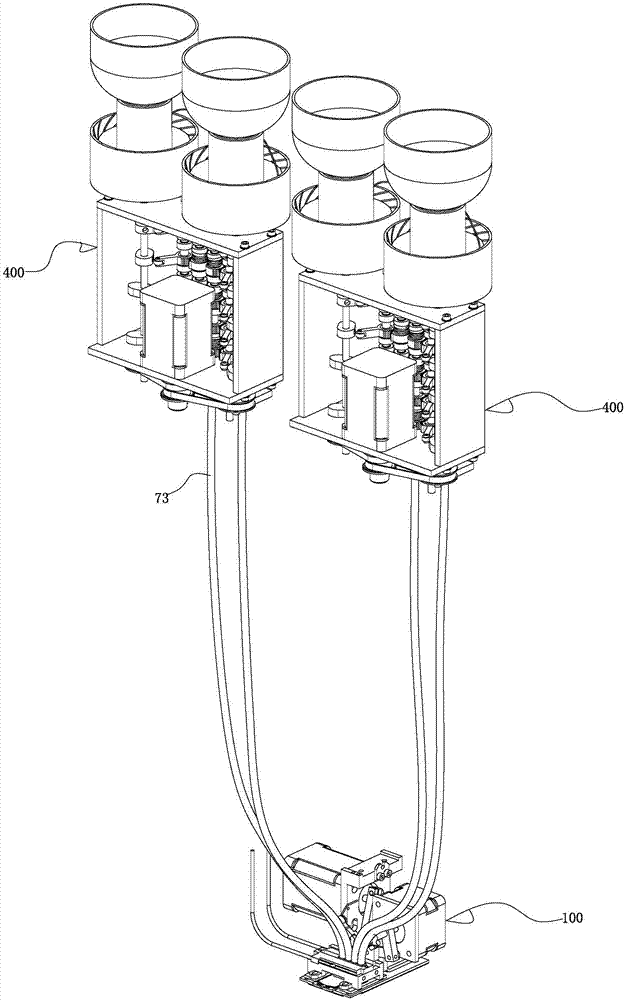

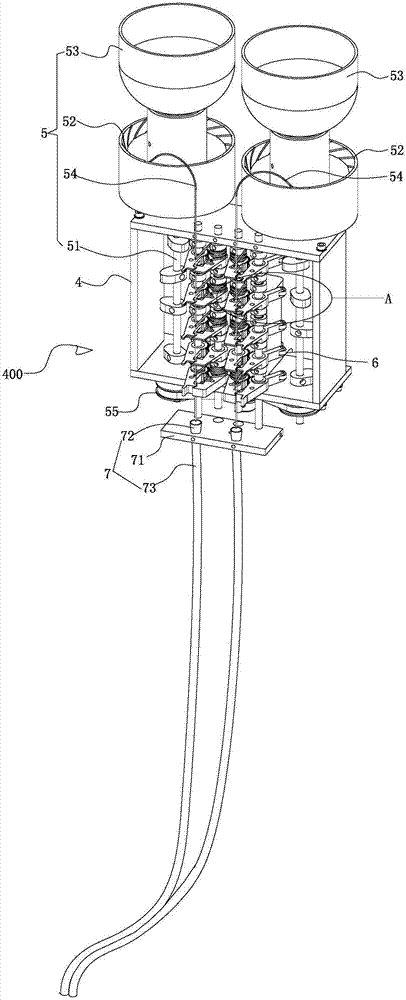

Multicolor bead and bead pipe embroidering device

The invention discloses a multicolor bead and bead pipe embroidering device, which comprises at least one group of multicolor bead embroidering and beading guidance pipe device and a multicolor bead embroidering and color-changing device. Each multicolor bead embroidering and beading guidance device comprises a rack, and a bead beading mechanism arranged on the upper end of the rack, a buffering bead discharging mechanism and a guidance pipe assembly; the bead beading mechanism comprises a drive shaft arranged in the rack in a penetrating way, a bead beading plate, a storage plate and a motor assembly; the upper end of a metal bead beading wire is bent to stretch into the bead beading plate; the lower end of the metal bead beading wire penetrates through the buffering bead discharging mechanism and is butt joint with the guidance pipe assembly; the multicolor bead embroidering and color-changing device is arranged under the multicolor bead embroidering and beading guidance pipe device, and comprises a base, and a clamping and pushing mechanism arranged on the base and a color-changing mechanism; the color-changing mechanism comprises a support seat arranged above the clamping and pushing mechanism, a color-changing bead discharging seat, a first drive mechanism and a positioning mechanism; the color-changing bead discharging seat is provided with a plurality of bead discharging channels; a positioning tooth seat adapt to the positioning mechanism is formed on the color-changing bead discharging seat; the positioning mechanism and the positioning tooth seat are positioned in a pressing way; the guidance pipe assembly is in butt joint with the color-changing bead discharging seat.

Owner:东莞市鸿锋电脑刺绣有限公司

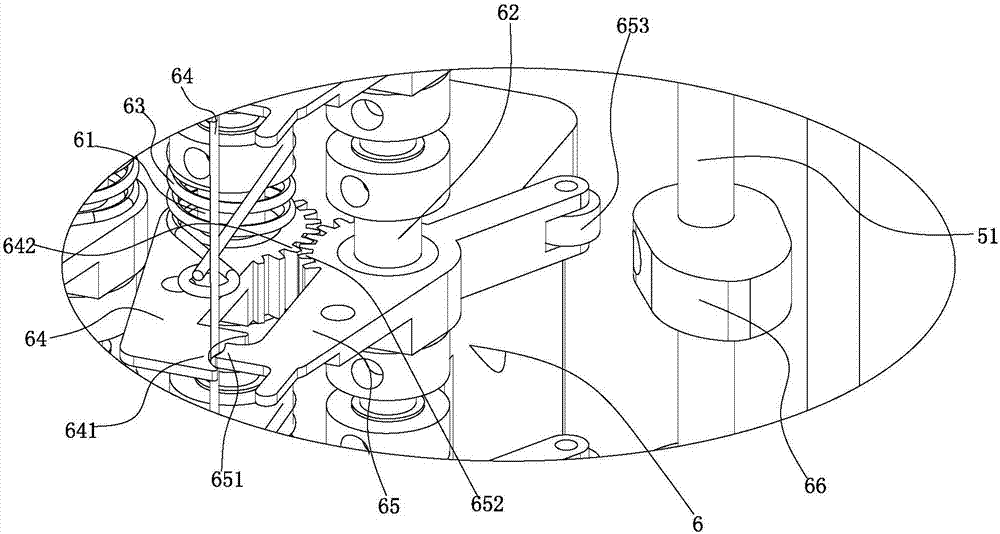

Bead embroidering device

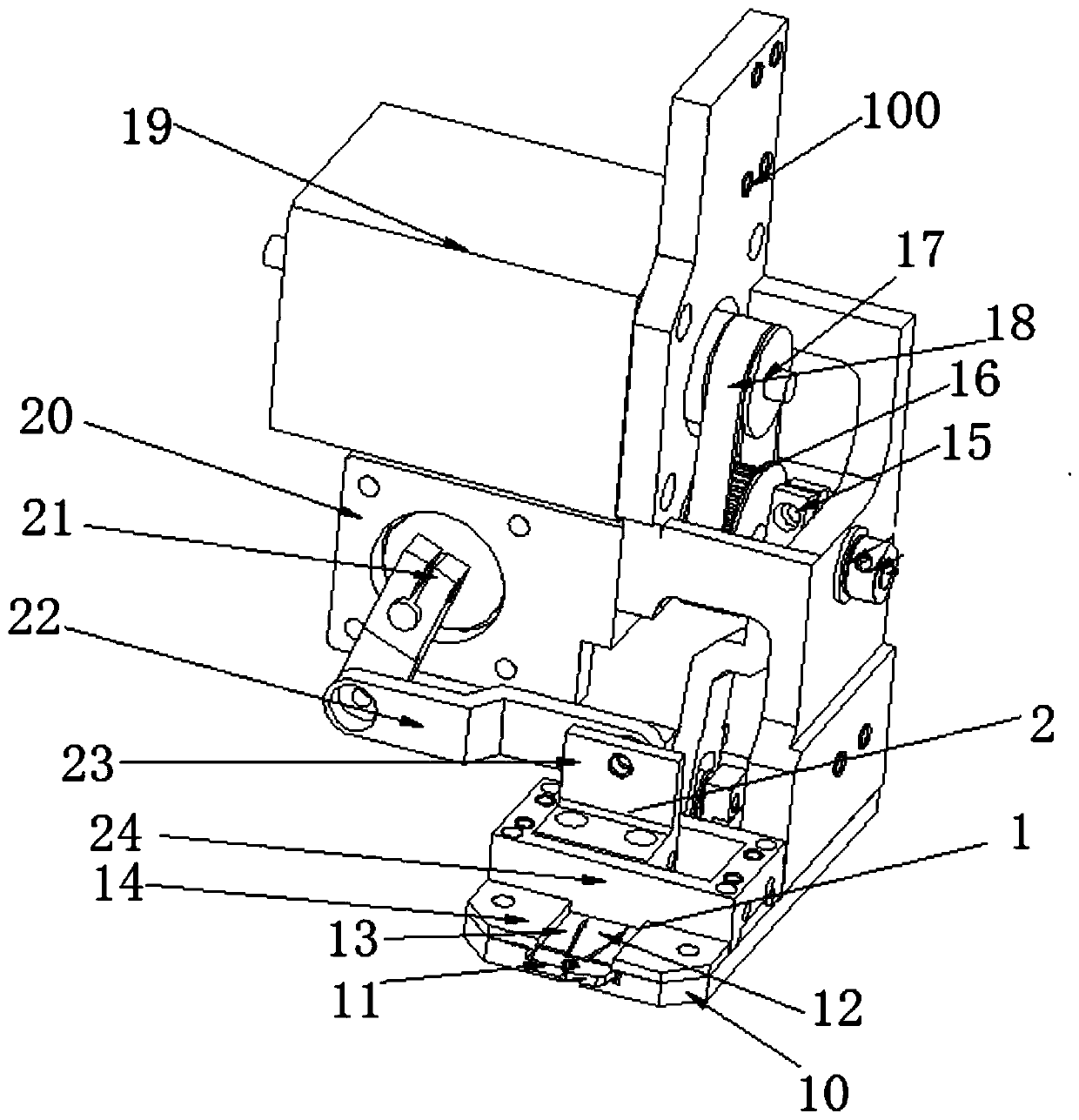

ActiveCN104264394ASimple structureEasy maintenanceAutomatic machinesAuxillary devicesProcessing costBead embroidery

The invention discloses a bead embroidering device. The bead embroidering device comprises a bead guide rod, a conveying mechanism, a positioning and clamping mechanism and a feeding mechanism; the positioning and clamping mechanism is arranged above the feeding mechanism, wherein one end of the positioning and clamping mechanism is pivoted on the feeding mechanism, a positioning and clamping opening formed in the other end of the positioning and clamping mechanism is driven by power to clamp or stretch, and the positioning center of the positioning and clamping opening is concentric with that of the bead guide rod. The bead embroidering device is driven by a shifting fork motor; beads are fixed by use of the positioning and clamping mechanism and then fed orderly, and then the beads are clamped, delivered and positioned by use of a special sliding clamping plate with a jaw; as a result, the bead embroidering device is simple in structure, convenient to maintain, low in processing cost, high in automatic production efficiency and wide in application prospect; besides, the labor intensity of a worker can be reduced.

Owner:WENZHOU OULUOHUA INDAL

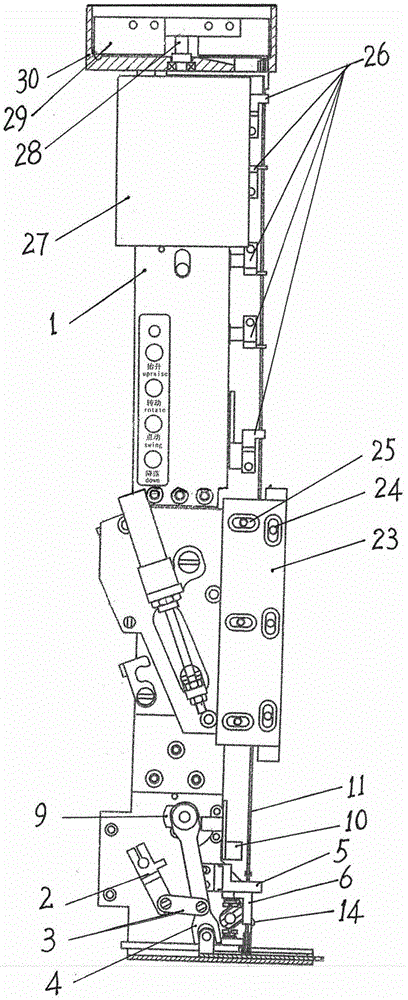

Multifunctional smart embroidery machine head of computerized embroidery machine

InactiveCN101538786AReduce the number of installationsEasy to useAutomatic machinesAuxillary devicesLow noiseElectric machinery

The invention relates to a multifunctional smart embroidery machine head of a computerized embroidery machine, comprising a support body, a control circuit board, an instruction operation circuit board, a feeding motor and a drive cylinder, and a driving belt wheel on the feeding motor is connected with a driven belt wheel on a thread guide port through a drive belt. The multifunctional smart embroidery machine head is mainly provided with an inner through hole in the thread guide port, the inner through hole is sleeved on the outside of a needle bar of a flat embroidery machine head; a tension motor, a mobile guide wheel, a tension swing spring, a first fixed guide wheel and a second fixed guide wheel are arranged on the support body; a stroke control switch is arranged between the driving belt wheel and a mounting base, and the stroke control switch is connected in a forward and backward rotation control circuit of the feeding motor. The multifunctional smart embroidery machine head does not need to change the mounting position of the original flat embroidery machine head, does not reduce the mounting number of the flat embroidery machine head and has the advantages of convenient installation and use, high production efficiency, low noise, long service life and so on. The multifunctional smart embroidery machine head is applicable to the computerized embroidery machines of flat embroidery, belt embroidery, rope embroidery, bead embroidery and coil embroidery.

Owner:永嘉县德宝机械有限公司

Embroidery machine glass bead feeding device

InactiveCN107059276AVariety of colorsImprove aestheticsAutomatic machinesParallel arrangementBead embroidery

The invention relates to an embroidery machine glass bead feeding device. The device comprises a frame, a mounting plate, a chassis, a harness frame, a belt feeding mechanism, a bead feeding mechanism, a lifting mechanism and a control mechanism. The chassis, belt feeding mechanism and bead feeding mechanism are installed on the frame; the frame is connected with the mounting plate through the lifting mechanism; the harness frame and the control mechanism are installed on the mounting plate; mainly, an upper bead feeding groove and a lower bead feeding groove are arranged in the plane on the chassis, wherein the upper bead feeding groove and lower bead feeding groove are in parallel arrangement in the horizontal direction; the bead feeding mechanism is composed of a swing motor, a swing controller and a belt dialing device; the belt dialing device is composed of a belt dialing stopper, an upper belt dialing rocker, a lower belt dialing rocker, an upper fork and a lower fork; the bead feeding mechanism can transfer two kinds of glass bead belts in the upper bead feeding groove and lower bead feeding groove simultaneously, and has the advantages of being multiple in embroidery colors, rich in embroidery pattern colors, and good in aesthetics and the like. The embroidery machine glass bead feeding device is suitable for computer embroidery machine glass bead embroidery machine head.

