Patents

Literature

49results about How to "Improve embroidery quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Real-time monitoring method and monitoring system for thread condition of computerized embroidery machine

InactiveCN102505381ADynamic tension adjustmentReduce labor intensityAuxillary devicesMonitoring systemElectric control

The invention discloses a real-time monitoring method and a monitoring system for the thread condition of a computerized embroidery machine. The monitoring method is mounting a thread flow condition monitoring device and a thread tension adjusting device on a machine head adjusting platform, so as to detect and judge the real-time condition of an embroidering thread during embroidery, carry out corresponding recording, warning or compensation according to the real-time condition, and transmit to an electric control system. The monitoring system comprises the machine head adjusting platform, wherein the thread flow condition monitoring device and the thread tension adjusting device are mounted on the machine head adjusting platform; and the embroidering thread can pass through the thread flow condition monitoring device and the thread tension adjusting device sequentially. The invention has the advantages that real-time embroidering thread condition monitoring, embroiderer tension adjustment and thread consumption calculation can be carried out during embroidery; thread breakage detection, real-time thread quantity variance compensation, and accurate judgment on thread flowing quantity and thread flowing direction can be carried out accurately, so as to reduce thread breakage rate, and improve embroidery quality and the like; and important information such as thread consumption quantity can be collected, so as to optimize production management.

Owner:HUI ZHOU SHENTIAN PRECISION MACHINES

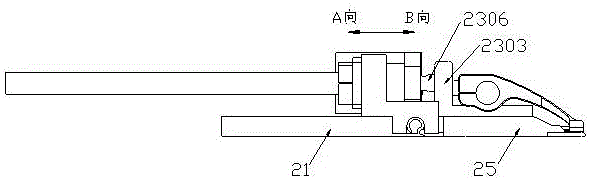

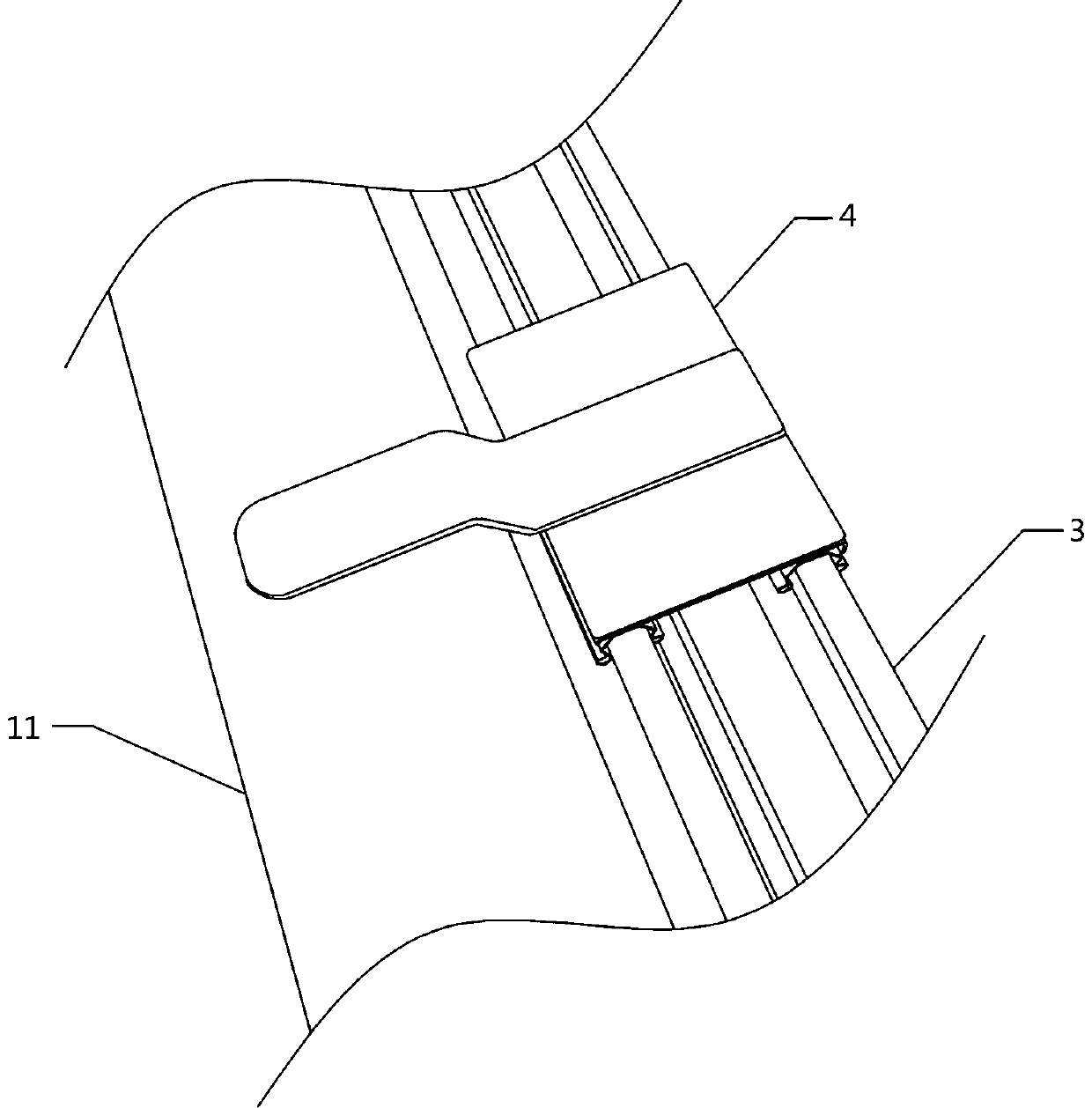

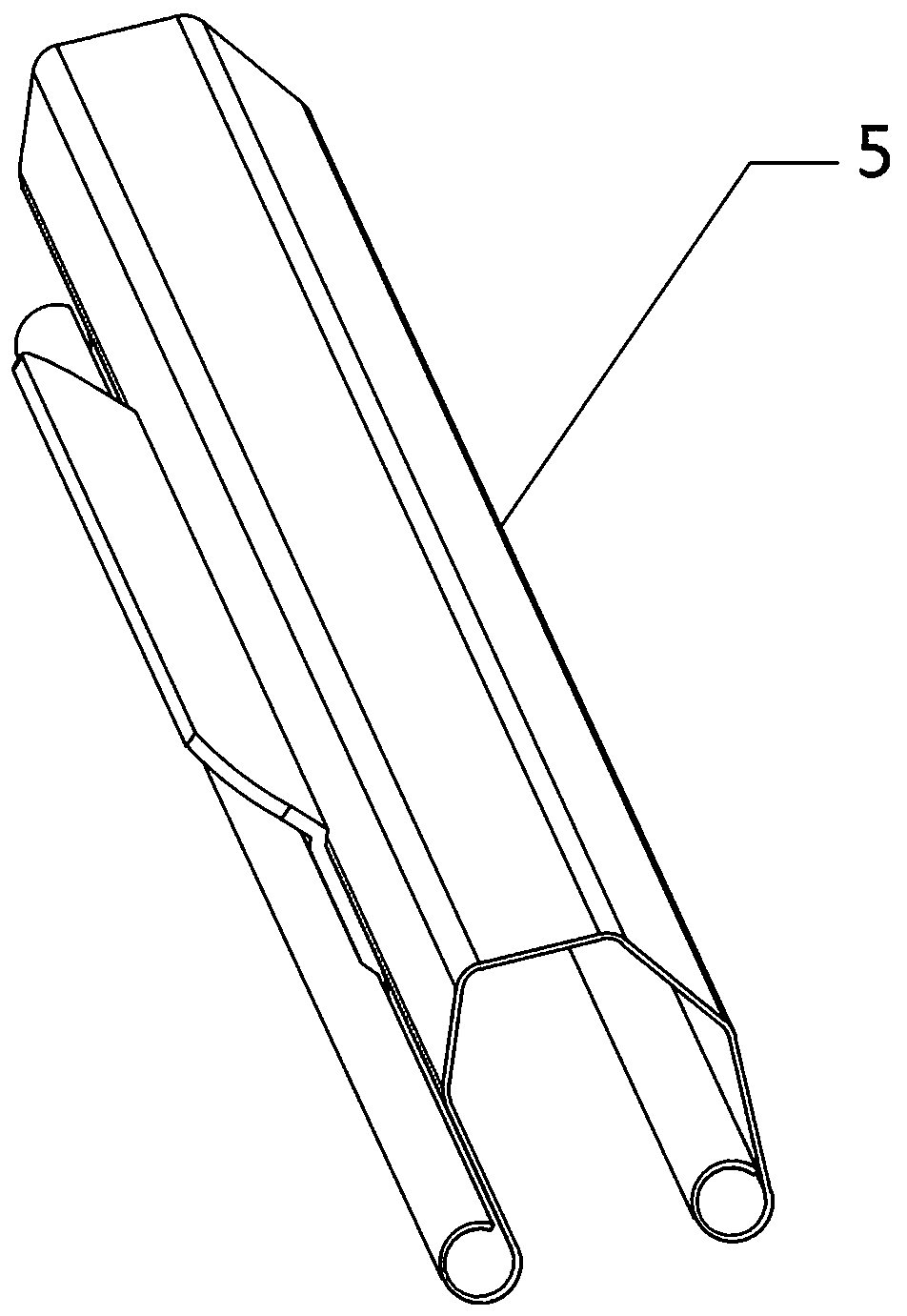

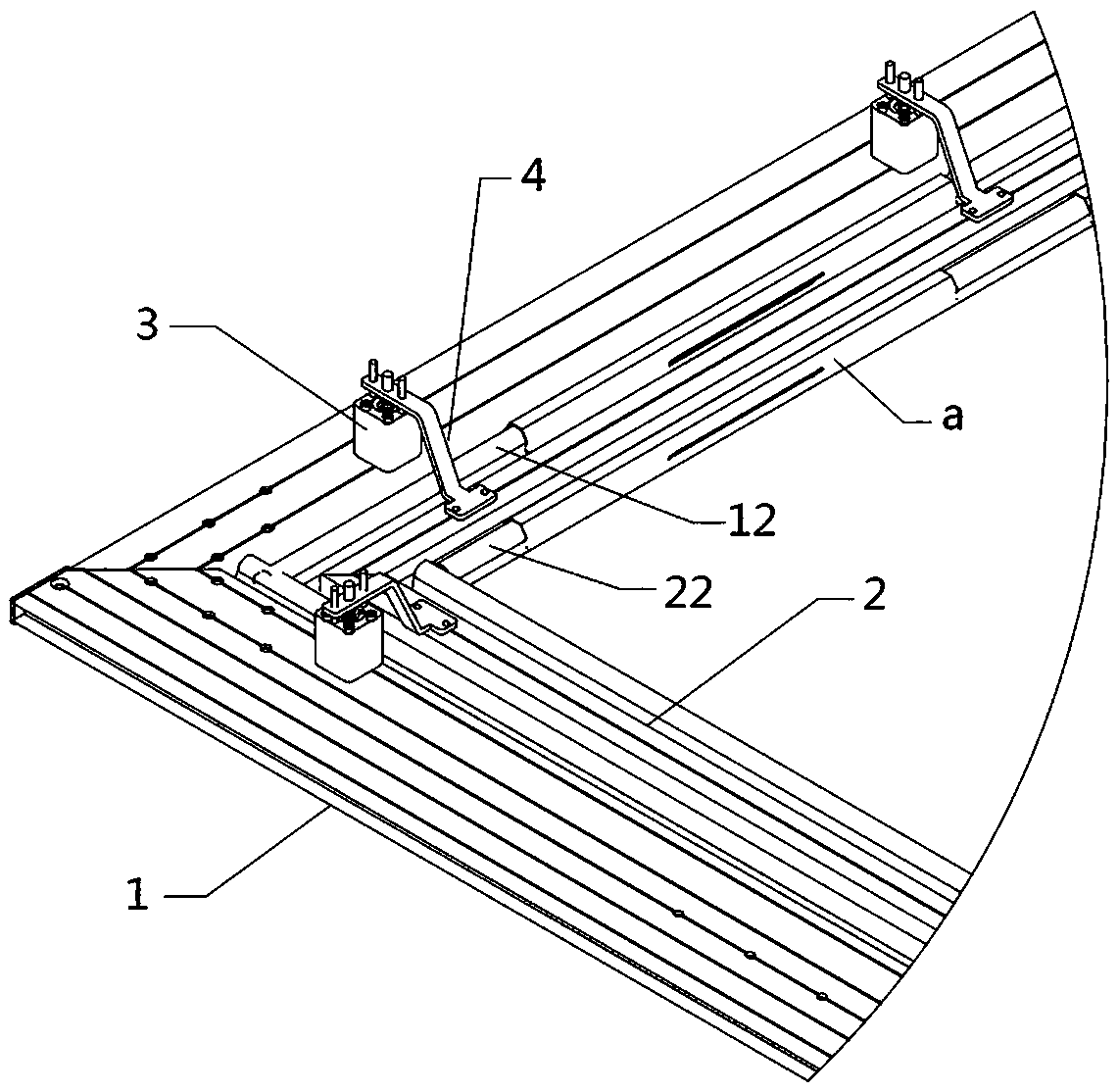

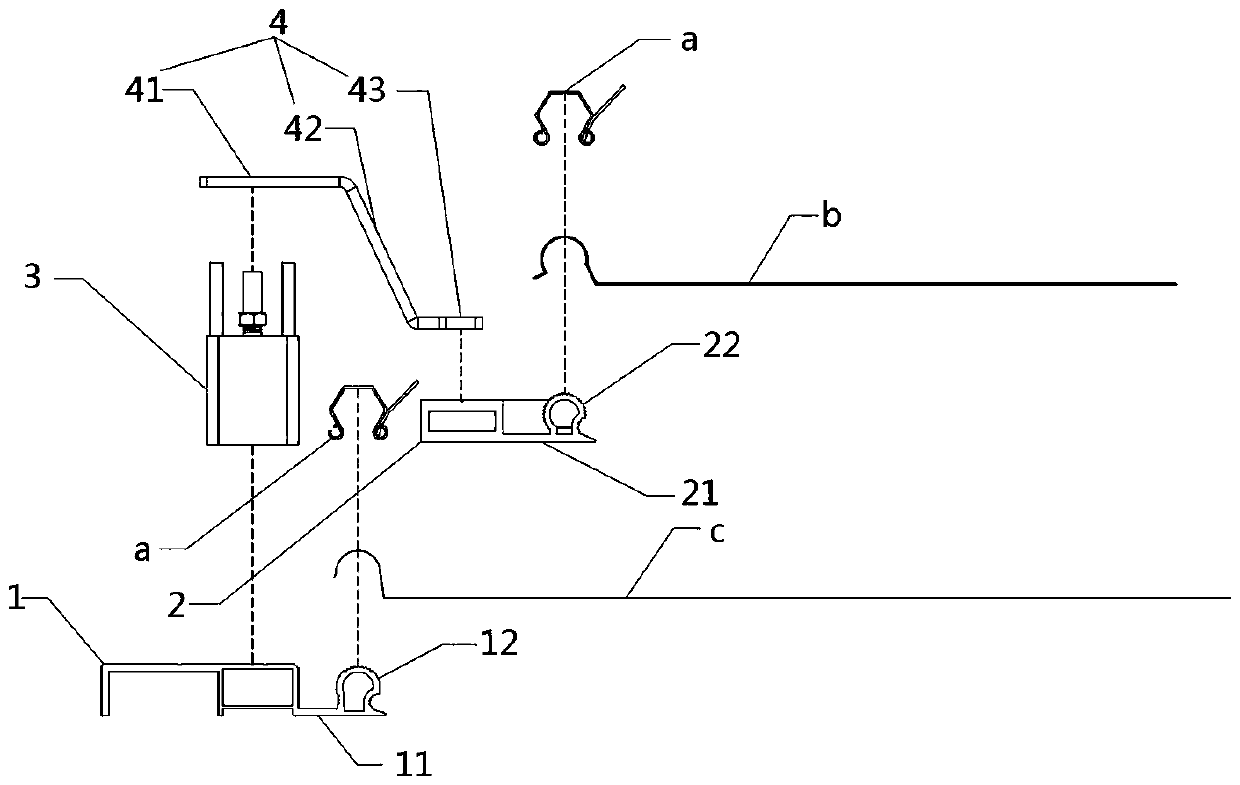

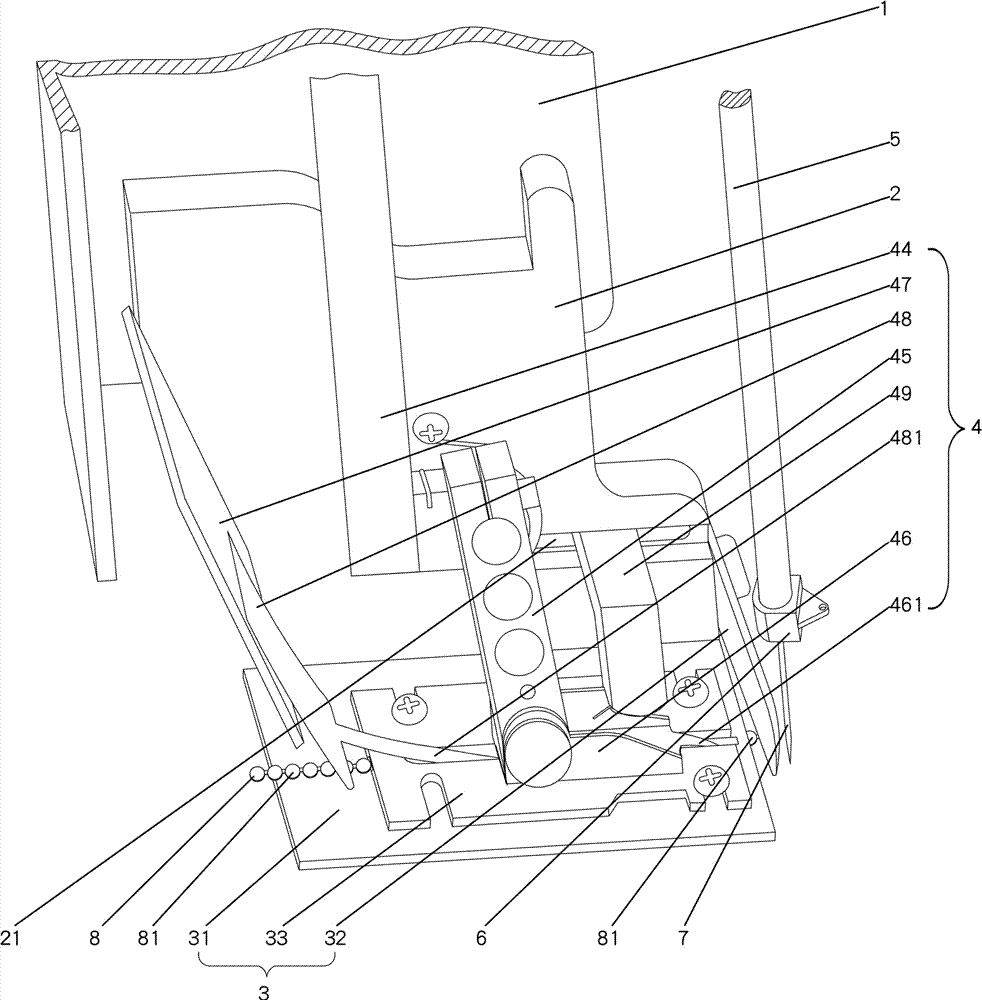

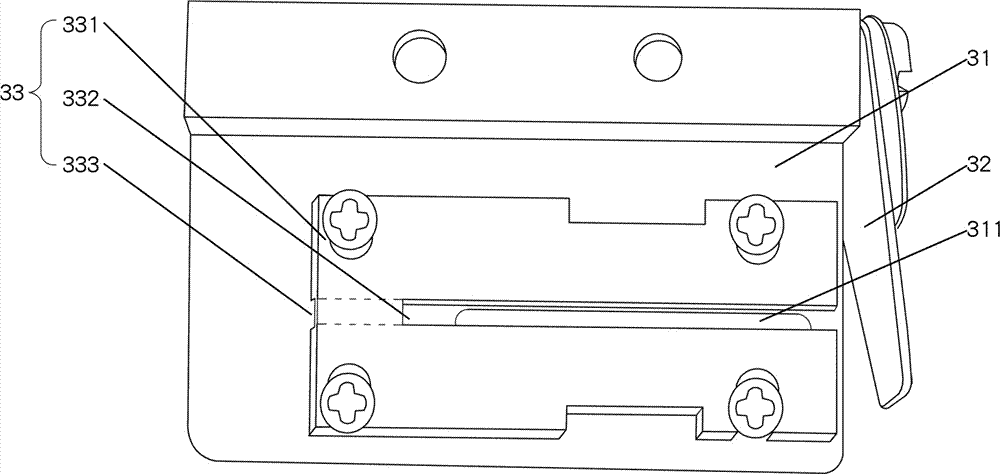

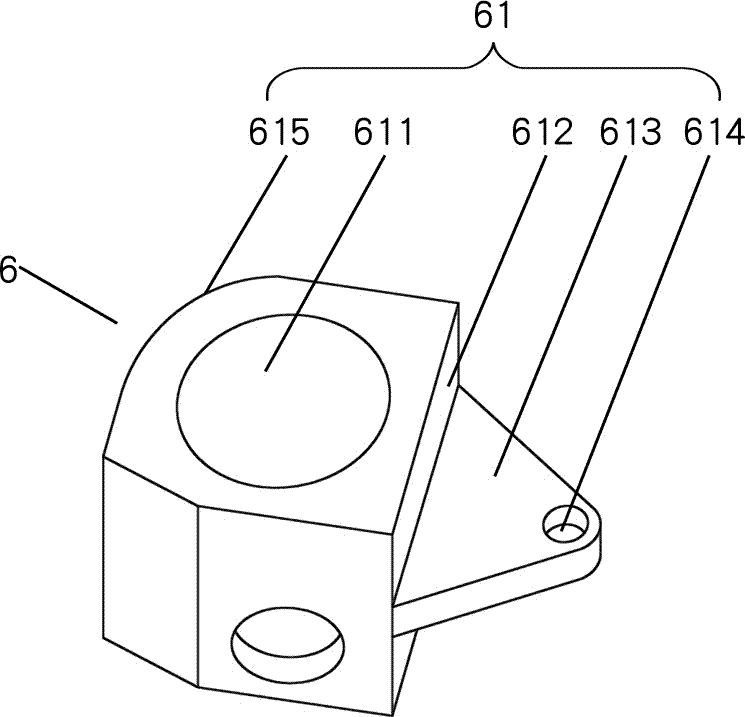

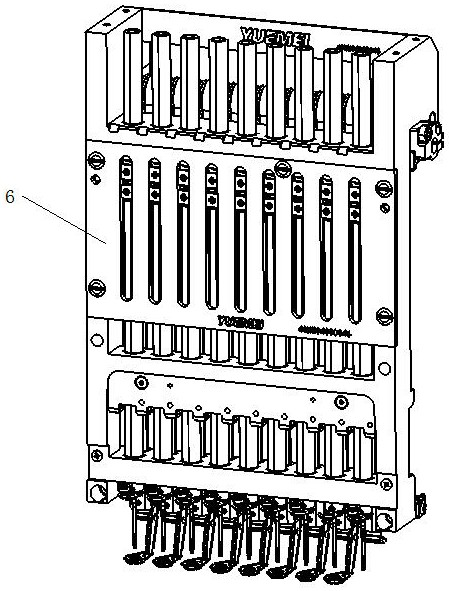

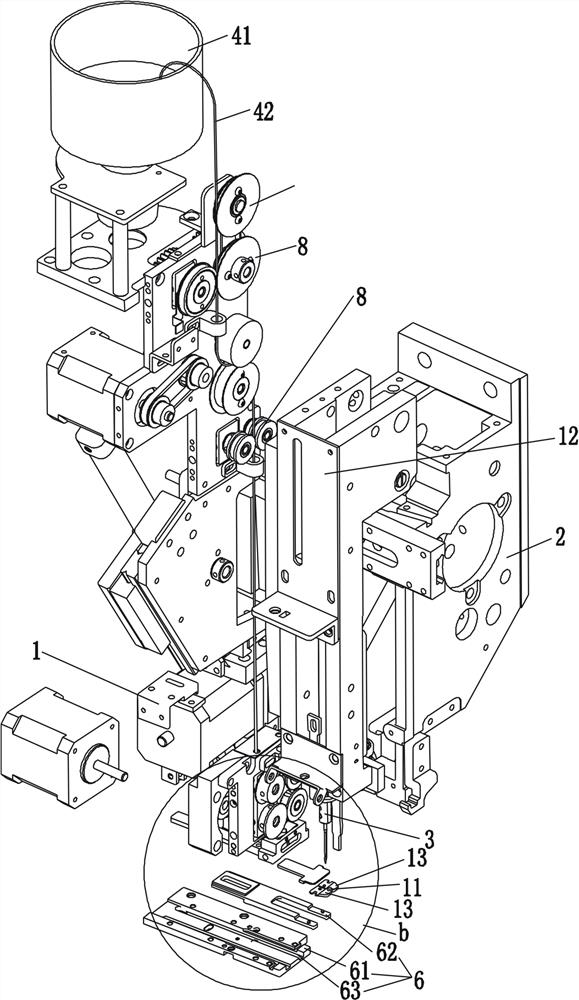

Pearl embroidery device for computerized embroidery machine

ActiveCN104514104ASimple structureEasy maintenanceAutomatic machinesAuxillary devicesRejection rateBead embroidery

The invention discloses a pearl embroidery device for a computerized embroidery machine. The pearl embroidery device comprises a conveying mechanism, a feeding mechanism and a pearl guiding wire, wherein the conveying mechanism comprises a base and a holder, a chute is arranged on the base, the holder is mounted in the chute in a matched manner, a jaw slideway is arranged on the base, a jaw formed by two parallelly arranged holding arms is arranged at one end of the holder, at least one group of hold-down devices is symmetrically arranged on two sides of the jaw slideway, and the hold-down devices enable the holding arms on the holder, which slides in the jaw slideway, to be always subjected to a force pressing the jaw. The pearl embroidery device is simple in structure; the hold-down devices enable pearls to be always subjected to a force pressing the jaw when sliding in the jaw slideway to ensure that the pearls are always in a pressing state, so that accurate positioning of the pearls is guaranteed, and the embroidery product is improved. The pearl embroidery device is convenient to maintain, safe and reliable in operation and smooth and uninterrupted in pearl supply, improves the working efficiency and lowers the rejection rate.

