An embroidery machine with super-number of heads and ultra-small head spacing

An embroidery machine and small head technology, which is applied to the field of embroidery machines with excessive head count and ultra-small head spacing, can solve problems such as difficulty in entering and exiting, and achieve the effects of increased embroidery efficiency and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

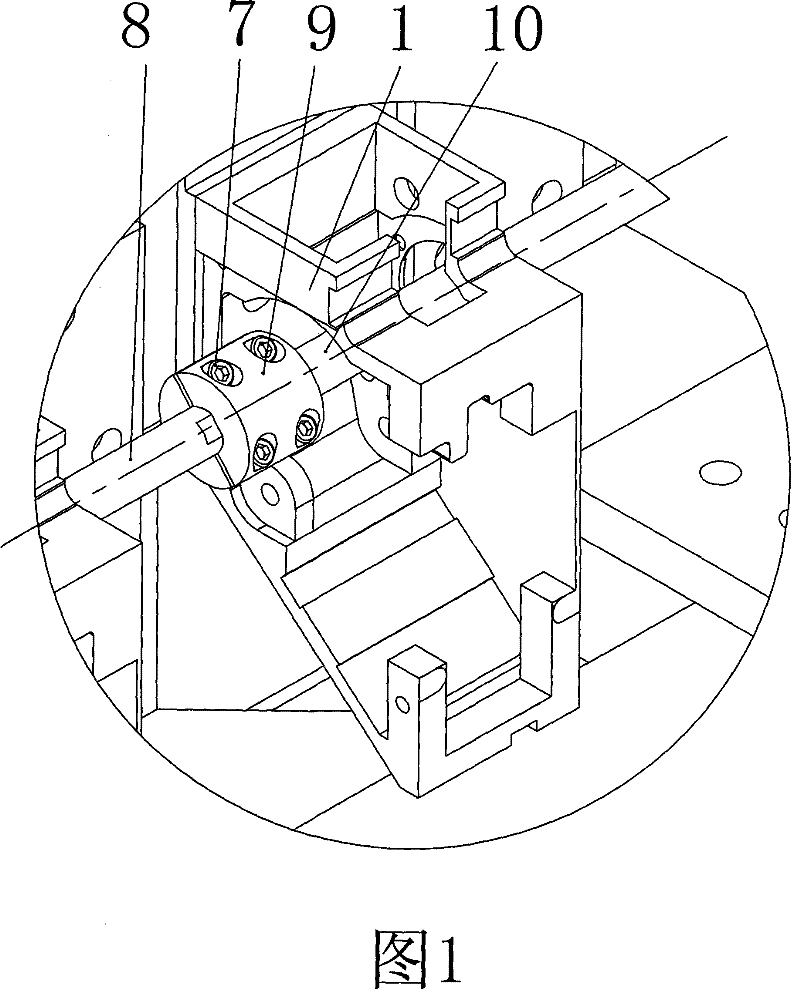

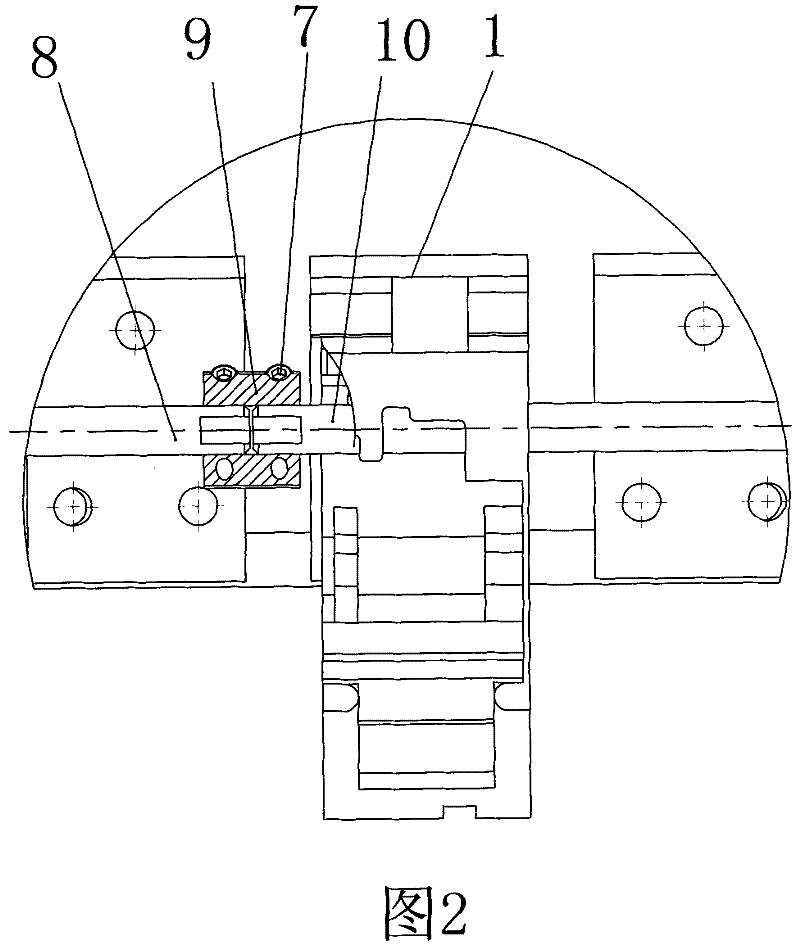

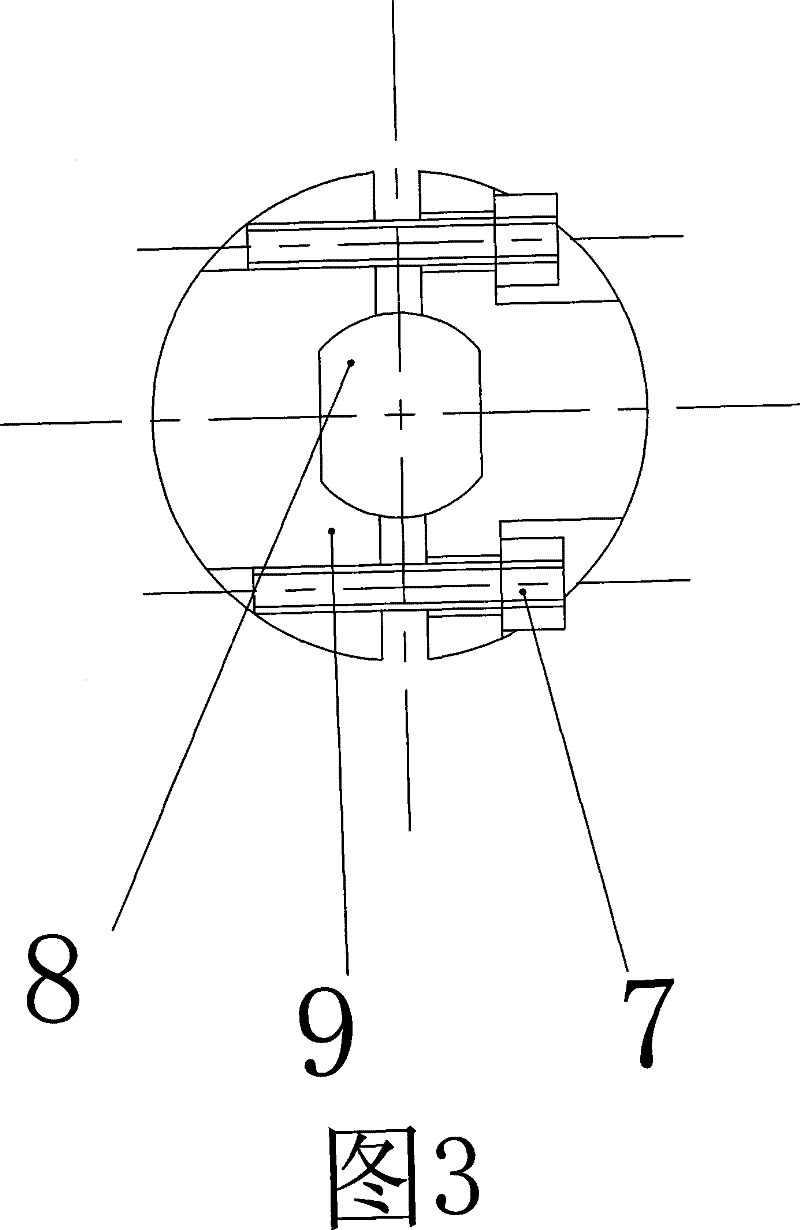

[0022] Such as figure 1 and figure 2 As shown, this embroidery machine with a super-number of heads and an ultra-small head spacing includes a machine head 1 and a hook box, and the upper left shaft 8 and the upper right shaft 10 are connected together by a coupling 9, wherein the coupling consists of two Two half cylinders constitute a complete cylinder, and a cylindrical hole for inserting the two ends of the upper left shaft 8 and the upper right shaft 10 is formed in the coupling. The specific structure of the coupling is as follows: first, on a cylinder Open a cylindrical hole, the diameter of the hole is the same as the diameter of the shaft, and the two ends of the two shafts can be inserted into the holes of the coupling, so that the two shafts are concentric; the second is to divide the cylinder into two parts Second, cut the cylinder in half alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com