Patents

Literature

31results about How to "Improve Embroidery Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Real-time monitoring method and monitoring system for thread condition of computerized embroidery machine

InactiveCN102505381ADynamic tension adjustmentReduce labor intensityAuxillary devicesMonitoring systemElectric control

The invention discloses a real-time monitoring method and a monitoring system for the thread condition of a computerized embroidery machine. The monitoring method is mounting a thread flow condition monitoring device and a thread tension adjusting device on a machine head adjusting platform, so as to detect and judge the real-time condition of an embroidering thread during embroidery, carry out corresponding recording, warning or compensation according to the real-time condition, and transmit to an electric control system. The monitoring system comprises the machine head adjusting platform, wherein the thread flow condition monitoring device and the thread tension adjusting device are mounted on the machine head adjusting platform; and the embroidering thread can pass through the thread flow condition monitoring device and the thread tension adjusting device sequentially. The invention has the advantages that real-time embroidering thread condition monitoring, embroiderer tension adjustment and thread consumption calculation can be carried out during embroidery; thread breakage detection, real-time thread quantity variance compensation, and accurate judgment on thread flowing quantity and thread flowing direction can be carried out accurately, so as to reduce thread breakage rate, and improve embroidery quality and the like; and important information such as thread consumption quantity can be collected, so as to optimize production management.

Owner:HUI ZHOU SHENTIAN PRECISION MACHINES

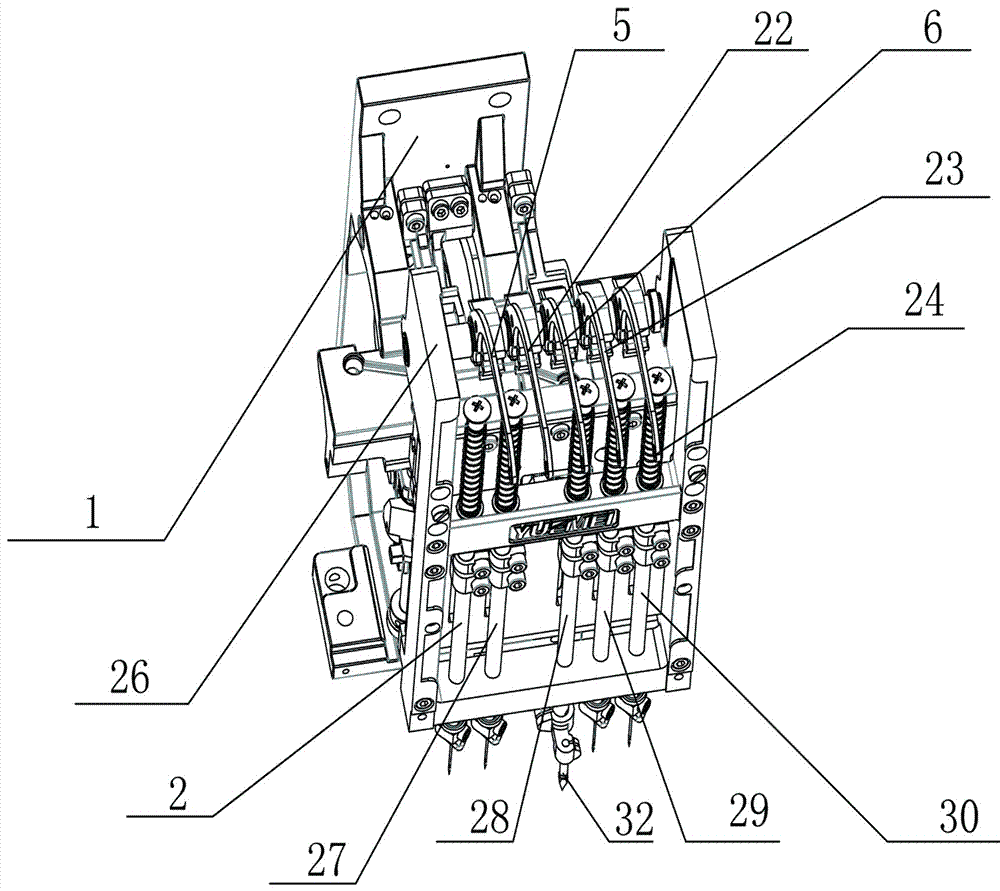

Over-three-thread embroidery machine nose with head-spacing function

ActiveCN107475935AIncrease diversityImprove efficiencyEmbroidering machines apparatusEngineeringHead parts

The invention discloses an over-three-thread embroidery machine nose with a head-spacing function. The over-three-thread embroidery machine nose comprises an embroidery machine nose body and a needle bar shelf, two or more needle bars and thread-picking bars are installed on the needle bar shelf, the needle bars are driven by a needle bar driver, thread-picking bars are driven by a thread picking shaft, the needle bar driver comprises a first needle bar driver body and a second needle bar driver body, the first needle bar driver body is inserted into the first needle bar to drive the first needle bar, and the second needle bar driver body is inserted into the second needle bar to drive the second needle bar at the same time. After the needle bar shelf is moved, the first needle bar driver body or the second needle bar driver body is inserted into the fifth needle bar to drive the fifth needle bar. Through the dual-needle embroidery function, the first kind of embroidery head distance is generated, after the needle bar shelf is moved, the first needle bar driver body or the second needle bar driver body is inserted into the fifth needle bar to drive the fifth needle bar, and the single fifth needle bar is combined with a fifth needle bar on an adjacent embroidery machine nose to generate the second kind of embroidery head distance, that is, the head-spacing function is enabled.

Owner:ZHEJIANG YUELONG SEWING EQUIP

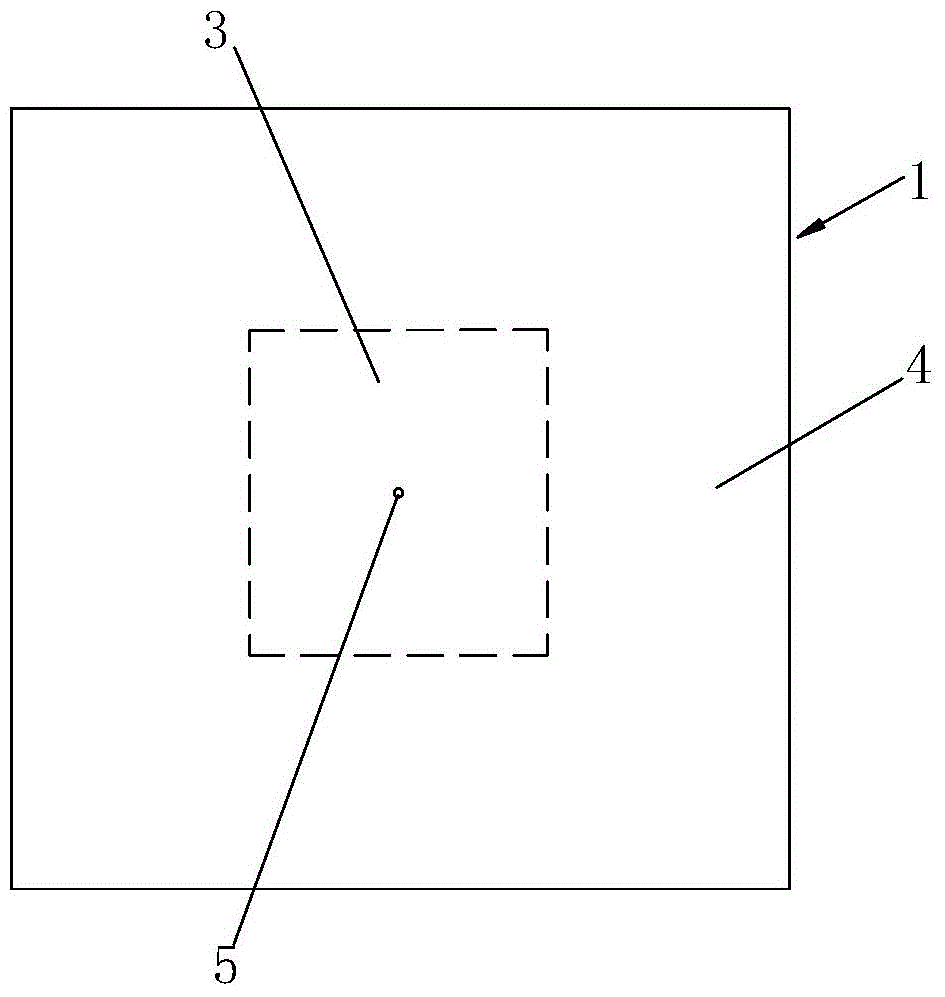

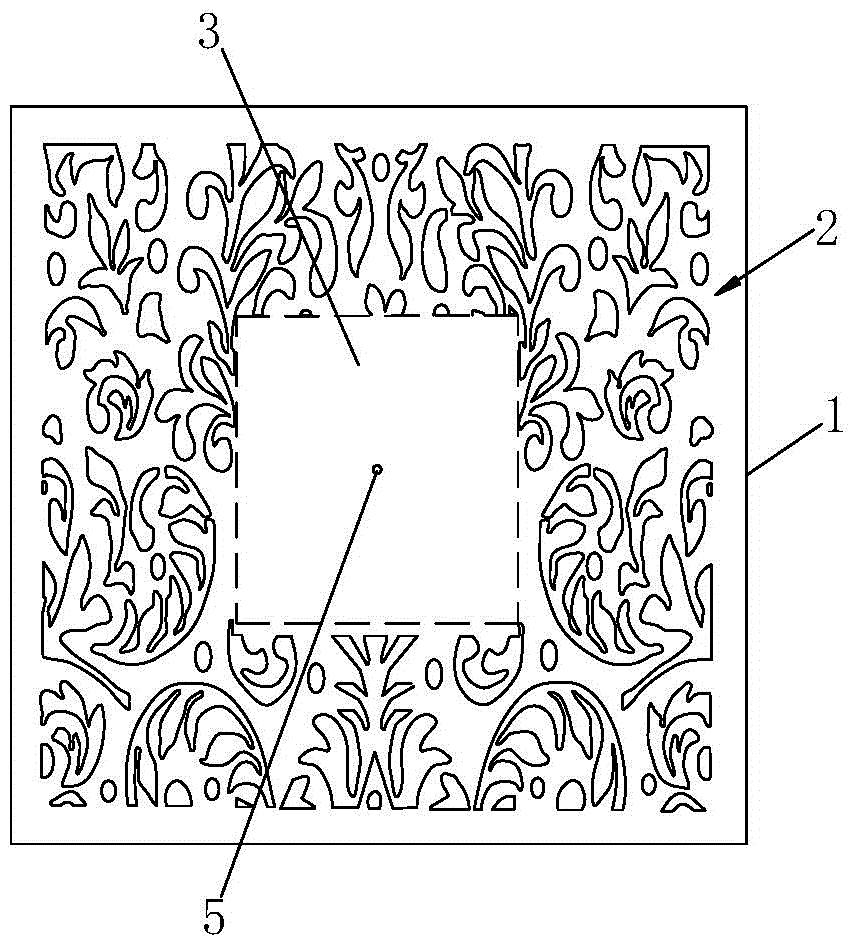

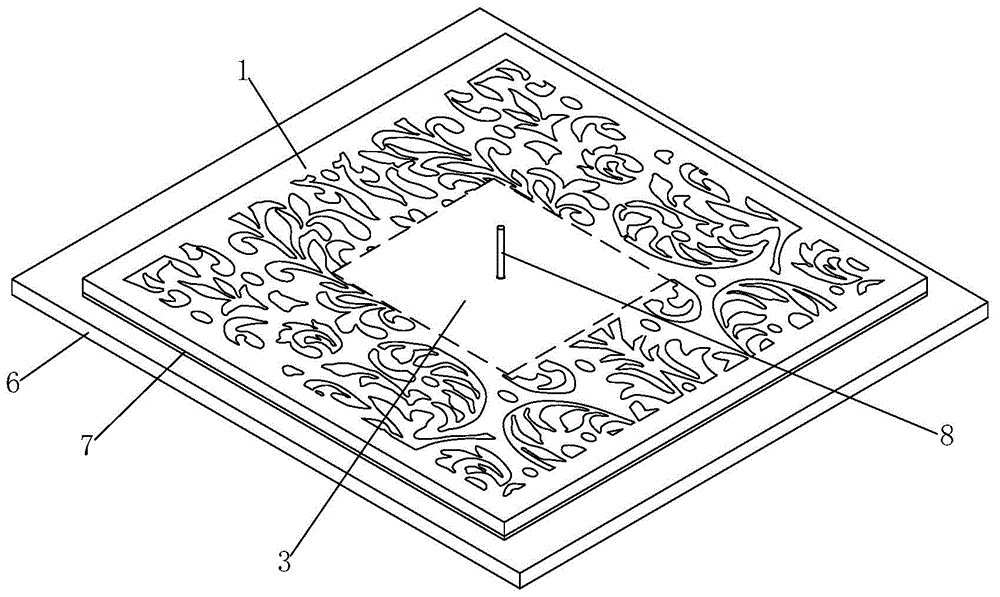

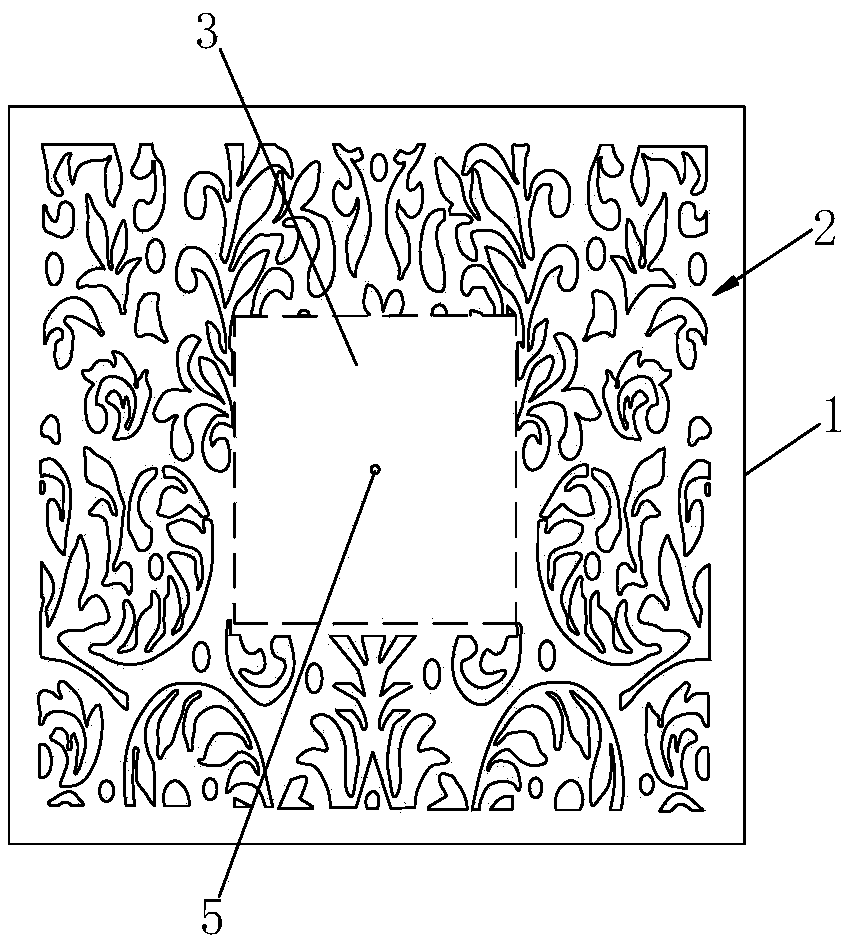

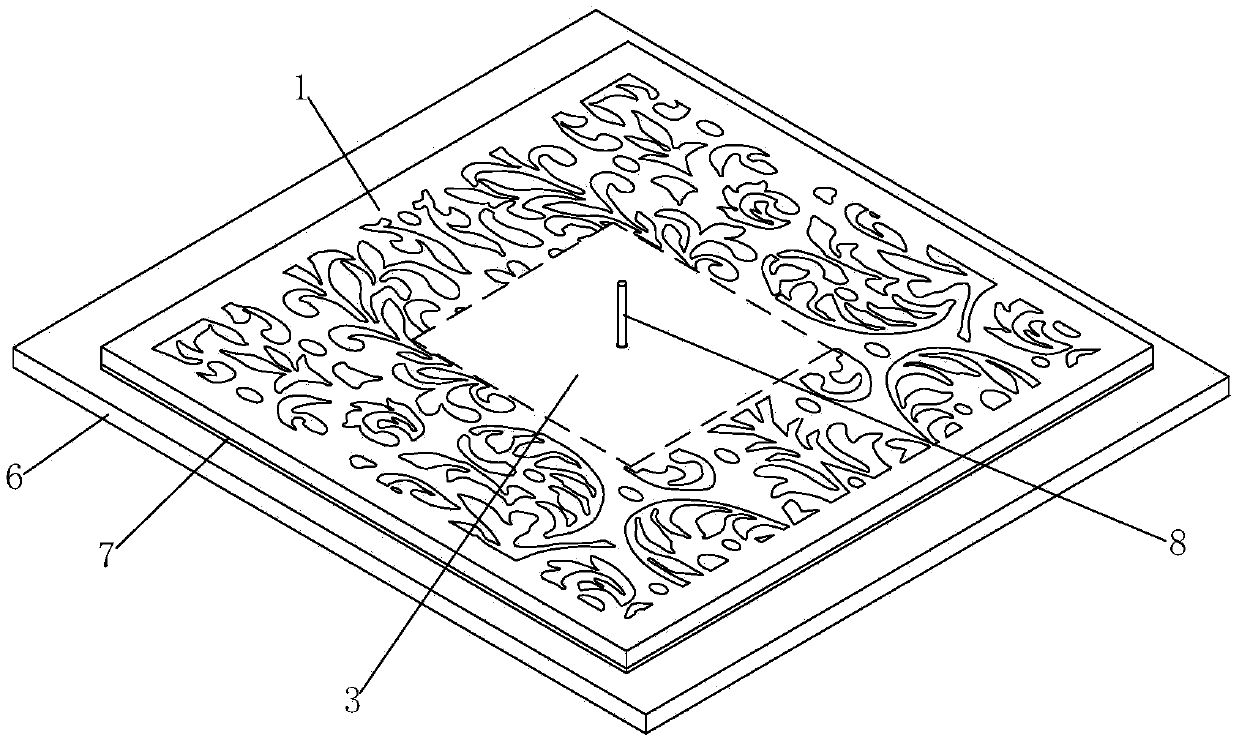

Positioning method of auxiliary patterns of inwrought applique decorative blanket

ActiveCN104313812AShorten the timeImprove efficacyEmbroidering machines apparatusHand embroideringSize matchingEngineering

The invention discloses a positioning method of auxiliary patterns of an inwrought applique decorative blanket. The positioning method comprises the following steps of 1, selecting a positioning plate, and on the positioning plate, setting aside a main pattern corresponding zone with the size matching with that of an inwrought applique decorative blanket main pattern and a blank zone located around the main pattern corresponding zone, 2, carving inwrought applique decorative blanket auxiliary pattern hollow structures on the blank zone by a computer engraving machine, and 3, superposing the main pattern of the screen cloth only with the inwrought applique decorative blanket main pattern and the main pattern corresponding zone, covering the screen cloth with a positioning plate, fixing the main pattern of the screen cloth to the corresponding position of the main pattern corresponding zone, and drawing the outlines of the inwrought applique decorative blanket auxiliary pattern hollow structures on the screen cloth by a paintbrush. The positioning method realizes whole positioning of the auxiliary patterns on the screen cloth of the inwrought applique decorative blanket so that in embroidering, an embroidering work does not use a coordinate drawing for contrast and embroidering efficiency is greatly improved.

Owner:SHANGLUO YIJIA NEEDLEPOINT ARTS & CRAFTS CO LTD

Method for embroidering cross-stitch embroidery on cloth

InactiveCN103485091AWill not deformIncreasing the thicknessAutomatic machinesAdhesiveRoom temperature

The invention relates to a method for embroidering cross-stitch embroidery on a cloth to solve present problems of easy deformation of a cross-stitch embroidery pattern on the cloth and unrealizable large pattern embroidering on the cloth. The method is realized through cross-stitch water-soluble cloth preparation, embroidering and cross-stitch water-soluble cloth removal, and concretely comprises the following steps: 1, punching a water-soluble cloth, and spraying with an embroidering pattern to prepare a cross-stitch water-soluble cloth; 2, bonding the cross-stitch water-soluble cloth to the cloth by using a cloth bonding adhesive, embroidering 2-6 strands of an embroidery thread according to the embroidering pattern on the cross-stitch water-soluble cloth to obtain a cloth having the cross-stitch water-soluble cloth; and 3, immersing the cloth in water at room temperature until the cross-stitch water-soluble cloth on the cloth having the cross-stitch water-soluble cloth is completely dissolved to complete the method for embroidering cross-stitch embroidery on the cloth. The method can be widely used in the field of methods for embroidering cross-stitch embroidery on a cloth.