Owner:WENZHOU OULUOHUA INDAL

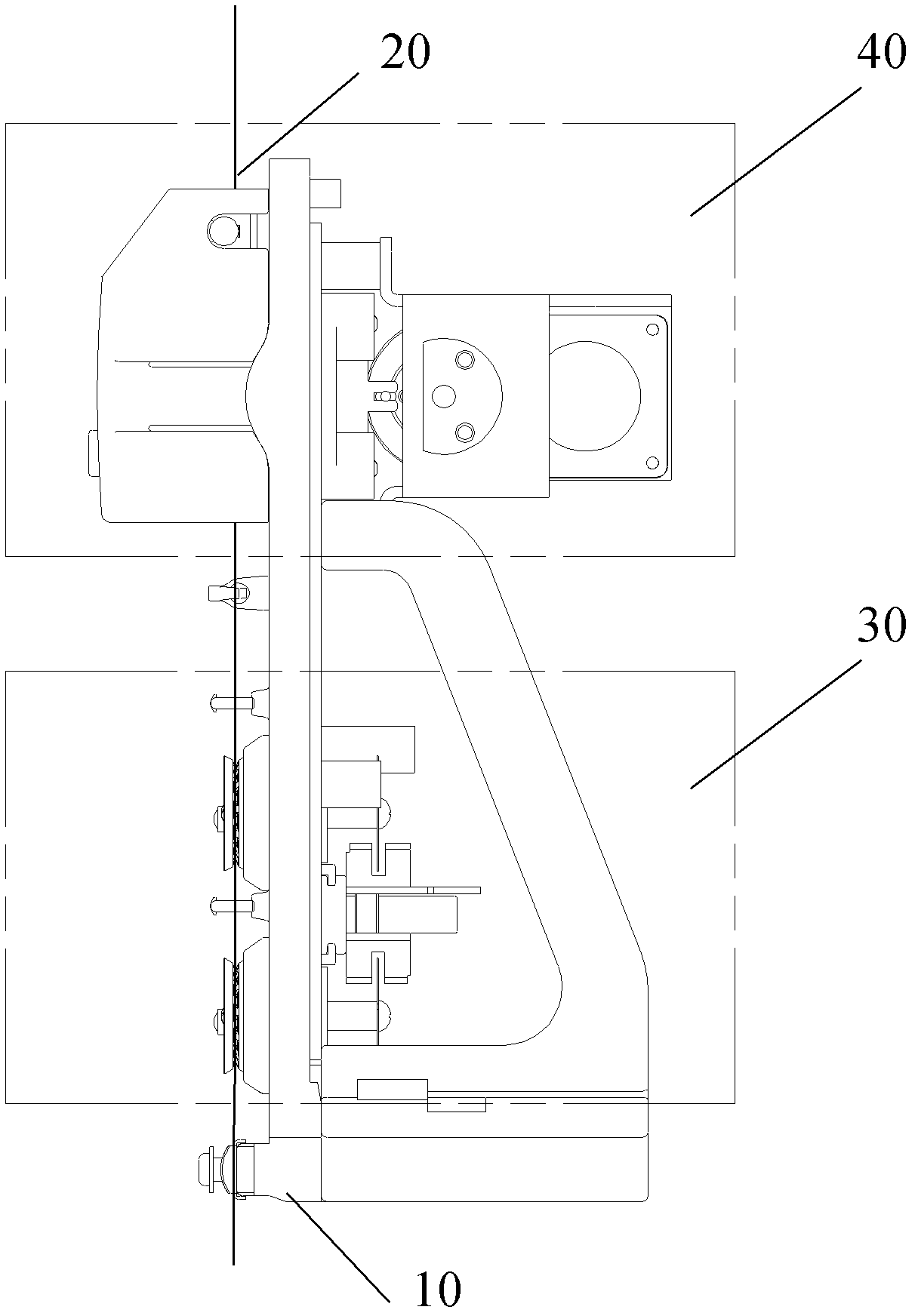

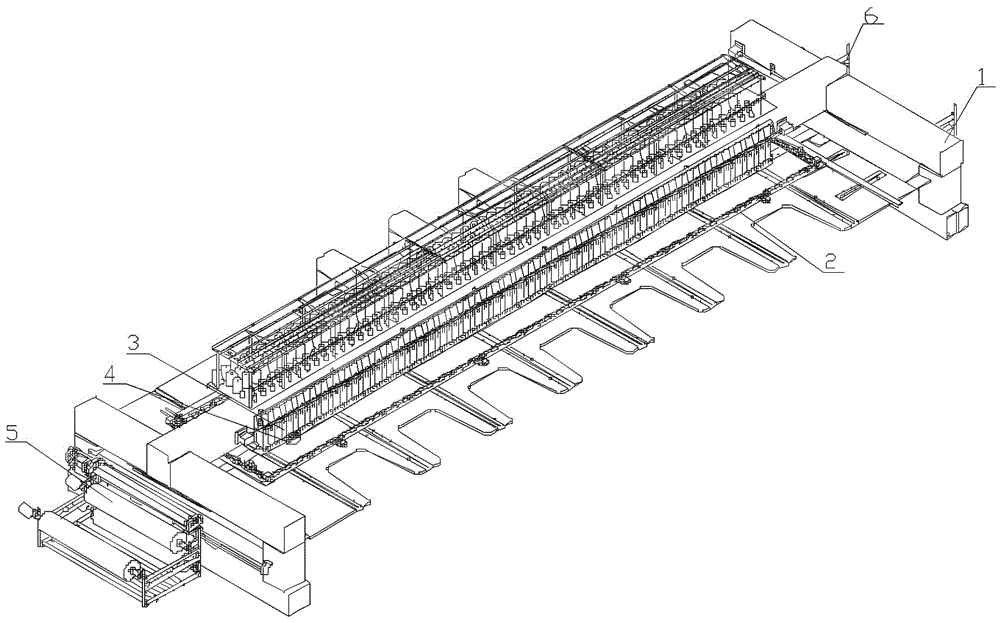

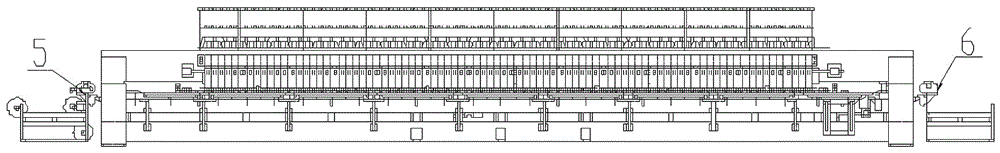

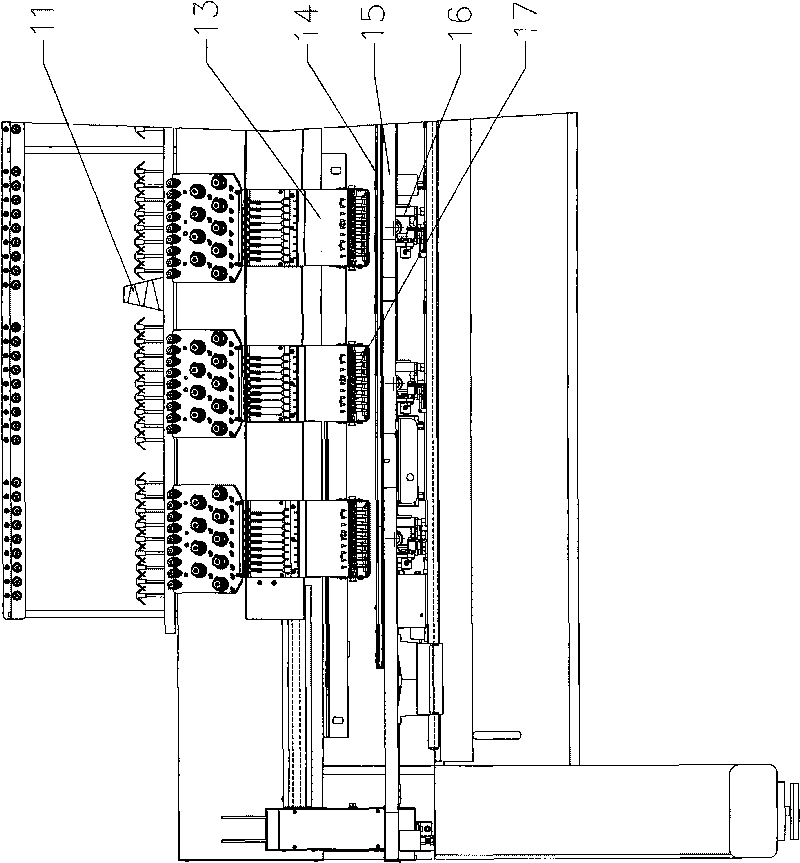

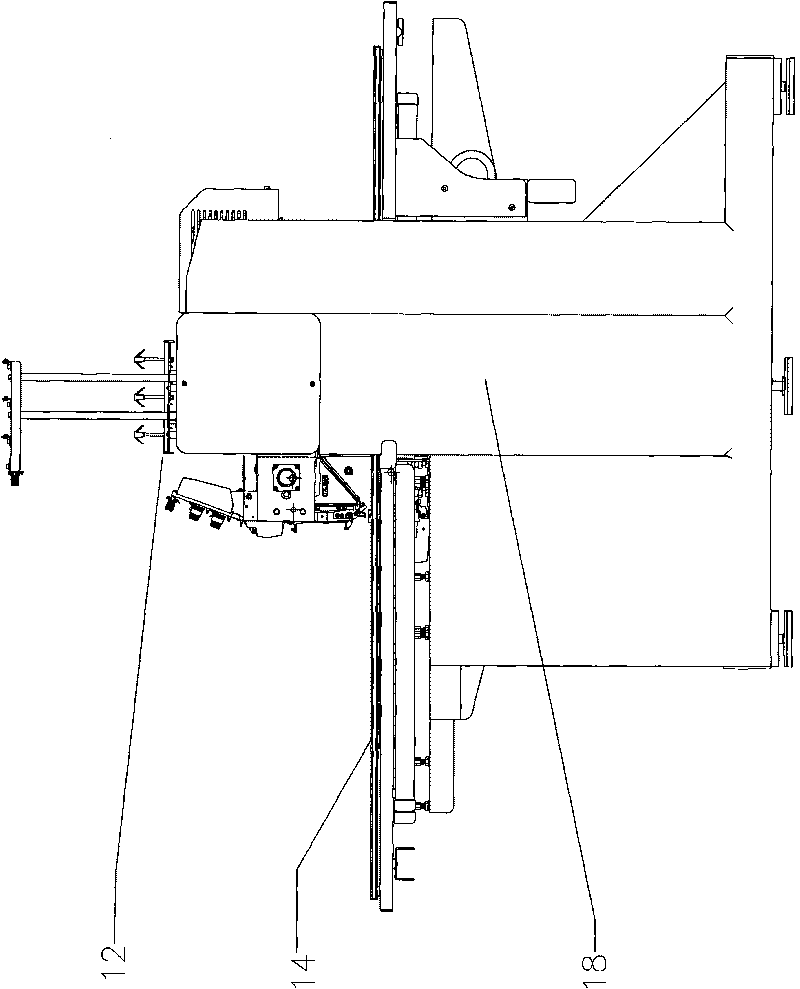

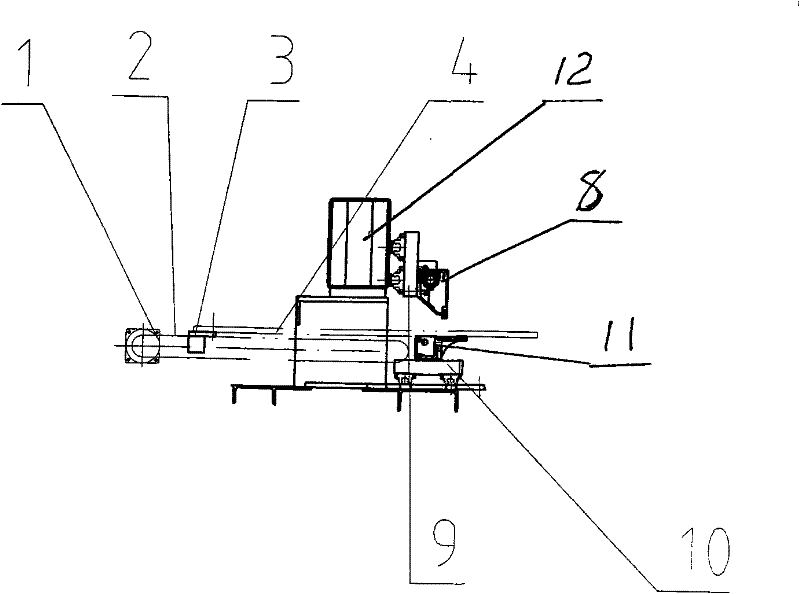

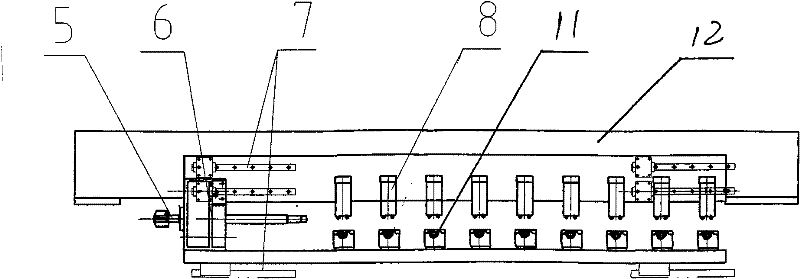

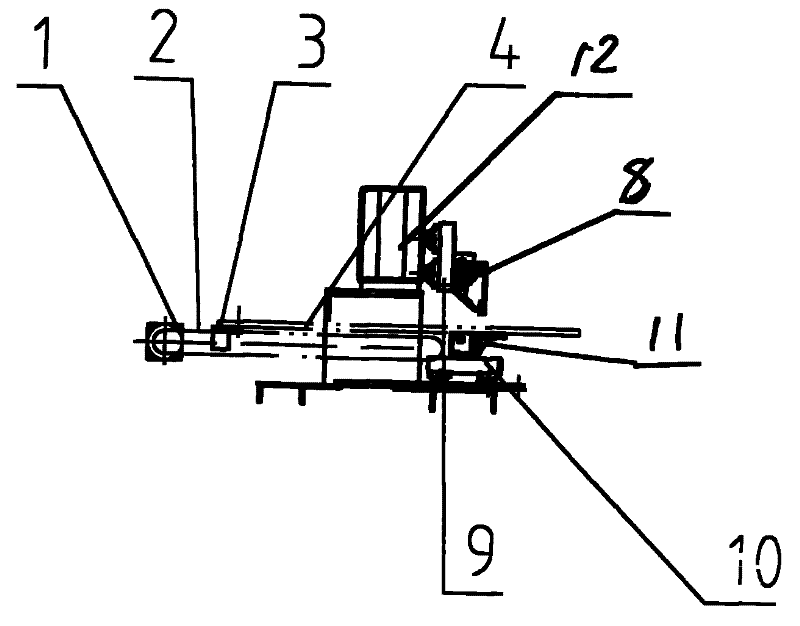

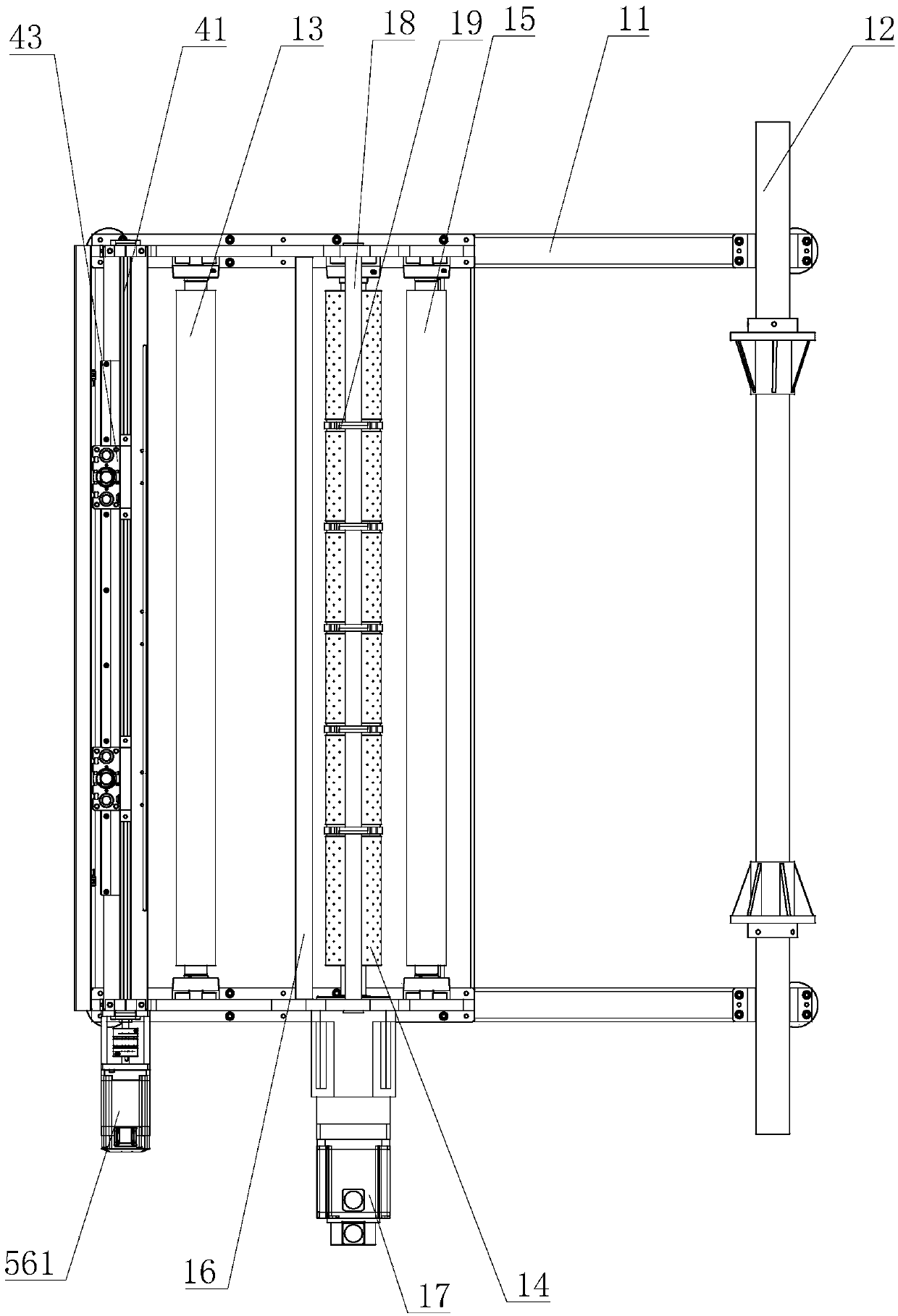

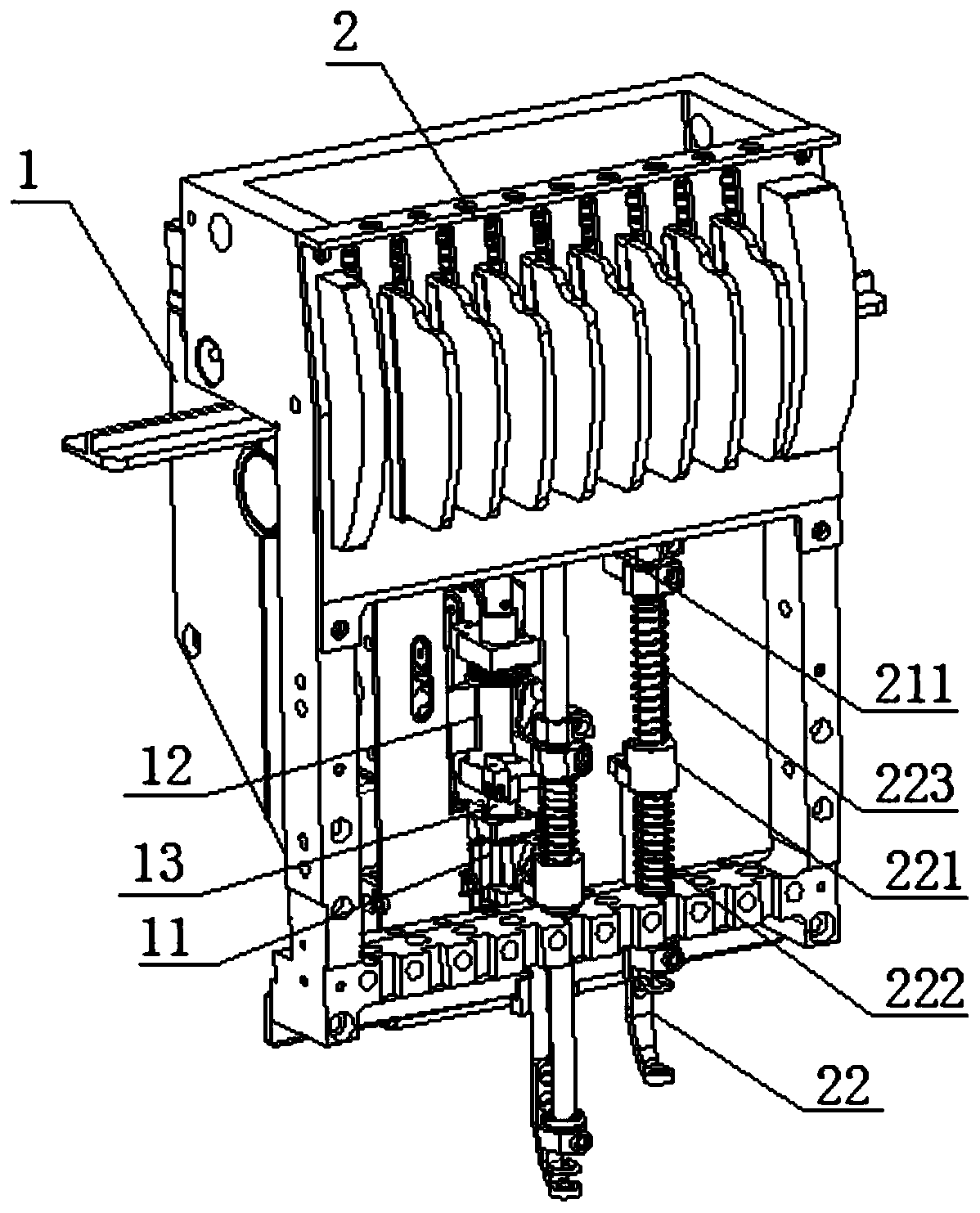

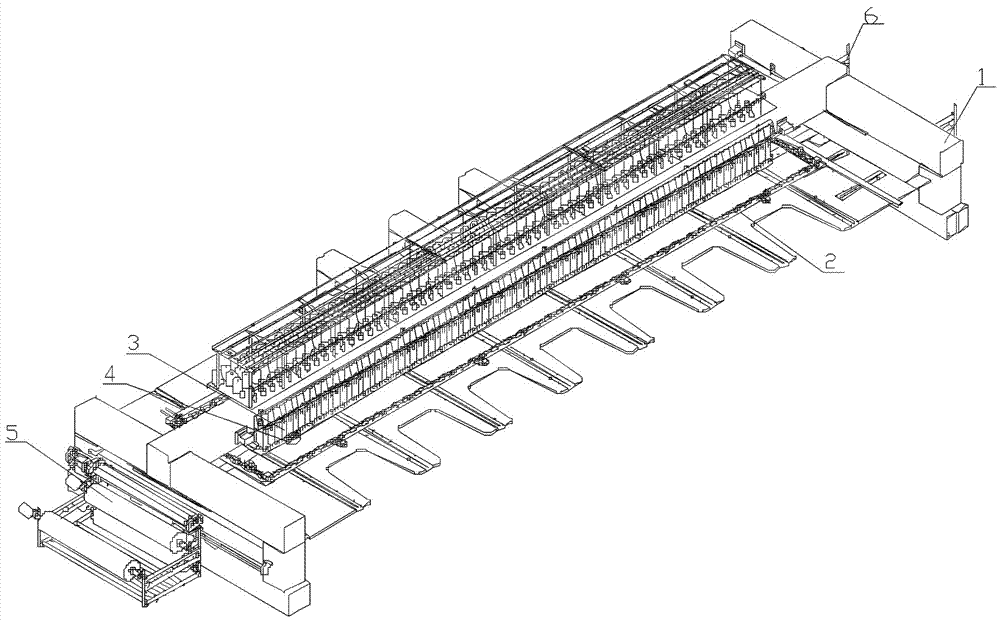

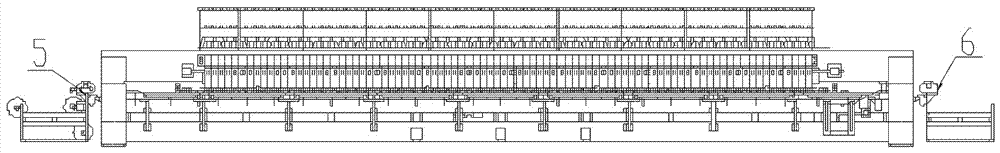

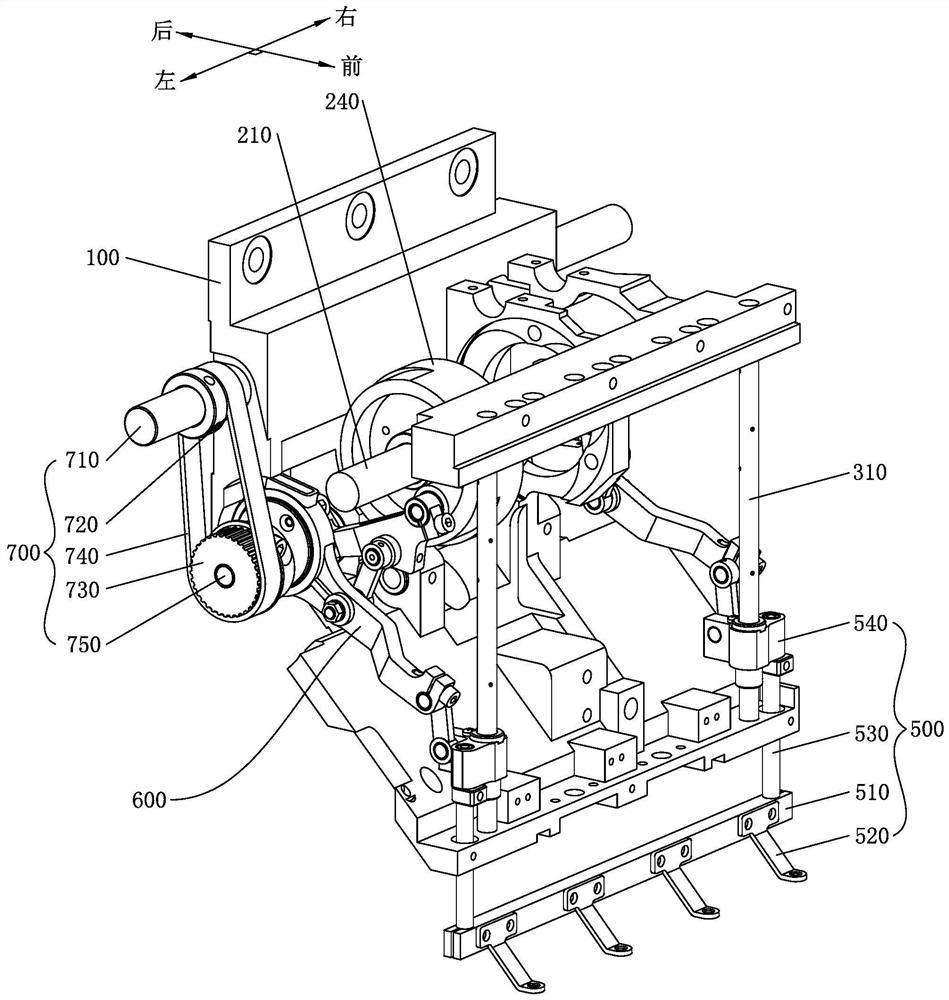

Embroidery processing center

ActiveCN106012357AImprove stabilityQuality improvementPressersMattress sewingEngineeringMechanical engineering

