Real-time monitoring method and monitoring system for thread condition of computerized embroidery machine

A real-time monitoring and embroidery technology, applied in the direction of embroidery machine, embroidery machine mechanism, textile and papermaking, etc., to achieve the effect of improving quality and embroidery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of those skilled in the art, the structural principles of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0030] To design a real-time monitoring system for computerized embroidery machine thread status, the present invention designs a real-time monitoring method for computerized embroidery machine thread status, comprising the following steps:

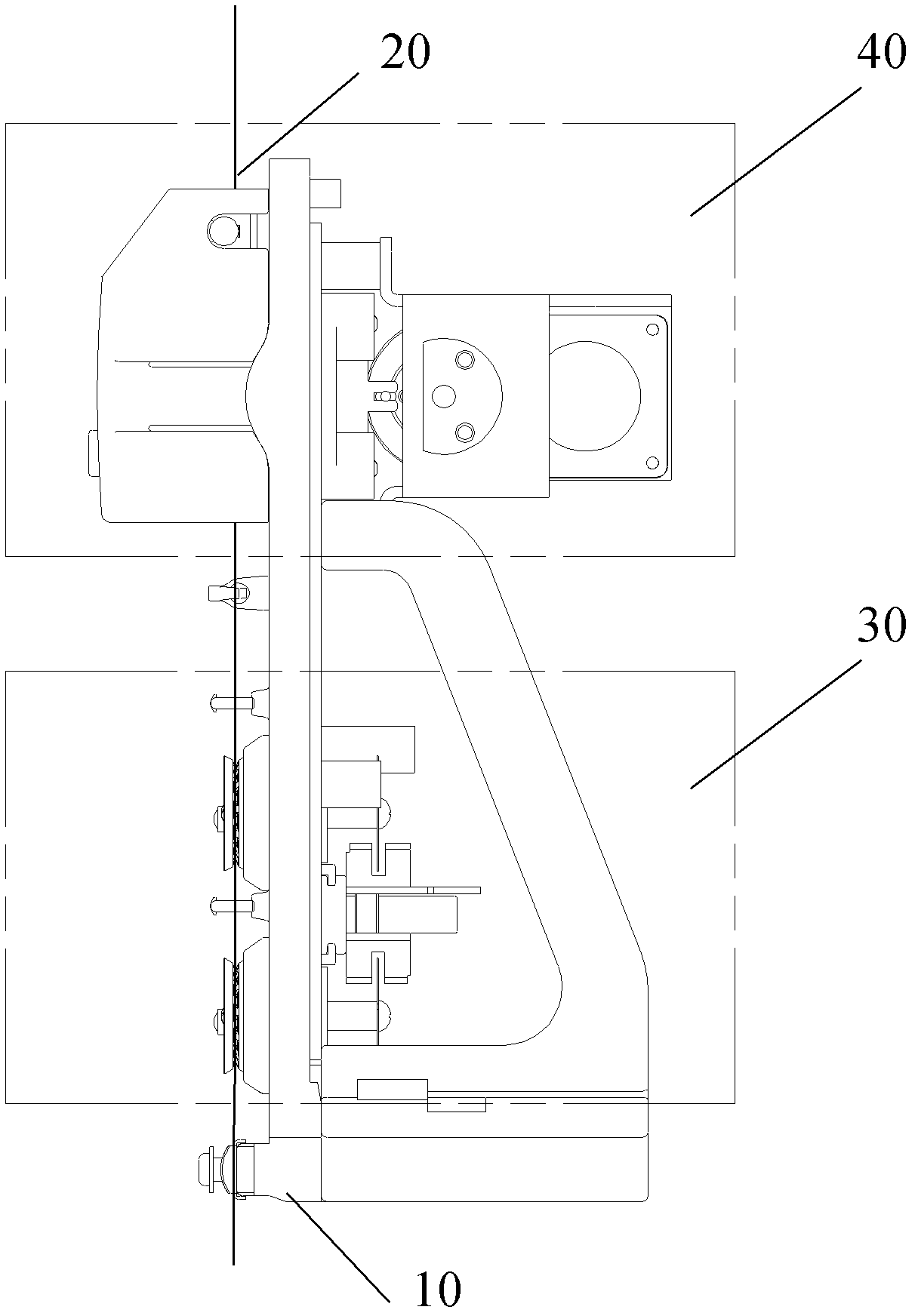

[0031] The first step is to install a wire flow state monitoring device and a thread tension adjustment device on the machine head adjustment table, which are used to detect and judge the real-time state of the embroidery thread during embroidery, and make corresponding records, warnings or compensations according to the state, and transmitted to the electronic control system;

