Embroidery machine trimming method

An embroidery machine and thread trimming technology, which is applied in the field of embroidery machine thread trimming, and can solve problems such as broken threads, messy thread ends, and uneven lengths of thread ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

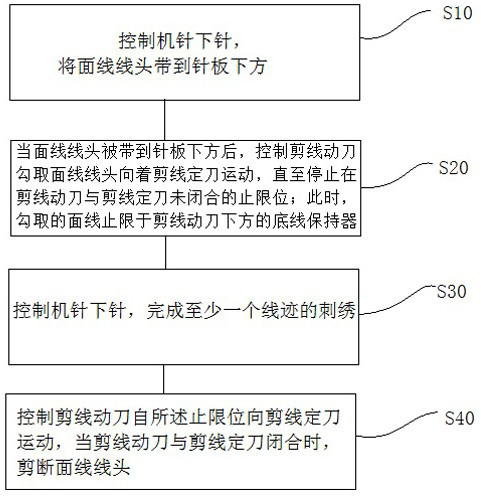

Method used

Image

Examples

Embodiment approach

[0033] The method of the present invention further includes the step of opening the thread-cutting moving knife to a position beyond the needle plate hole. In one embodiment, step S10 further includes: before the needle passes through the needle plate hole, controlling the thread trimmer movable knife to open, so that the upper thread can pass through the needle plate hole and through the thread trimmer fixed knife and the thread trimmer movable knife space between, and then enter the rotary hook. In another embodiment, step S10 further includes: after the thread end of the upper thread is brought under the needle plate and before the needle passes through the needle plate hole next time, controlling the thread trimmer moving knife to open, so that the upper thread can pass through the thread trimmer The space between the fixed knife and the thread-cutting moving knife and the upper thread can be hooked by the thread-cutting moving knife. In the former embodiment, the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com