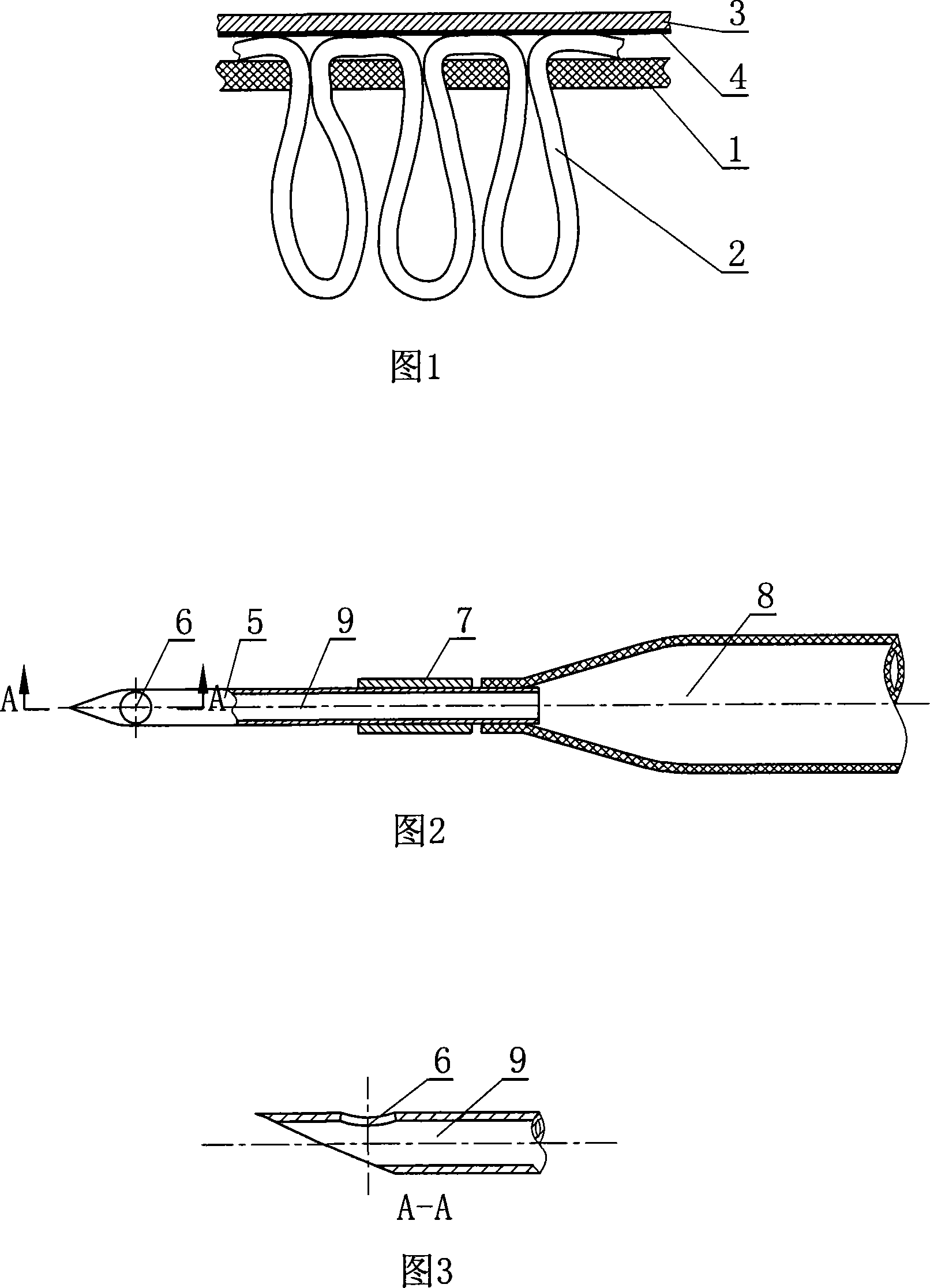

Tambour needle used for thick line and embroidery method thereof

An embroidery and thick thread technology, which is applied to embroidery machines, hand embroidery, embroidery machine mechanisms, etc., can solve the problems of not being able to use thick threads and hand embroidery, etc., to prevent hand soreness, improve embroidery efficiency, and facilitate penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] First outline the pattern to be embroidered with lines on the cloth to be embroidered, fix the cloth to be embroidered on the wooden frame with nails, then select the color of the thick line according to the color required by the pattern, and embroider the outline of the pattern along the drawn lines , and then embroider the area inside the outline with the required thick thread of various colors in the same way, remove the embroidered surface from the wooden frame, and paste the adhesive lining with hot melt adhesive on the embroidery surface, Then press it with an iron or a heat press, and finally hook and sew the embroidered cloth to produce cushions, tapestries, pillows and other products with thick thread embroidery patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com