Owner:永嘉县信诚科技服务有限公司

Bead feeding mechanism for bead embroidery machine and bead embroidery machine

ActiveCN110592834ASolve the problem of flying beadsSimple structureAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses a bead feeding mechanism for a bead embroidery machine and the bead embroidery machine. The bead feeding mechanism comprises a bottom plate with a bead pushing sliding groove,and a bead pusher which slides front and back along the bead pushing sliding groove, wherein the bead pusher comprises two clamping pieces which can be relatively clamped or opened, clamping heads arearranged on the front portions of the clamping pieces, clamp notch grooves for clamping beads are formed in the inner sides of the clamping heads, and the front of the clamping head of one of the clamping pieces is provided with a stopper which extends to the front side of the clamping head of the other clamping piece. In the bead pushing process of the bead pusher, embroidery threads penetratinginto a cloth cover move upwards, and the stopper stops the embroidery threads from entering the clamp notch grooves. By means of the technical scheme, in the embroidery process, when the two clampingpieces are clamped and the beads are clamped through the clamp notch grooves to be pushed forwards, the embroidery threads penetrating into the cloth cover move upwards to be close to the clamping heads, because of stopping of the stopper, the situation that the embroidery threads enter clamping notches through gaps between the threads to make contact with the beads cannot be generated, and therefore, the problem of bead scattering can be solved.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

Computer embroidery machine glass bead multicolor bead sending device

InactiveCN107083624AVariety of colorsImprove aestheticsAutomatic machinesAuxillary devicesComputer engineeringBead embroidery

The invention relates to a computer embroidery machine glass bead multicolor bead sending device. The device includes a frame, a mounting plate, a chassis, a dribble frame, a dribble sending mechanism, a bead sending mechanism, a lifting mechanism and a control mechanism, wherein the chassis, the dribble sending mechanism and the bead sending mechanism are installed on the frame; the frame is connected to the mounting plate through the lifting mechanism; the dribble frame and the control mechanism are installed on the mounting plate; an upper dribble sending trough and a lower dribble sending trough parallelly arranged in the horizontal direction are arranged in the plane on the chassis; the dribble sending mechanism is composed of a swing motor, a swing controller and a dribble striking device; the dribble striking device is composed of a dribble striking block, an upper dribble striking rocking bar, a lower dribble striking rocking bar, an upper striking fork disc and a lower striking fork disc; the dribble sending mechanism can send two kinds of glass beads in the upper dribble sending trough and the lower dribble sending trough at the same time. The device has the advantages of being colorful in embroidery, various in embroidery pattern color, and attractive in appearance and the like, and is applicable to a computer embroidery machine glass bead embroidery machine head.

Owner:永嘉县德宝机械有限公司

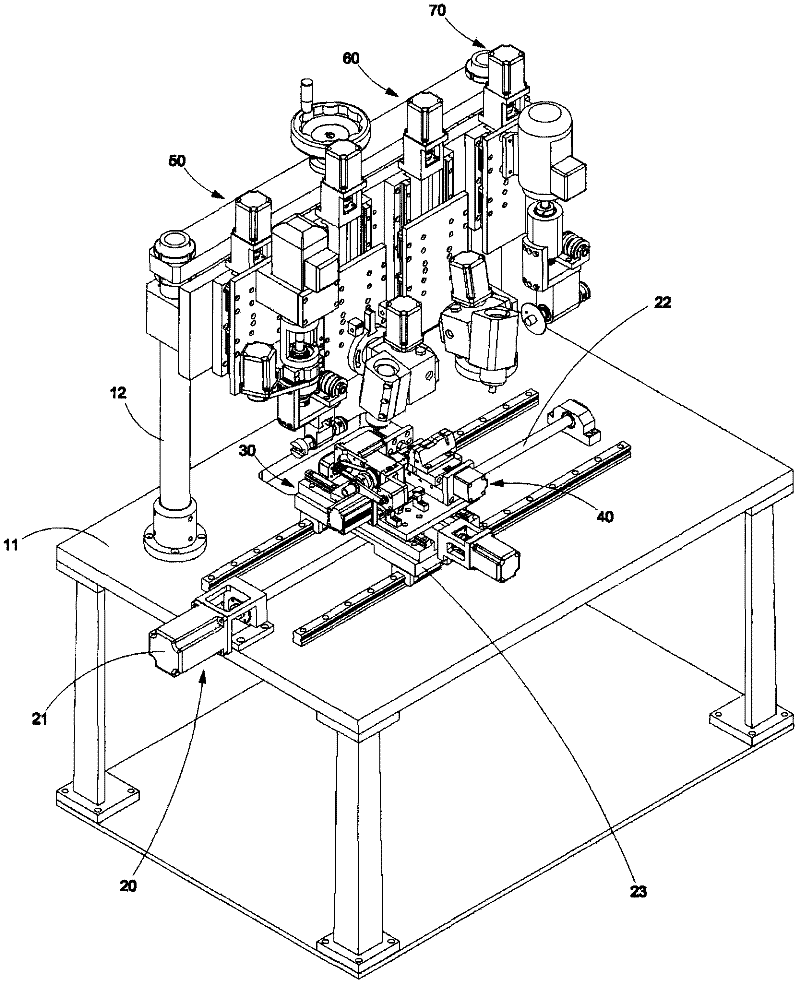

Numerical-control pipe bead embroidery machine

The invention provides a numerical-control pipe bead embroidery machine, comprising a rack, an automatic material pushing device, an automatic material clamping device, an equal automatic rotation device for patterns, at least one tool turning-around device and an automatic material cutting device, wherein the rack comprises a workbench and a mounting rack; a mobile device comprises a stepping motor, a ball screw pair and a mobile station, the ball screw pair is in drive connection with the stepping motor, and the mobile table is connected with the nut of the ball screw pair; the automatic material pushing device is installed on the mobile station; the automatic material clamping device is cooperated with the automatic material pushing device to be installed on the mobile station; the equal automatic rotation device for patterns is fixed on the mounting rack; the tool turning-around device is fixed on the mounting rack; and the automatic material cutting device is fixed on the mounting rack and is adjacent to the tool turning-around device. The numerical-control pipe bead embroidery machine has high automation degree; and according to the numerical-control pipe bead embroidery machine, the production efficiency is improved, manual operation is effectively avoided, the appearance exquisite degree of pipes and beads is improved, and manual cost is saved.

Owner:深圳市龙兴机械科技有限公司

Glass bead conveying device of computer embroider machine

The invention relates to a glass bead conveying device of a computer embroider machine. The glass bead conveying device comprises a mounting plate, a bead material cylinder, a bead conveying impeller, a bead conveying track, a bead conveying control mechanism and a feeding mechanism, wherein the bead material cylinder is fixedly mounted at the upper end part of the mounting plate, the bottom part of the bead material cylinder is provided with a bead outlet, the upper end of the bead conveying track is located directly below the bead outlet, the bead conveying impeller is located in the bead material cylinder and is fixedly mounted at the end part of a bead conveying motor shaft; the feeding mechanism consists of a bottom plate, a feeding motor, a bead pushing plate, a pushing plate feeding mechanism and a control signal device; an upper elastic bead embracing block and a lower elastic bead embracing block are arranged at the outside of the bead conveying track at the upper side of the bead pushing plate, a switch striking block is arranged between the upper elastic bead embracing block and the lower elastic bead embracing block, a glass bead is conveyed into the bead conveying track through a bead conveying motor, and is conveyed into an elastic clamping opening of the bead pushing plate through the upper elastic bead embracing block and the lower elastic bead embracing block, and bead embroidery is realized under the control of the feeding motor; the glass bead feeding device is simple in structure, low in cost, good in bead conveying reliability, and suitable for a bead embroidery conveying device of the computer embroider machine.

Owner:阳信思踏奇实业有限责任公司

Multi-bead embroidery device

ActiveCN107641916AAvoid deflectionCooperate accuratelyAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses a multi-bead embroidery device. The device comprises a first rack, a second rack, a hopper, an automatic bead unloading mechanism, a bead delivery mechanism and a bead dashingmechanism, the first rack is connected with a second rack in a movable arrangement way, the hopper and the automatic bead unloading mechanism are arranged on the first rack in sequence, the bead delivery mechanism and the bead dashing mechanism are arranged on the second rack, at least two material unloading grooves are arranged in the hopper, the automatic bead unloading mechanism comprises a material unloading guide rail and at least two material delivery wheels, the material delivery wheel delivering an embroidered bead located in the corresponding material unloading groove into a corresponding elastic clamp located on the material unloading guide rail, the first rack is moved to enable the corresponding elastic clamp move to the bead dashing mechanism, and the embroidered bead locatedin the corresponding elastic clamp is dashed into a clamping mouth of the bead delivery mechanism to complete bead unloading and realize bead exchanging under the action of the bead dashing mechanism.The multi-bead embroidery device has the advantages that continuous, accurate delivery of variety of colors of embroidered beads can be met, and accurate bead embroidery can be ensured.

Owner:朱月眉

Double-color bead embroidery device on embroidery machine

ActiveCN114016222ASave spaceEmbroidery effect is goodAutomatic machinesReciprocating motionEngineering

The invention provides a double-color bead embroidery device on an embroidery machine, the double-color bead embroidery device comprises a feeding assembly, a lifting assembly and a bead embroidery assembly which are sequentially arranged from top to bottom, the bead embroidery assembly comprises a fixedly arranged first bottom plate, the first bottom plate is provided with a first side plate, the first bottom plate is slidably provided with a bead clamp and a pusher, the bead clamp is provided with a bead clamping hole, the first side plate is provided with a swing arm used for pushing the pusher to do reciprocating motion, the first bottom plate is fixedly provided with a bead guide block, the bead guide block is provided with a front bead hole and a rear bead hole, and the bead guide block is provided with a bead locking strip used for closing or opening the front bead hole. The double-color bead embroidery device on the embroidery machine provided by the invention can be used for simultaneously embroidering beads of two specifications, has a better embroidery effect, reduces the production cost, saves the field use space and is suitable for popularization and application.

Owner:丹阳德顺刺绣机械有限公司

Glass bead conveying device of computer embroider machine

InactiveCN105544107ASimple structureLow costAutomatic machinesAuxillary devicesImpellerControl signal

The invention relates to a glass bead conveying device of a computer embroider machine. The glass bead conveying device comprises a mounting plate, a bead material cylinder, a bead conveying impeller, a bead conveying track, a bead conveying control mechanism and a feeding mechanism, wherein the bead material cylinder is fixedly mounted at the upper end part of the mounting plate, the bottom part of the bead material cylinder is provided with a bead outlet, the upper end of the bead conveying track is located directly below the bead outlet, the bead conveying impeller is located in the bead material cylinder and is fixedly mounted at the end part of a bead conveying motor shaft; the feeding mechanism consists of a bottom plate, a feeding motor, a bead pushing plate, a pushing plate feeding mechanism and a control signal device; an upper elastic bead embracing block and a lower elastic bead embracing block are arranged at the outside of the bead conveying track at the upper side of the bead pushing plate, a switch striking block is arranged between the upper elastic bead embracing block and the lower elastic bead embracing block, a glass bead is conveyed into the bead conveying track through a bead conveying motor, and is conveyed into an elastic clamping opening of the bead pushing plate through the upper elastic bead embracing block and the lower elastic bead embracing block, and bead embroidery is realized under the control of the feeding motor; the glass bead feeding device is simple in structure, low in cost, good in bead conveying reliability, and suitable for a bead embroidery conveying device of the computer embroider machine.

Owner:应建忠

Glass bead feeding device of glass bead embroidery

InactiveCN107119398AReasonable structureEasy to manufactureAutomatic machinesAuxillary devicesTransverse grooveSlide plate

The invention relates to a glass bead feeding device of glass bead embroidery. The glass bead feeding device comprises a fixed bottom plate, a glass bead clamping sliding plate, a pressing plate, an elastic glass bead clamping plate and a transverse slippage driving mechanism, wherein a transverse sliding groove is formed in the upper side of the fixed bottom plate; transverse guide grooves are formed in two sides of the transverse sliding groove; the glass bead clamping sliding plate comprises a pushing seat and guide plates arranged at two sides of the pushing seat; the elastic glass bead clamping plate is clamped by the guide plates at two sides and is arranged on the transverse sliding groove; the guide plates at two sides are in guiding connection with the transverse guide grooves at two sides of the transverse sliding groove; the transverse slippage driving mechanism is in transmission connection with the pushing seat; the elastic glass bead clamping plate comprises an ejection plate and clamping plates which are connected to the two sides of the top plate and extend frontward; the front end of the ejection plate is used as a glass bead ejection end and inclined edges are arranged at two sides of the ejection plate; glass bead clamping inclined edges, opposite to the inclined edges at two sides, are formed in one side, close to the front end of the ejection plate, of the front ends of the clamping plates at two sides; a region formed by the glass bead clamping inclined edges at two sides and the glass bead ejection end is used as a glass bead clamping opening; inclined notches are formed in the inner sides of the front ends of the guide plates at the two sides and clamping inclined planes are formed in the outer sides of the front ends of the clamping plates at two side in the corresponding guide plates at two sides respectively.

