Intermediate Thread Passing Device of Computerized Embroidery Machine

An embroidery machine and thread passing technology, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve the problems of affecting the normal operation of the machine, affecting the quality of embroidery, easy winding, thread entanglement, etc., and achieves the improvement of embroidery. The effect of quality, motion stability, and good looks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

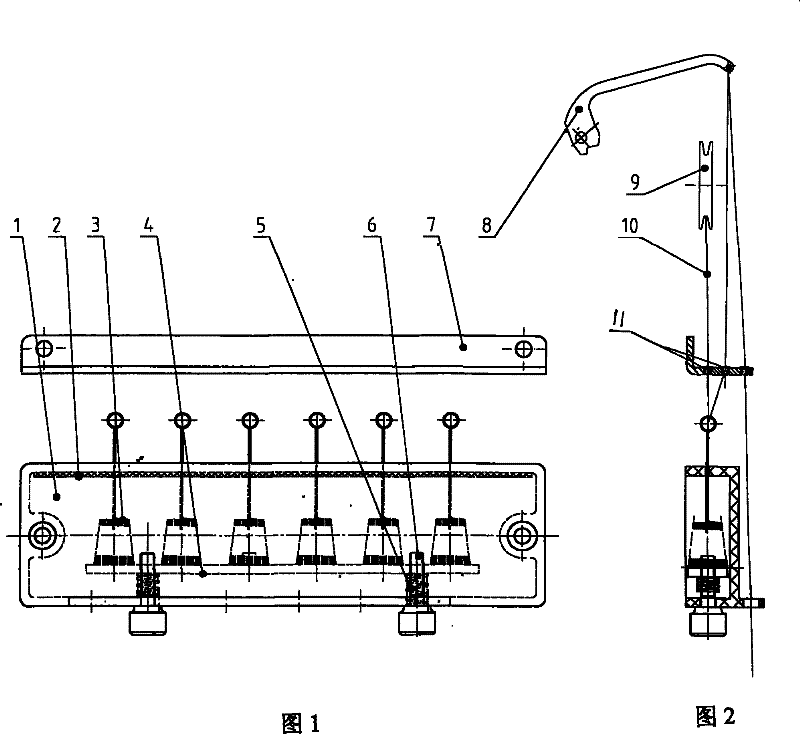

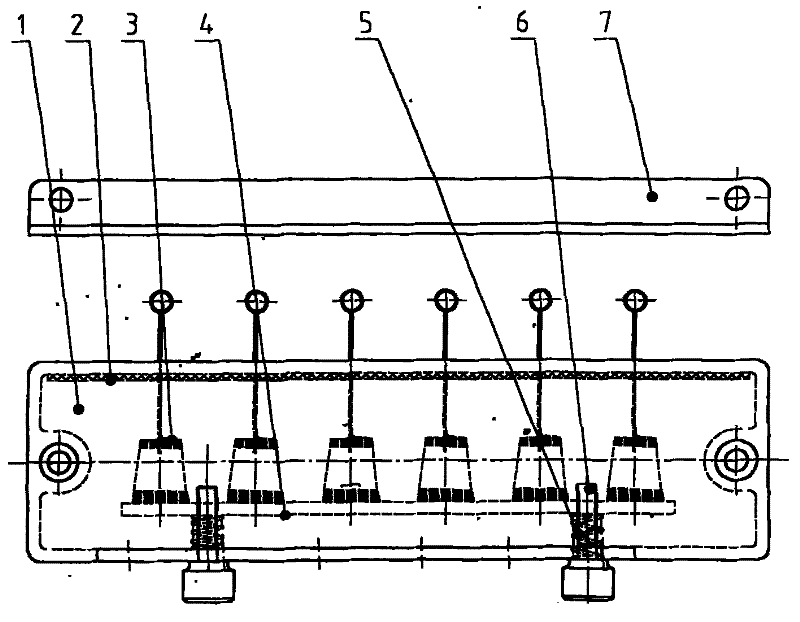

[0010] Such as figure 1 As shown, the present invention is arranged on the frame of the computerized embroidery machine, and is composed of a middle thread seat 1 below the upper thread system, and a pagoda spring support plate 4 is arranged on the middle thread seat 1, and the pagoda spring support plate 4 is provided with some pagoda springs 3, and the quantity of pagoda springs 3 is determined according to the quantity of embroidery machine needles. The below of pagoda spring supporting plate 4 is provided with adjusting screw 6 and the supporting spring 5 that is located on adjusting screw 6. A buffer pad 2 is provided inside the middle thread seat 1, and a thread limit plate 7 is provided above the middle thread seat 1,

[0011] Such as figure 2 As shown, the wire passing limit plate 7 is provided with a wire passing hole 11 . The suture 10 passes through the thread hole 11 on the thread limit plate 7 from the broken inspection wheel 9, the pagoda spring 3 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com