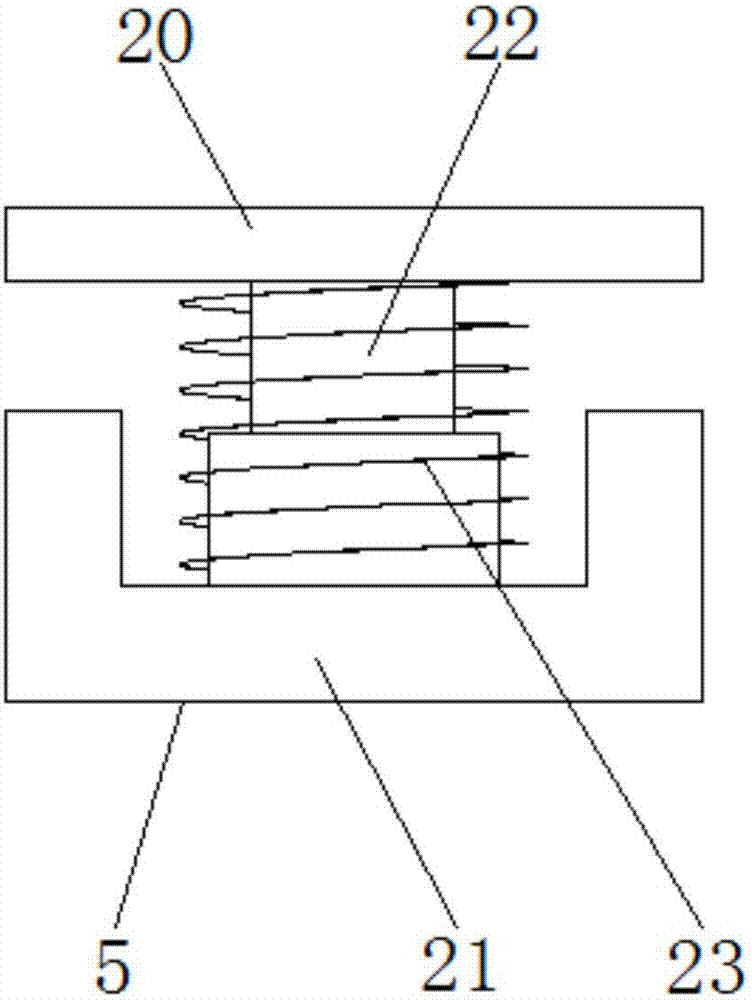

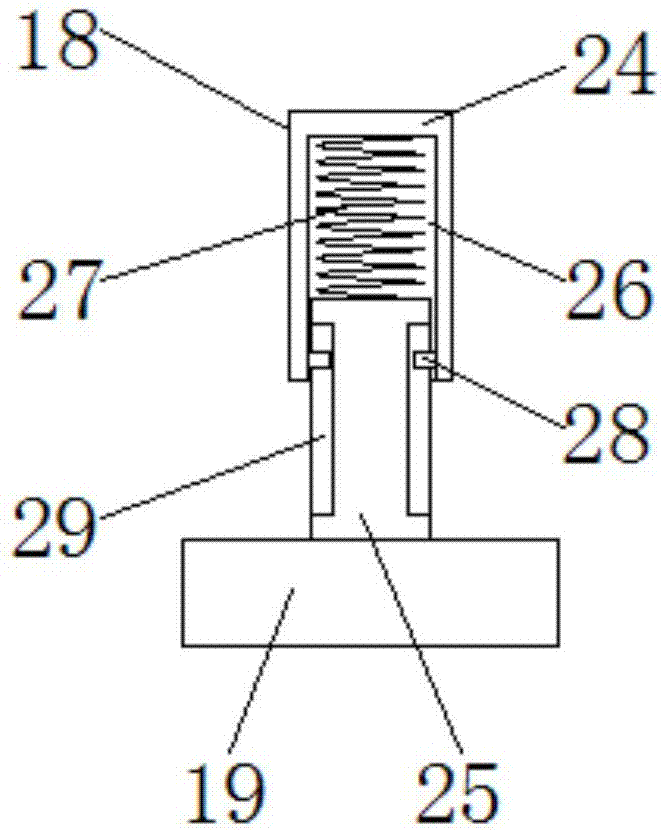

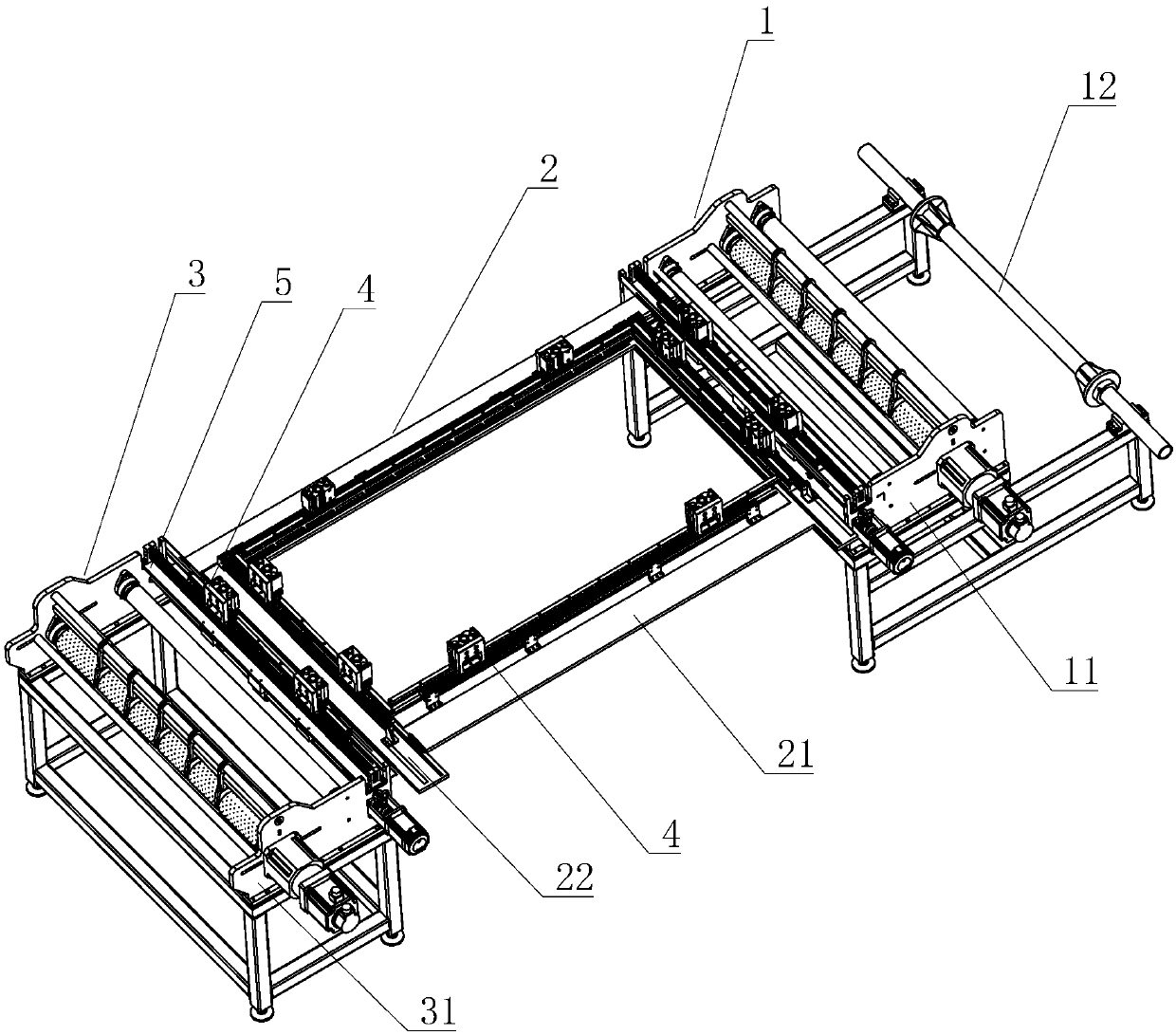

The invention discloses an embroidery processing center which comprises a rack structure, an embroidery frame structure, an embroidery mechanism and a feeding and discharging mechanism. The feeding and discharging mechanism comprises a fabric feeding device and a fabric discharging device located at the left end and the right end of a crossbeam of the rack structure, the embroidery frame structure comprises a movable frame and a fabric clamping device and a fabric tensioning device installed on the movable frame, the embroidery mechanism comprises multiple machine head assemblies and rotary shuttle box assemblies corresponding to the lower portions of the machine head assemblies, the machine head assemblies are installed on the crossbeam of the rack structure, and the embroidery frame structure is arranged on a platen under the crossbeam. The fabric feeding device inputs an embroidery fabric into an embroidery region, the embroidery fabric enters the movable frame and is clamped by the fabric clamping device, the embroidery fabric in the embroidery region is in a tensioned state under the effect of the fabric tensioning device, meanwhile an embroidery process is completed through the embroidery mechanism, and finally a finished product fabric with embroidered patterns is output by the fabric discharging device. Embroidering, quilting seaming and seaming embroidering integrated functions are integrally controlled by a computer, various single-layer or multi-layer fabrics required for embroidering, quilting seaming and seaming embroidering are operated in the same device, and embroidering processing is completed through one program command.

Owner:JIANGSU DADAO MACHINE GROUP +1

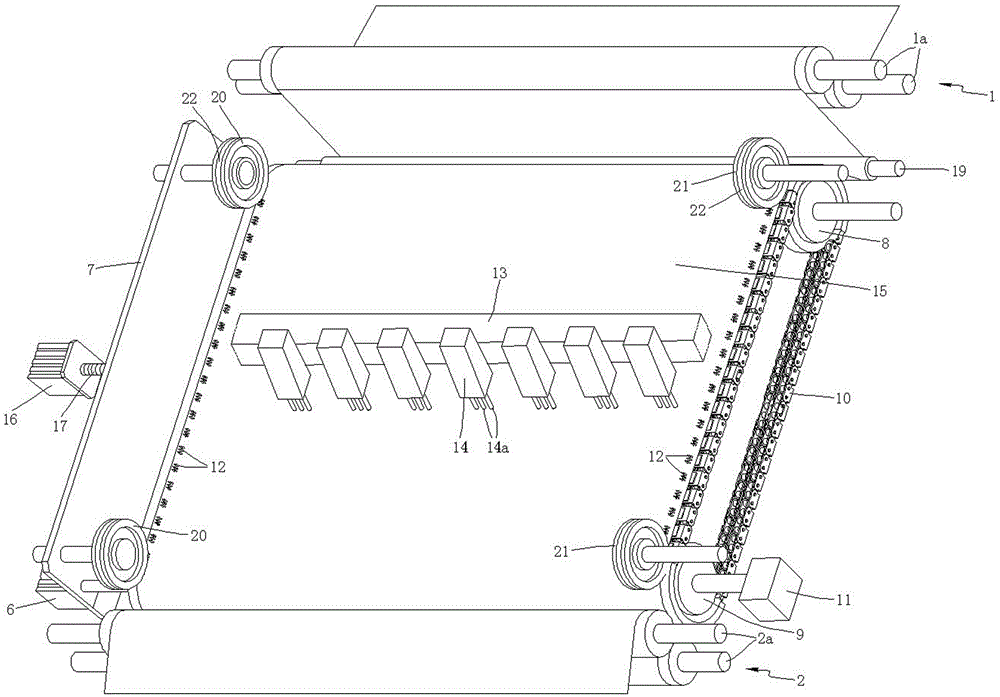

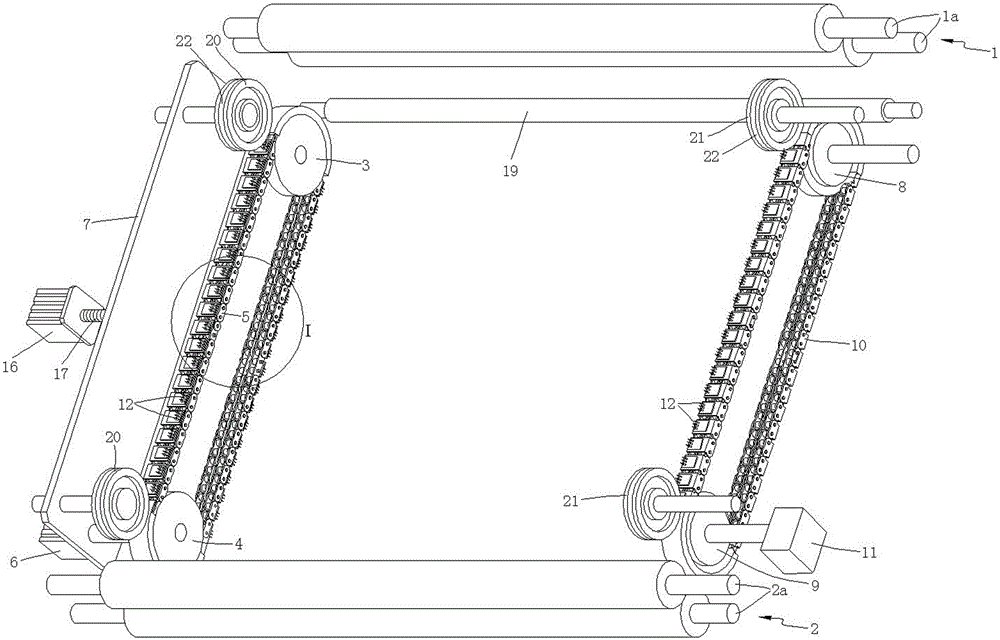

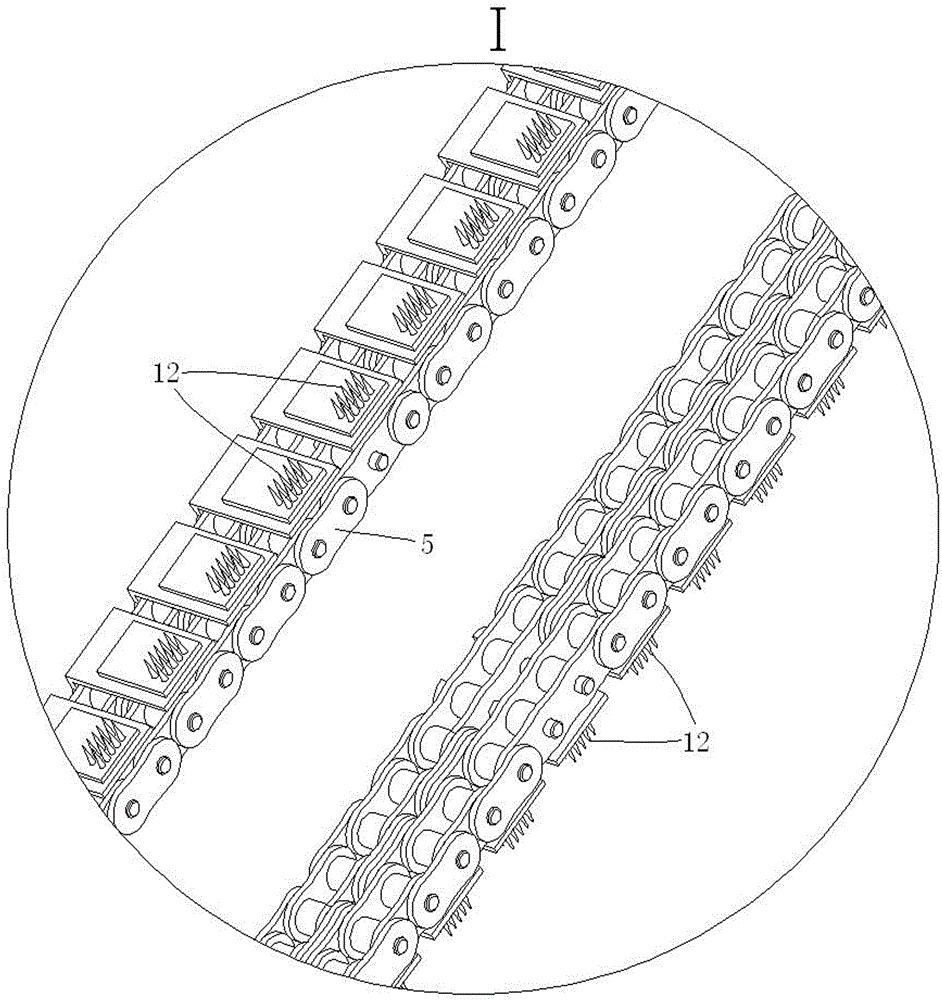

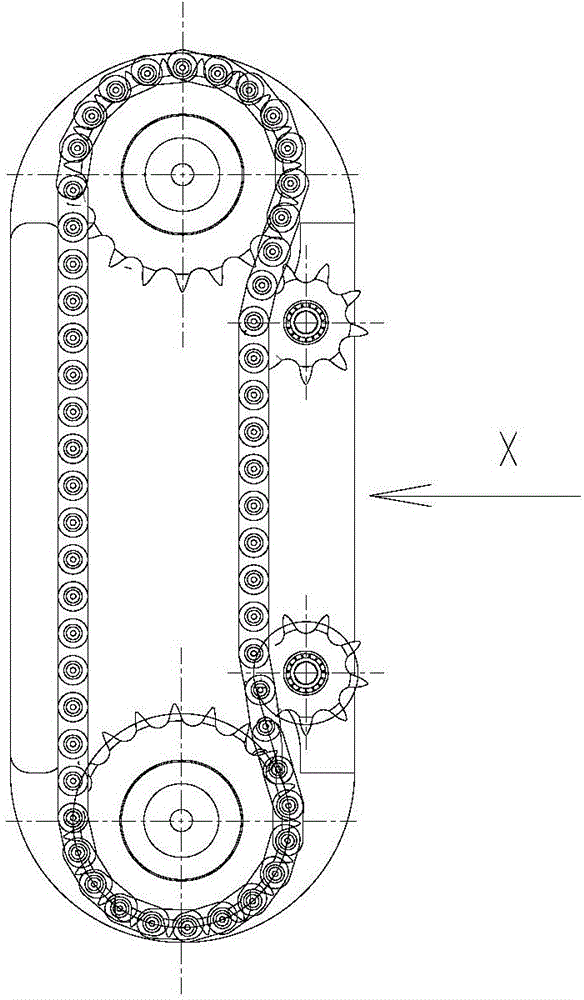

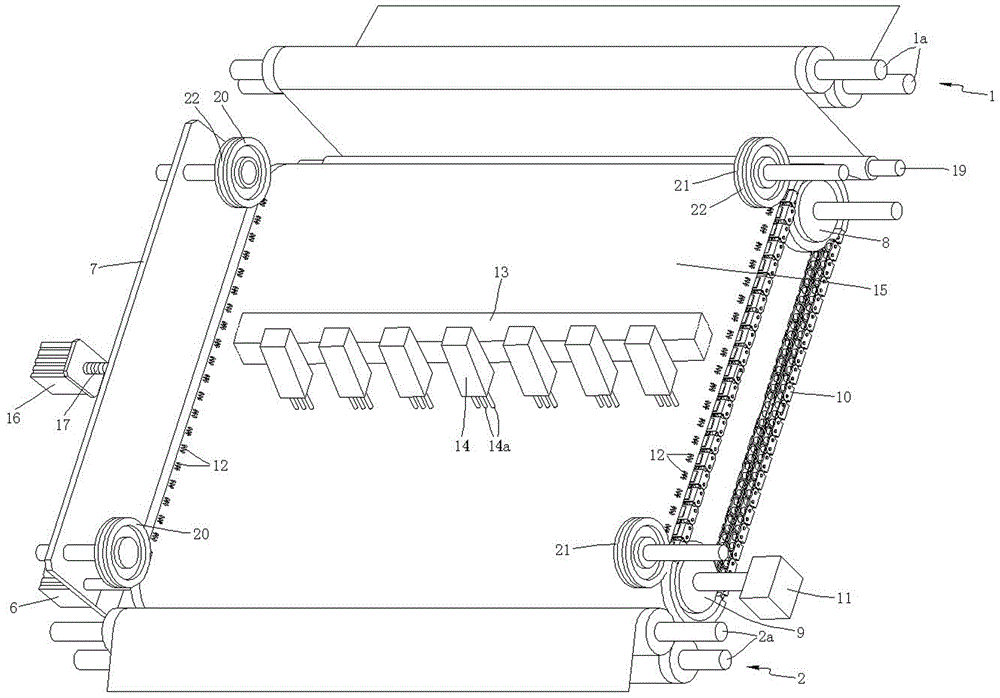

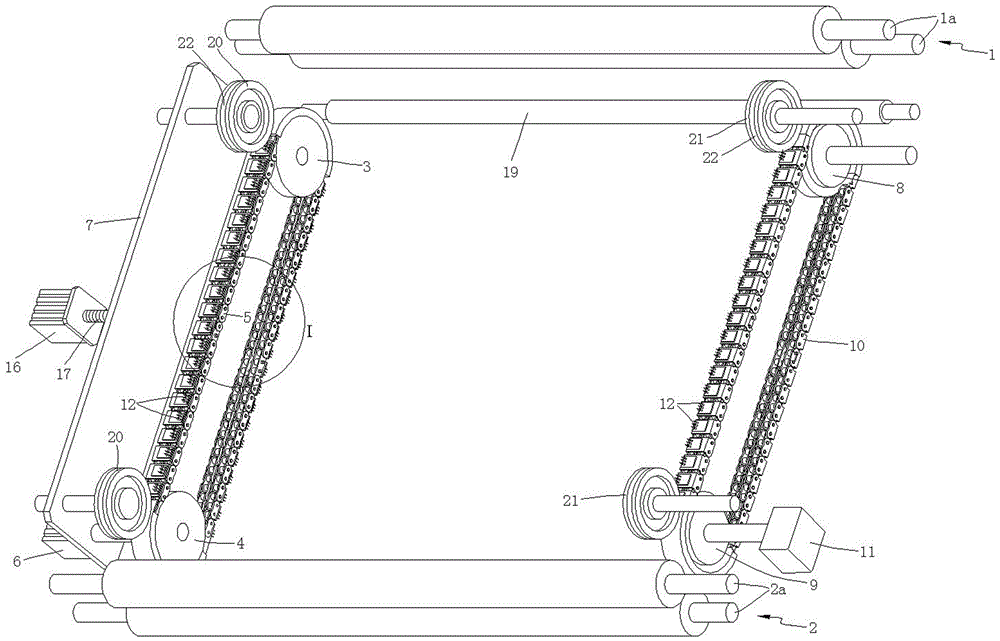

Cloth feeding mechanism of embroidery machine

The invention discloses a cloth feeding mechanism of an embroidery machine. The cloth feeding mechanism comprises a front cloth clamping roller set, a rear cloth clamping roller set, a left chain transmission mechanism and a right chain transmission mechanism, wherein the front cloth clamping roller set and the rear cloth clamping roller set are arranged in front of and at back of a machine head respectively; the left chain transmission mechanism and the right chain transmission mechanism are arranged on the left side and the right side of the machine head respectively; the left chain transmission mechanism comprises a first driven chain wheel, a first driving chain wheel and a first chain, the first driving chain wheel is driven by a first motor to rotate, the first motor is fixedly mounted on a vertical plate which is parallel with the first chain and spaced with the first chain by a certain distance, the first driven chain wheel is rotationally mounted on the vertical plate, and the vertical plate is driven by a linear drive device to move horizontally; the right chain transmission mechanism comprises a second driven chain wheel, a second driving chain wheel and a second chain, the second driving chain wheel is driven by a second motor to rotate, the second driven chain wheel is rotationally mounted on a rack of the embroidery machine, and a plurality of insertion needles are mounted on the outside of each chain link of the first chain and the second chain. The cloth feeding mechanism of the embroidery machine guarantees the flatness of cloth between the front cloth clamping roller set and the rear cloth clamping roller set, and the embroidery quality is improved.

Owner:江苏润源控股集团有限公司

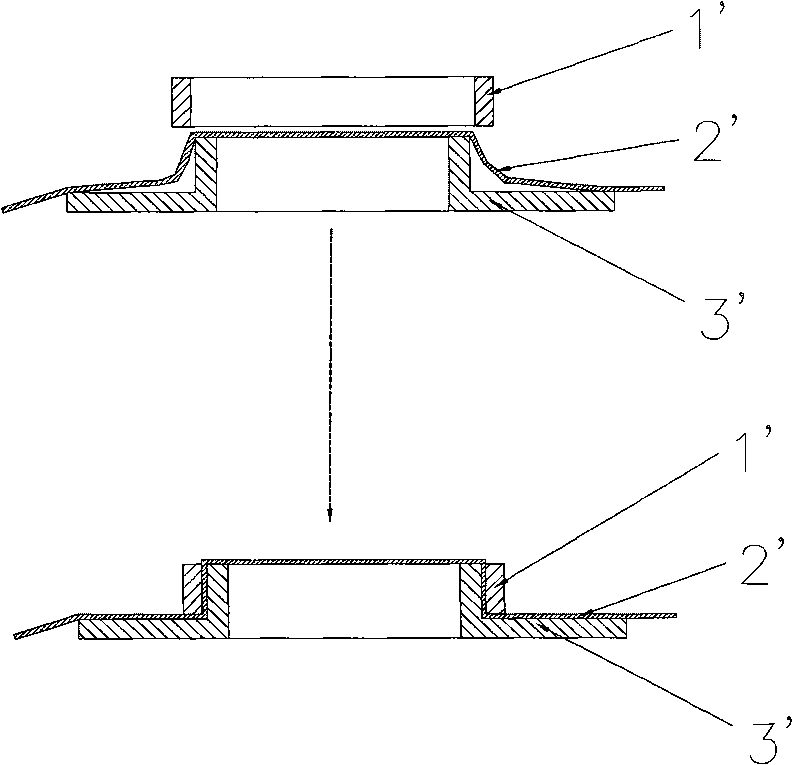

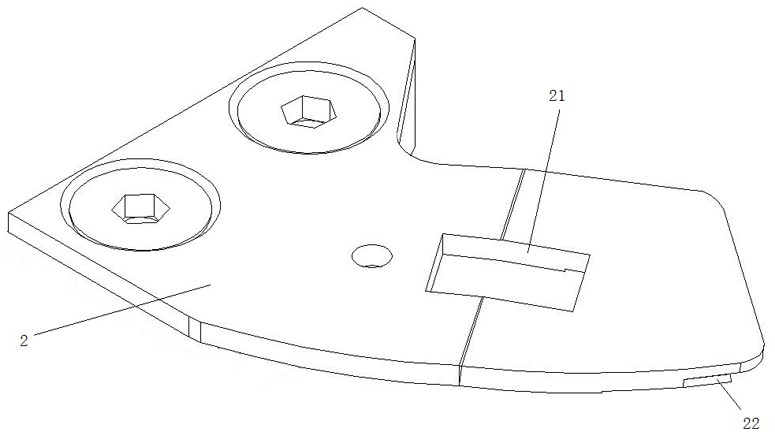

Magnetic cloth clamp device of computer embroidery machine

The invention provides a magnetic cloth clamp device of a computer embroidery machine with the advantages of simple and reasonable structure and convinient operation, which improves the embroidery quality, and is particularly applicable to high elastic materiel, such as knitted materiel, sweater materiel and the like. The device comprises a framework; the framework is provided with an embroidery frame; a top frame is arranged on the embroidery frame; a plurality of magnetic blocks are arranged in the top frame; a bottom frame which can be magnetically absorbed is arranged at the lower part of the top frame; and the top end of the bottom frame is hinged with the top end of the top frame through a hinge. The cloth clamp device for embroidery mainly comprises the top frame, the bottom frame, upper magnetic blocks, the hinge and frame fixing blocks; the magnetic blocks installed in the top frame are adopted to ensure that embroidery cloth is arranged between the top frame and the bottom frame and the surfaces of the top frame and the bottom frame are absorbed together, thus the embroidery cloth is clamped between the top frame and the bottom frame, the cloth can not be pulled without tensile force applied in advance, and cloth marks and embroidery effect can not be affected, therefore, the device is particularly applicable to high elastic materiel, such as knitted materiel, sweater materiel and the like.

Owner:HUI ZHOU SHENTIAN PRECISION MACHINES

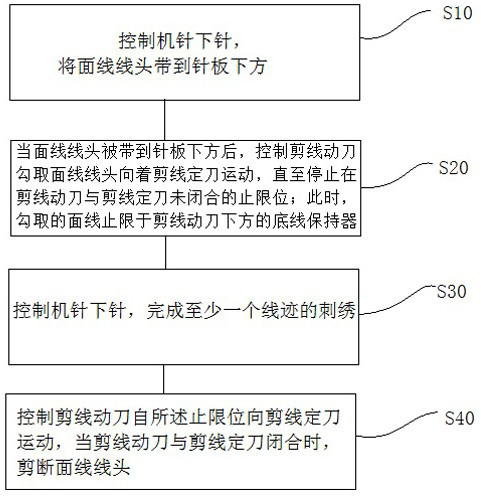

Embroidery machine trimming method

ActiveCN112647208ASame lengthImprove embroidery qualityEmbroidering machines apparatusEngineeringMechanical engineering

The invention discloses an embroidery machine trimming method, and belongs to the technical field of embroidery machines. The embroidery machine trimming method is applied to a control end of an embroidery machine and comprises the following steps that step S10, a machine needle is controlled to drop, and an upper thread end is brought to a position below a needle plate; S20, after the upper thread end is brought to the position below the needle plate, a thread trimming movable knife is controlled to hook the upper thread end to move towards the thread trimming fixed knife until the thread trimming movable knife and the thread trimming fixed knife are stopped from being limited when not closed, at the moment, the hooked upper thread is limited to a bottom thread retainer below the thread trimming movable knife; S30, the machine needle is controlled to lower to complete embroidery of at least one stitch; and S40, the thread trimming movable knife is controlled to move from the stop limit to the thread trimming fixed knife, and the upper thread end is cut off when the thread trimming movable knife and the thread trimming fixed knife are closed. Thread ends below the cloth cover can be prevented from being messy and different in lengths, and the problems that thread disengaging and breaking happen due to the fact that stitches are too loose, bottom threads are prone to struggling off are solved.

