Ultrafine-sequin needle-embroidering mechanism for needle-embroidery production line

A production line and sequin technology, which is applied to the mechanism of embroidery machines, embroidery machines, and automatically controlled embroidery machines. The string cannot be prepared for transportation, etc., to achieve the effect of improving work efficiency and embroidery quality, accurate piece output, and preventing left and right swaying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

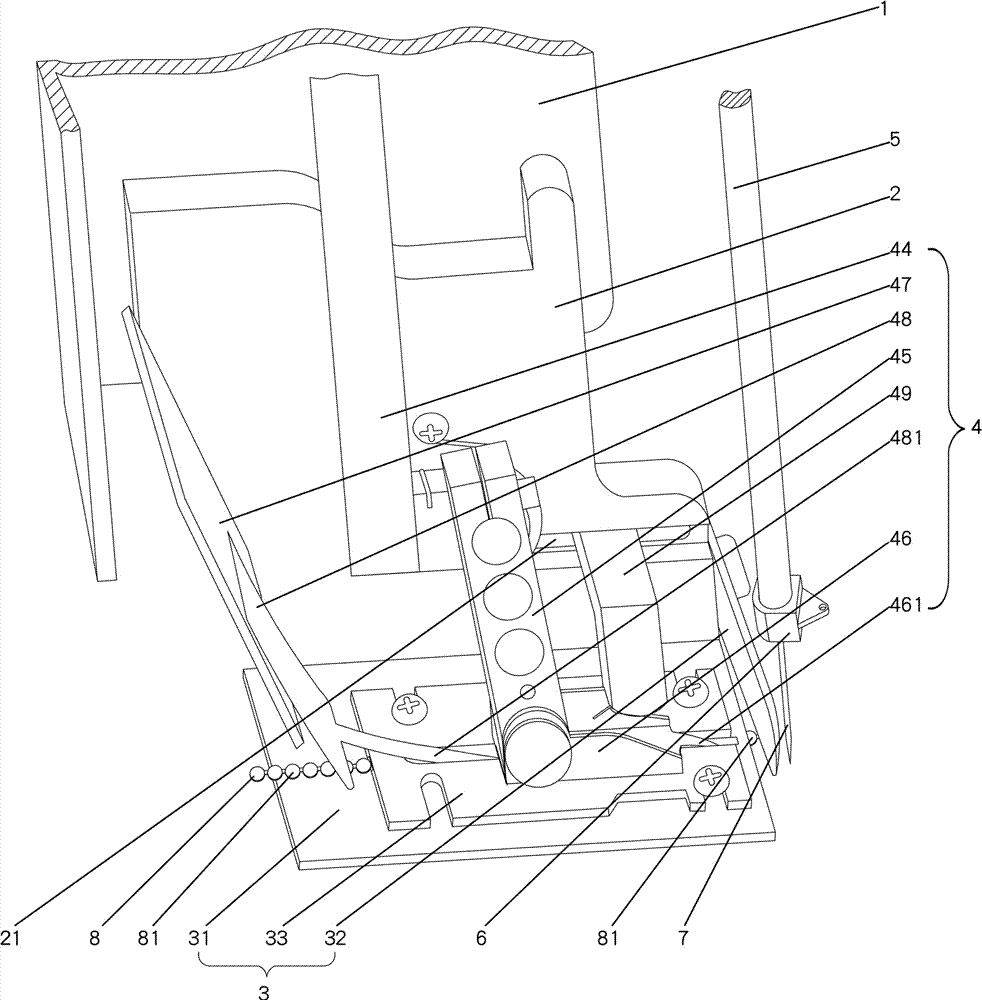

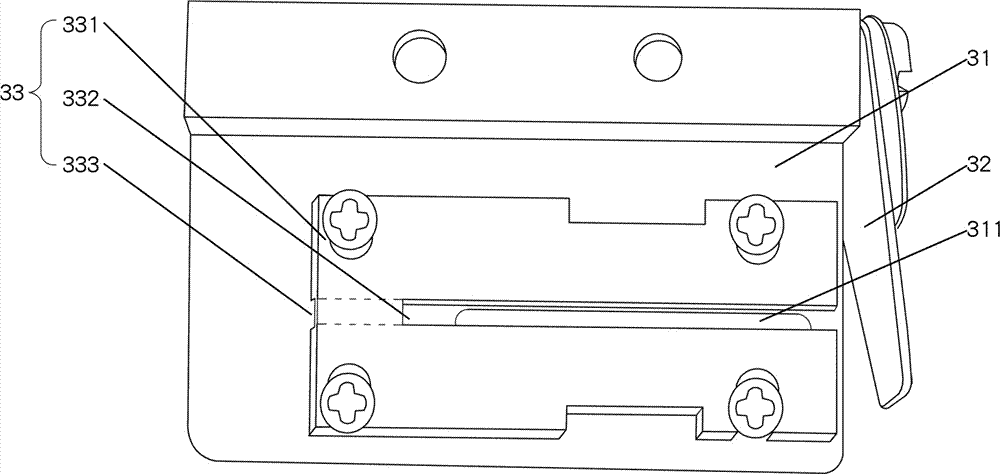

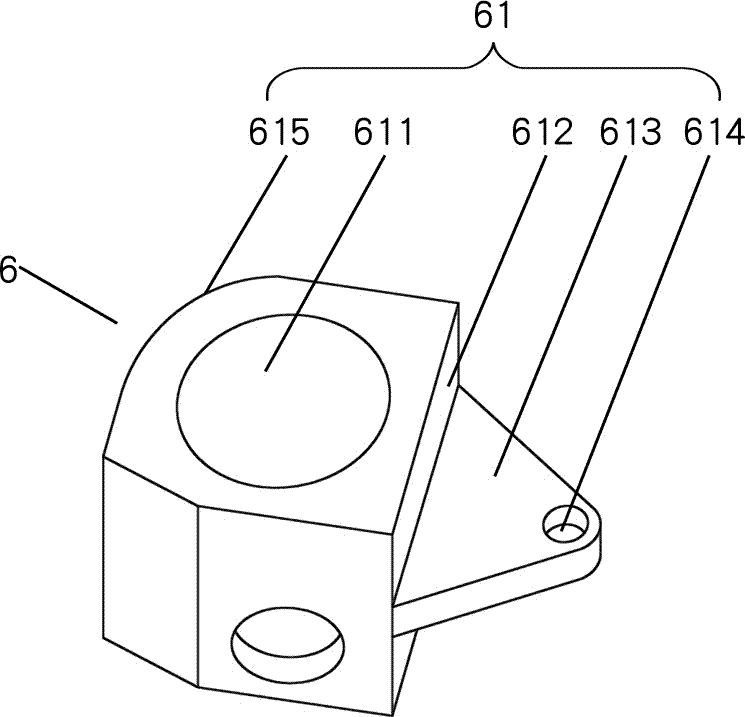

[0027] Such as figure 1As shown, the ultra-fine sequin embroidery mechanism of the needle embroidery production line in this embodiment includes a stand 1, a connecting side plate 2, a sequin feeding mechanism 3, a sequin pressing mechanism 4, a needle bar 5, and a needle bar Clamping block 6 and embroidery needle 7, connecting side plate 2 is fixed at the bottom of stand 1, sequin feeding mechanism 3 is installed at the bottom of connecting side plate 2, bead pressing mechanism 4 is movably hinged on connecting side plate 2 And located above the sequin feeding mechanism 3, the needle bar 5 is movably installed at the right end of the stand 1, the needle bar clamping block 6 is fixedly installed at the bottom of the needle bar 5, and the embroidery needle 7 is fixed at the bottom of the needle bar 5 and is positioned at the needle bar clamping position. Below the block 6; the feeding mechanism 3 sends the bead string 8 to the position to be processed and cuts the bead 81 from ...

Embodiment 2

[0037] The difference between the ultra-fine sequin embroidery mechanism of the needle embroidery production line in this embodiment and Embodiment 1 is that:

[0038] The width of the film passing groove is 1.50mm; the width of the bottom groove is 0.07mm; the width of the cutting edge is 0.01mm. If the width of the slot is 1.50mm, the diameter of the bead should be less than 1.50mm, so that the bead can pass through the slot.

Embodiment 3

[0040] The difference between the ultra-fine sequin embroidery mechanism of the needle embroidery production line in this embodiment and Embodiment 1 is that:

[0041] The width of the film passing groove is 2.20mm; the width of the bottom groove is 0.10mm; the width of the cutting edge is 0.02mm. If the width of the film feeding slot is 2.20mm, it is suitable for sending sequins with a diameter of less than 2.0mm, so as to prevent the bead string from being out of shape and shaking left and right when feeding the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com