Owner:杭州慧群机电设备有限公司

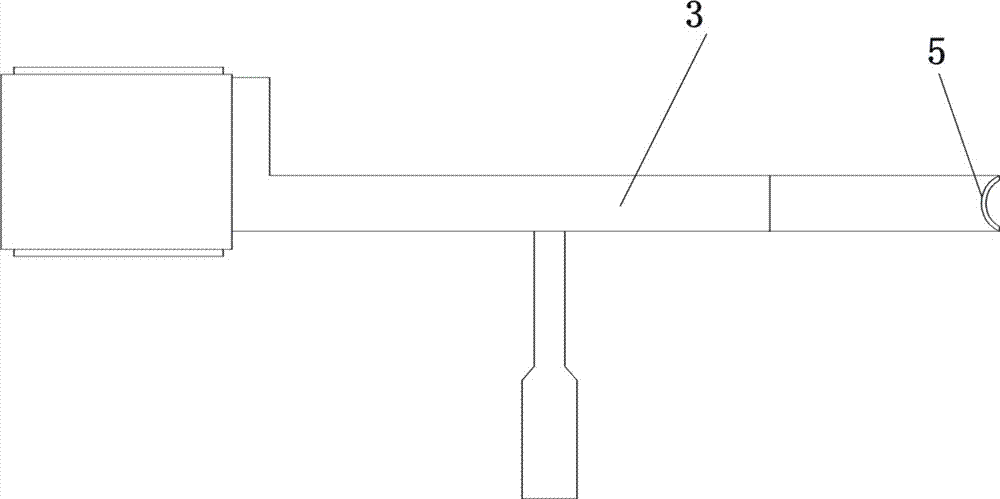

Embroidery bead feeding device and embroidery machine comprising same

ActiveCN104032498APrecise positioningPositioning; the precise positioning of the lower guide bead sectionAutomatic machinesAuxillary devicesDrive wheelEngineering

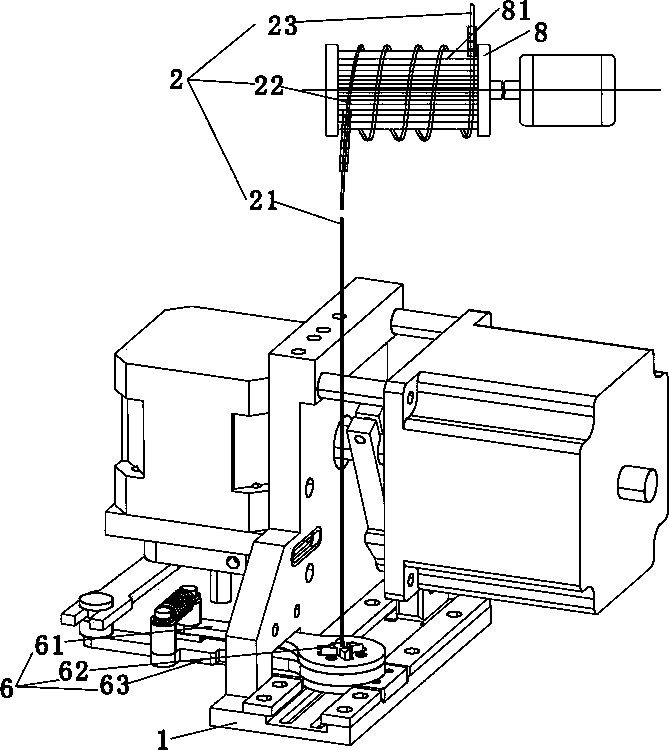

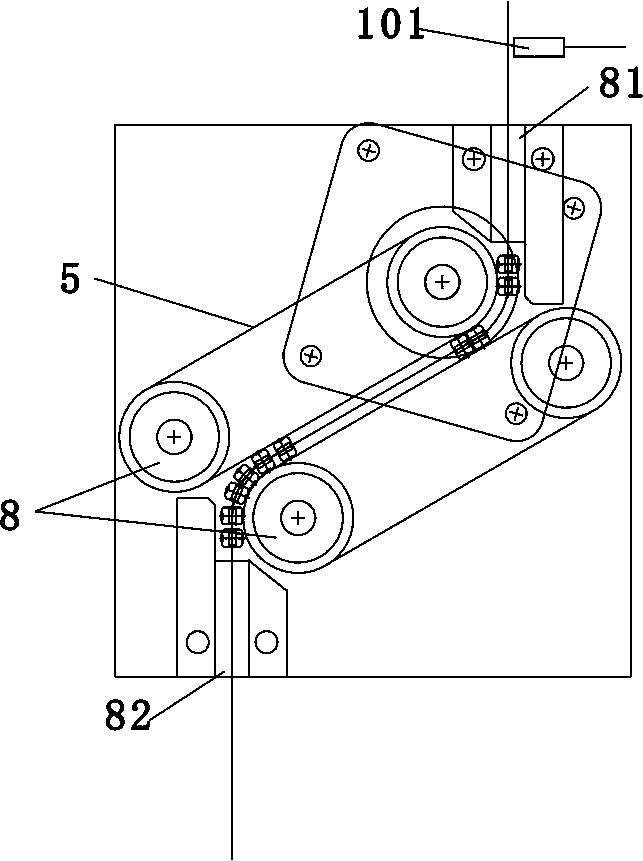

The invention discloses an embroidery bead feeding device and an embroidery machine comprising the embroidery bead feeding device. The embroidery bead feeding device comprises a feeding mechanism connected to the nose of the embroidery machine and used for conveying embroidery beads to positions directly under the embroidery needles of the embroidery machine one by one; as improved, a bead guide rod for feeding the embroidery beads to the feeding mechanism is suspended above the feeding mechanism; the bead guide rod comprises a lower bead guide section matched with the feeding mechanism, a bent middle section for positioning the bead guide rod and an upper bead guide section for stringing beads; the bent middle section is provided with a driving wheel which is used for positioning the bent middle section and conveying the embroidery beads. The feeding device is capable of positioning the embroidery beads with the lower bead guide section of the embroidery machine, positioning the bead guide rod with the bent middle section and stringing the beads with the upper bead guide section, the bead guide rod comprising three sections is capable of continuously feeding the embroidery beads, and the embroidery beads can be accurately positioned, and therefore, the problems of the bead embroidery industry are solved.

Owner:ZHUJI GUANXIANG MACHINERY TECH CO LTD

Preparation method for bead-like transfer printed fabric

InactiveCN106494108ABrightness is not affectedExcellent transfer printing fastnessDuplicating/marking methodsTransfer printing processDisperse dyeLaser cutting

The invention discloses a preparation method for a bead-like transfer printed fabric. The preparation method comprises the following steps: (1) preparing disperse dyes according to the colour of a pattern, printing transfer paper and drying to obtain heat transfer printing paper; (2) bonding the heat transfer printing paper with a carving film in a hot-pressing manner, carrying out colour fixation through steam, and stripping; (3) peeling and washing the carving film and the heat transfer printing paper after the stripping to obtain a bead-like carving film; and (4) cutting the bead-like carving film into a needed bead-like shape by virtue of a laser cutting machine, and pressing the bead-like carving film onto a needed cloth. The method is different from traditional picture sublimation, a picture is sublimated on the carving film, and the pattern reserves the original brightness without influence. Meanwhile, the bead-like transfer printed fabric has a bead-like effect and a gloss of bead embroidery, and is unlimited by the colour of the pattern, the printing fastness is superior to that of the bead embroidery, and the cost is also greatly reduced.

Owner:LEACHENG APPL

Bead delivery device for bead embroidery and embroidery machine thereof

ActiveCN107245823AAvoid distortionPrevent rotationAutomatic machinesAuxillary devicesContour matchingElastic compression

The invention provides a bead delivery device for bead embroidery of a bead belt and an embroidery machine thereof. The bead delivery device comprises a bead belt guide rail, wherein the bead belt can pass through the bead belt guide rail; the bead belt guide rail is provided with a bead belt fork rod; the front end of the bead belt fork rod is in contact with a bead in an inclining way, and is provided with a concave fork opening which is matched with the contour of the bead; the bead belt fork rod is connected with an intermittent pushing mechanism; the back part of the bead belt fork rod is provided with a spring to press the front end of the bead belt fork rod against the bead belt; an elastic press sheet is arranged on the bead belt guide rail; a clamp buckle is arranged at the front end of the elastic press sheet and is used for blocking the retreating of the bead belt. The bead delivery device can avoid the pushing failure of the beads or empty needle because of the push rod failing to align with a through hole or the through hole of the bead failing to align with an embroidery needle after the bead is pushed out.

Owner:汕头市龙琦工贸有限公司

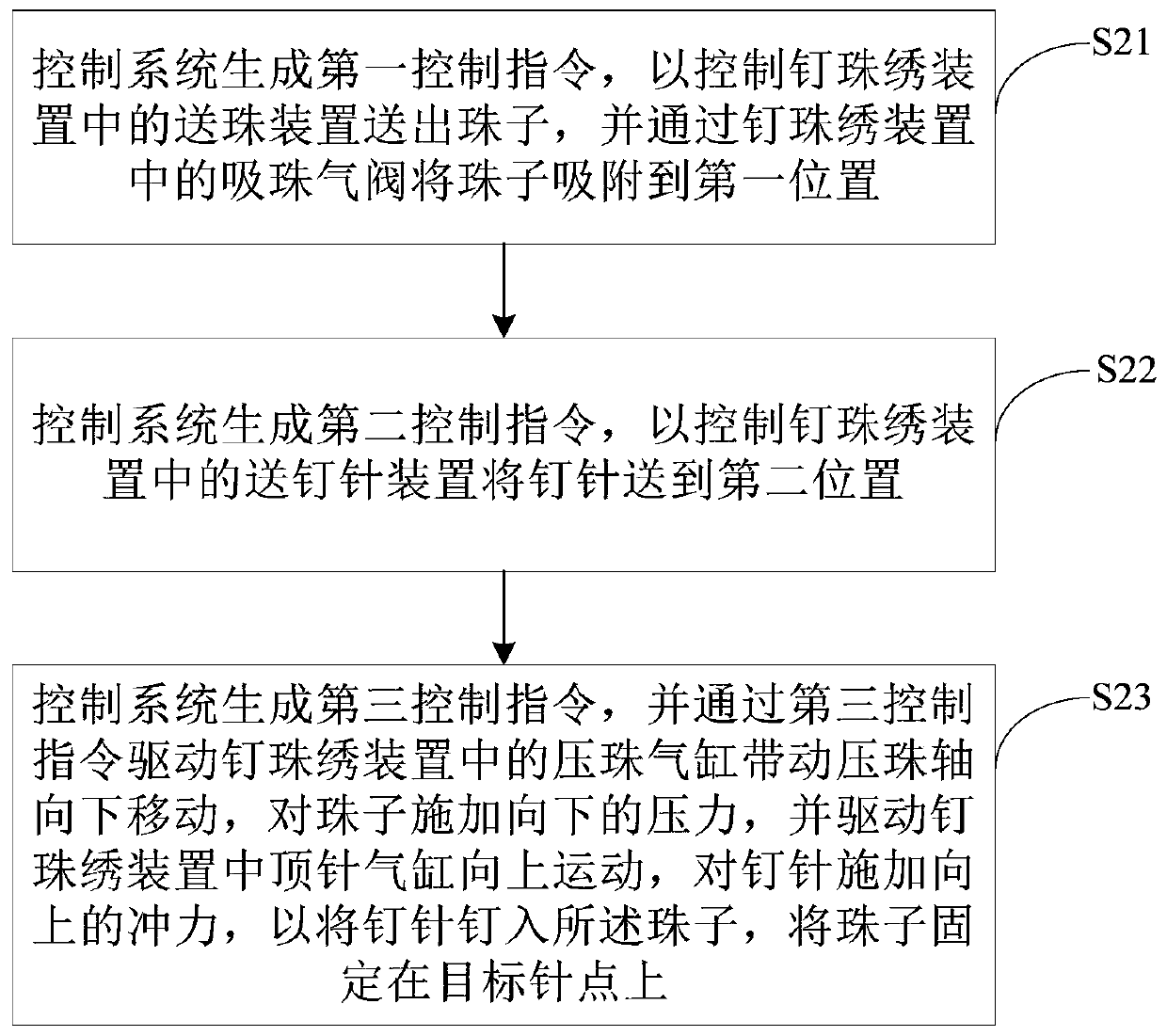

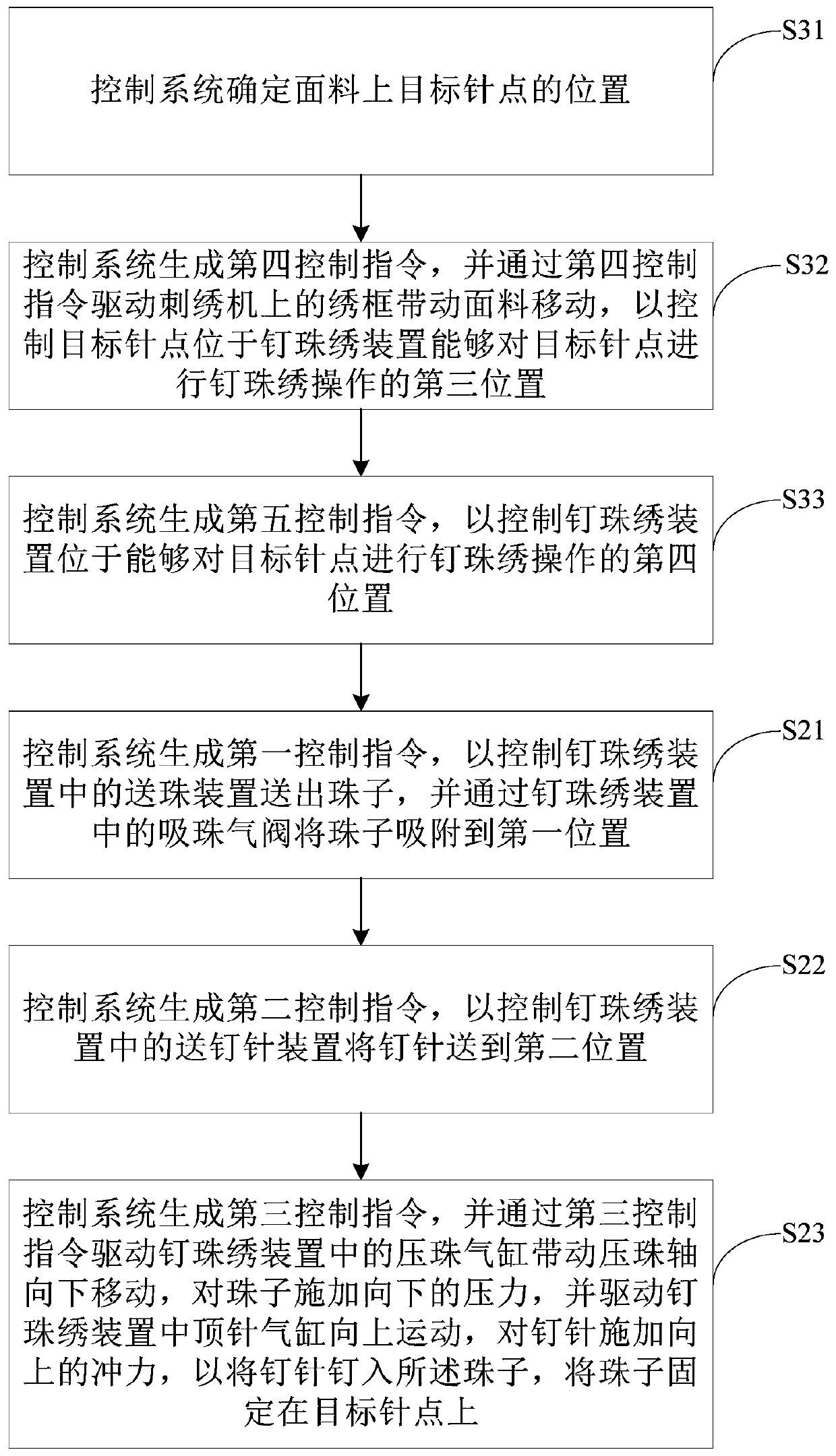

Beading embroidery control method and device, equipment and storage medium

InactiveCN110644155ARealize automatic controlQuality assuranceAutomatic machinesMechanical engineeringGeneral surgery

The application provides a beading embroidery control method and device, equipment and a storage medium. The method comprises the steps: generating a first control instruction to control a bead feeding device in a beading embroidery device to send out beads, and attracting the beads to a first position through a bead suction air valve in the beading embroidery device; generating a second control instruction to control an ejector pin feeding device in the beading embroidery device to feed a beading needle to a second position; generating a third control instruction to drive a bead pressing cylinder in the beading embroidery device to drive a bead pressing shaft to move downwards, applying downward pressure on the beads, driving a beading needle cylinder in the beading embroidery device to move upwards and apply upward impact force on the beading needle to nail the beading needle into the beads, and fixing the beads to a target needle point, wherein the target needle point is a needle point that requires beading embroidery. Automatic control of the beading embroidery device and embroidery machine is realized.