Owner:姜艳艳

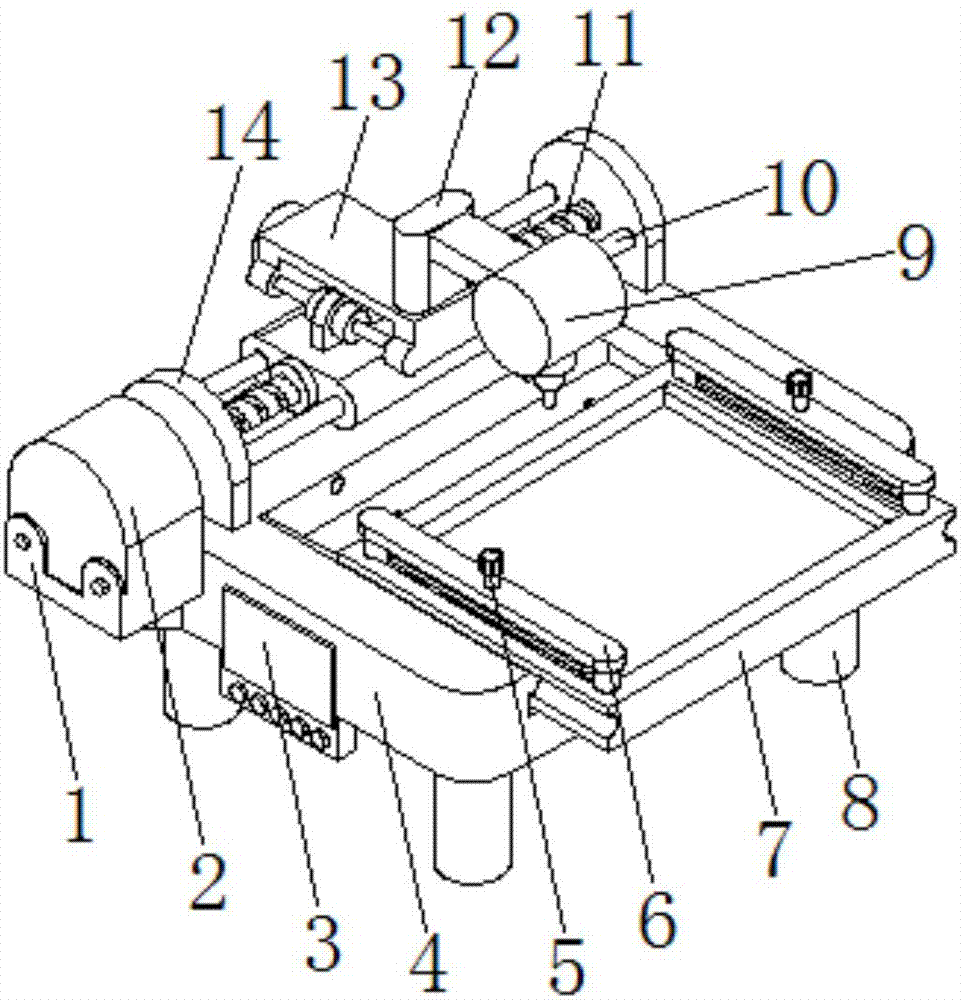

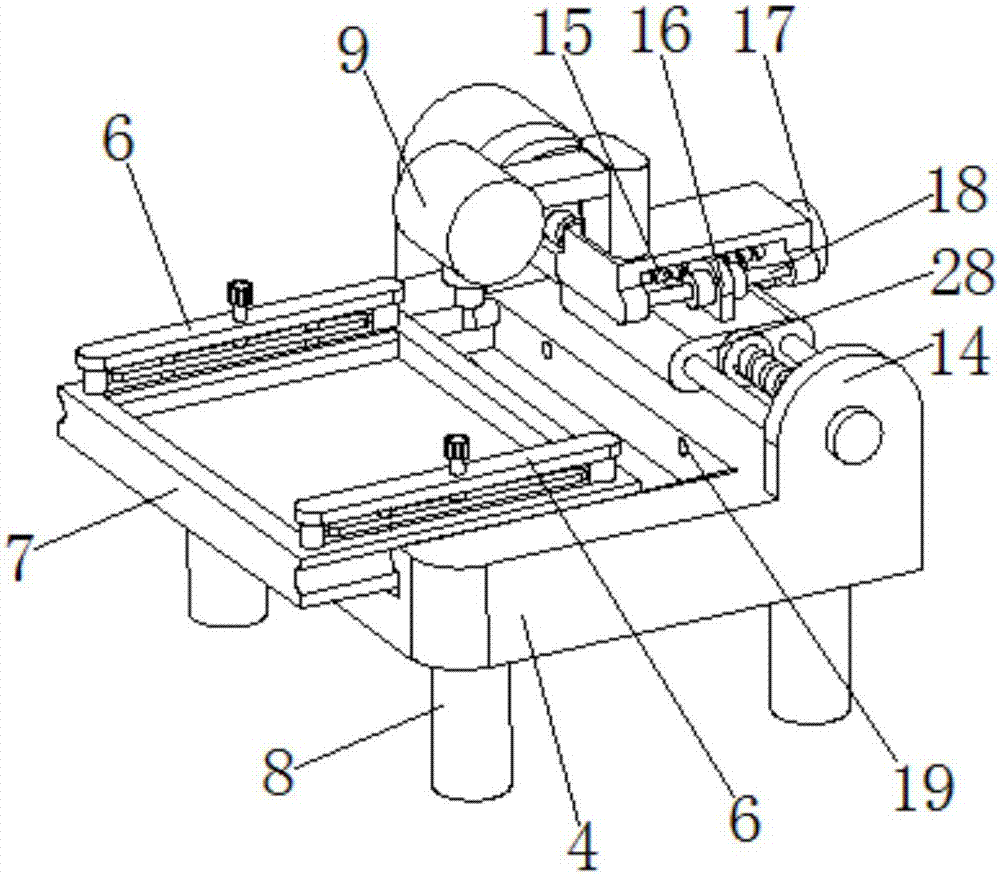

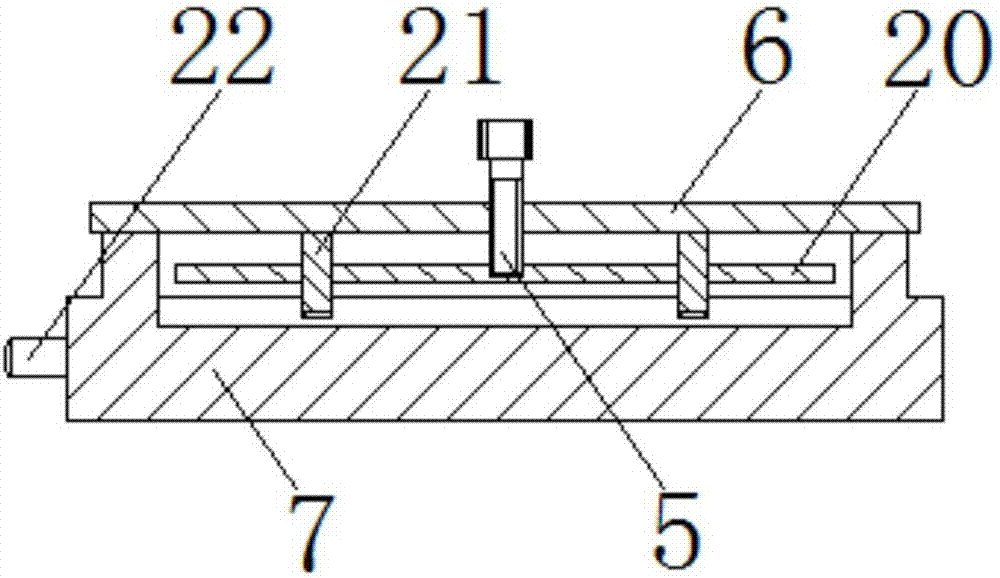

Embroidery machine with replaceable and detachable embroidery frame

InactiveCN107488950AEmbroidery is smooth and efficientTo achieve the effect of replaceable disassemblyAutomatic machinesFeedersEngineeringSupport plane

The invention discloses an embroidery machine with a replaceable and detachable embroidery frame, which comprises an operating table, and the lower side of the operating table is provided with more than four groups of upright columns equidistant and symmetrically distributed, and a PLC controller is provided on one side of the operating table. , the first lead screw is connected to the support frame through a bearing, and two sets of first slide shafts are symmetrically distributed on both sides of the shaft support frame close to the first lead screw, and the first slide shafts are all operated in the X direction. The upper side of the Y-direction operation platform is provided with a fixed sliding table, the middle position of the fixed sliding table is provided with a second screw, and the two sides of the fixed sliding table close to the second screw are provided with symmetrical distribution. Two sets of second sliding shafts, the present invention sets the adjustment handle, support plate, embroidery frame, positioning hole, third sliding shaft and positioning column, and the embroidery frame is slidingly connected with the operation table, so as to achieve the effect of replaceable and dismountable and the positioning accuracy The requirement and tightening and fixing of the embroidered cloth to be processed improves the embroidery efficiency and facilitates the user.

Owner:孙巧丽

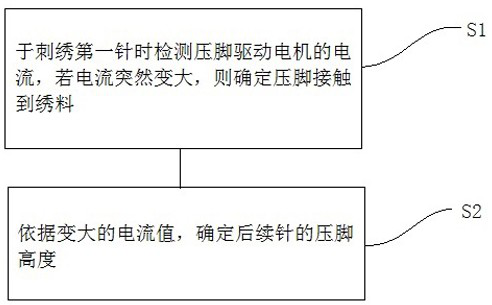

Presser foot height self-adaptive adjusting method

ActiveCN112195579AImprove qualitySkip pre-configured stepsFeedersPhysical medicine and rehabilitationEngineering

Owner:浙江镨美科智能刺绣设备有限公司

Multifunctional laser embroidering all-in-one machine

InactiveCN107904807AConvenient for fixed rewinding and conveyingEasy to fixAutomatic machinesFeedersLaser cuttingMechanical engineering

The invention discloses a multifunctional embroidery laser integrated machine, which comprises an embroidery base, a winding roller, a laser embroidery mechanism, a laser cutting mechanism, a pressing roller and a supporting roller. Cloth storage roller, the other end of the upper side of the embroidery base is equipped with a winding roller through the second support rod, embroidery cloth is wound between the cloth storage roller and the winding roller, and a vertical wall is installed on one side of the upper end of the embroidery base, A slide bar is installed on one side of the upper end of the vertical wall, and a laser embroidery mechanism and a laser cutting mechanism are installed on the slide bar, and the laser embroidery mechanism and the laser cutting mechanism are arranged directly above the embroidery cloth, and the upper side of the embroidery base is provided with a Two support rollers, a multifunctional embroidery laser integrated machine of the present invention, the embroidery cloth is wound between the cloth storage roller and the winding roller, and the lower side of the embroidery cloth is supported by the support roller, so that the embroidery cloth can be fixed, wound and transported , improve embroidery efficiency.

Owner:LIMING VOCATIONAL UNIV

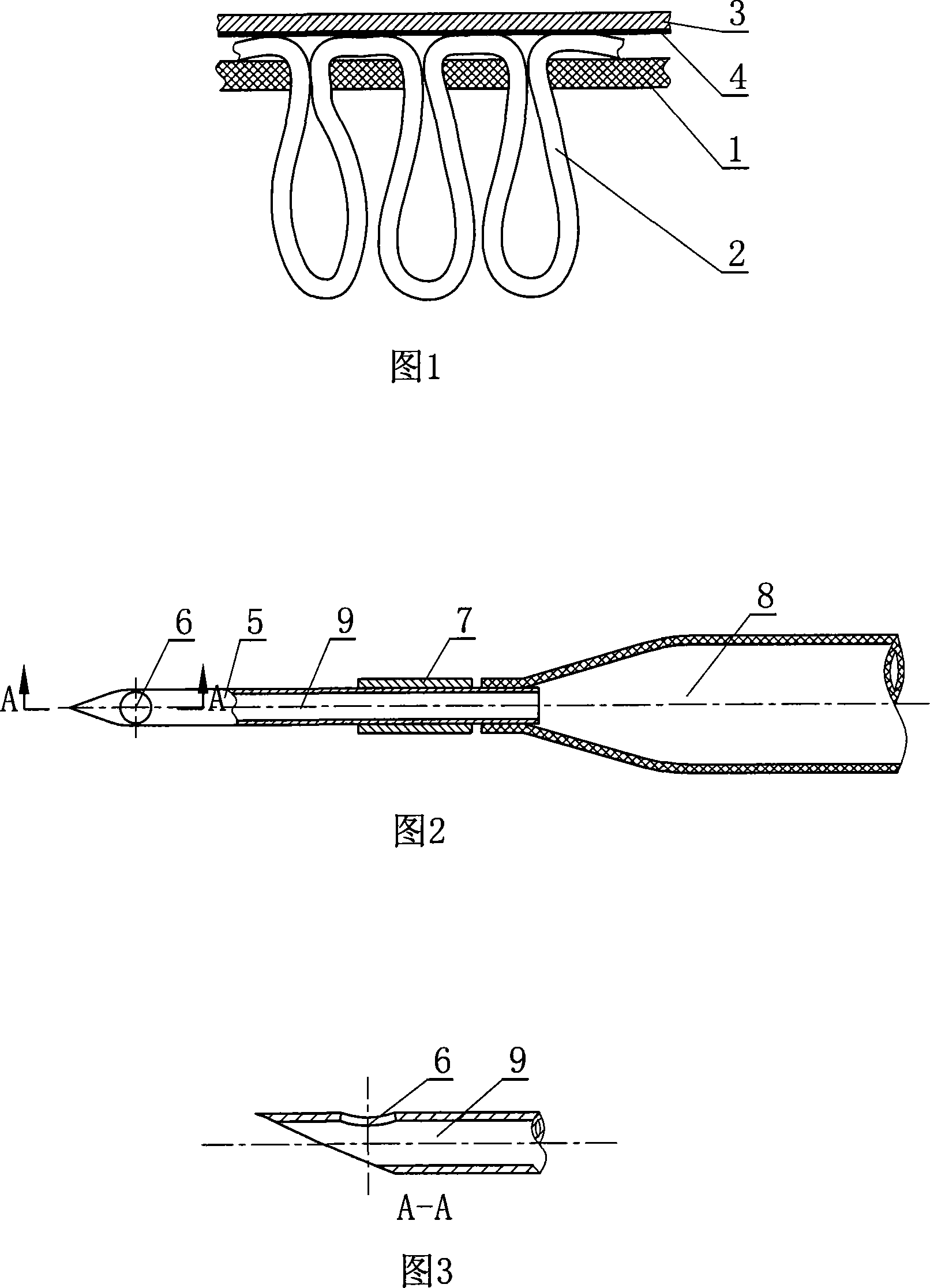

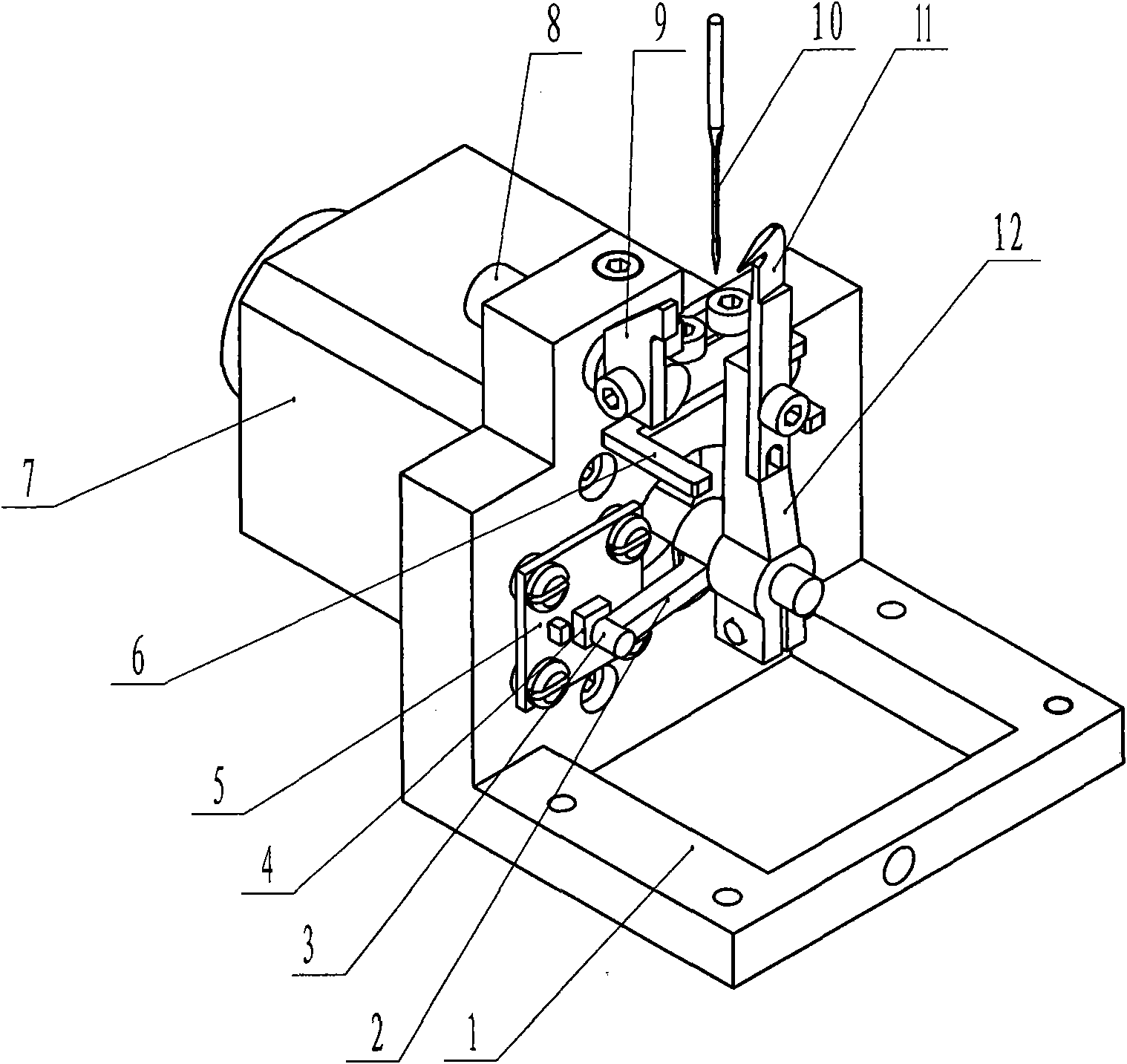

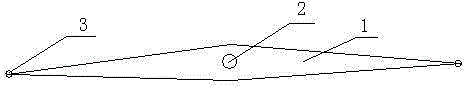

Tambour needle used for thick line and embroidery method thereof

InactiveCN101215765AImprove Embroidery EfficiencyReduce labor intensityEmbroidering machines apparatusHand embroideringThick lineHot-melt adhesive

The invention relates to an embroidery needle for thick lines and a method for embroidering, which relates to an embroidering requisite and a embroidering method, the diameter of an inner cavity of a needle body of the embroidery needle is 1mm-3mm, a round needle hole is opened on the needle body wall on a needle point, an adjusting tube is sleeved on the needle body, and a handle is a through cavity structure. The process comprises firstly, leading the embroidery needle which is threaded with a line to be punched in an awaiting embroidery cloth, secondly, vertically pulling out the embroidery needle when the adjusting tube on the embroidery needle which is punched contacts with embroidery surface, thirdly, vertically punching a second needle at the needle hole with the diameter of the needle to be a distance with the same method, and reciprocating to complete such embroidery, fourth, adhering a bonding fabric which is provided with hot melt adhesive on the embroidery face, and then adopting a flat iron or a heating press to press and adhere, fifth, crispening and sewing cloth which is chosen. The process adopts thick lines which are matched with the cloth to embroider, which solves the difficult problem that thick lines can not be adopted to do hand embroidery.

Owner:夏芬

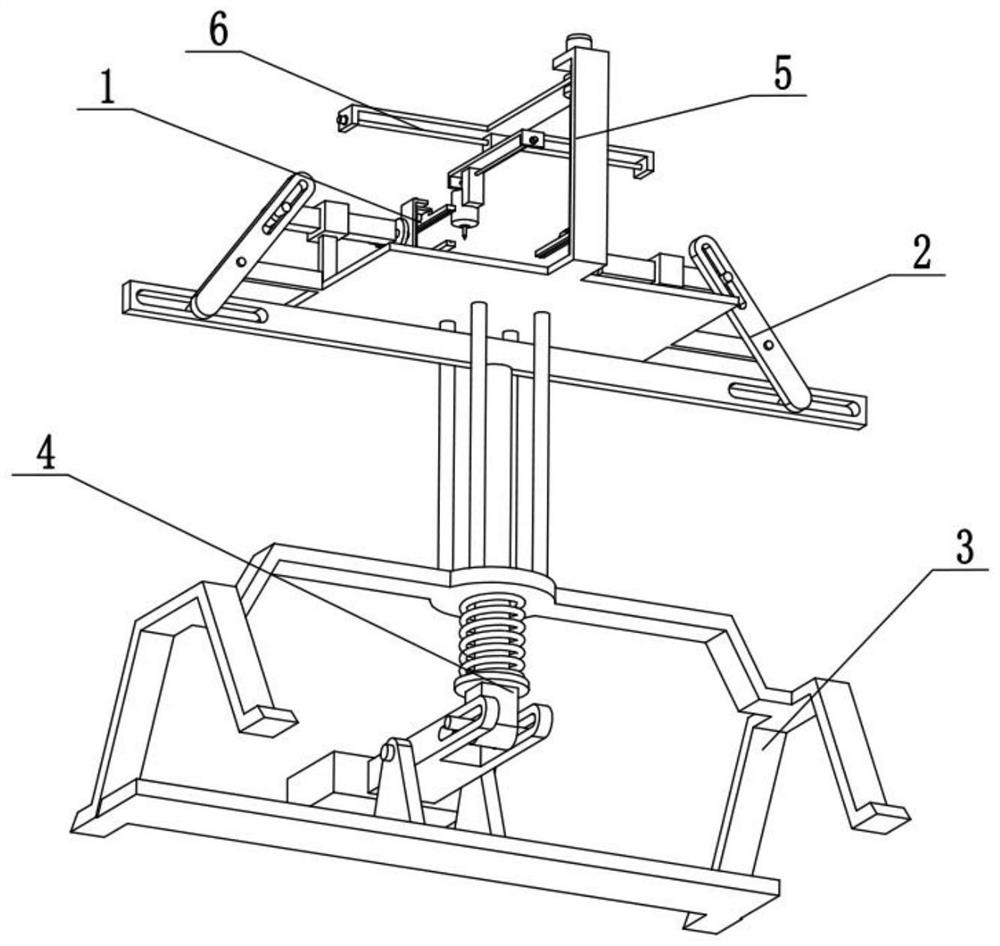

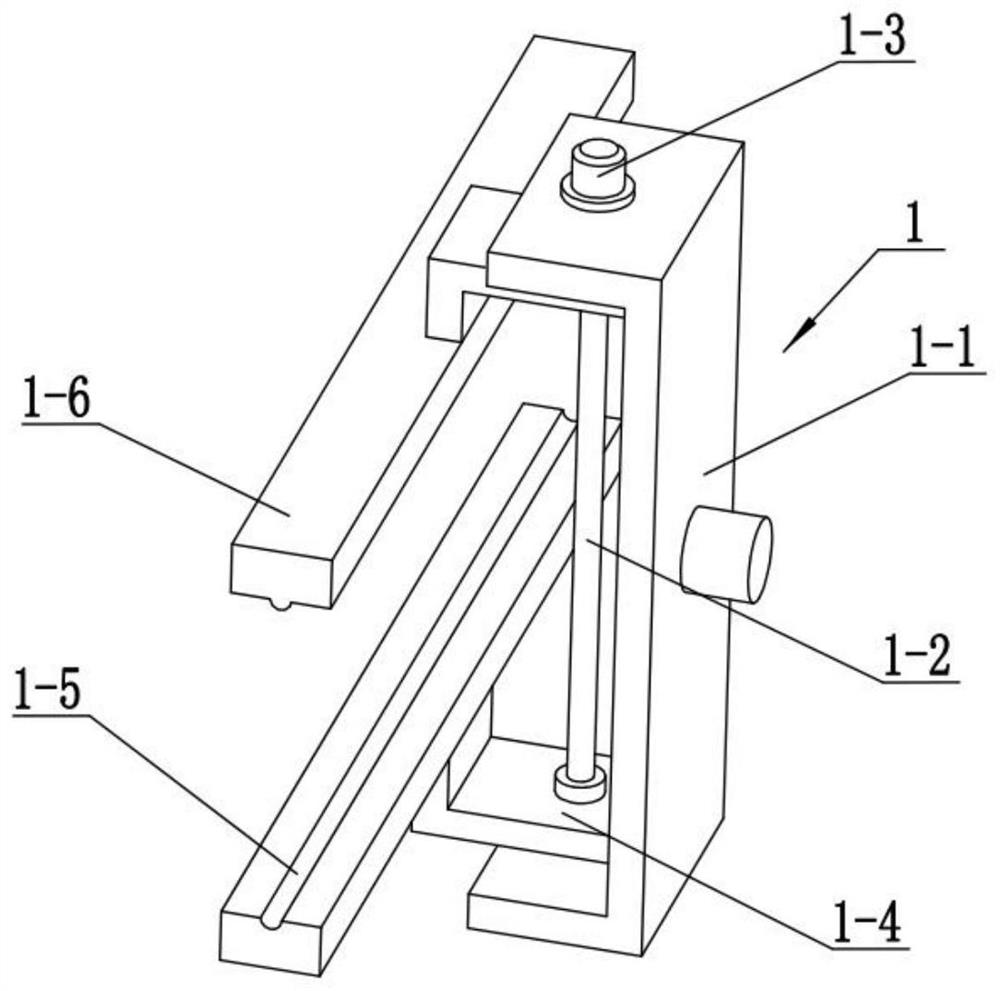

Spinning embroidery machine for textile processing and convenient to use

InactiveCN107338589AStable supportEasy to moveAutomatic machinesAuxillary devicesArchitectural engineeringTextile processing

The invention discloses a textile embroidery machine for textile processing which is convenient to use, comprising a textile embroidery machine body, the textile embroidery machine body including a textile work embroidery table, the front of the textile work embroidery table is fixedly connected with a fixing frame, the An extension frame is fixedly connected to the top of the fixing frame, a compression rod is fixedly connected to the bottom of the extension frame, and a compression plate is fixedly connected to the bottom of the compression rod. The present invention provides shock-absorbing support for the textile embroidery machine body by arranging a shock-absorbing support seat, thereby ensuring the stability of the textile embroidery machine body, thereby facilitating the embroidery operation of the textile embroidery machine body, improving the embroidery quality, and providing compression by setting a compression rod. force, so that the pressing plate can press the embroidery cloth placed on the textile work embroidery table, which is convenient for the embroidery equipment to carry out embroidery processing, and achieves the advantage of convenient use, thus effectively solving the inconvenient use of the existing textile embroidery machines. Problems with textile embroidery operations.

