Multicolor bead change device for bead embroidery

A bead embroidery and bead seat technology is applied in the field of multi-color bead changing devices for bead embroidery, which can solve the problems of complex overall mechanism, high maintenance cost, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

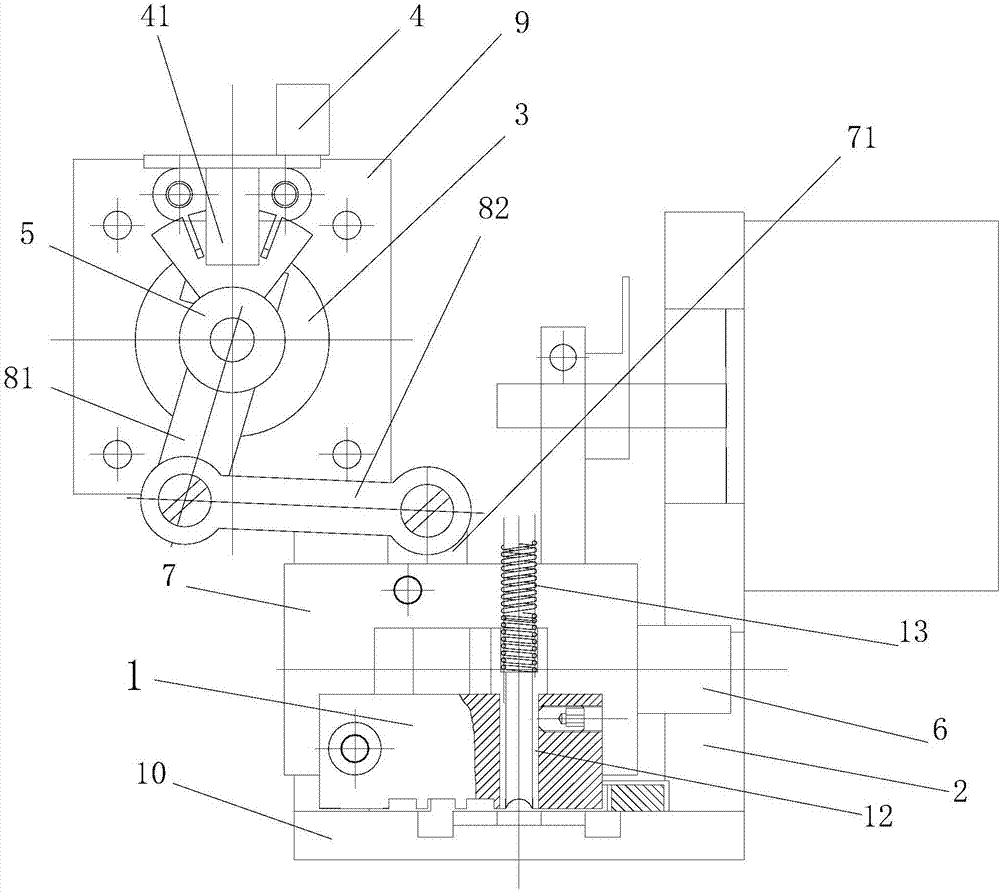

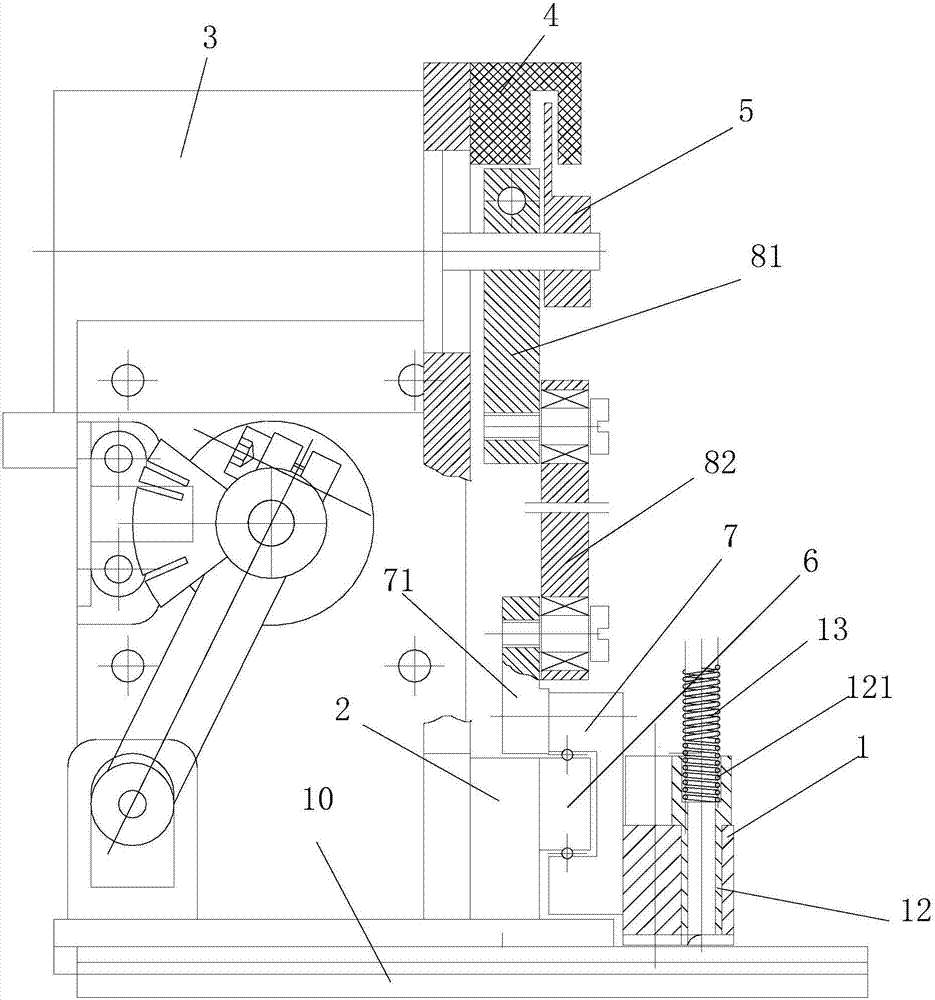

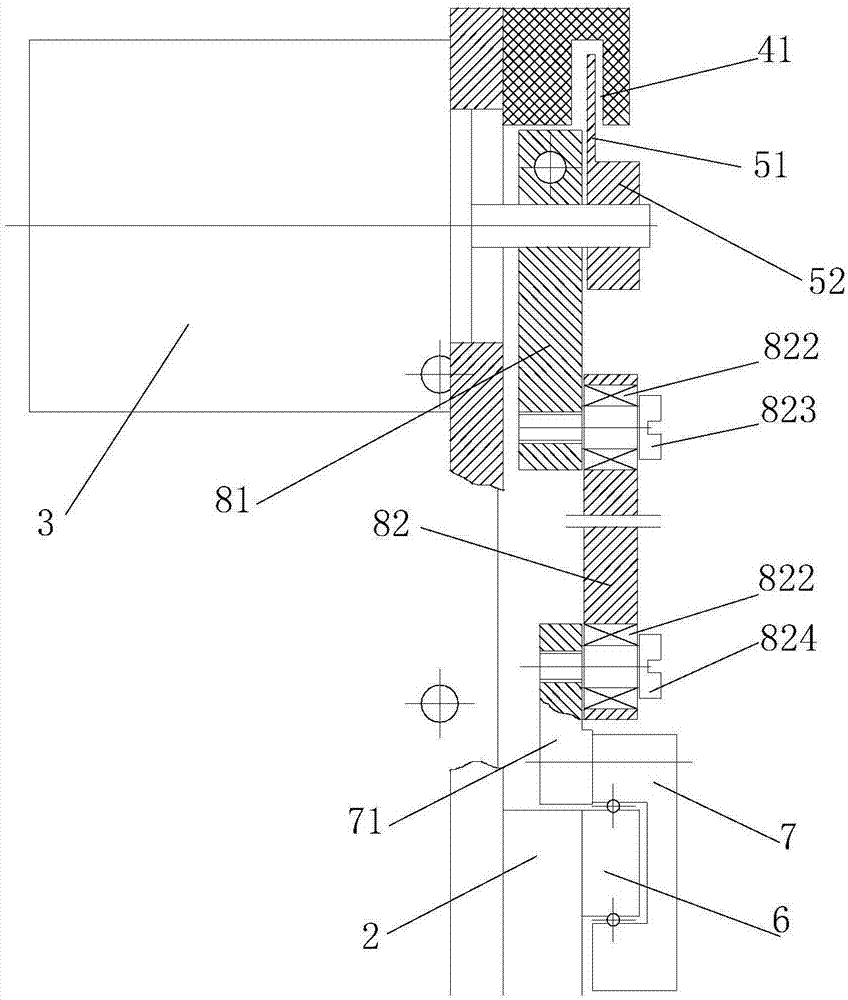

[0027] Embodiment 1: refer to Figure 1-8 . A bead embroidery multi-color bead changing device, comprising a bead output seat 1, a fixed base 2, a drive motor 3, a connecting rod drive mechanism, an optocoupler sensor 4, and an induction pick 5, the bead output seat 1 and the fixed base 2 Horizontally guided connection, the bead outlet seat 1 is longitudinally provided with several bead outlet holes 11, the drive motor 3 is arranged above the rear side of the fixed base 2, and its power output end is driven and connected to the bead outlet seat 1 through a linkage mechanism , make the bead seat 1 reciprocate and slide laterally along the fixed base 2; the induction paddle 5 includes a fan portion 51 and a shaft sleeve portion 52, the shaft sleeve portion 52 is coaxially connected with the power output end of the drive motor 3, and the fan portion 51 Connected to the radial side of the shaft sleeve part 52, the fan part 51 is radially provided with a number of induction slots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com