The method of bead delivery

A technology of embroidery beads and conveying mechanism, which is applied in the direction of embroidery machine mechanism, embroidery machine, automatic control embroidery machine, etc., can solve the problems of damage, damage, and loss of embroidery beads, so as to reduce leakage of beads and avoid wear and tear. effect of beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

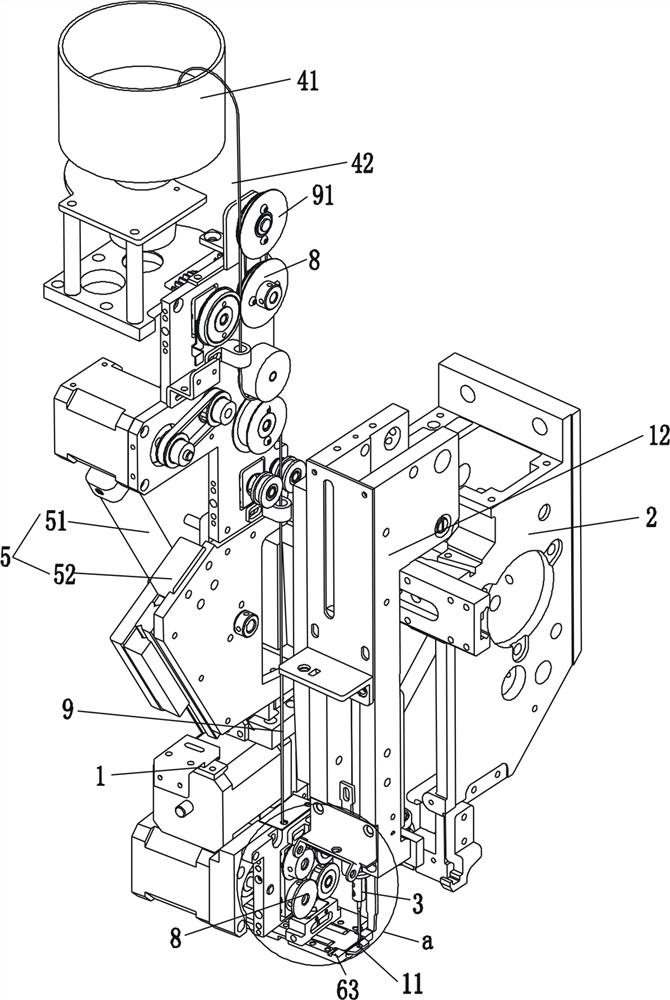

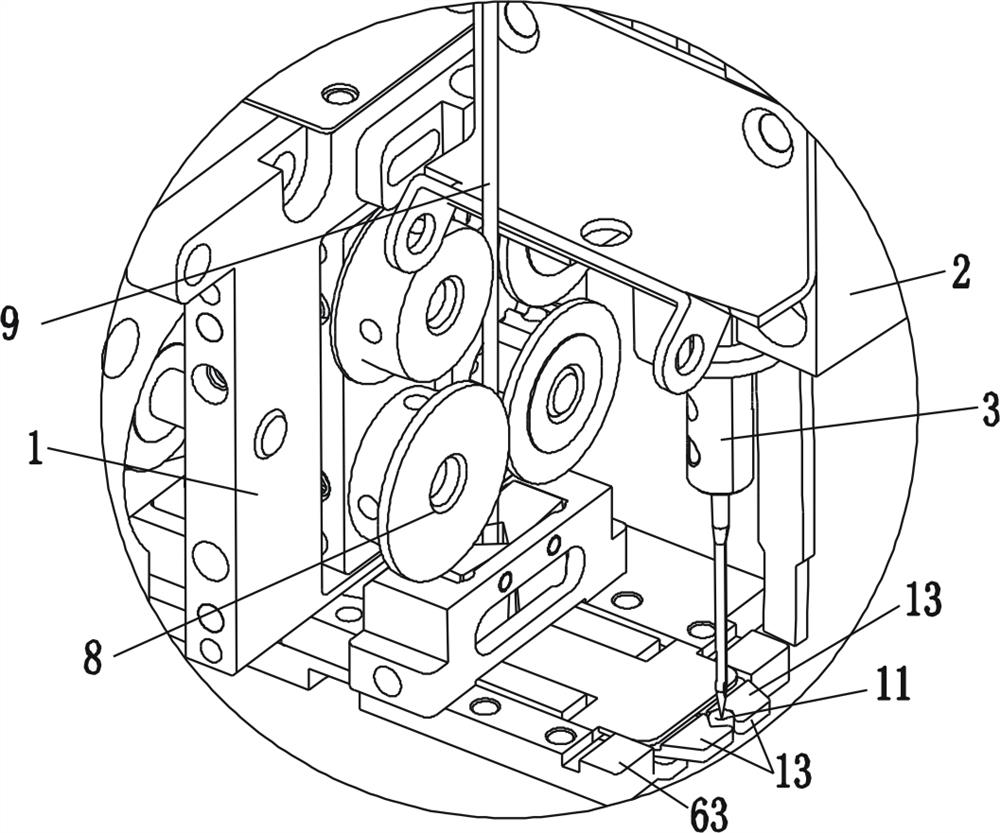

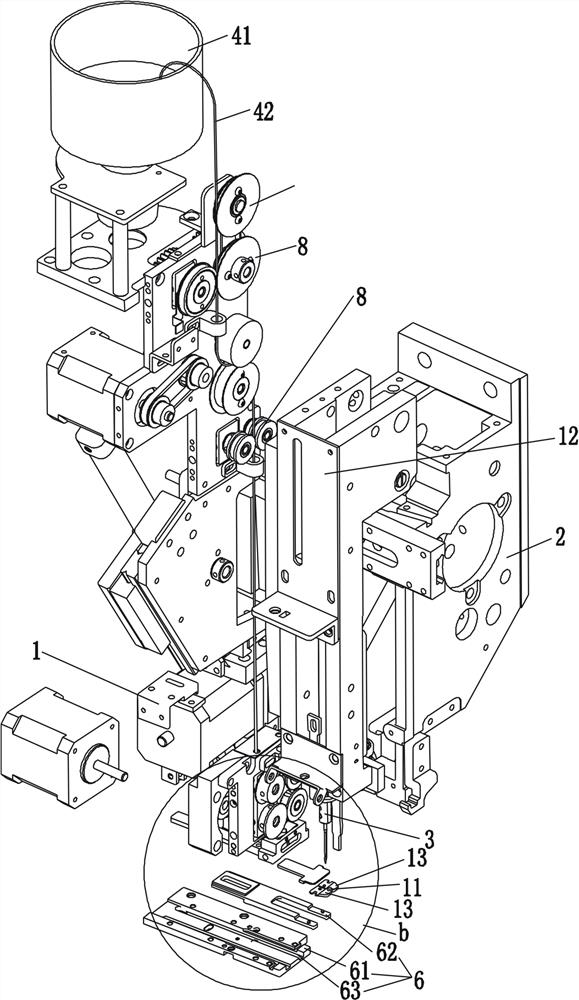

[0020] see Figure 1-7 , this implementation case includes a method for conveying embroidered beads. The clamping port 11 on the driving plate of the bead conveying mechanism 1 clamps the beads, and before the beads are conveyed to the embroidery needle directly below the needle bar 3, the needle bar will wait for the first appropriate needle. The number of stitches, the appropriate number of stitches is to adapt to the beading process, the last stitch with the least number of stitches will be able to embroider the beads on the bead embroidery medium, usually two to three stitches, the appropriate number of stitches can be the second The needle can be changed according to the requirements of the corresponding bead embroidery. The embroidery needle on needle bar 3 with the appropriate number of stitches moves downward with the needle bar. After entering the bead pinhole, at the latest before the equal diameter of the front end of needle bar 3 enters the bead pinhole, that is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com