Owner:BEIJING DAHAO TECH +2

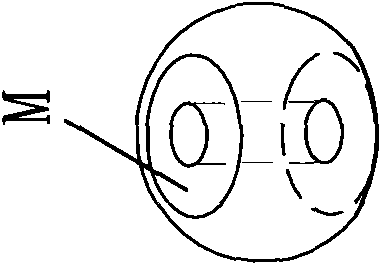

Multicolor bead change device for bead embroidery

InactiveCN107326559AReasonable structureEasy to manufactureAutomatic machinesAuxillary devicesTransducerElectric machinery

This application relates to a bead embroidery multi-color bead changing device, which includes a bead outlet seat, a fixed base, a drive motor, a connecting rod drive mechanism, an optocoupler sensor, and an induction pick. A number of bead outlet holes are longitudinally arranged on the bead outlet seat, the drive motor is arranged above the rear side of the fixed base, and its power output end is driven and connected to the bead outlet seat through a connecting rod mechanism, so that the bead outlet seat moves horizontally along the fixed base. Reciprocating sliding; the induction plectrum includes a fan part and a shaft sleeve part, the shaft sleeve part is coaxially connected with the power output end of the drive motor, the fan part is connected to the radial side of the shaft sleeve part, and the fan part is connected with the shaft sleeve part The central axis of the center is radially provided with a number of induction slots matching the number of bead holes, the housing of the drive motor is provided with an optocoupler sensor, and the fan is located in the photoelectric induction area of the optocoupler sensor. The application has the advantages of reasonable structure, convenient manufacture, and can realize multi-channel or multi-color multi-channel selection of beads.

Owner:杭州慧群机电设备有限公司

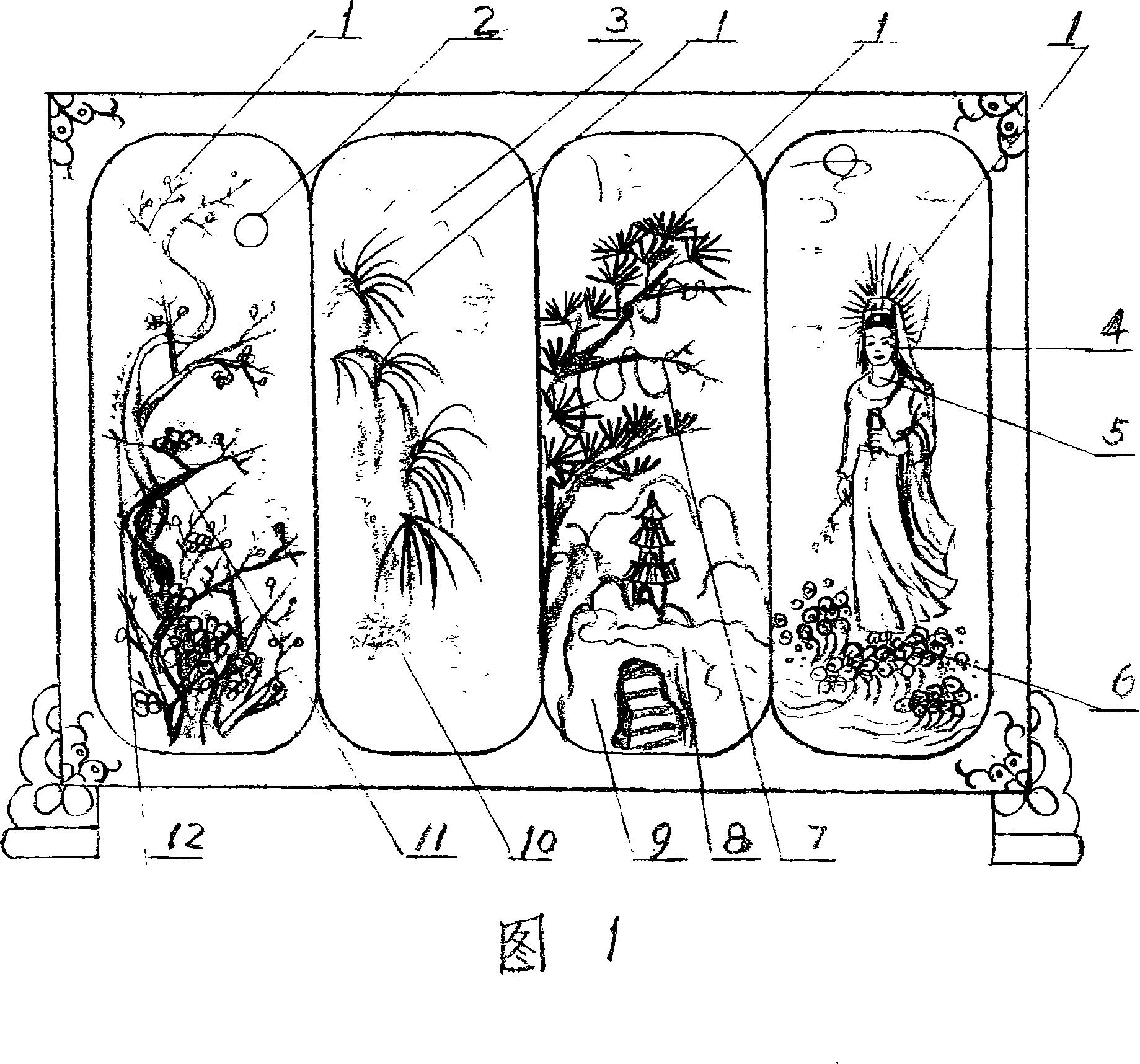

Method for making pearl embroidered handicraft picture and pearl embroidered handicraft picture

ActiveCN101077675ANovel preparation methodNovel and perfect production methodDecorative surface effectsSpecial ornamental structuresEngineeringBead embroidery

The present invention relates to handicraft, and is especially one kind of bead embroidery picture and its making process. The making process of the bead embroidery picture includes the following steps: spraying and painting background pattern and auxiliary pattern on the gauze as the base material; local treating through embroidering with glass beads, paillett and bead pipe to make bridge, suspension, etc; molding partial scenes and embedding into the picture; local building up and masking; spraying sand; and framing. The bead embroidery picture is used as indoor decoration.

Owner:胡晨光

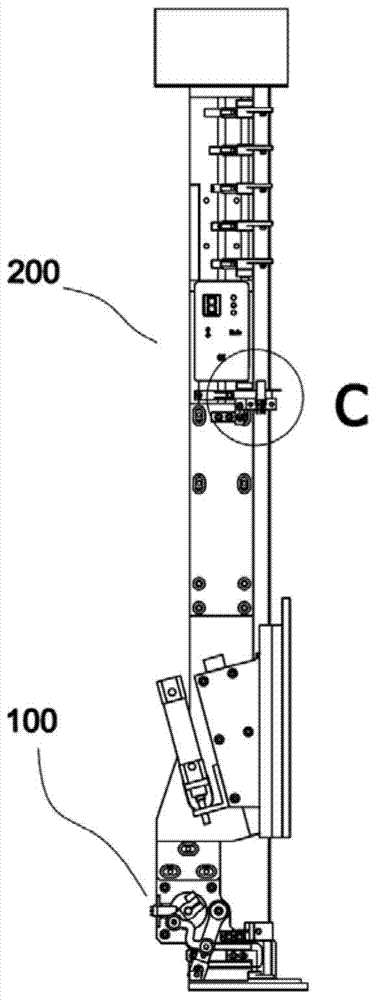

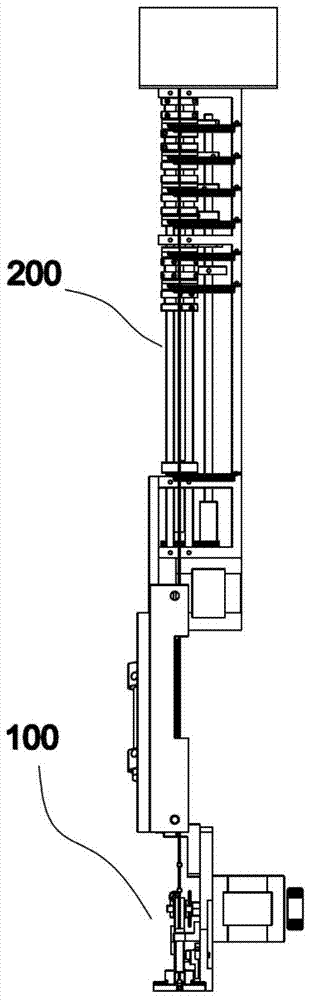

Bead row and bead feeding device for bead embroidery device

ActiveCN104372542BGuaranteed to stay the sameAchieve teleportationAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses a bead arranging and feeding device of a bead embroidery device. The bead arranging and feeding device comprises a rack, a power driving and distributing device which is fixedly arranged on the rack, a bead guide rod for guiding beads to drop and provided with a bead containing section, an upper bead feeding section movably arranged on the rack, and a lower bead feeding section movably arranged on the rack, wherein a bead arranging device is arranged at the upper part of the rack, the upper bead feeding section comprises a plurality of upper section clamping devices, the power driving an distributing device drives at least one upper section clamping device which is used for clamping the bead guide rod; and the lower bead feeding section comprises a lower section clamping device, the power driving and distributing device drives the lower section clamping device to clamp the bead guide rod, and the lower section clamping device is away from the closest upper section clamping device by a distance, so that the enough beads can penetrate the bead containing section between the lower section clamping device and the closest upper section clamping device. The bead arranging and feeding device has a simple structure, can be used conveniently, has the high production efficiency and can clamp the bead guide rod stably.

Owner:WENZHOU OULUOHUA INDAL

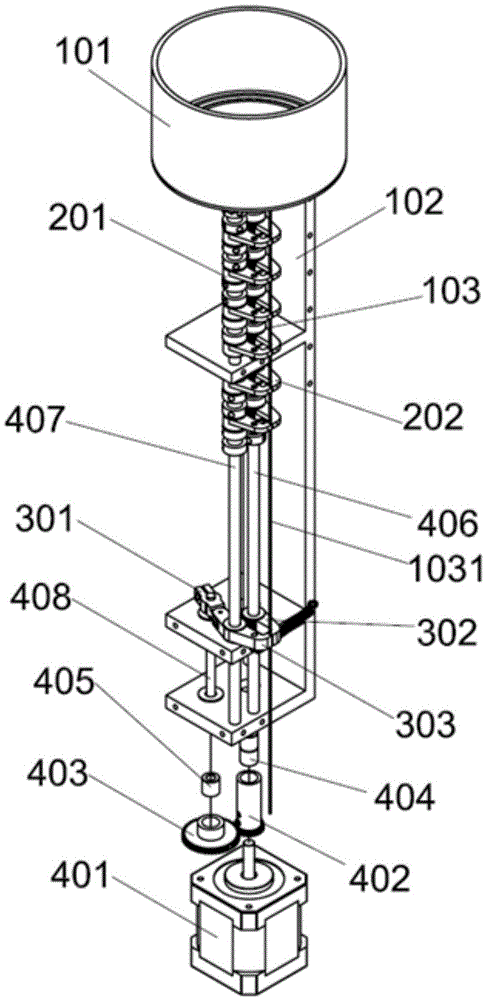

Bead feeding device and embroidery machine

PendingCN108166181APrecise positioningThe delivery process is controllableAutomatic machinesAuxillary devicesDrive wheelEngineering

The invention discloses a bead feeding device. The bead feeding device comprises a conveying carrier for positioning at a bead feeding mechanism and conveying beads from the bead feeding mechanism toa corresponding position of a feeding mechanism, the conveying carrier is a chain or a belt, the conveying carrier is provided with a driving wheel for driving the conveying carrier, the conveying carrier is provided with at least one material storage hole, the each material storage hole can store a bead for embroidery, and a positioning rod fitting to a bead hole to position the bead for embroidery is arranged in the material storage hole. Compared with the existing feeding device, the bead feeding device has the advantages of use of the conveying carrier, direct picking of beads from the feeding mechanism, directed conveying, controllable conveying, accurate bead positioning, simple structure, small size and large use range. The bead feeding device fits to the existing bead embroidery bead feeding mechanism and conveys beads. Through combination with a material hopper, loose beads are directionally conveyed to the corresponding position of the bead feeding mechanism so that the embroidery machine can directly embroider the loose beads.

Owner:ZHUJI GUANXIANG MACHINERY TECH CO LTD

Three-color bead embroidery device on embroidery machine

ActiveCN114150448AReasonable structurePowerfulAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention provides a three-color bead embroidery device on an embroidery machine, which comprises a lifting assembly, a first feeding assembly and a second feeding assembly are fixedly mounted above the lifting assembly, a first bead feeding assembly and a second bead feeding assembly are fixedly mounted below the lifting assembly, the first feeding assembly and the first bead feeding assembly are arranged in a matched manner, and the second feeding assembly and the second bead feeding assembly are arranged in a matched manner. The second feeding assembly and the second bead feeding assembly are arranged in a matched mode. The three-color bead embroidering device can perform bead embroidering operation on three different specifications of beads at the same time, the bead embroidering effect is good, the equipment cost is effectively reduced, and the use area of a site is reduced. In conclusion, the three-color bead embroidery device on the embroidery machine is reasonable in structure, powerful in function and suitable for popularization and application.

Owner:丹阳德顺刺绣机械有限公司

Multi-specification bead embroidery device and embroidery machine

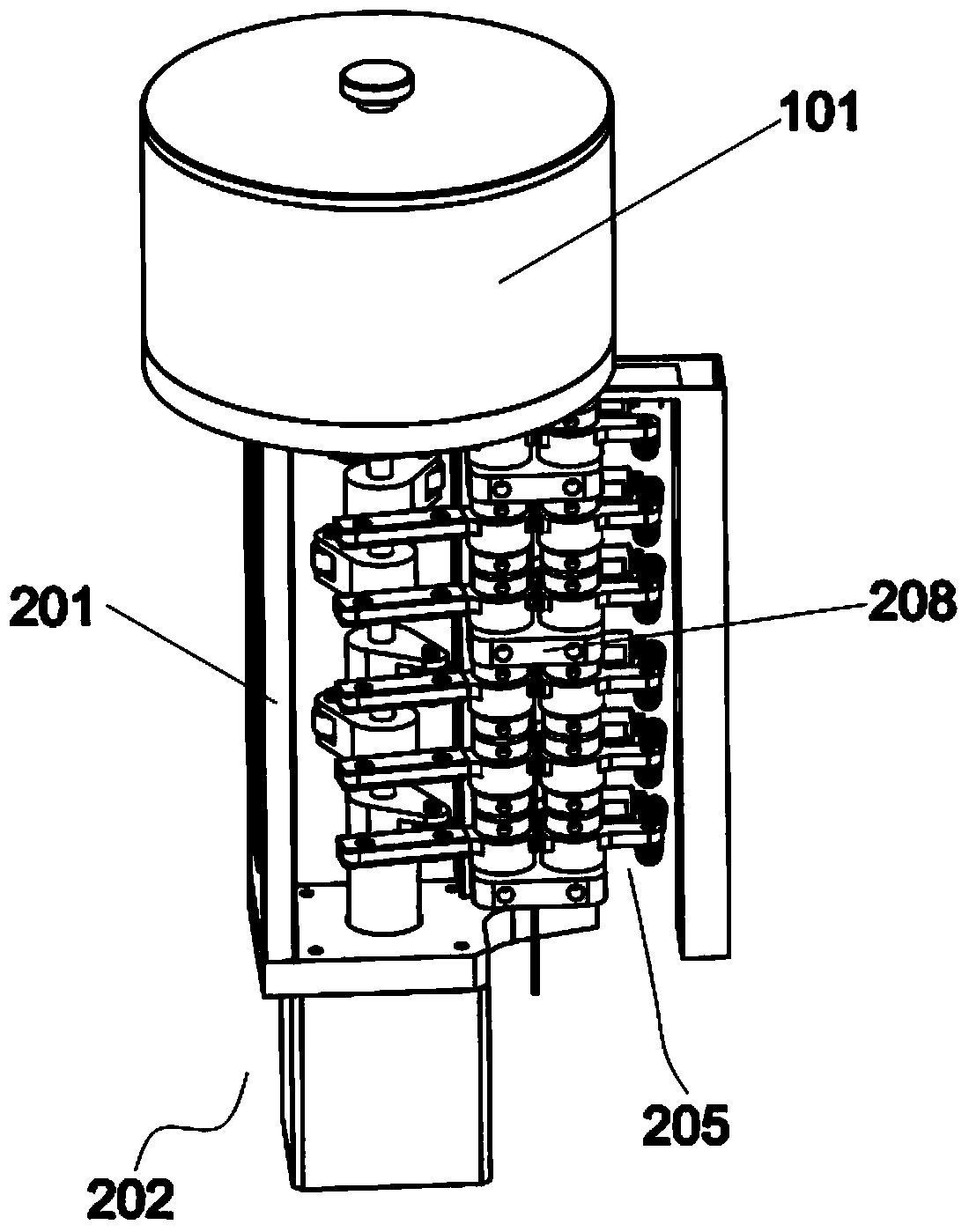

PendingCN109706654AImprove concentrationSmall footprintAutomatic machinesAuxillary devicesBead embroideryElectrical and Electronics engineering

The invention provides a multi-specification bead embroidery device. The device comprises an upper segment, a middle segment and a lower segment which are connected from top to bottom in sequence, thelower segment is provided with two or more pushing channels which are evenly distributed along an arc, and the pushing channels radially extend; a pushing assembly is arranged in each pushing channel, all the pushing assemblies are alternatively away from or close to the position under the same needle rod on a handpiece under the effect of a bead pushing driving mechanism of the lower segment, and beads different in color are output in order. The multi-specification bead embroidery device and an embroidery machine are small in size and high in working efficiency.

