Novel cross-stitch needle

A cross-stitch needle and a new type of technology, applied in embroidery machines, manual embroidery, textiles and papermaking, etc., can solve the problems of time-consuming and labor-intensive cross-stitch efficiency, and achieve the effects of low cost, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

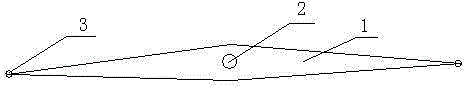

[0018] Accompanying drawing is the specific embodiment of the present invention.

[0019] Such as figure 1 The novel cross-stitch needle of the present invention shown includes a streamlined needle body 1 with a thick middle and thin ends, a through hole 2 is provided in the middle of the needle body 1, a sphere 3 is provided at both ends of the needle body 1, and the diameter of the through hole 2 is 0.6 mm, the diameter of the sphere 3 is 0.2mm.

[0020] During operation, the two hands are respectively on both sides of the embroidery cloth, and the fingers of the left and right hands respectively hold the two ends of the needle body 1 to shuttle back and forth in the embroidery cloth holes, which greatly improves the embroidery efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com