Presser foot driving assembly with stable driving and embroidery machine

A technology of driving components and driving parts, which is applied in the field of embroidery machines, can solve problems such as loud noise, affecting embroidery quality, and generating vibration, and achieve the effects of reducing noise, improving embroidery quality, and facilitating fitting and disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

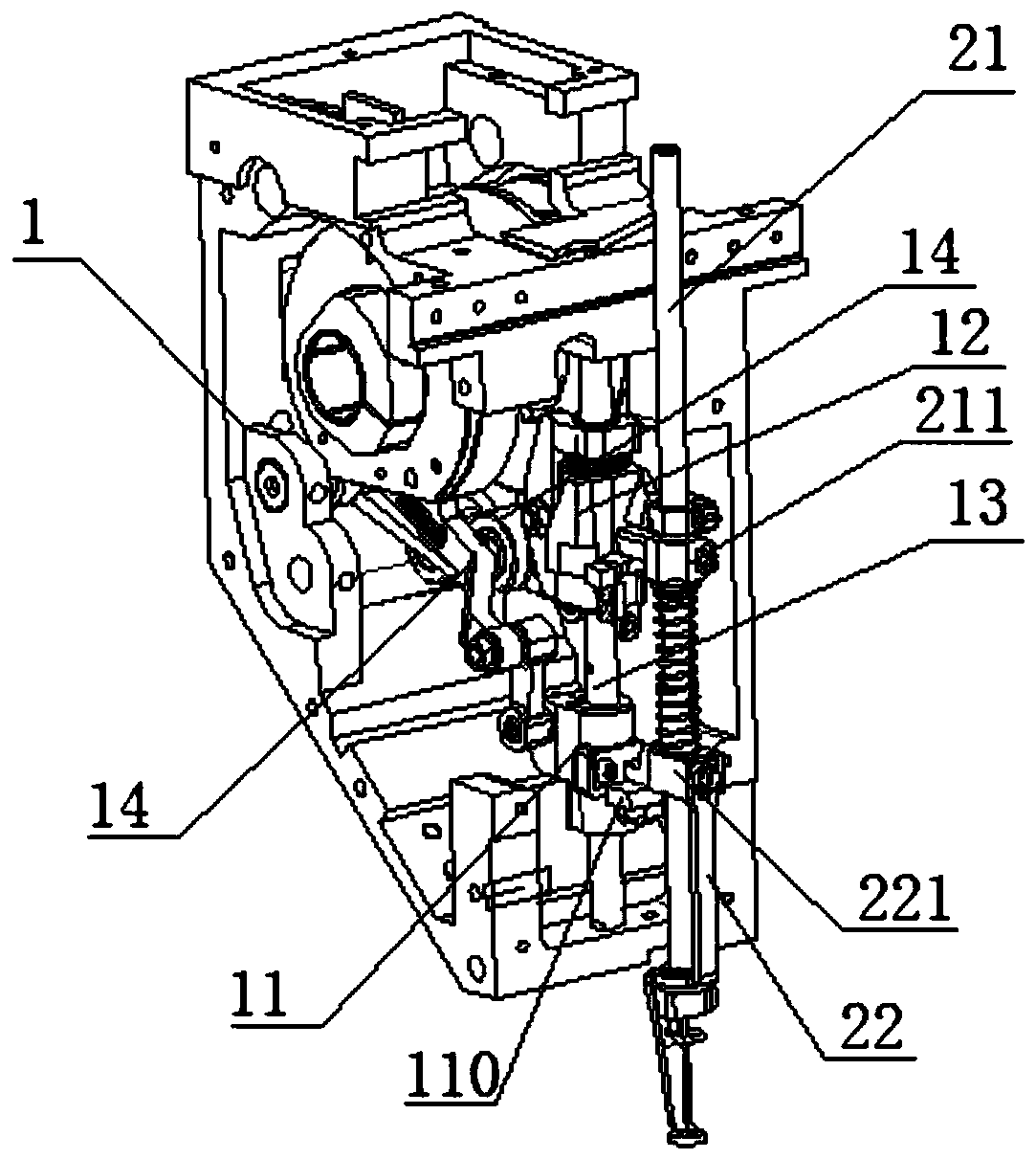

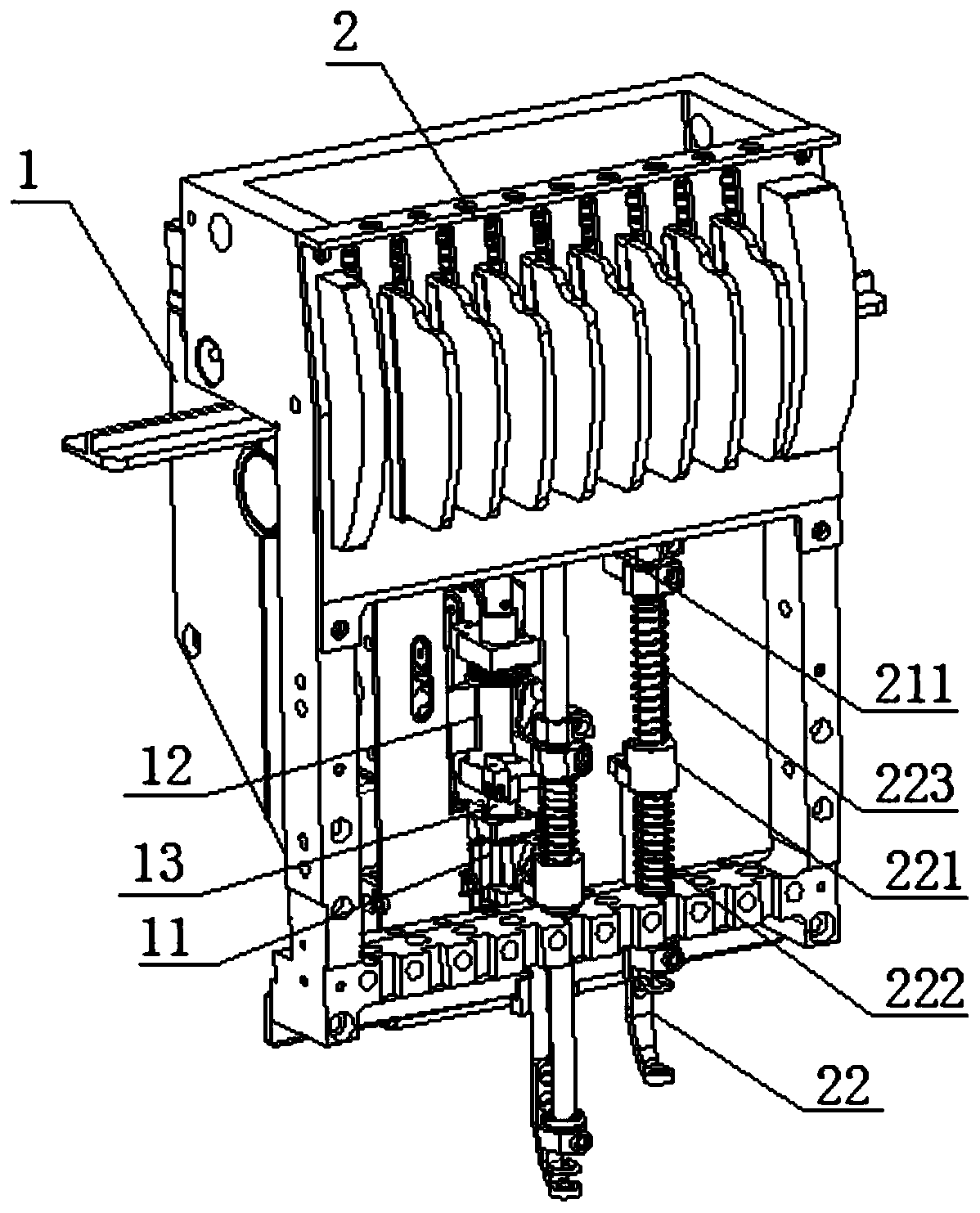