Owner:浙江镨美科智能刺绣设备有限公司

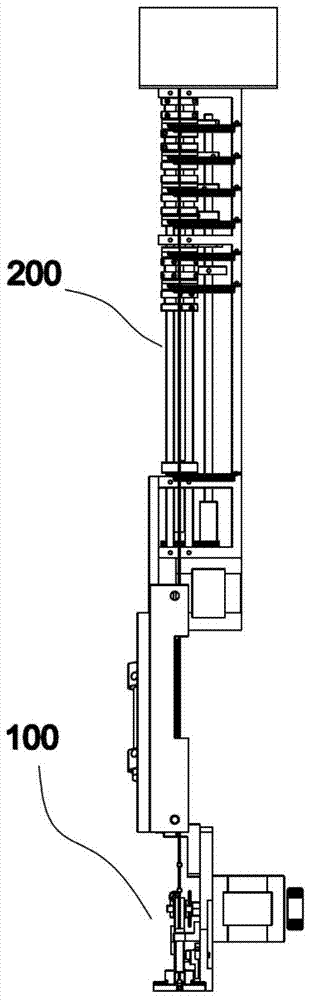

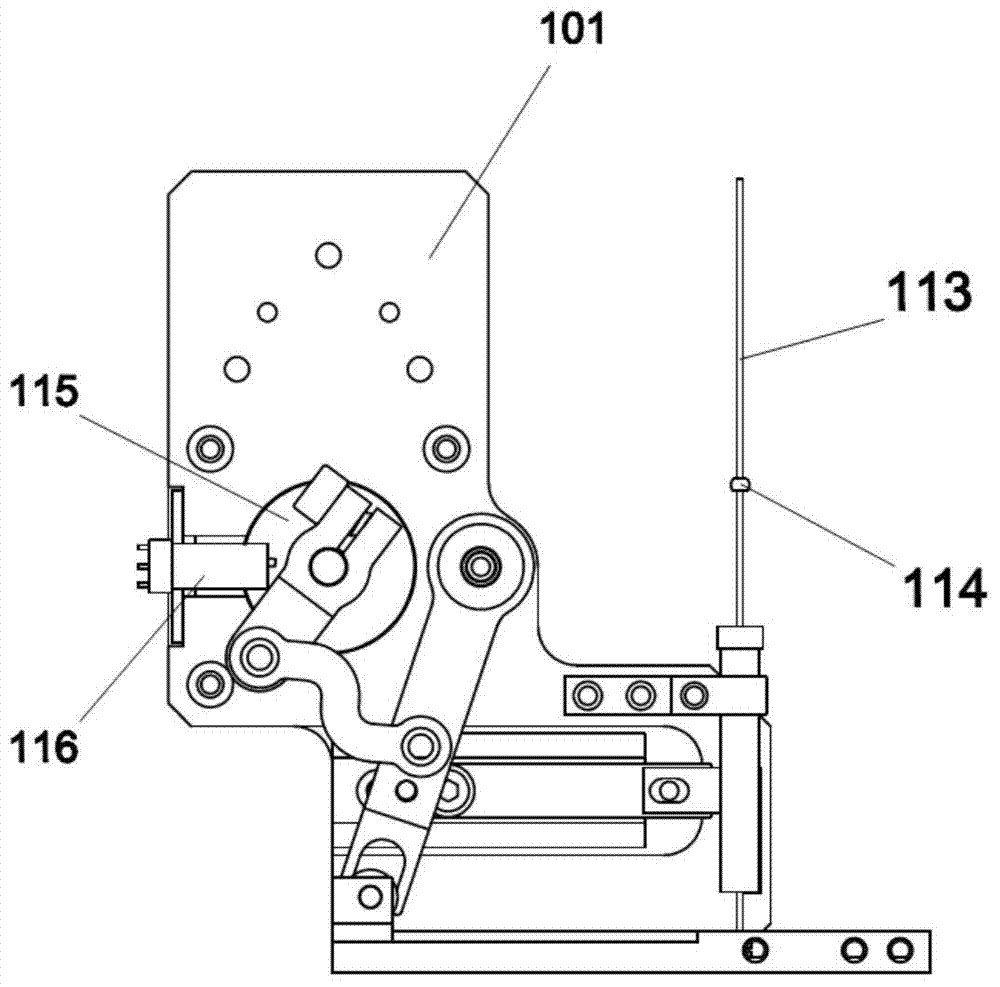

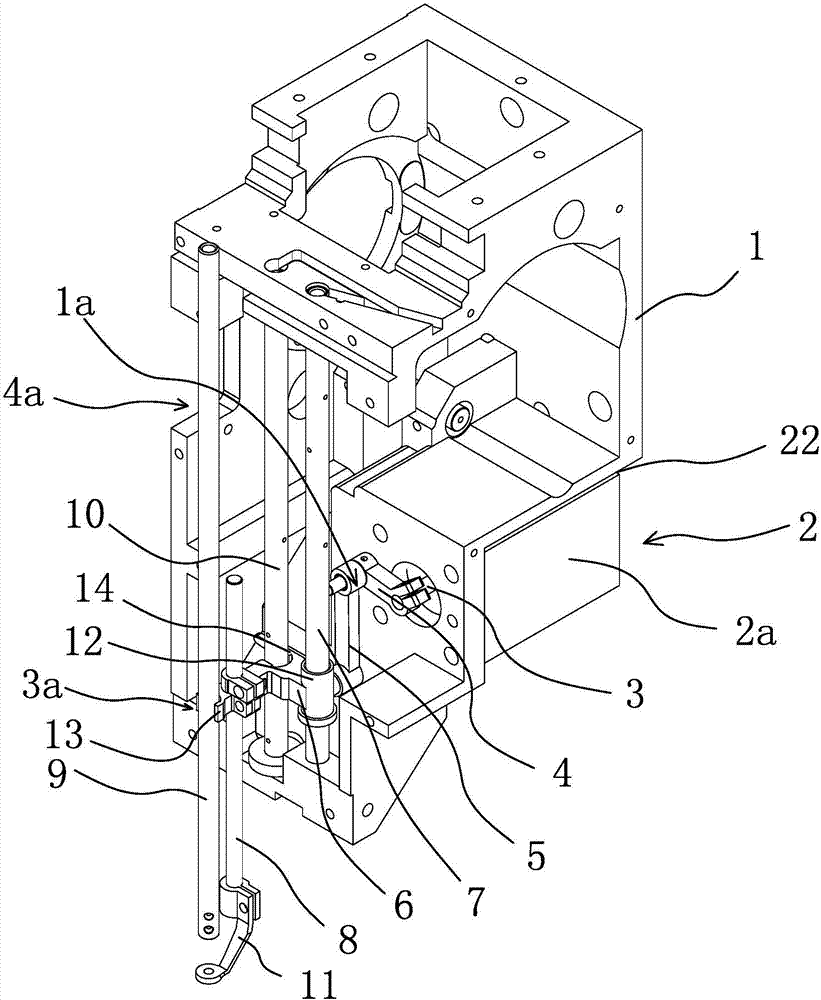

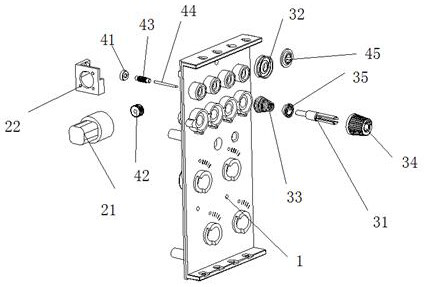

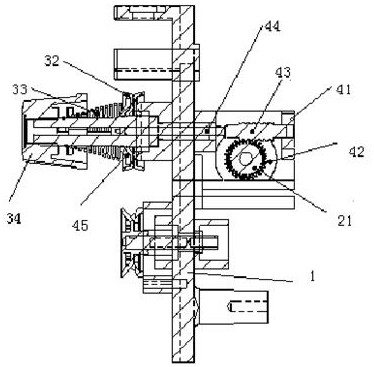

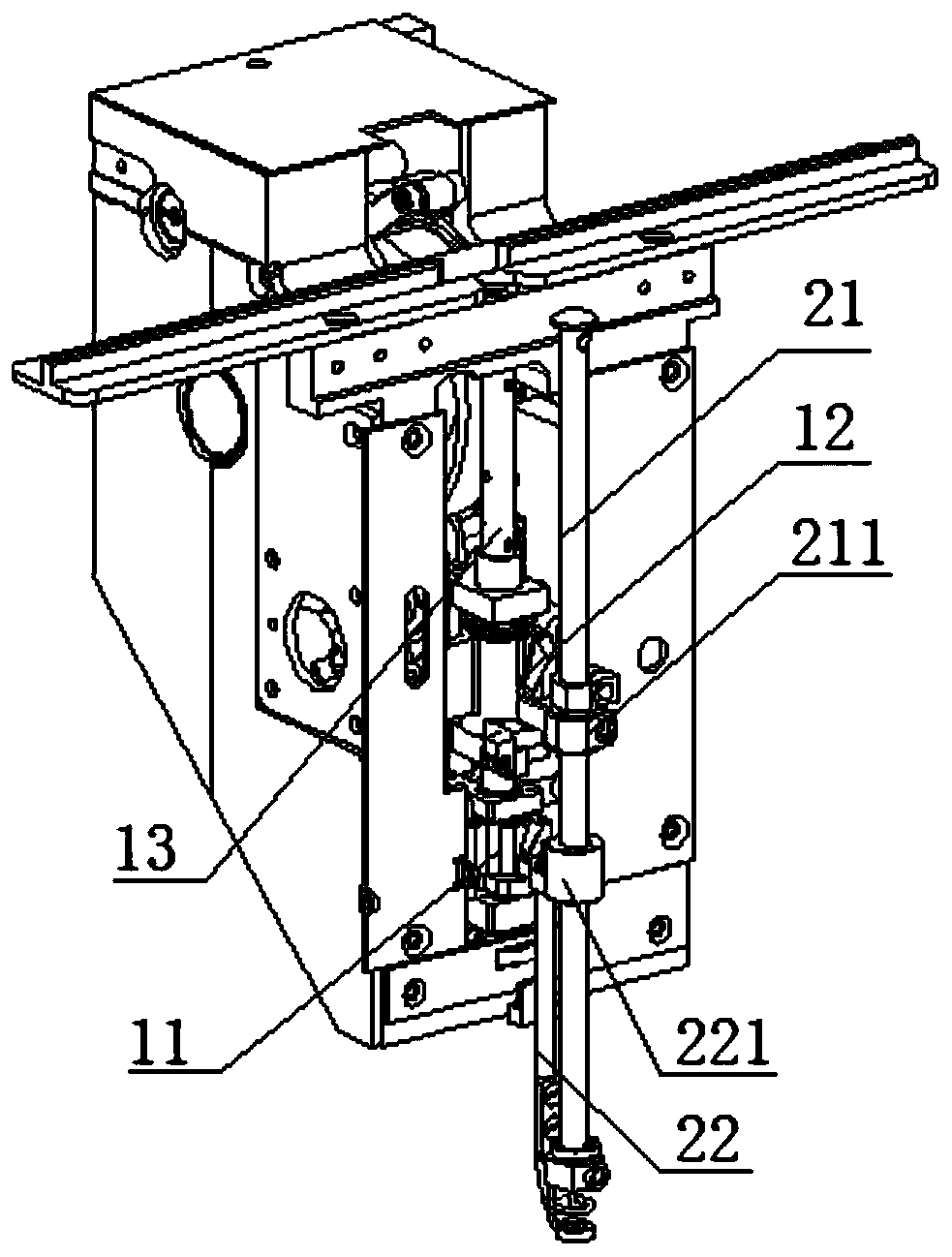

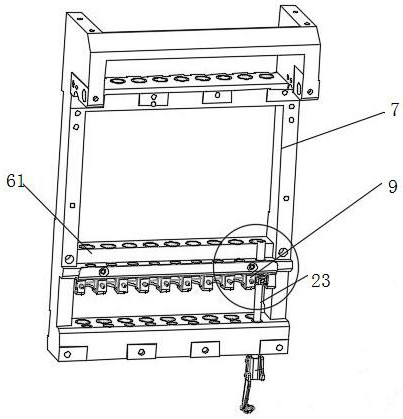

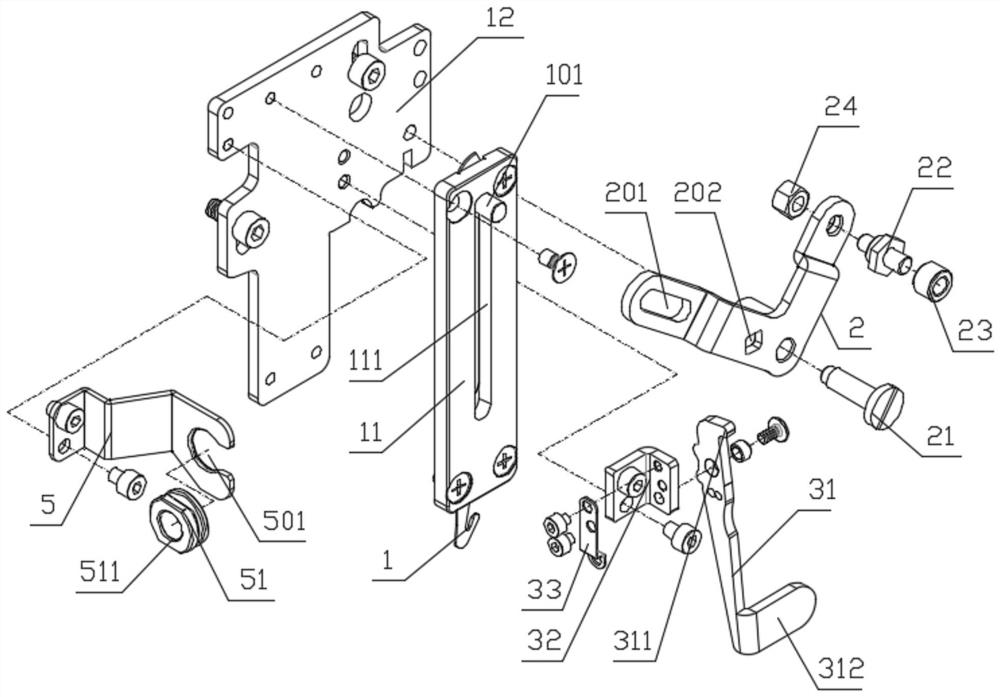

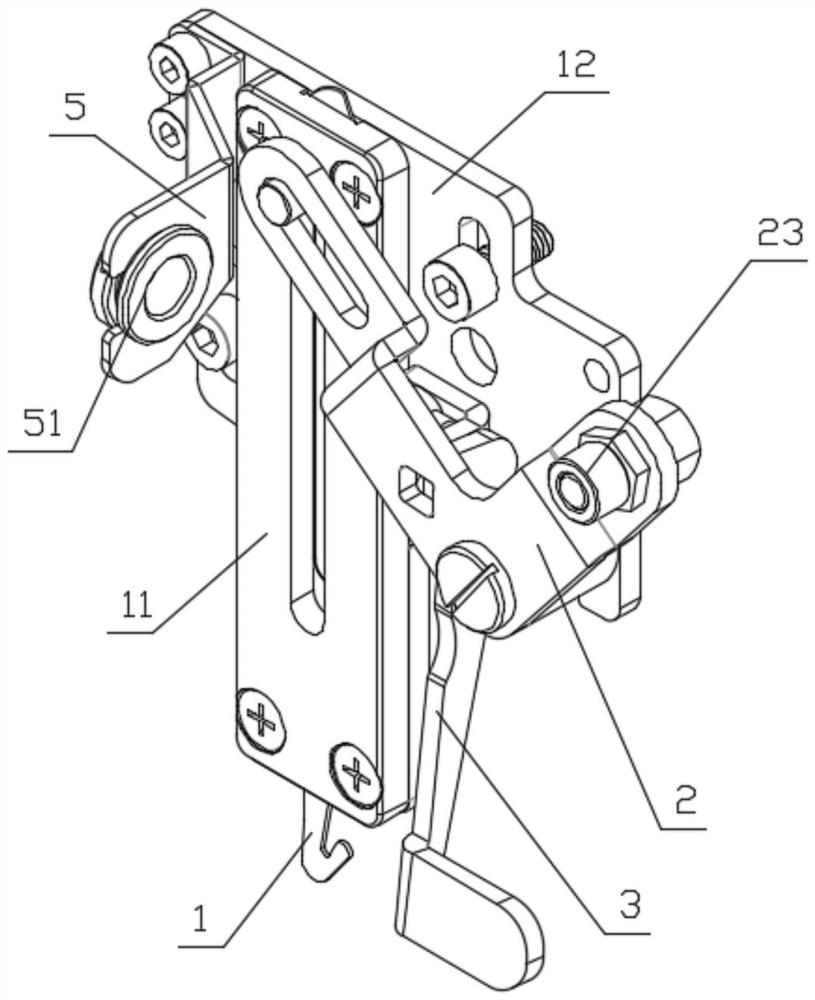

Independent presser foot control mechanism of embroidery machine

ActiveCN107385713AImprove embroidery qualityRealize the loadTotal factory controlFeedersBody positioningPRESSURE FEET

The invention provides an independent presser foot control mechanism of an embroidery machine, aiming at solving the existing technical problem. The independent presser foot control mechanism comprises a machine head seat, wherein a driving mechanism is arranged on the machine head seat and connected with a presser foot driving seat through a connecting rod transmission structure; the presser foot driving seat movably sleeves a presser foot driving rod which is fixedly connected with the machine head seat; one end of the presser foot driving seat is connected with a presser foot needle bar which can synchronously move along the presser foot driving seat when the presser foot driving seat moves up and down along the axial direction of the presser foot driving rod; a presser foot is connected onto the presser foot needle bar; and a needle bar assembly which is movably arranged relative to the presser foot driving seat and does not interfere the presser foot driving seat when the presser foot driving seat moves up and down is connected to the peripheral outer side of the presser foot driving seat through a rod body positioning structure. The independent presser foot control mechanism disclosed by the invention has the advantages of adjustable initial height of the presser foot, low spindle load and the like.

Owner:ZHUJI MAYA ELECTRIC APPLIANCE MACHINERY

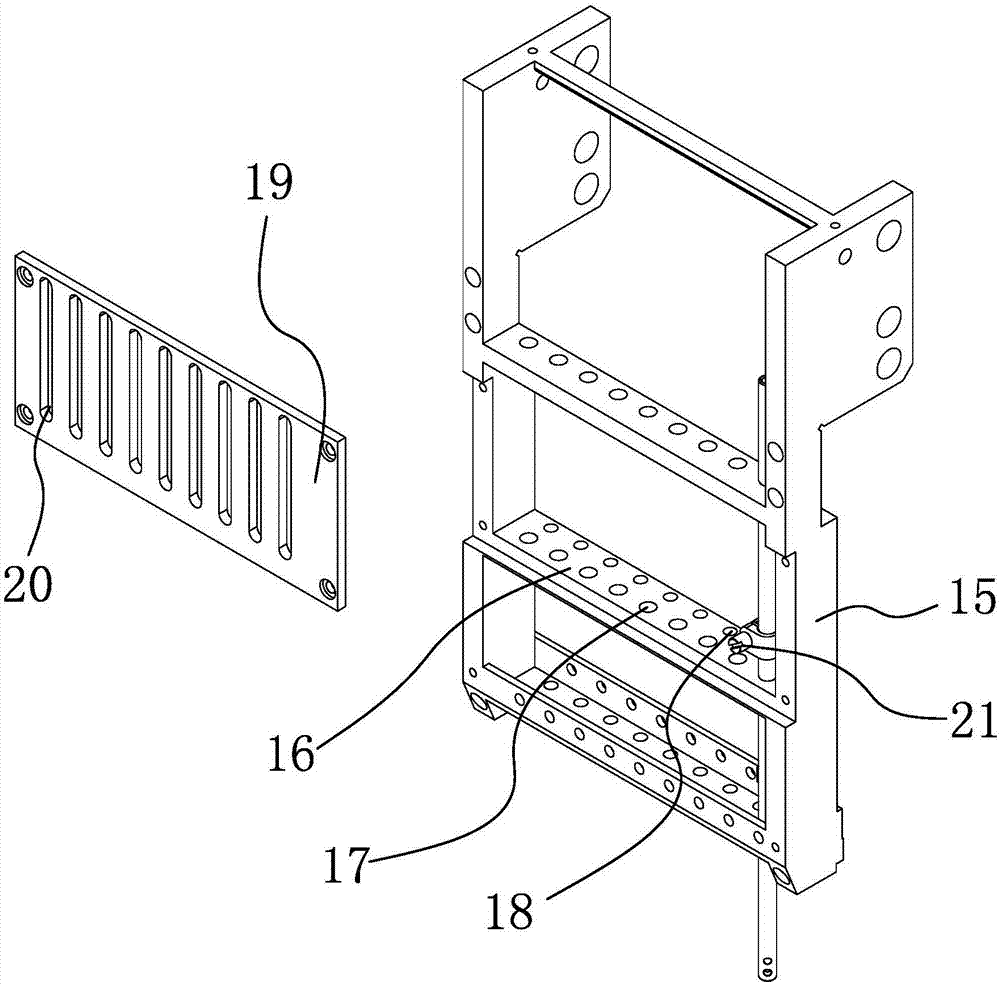

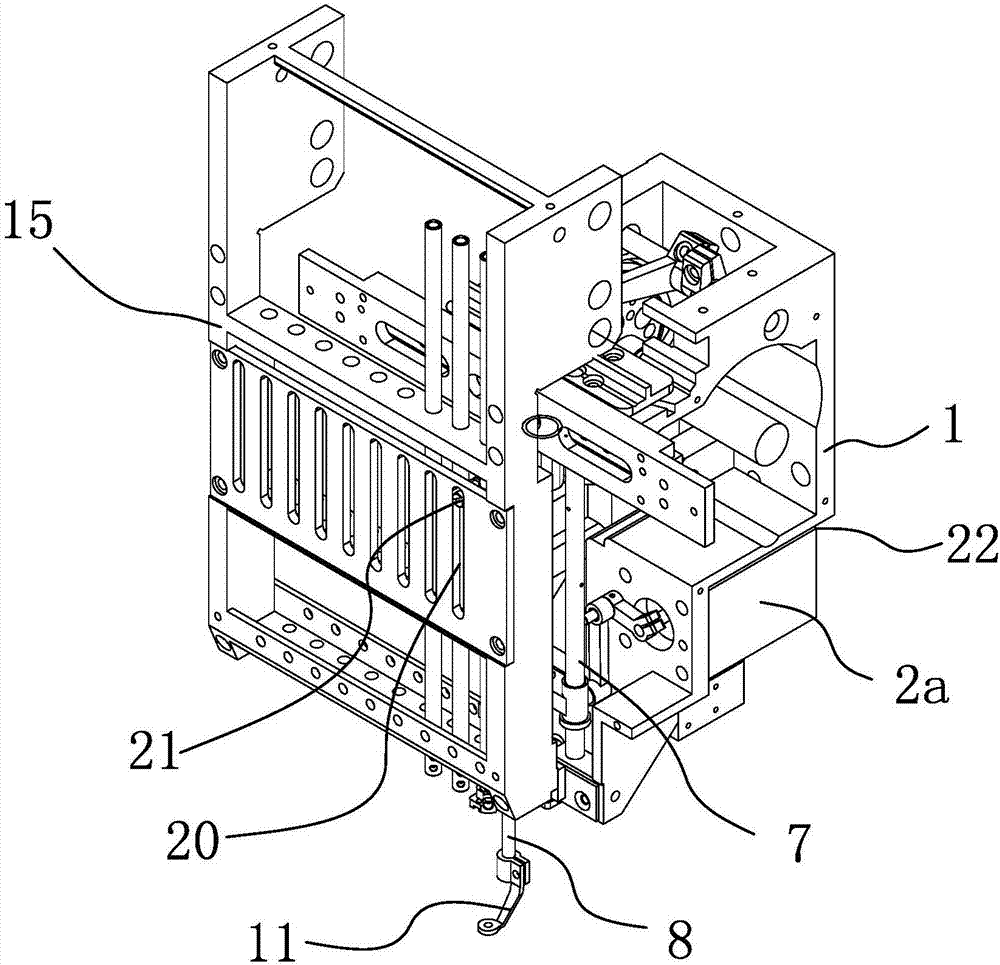

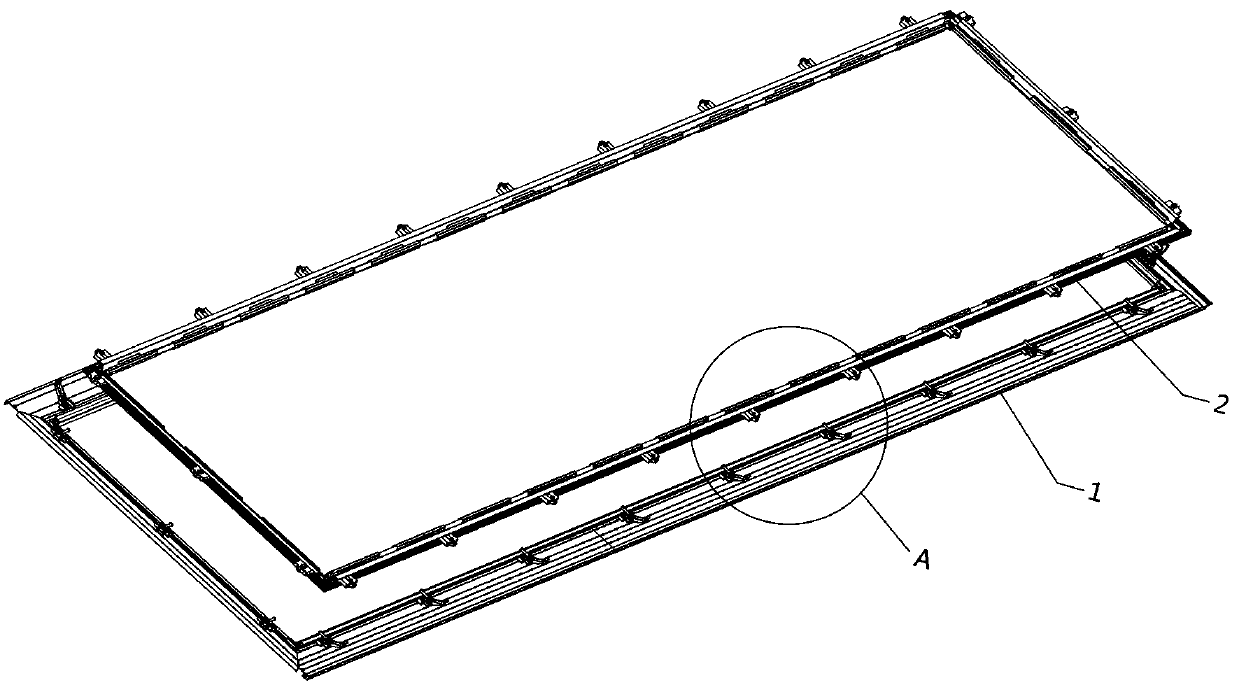

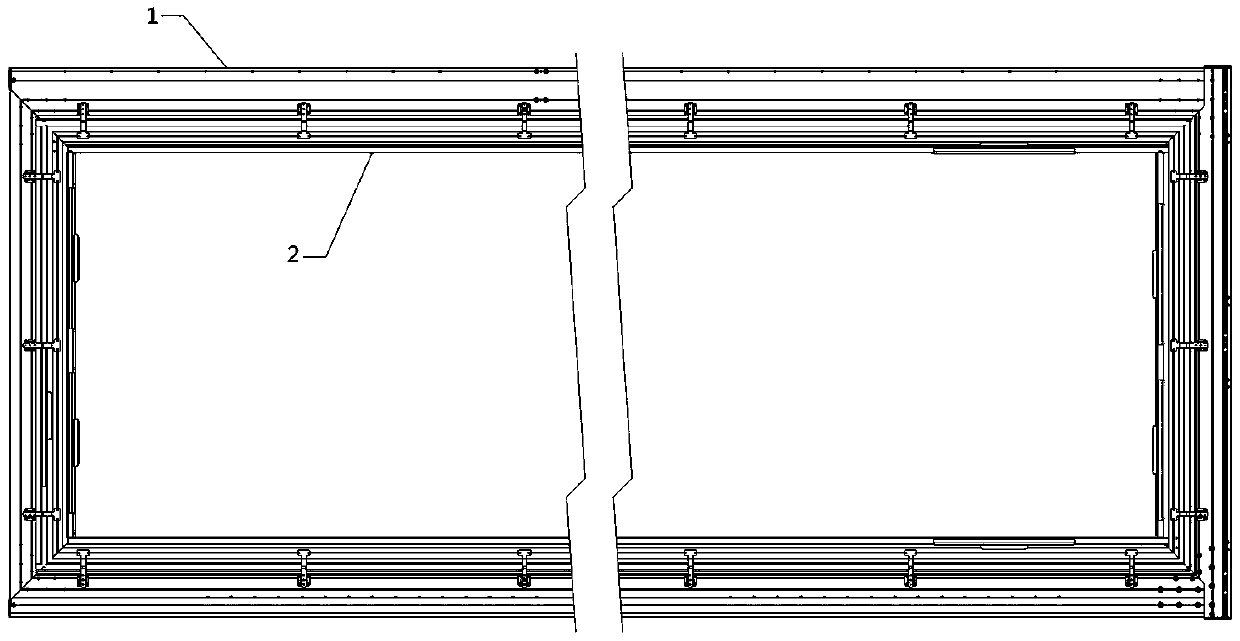

Embroidered material clamping frame system applied to multi-layer embroidery

The invention discloses an embroidered material clamping frame system applied to multi-layer embroidery. The embroidered material clamping frame system comprises an embroidery frame, and further comprises an auxiliary clamping part and a tensioning assembly; an embroidery frame inner side clamping face is arranged on the embroidery frame; a front side embroidered material clamping face and a rearside embroidered material clamping rung are arranged on the auxiliary clamping part, the front side embroidered material clamping face is used for tightly fitting the embroidery frame inner side clamping face to clamp an embroidered material, and the rear side embroidered material clamping rung is used for cooperating with an embroidered material clamp to clamp the embroidered material; the embroidery frame and the cooperating auxiliary clamping part correspond to the tensioning assembly, and the auxiliary clamping part is pulled by the tensioning assembly to the embroidery frame until the auxiliary clamping part is tightly attached and fixed to the embroidery frame. The embroidered material clamping frame system is simple in structure and convenient to use, can well complete single-layeror multi-layer embroidery, is simple and convenient to disassemble and assemble and effortless, lowers the operation difficulty of workers, has good tautness and stationarity, cannot rub and damage the embroidered material, has a good positioning effect, improves the operation efficiency of the workers and the quality of obtained embroidery products, and is extremely worthy of application and promotion in the field.

