Double-needle bi-color embroidery machine head with stiletto function

An embroidery machine and machine head technology, which is applied to the mechanism of the embroidery machine, the automatically controlled embroidery machine, the embroidery machine, etc., can solve the problems of the single color of the pattern, cannot be realized, change the color, etc., and achieve the effect of improving the embroidery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

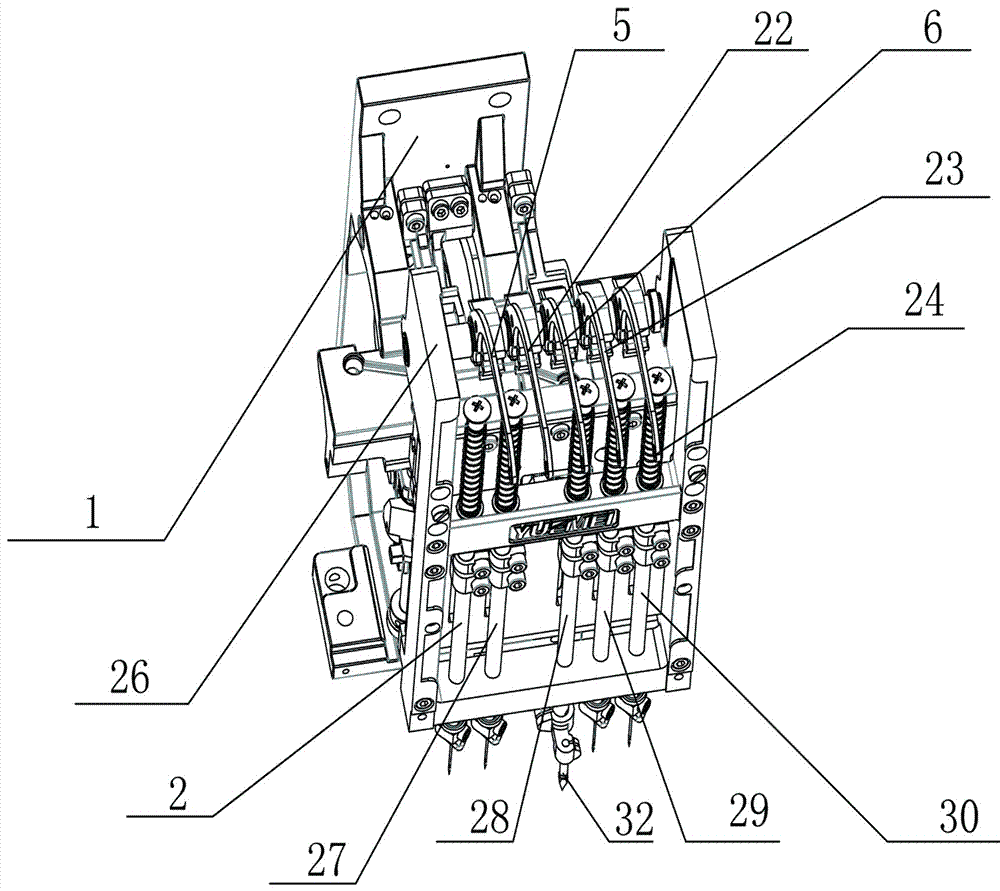

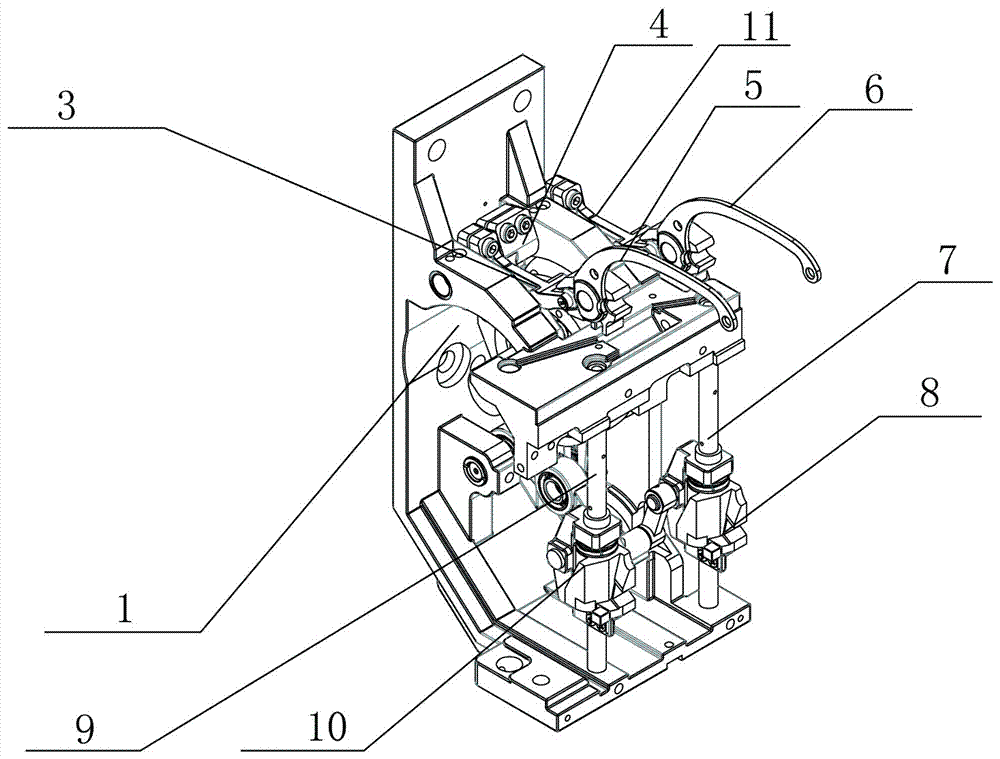

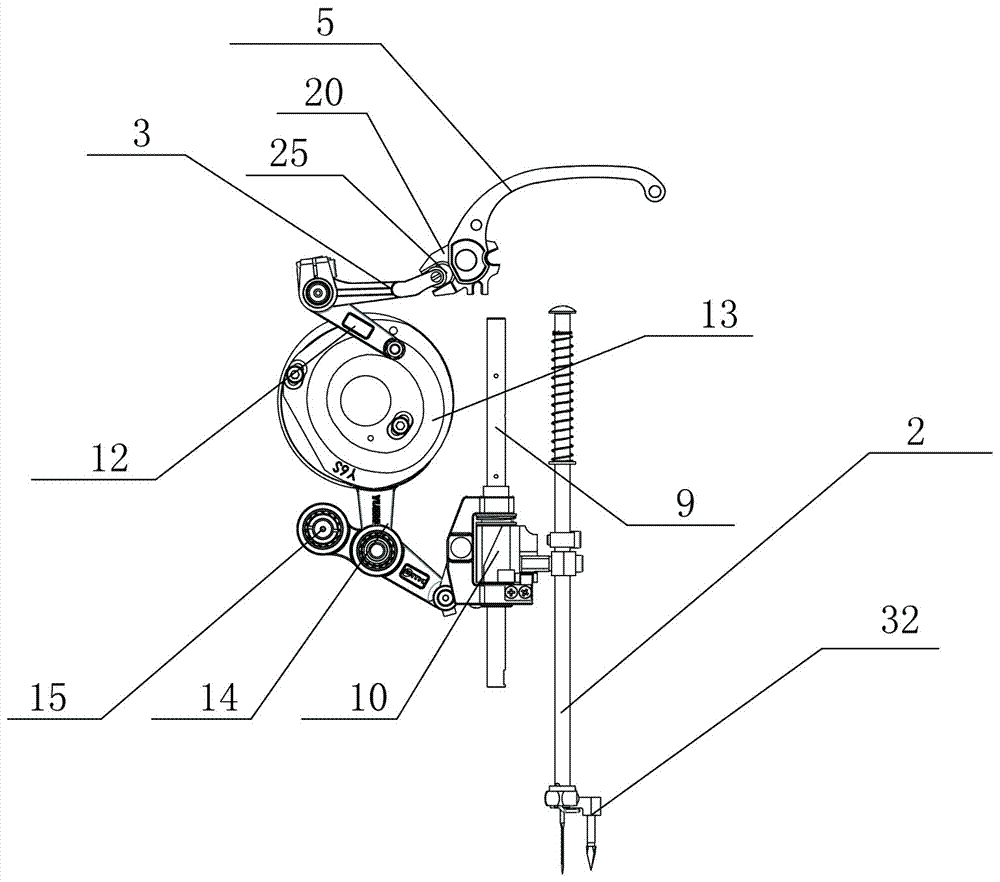

[0019] Such as figure 1 , 2 , 3, 4, and 5 show a double-needle double-color embroidery machine head with the function of carving holes, including an embroidery machine head 1, which is connected with a needle bar frame 26 that can move left and right, and on the needle bar frame 26 More than two needle bars and thread take-up bars are installed, the needle bar is driven by the pressing block 31 in cooperation with the needle bar driver, the thread take-up bar is driven by the thread take-up shaft, and the needle bar driver includes a first needle bar driver 10 and a second needle bar driver 8 , the first needle bar driver 10 plugs and drives the first needle bar 2, and at the same time the second needle bar driver 8 plugs and drives the second needle bar 29, and after the needle bar frame moves, the first needle bar driver 10 plugs and drives the third needle bar 27. At the same time, the second needle bar driver is engaged to drive the fourth needle bar 30. The yarn of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com