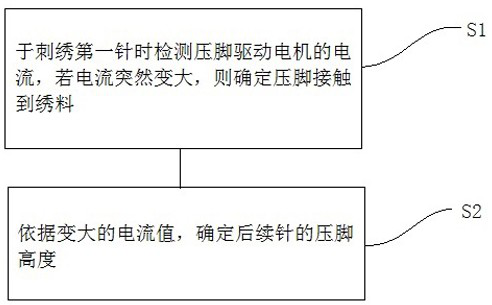

Presser foot height self-adaptive adjusting method

An adaptive adjustment and presser foot height technology, applied in the field of embroidery machines, to achieve flexible and convenient adjustment, improve embroidery efficiency and embroidery quality, and improve embroidery efficiency and embroidery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] In one embodiment, the S12 specifically includes: when it is detected that the current is greater than the current threshold, then determining that the presser foot touches the embroidery material at the moment when the current becomes larger. In this embodiment, if the instantaneous value of the sudden change of current is detected, it is determined that the presser foot just touches the embroidery material at the moment when the current becomes larger. In another embodiment, when it is detected that the current is greater than the current threshold, it is determined that the presser foot touches the embroidery material at a certain moment before the detection of the above-mentioned current. In this embodiment, the current value that has increased after the current mutation is detected, that is, the presser foot has touched the embroidery material and is still moving downward toward the embroidery material. The time at which the current value is currently detected is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com