Owner:浙江镨美科智能刺绣设备有限公司

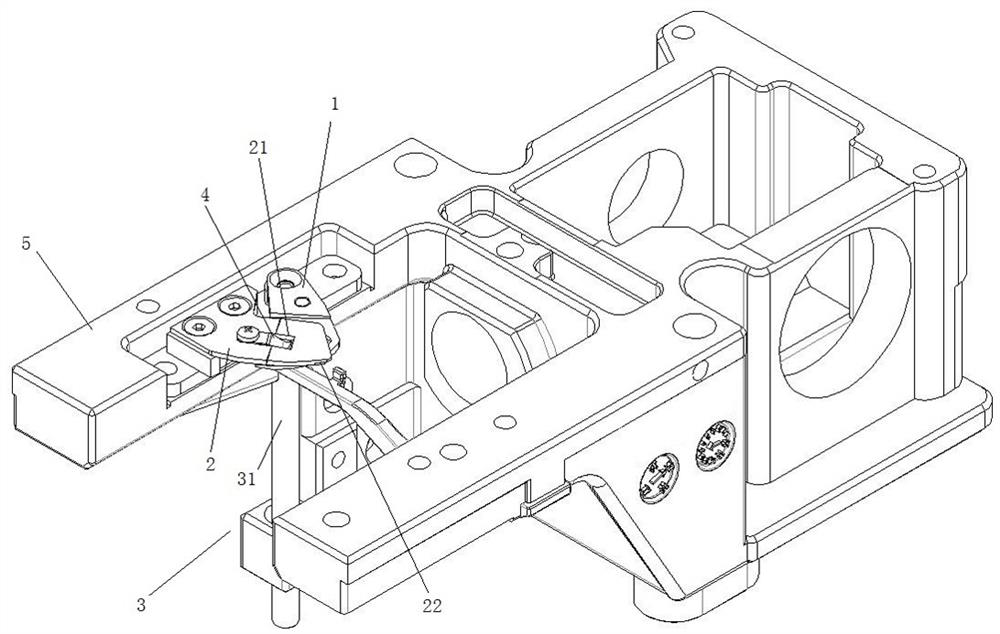

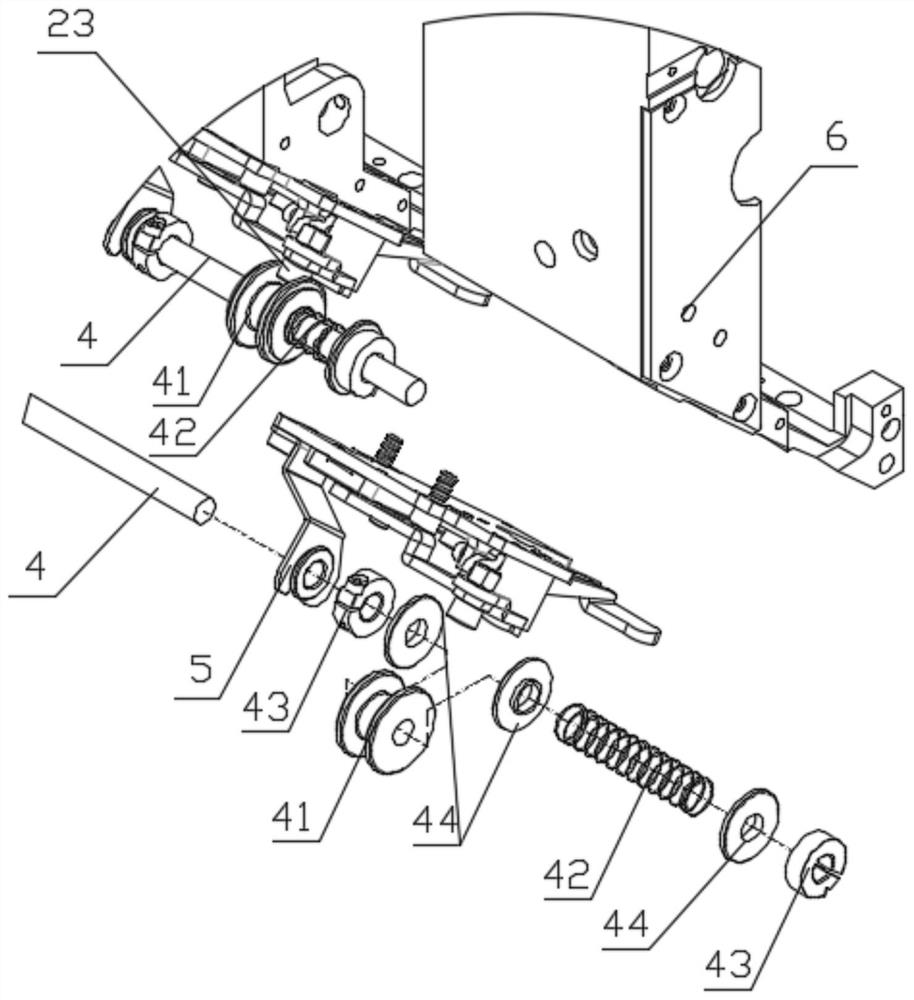

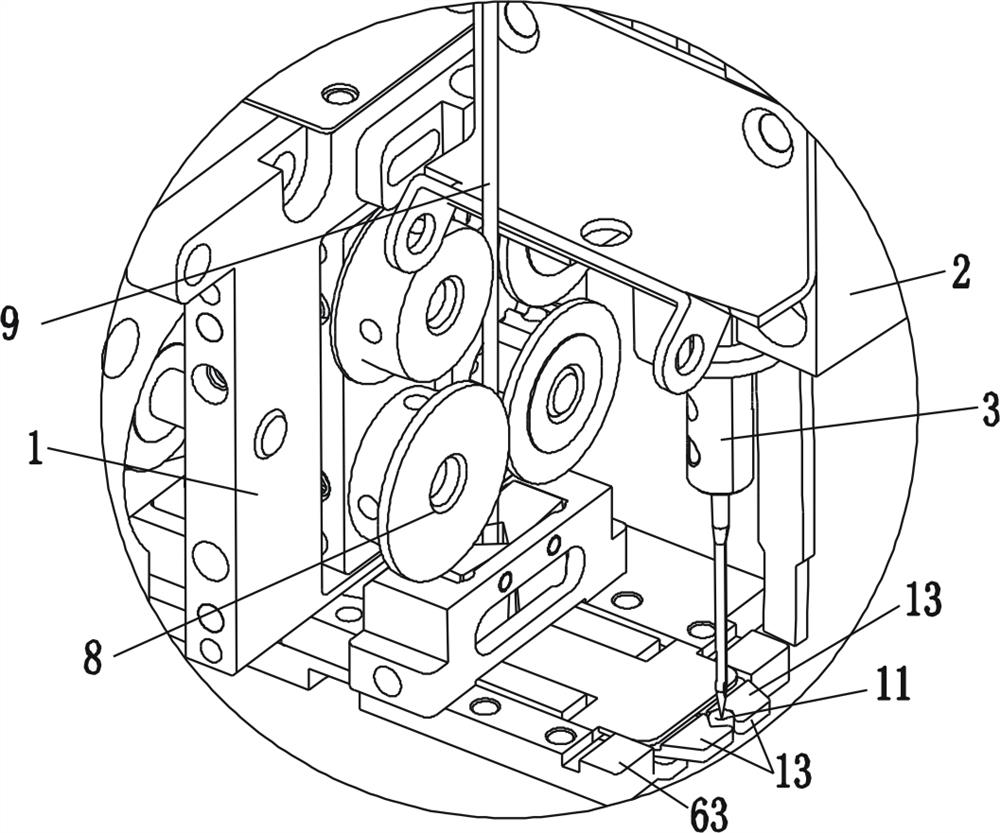

Thread trimming device and thread trimming method of embroidery machine

PendingCN113322593AImprove embroidery qualityAvoid waste residueEmbroidering machines apparatusMechanical engineering

The invention discloses a thread trimming device and thread trimming method of an embroidery machine, and belongs to the technical field of embroidery machines. The device comprises a movable cutter, a fixed cutter and a movable cutter driving mechanism; the movable cutter is mounted on a cutter bar of the movable cutter driving mechanism; a through hole is formed in the rear side of a fixed cutter edge of the fixed cutter; an embroidery thread retaining structure is arranged between the movable cutter and the fixed cutter and comprises an embroidery thread retaining body which at least partially acts on the upper surface of the movable cutter, and the acting part is located on the front side of a movable cutter edge; the front end of the embroidery thread retaining body extends in an upward trend to form the free end of the embroidery thread retaining structure, and the free end extends into the through hole; the embroidery thread retaining structure is used for binding the end of a bottom thread and / or an upper thread between the acting part and the movable cutter before thread trimming; and the movable cutter driving mechanism drives the movable cutter to move towards the fixed cutter, the movable cutter forks out the bottom thread and the upper thread to be cut during movement and continues to move towards the fixed cutter, and until the movable cutter coincides with the fixed cutter, the bottom thread and the upper thread are cut off. The method is realized based on the device. According to the invention, the thread end of the upper thread is prevented from being brought into a rotating shuttle to form a new stitch so as to affect the embroidery quality.

Owner:浙江镨美科智能刺绣设备有限公司

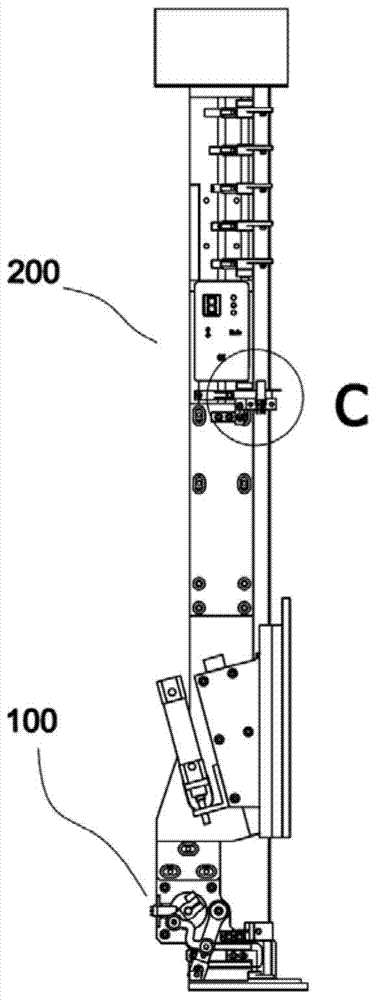

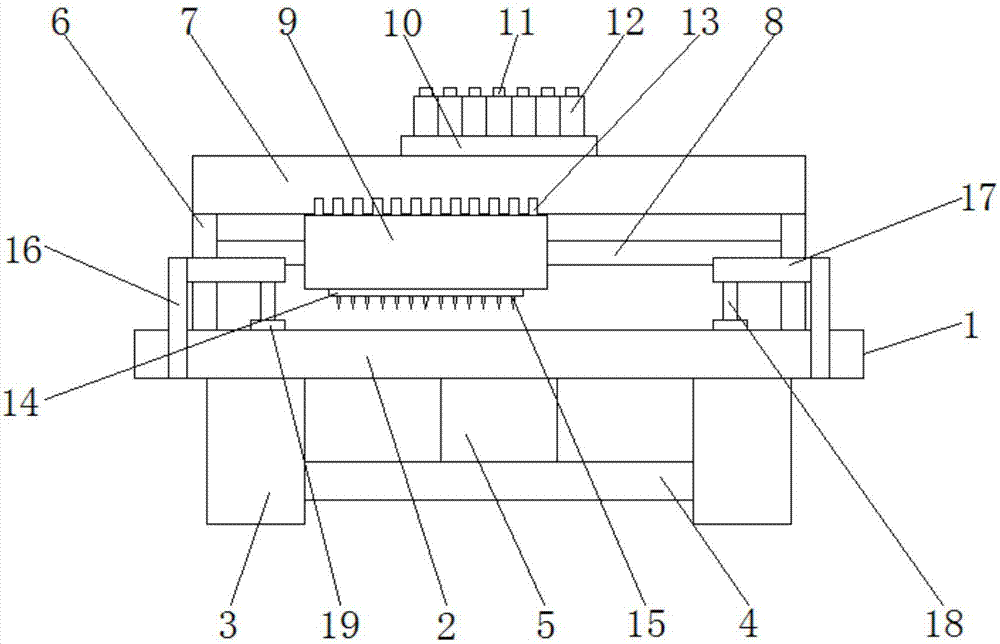

High-precision embroidery machine combining Z-axis movement with Y axis

The invention discloses a high-precision embroidery machine combining Z-axis movement with a Y axis, which consists of a cross beam on a frame and a frame arranged below the cross beam. A machine head mounting plate and a shuttle box body mounting plate on the cross beam are respectively provided with an upper shaft and a lower shaft; a machine head is mounted on the upper shaft of the machine head mounting plate; a shuttle box body component is mounted on the lower shaft of the shuttle box body mounting plate; a linear guide rail and an upper and lower shaft conjoining box body are further arranged at the end part of the cross beam; the machine head and the shuttle box body component are respectively formed into a whole by the machine head mounting plate and the shuttle box body mounting plate through the upper and lower shaft conjoining box body; the upper and lower shaft conjoining box body is connected with a ball screw and a servo motor; the left-right movement, namely the X-direction movement is achieved by the servo motor through the ball screw and the linear guide rail; and synchronously, the servo motor drives the upper shaft and the lower shaft to rotate through the ball screw and the upper and lower shaft conjoining box body, so as to drive the machine head and the shuttle box body component to carry out the Z-axis movement. The front-rear movement, namely the Y-direction movement of the frame is achieved by a Y driving motor through driving a synchronous belt and a sliding block. The high-precision embroidery machine combining the Z-axis movement with the Y axis is applicable to embroidery machines.

Owner:浙江盛名机电制造有限公司

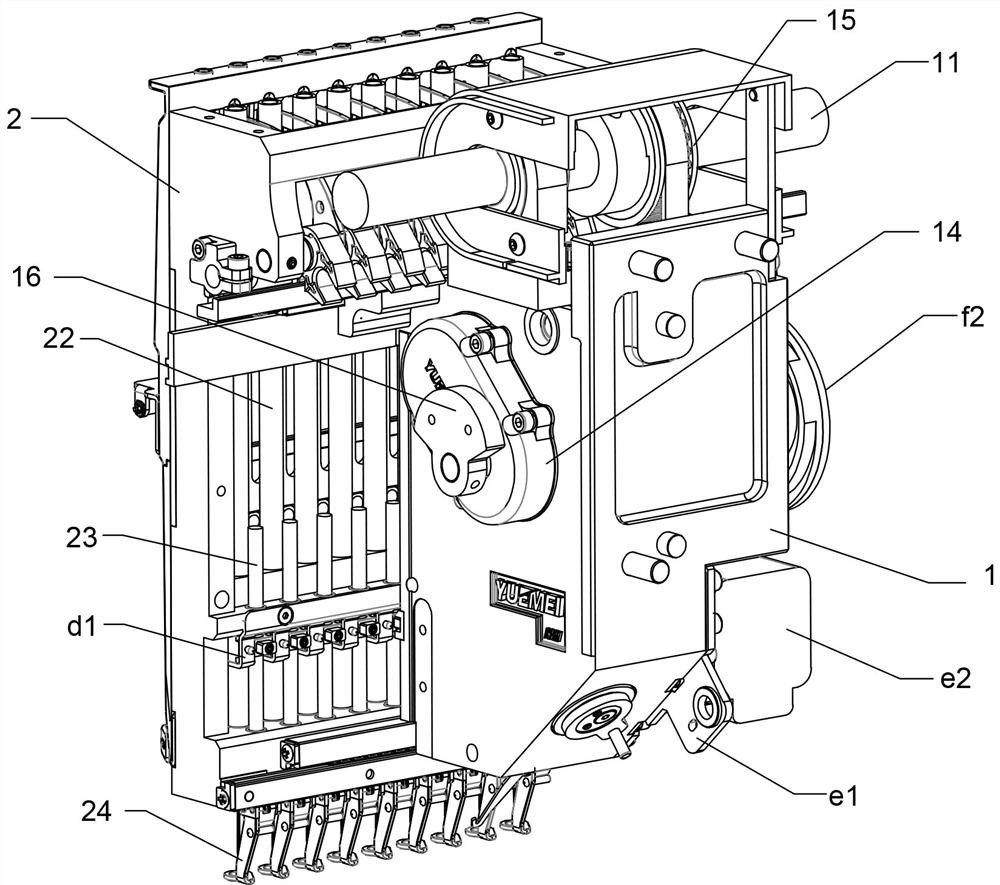

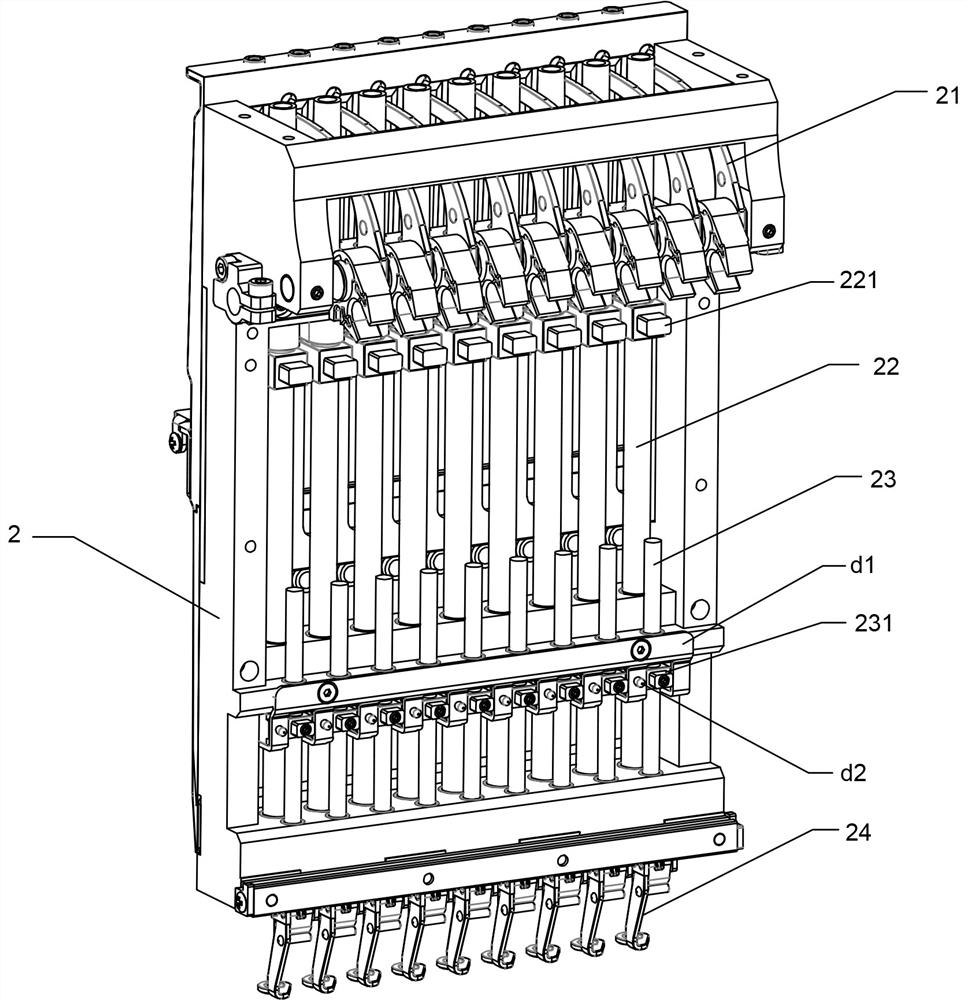

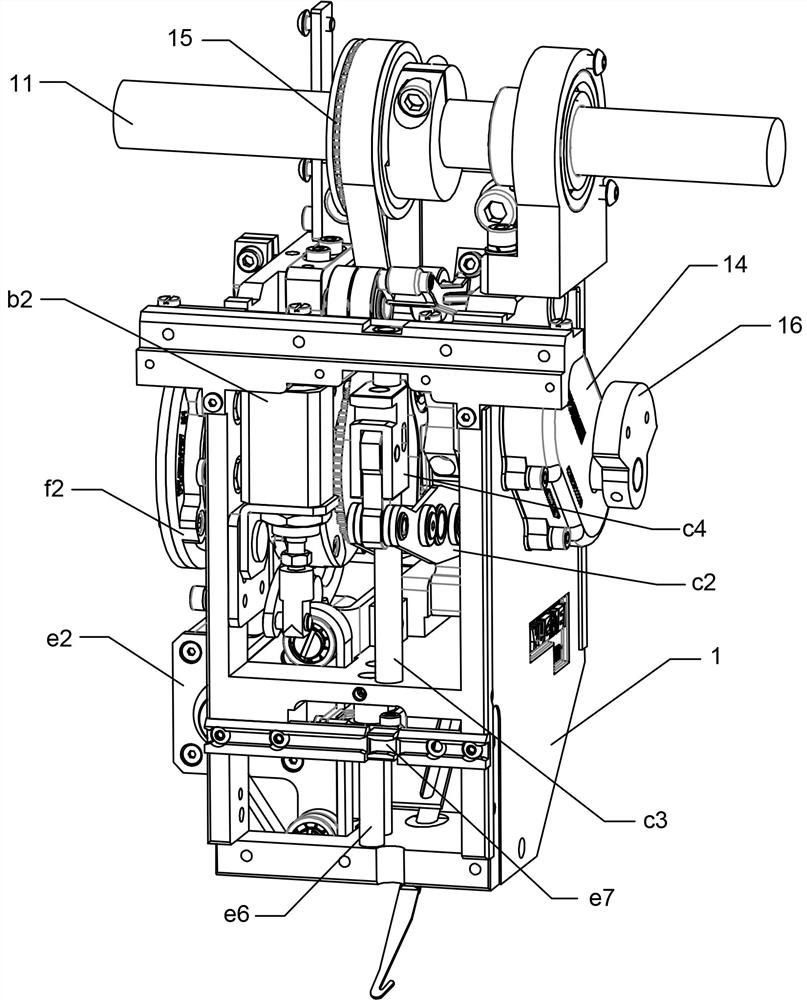

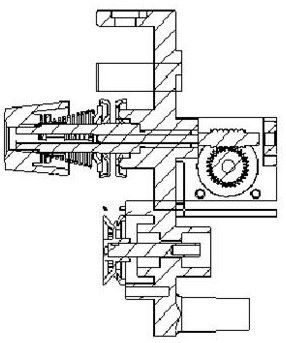

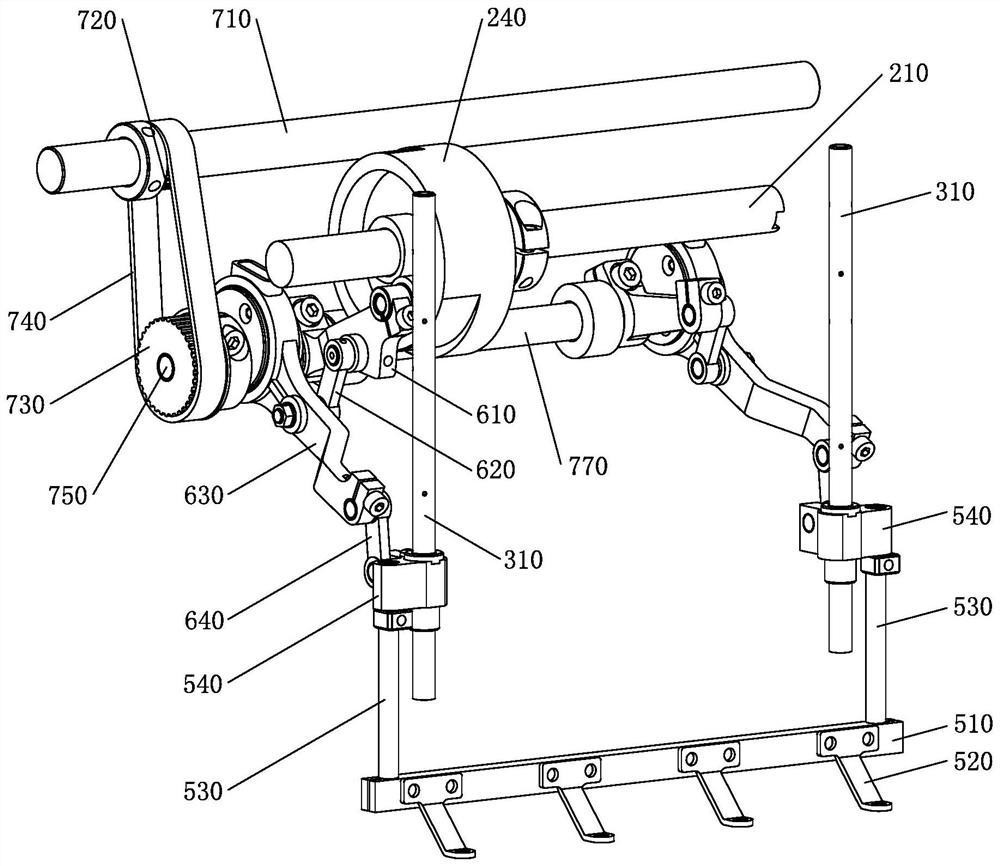

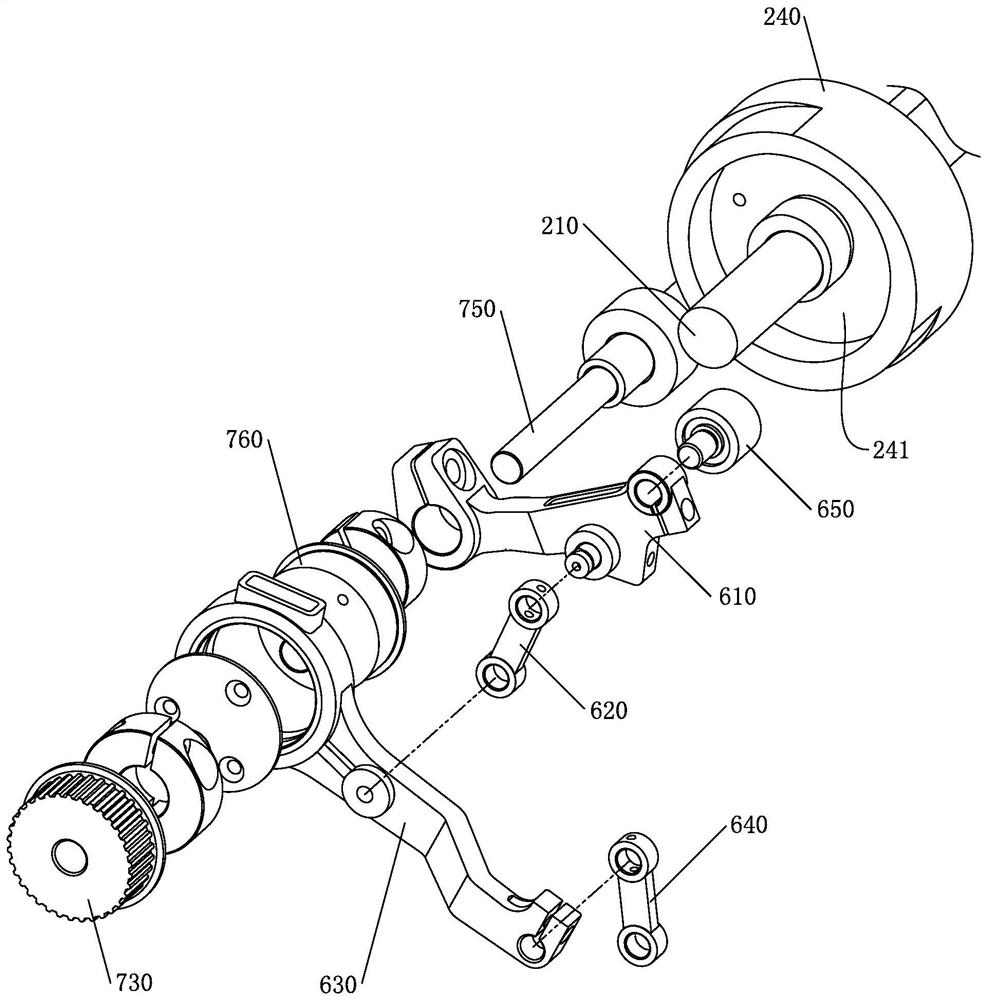

Embroidery machine head suitable for high-speed embroidery

An embroidery machine head suitable for high-speed embroidery comprises a machine shell and a needle bar frame, wherein the needle bar frame is connected to the machine shell in a sliding mode and canslide horizontally, a take-up lever, a needle bar, a presser foot shaft and a presser foot are arranged on the needle bar frame, a main shaft, a needle rod driving mechanism used for driving a needlerod, a presser foot driving mechanism used for driving the presser foot shaft and a take-up driving mechanism used for driving the take-up lever are arranged on the machine shell, and a clutch mechanism, a clutch driving mechanism, an input transmission shaft and an output transmission shaft are further arranged on the machine shell. On the basis of a traditional framework that the main shaft drives a machine head, comprehensive and perfect improvement and adaptation are conducted, so that all the components are organically combined into a whole, the universality and stability are excellent,various embroidery function requirements are met, the embroidery quality is good, and the embroidery machine head is worthy of application and popularization in the field.

