Thread-hooking oscillating shuttle device of tuft embroidery machine and automatic control method thereof

An embroidery machine and flocking technology, which is applied in the hook thread shuttle device and its automatic control field, can solve the problems of high machine manufacturing cost, noise pollution in the workplace, complex cam processing technology, etc., to improve embroidery efficiency and improve the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

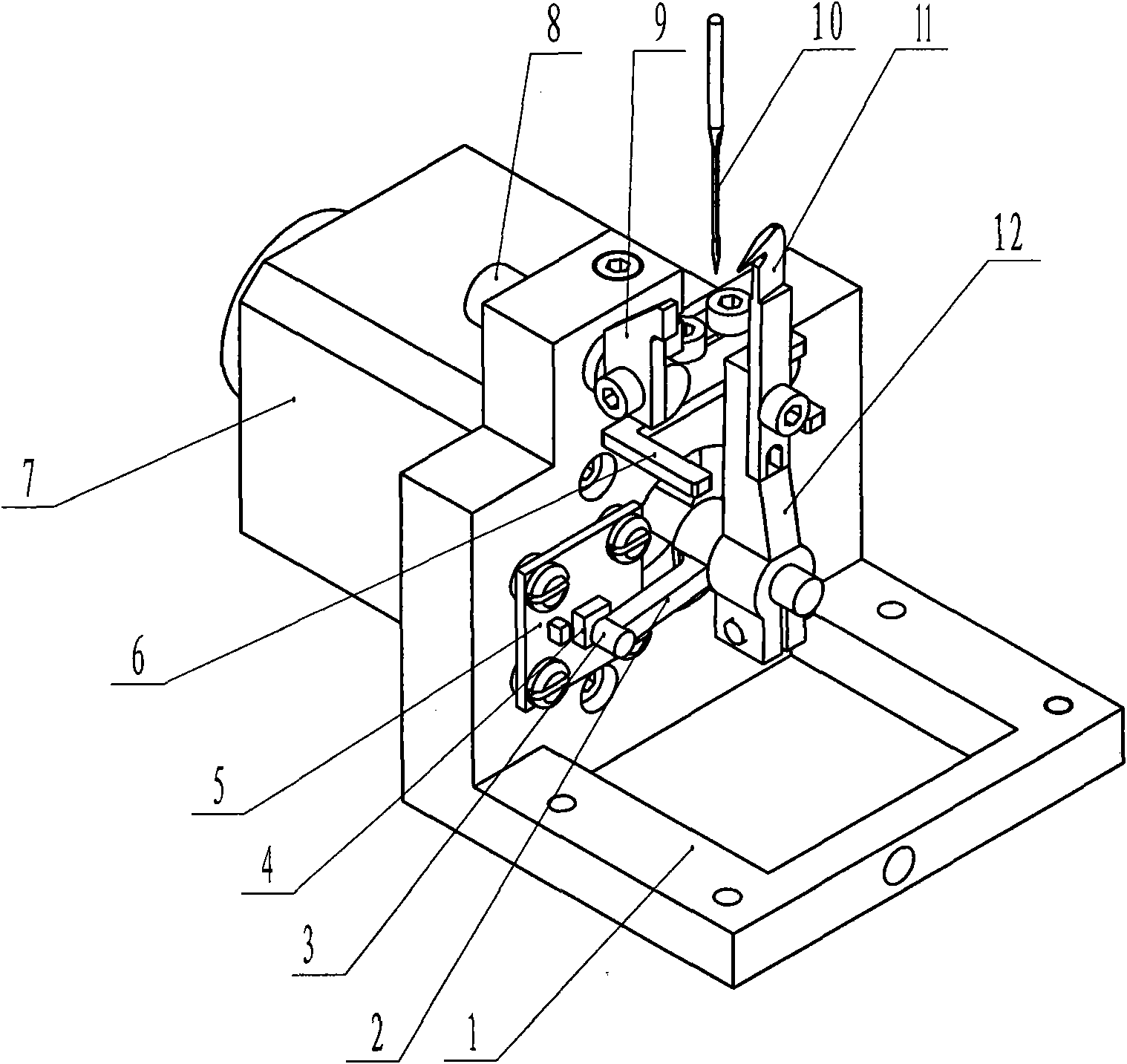

[0030] Each machine head adopts a 2-phase hybrid stepping motor to replace the cam to drive the hook thread shuttle support 12, and the Hall element 4 and the permanent magnet 3 are used to detect and determine the initial position of the stepping motor 7.

[0031] Every two heads are designed to use a stepper motor driver board. The main functions of the stepping motor drive board are: to drive the motor to run; to detect and determine the initial position of the stepping motor 7; to receive the thread hook command signal and the thread trimming command signal from the main control board.

[0032] The thread hook shuttle device of the flocking embroidery machine, which includes a stepping motor 7, a limit block 6, a position plate 5, a Hall element 4, a permanent magnet 3, a position pendulum bar 2, a rotary hook bracket 1, and a thread hook shuttle Support 12 and fixed knife support 8;

[0033] The rotary hook support 1 is L-shaped, the lower plane of the rotary hook suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com