Multi-functional embroidery machine and embroidery method thereof

An embroidery machine and multi-functional technology, applied in the field of embroidery machines, can solve the problems of not being able to tighten, not being able to embroider on fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

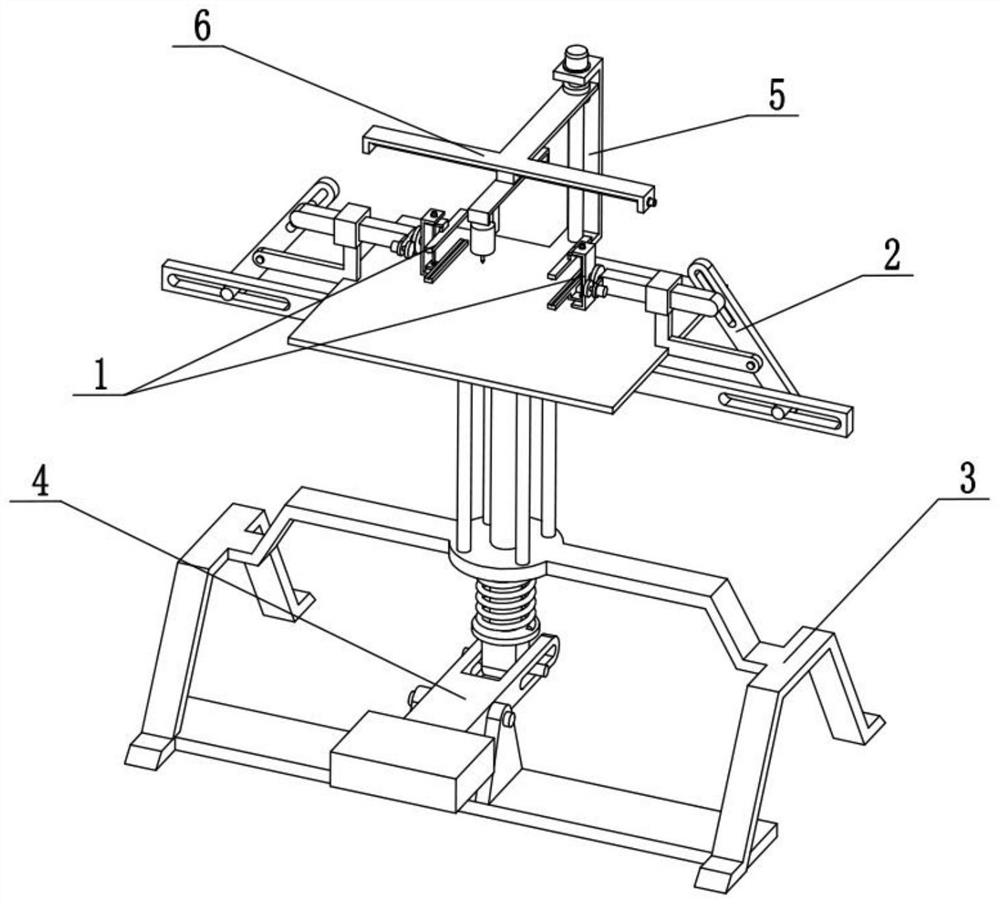

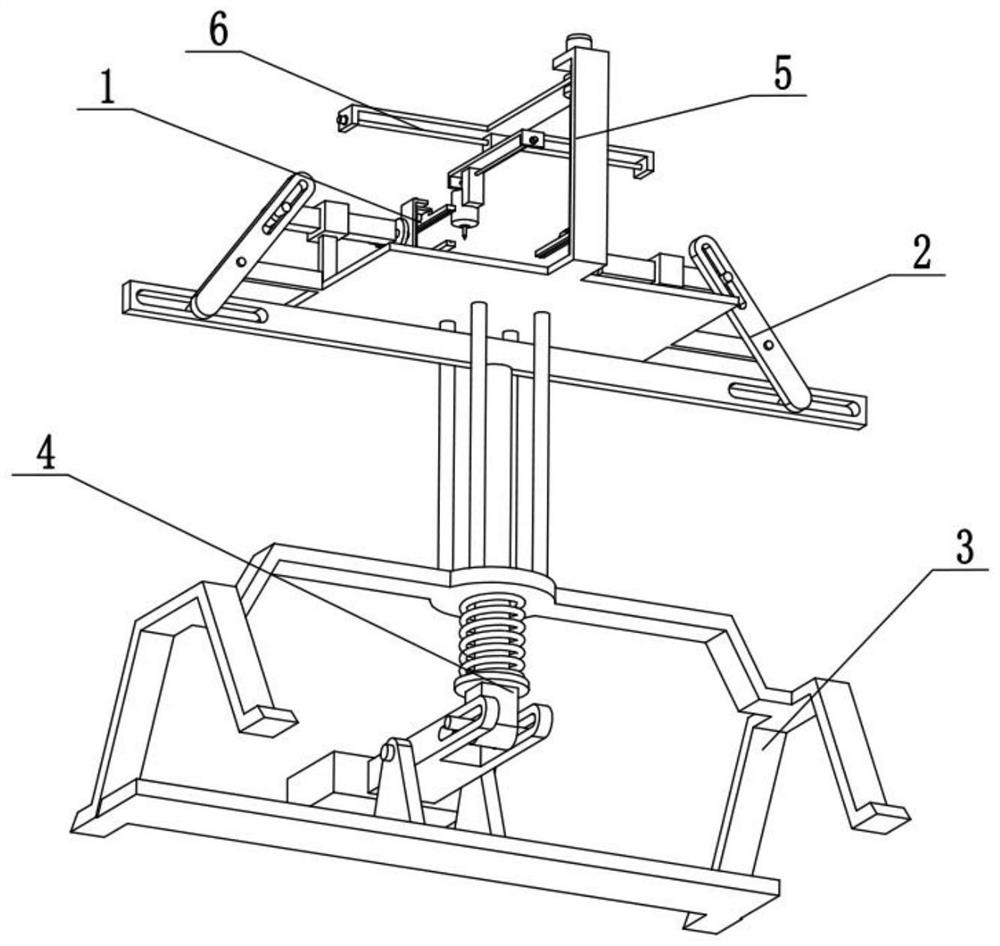

[0031] Combine below Figure 1-8 To illustrate this embodiment, the present invention relates to the technical field of embroidery machines, more specifically, a multi-functional embroidery machine, which includes a fabric clamping assembly 1, a fabric tensioning assembly 2, an integral frame assembly 3, and a pedal linkage assembly. 4. The height adjustment assembly 5 and the web moving assembly 6, the web moving assembly 6 is connected to the height adjustment assembly 5, the height adjustment assembly 5 is connected to the overall frame assembly 3, two fabric clips Tightening assembly 1 is respectively connected to two fabric tensioning assemblies 2, and two fabric tensioning assemblies 2 are respectively connected to the left and right ends of the overall frame assembly 3, and foot pedal linkage assembly 4 is connected to the overall frame assembly 3, two fabric tensioning assemblies 2 are respectively connected to the left and right ends of the pedal linkage assembly 4. ...