Owner:梅明会

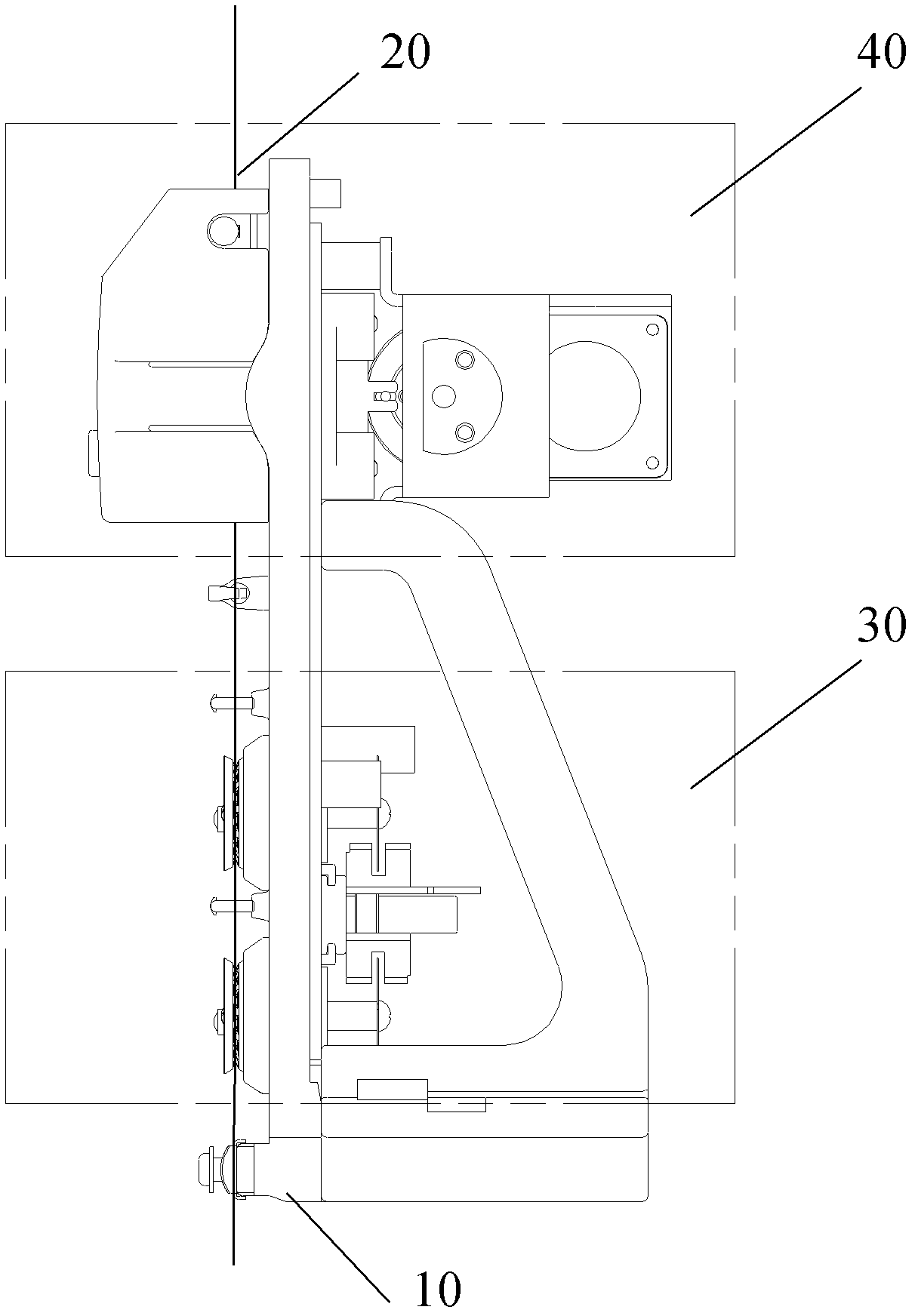

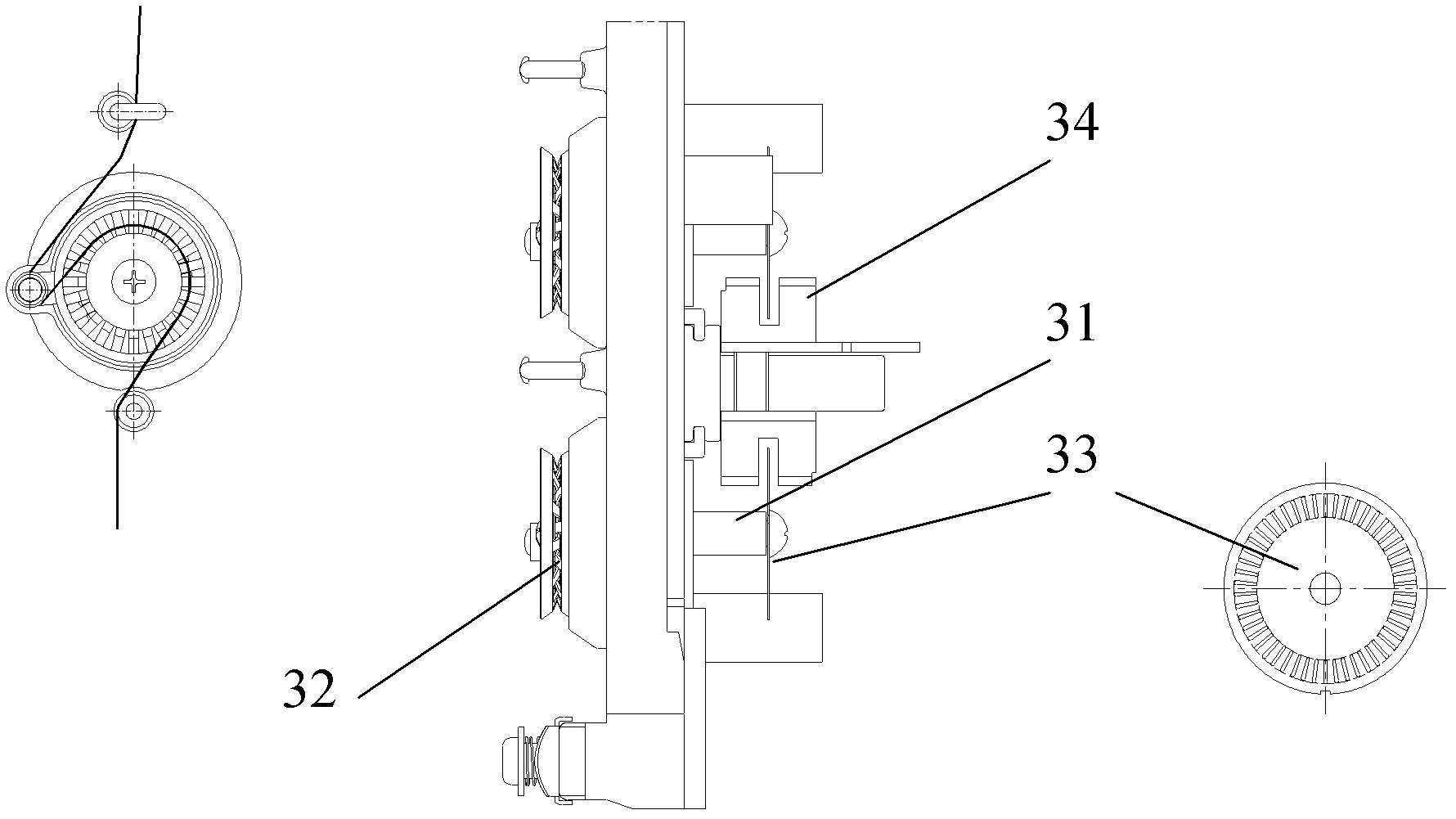

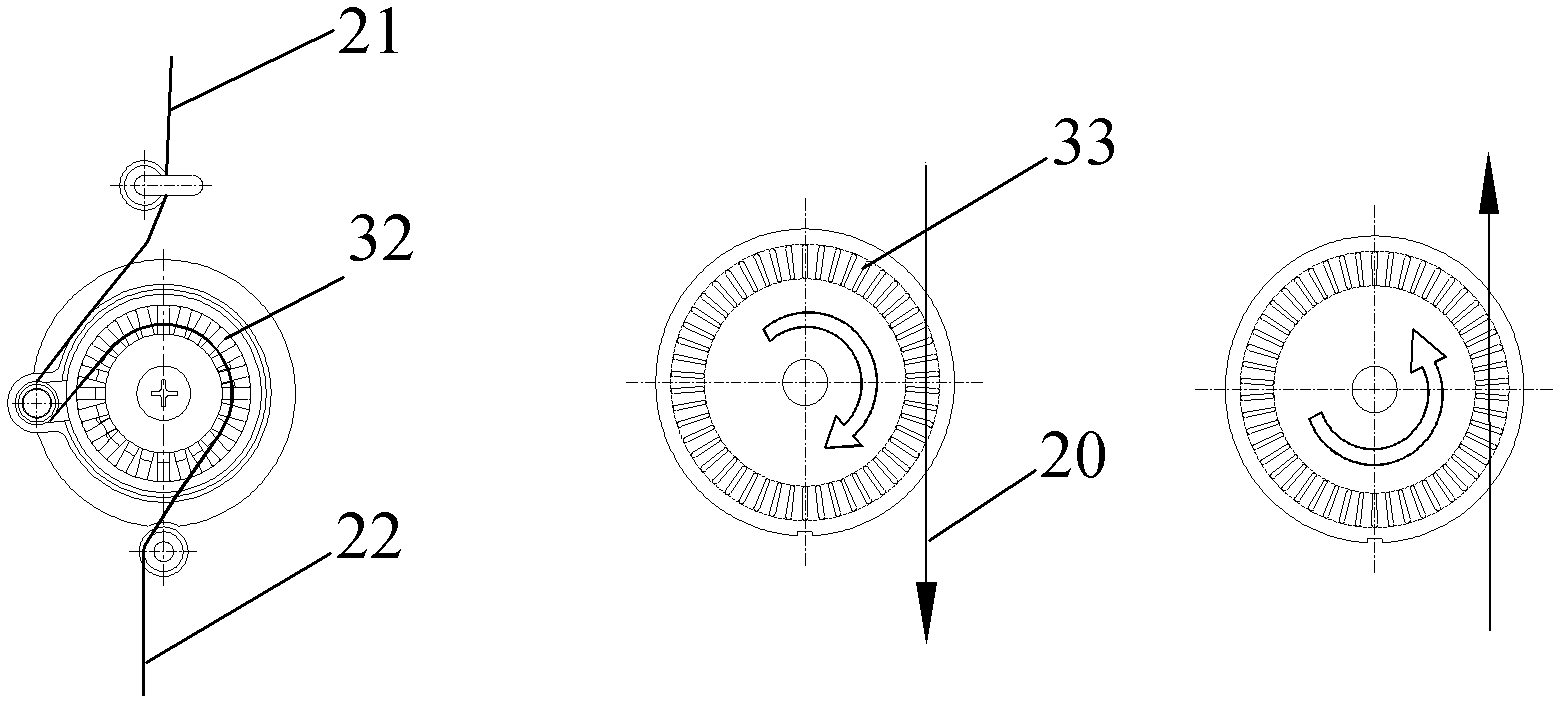

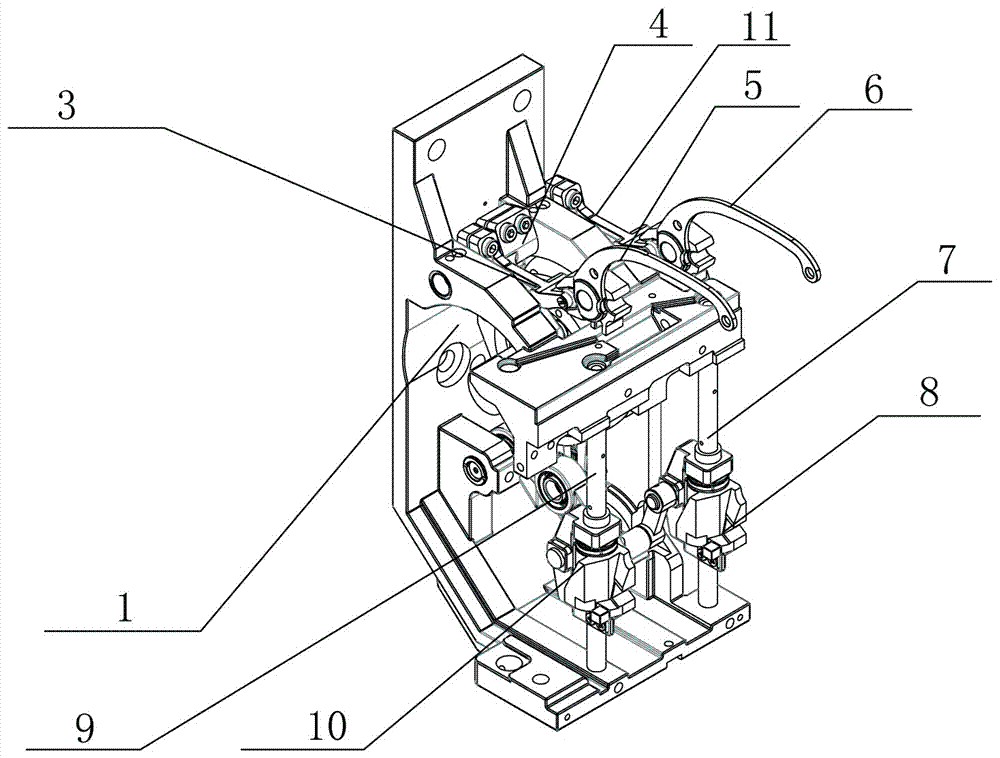

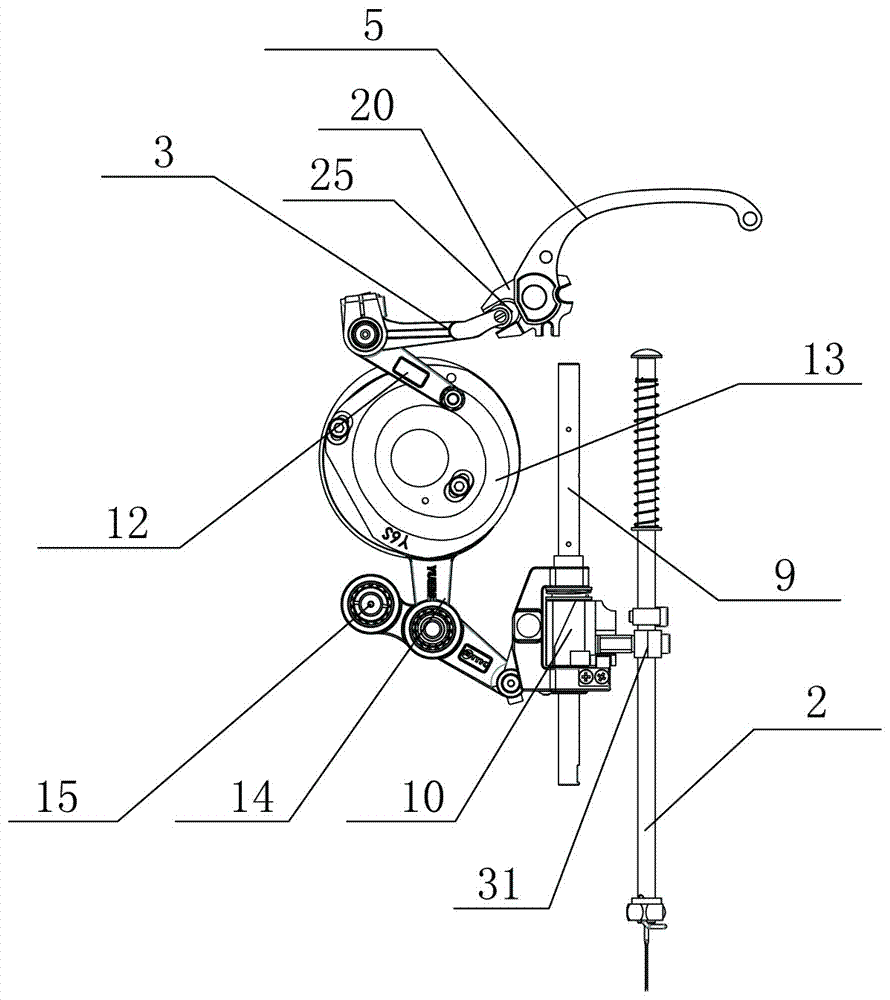

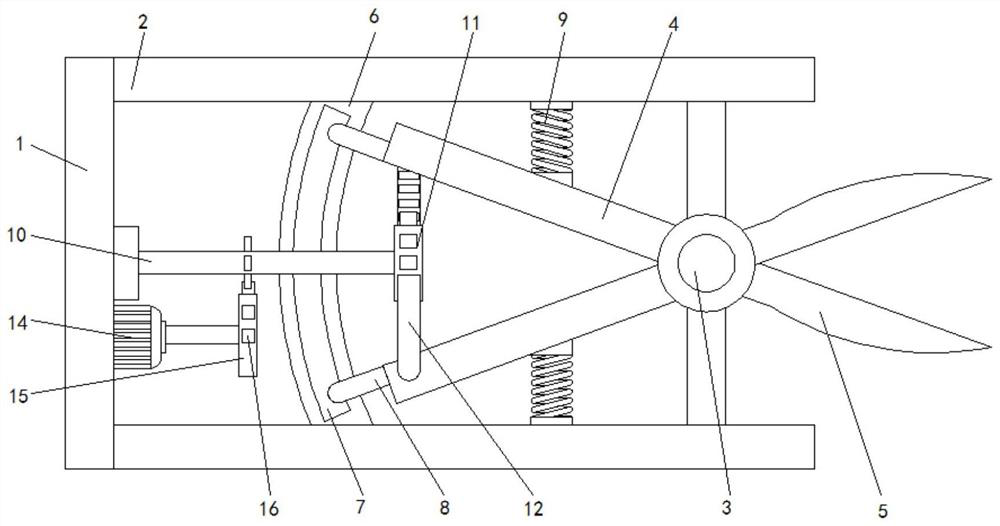

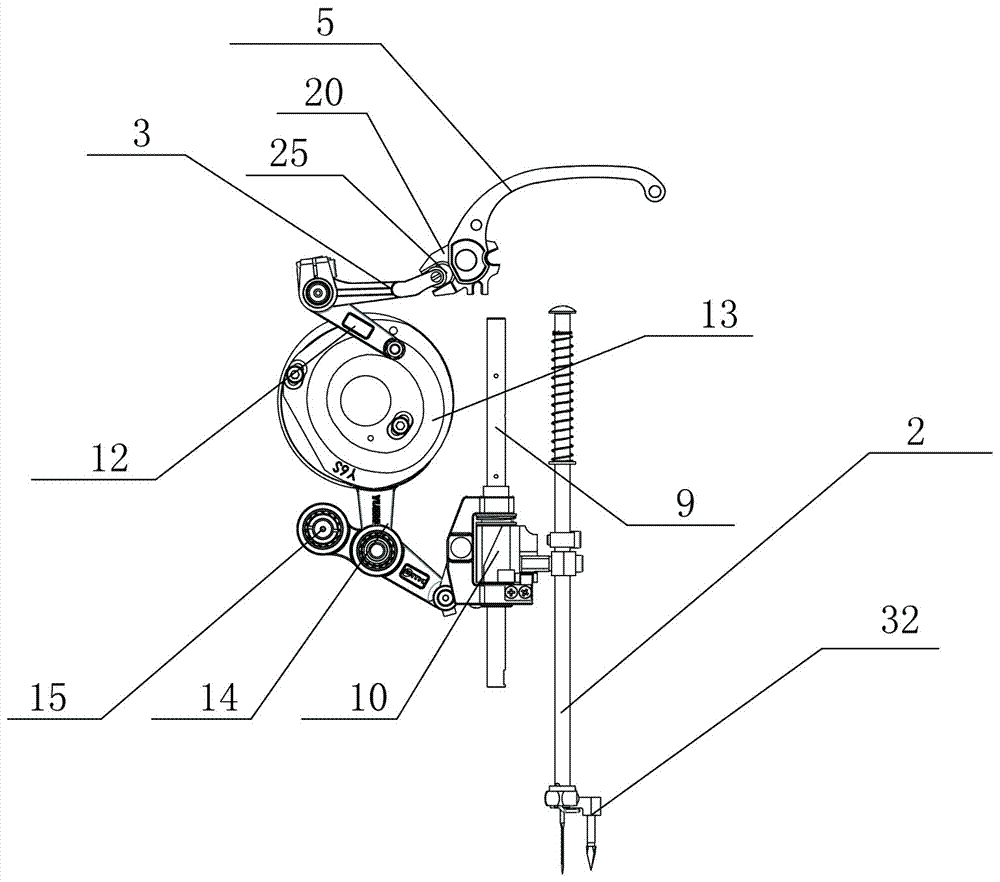

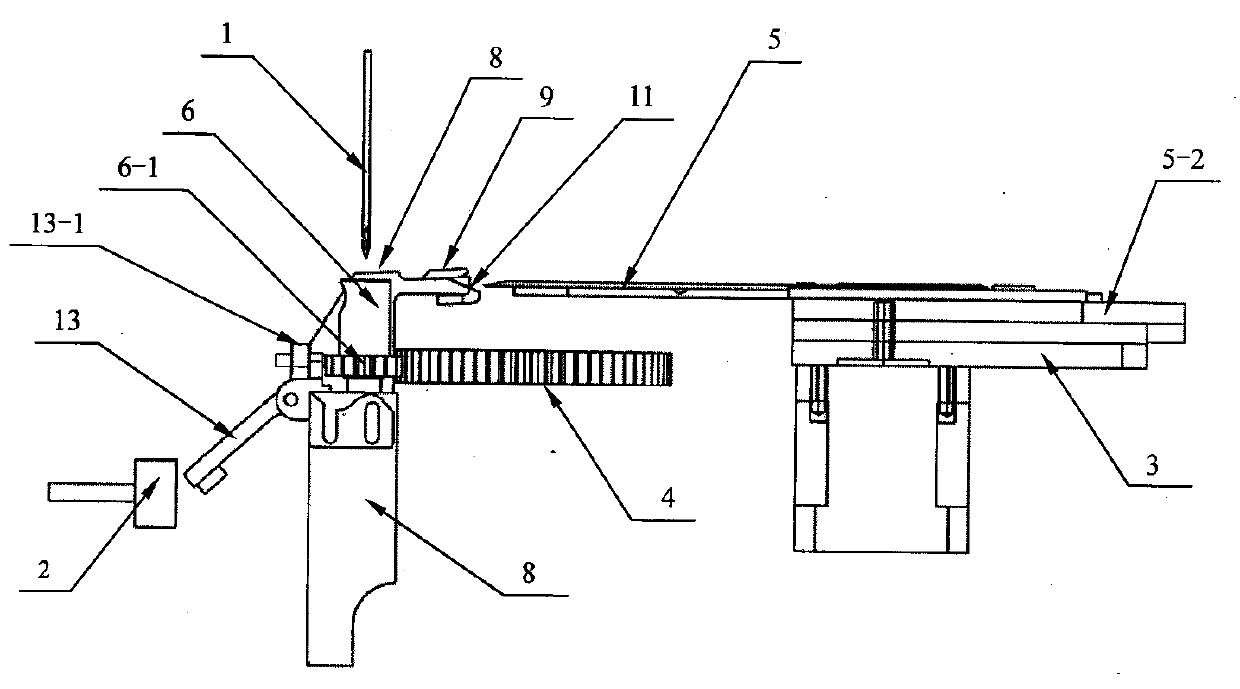

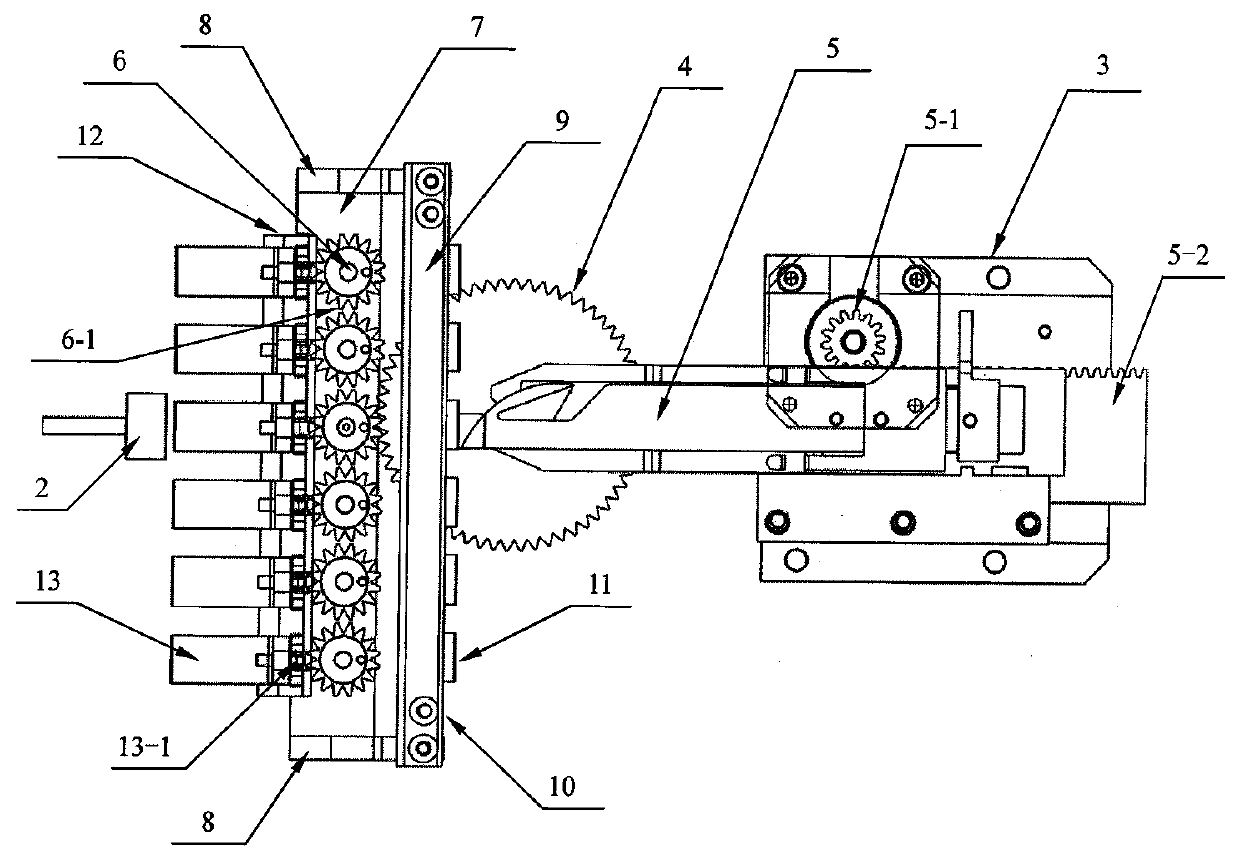

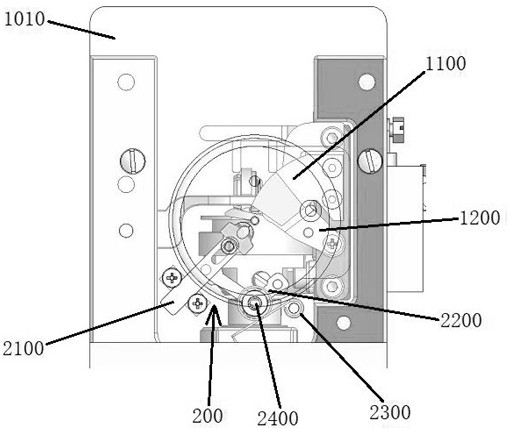

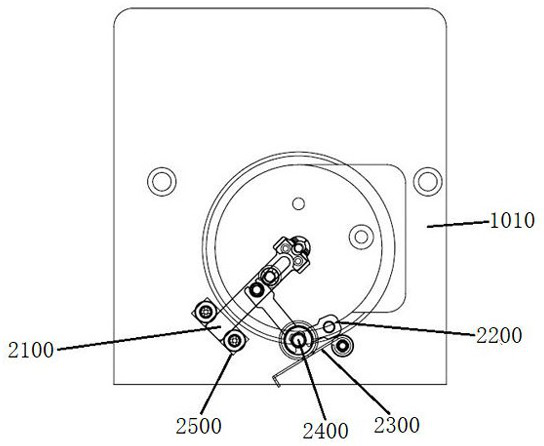

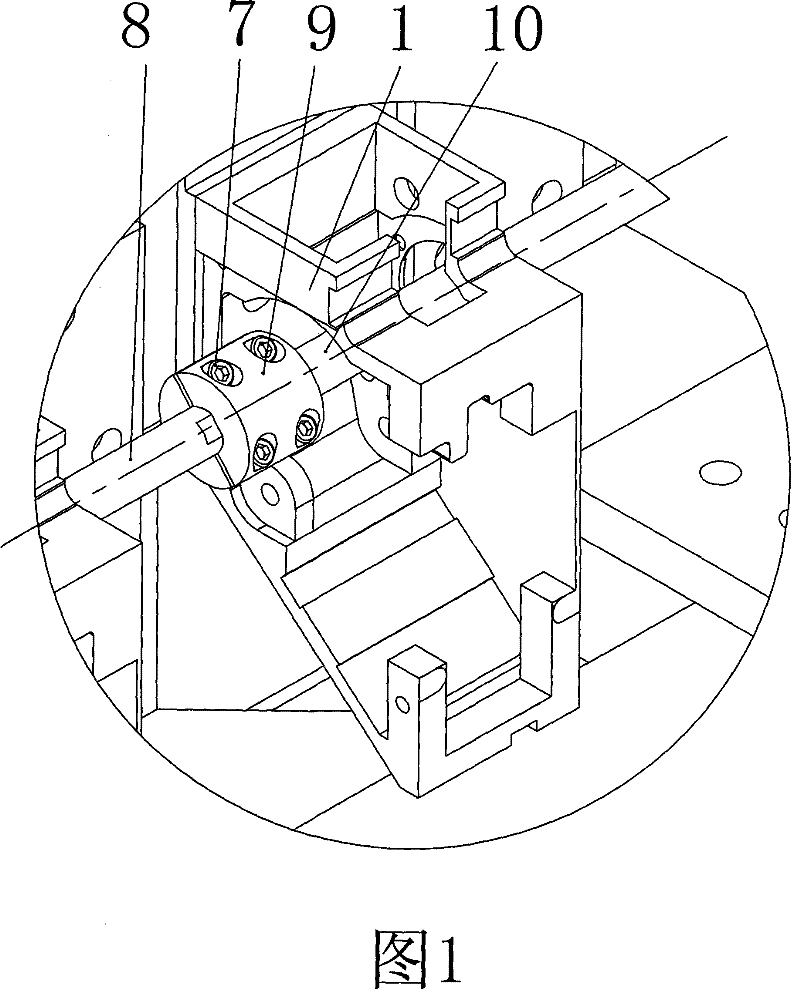

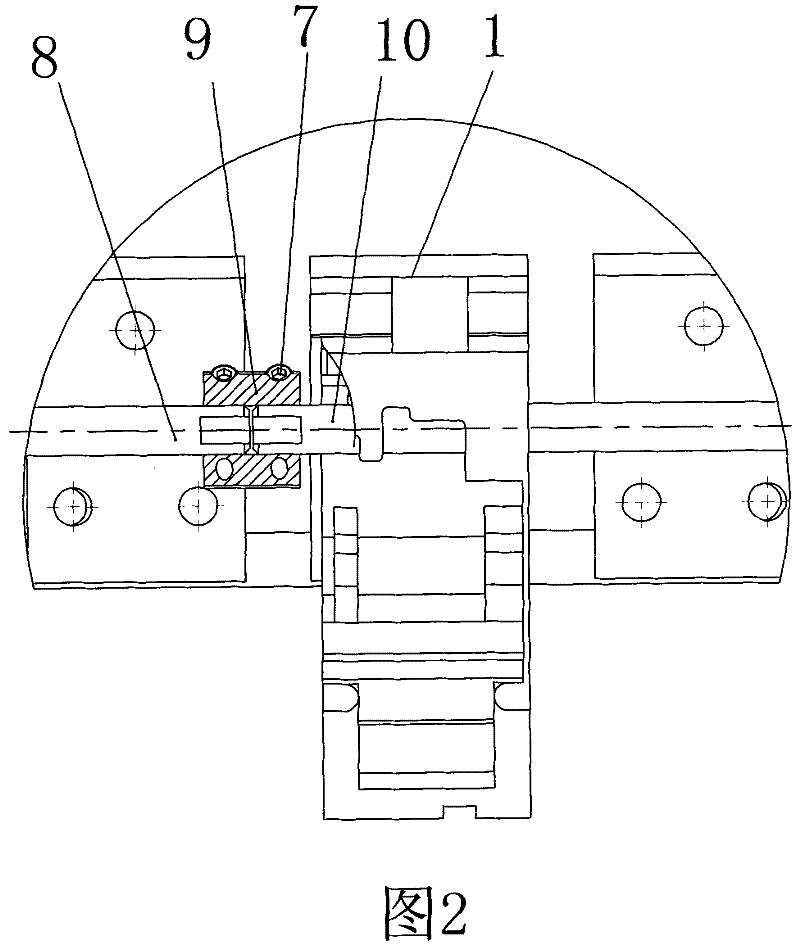

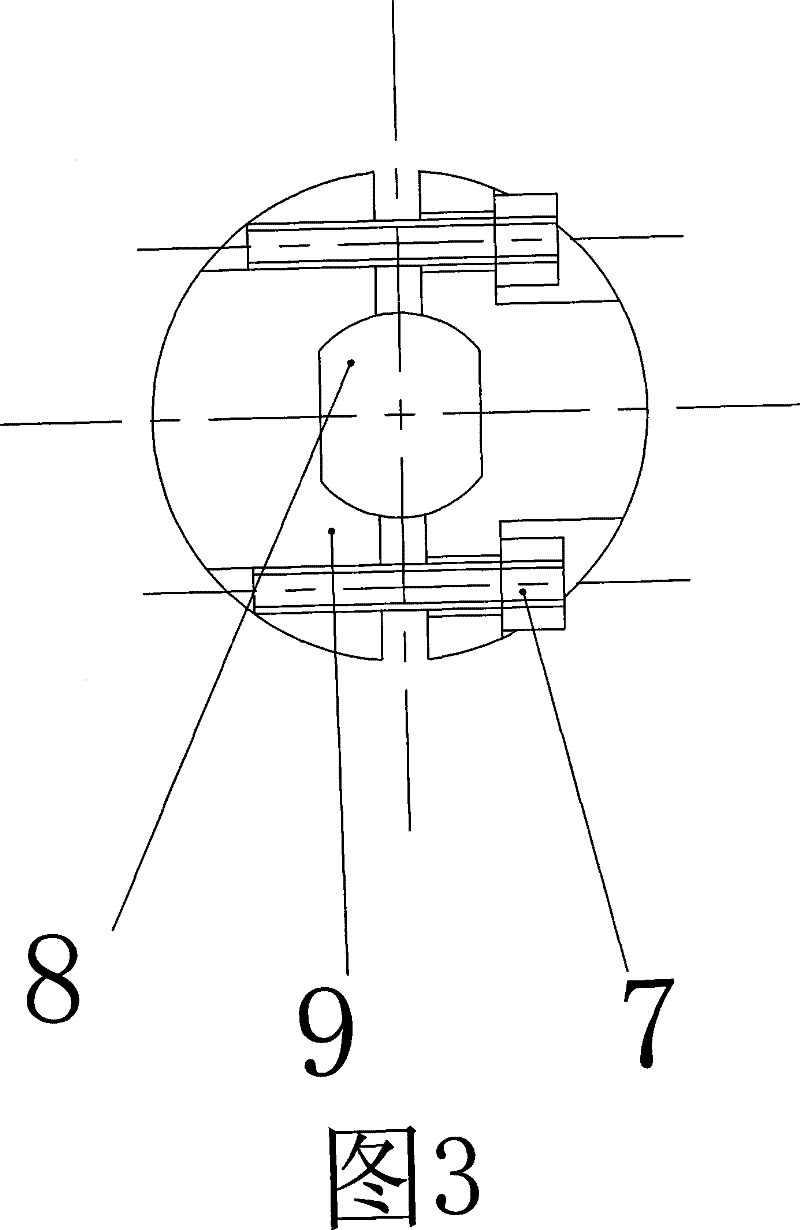

Thread-hooking oscillating shuttle device of tuft embroidery machine and automatic control method thereof

InactiveCN101629364AIncrease speedImprove Embroidery EfficiencyTufting apparatusAutomatic controlAutomotive engineering

The invention relates to a thread-hooking oscillating shuttle device of a tuft embroidery machine and an automatic control method thereof, belonging to the technical field of embroidering machines. The thread-hooking oscillating shuttle device drives the tuft embroidery machine by using a stepping motor. As for the structure of the thread-hooking oscillating shuttle device, a rotating shuttle bracket is L-shaped; the lower plane of the rotating shuttle bracket is fixed on a frame of the tuft embroidery machine; the stepping motor is fixed on a vertical plate of the rotating shuttle bracket; a transmission spindle of the stepping motor is sheathed in a mounting hole of the rotating shuttle bracket; a thread-hooking oscillating shuttle bracket is fixed at an outer end of the transmission spindle of the stepping motor; and a thread-hooking oscillating shuttle tip is arranged at the upper end of the thread-hooking oscillating shuttle bracket. The thread-hooking oscillating shuttle device is widely applied in tuft embroidery machines.