Owner:黄宇婷

A bead screening device and a bead embroidery machine using the device

ActiveCN104593962BRealize continuous detectionRealize screeningAutomatic machinesAuxillary devicesEngineeringMechanical engineering

Owner:浙江冠炯智能科技有限公司

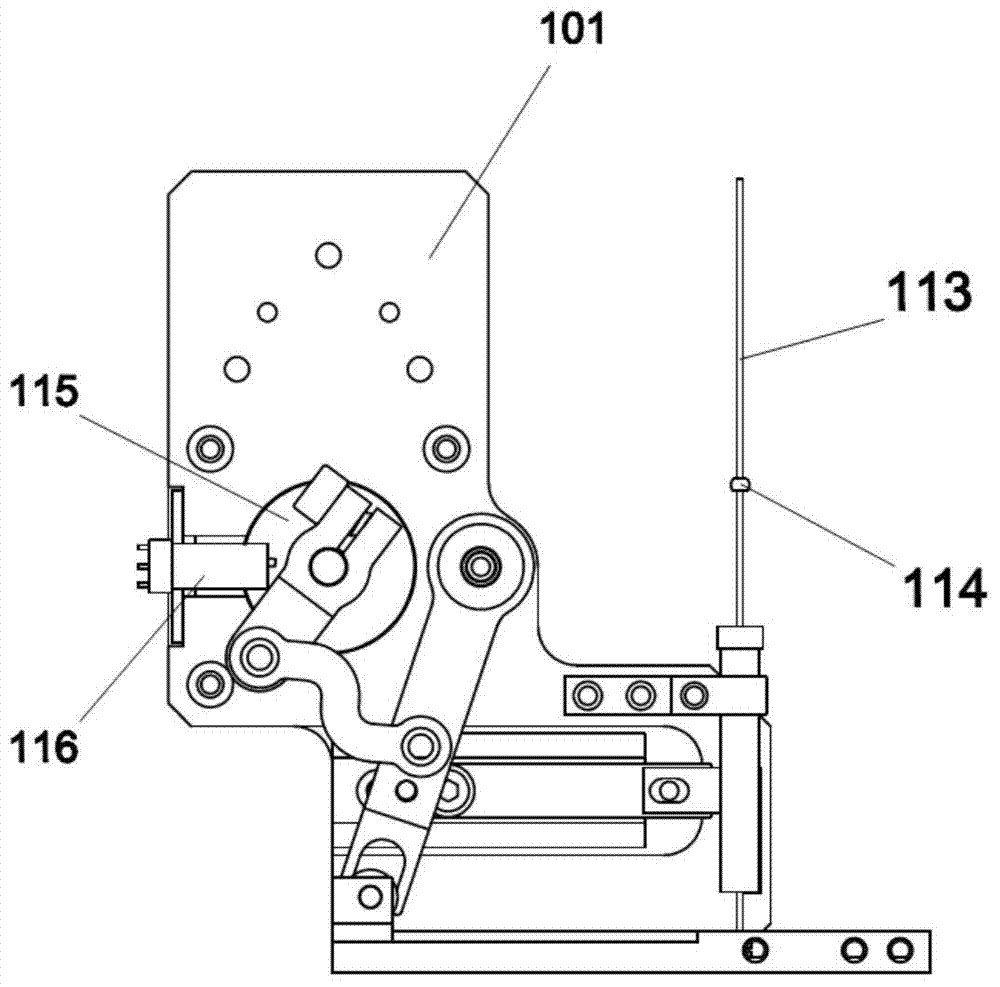

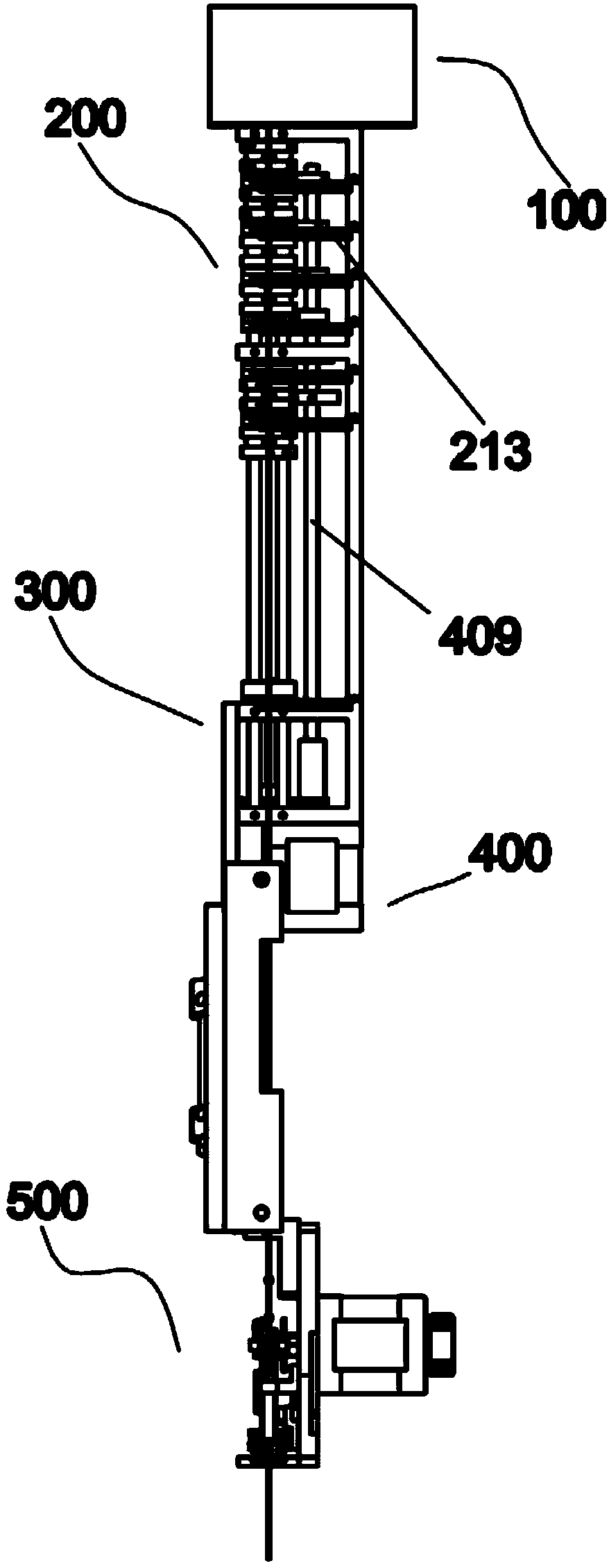

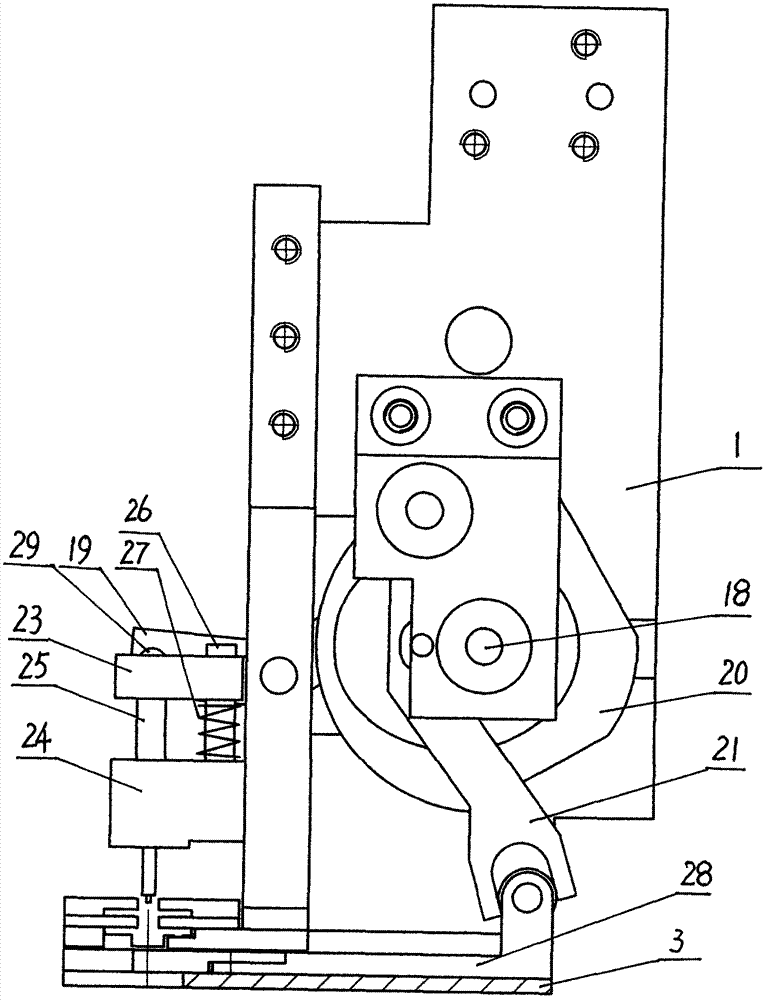

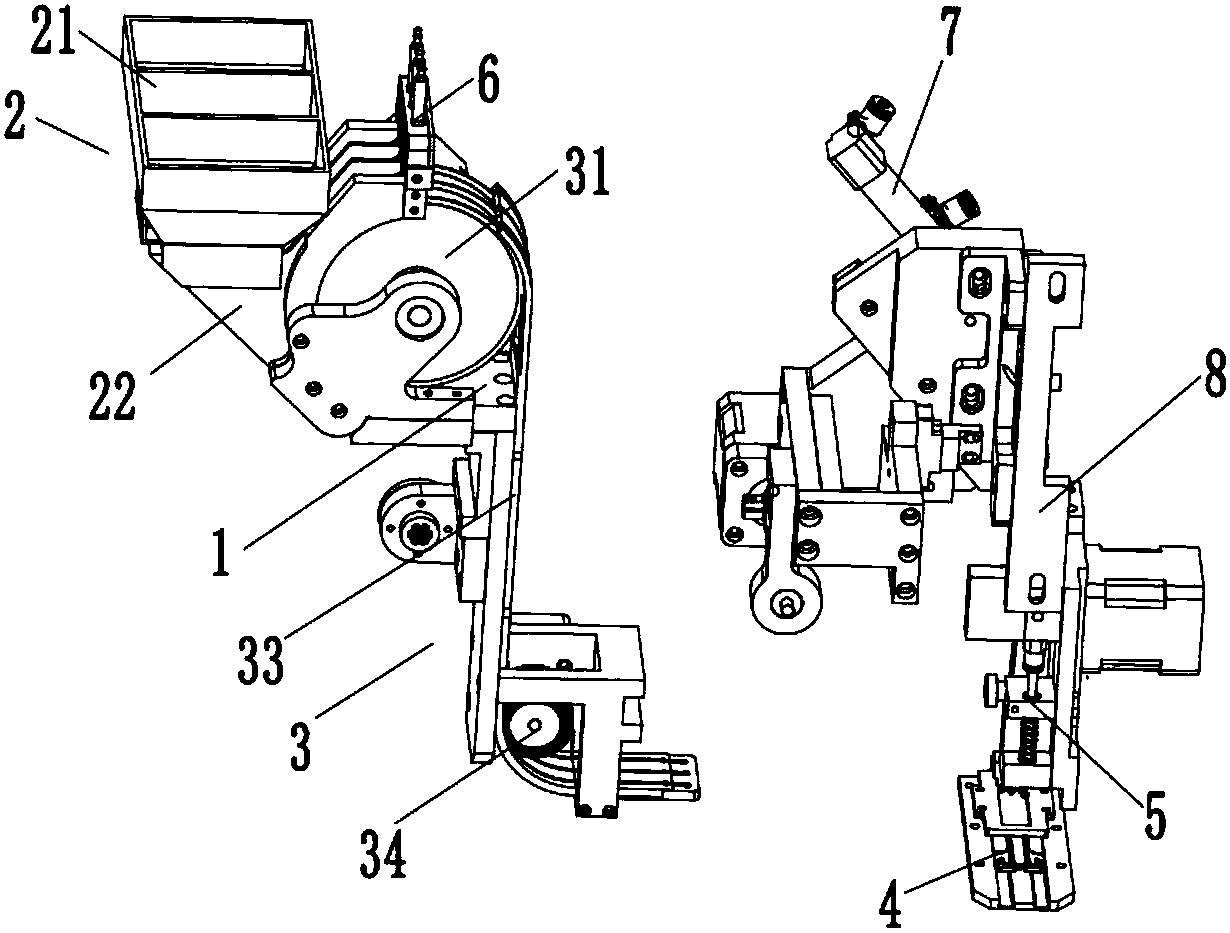

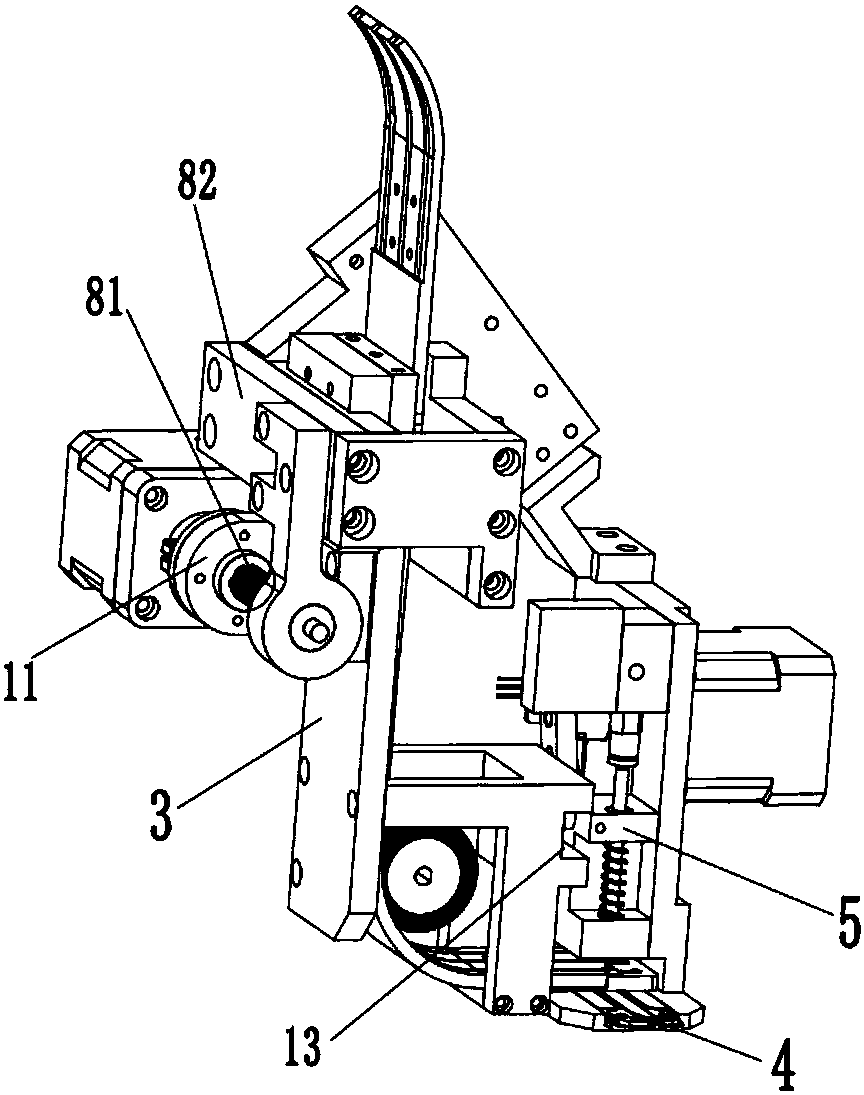

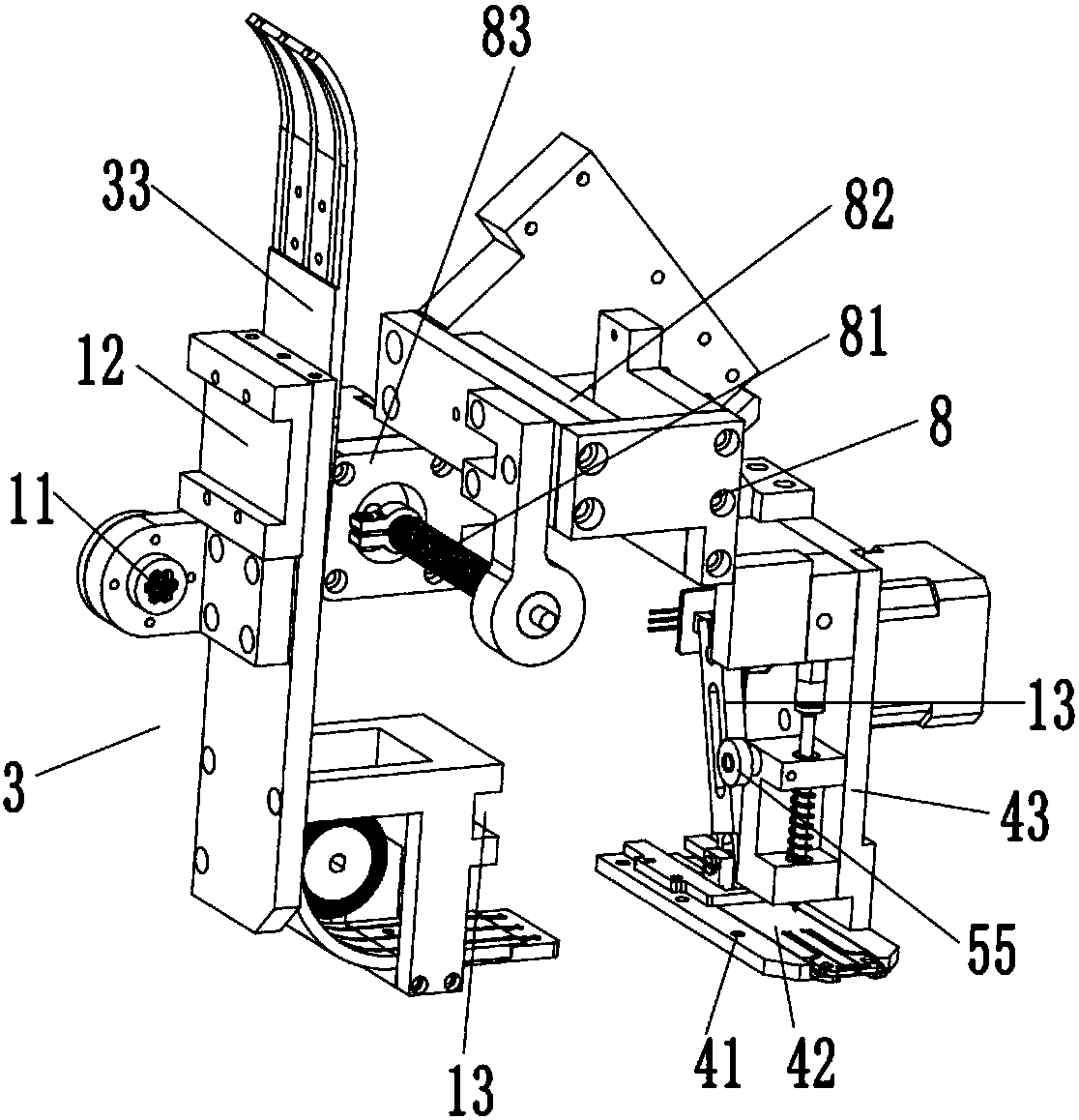

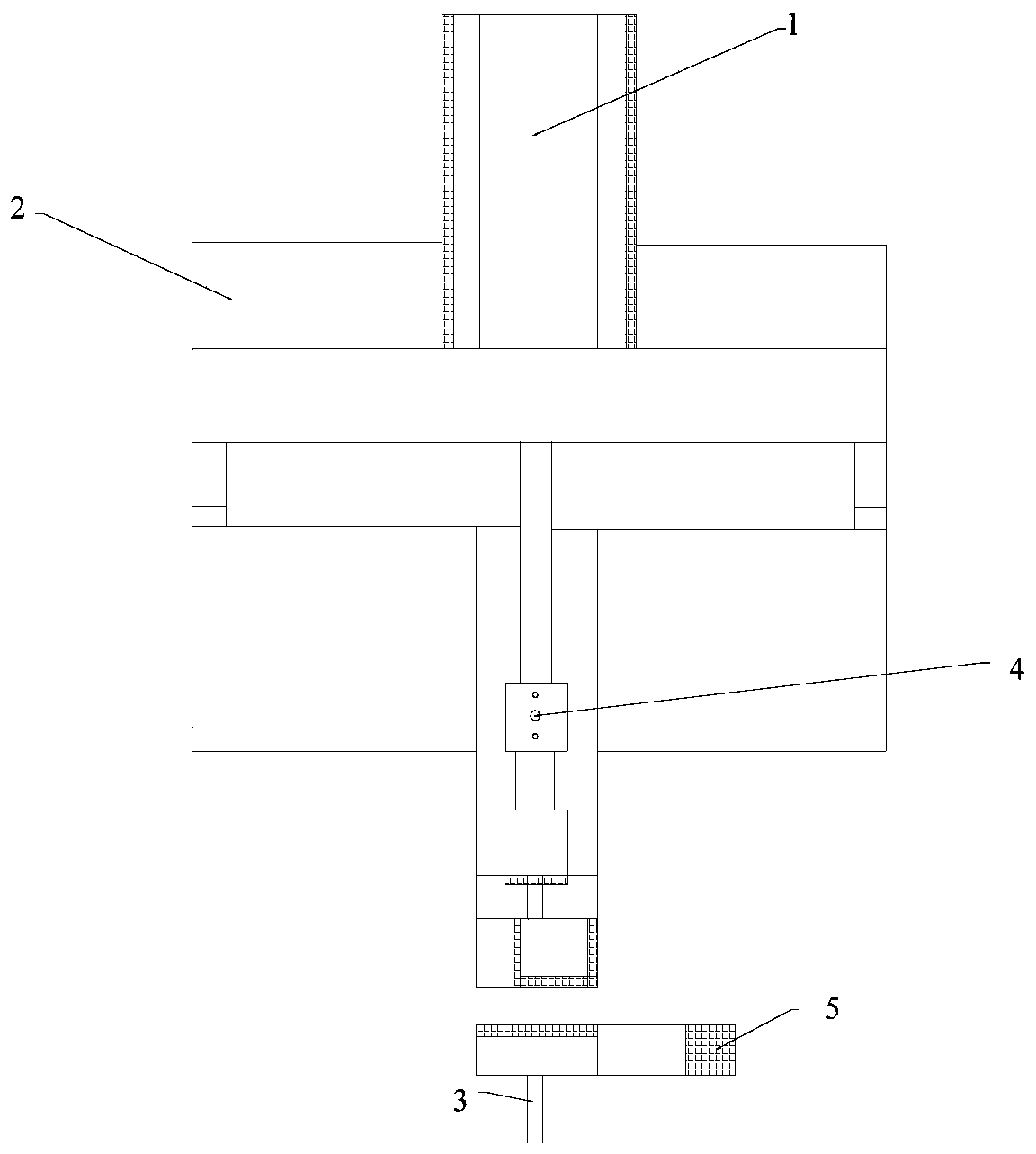

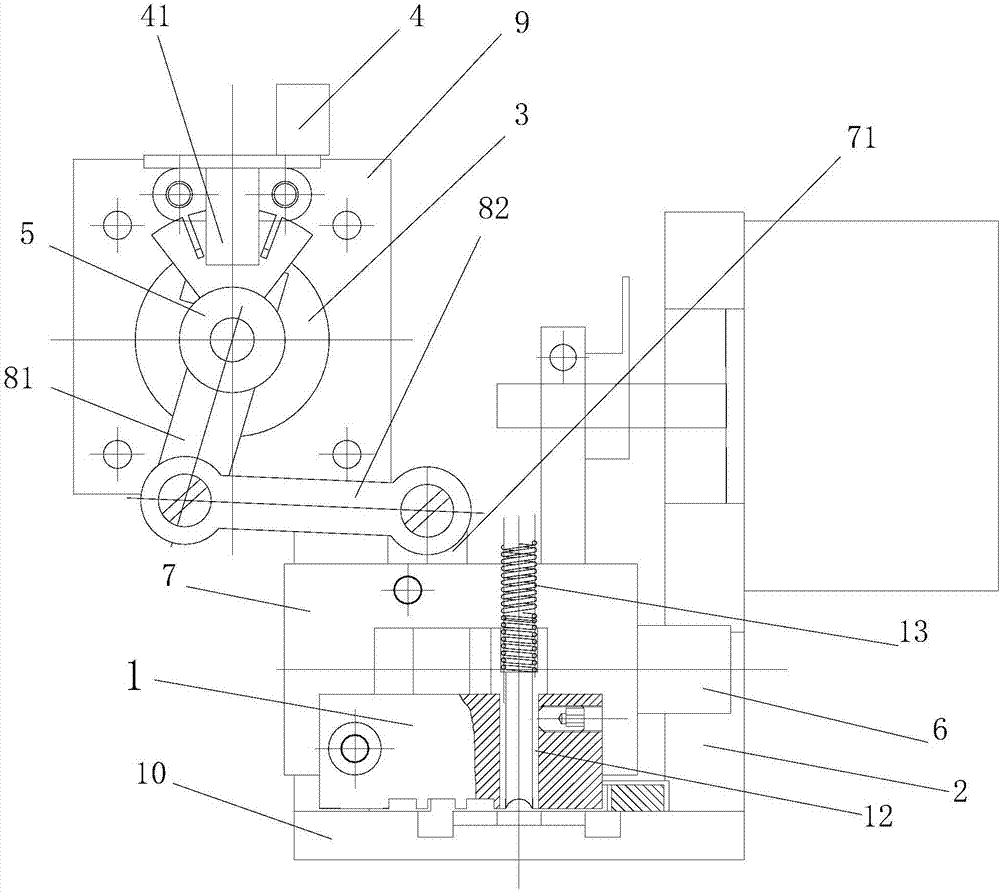

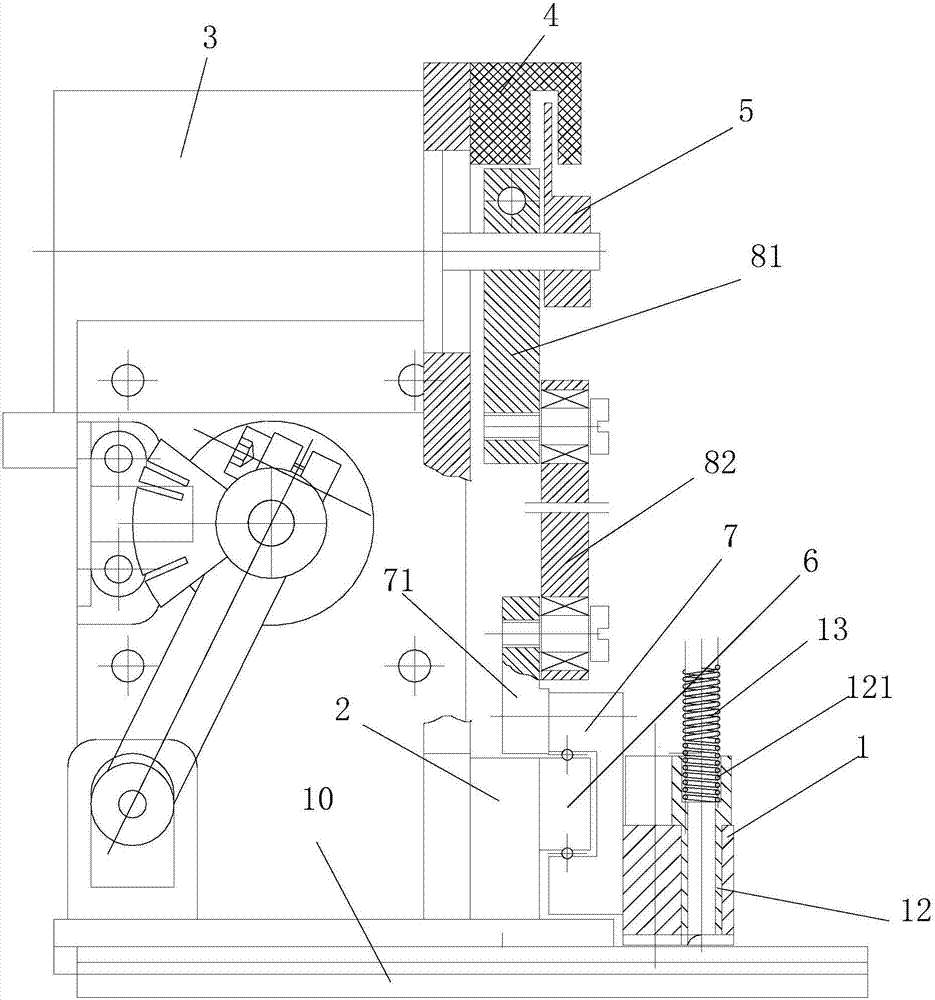

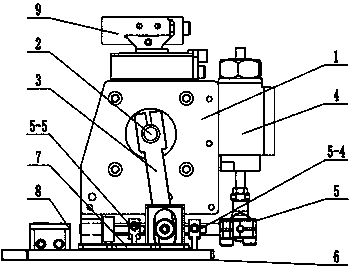

