Pearl embroidery device for computerized embroidery machine

An embroidery machine and bead embroidery technology, applied in the field of bead embroidery devices, can solve the problem of high production cost, achieve the effects of reducing the scrap rate, ensuring accurate positioning, and improving the quality of embroidery products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

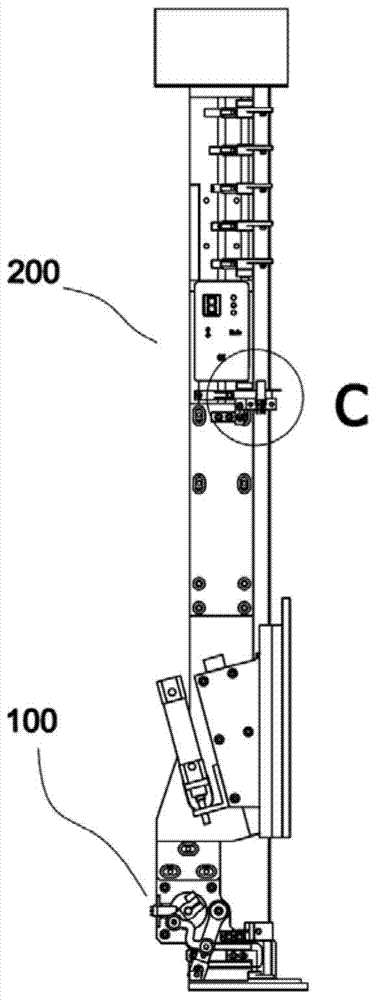

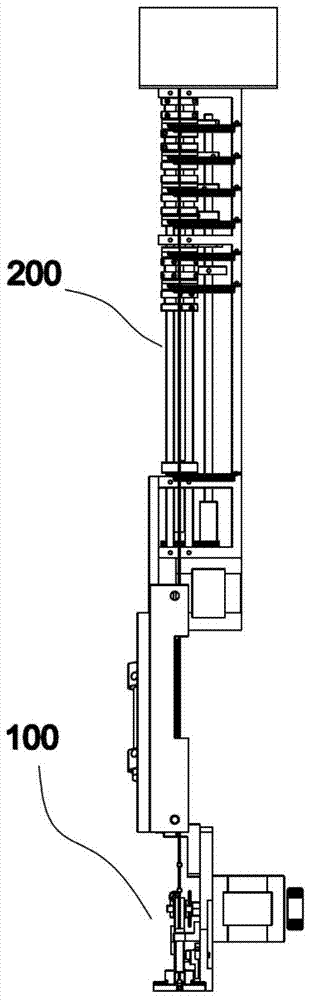

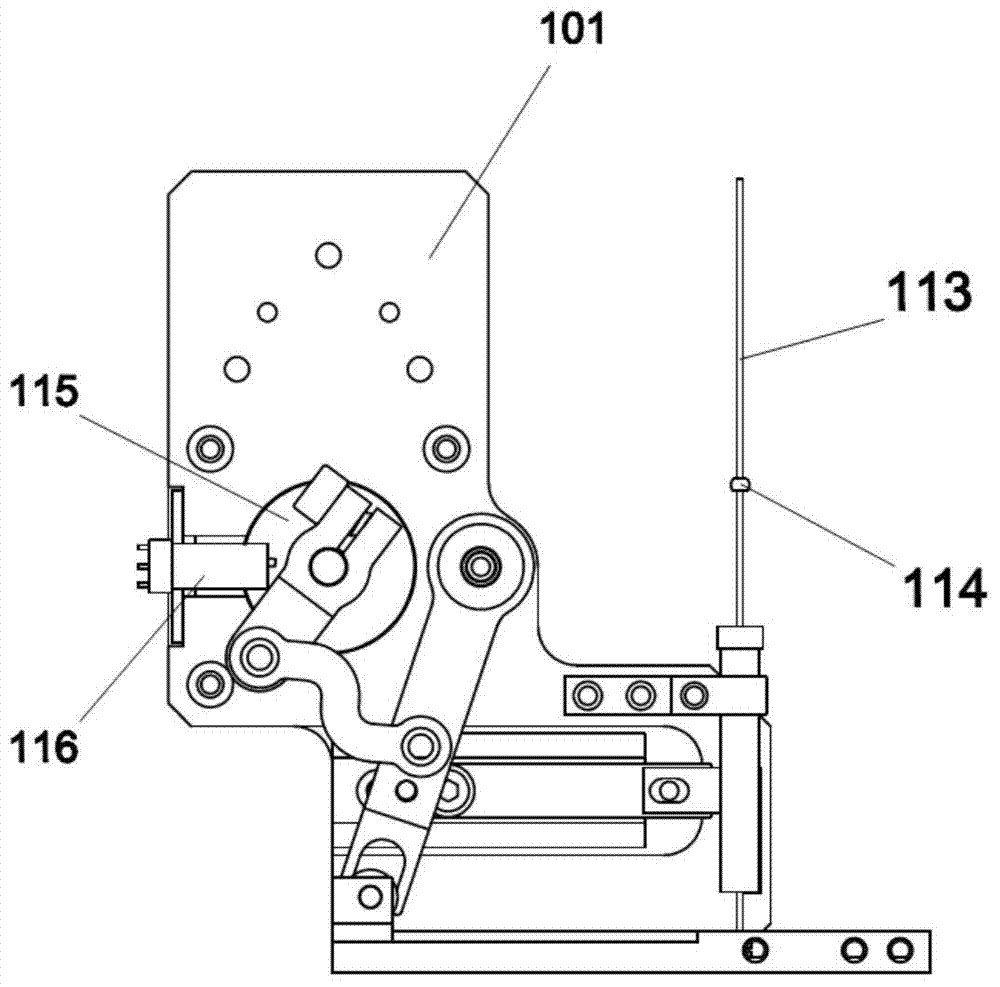

[0044] refer to Figure 1 to Figure 18 ,Such as Figure 1 to Figure 12The shown bead embroidery device for computerized embroidery machines includes a feeding mechanism 100 and a feeding mechanism 200, wherein the feeding mechanism 100 includes a stepping motor 102, a first connecting rod 103, a second connecting rod 104, The third connecting rod 106, the cover plate 124, the base 120 and the clamper 132, the stepper motor 102 is arranged on one side of the feeding motor mounting plate 101, the base 120 is provided with a chute 122, and the clamper 132 is installed in the chute 122, and the cover plate 124 is located on the cover plate groove 121 of the base 120, and is fixedly connected with the base 120; the base 120 is provided with a jaw slidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com