Owner:TAIYUAN DAHAOYIDA ELECTRICAL CONTROL +2

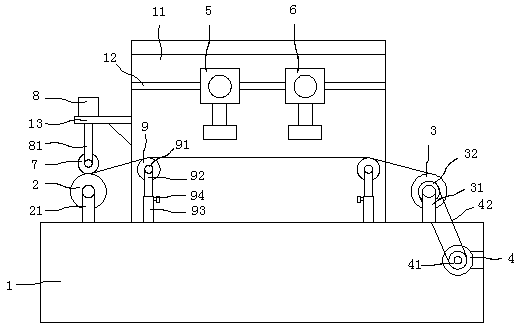

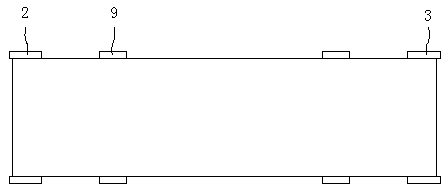

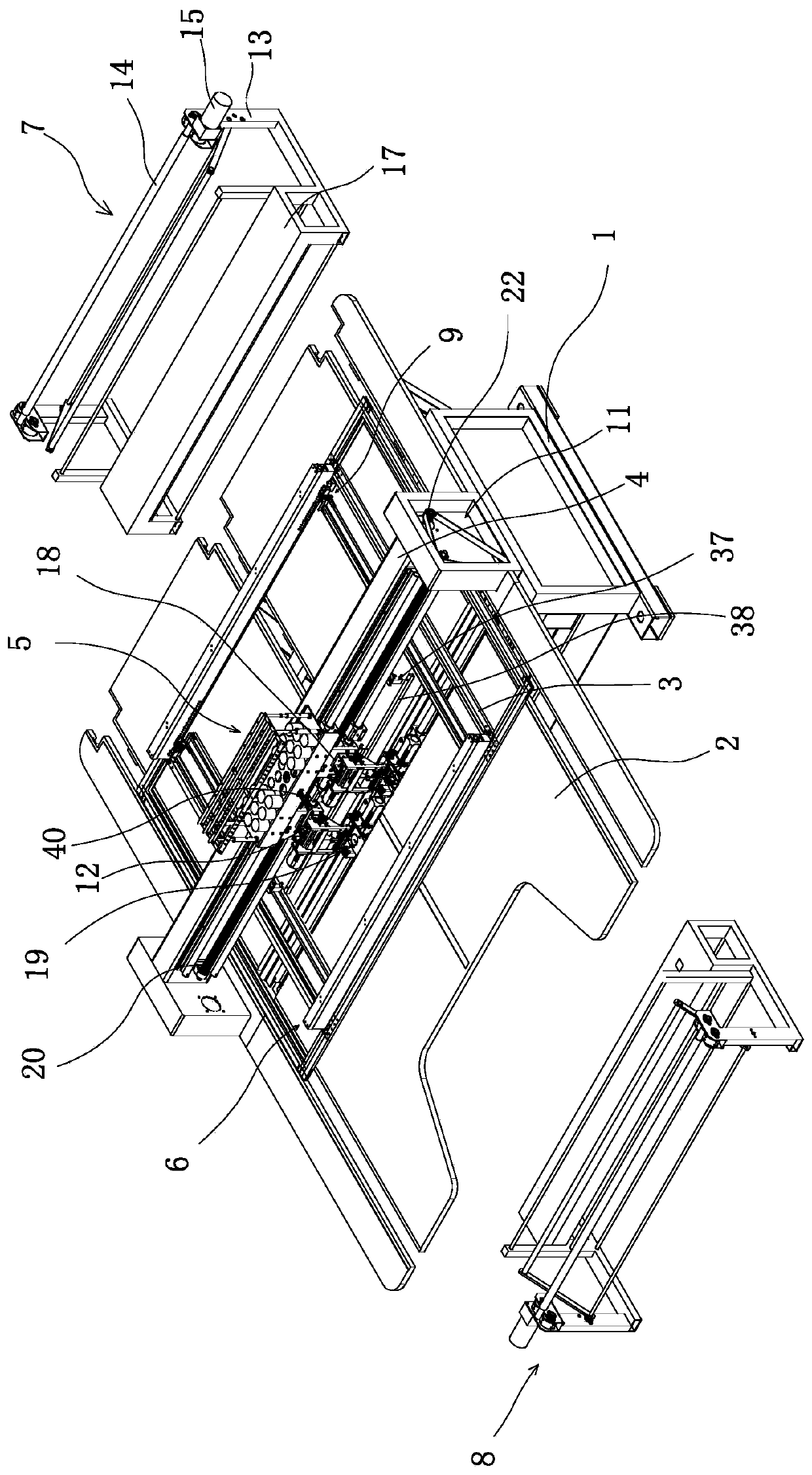

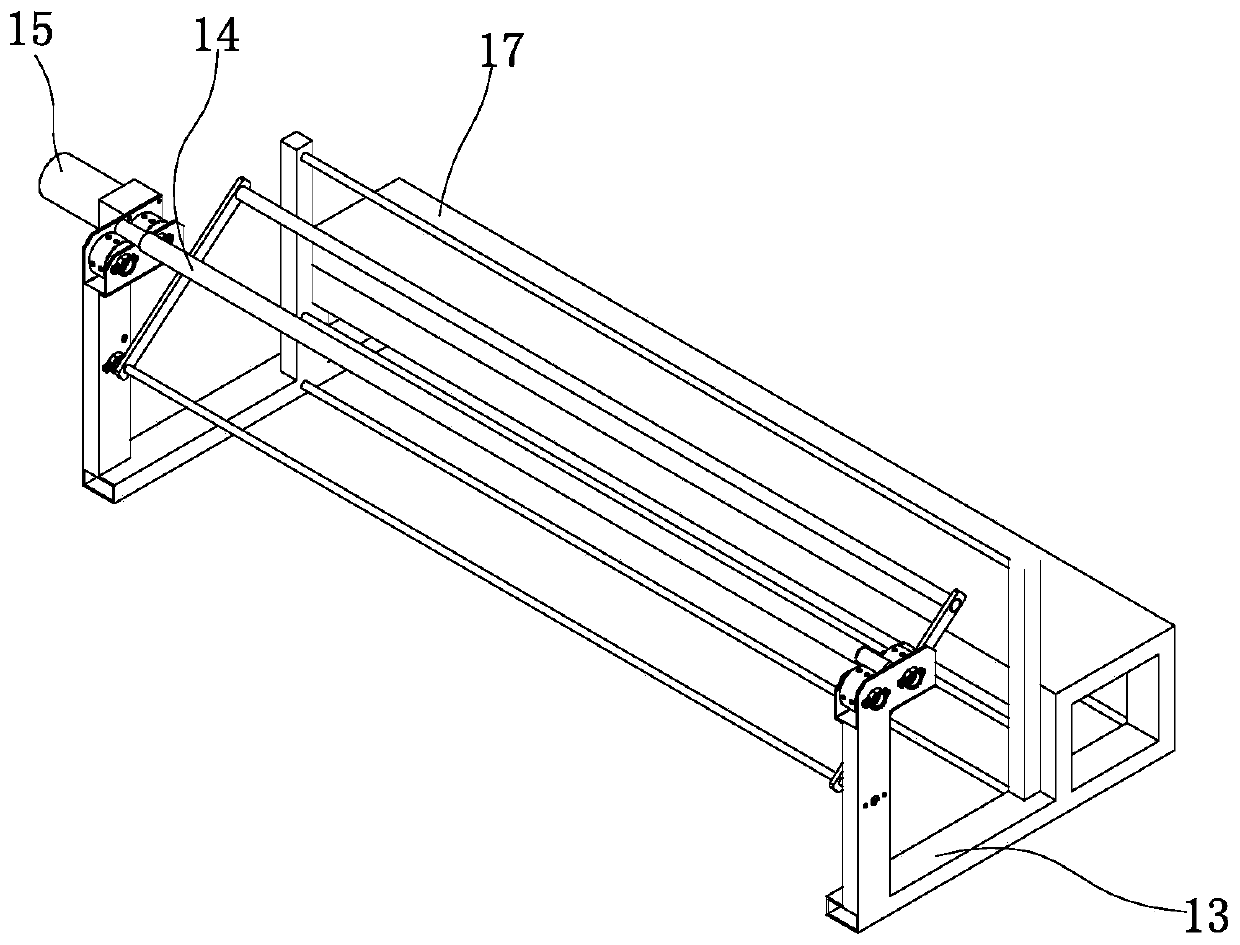

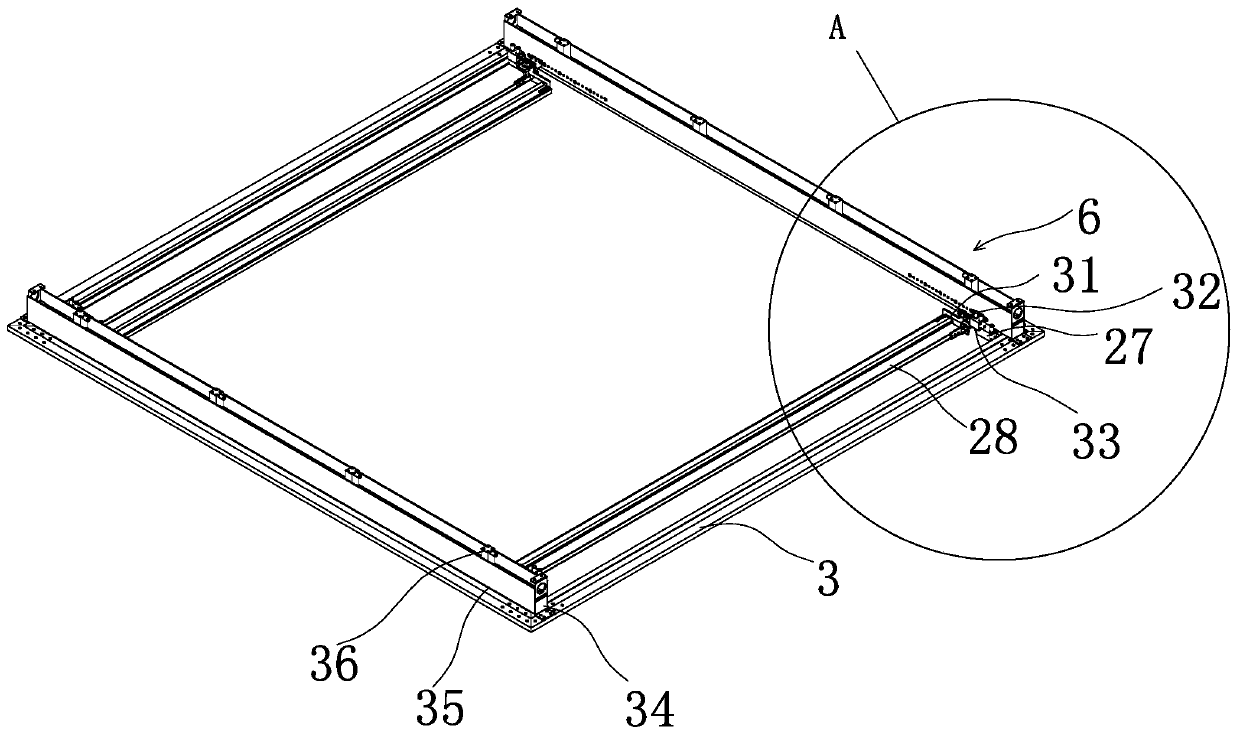

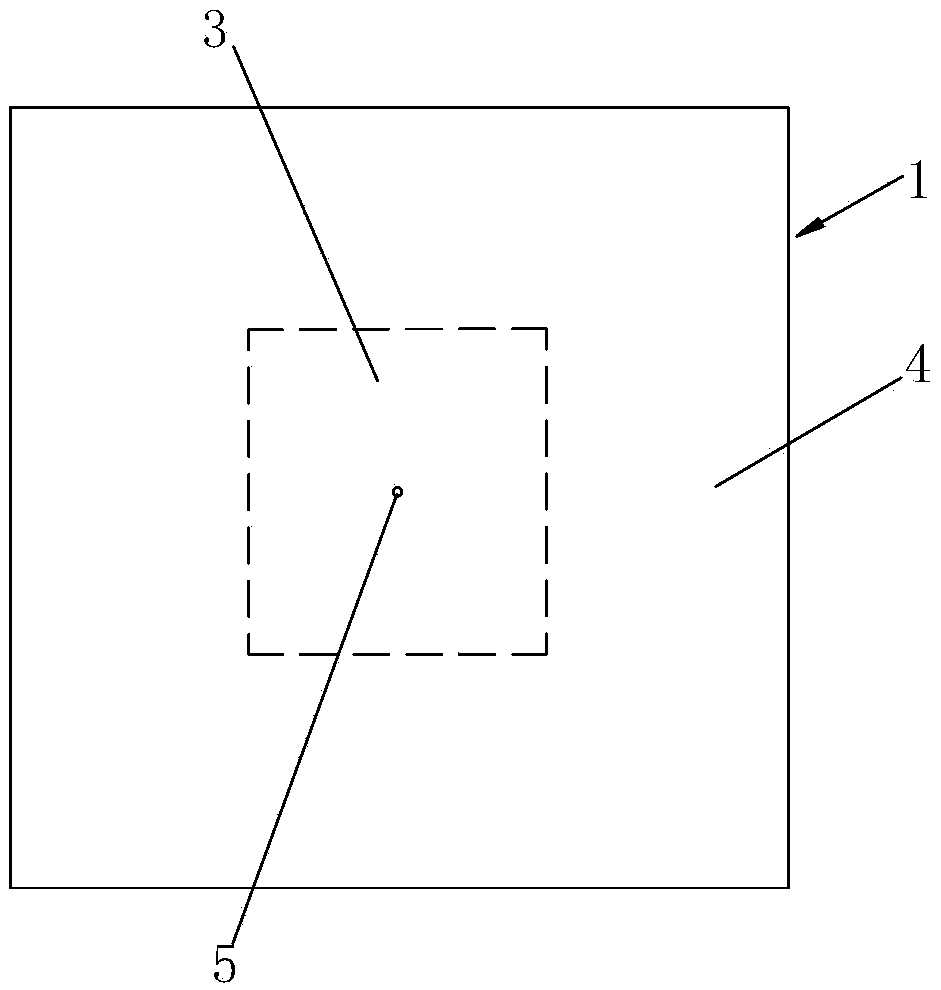

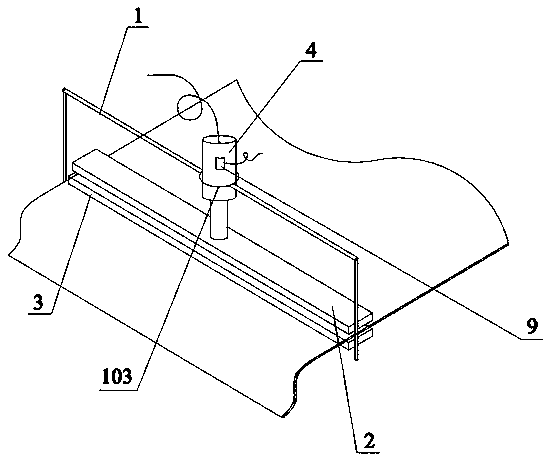

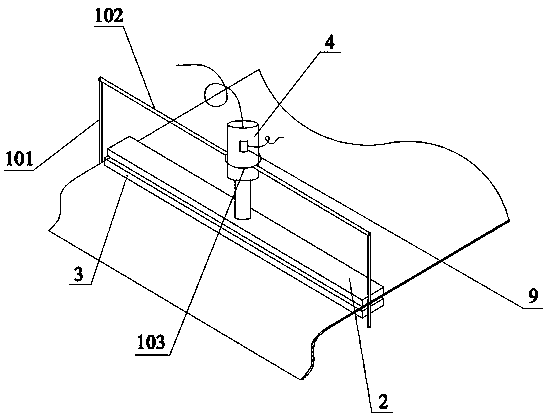

Automatic cloth spreading visual-positioning embroidery equipment

PendingCN110629423AOmit continuous embroideryImprove Embroidery EfficiencyUsing optical meansFeedersImaging processingEngineering

The invention belongs to the field of embroidery equipment and provides automatic cloth spreading visual-positioning embroidery equipment. The equipment comprises a frame, an embroidery frame is arranged on a countertop of the frame, a crossbeam of the frame is provided with an embroidery component, the embroidery frame is provided with a cloth clamping component, and a first cloth rolling mechanism and a second cloth rolling mechanism are arranged on two sides, perpendicular to the crossbeam, of the frame respectively. At least one image collector is arranged on the crossbeam or the embroidery component. Cloth entering the embroidery frame is shot through the image collector, the cloth position and embroidery positions on the cloth are determined after image processing, a needling originis provided for an embroidery mechanism, continuous embroidery is realized while needle alignment is avoided, and embroidery efficiency is improved.

Owner:赵海

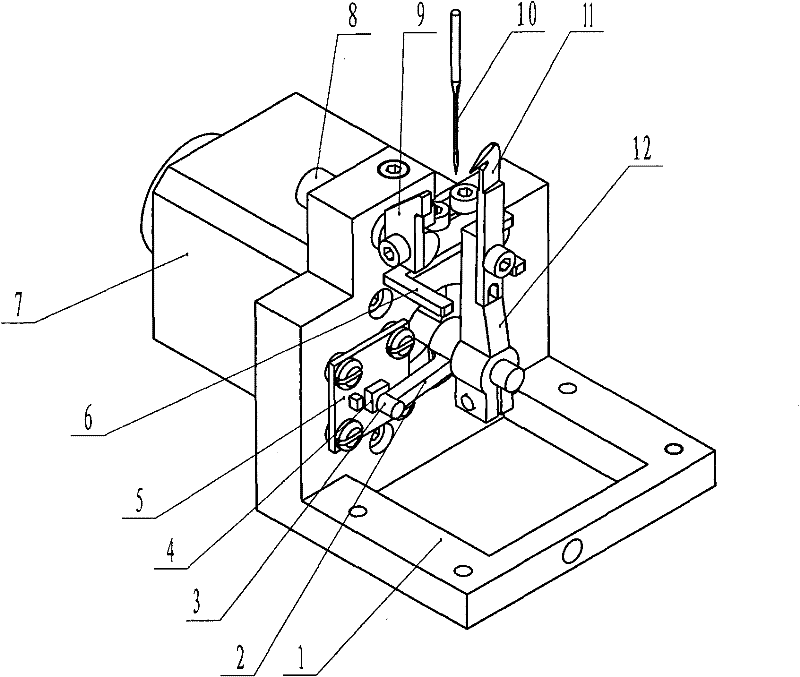

Automatic thread trimmer

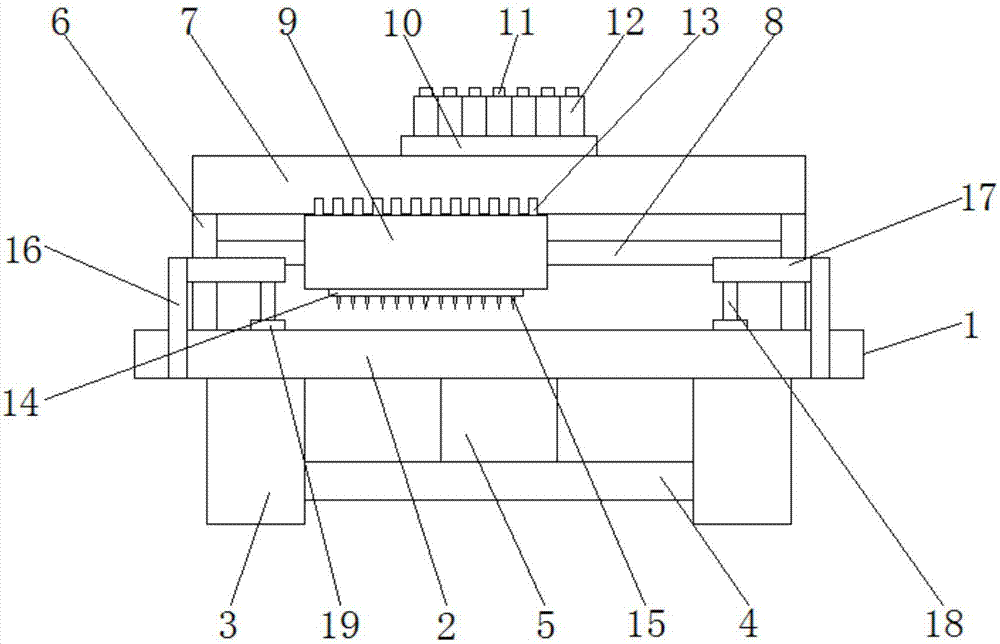

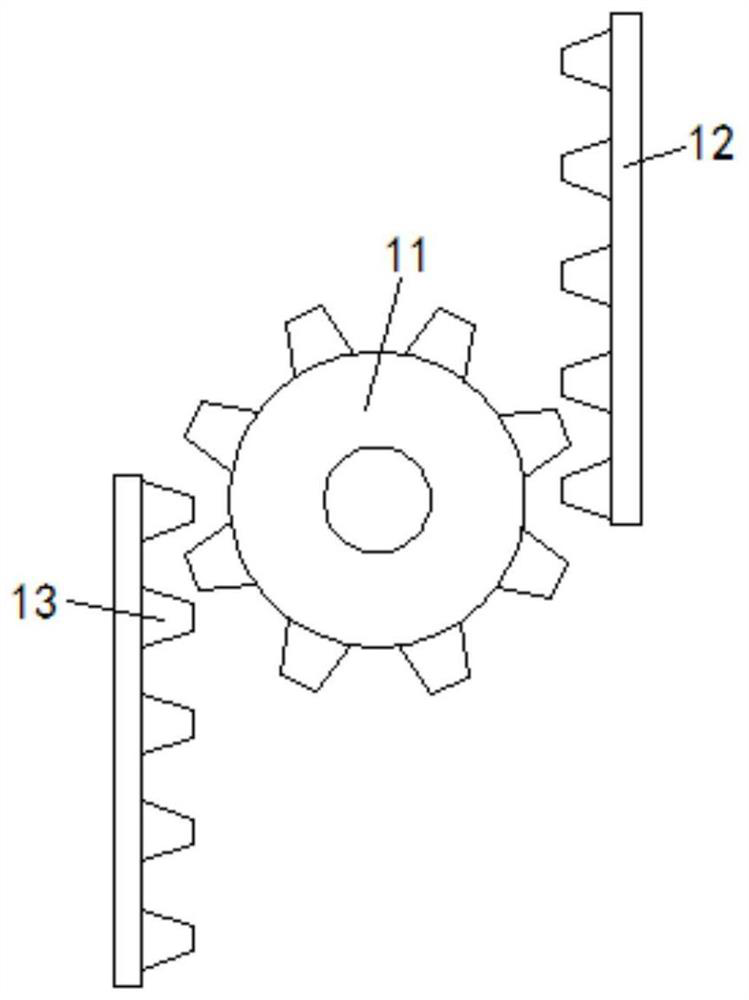

InactiveCN112760847ANo deviationImprove thread cutting efficiencyEmbroidering machines apparatusGear wheelElectric machinery

The invention discloses an automatic thread trimmer. The automatic thread trimmer comprises a mounting plate, two symmetrical combination plates are fixedly connected to the right side of the mounting plate, hinge pieces are fixedly connected to the sides, close to each other, of the combination plates through connecting rods, and two symmetrical power rods and two symmetrical shearing plates are correspondingly and movably connected to the left sides and the right sides of the hinge pieces. The sides, close to each other, of the two combination plates are fixedly connected with a guide plate located on the left side of a hinged plate. A driving motor and a driving tooth block are arranged to enable a traction gear to pull a shearing plate to perform reciprocating thread shearing work, the guide plate and a guide groove are arranged to limit the motion trail of a thread shearing structure, and a reset spring is arranged to perform reset pulling after thread shearing work is finished. Therefore, deviation of the trimming horizontal height and position is avoided, the effect of improving the trimming efficiency is achieved by ensuring that deviation and errors of the trimming position are avoided, and the effect of improving the overall working efficiency is achieved.