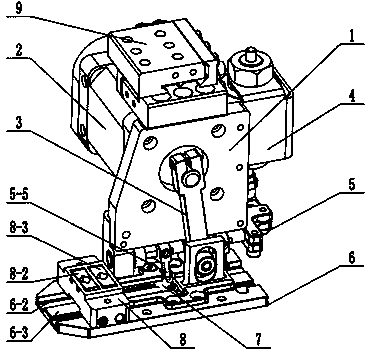

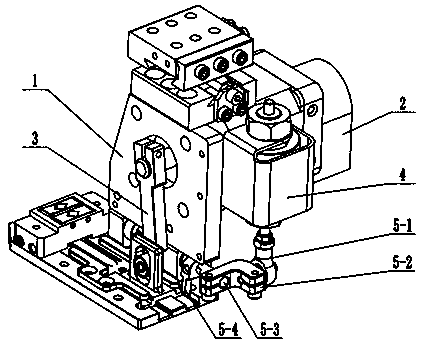

Bead embroidery device for embroidery machine

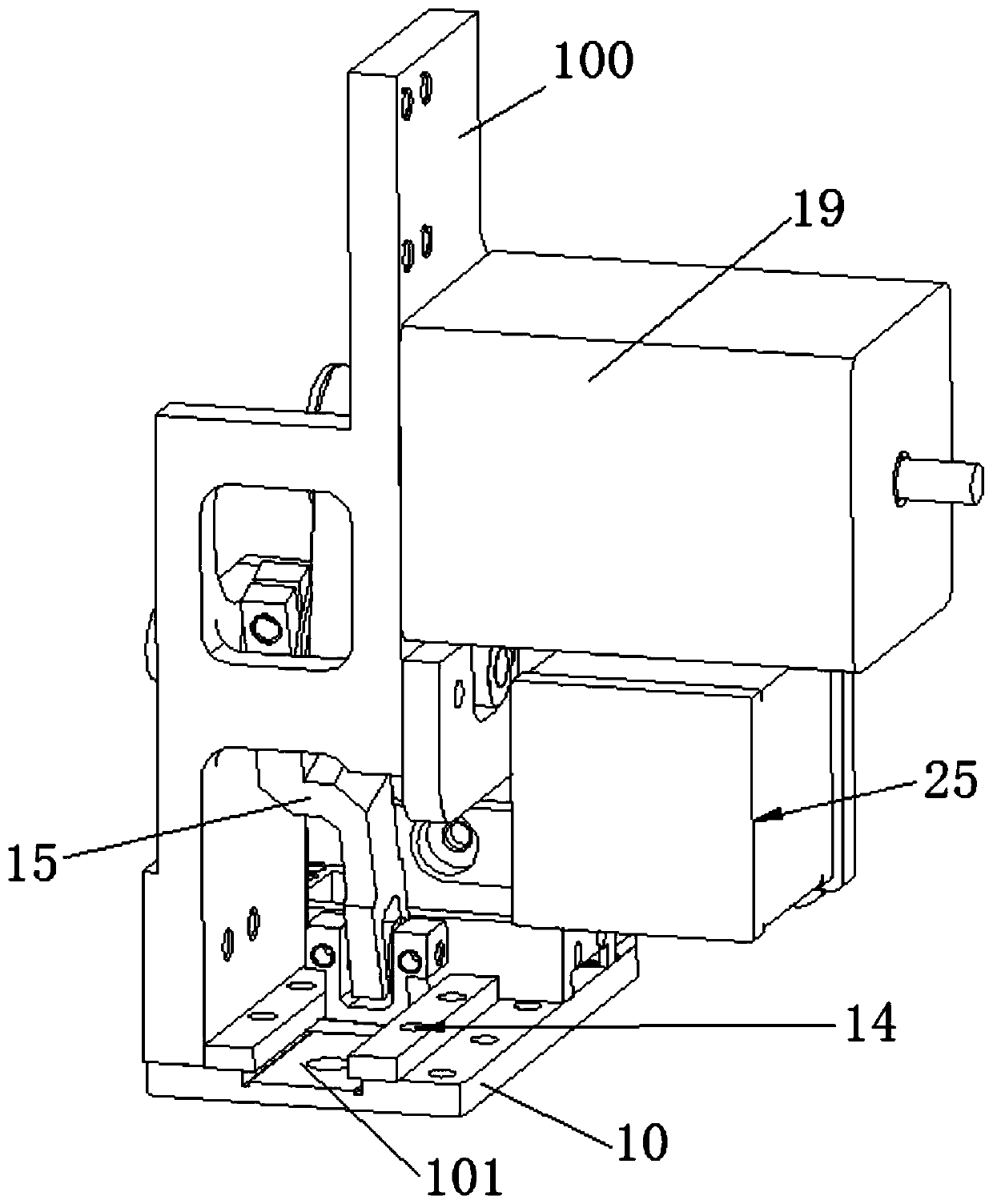

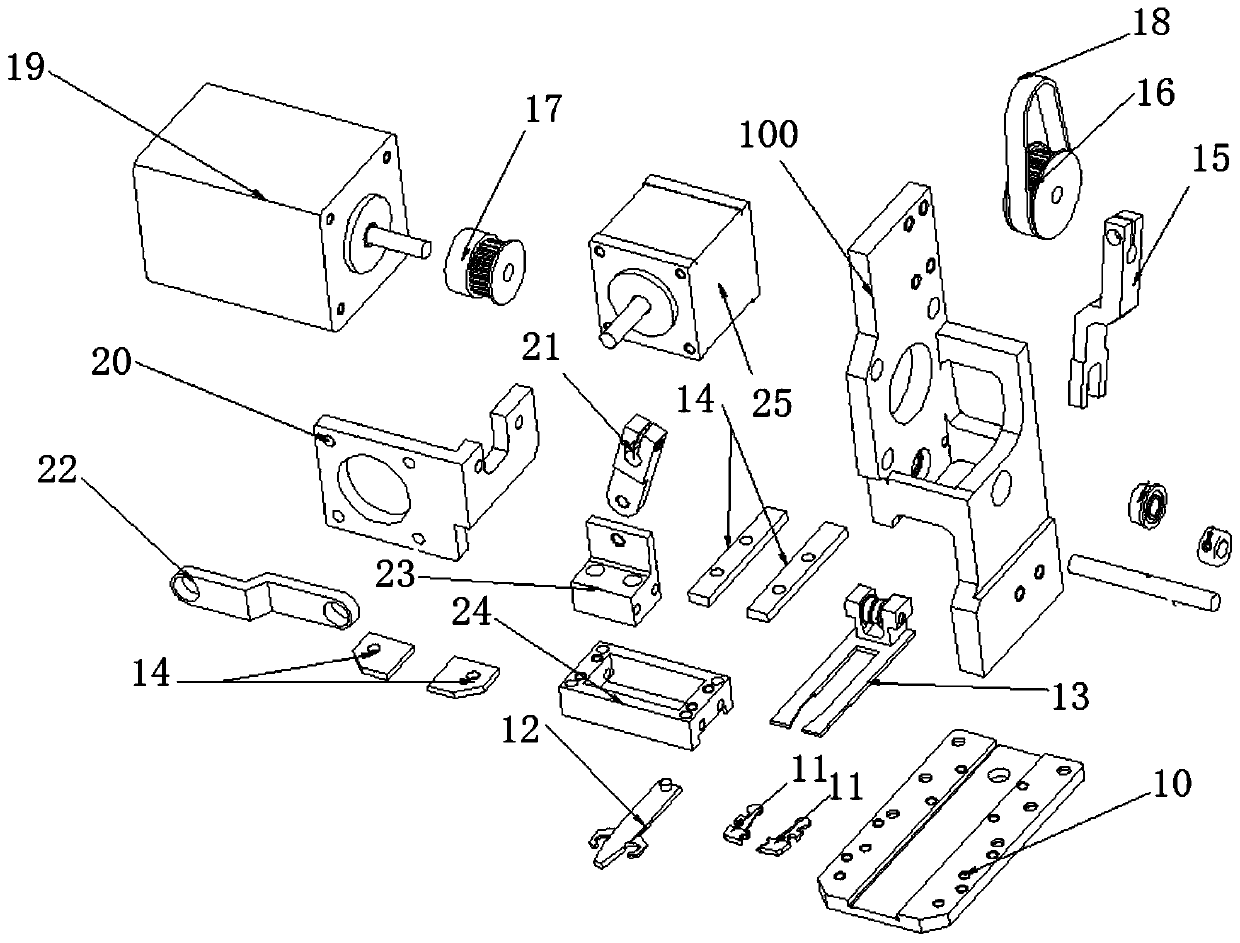

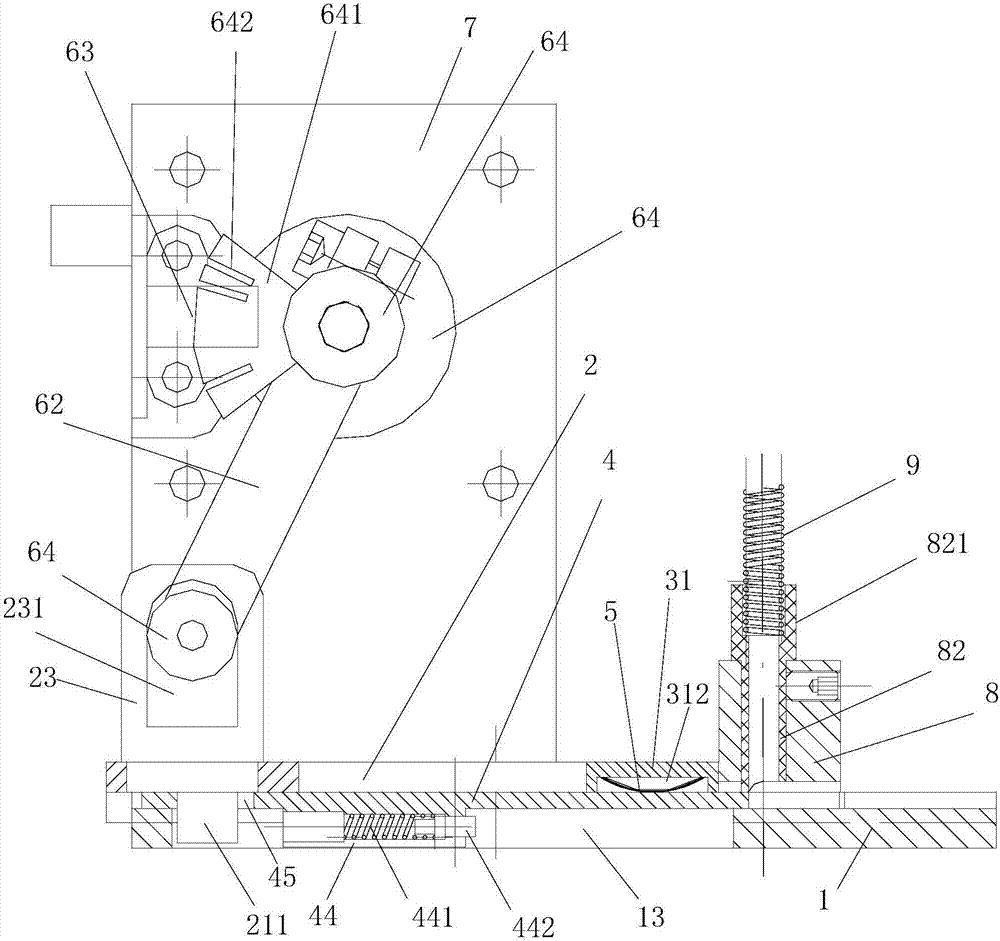

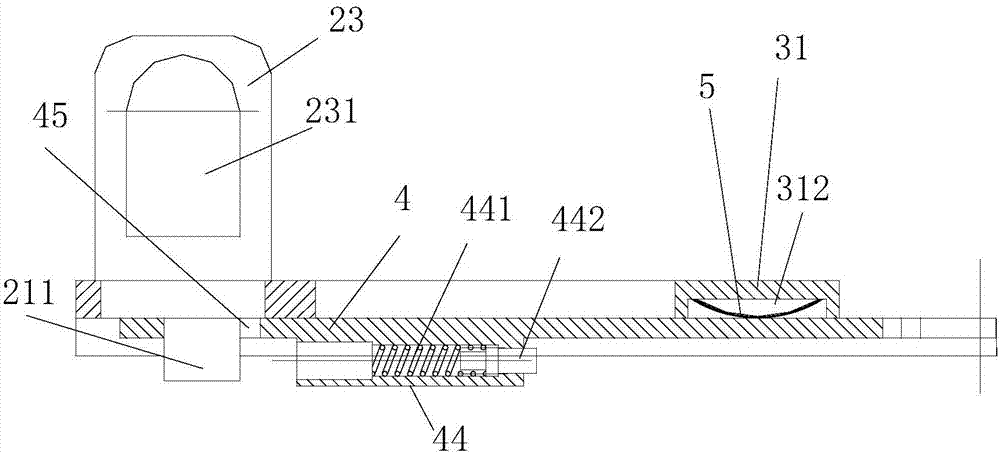

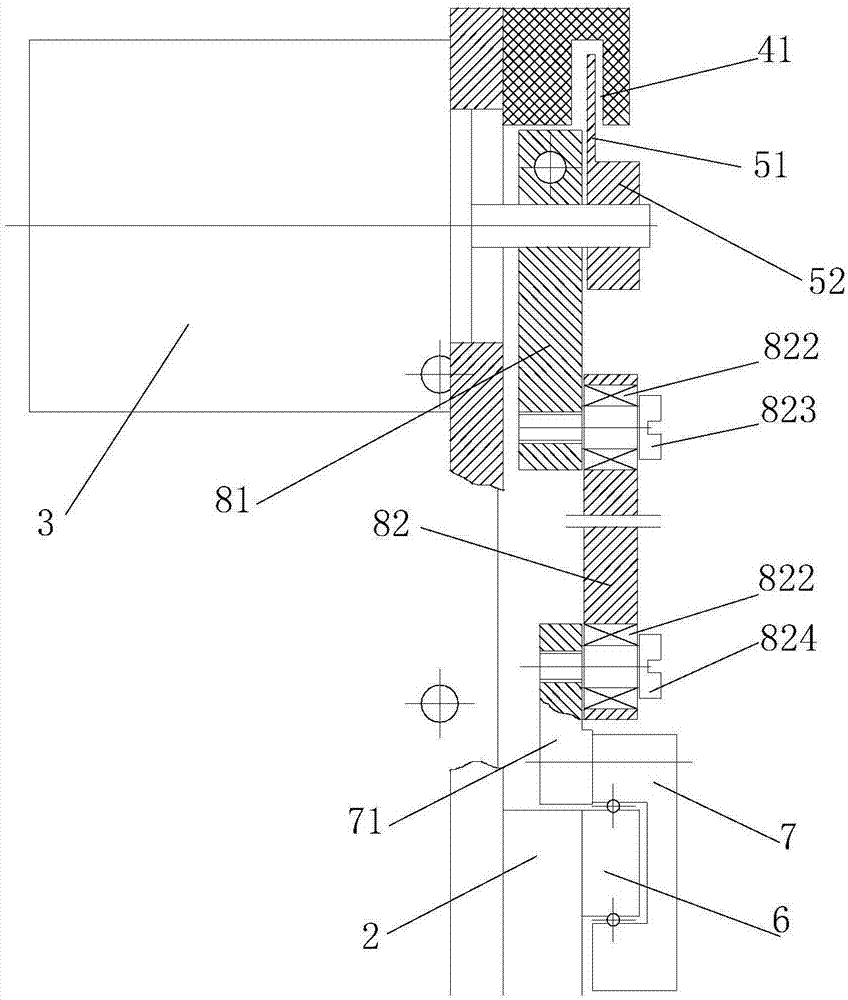

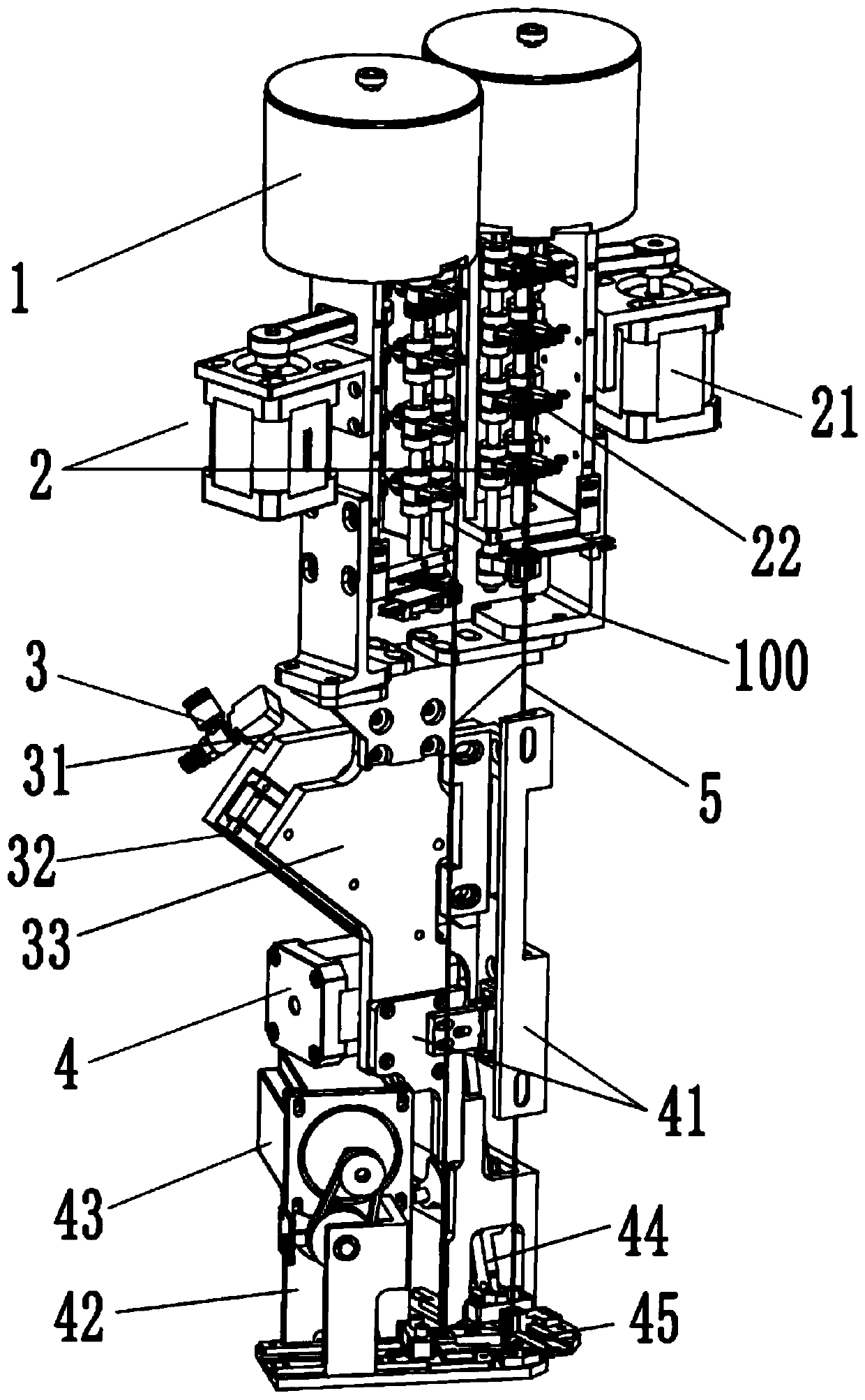

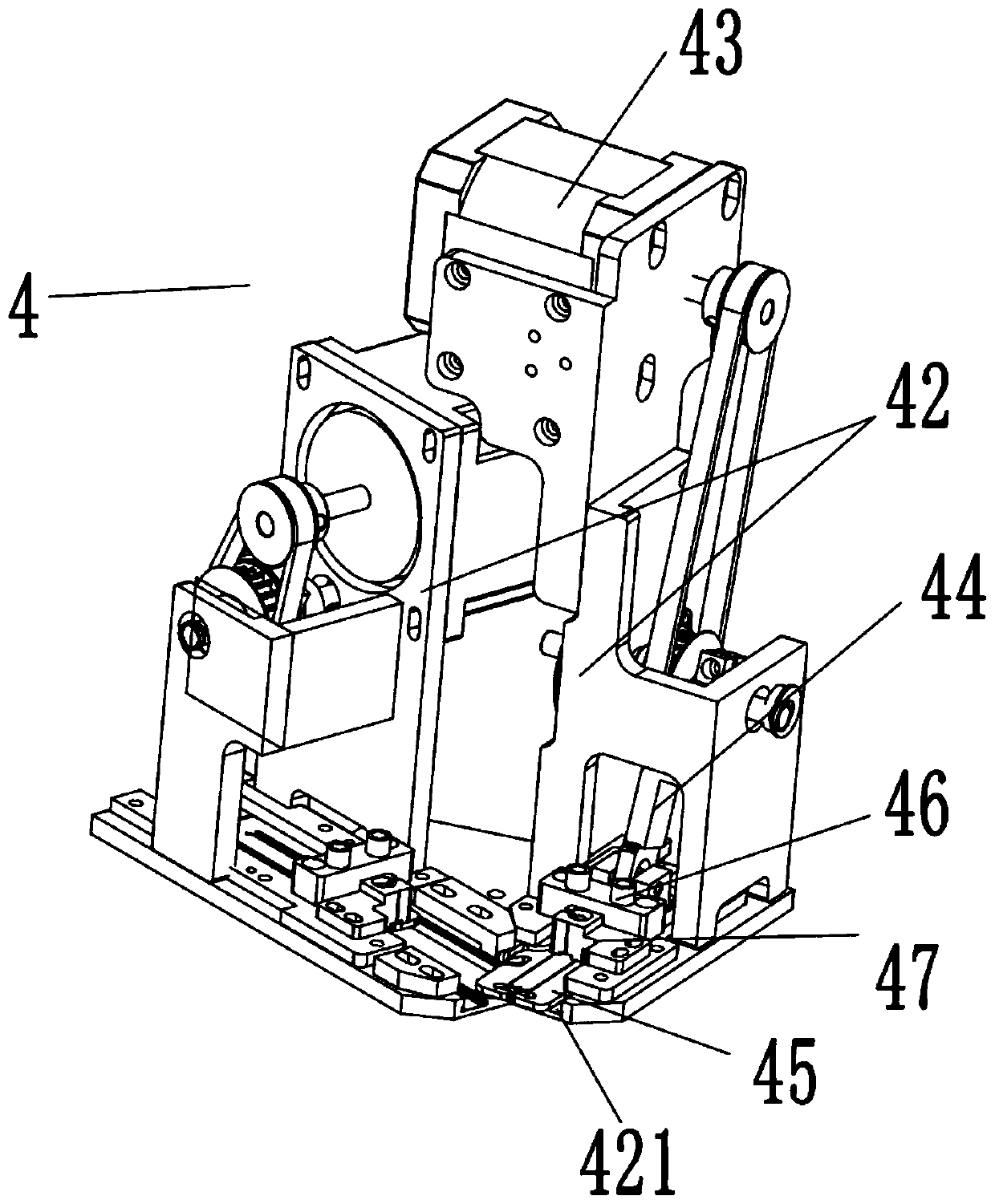

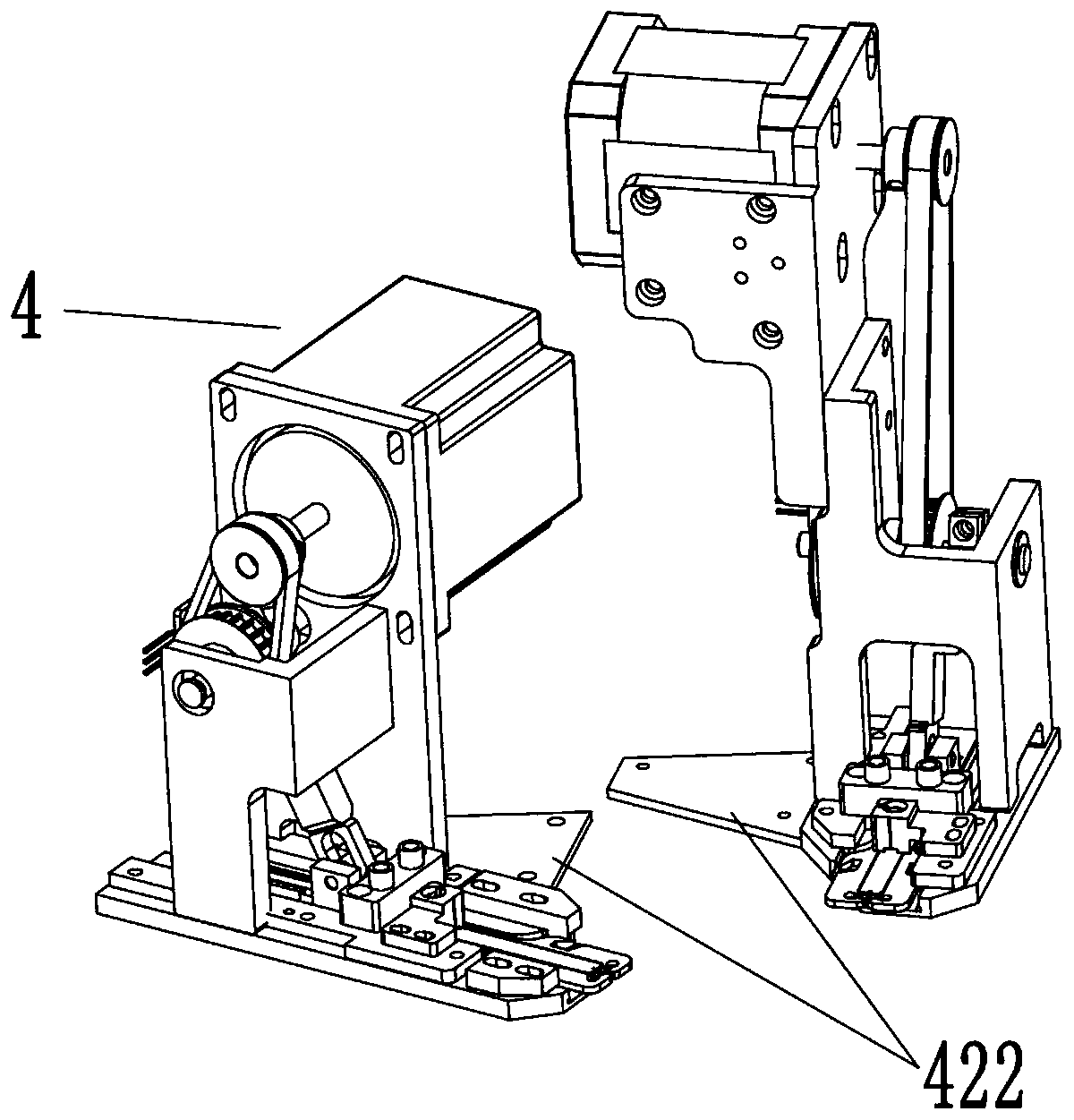

ActiveCN111235778AIncrease productivityReduce use costAutomatic machinesManufacturing computing systemsStructural engineeringMechanical engineering

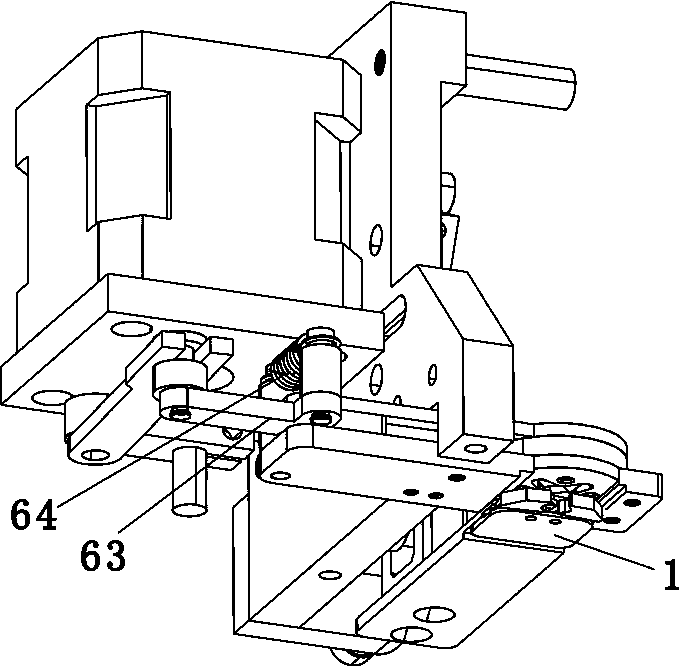

Disclosed is a bead embroidery device for an embroidery machine. A first driving assembly (2) is mounted on the back of a base plate assembly (1); a swing arm (3) is connected with the first driving assembly (2); a second driving assembly (4) is fixed on the side of the base plate assembly (1); a switching assembly (5) is connected with the second driving assembly (4); a base (6) is fixed at the bottom of the base plate assembly (1); a feeding assembly (7) is mounted on a sliding groove (6-2) of the base (6) in a matched mode; the front end of the swing arm (3) is assembled and connected withthe feeding assembly (7) in a matched mode; and a material separating assembly (8) is mounted on the base (6) in a transverse span mode. According to the bead embroidery device, two single clamp headsare combined into a material separating clamp head, and the cross section of an inner cavity in the combined material separating clamp head is of a quadrilateral structure, so that feeding of beads of multiple diameters can be applicable, and the operation of frequently changing the material separating clamp heads due to different diameters of beads can be omitted, thereby greatly improving the production efficiency and lowering the use cost.

Owner:丹阳德顺刺绣机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com