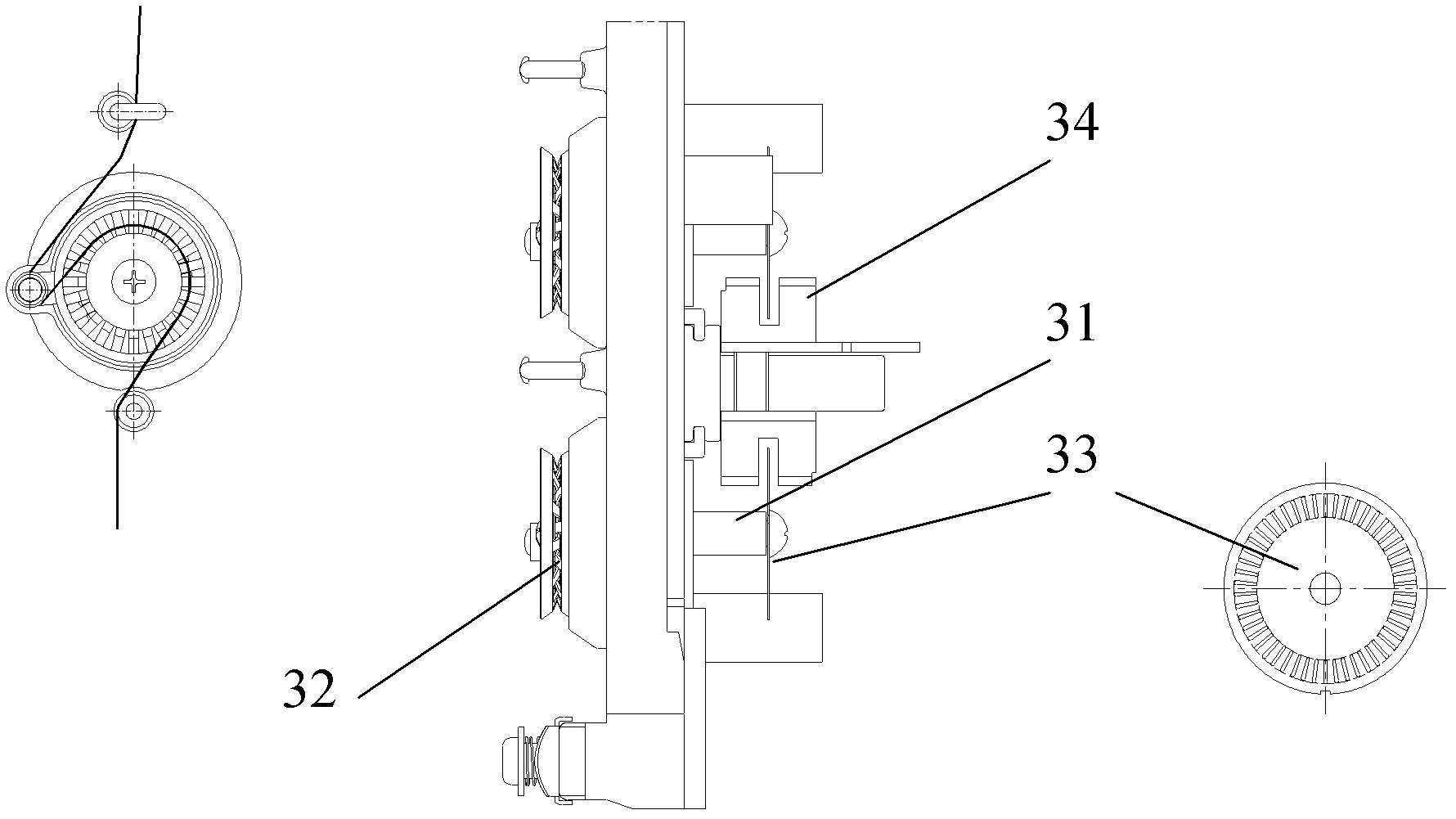

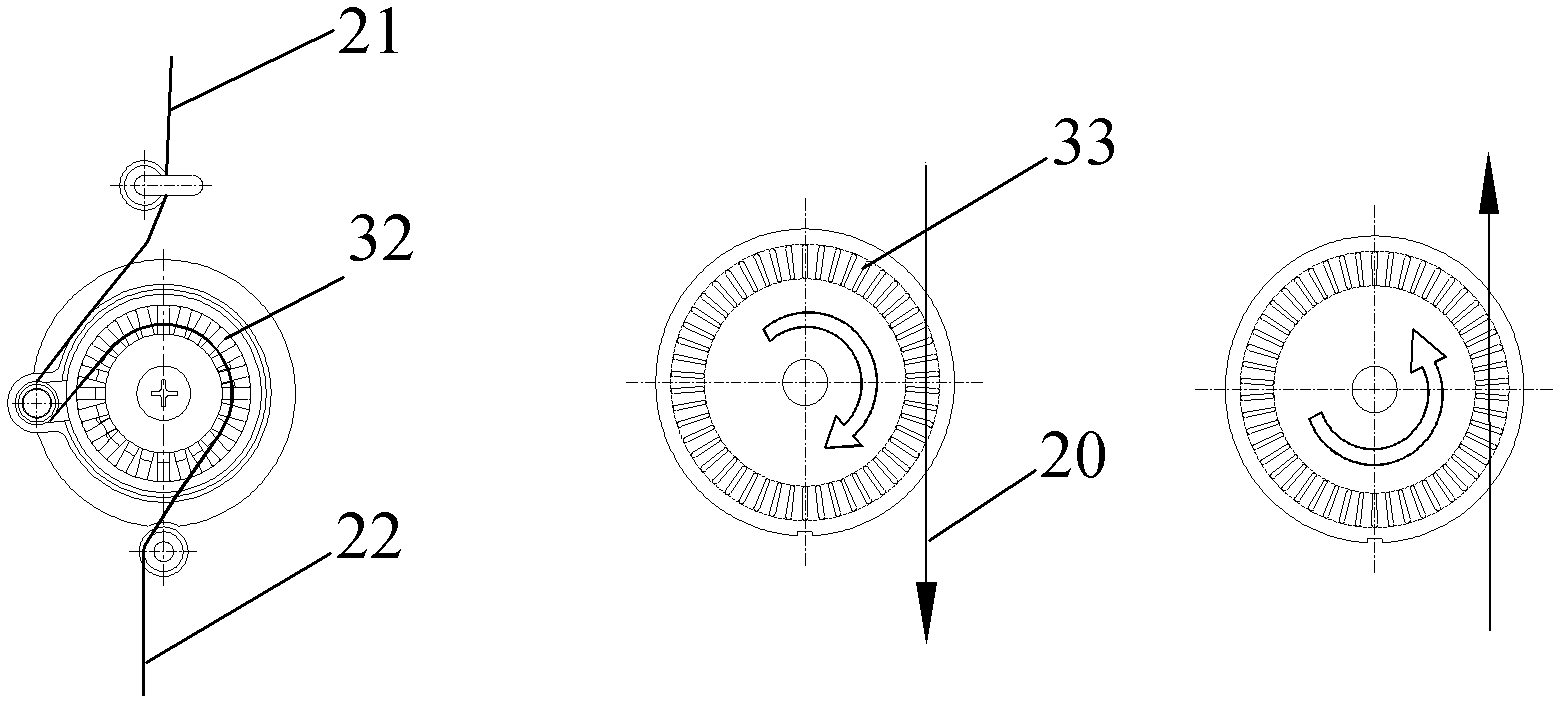

[0032] In the second step, the turntable, code wheel and bidirectional photoelectric sensor on the thread flow state monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com