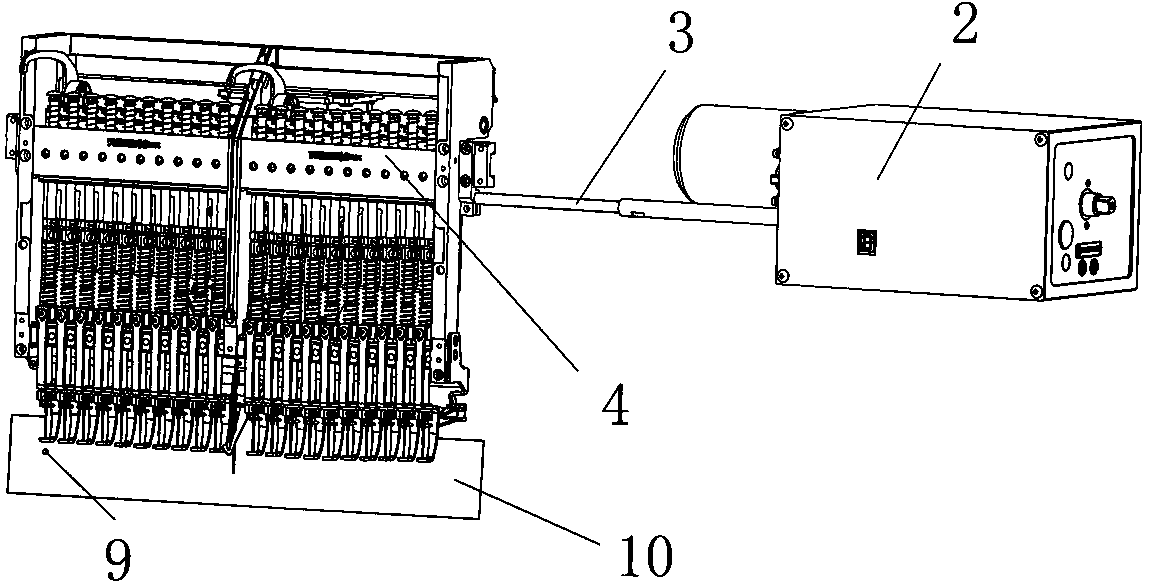

An embroidery machine color changing red light positioning system and method

A red light positioning and embroidery machine technology, applied in the field of embroidery machines, can solve the problems of cumbersome adjustment of positioning points, difficulty in precise positioning, and tilt deformation, etc., and achieve the effects of improving embroidery precision, adapting to pattern spacing changes, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

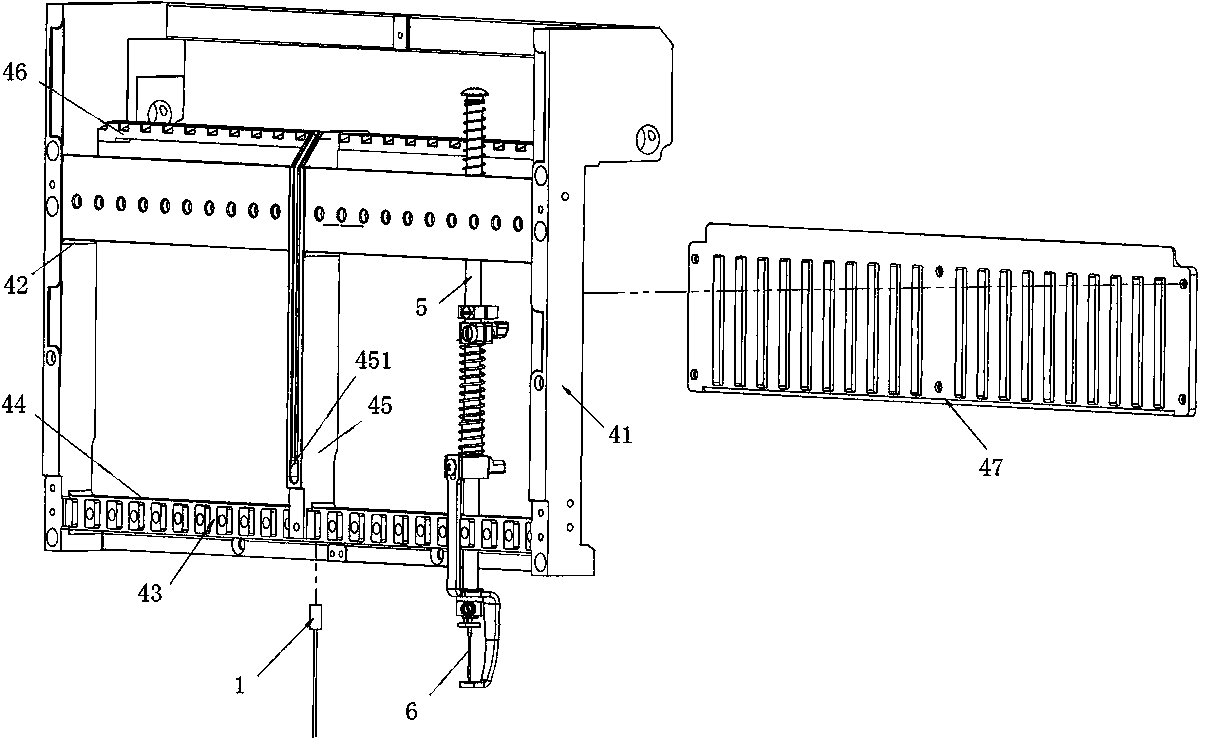

[0031] In one embodiment, the position of the partition 45 on the upper beam 42 is not equal to the distance between the adjacent needle bar holes on both sides, and is not equal to the distance between any adjacent needle bar holes 4 on the upper beam 42 . In another embodiment, the position of the partition 45 on the upper beam 42 is equal to the distance between adjacent needle bar holes on both sides, but not equal to the distance between any adjacent needle bar holes 4 on the upper beam 42 . In another embodiment, one end of the partition 45 is fixedly installed on the upper beam 42, and the other end is fixedly installed on the lower beam 43. The distance between the position of the partition 45 on the upper beam 42 and the adjacent needle bar holes 44 on both sides is equal to that of the upper beam. 42 the spacing between any adjacent needle bar holes 44. The distance between the position of the partition 45 on the lower beam 43 and the adjacent needle bar holes 44 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com