Owner:江门市新会区佰通电器科技有限公司

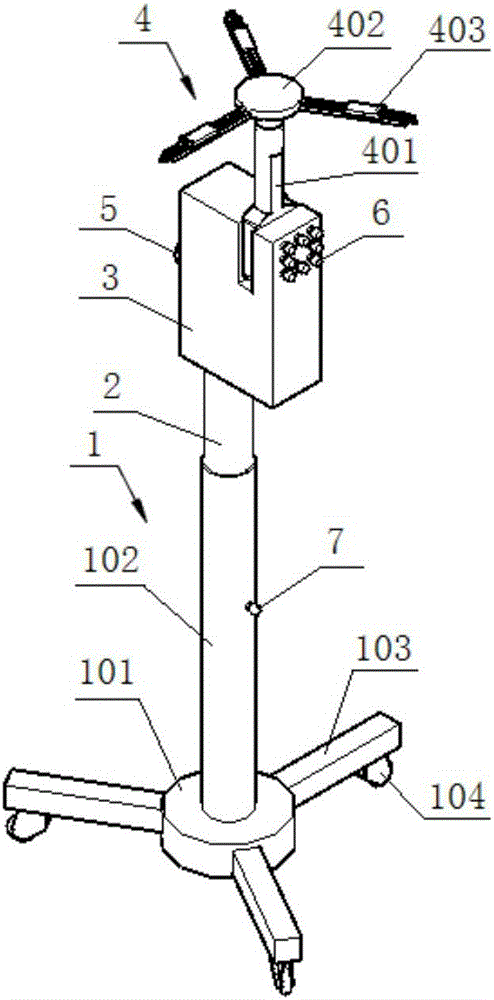

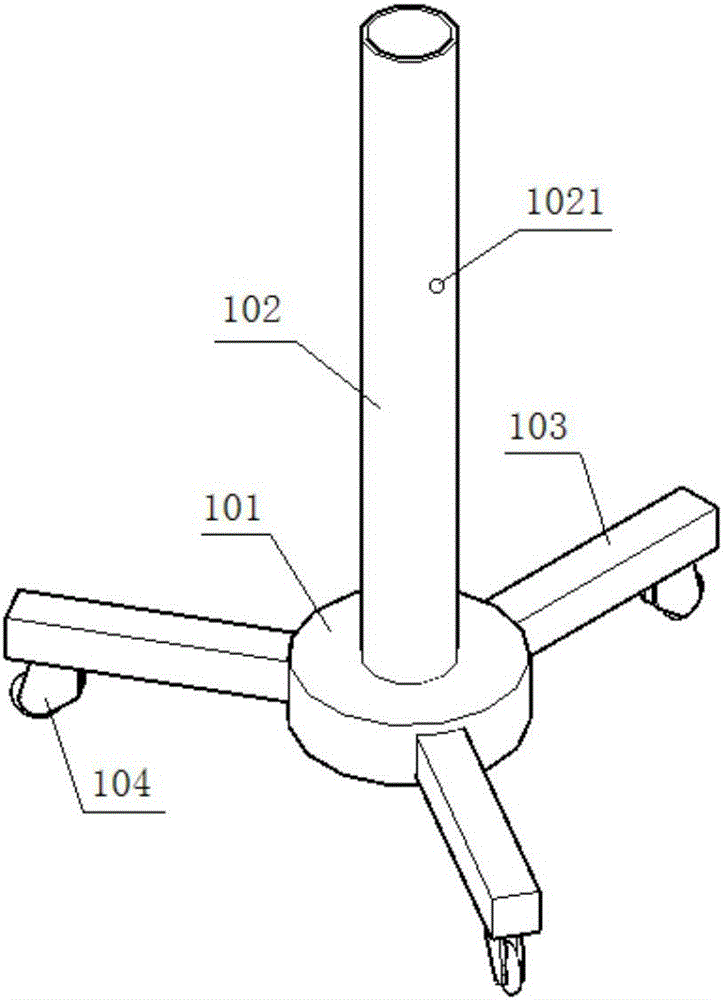

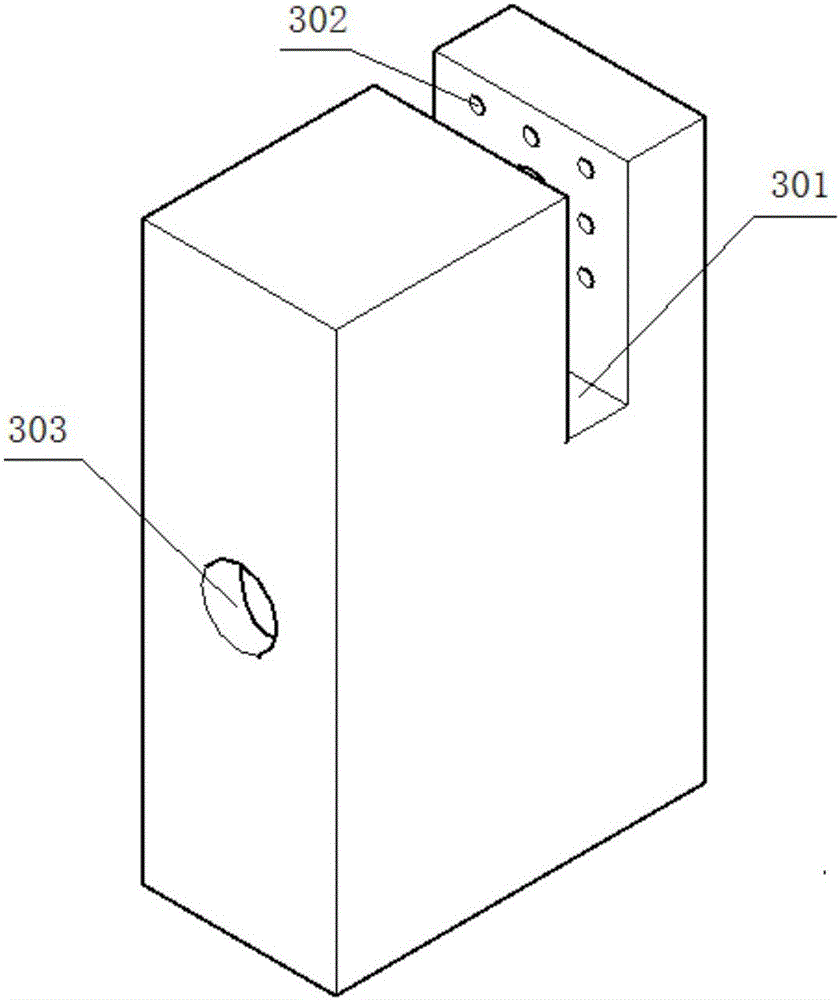

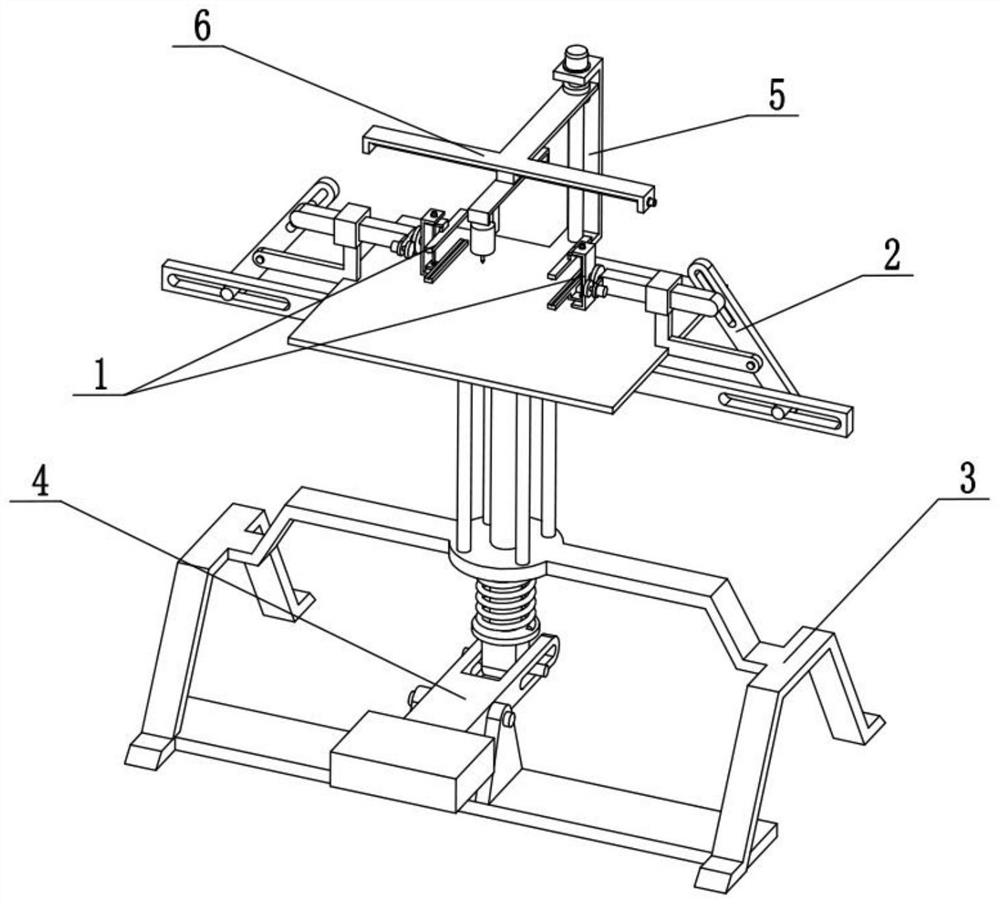

Adjustable embroidering device

InactiveCN106192250AReduce manufacturing costImprove Embroidery EfficiencyHand embroideringEngineeringMaterial resources

The invention provides an adjustable embroidering device. The embroidery device comprises a supporting frame, an adjusting rod, a mounting box and a workbench, wherein the supporting frame comprises a bottom plate and a tubular column fixed to the bottom plate; the adjusting rod is mounted inside the tubular column, and is fixed through an adjusting rod locking component; the mounting box sleeves the upper end of the adjusting rod, and is fixed through a mounting box locking component; the workbench is mounted on the mounting box, and is fixed through a plurality of rotating shaft fixing components. Through arrangement of the adjusting rod, adjustment of an embroidering frame in the height direction can be achieved; through arrangement of the mounting box, the adjusting rod is connected with the workbench, so that any-angle rotational adjustment of the workbench in a plane can be achieved, and the inclination can be adjusted; in addition, through arrangement of adjusting components, using requirements of embroidering supports with different sizes can be met, so that manpower and material resources for producing a plurality of embroidering frames in allusion to the embroidering supports with different sizes are avoided, the using cost of the embroidering frame is greatly reduced, and the production efficiency is improved.

Owner:贵州省台江吉玉鸟文化产业有限责任公司

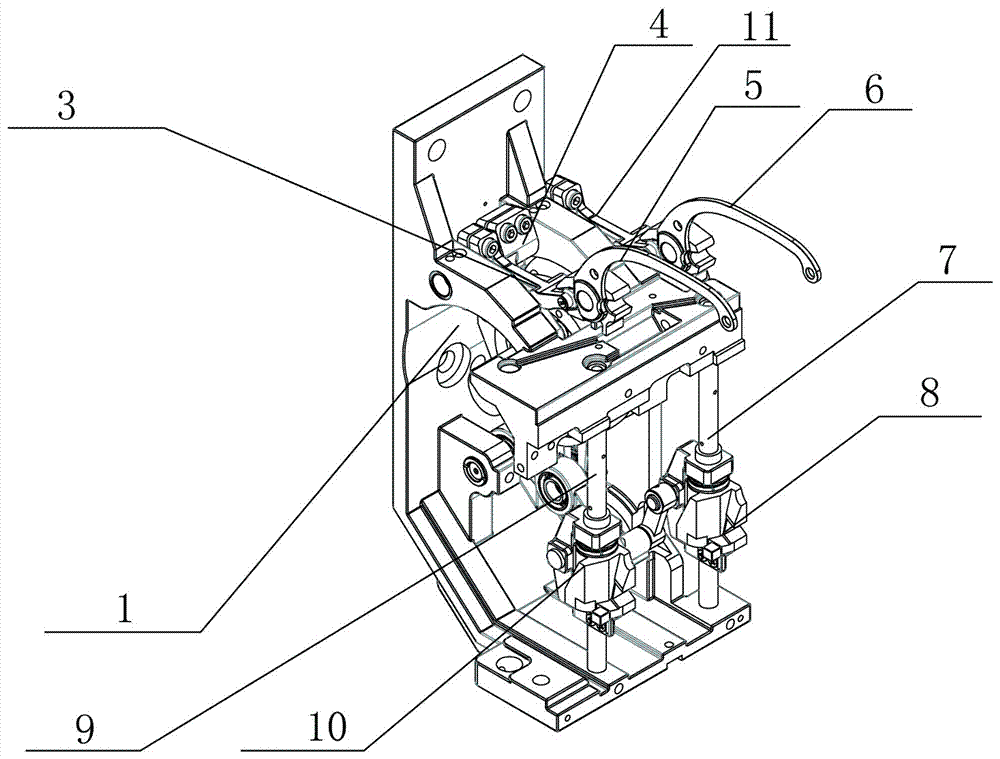

Multi-gold sheet conveying device and embroidery machine

PendingCN109695108AAvoid flippingOmit rise timeAutomatic machinesAuxillary devicesEngineeringMechanical engineering

Owner:黄宇婷

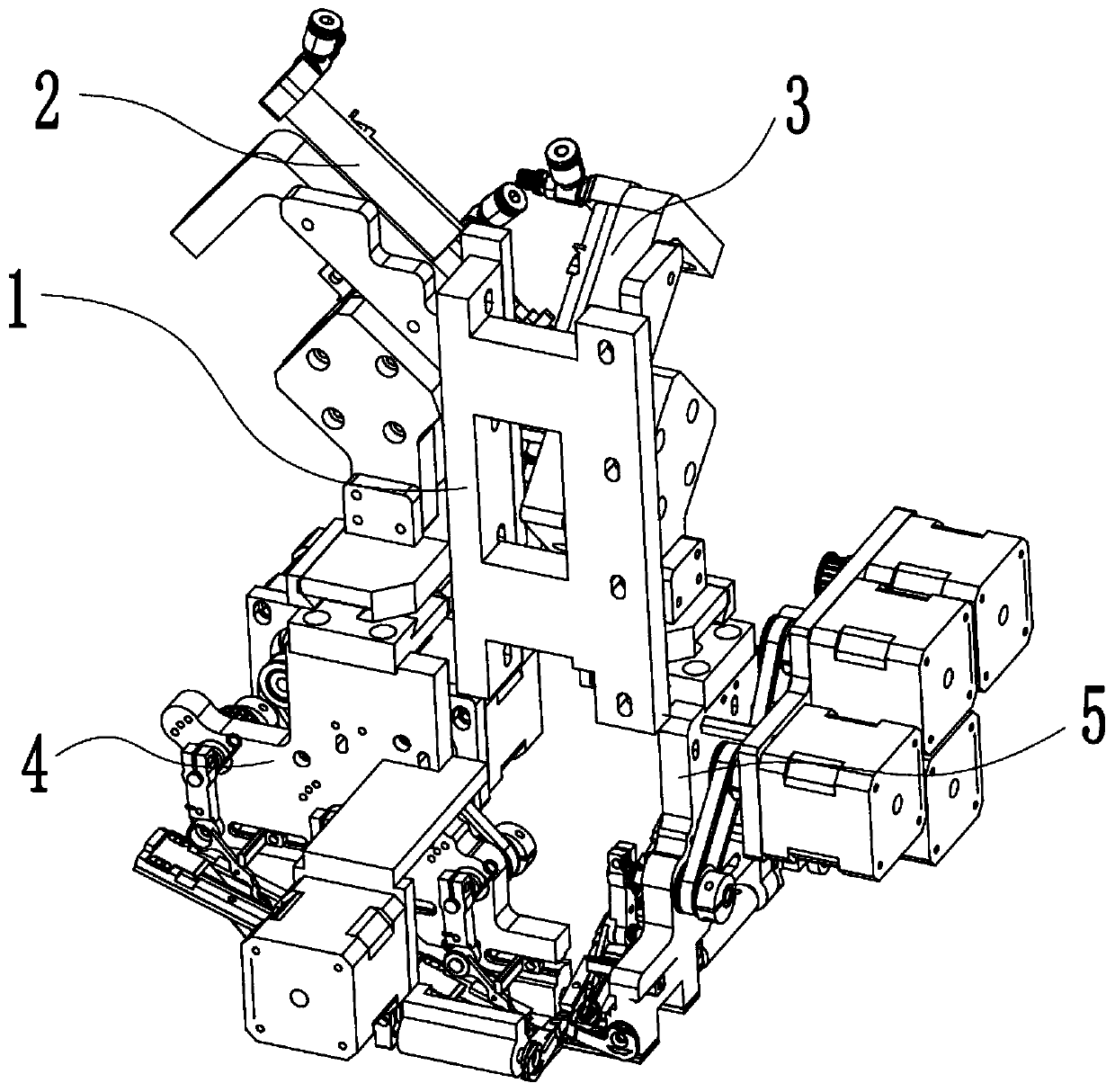

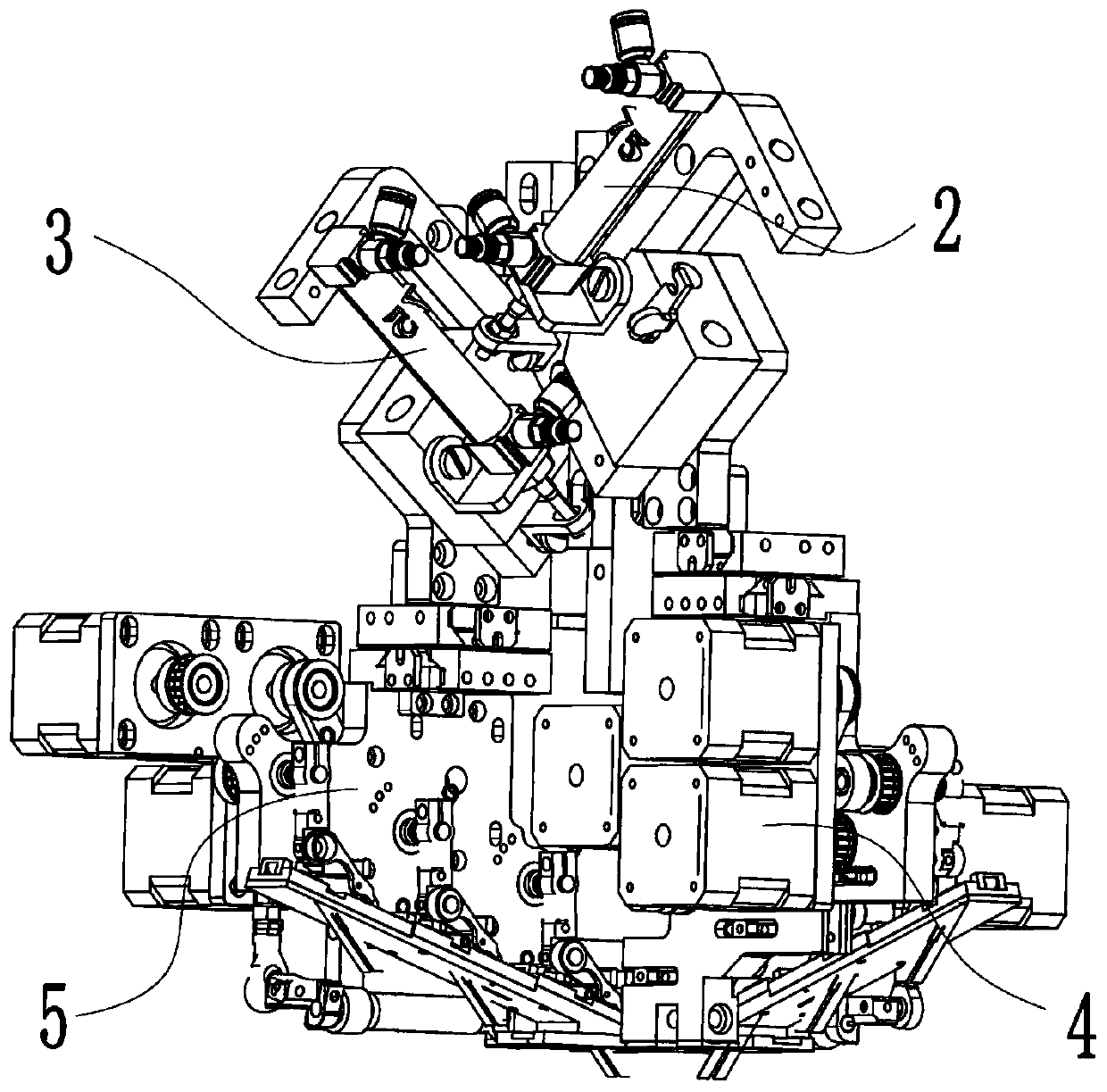

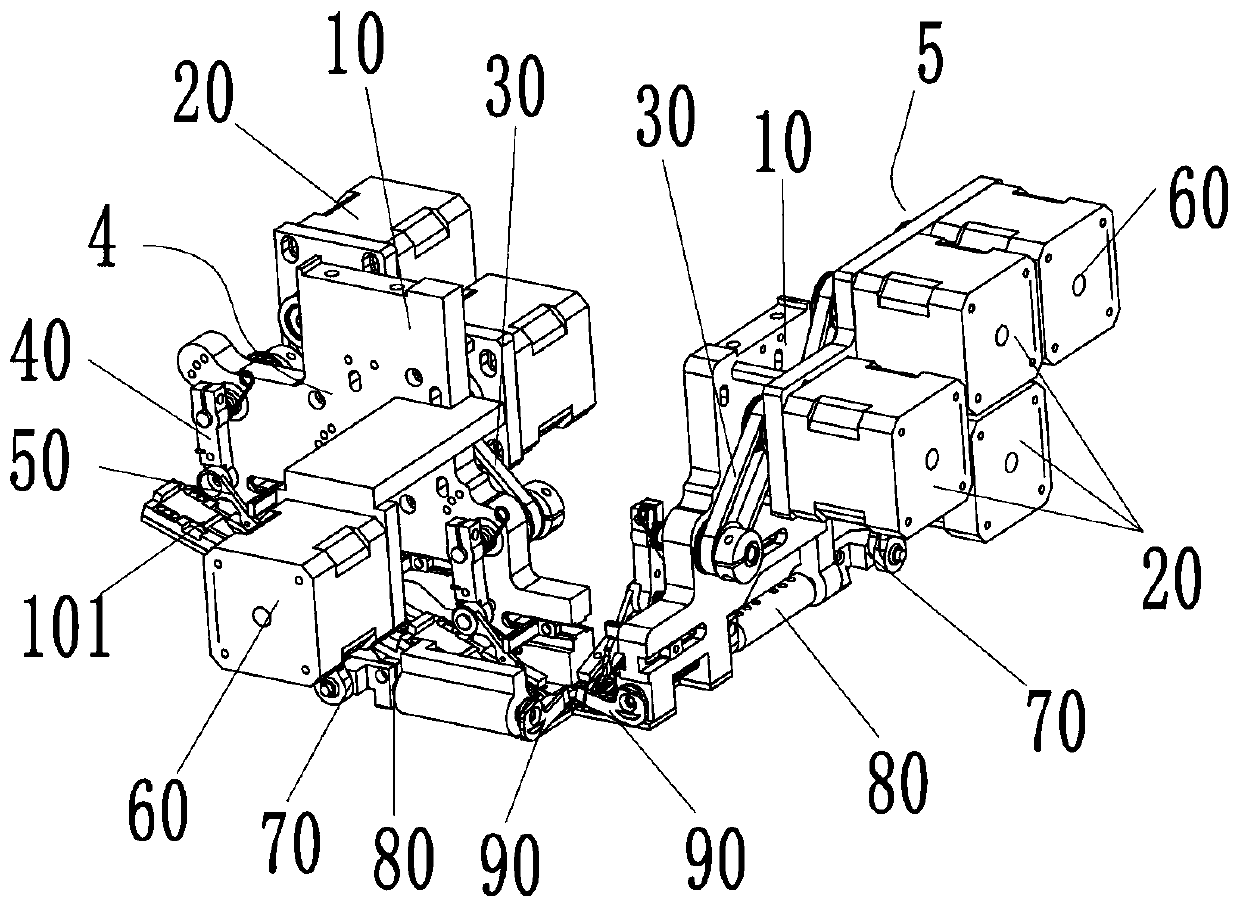

Double-needle bi-color embroidery machine head with stiletto function

The invention discloses a two-needle two-color embroidery machine head with the function of carving holes, which comprises the embroidery machine head, a needle bar frame which can move left and right is connected to the machine head, and more than two needle bars are installed on the needle bar frame and a thread take-up bar, the needle bar is driven by a needle bar driver, the thread take-up bar is driven by a thread take-up shaft, the needle bar driver includes a first needle bar driver and a second needle bar driver, the first needle bar driver inserts and drives the first needle At the same time, the second needle bar driver is inserted to drive the second needle bar. After the needle bar frame moves, the first needle bar driver is inserted to drive the third needle bar, and the second needle bar driver is inserted to drive the fourth needle bar. In the present invention, the first needle bar driver and the second needle bar driver cooperate with two sets of double-needle needle bars respectively to realize two sets of double-needle embroidery functions, thereby greatly improving embroidery efficiency.