Owner:ZHEJIANG YUELONG SEWING EQUIP

Spinning embroidery machine for textile processing and convenient to use

InactiveCN107338589AStable supportEasy to moveAutomatic machinesAuxillary devicesArchitectural engineeringTextile processing

The invention discloses a textile embroidery machine for textile processing which is convenient to use, comprising a textile embroidery machine body, the textile embroidery machine body including a textile work embroidery table, the front of the textile work embroidery table is fixedly connected with a fixing frame, the An extension frame is fixedly connected to the top of the fixing frame, a compression rod is fixedly connected to the bottom of the extension frame, and a compression plate is fixedly connected to the bottom of the compression rod. The present invention provides shock-absorbing support for the textile embroidery machine body by arranging a shock-absorbing support seat, thereby ensuring the stability of the textile embroidery machine body, thereby facilitating the embroidery operation of the textile embroidery machine body, improving the embroidery quality, and providing compression by setting a compression rod. force, so that the pressing plate can press the embroidery cloth placed on the textile work embroidery table, which is convenient for the embroidery equipment to carry out embroidery processing, and achieves the advantage of convenient use, thus effectively solving the inconvenient use of the existing textile embroidery machines. Problems with textile embroidery operations.

Owner:梅明会

Conveying device of tufting embroidering machine

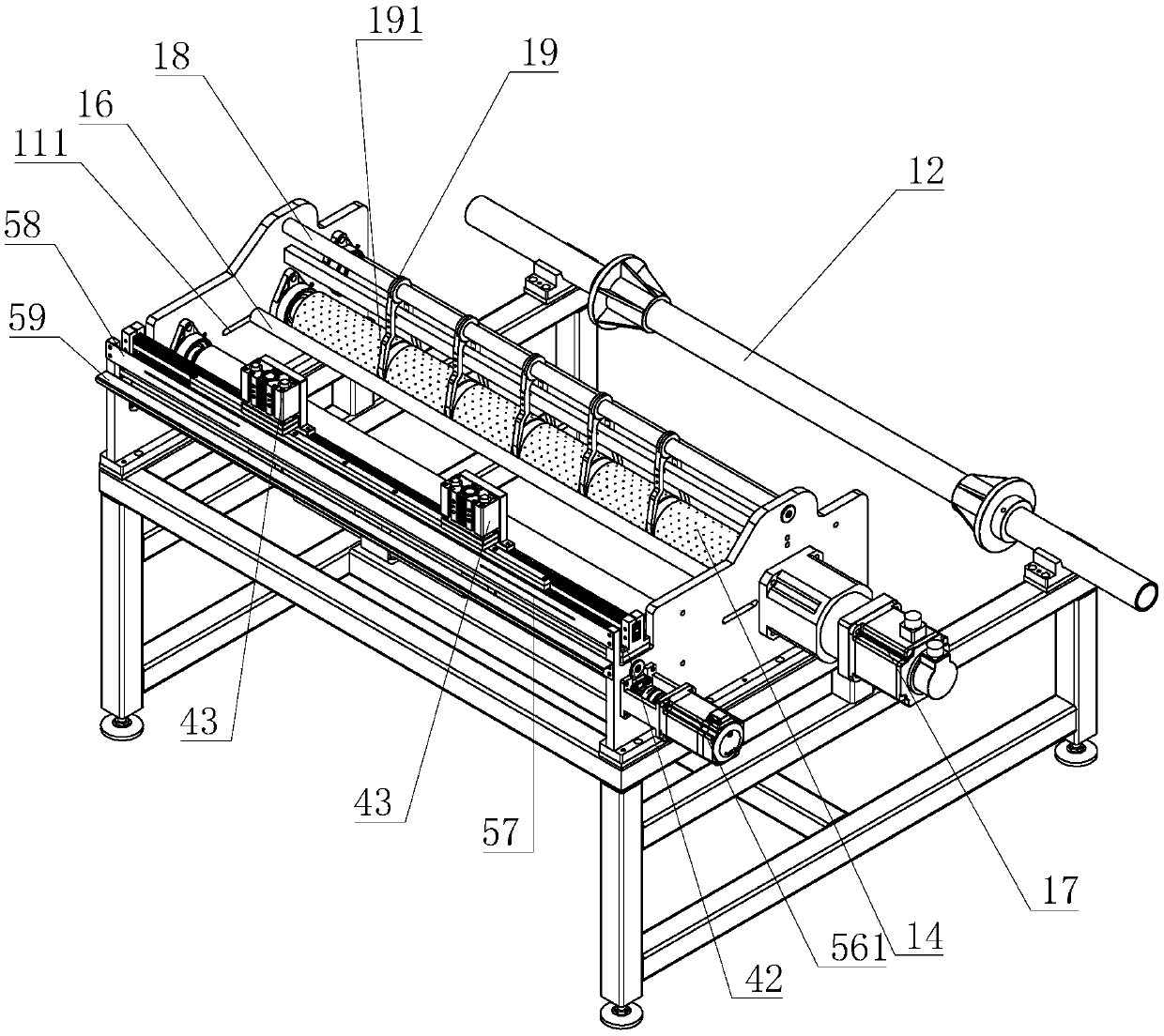

PendingCN109537201AImprove embroidery qualityPrecise positioningFeedersDegrees of freedomEngineering

The invention discloses a conveying device of a tufting embroidering machine. The device comprises a conveying part for conveying base blanket cloth to the lower part of the tufting embroidering machine for embroidering, a positioning part which is positioned below the tufting embroidering machine and is used for fixing and tensioning the base blanket cloth, and a collecting part for collecting the embroidered blanket cloth, wherein a discharging end of the conveying part and a feeding end of the collecting part are correspondingly provided with positioning mechanisms for fixing and releasingthe base blanket cloth; correcting mechanisms for correcting skewed base blanket cloth are arranged below the positioning mechanisms. According to the device, the conveying part, the positioning partand the collecting part are matched to realize automatic conveying of the tufting embroidering machine, so that the tufting embroidering efficiency is improved; a plurality of sets of positioning mechanisms are matched to effectively limit the degree of freedom, to be limited during tufting embroidering, of the base blanket cloth, so that the coaxiality in tufting embroidering can be greatly controlled, and the stability of surface tension of the base blanket cloth can also be greatly controlled; and the two sets of correcting mechanisms are matched to correct the skewed base blanket cloth, sothat the embroidering quality is improved.

Owner:JINHUA JIELING HOUSE WARES CO LTD

Embroidered material clamping frame system for dual-layer embroidery

An embroidered material clamping frame system for dual-layer embroidery comprises an embroidery frame and an auxiliary frame. A lower layer embroidered material clamping part is arranged on the embroidery frame. An upper layer embroidered material clamping part is arranged on the auxiliary frame. The embroidered material clamping frame system further comprises at least one lifting assembly for driving the auxiliary frame to rise or fall in the vertical direction. The embroidered material clamping frame system is simple in structure and convenient to use; the auxiliary frame is directly controlled by the lifting assembly to rise or fall vertically, the laying of a lower layer embroidered material and the clamping and force executing of the lower layer embroidered material are facilitated, the embroidered material is not prone to damage, the upper and lower layer embroidered material is not prone to large position deviation, the automation degree is high, the work efficiency is improved, and the quality of the embroidery is improved.

Owner:浙江镨美科智能刺绣设备有限公司

Novel wire clamping device wire pressing mechanism

PendingCN112080870AQuality improvementSimple structureEmbroidering machines apparatusStructural engineeringManufacturing engineering

Owner:浙江兆山机电有限公司

Presser foot driving assembly with stable driving and embroidery machine

The invention discloses a presser foot driving assembly with stable driving and an embroidery machine. The presser foot driving assembly comprises a presser foot and a presser foot driver, wherein thepresser foot is provided with a sliding sleeve which is slidably mounted on a needle rod; the presser foot driver comprises a driving piece; the driving piece is movably connected with the sliding sleeve in an embedded mode; and the driving piece drives the sliding sleeve to synchronously move up and down in an embedded state. According to the technical scheme adopted by the invention, in a high-speed embroidering process, the driving piece and the sliding sleeve are movably connected in an embedded mode, and the driving piece drives the sliding sleeve to synchronously move up and down in anembedded state, so that impact is avoided, noises can be reduced, and embroidering quality is improved.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

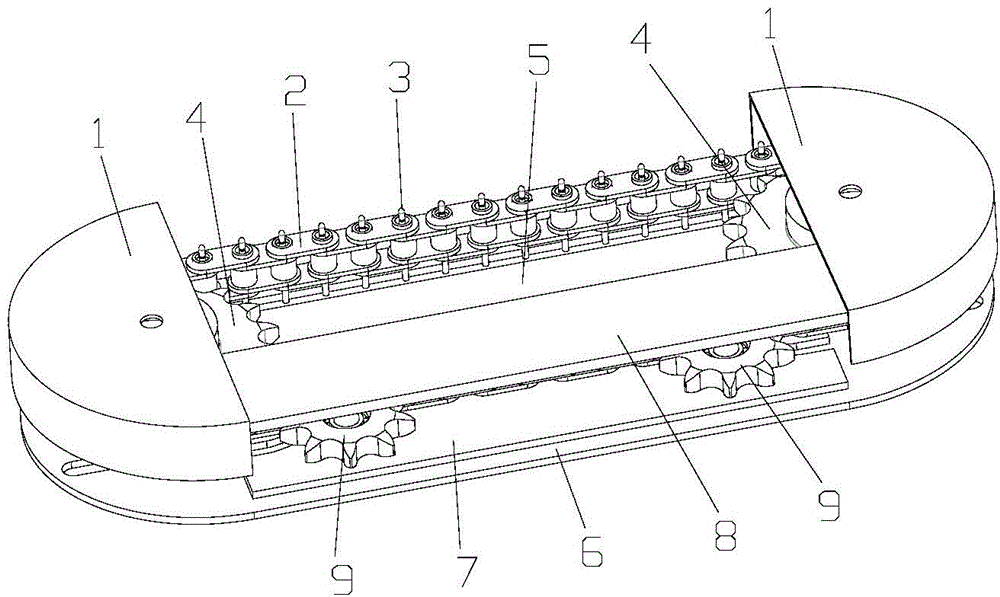

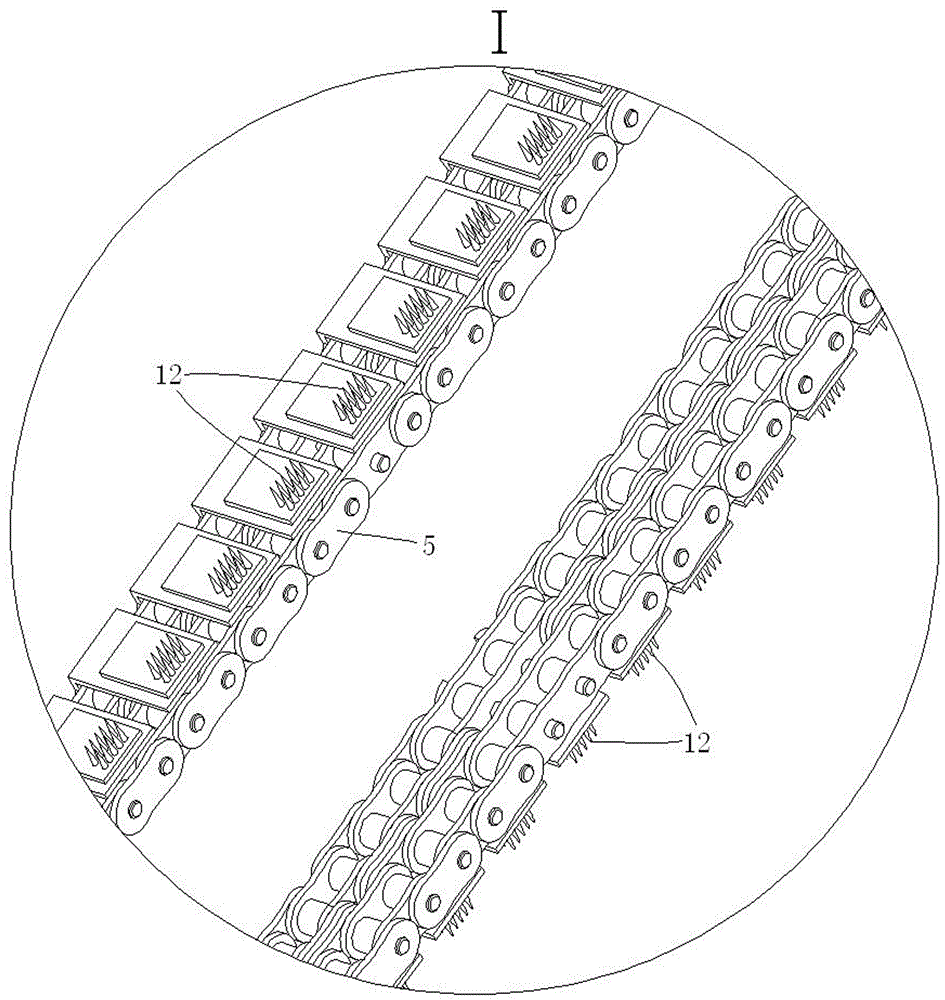

Novel cloth clamping device

The invention discloses a novel cloth clamping device for a computer embroidery machine. The device comprises a base board and two chain wheels mounted on the base board; a middle partition board is arranged between the two chain wheels, two small chain wheels are arranged on a left partition board, and a press plate is arranged above the two small chain wheels correspondingly; and special chains are arranged on the two chain wheels and two small chain wheels provided, and the chain has hollow pin shaft and is provided with an elastic pin structure. The device uses movement track of the chains to drag the cloth to move, in order to reach the purpose of increasing pulling force; when the cloth is pulled into a cloth sliding rail, under the action of the press plate with wedge structure, the needles press a certain distance towards to needle tip direction and prick into the cloth; and in the traction of cloth, the needles drive the chains to move along the chain wheels, and needles prick into the cloth in order from the chain wheel pin shafts. Due to the movement track of the chains, the needles move a certain distance in the X direction along the sliding groove, and pull the cloth in the X direction to a certain distance, so the relaxing cloth will be tightened. The device improves the quality of the embroidery, makes the embroidery stitch surface neat and shows clear stitch seam.

Owner:上工富怡智能制造(天津)有限公司

Cloth feeding mechanism of embroidery machine

Owner:江苏润源控股集团有限公司

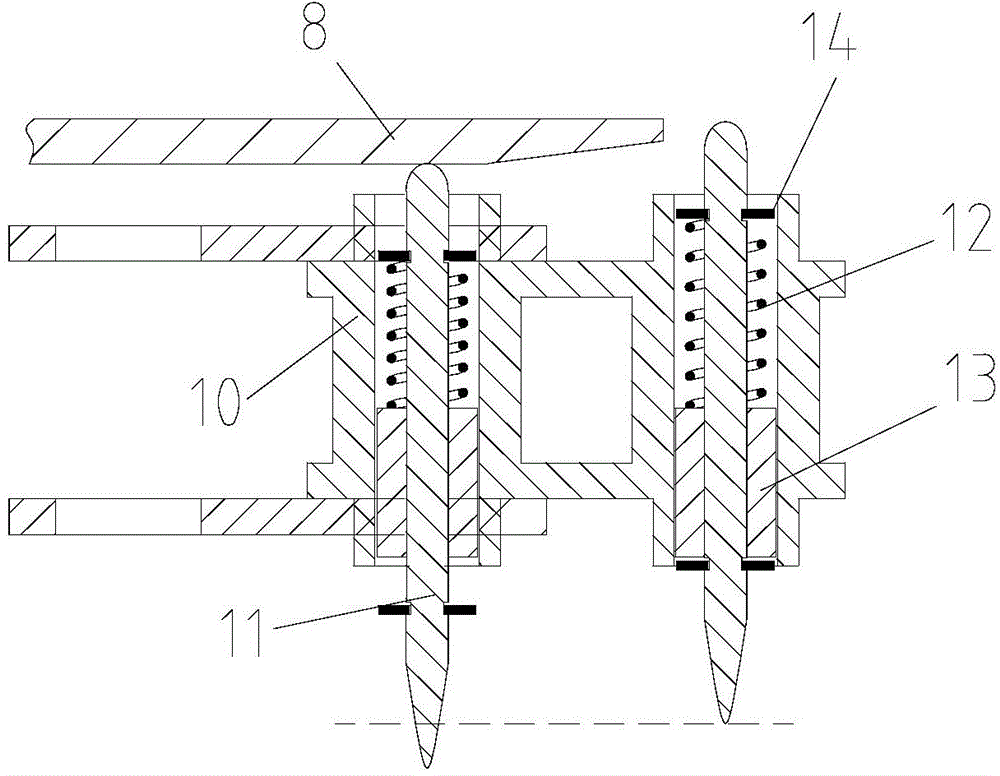

Intermediate Thread Passing Device of Computerized Embroidery Machine

The invention discloses a middle thread passing device of a computerized embroidery machine, which is composed of a middle thread passing seat arranged on the frame of the computer embroidery machine and below the upper thread passing system, and a pagoda spring is arranged on the middle thread passing seat Supporting plate, pagoda spring The supporting plate is provided with several pagoda springs, and the quantity of pagoda springs is determined according to the quantity of embroidery machine needles. The below of the pagoda spring support plate is provided with an adjustment screw and a support spring located on the adjustment screw. A buffer pad is arranged inside the middle thread seat, and a thread limit plate is arranged above the middle thread seat. A wire hole is provided on the wire limit plate. The invention is suitable for computerized embroidery machines.