specific Embodiment approach 2

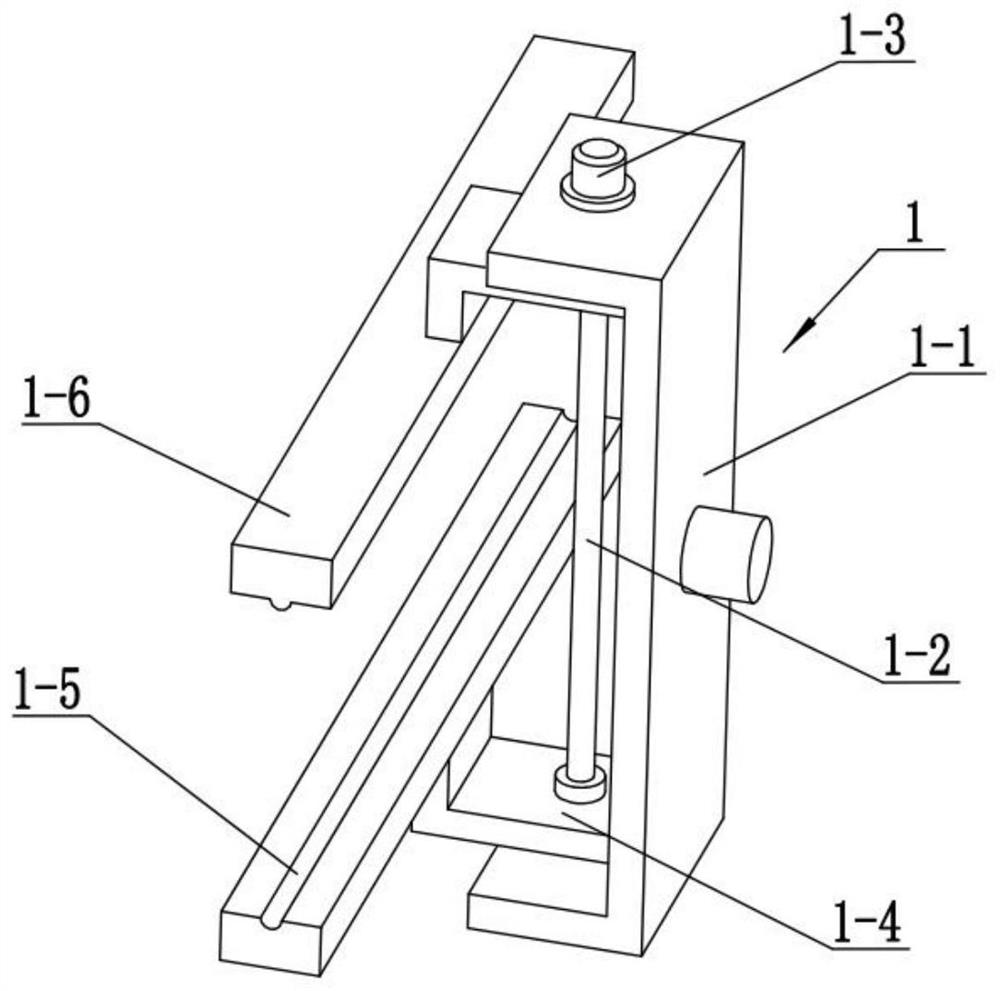

[0034] Combine below Figure 1-8Describe this embodiment, this embodiment will further explain the first embodiment, the cloth clamping assembly 1 includes a vertical slide 1-1, a clamping screw 1-2, a clamping motor 1-3, a clamping force Arm 1-4, groove base plate 1-5 and bump cover plate 1-6, groove base plate 1-5 and bump cover plate 1-6 are fixedly connected on two clamping force arms 1-4 respectively, two Two clamping arms 1-4 are respectively threaded on the upper and lower sides of the clamping screw rod 1-2, and the clamping screw rod 1-2 is rotatably connected to the vertical slide plate 1-1, and the clamping screw rod 1-2 Fixedly connected to the output shaft of the clamping motor 1-3, the clamping motor 1-3 is fixedly connected to the vertical slide 1-1, and both clamping arms 1-4 are slidingly connected to the vertical slide 1-1 superior.

[0035] The clamping motor 1-3 drives the clamping screw rod 1-2 to rotate, and the clamping screw rod 1-2 will drive the two...

specific Embodiment approach 3

[0037] Combine below Figure 1-8 Describe this embodiment, this embodiment will further explain the second embodiment, the fabric tensioning assembly 2 includes a right-angle arm 2-1, a horizontal sliding sleeve 2-2, a push-pull rod 2-3, a push-pull slideway 2- 4. Tighten slide bar 2-5, gear 2-6, overturn motor 2-7 and drive gear 2-8, drive gear 2-8 is fixedly connected on the output shaft of overturn motor 2-7, overturn motor 2-7 Fixedly connected on the tensioning slide bar 2-5, the tensioning slide bar 2-5 is slidably connected in the horizontal sliding sleeve 2-2, the horizontal sliding sleeve 2-2 is fixedly connected on the right-angle arm 2-1, and the push-pull rod 2- 3 Rotationally connected to the right-angle arm 2-1, the push-pull rod 2-3 is provided with a push-pull slideway 2-4, the tensioned slide rod 2-5 is slidably connected to the push-pull slideway 2-4, and the gear 2-6 is rotatably connected On the tensioning slide bar 2-5, the gear 2-6 is meshed with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com