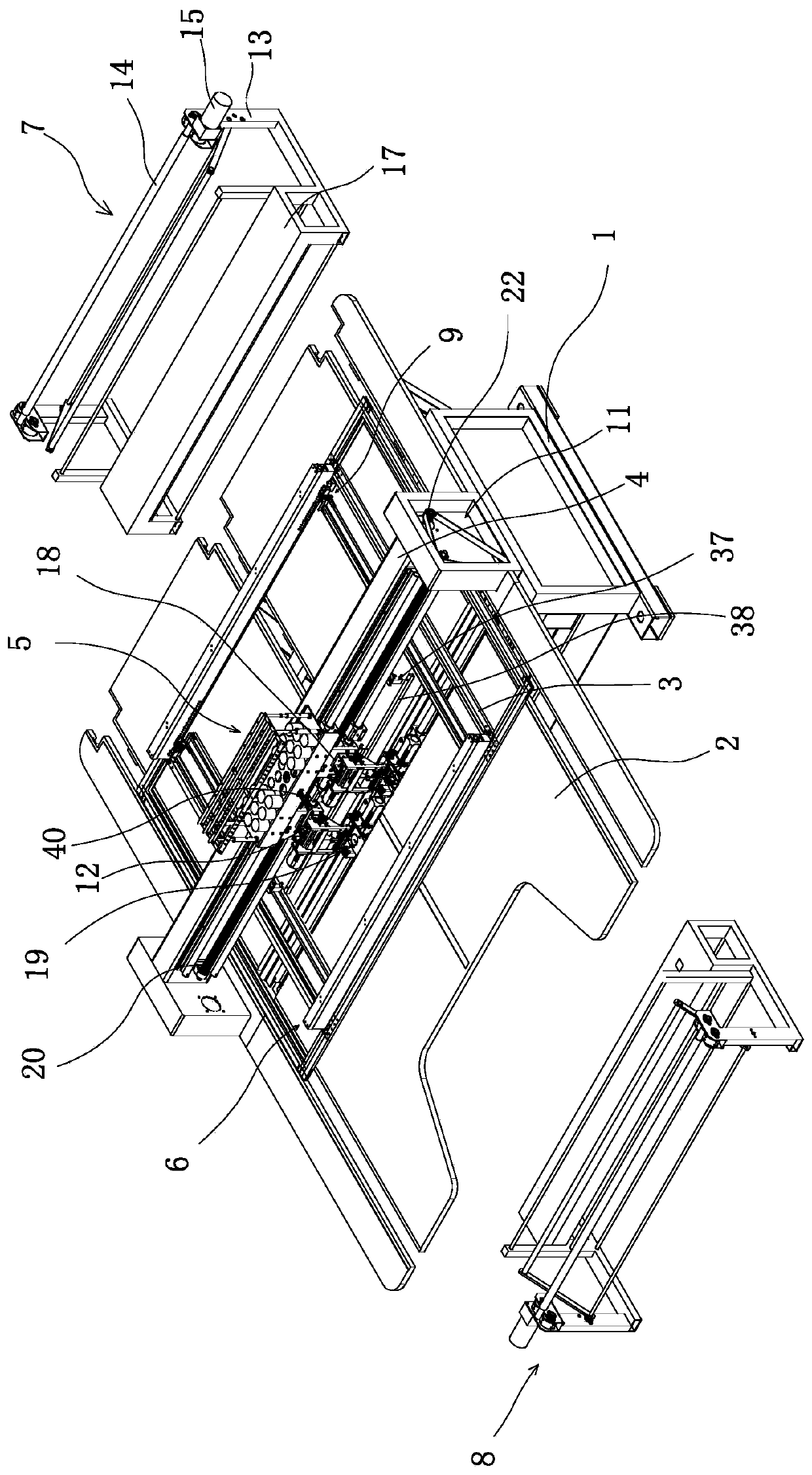

Automatic cloth spreading visual-positioning embroidery equipment

A visual positioning and embroidery technology, which is applied in the field of towel embroidery, can solve problems such as difficulty in ensuring embroidery continuity and affecting work efficiency, and achieve the effects of omitting manual cloth changes, increasing automation, and improving embroidery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