Owner:ZHEJIANG YUELONG SEWING EQUIP

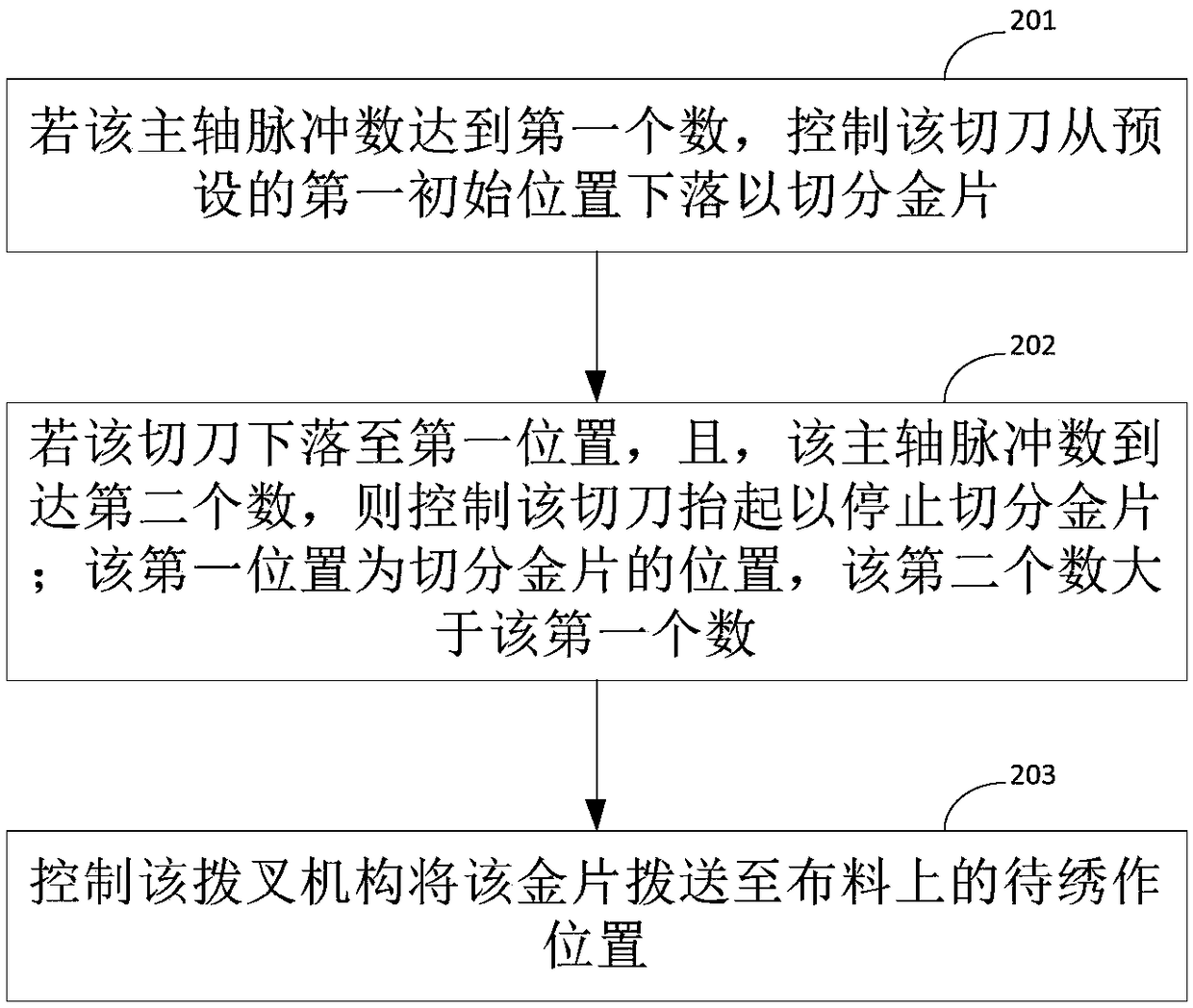

Embroidery control method, embroidery control apparatus, embroidery control equipment and storage medium

InactiveCN109281079AEasy to controlAccurate judgmentAutomatic machinesAuxillary devicesControl equipmentCotton material

The invention provides an embroidery control method, an embroidery control apparatus, embroidery control equipment and a storage medium. The embroidery control method comprises: if the number of the pulses of a main shaft achieves a first number, controlling a cutter to fall from a preset first initial position to cut a gold sheet; if the cutter falls to the first position and the number of the pulses of the main shaft achieves a second number, controlling the cutter to be lifted to stop the cutting of the gold sheet, wherein the first position is the gold sheet cutting position, and the second number is greater than the first number; and controlling a fork mechanism to push the gold sheet to a to-be-embroidered position on a fabric. With the method of the present invention, the embroideryefficiency is improved, and the stability of the embroidery product quality is improved.

Owner:BEIJING DAHAO TECH +2

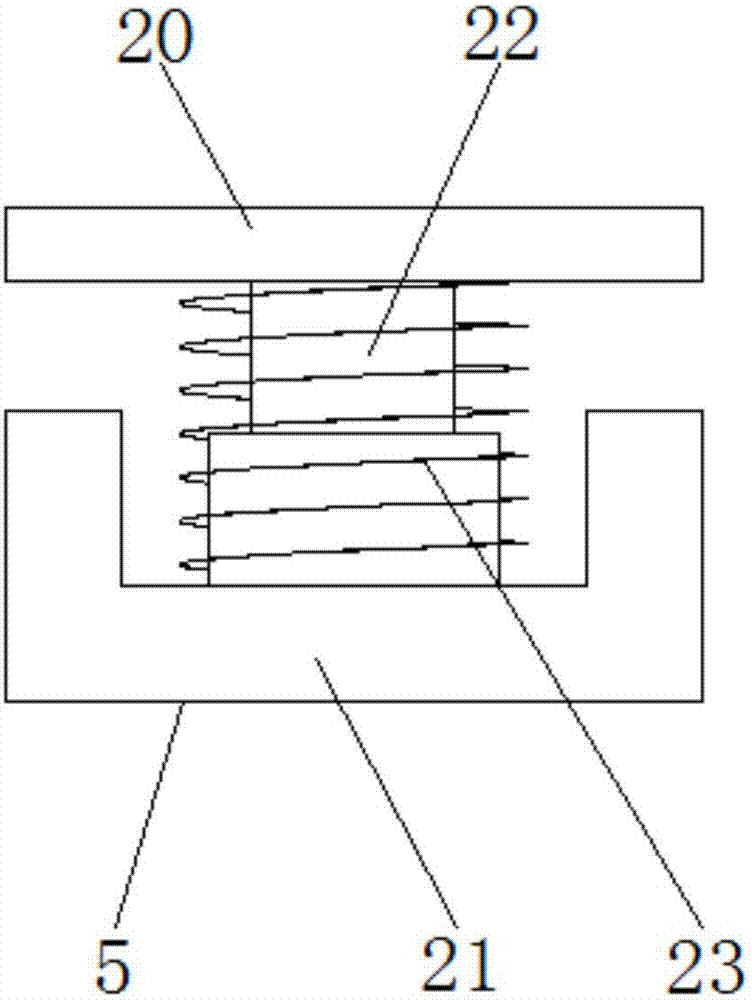

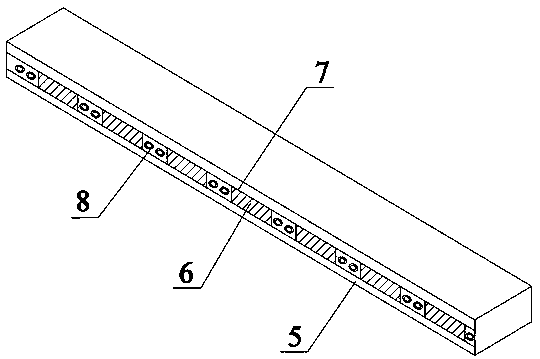

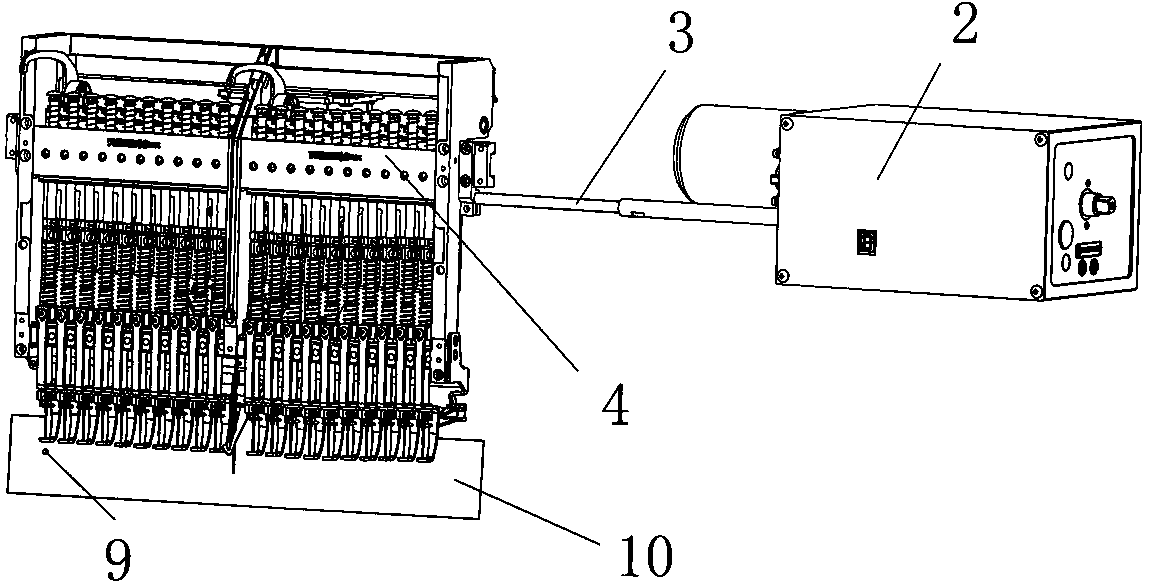

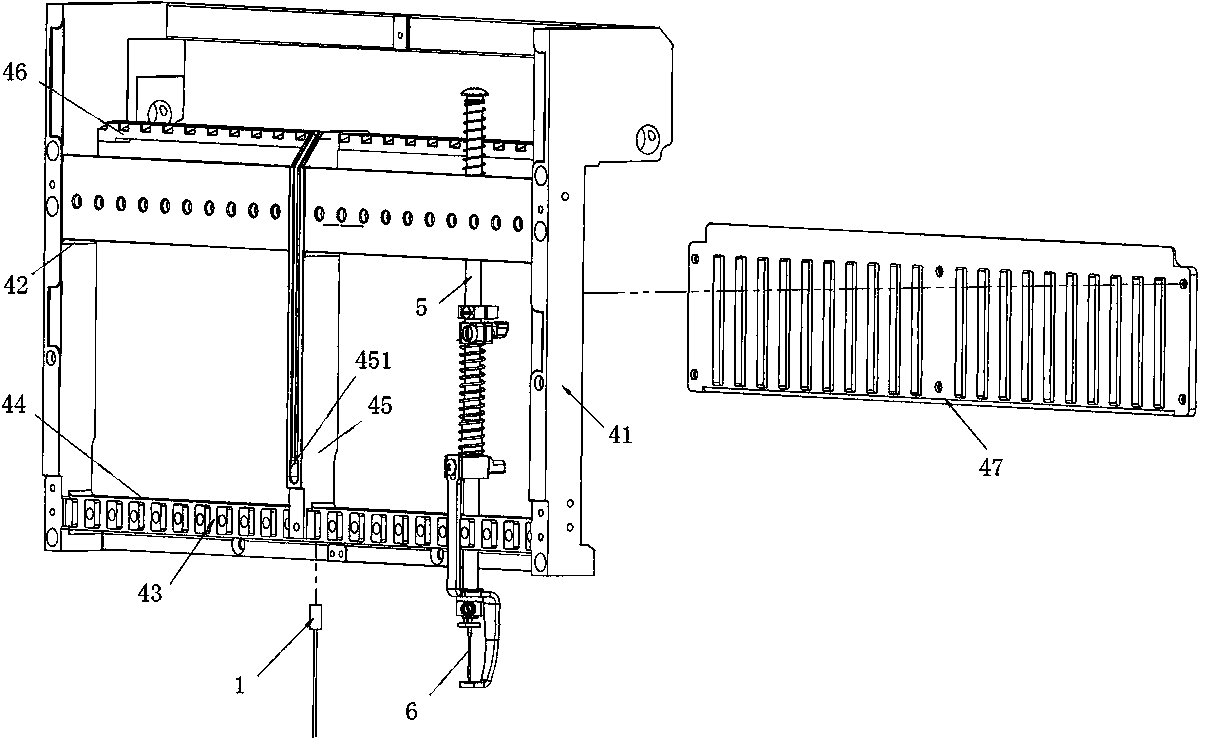

Ring making mechanism of towel embroidery computer embroidery machine

PendingCN110965223AOvercome the raised ringwormOvercoming failures caused by descentEmbroidering machines apparatusEngineeringStructural engineering

The invention relates to a ring making mechanism of a towel embroidery computer embroidery machine. Multiple ring shuttles are horizontally arranged on a ring shuttle installation plate in equal height and distance; fixed cutter brackets are respectively installed at two ends of the ring shuttle installation plate; two tops of a trimming fixed cutter and an elastic sheet support part are stacked,and respectively connected with two tops of the fixed cutter brackets fixedly; line clamping elastic-sheets in one-to-one correspondence with the ring shuttles are arranged on the elastic sheet support part; a locating rod bracket and a locating rod corresponding to each ring shuttle are arranged outside the ring shuttle installation plate; and a locating wedge nail in inter-tooth matched movablecontact connection with corresponding ring shuttle teeth is arranged at the inner end part of the locating rod. By means of the ring making mechanism of the towel embroidery computer embroidery machine in the invention, the machine fault due to the fact that the ring shuttles need to frequently lift in ring making, colour changing and trimming processes and the offset problem due to resetting of the ring shuttles after trimming can be solved; therefore, the stability and the reliability of a machine are improved; furthermore, the production efficiency is increased; and the product quality is ensured.

Owner:FOSHAN QICHUANG TECH DEV

Multi-functional embroidery machine and embroidery method thereof

InactiveCN112323281AAvoid crooked embroideryImprove Embroidery EfficiencyAuxillary devicesFeedersStructural engineeringMechanical engineering

The invention relates to the technical field of embroidery machines, in particular to a multi-functional embroidery machine and an embroidery method thereof, which can tighten cloth and carry out embroidery on the reverse side of the cloth at the same time. The multi-functional embroidery machine comprises a cloth clamping assembly, a cloth tightening assembly, an integral frame assembly, a foot stepping linkage assembly, a height adjusting assembly and a breadth moving assembly. The method comprises the following steps: 1, stepping on a pedal plate with a foot, thus allowing a groove bottom plate and a convex block cover plate at the left end to be close to a groove bottom plate and a convex block cover plate at the right end; 2, flatly laying two ends of cloth between the groove bottom plates and the convex block cover plates on the same sides correspondingly, driving the groove bottom plates and the convex block cover plates on the same sides by two clamping motors to get close to clamp the two ends of the cloth correspondingly, loosening the pedal plate, and thus enabling two tightening sliding rods to get away from each other to tighten the cloth; and 3, after the embroidery machine finishes embroidery on the front surface, simultaneously driving two vertical sliding plates by two turnover motors to rotate in the same direction, driving the cloth to turn over through the two pairs of groove bottom plates and convex block cover plates, and thus enabling the back surface of the cloth to be upward.

Owner:张秋菊

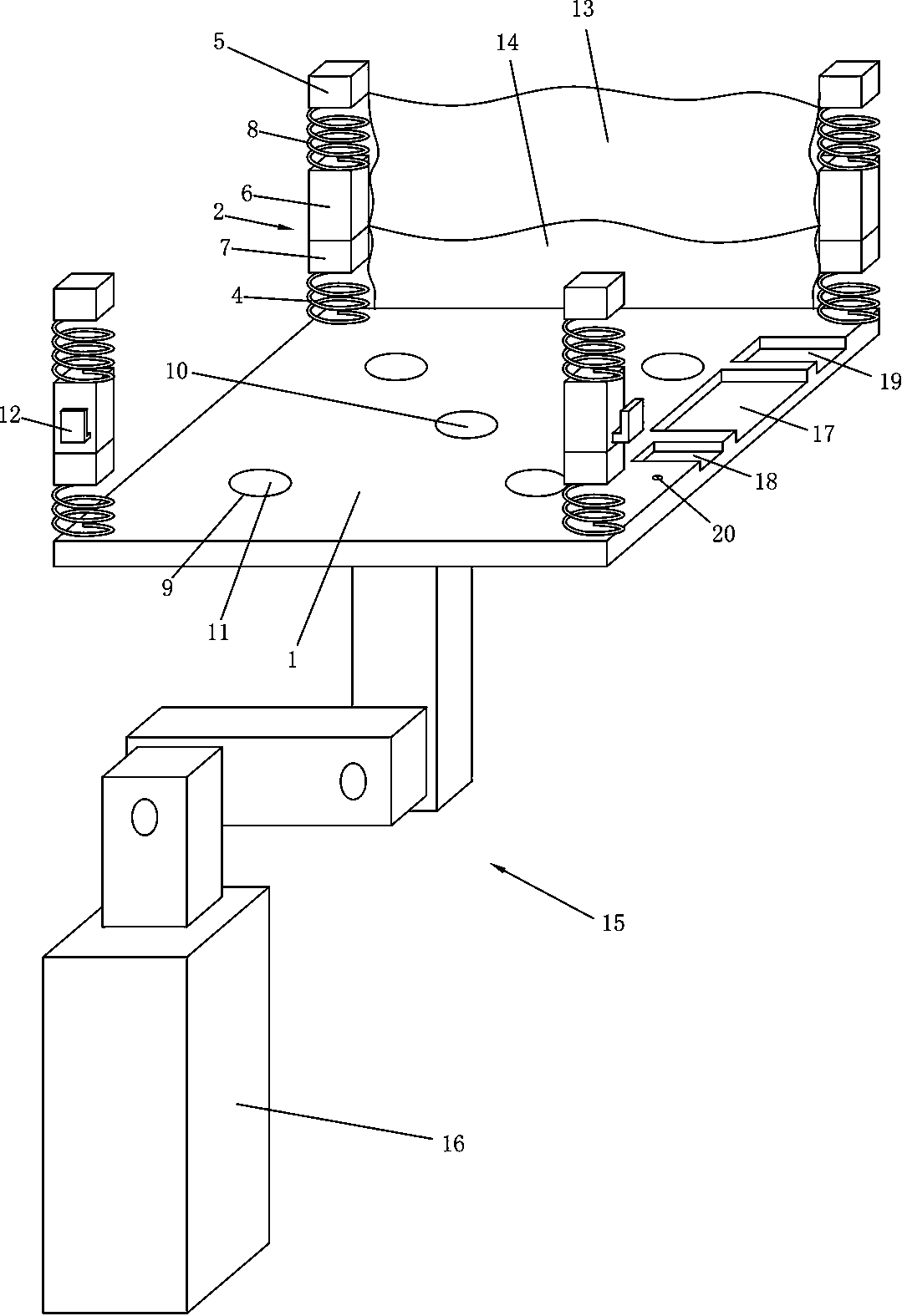

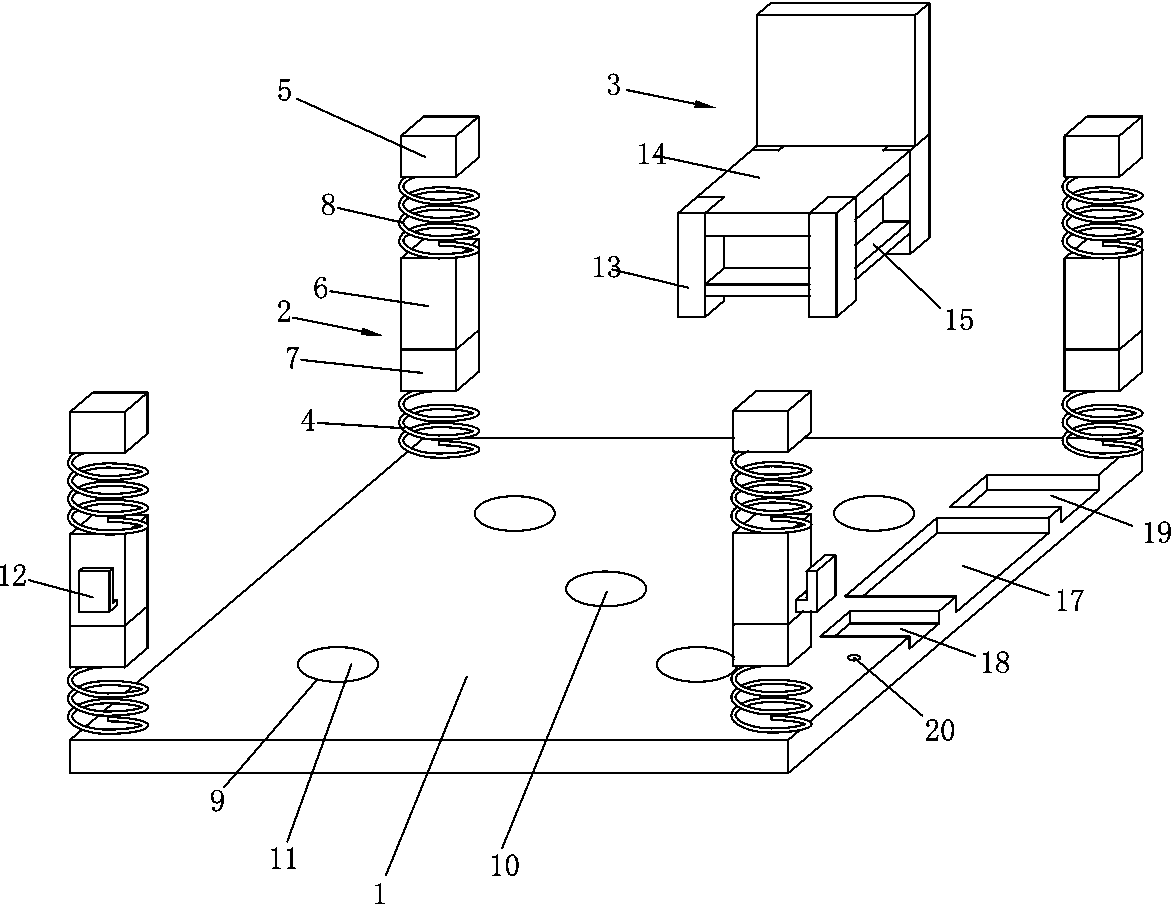

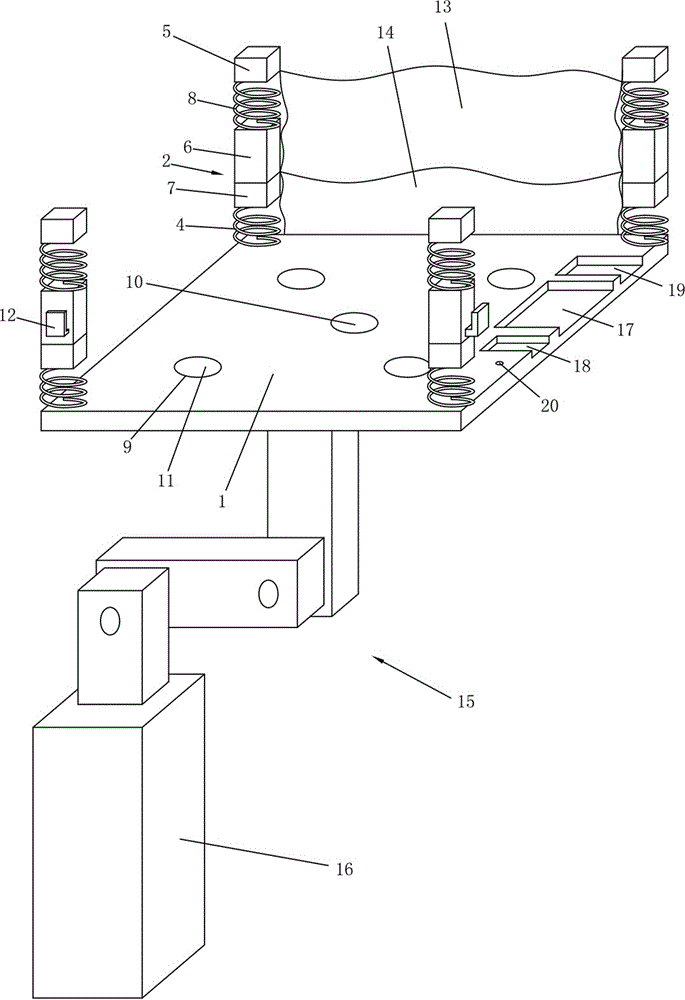

A cross-stitch rocker stand

ActiveCN106192249BGuaranteed stable workSolve problems that are difficult to embroider by handHand embroideringEngineeringRocker arm

The invention discloses a cross-stitch rocker arm platform. The cross-stitch rocker arm platform comprises a base plate, four upright pillars and a chair, wherein the four upright pillars are connected with the base plate, a hydraulic arm is connected to the lower surface of the base plate and comprises a base, and the base is placed on the ground and can move and overturn relatively to the ground; first springs are arranged at the bottom ends of the upright pillars, buckles to be connected with cross-stitch cloth are arranged on the top ends of the upright pillars, and the upright pillars are fixedly connected with the first springs and are connected with the base plate through the first springs; and the base plate is of a rectangle, the four upright pillars are respectively distributed at four corners of the base plate and comprise lower pillars and upper pillars, the lower pillars are connected with the first springs, and the upper pillars are connected with the buckles through second springs and are connected with the lower pillars. The cross-stitch rocker arm platform is a cross-stitch cloth expanding tool designed aiming at big cross-stitches, the big cross-stitches can be well expanded and fixed, and multiple different cross-stitch cloth placement manners such as horizontal placement, oblique placement and vertical placement can be provided, thereby meeting requirements of different workers.

