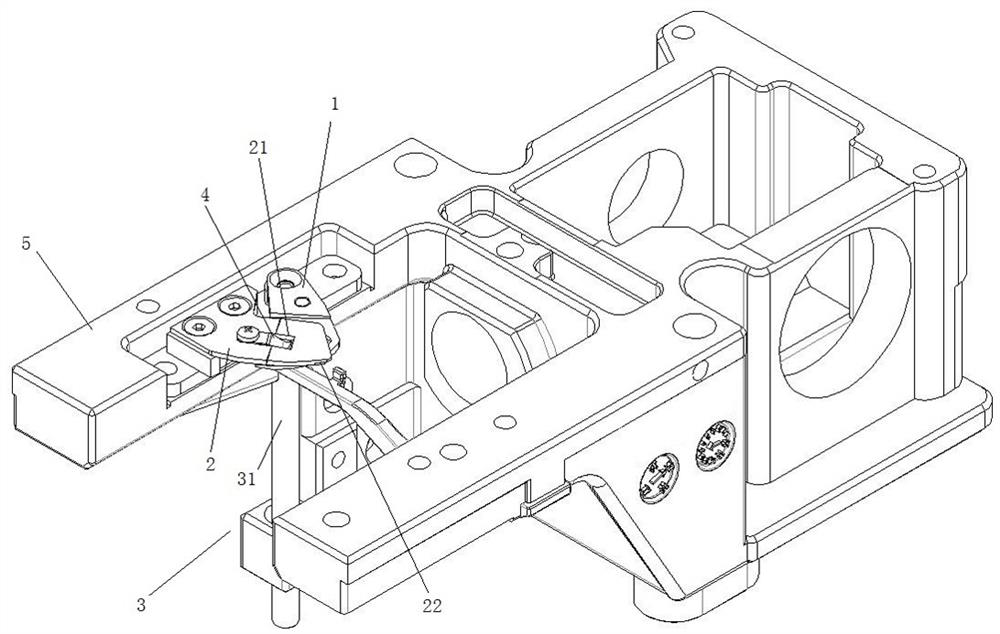

Thread trimming device and thread trimming method of embroidery machine

A technology for thread cutting and embroidery machines, which is applied in the field of thread trimming devices for embroidery machines. It can solve problems such as broken threads, off-threads, and messy thread ends, and achieve the effects of avoiding accidental cutting, improving the quality of embroidery, and avoiding waste residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

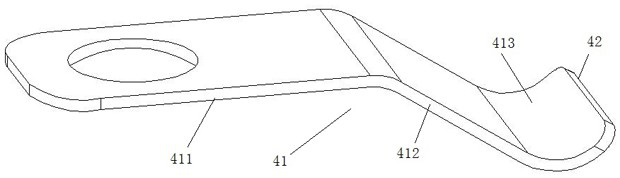

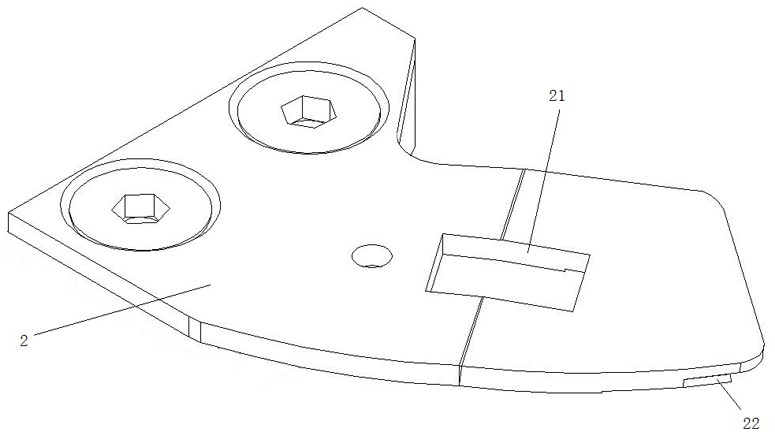

[0055] like image 3 , 5 Cutlery set the bottom portion of the thread, said fixed knife blade 2 towards a fixed knife blade 22 is provided. Fixed knife blade material is welded to the bottom of the fixed blade, by grinding the fixed knife blade is obtained. In one embodiment, the front end of the fixed cutter blade and the fixed portion of the thread scissors 22 is flush with the front end. In another embodiment, the predetermined portion of the front end of the thread scissors has an extended portion extending in the direction of the blade 1, so that the fixed knife blade 22 extending in the condensing portion. In the former embodiment, when the front edge and the knife blade intersects the fixed knife, scissors given once Spiraea taut the thread portion and the fixed knife blade, the cut will advance embroider, embroider or shearing. In the latter embodiment, since the presence of the extension portion, the extension portion blocking the advance Spiraea contact with the knife bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com