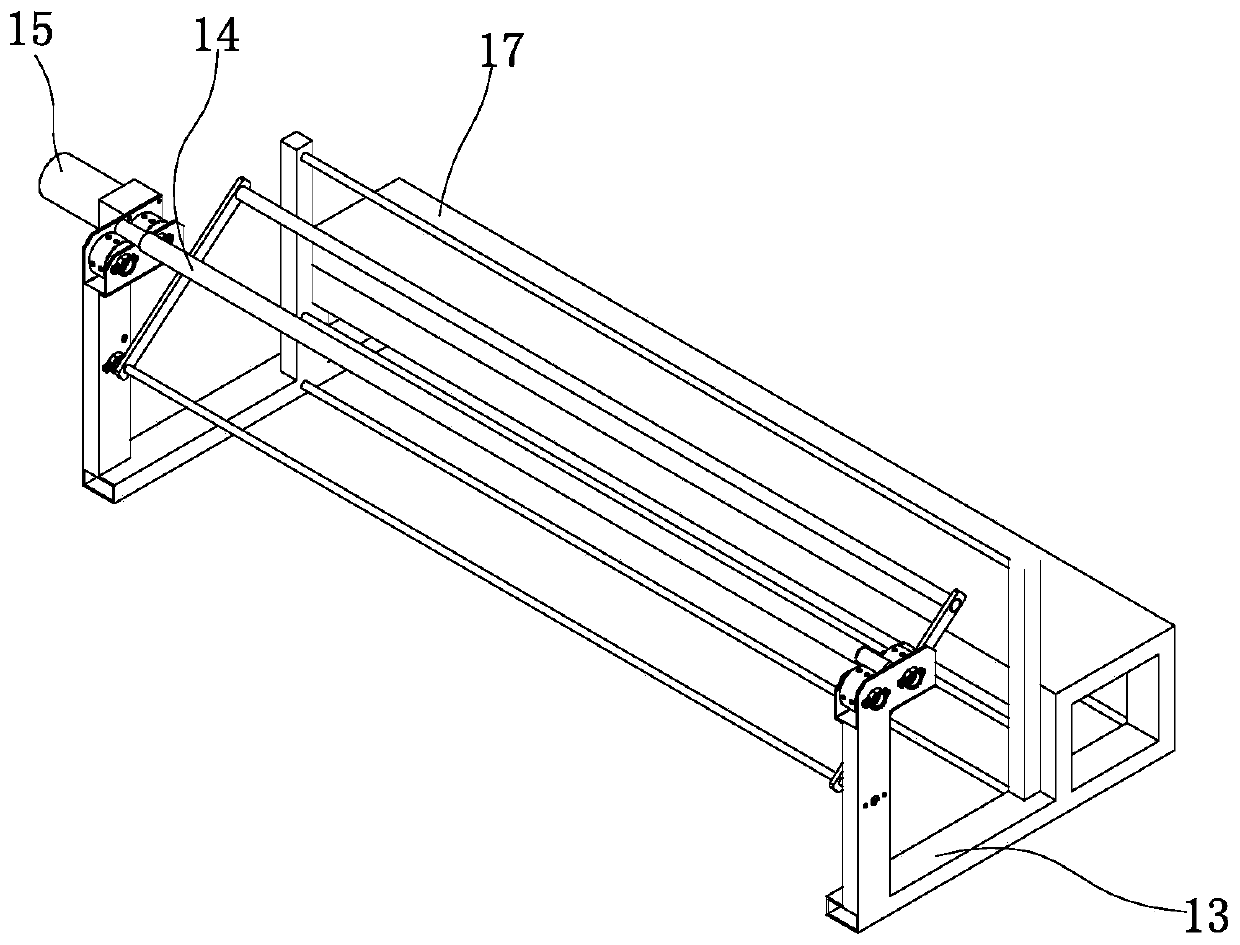

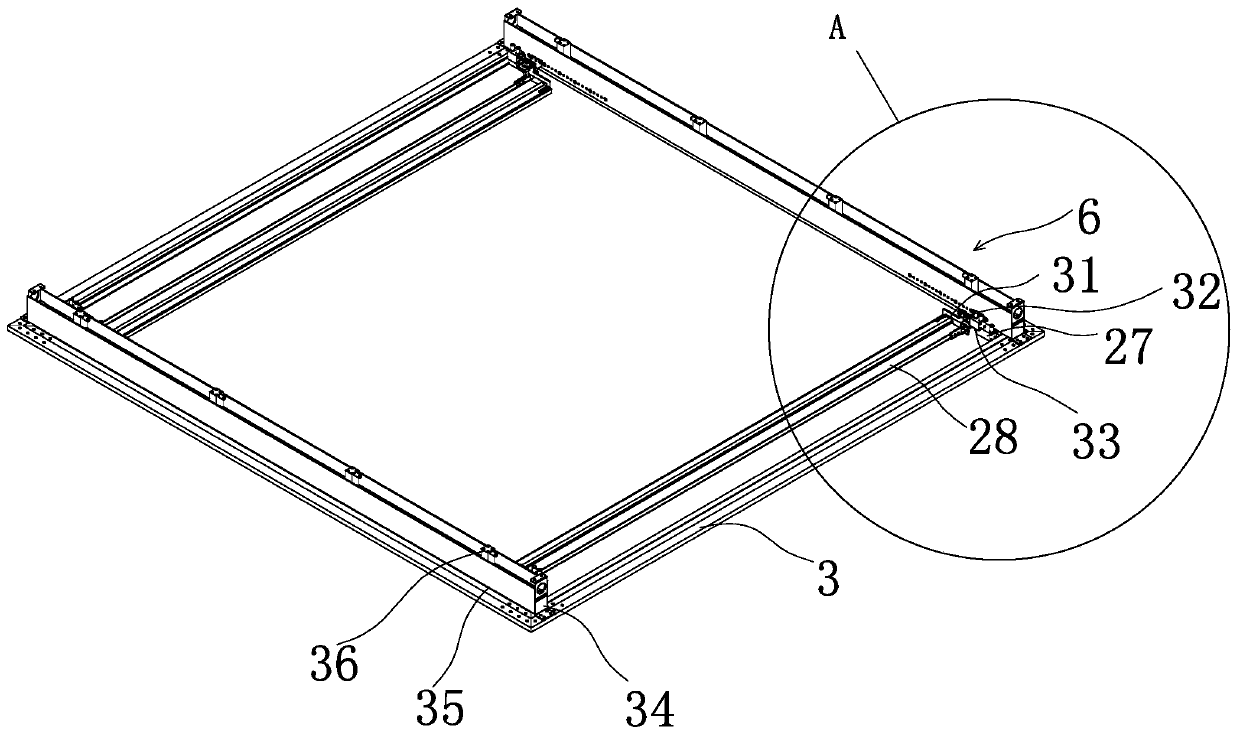

[0049] The basic principle of the second embodiment is basically the same as that of the first embodiment, except that the embroidery frame 3 is transmission-connected with at least one group of embroidery frame driving components that drive the embroidery frame 3 in a direction perpendicular to the beam 4 . Embroidery assembly 5 transmission connection and drive embroidery assembly 5 move along the head drive assembly 11 of beam 4 direction, embroidery assembly 5 includes head assembly 18 and shuttle box assembly 19, and described head drive assembly 11 includes the The first screw rod 20 in the assembly 18 and the second screw rod 21 passing through the shuttle box assembly 19, the first screw rod 20 and the second screw rod 21 are respectively parallel to the beam 4, and the head assembly 18 and the shuttle The box assembly 19 is connected to the first screw 20 and the second screw 21 through a nut driving connection, and the same end and the same side of any of the first sc...

Embodiment 3

[0052] The basic principle of the third embodiment is basically the same as that of the first embodiment, the difference is that the image collector 12 is fixedly arranged on the girder 4, and the image collector 12 is connected to the girder 4 or the embroidery assembly 5 through the bracket seat 40 superior. The bracket base 40 includes a base body 41 and a bracket 42 protruding from the base body 41, the image collector 12 is arranged at the end of the bracket 42 away from the base body, and the base body 41 is slidably connected to the girder 4 . A first guide mechanism is provided on the seat body 41, a second guide mechanism is provided on the embroidery assembly 5 or the beam 4, the first guide mechanism and the second guide mechanism cooperate, and the seat The body 41 is connected with a linear driver that drives the seat body 41 to move linearly along the second guide mechanism.

[0053] The linear driver pushes the seat body 41 to move horizontally along the girde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com