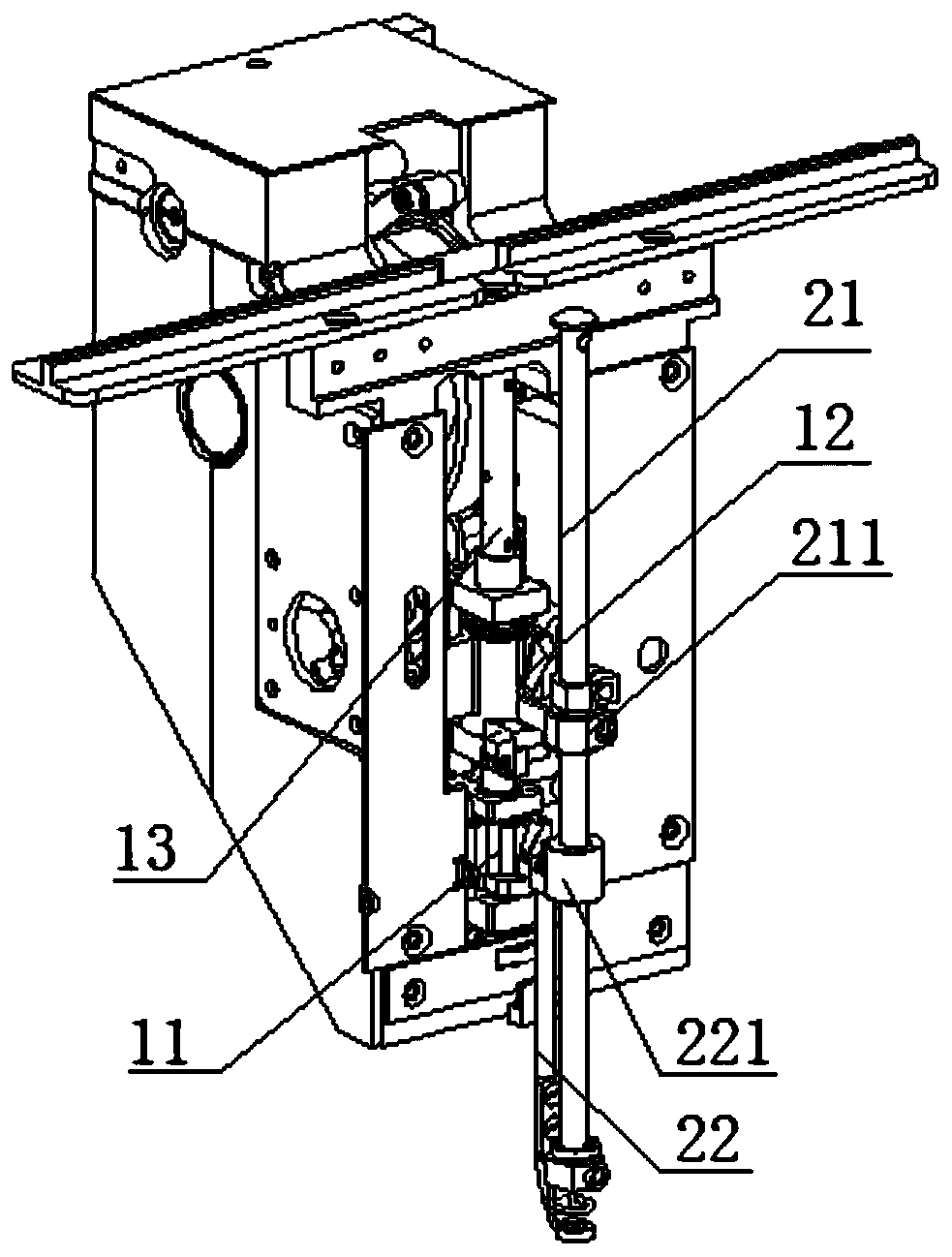

[0030] Such as Figure 2 to Figure 4 As shown, a presser foot driving assembly with stable driving includes a presser foot 22 and a presser foot driver 11, the presser foot 22 has a sliding sleeve 221 slidably installed on the needle bar, and the presser foot driver 11 includes a driving member 112 The driving member 112 is movably engaged with the sliding sleeve 221 and in the fitted state, the driving member 112 drives the sliding sleeve 221 to move up and down synchronously, thereby avoiding impact, reducing noise and improving embroidery quality.

[0031] Wherein, the needle bar 21 is installed on the needle bar frame 2, the needle bar frame 2 has an upper beam and a lower beam, the needle bar 21 moves through the upper beam and the lower beam, and the needle bar 21 is below the upper beam A needle bar driving sleeve 211 is connected, and the needle bar 21 is covered with a presser foot spring 223 that springs downward to press the presser foot between the needle bar drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com