Bead embroidery device for embroidery machine

An embroidery machine and bead technology, applied in the field of embroidery machines and embroidery machines, can solve the problems of complex mechanical structure, easy occurrence of leaking beads, easy occurrence of mechanical failures, etc., and achieves the effect of reducing use cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

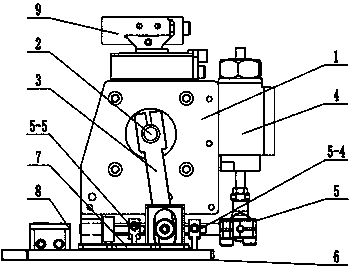

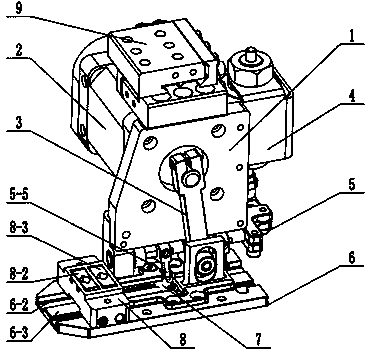

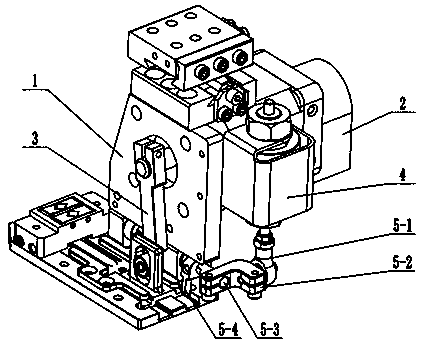

[0029] Depend on Figure 1 to Figure 14 Known, a schematic diagram of a bead embroidery device for an embroidery machine, including a base plate assembly 1, a first drive assembly 2, a swing arm 3, a second drive assembly 4, a switch assembly 5, a base 6, a feeding assembly 7, and a material distribution assembly 8. The above-mentioned first driving assembly 2 is installed on the back of the substrate assembly 1, the swing arm 3 is connected to the first driving assembly 2, the second driving assembly 4 is fixed on the side of the substrate assembly 1, and the switching assembly 5 is connected to the second driving assembly 4 , the base 6 is fixed on the bottom of the substrate assembly 1, the feeding assembly 7 is mounted on the chute 6-2 of the base 6, the front end of the swing arm 3 is assembled and connected with the feeding assembly 7, and the swing arm 3 is mounted on the first driving assembly 2 Under the effect of swinging left and right, the feeding assembly 7 is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com