Owner:吴琳方

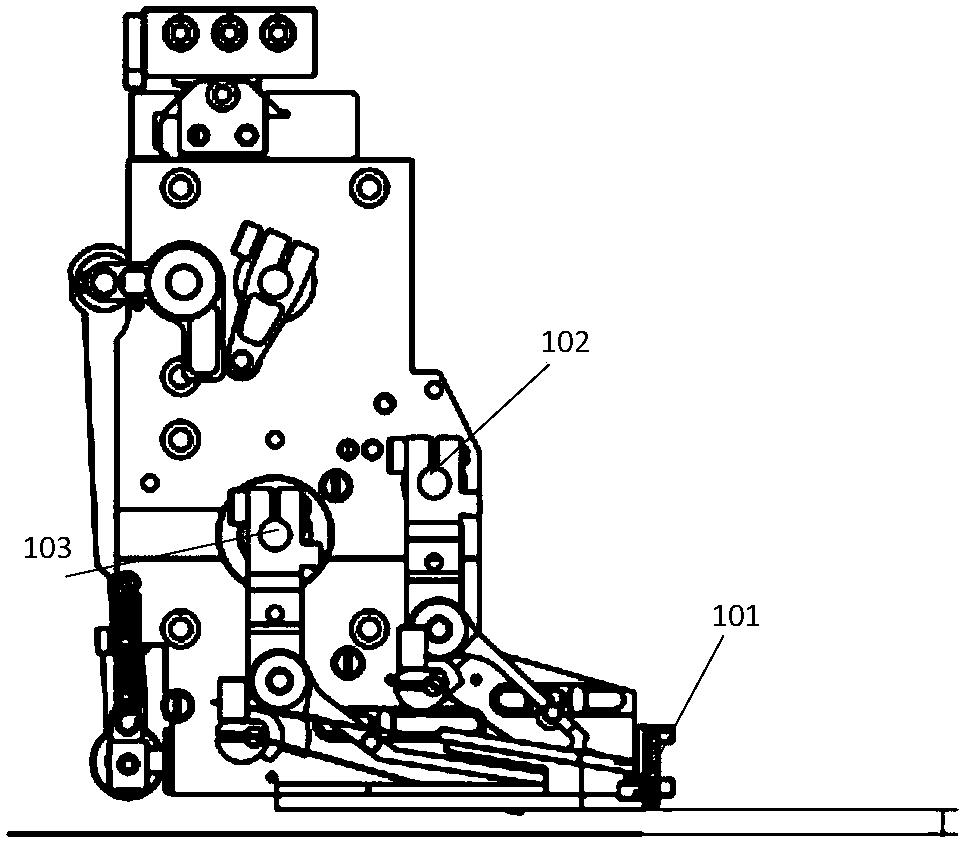

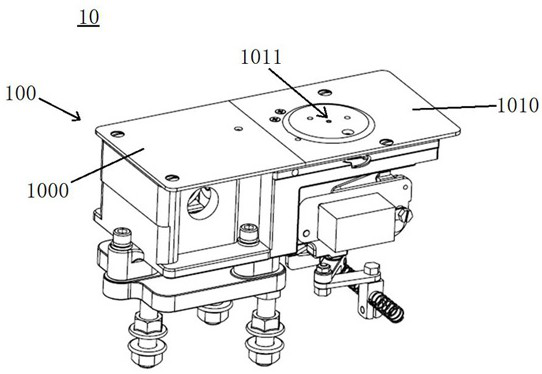

Computerized embroidery machine with dynamic keeping mechanism and working method of computerized embroidery machine

PendingCN113106648AHigh success rate of knottingSimple structureEmbroidering machines apparatusEngineeringMechanical engineering

The invention discloses a computerized embroidery machine with a dynamic keeping mechanism and a working method of the computerized embroidery machine, and relates to the technical field of computerized embroidery machines. The computerized embroidery machine comprises a shuttle box body component and the dynamic keeping mechanism; the shuttle box body component comprises a shuttle box with a needle plate, a fixed cutter and a movable cutter, wherein the fixed cutter and the movable cutter are arranged in the shuttle box; a needle plate hole is formed in the needle plate; the dynamic keeping mechanism is arranged in the shuttle box and comprises a keeping piece located on the back side of the needle plate, and a shifting piece, a torsional spring and a mounting pin; the mounting pin is fixedly connected to the back face of the needle plate; the shifting piece is rotatably arranged on the mounting pin in a sleeving mode; the torsional spring is arranged between the needle plate and the shifting piece to provide restoring force for the shifting piece, and the shifting piece is connected with the keeping piece; a central hole is formed in one end of the keeping piece; and when the movable cutter is opened relative to the fixed cutter, the movable cutter drives the shifting piece to rotate around the mounting pin, and meanwhile the shifting piece drives the keeping piece to linearly move towards the needle plate hole till the central hole is aligned with the needle plate hole. The embroidery quality and efficiency of the embroidery machine can be improved, the structure of the embroidery machine is simplified, and the cost is reduced.

Owner:ZHEJIANG YUELONG SEWING EQUIP

Thread-hooking oscillating shuttle device of tuft embroidery machine and automatic control method thereof

InactiveCN101629364BIncrease speedImprove Embroidery EfficiencyTufting apparatusAutomatic controlAutomotive engineering

Owner:TAIYUAN DAHAOYIDA ELECTRICAL CONTROL +2

a cross stitch tool

InactiveCN106012355BImprove Embroidery EfficiencyImprove qualityHand embroideringEngineeringFastener

The invention discloses a cross-stitch tool. The cross-stitch tool comprises a rectangular base plate, four standing columns connected with the base plate and a chair, wherein a rotary disc placed on the ground is connected to the lower surface of the base plate, the base plate can rotate relative to the ground, a first spring is arranged at the bottom end of each standing column, a fastener for being connected with cross-stitch cloth is arranged at the top end of each standing column, each standing column is connected with the base plate through the corresponding first spring, the four standing columns are distributed at the four corners of the base plate, each standing column comprises a lower column connected with the corresponding first spring and an upper column connected with the corresponding fastener, each upper column is connected with the corresponding fastener through a second spring, each upper column is connected with the corresponding lower column, the lower end of each upper column is provided with an outer thread and a groove close to the outer thread, the upper end of each lower column is provided with an inner thread which meshes with the corresponding outer thread, and the length of each inner thread is equal to the sum of the lengths of the corresponding outer thread and the corresponding groove. By the cross-stitch tool which is specially designed for the spreading of the cross-stitch cloth of a large cross-stitch product, the large cross-stitch cloth can be well spread and fixed.

Owner:ZHEJIANG JINYUAN IND CO LTD

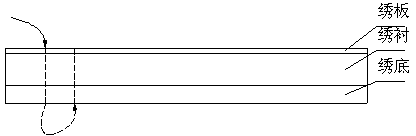

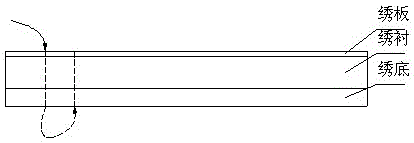

Straight-line type manual embroidery

InactiveCN104178946AVarietyUnique three-dimensional effectEmbroidering machines apparatusEngineeringWool

The invention discloses a straight-line type manual embroidery. The straight-line type manual embroidery comprises an embroidery plate, an embroidery lining and an embroidery bottom. The embroidery is embroidered through the following steps: firstly, printing or drawing a to-be-embroidered pattern on the surface of the embroidery plate; putting the embroidery bottom on a special workbench, then pressing the embroidery lining on the surface of the embroidery bottom, finally, putting the embroidery plate with the pattern on the surface of the embroidery lining, guaranteeing that the surface with the pattern of the embroidery plate faces upward, and fixing a circle with a line along the periphery; according to the pattern on the embroidery plate, inserting an embroidery needle with an embroidery thread from the embroidery plate and passing through the embroidery lining and the embroidery bottom, so as to complete a first stitch, then inserting from the back surface of the embroidery bottom and passing through the embroidery lining and the embroidery plate, so as to complete a second stitch, repeating the steps, and keeping uniform distance between the stitches until the integral pattern is embroidered; splitting between the embroidery bottom and the embroidery lining with a special tool, and taking out the embroidery lining, so as to see wool left on the back of the embroidery plate and form a space pattern. The straight-line type manual embroidery has a unique three-dimensional effect and has the advantages of simplicity and convenience in manufacturing and high efficiency, and the embroidery can be changed according to different patterns.

Owner:孔林飞

A method for positioning auxiliary patterns of needle-embroidered intarsia decorative blankets

ActiveCN104313812BVery popularShorten the timeEmbroidering machines apparatusHand embroideringPaintbrushEngineering

The invention discloses a positioning method of auxiliary patterns of an inwrought applique decorative blanket. The positioning method comprises the following steps of 1, selecting a positioning plate, and on the positioning plate, setting aside a main pattern corresponding zone with the size matching with that of an inwrought applique decorative blanket main pattern and a blank zone located around the main pattern corresponding zone, 2, carving inwrought applique decorative blanket auxiliary pattern hollow structures on the blank zone by a computer engraving machine, and 3, superposing the main pattern of the screen cloth only with the inwrought applique decorative blanket main pattern and the main pattern corresponding zone, covering the screen cloth with a positioning plate, fixing the main pattern of the screen cloth to the corresponding position of the main pattern corresponding zone, and drawing the outlines of the inwrought applique decorative blanket auxiliary pattern hollow structures on the screen cloth by a paintbrush. The positioning method realizes whole positioning of the auxiliary patterns on the screen cloth of the inwrought applique decorative blanket so that in embroidering, an embroidering work does not use a coordinate drawing for contrast and embroidering efficiency is greatly improved.

Owner:SHANGLUO YIJIA NEEDLEPOINT ARTS & CRAFTS CO LTD

Cross-stitch rocker arm platform

ActiveCN106192249AGuaranteed stable workSolve problems that are difficult to embroider by handHand embroideringEngineeringRocker arm

The invention discloses a cross-stitch rocker arm platform. The cross-stitch rocker arm platform comprises a base plate, four upright pillars and a chair, wherein the four upright pillars are connected with the base plate, a hydraulic arm is connected to the lower surface of the base plate and comprises a base, and the base is placed on the ground and can move and overturn relatively to the ground; first springs are arranged at the bottom ends of the upright pillars, buckles to be connected with cross-stitch cloth are arranged on the top ends of the upright pillars, and the upright pillars are fixedly connected with the first springs and are connected with the base plate through the first springs; and the base plate is of a rectangle, the four upright pillars are respectively distributed at four corners of the base plate and comprise lower pillars and upper pillars, the lower pillars are connected with the first springs, and the upper pillars are connected with the buckles through second springs and are connected with the lower pillars. The cross-stitch rocker arm platform is a cross-stitch cloth expanding tool designed aiming at big cross-stitches, the big cross-stitches can be well expanded and fixed, and multiple different cross-stitch cloth placement manners such as horizontal placement, oblique placement and vertical placement can be provided, thereby meeting requirements of different workers.

Owner:吴琳方

Novel cross-stitch needle

InactiveCN106283428AEasy accessReduce difficultyHand embroideringBiomedical engineeringNeedle biopsy

Owner:于家琪

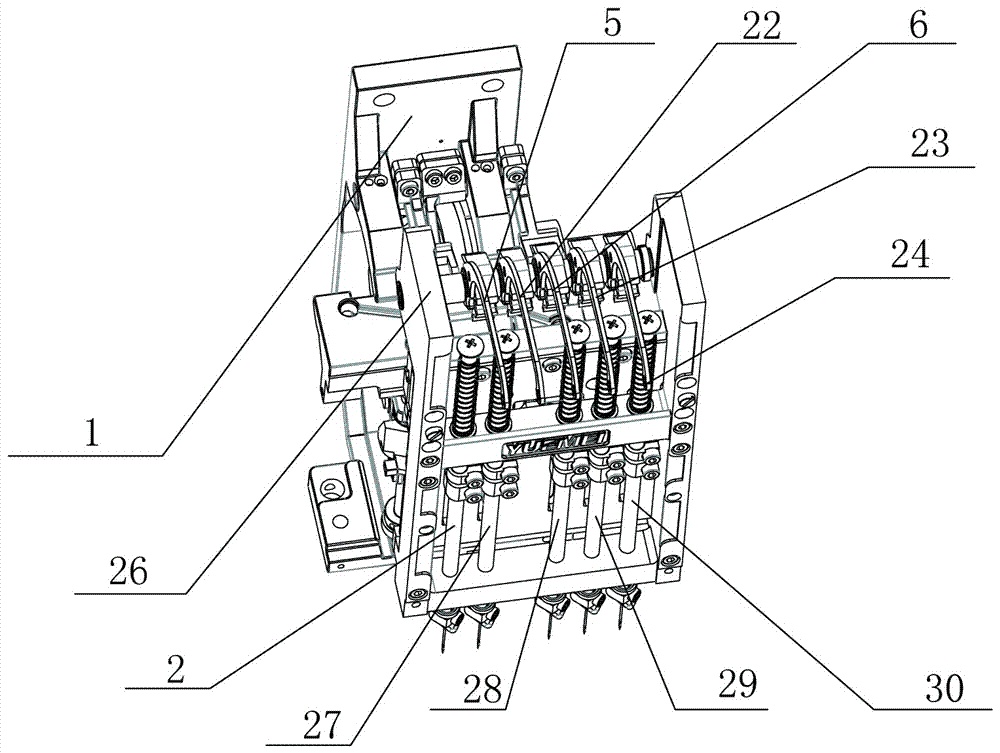

An embroidery machine with super-number of heads and ultra-small head spacing

InactiveCN101225587BIncrease the number of headsEasy to installAuxillary devicesCouplingOptical axis

The invention relates to an embroidery machine, mainly an embroidery machine with a super-number of heads and a super-small head spacing, including a machine head and a hook box, and the upper left shaft and the upper right shaft are connected together by a coupling, wherein the coupling consists of Two semi-cylindrical bodies form a complete cylinder. A baffle is provided on the upper part of the side of the machine head. The side plate is provided with a U-shaped groove that is plugged in with the baffle. The upper part of the side plate passes through the second screw and the baffle. It is connected with the machine head, and the lower part of the side plate is fixedly connected with the machine head through the third screw; the third pin is an optical axis with the same diameter without a shoulder, and the first retaining ring and the second retaining ring are set on the third pin. A three-eye connecting rod is arranged between the first retaining ring and the second retaining ring. The beneficial effects of the present invention are: 1. The coupling can be installed and removed without moving the coupling, and the installation and maintenance are convenient; 2. The difficult problem of side panel installation due to the small distance is solved; The number of heads of ordinary embroidery machines is increased to 60, and the embroidery efficiency is doubled.

Owner:HANGZHOU JINGWEI ELECTRONICS MECHANICAL MFG

one word embroidery hand embroidery

InactiveCN104178946BVarietyUnique three-dimensional effectEmbroidering machines apparatusEngineeringWool

The invention discloses a straight-line type manual embroidery. The straight-line type manual embroidery comprises an embroidery plate, an embroidery lining and an embroidery bottom. The embroidery is embroidered through the following steps: firstly, printing or drawing a to-be-embroidered pattern on the surface of the embroidery plate; putting the embroidery bottom on a special workbench, then pressing the embroidery lining on the surface of the embroidery bottom, finally, putting the embroidery plate with the pattern on the surface of the embroidery lining, guaranteeing that the surface with the pattern of the embroidery plate faces upward, and fixing a circle with a line along the periphery; according to the pattern on the embroidery plate, inserting an embroidery needle with an embroidery thread from the embroidery plate and passing through the embroidery lining and the embroidery bottom, so as to complete a first stitch, then inserting from the back surface of the embroidery bottom and passing through the embroidery lining and the embroidery plate, so as to complete a second stitch, repeating the steps, and keeping uniform distance between the stitches until the integral pattern is embroidered; splitting between the embroidery bottom and the embroidery lining with a special tool, and taking out the embroidery lining, so as to see wool left on the back of the embroidery plate and form a space pattern. The straight-line type manual embroidery has a unique three-dimensional effect and has the advantages of simplicity and convenience in manufacturing and high efficiency, and the embroidery can be changed according to different patterns.

Owner:孔林飞

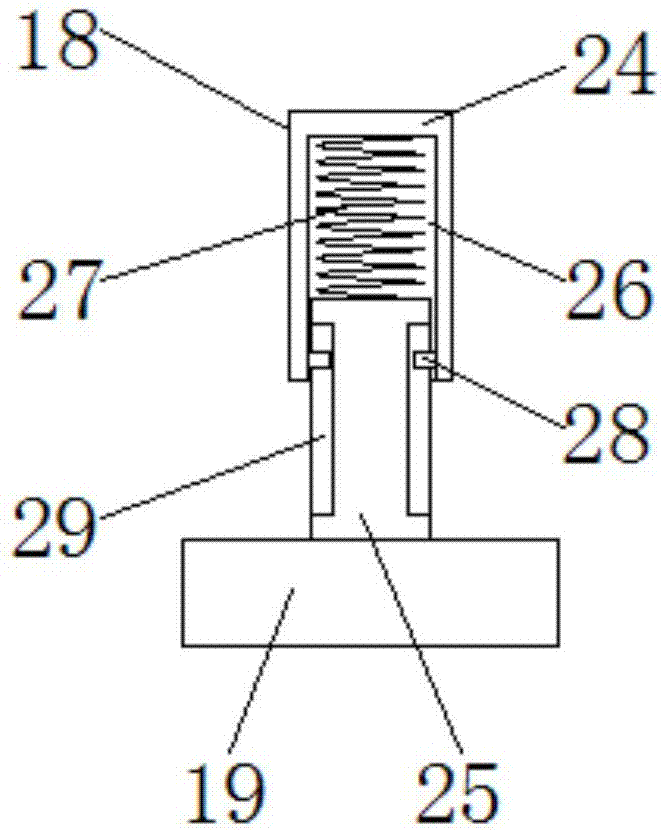

Cloth blocking mechanism used for clothing embroidery device

The invention discloses a cloth blocking mechanism used for a clothing embroidery device. The cloth blocking mechanism comprises a fixed frame, an upper pressing plate, a lower pressing plate and an air cylinder, wherein the upper pressing plate is arranged above the lower pressing plate; the fixed frame comprises supporting columns and a cross rod; the supporting columns are separately arranged at the two ends of the lower pressing plate; a fixed ring is arranged on the center of the cross rod; the upper end of the air cylinder is arranged in the fixed ring; the lower end of the air cylinderis connected with the upper pressing plate; both the upper pressing plate and the lower pressing plate are of sandwich structures, and each comprises a bottom plate, a magnet layer arranged on the bottom plate, and a soft layer which is coated outside the magnet layer, the magnet layer comprises a plurality of strip-shaped magnets which are arranged in a spaced mode, a hot circulating pipeline isarranged among the strip-shaped magnets, the hot circulating pipeline comprises a plurality of U-shaped bent tubes, the U-shaped bent tubes are arranged between adjacent two strip-shaped magnets to form a cycle, and a pipeline inlet and a pipeline outlet of the hot circulating pipeline are positioned at the same end. The cloth blocking mechanism solves the problem that embroidered cloth of an existing embroidery device is liable to drop, is liable to deform and wear, and is low in embroidery efficiency.

Owner:HENAN XUMIAN TEXTILE CO LTD

An embroidery machine color changing red light positioning system and method

ActiveCN109706657BAvoid the phenomenon that the needle point cannot be accurately placed in the pattern and the pattern is misplacedPrecise positioningAuxillary devicesControl systemEngineering

The invention discloses an embroidery machine color changing and infrared-light positioning system, and belongs to the technical field of embroidery machines. The system comprises an infrared positioning device, a color changing box and a color changing pull rod; the color changing pull rod is connected with a needle bar frame through a color changing bracket; the color changing box is arranged ona rack cross beam of the needle bar frame and used for controlling the color changing pull rod to drive the needle bar frame to move left and right; a lower cross beam of a frame body of the needle bar frame is provided with the infrared positioning device, so that the infrared positioning device and a needle bar are distributed on a straight line, and a vertical positioning light source is emitted. The system is adopted for the method, and the method comprises the steps that when the color changing box executes a color changing instruction, the needle bar frame is controlled to move to a needle position where the infrared positioning device is arranged according to color changing code parameters, and starting and stopping of the infrared positioning device are triggered. The embroidery machine color changing and infrared-light positioning system and method are precise in positioning and not limited to fixing and positioning of one embroidery needle; moreover, color changing and positioning systems are combined into one system, an embroidery control system is simplified, and the embroidery efficiency is improved.

Owner:浙江镨美科智能刺绣设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com