A printing and dyeing treatment device capable of improving the printing and dyeing quality of printed and dyed cloth

A processing device and quality technology, applied in printing devices, inking devices, thin material processing and other directions, can solve the problems of fabric damage on the surface of the fabric, excessive deformation of the fabric, etc., to improve the quality, avoid fabric damage, and reduce the leveling of fabrics. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

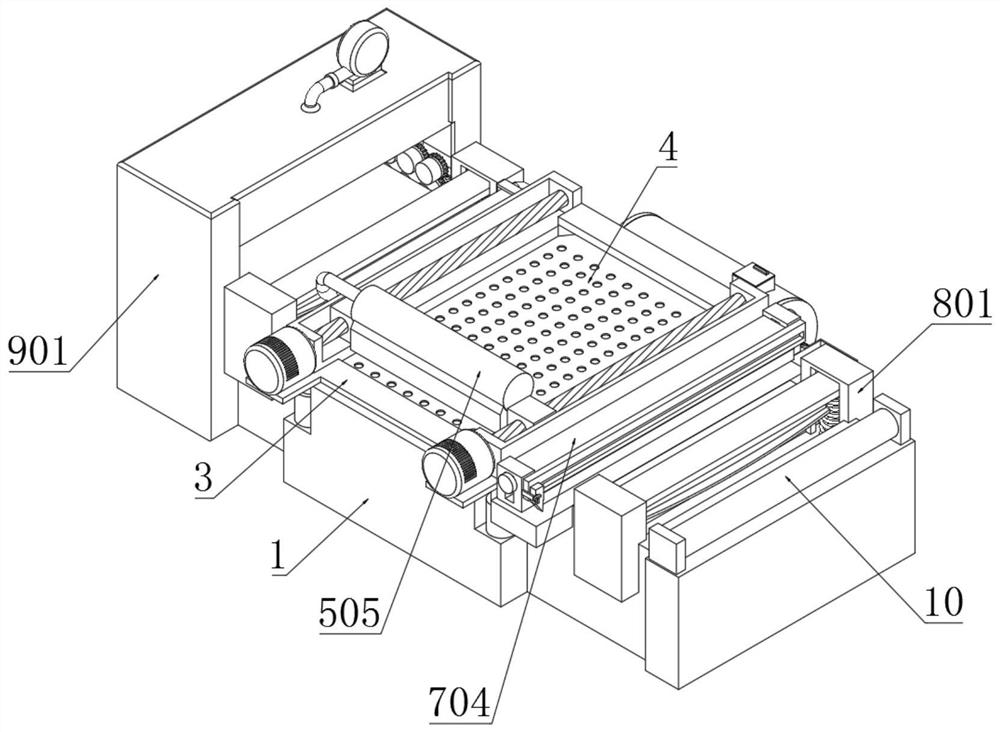

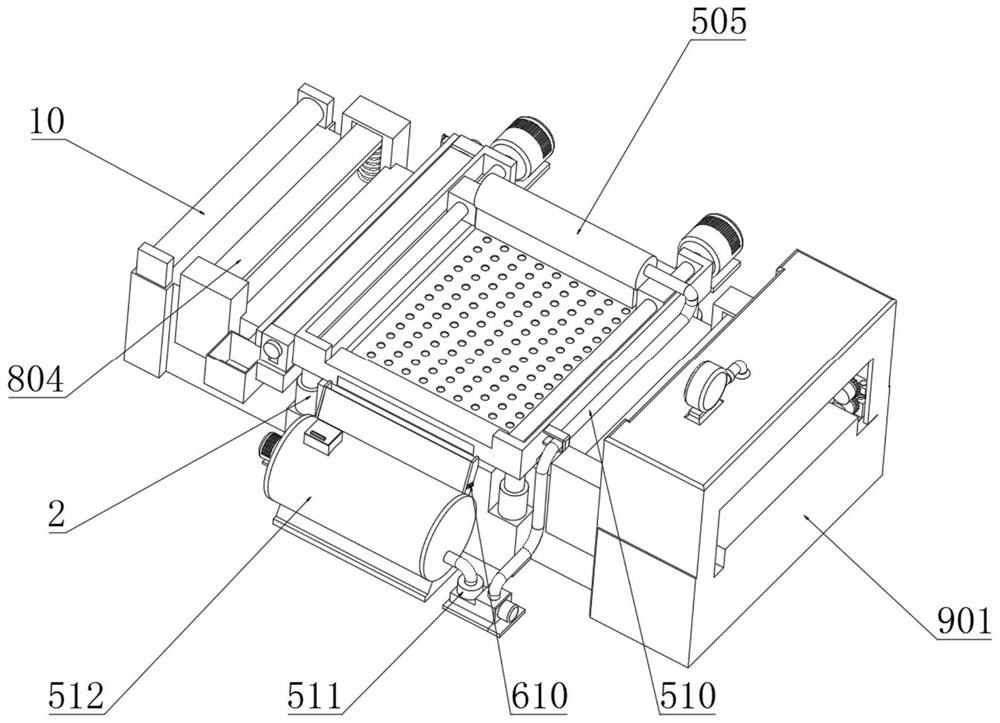

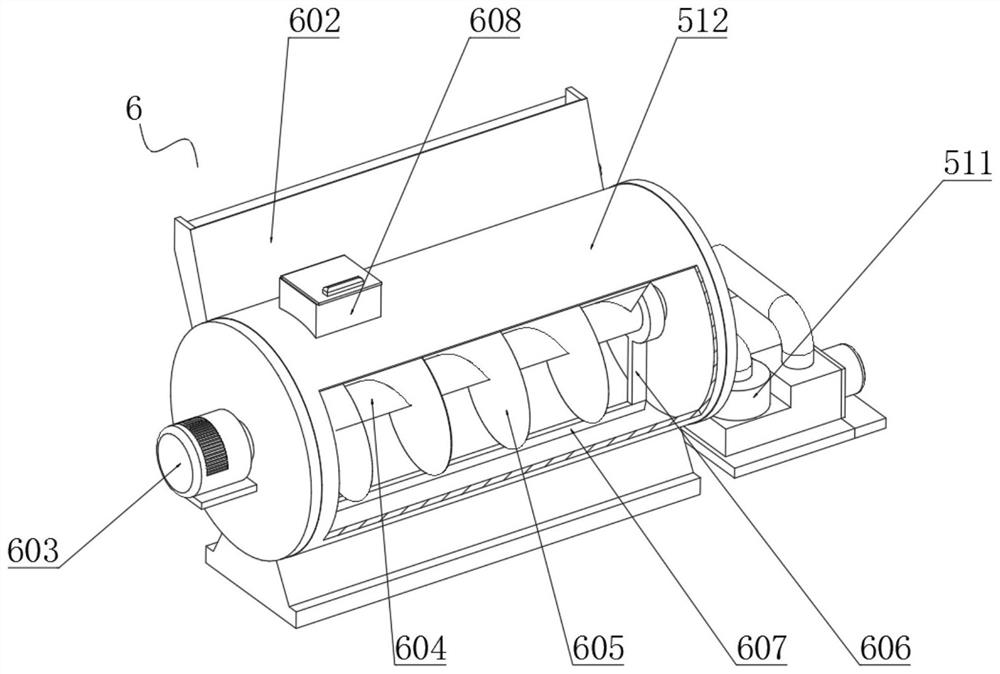

[0051] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a printing and dyeing treatment device that can improve the printing and dyeing quality of printed and dyed cloth, including a base 1, and hydraulic telescopic rods 2 are fixedly installed at the four corners of the top of the base 1, and the hydraulic telescopic rods The top of the top plate 2 is fixedly connected with a top plate 3, the middle part of the top plate 3 is embedded with a printing plate 4, the top of the top plate 3 is fixedly installed with a paint mechanism 5, one end of the top of the base 1 is equipped with a circulation mechanism 6, and the top of the base 1 is located on the side of the top plate 3 A cleaning mechanism 7 is fixedly installed at the position of the base 1, a leveling mechanism 8 is fixedly installed symmetrically at both ends of the top of the base 1, and a fabric guide roller 10 is fixedly installed at a position on one side of the leveling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com