Owner:浙江盛名机电制造有限公司

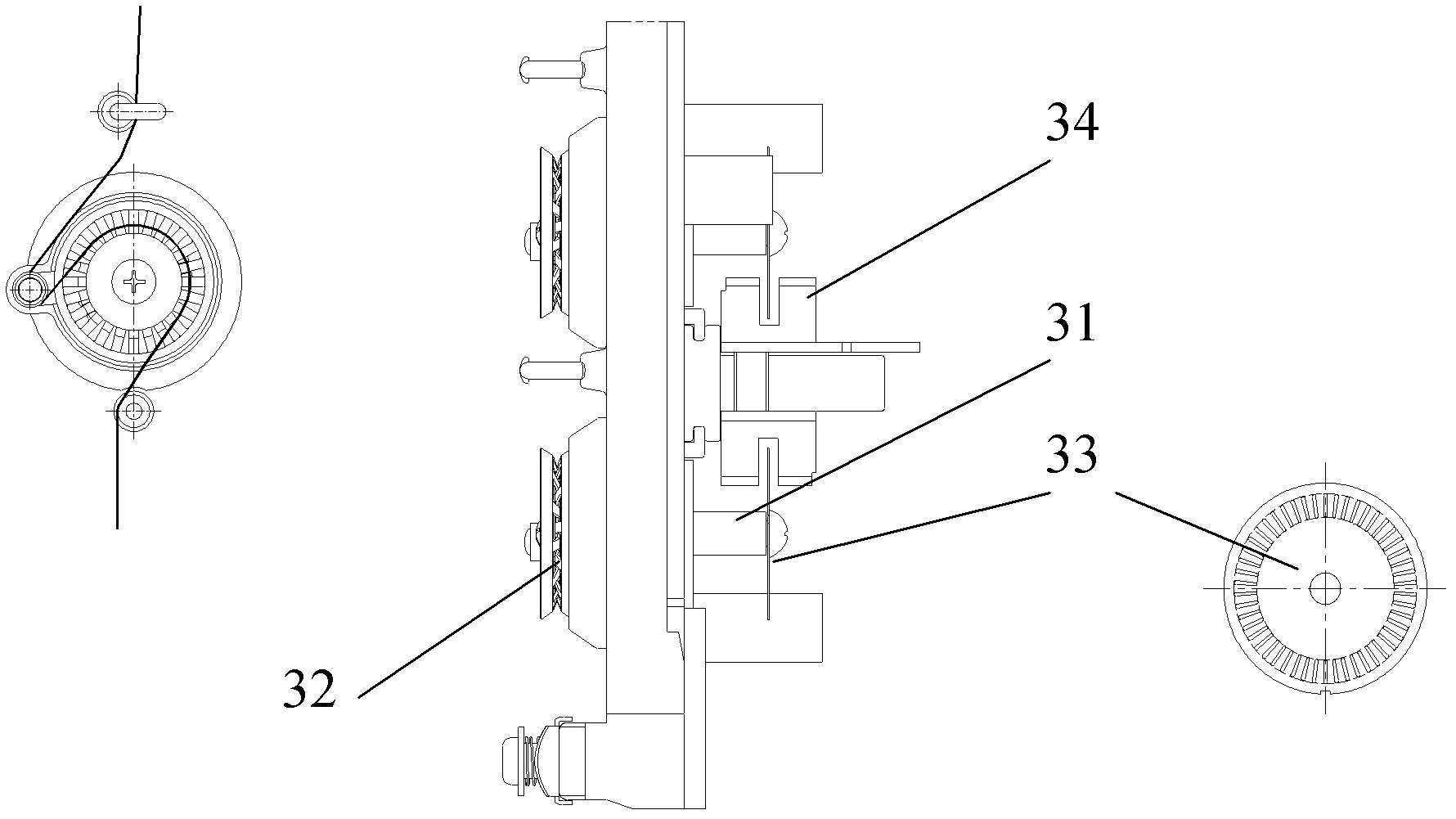

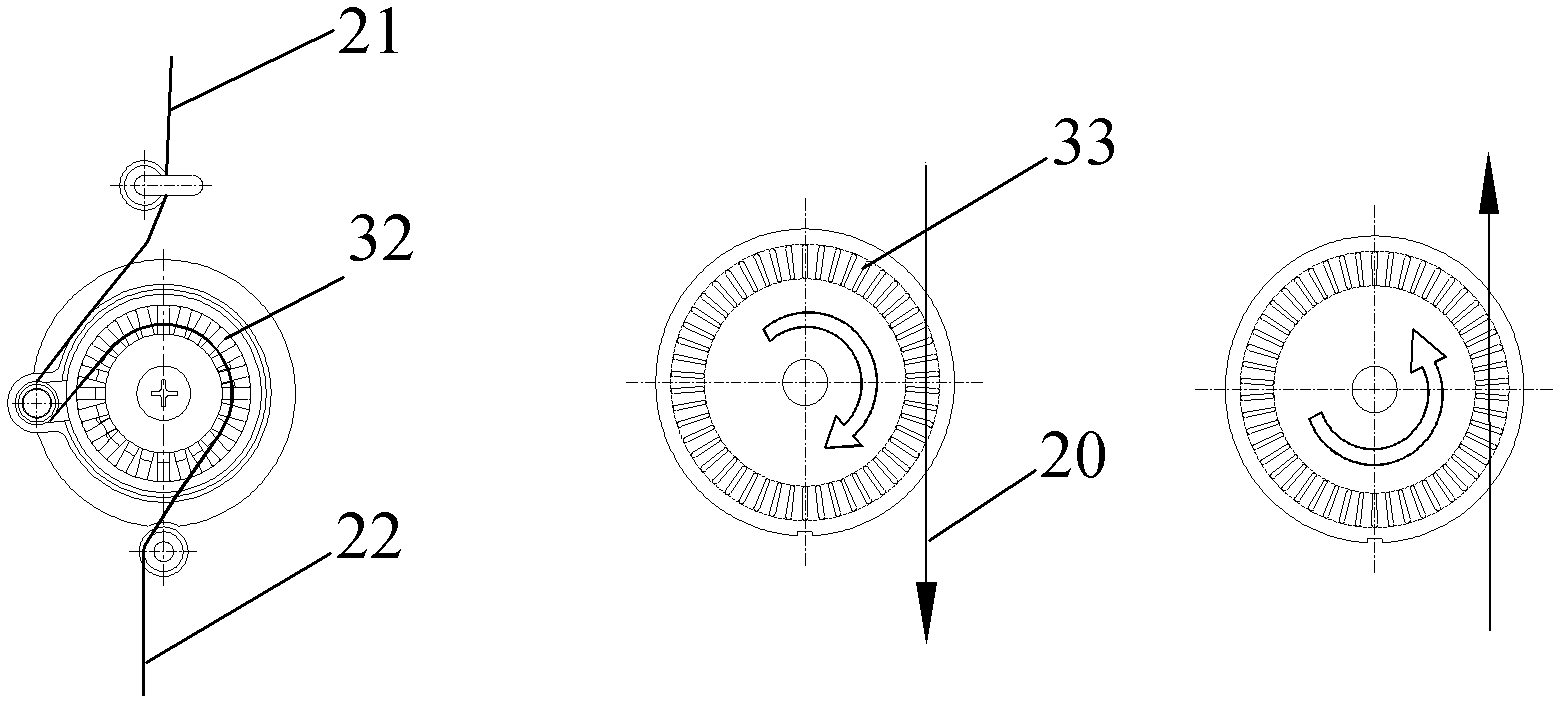

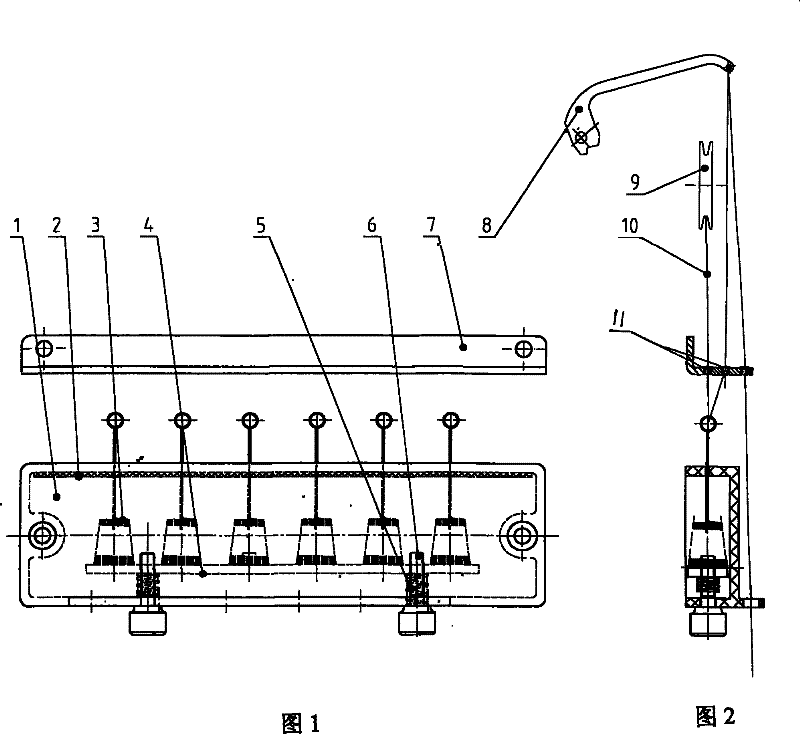

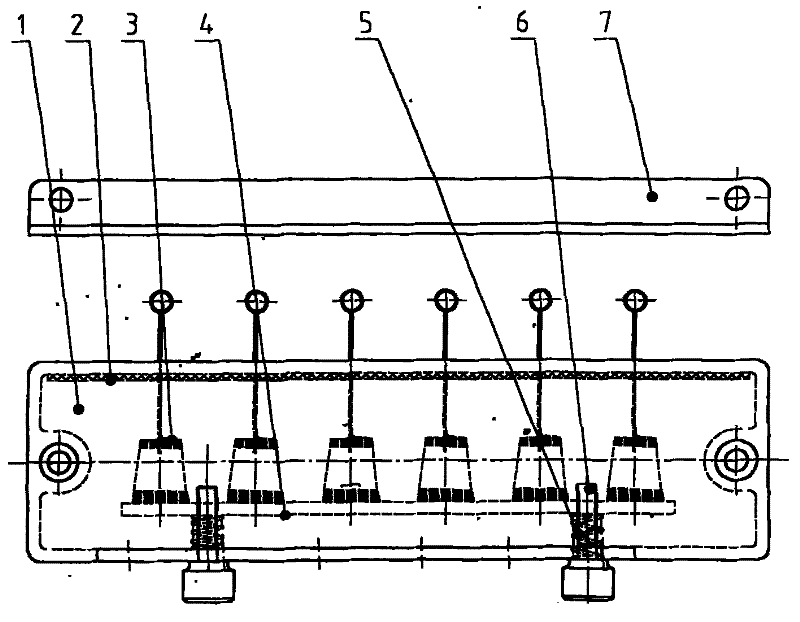

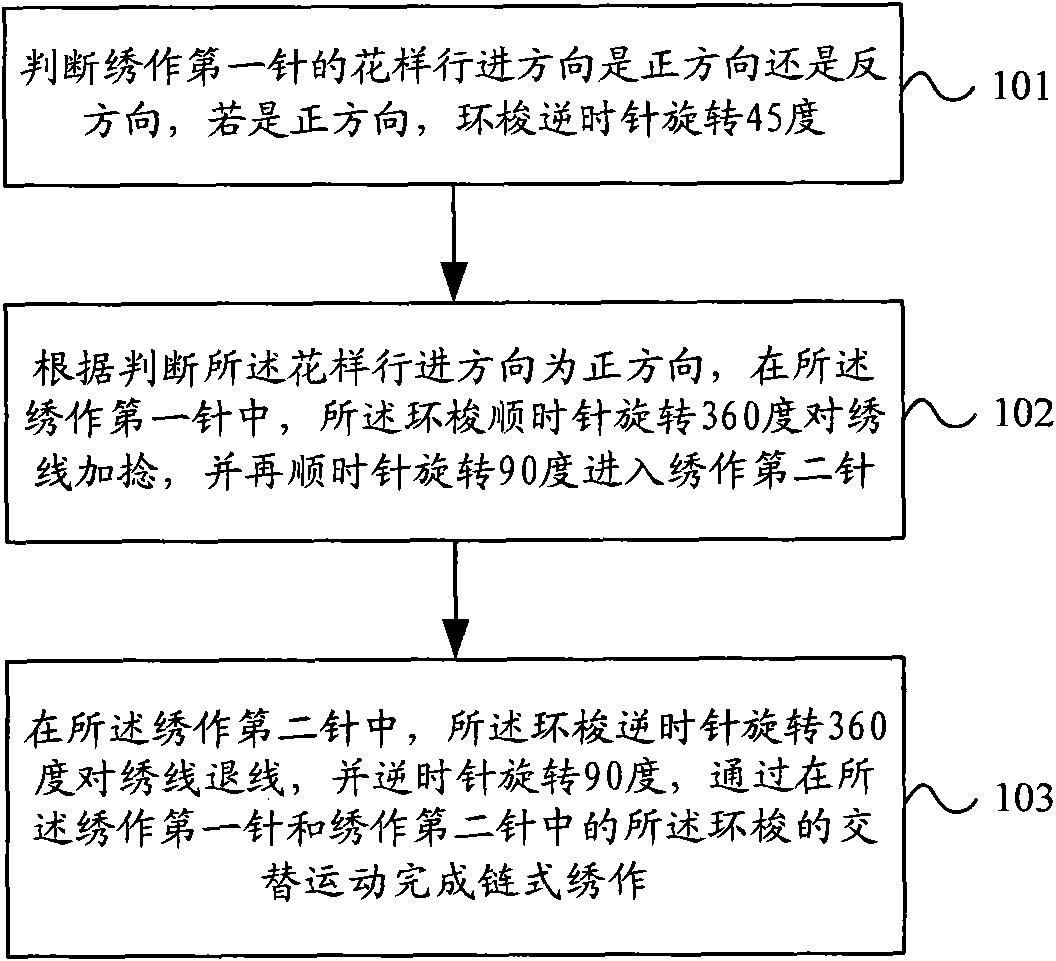

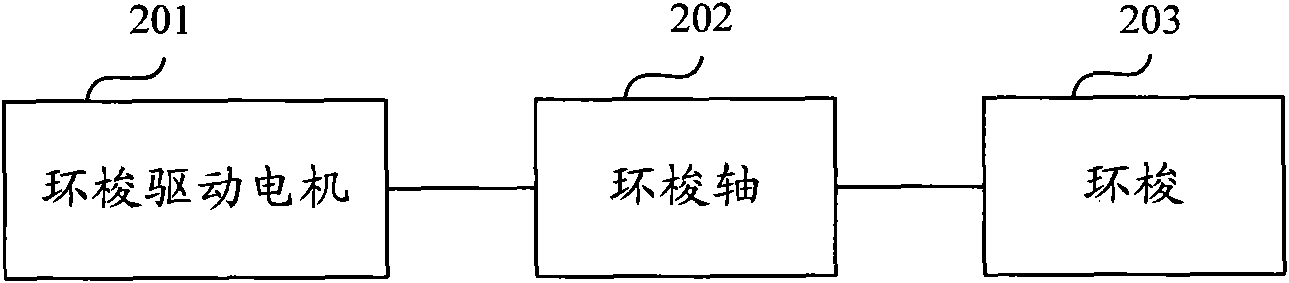

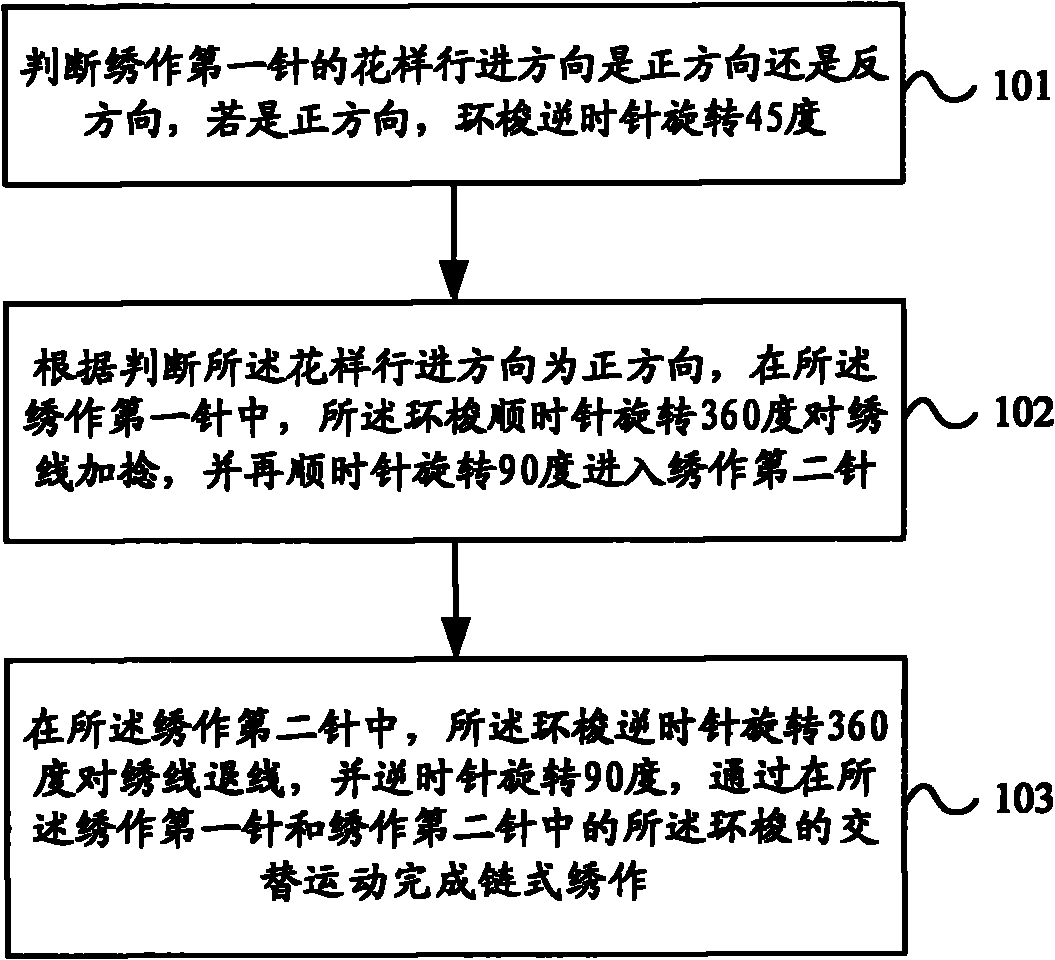

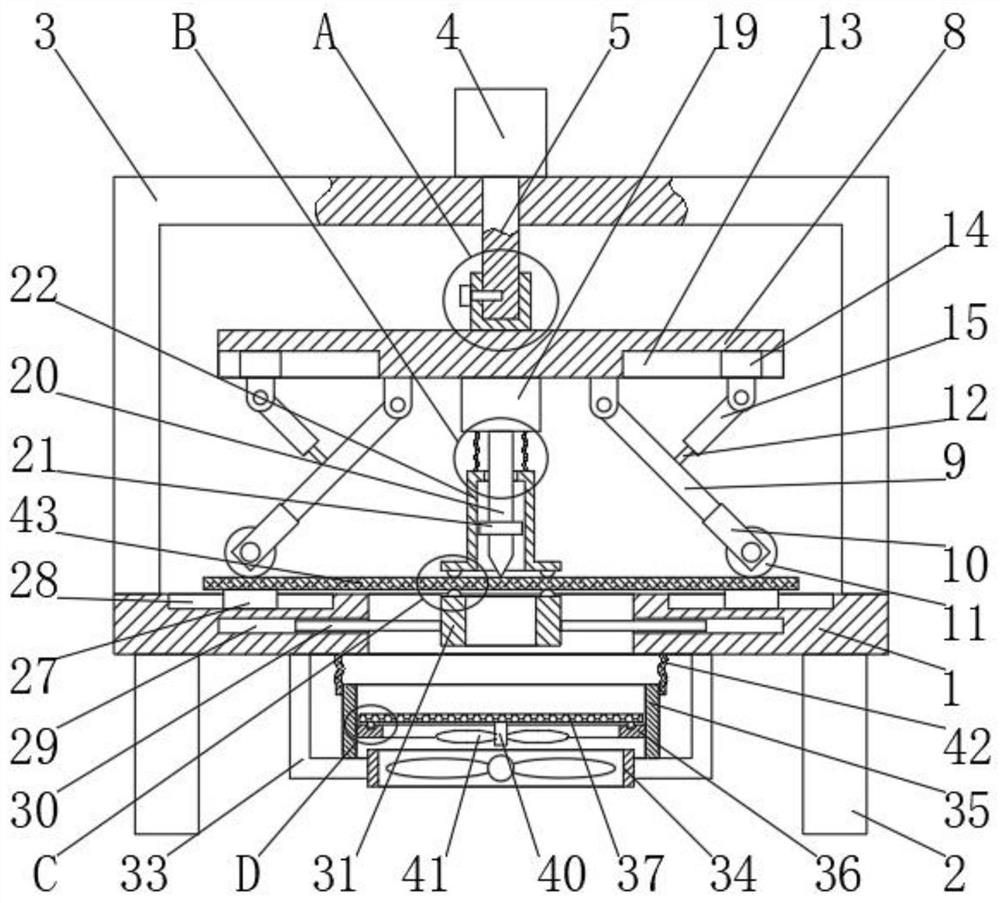

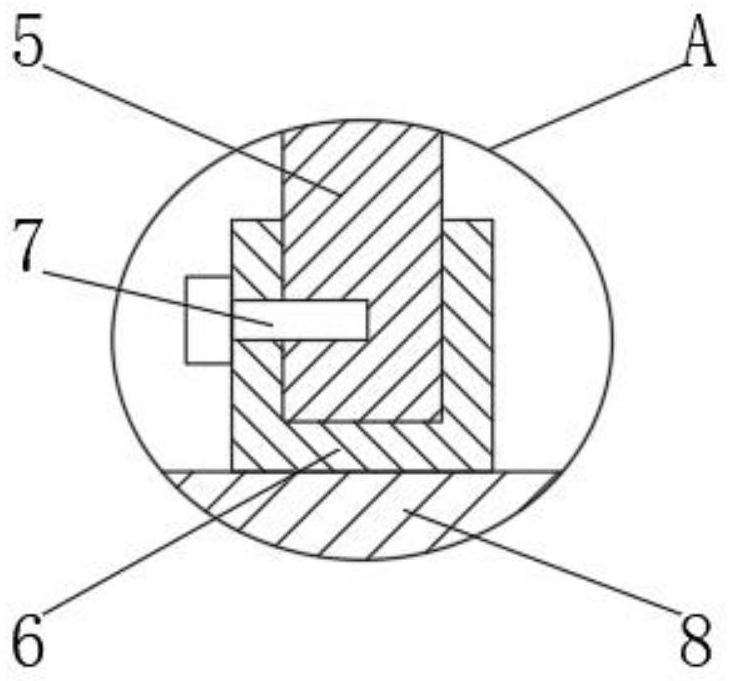

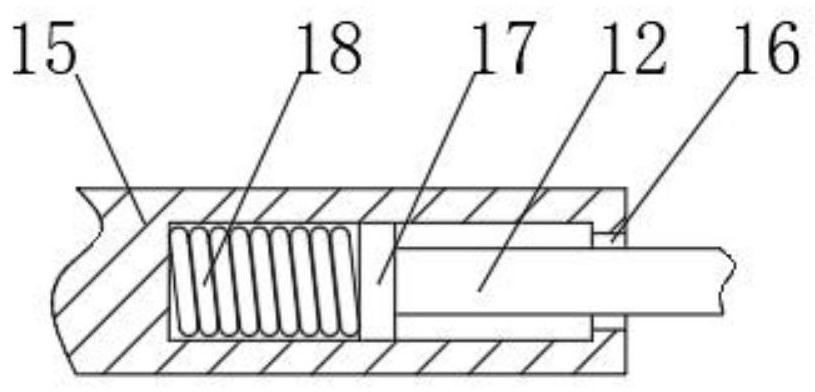

Method and system for controlling alternating movement of central shuttle

ActiveCN101935925ASolve technical problems with heavy workloadIncrease productivityEmbroidering machines apparatusLoop takersEngineeringChain type

The invention discloses a method and a system for controlling the alternating movement of a central shuttle. The method comprises the following steps of: judging whether the advancing direction of the pattern which is embroidered as the first needle is a positive direction or a negative direction; counterclockwise rotating the central shuttle if the advancing direction is a positive direction; inthe first needle, clockwise rotating the central shuttle for 360 degrees to twist the embroider line and then clockwise rotating the central shuttle for 90 degrees to embroider the second needle according to the condition that the advancing direction of the pattern is positive direction; in the second needle, counterclockwise rotating the central shuttle for 360 degrees to retire the embroider line and then counterclockwise rotating the central shuttle for 90 degrees to finish the chain-type embroidery through the central shuttle alternating movement in the first and the second needles. The invention solves the technical problems of high requirement on mechanical load of a central shuttle motor and great workload of a central shuttle shaft in the traditional method for controlling the double-movement of the central shuttle, thereby achieving the purpose of improving the production efficiency of a computer embroidery machine, the stability of the whole chain type computer embroidery machine and the quality of the embroidery during high-speed embordering.

Owner:BEIJING DAHAO TECH

Cloth clamping device of embroidery machine

The invention discloses a cloth clamping device of an embroidery machine. The device comprises a bottom plate; supporting legs are welded to the bottom plate; a frame is welded to the end, away from the supporting legs, of the bottom plate; an air cylinder is fixedly installed at the end, away from the bottom plate, of the frame; an air cylinder rod is arranged at the end, close to the bottom plate, of the air cylinder; the air cylinder rod is slidably connected inside the frame in a sleeved mode; the outer side of the end, away from the air cylinder, of the air cylinder rod is sleeved with a connecting sleeve; a supporting plate is welded to the end, away from the air cylinder, of the connecting sleeve; two connecting rods are hinged to the end, away from the air cylinder, of the supporting plate and symmetrically distributed on the supporting plate; a mounting frame is welded to the tail end of each connecting rod; a pressing roller is arranged on each mounting frame; and the outer sides of the two pressing rollers are in contact connection with cloth. The cloth clamping device has the characteristics that the cloth is clamped smoothly and is not easy to shake during cloth processing.

Owner:YANCHENG INST OF TECH

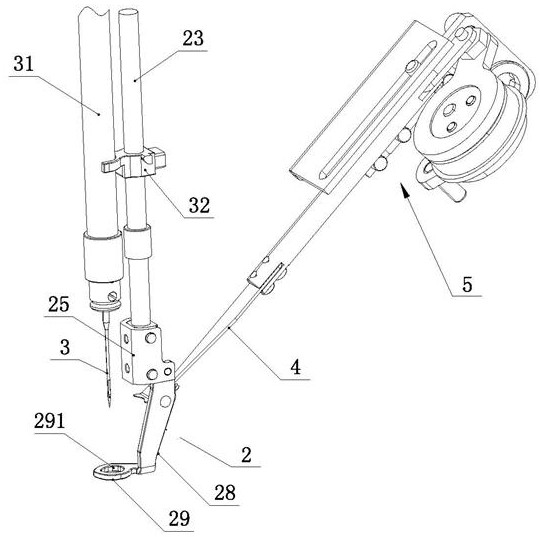

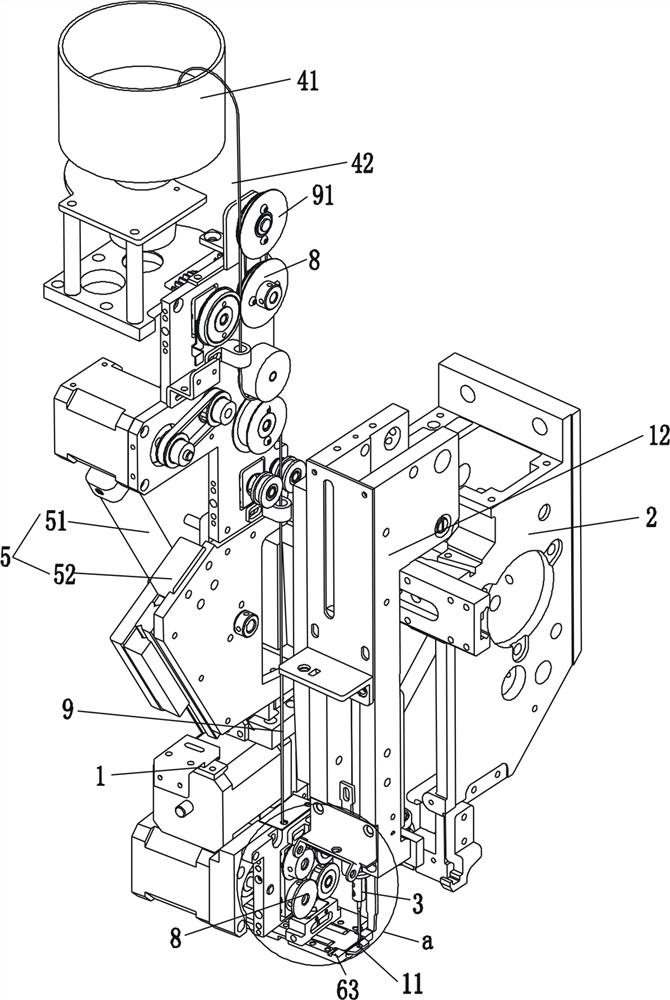

Ultrafine-sequin needle-embroidering mechanism for needle-embroidery production line

ActiveCN106939473AMeet production needsSimple structural designAutomatic machinesAuxillary devicesManufacturing line

The invention discloses an ultrafine-sequin needle-embroidering mechanism for a needle-embroidery production line. The ultrafine-sequin needle-embroidering mechanism comprises a vertical base, a connection side plate, a sequin feeding mechanism, a sequin pressing mechanism, a needle bar, a needle bar clamping block and an embroidering needle, wherein the connection side plate is fixed on the bottom end of the vertical base; the sequin feeding mechanism is mounted on the bottom of the connection side plate; and the sequin pressing mechanism is movably hinged with the connection side plate and located above the sequin feeding mechanism. The ultrafine-sequin needle-embroidering mechanism is characterized in that the needle bar is mounted on the right end of the vertical base; the needle bar clamping block is fixedly mounted on the bottom of the needle bar; the embroidering needle is fixed on the bottom of the needle bar and located below the needle bar clamping block; the sequin feeding mechanism conveys a sequin string to a to-be-processed position and cuts sequins off from the sequin string; and the sequin pressing mechanism presses the sequin string and allows a sequin at the forefront to be located on the to-be-processed position. The ultrafine-sequin needle-embroidering mechanism provided by the invention can overcome shortcomings of the prior art, is simple in structural design, can meet production needs of needle embroidering of ultrafine sequins with diameters of less than 2.0 mm, guarantees stable feeding and cutting of intact sequins, and improves embroidery quality.

Owner:广东织锦新型材料有限公司

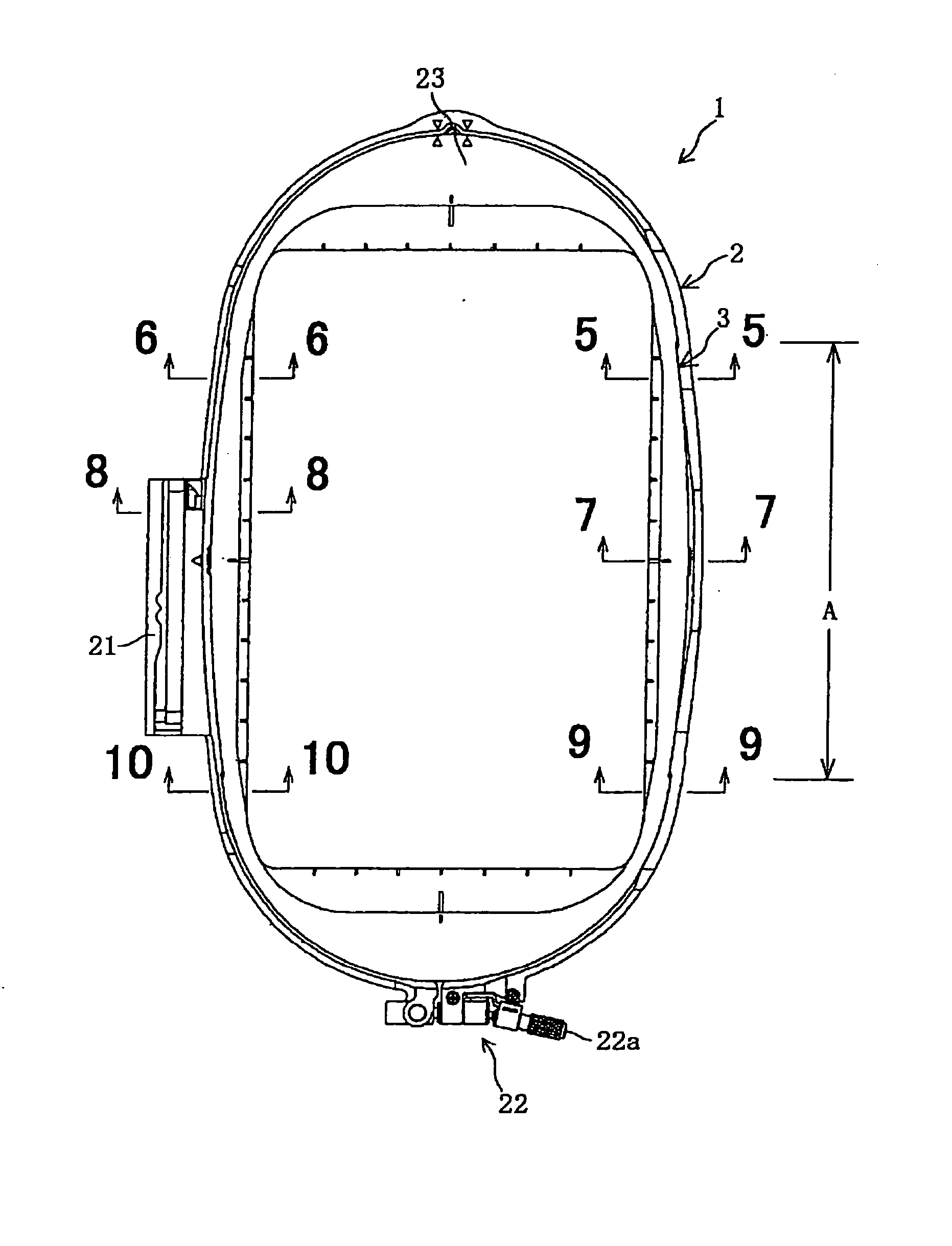

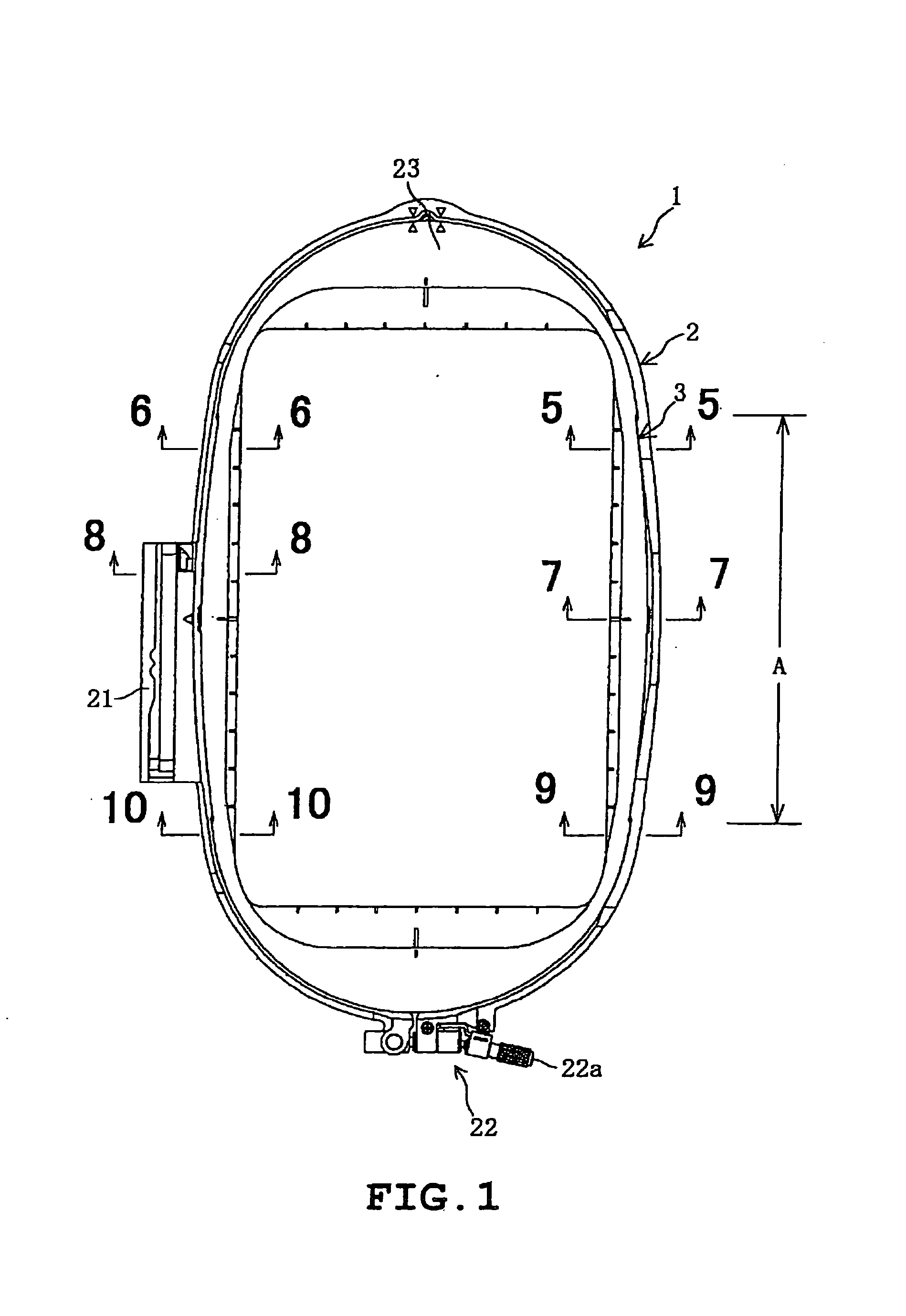

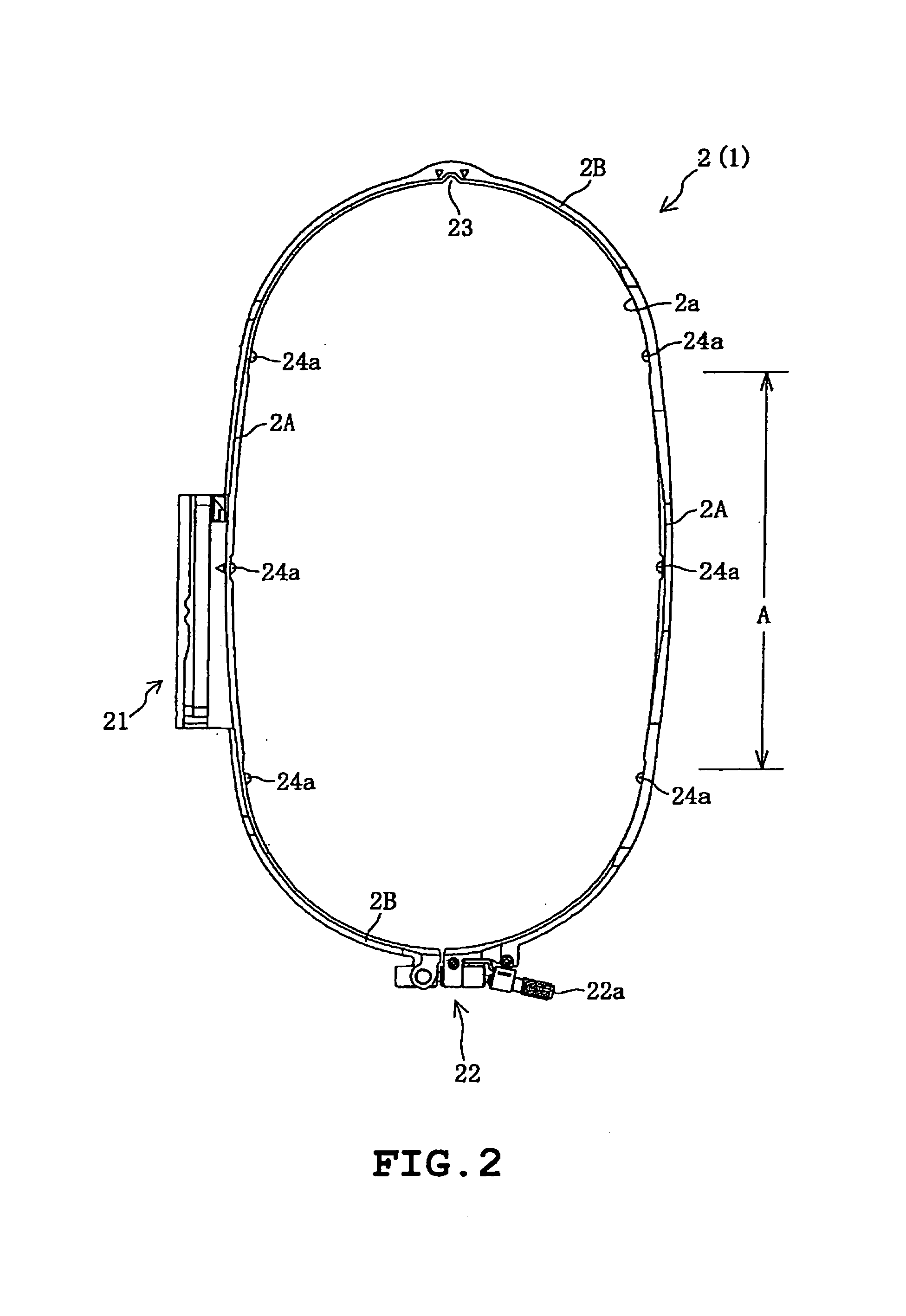

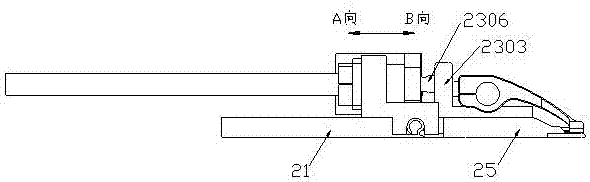

Embroidery frame

ActiveUS20060107881A1Prevents upward-bending deformationImprove embroidery qualityAutomatic machinesHand embroideringEngineering

Owner:BROTHER KOGYO KK

On-line embroidery method corresponding to design color matching template and embroidery thread color change sequence number

The invention discloses an on-line embroidery method for designing color-matching templates corresponding to embroidery thread color-changing serial numbers, comprising embroidery plate-making software, an online embroidery service platform, embroidery equipment connected to the online embroidery service platform, and the embroidery plate-making software uploading design pattern data to the online embroidery plate-making software. Embroidery service platform, the online embroidery service platform outputs embroidery machine data to the embroidery equipment connected to the online embroidery service platform to complete remote online embroidery; the embroidery plate-making software includes the function of designing color and color system, the function of embroidery thread color change serial number information document function, and design The color system corresponds to the matching electronic color card function. The invention uploads the design pattern data to the online embroidery service platform through the embroidery plate-making software, and the online embroidery service platform outputs the embroidery machine data to the embroidery equipment connected to the online embroidery service platform to complete the remote online embroidery, from the design pattern to the embroidery thread color matching and then to the online embroidery The equipment completes the full digital processing technology to realize the customized experience of what you see is what you embroider.

Owner:徐伟光

Embroidery processing center

ActiveCN106012357BImprove stabilityQuality improvementPressersMattress sewingEngineeringMechanical engineering

The invention discloses an embroidery processing center which comprises a rack structure, an embroidery frame structure, an embroidery mechanism and a feeding and discharging mechanism. The feeding and discharging mechanism comprises a fabric feeding device and a fabric discharging device located at the left end and the right end of a crossbeam of the rack structure, the embroidery frame structure comprises a movable frame and a fabric clamping device and a fabric tensioning device installed on the movable frame, the embroidery mechanism comprises multiple machine head assemblies and rotary shuttle box assemblies corresponding to the lower portions of the machine head assemblies, the machine head assemblies are installed on the crossbeam of the rack structure, and the embroidery frame structure is arranged on a platen under the crossbeam. The fabric feeding device inputs an embroidery fabric into an embroidery region, the embroidery fabric enters the movable frame and is clamped by the fabric clamping device, the embroidery fabric in the embroidery region is in a tensioned state under the effect of the fabric tensioning device, meanwhile an embroidery process is completed through the embroidery mechanism, and finally a finished product fabric with embroidered patterns is output by the fabric discharging device. Embroidering, quilting seaming and seaming embroidering integrated functions are integrally controlled by a computer, various single-layer or multi-layer fabrics required for embroidering, quilting seaming and seaming embroidering are operated in the same device, and embroidering processing is completed through one program command.

Owner:JIANGSU DADAO MACHINE GROUP +1

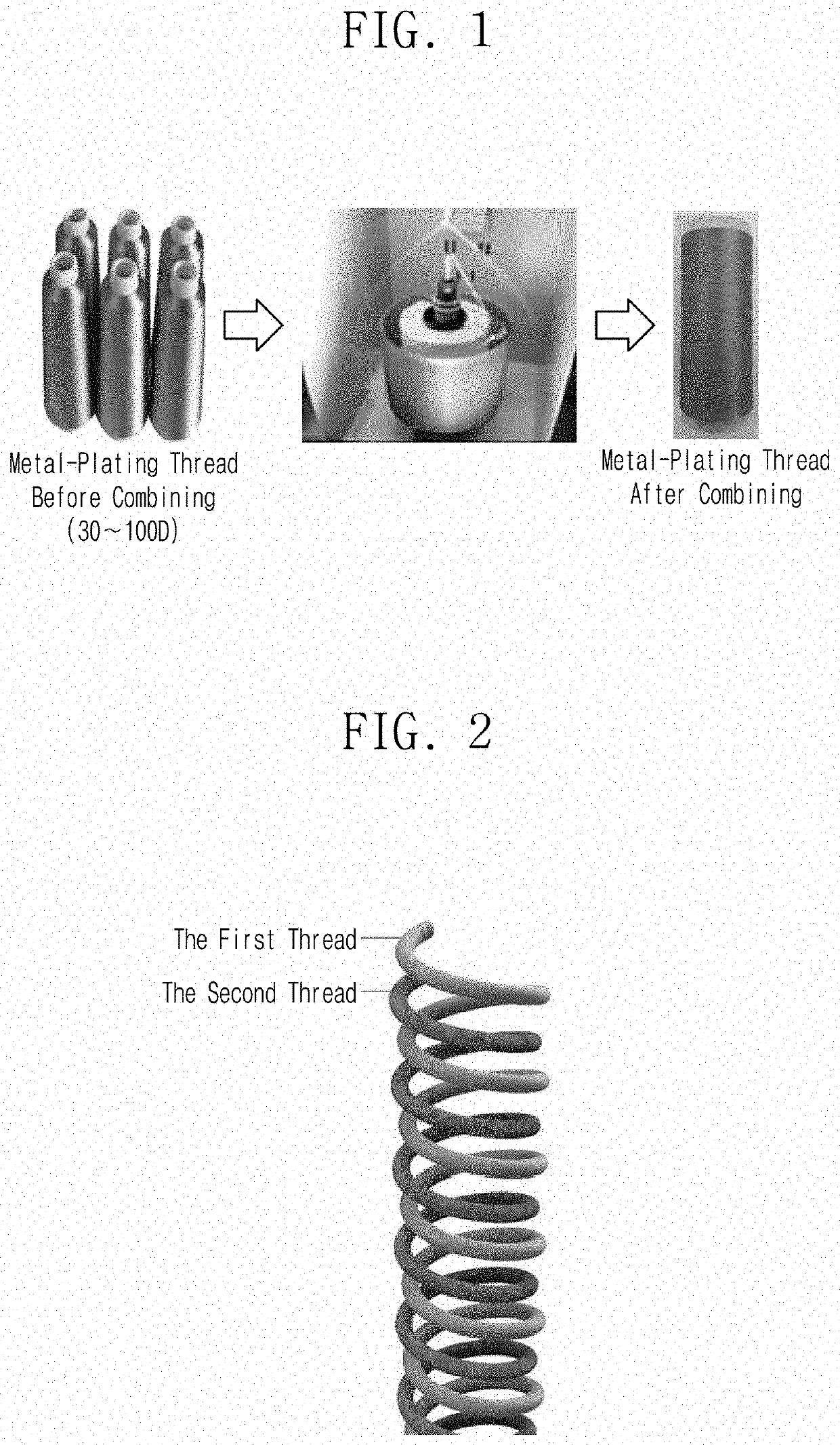

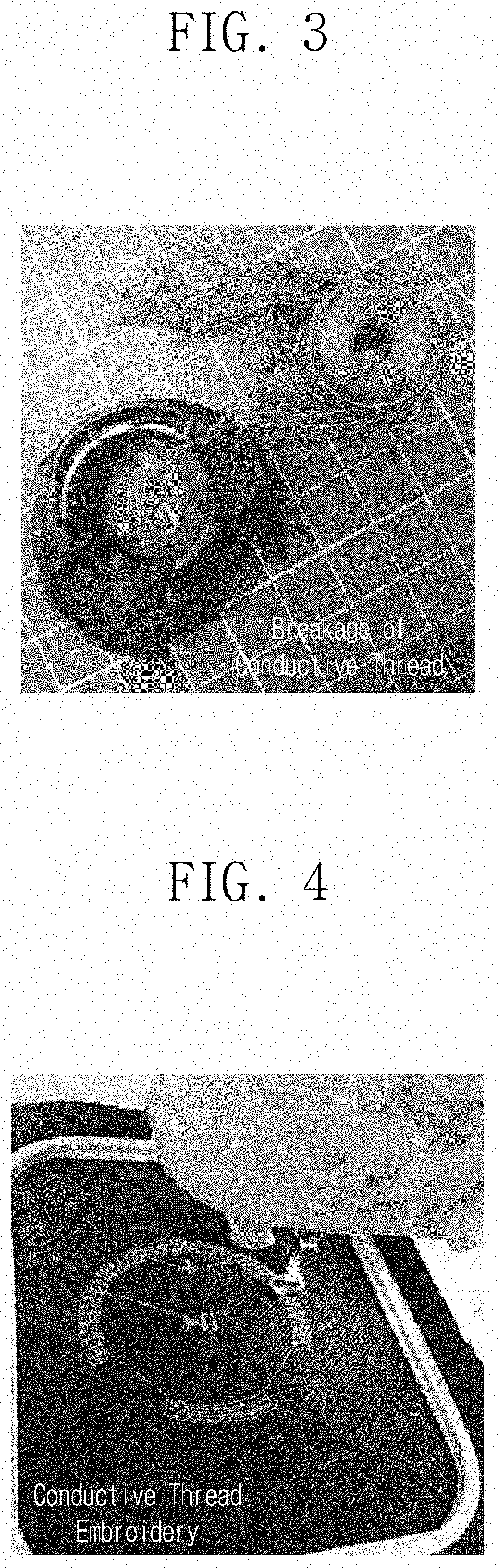

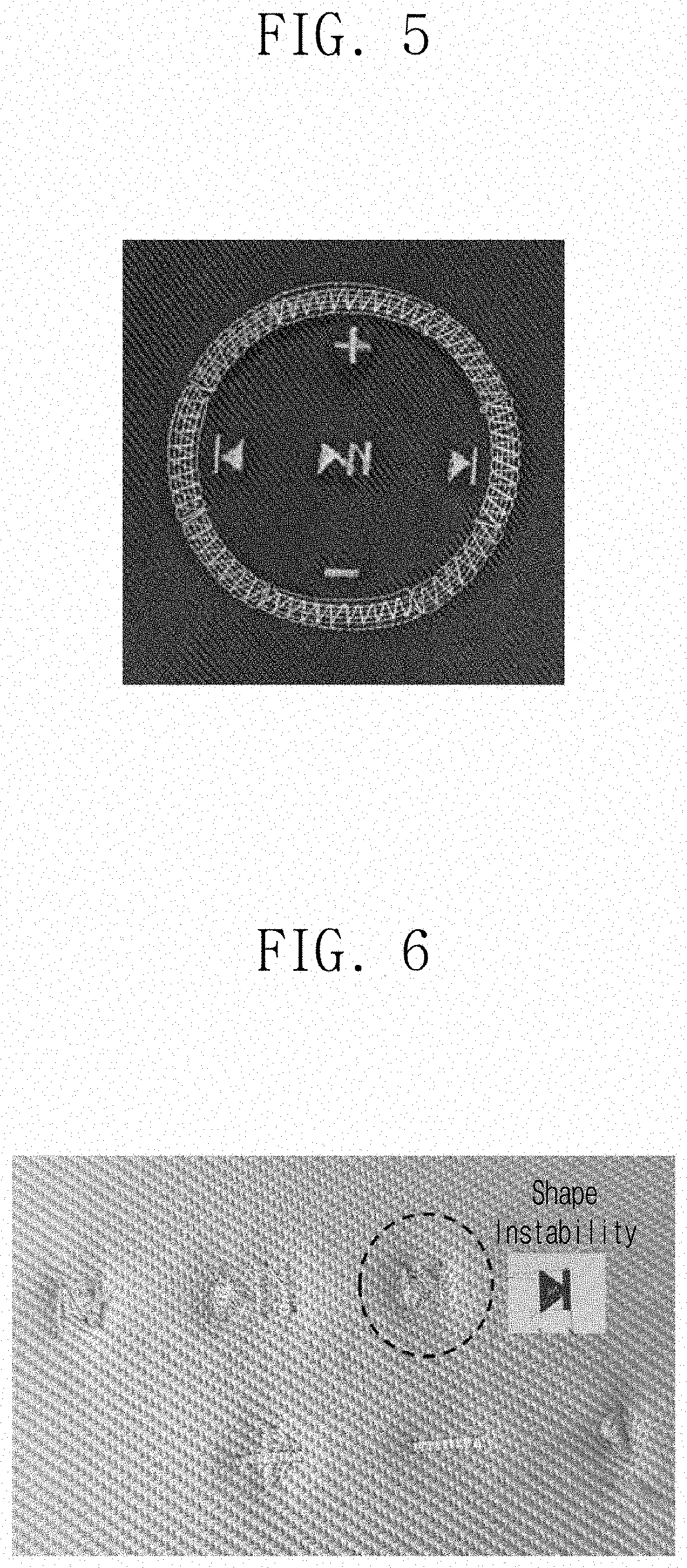

Conductive Embroidery Thread, Conductive Embroidery Fabric Using the Same, and Use of the Conductive Embroidery Fabric

InactiveUS20200248342A1Improve embroidery qualityEfficient productionSuperstructure subunitsYarnFiber typeMechanical engineering

A conductive embroidery thread, a conductive embroidery fabric using the same and use of the conductive embroidery fabric are provided. The conductive embroidery thread of high embroidery quality is without thread tangles and breaks by plying and twisting conductive threads together at 600 or less turns per 1 M to satisfy the strength and elongation requirements suitable for embroidery process application. The conductive embroidery fabric has lightweight and high sensibility advantages by embroidering a skin layer fabric using the conductive embroidery thread at optimal embroidery density and embroidery speed. The conductive embroidery thread and fabric made therefrom may be used for a fiber type electrical and electronic device useful for an automotive interior touch sensor and an automotive interior material.

Owner:DUAL

Needle bar frame body of high-speed embroidery machine

PendingCN112501811AImprove embroidery qualityHigh degree of functional integrationFeedersEngineeringPRESSURE FEET

The invention discloses a needle bar frame body of a high-speed embroidery machine. The needle bar frame body comprises a needle bar frame, a needle bar installed on the needle bar frame and a presserfoot matched with the needle bar, wherein the presser foot comprises a presser foot rod and a presser foot structure connected to the bottom end of the presser foot rod, the presser foot structure isprovided with a first thread clamping structure and a second thread clamping structure, a hook knife penetrates through the space between the first thread clamping structure and the second thread clamping structure, the first thread clamping structure can move relative to the second thread clamping structure and can reset, the first thread clamping structure makes contact with the second thread clamping structure when being located at a reset position, the presser foot rod is provided with a matching structure, the needle rod frame is provided with a locking structure used for preventing thematching structure from moving forwards, the needle rod frame is provided with an unlocking mechanism capable of enabling the locking structure and the matching structure to generate relative displacement so as to relieve the blocking effect of the locking structure on the matching structure. The needle bar frame body has the beneficial effects that the higher function integration degree is achieved, and the technical purpose of stably keeping upper thread clamping is achieved.

Owner:ZHEJIANG YUELONG SEWING EQUIP

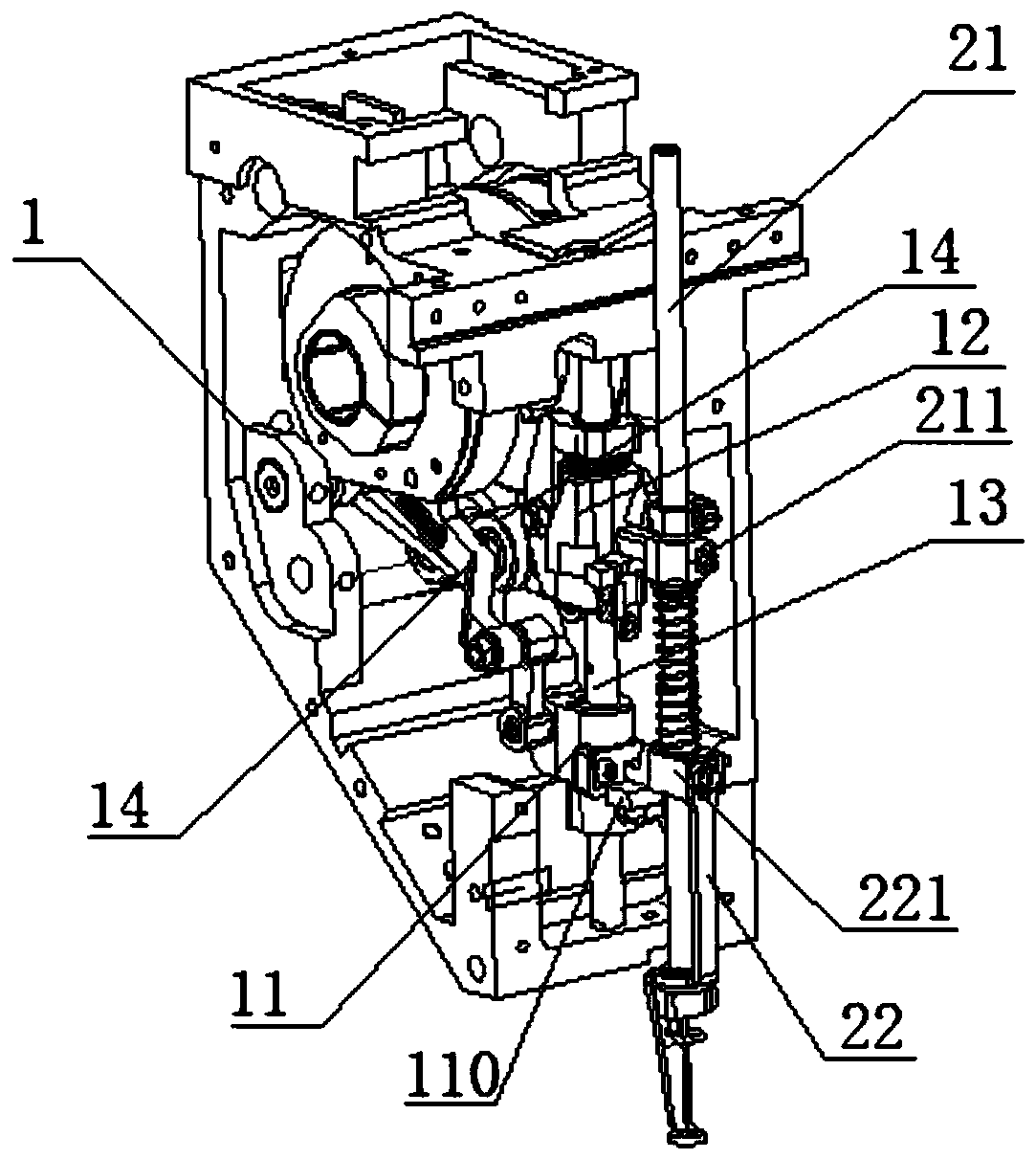

Multi-needle presser foot embroidery machine head and embroidery machine

PendingCN112663235AImprove scalabilityEfficient compressionFeedersPhysical medicine and rehabilitationEngineering

The invention discloses a multi-needle presser foot embroidery machine head and an embroidery machine, and belongs to the technical field of embroidery machines. The embroidery machine head comprises a machine shell, a needle rod driving shaft, a presser foot driving wheel, a presser foot mechanism, a presser foot transmission mechanism and a presser foot adjusting mechanism, wherein the presser foot mechanism comprises a presser foot strip, a presser feet and a presser foot lifting rod; the presser foot transmission mechanism is arranged between the presser foot driving wheel and the presser foot lifting rod and used for driving the presser foot mechanism to move up and down; and the presser foot adjusting mechanism is arranged on the machine shell and adjusts the vertical position of the presser foot mechanism through the presser foot transmission mechanism. The needle rod driving shaft drives the presser foot mechanism to move up and down through the presser foot driving wheel and the presser foot transmission mechanism, so that the presser foot mechanism can effectively press an upper thread when the embroidery machine works, and thus the embroidery quality is improved. The presser foot adjusting mechanism can adjust the vertical position of the presser foot mechanism through the presser foot transmission mechanism, the presser foot mechanism is convenient to lift, and thus the presser foot mechanism is prevented from interfering with embroidery cloth replacement and other operations.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

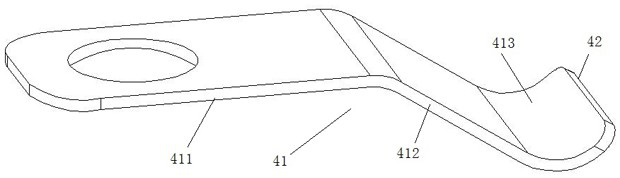

Thread hooking device for preventing deformation of pull rod and embroidery machine

ActiveCN113186669AHook line action is stableImprove embroidery qualityEmbroidering machines apparatusEngineeringStructural engineering

The invention discloses a thread hooking device for preventing deformation of a pull rod and an embroidery machine. The thread hooking device comprises a thread hooking driver, the thread hooking pull rod, a thread hooking shifting fork and a hooking knife; the thread hooking driver drives the thread hooking pull rod to do linear reciprocating motion; the thread hooking pull rod is rotationally connected with a ball guide block; the ball guide block is provided with a ball guide groove annularly formed around the thread hooking pull rod; the thread hooking shifting fork is provided with a ball; the ball guide block is driven by the thread hooking pull rod to do linear reciprocating motion; the ball rolls in the ball guide groove to enable the thread hooking shifting fork to do reciprocating swing motion; the thread hooking shifting fork drives the hooking knife to do linear reciprocating motion to achieve thread hooking; the thread hooking pull rod is movably nested with a compression spring on the side of the ball guide block; and the thread hooking pull rod is fixedly provided with two limiting ferrules correspondingly on the two sides of a combination body of the ball guide block and the pressure spring. Even if the ball guide block rotates relative to the thread hooking pull rod, the ball is still in the ball guide groove and cannot be separated; and the compression spring is adopted to replace a torsional spring, and the compression spring is long in service life and relatively low in cost, so that the maintenance cost can be reduced.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

The method of bead delivery

ActiveCN107653590BPrevent jumpingAvoid missingAutomatic machinesAuxillary devicesSurgeryMechanical engineering

The invention discloses an embroidered bead conveying method. The clamping port on the drive plate of the bead conveying mechanism holds the beads, and before the beads are conveyed to the directly below the embroidery needle on the needle bar, the needle will wait for the appropriate number of needles on the needle bar to be lowered. The first appropriate number of stitches is to adapt to the beading process. The last stitch with the least number of stitches will be able to embroider the beads on the bead embroidery medium. As an improvement, the needle bar embroidery needle with the first appropriate number of stitches will move down with the needle bar . In the present invention, before the equal diameter of the front end of the needle bar embroidery needle enters the bead pinhole at the latest, the clamping opening of the drive plate is opened to release the beads, so that the beads can fall freely, and the freely falling beads are embroidered by the needle bar during the falling process. Needlework with medium. The beneficial effect is that in the process of fixing the beads with the needle bar embroidery needle, the beads will not be hit relatively "strongly", preventing the beads from bouncing off and missing from the clamping mouth, and avoiding wearing and tearing of the beads. The method of the invention can reduce the phenomenon of bead leakage to the greatest extent, improve the surface smoothness of the beads and improve the quality of embroidery.

Owner:ZHUJI GUANXIANG MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com