Cloth feeding mechanism of embroidery machine

A technology of a cloth feeding mechanism and an embroidery machine, which is applied in the field of embroidery machines, can solve problems such as reducing embroidery quality, achieve the effect of improving embroidery quality and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

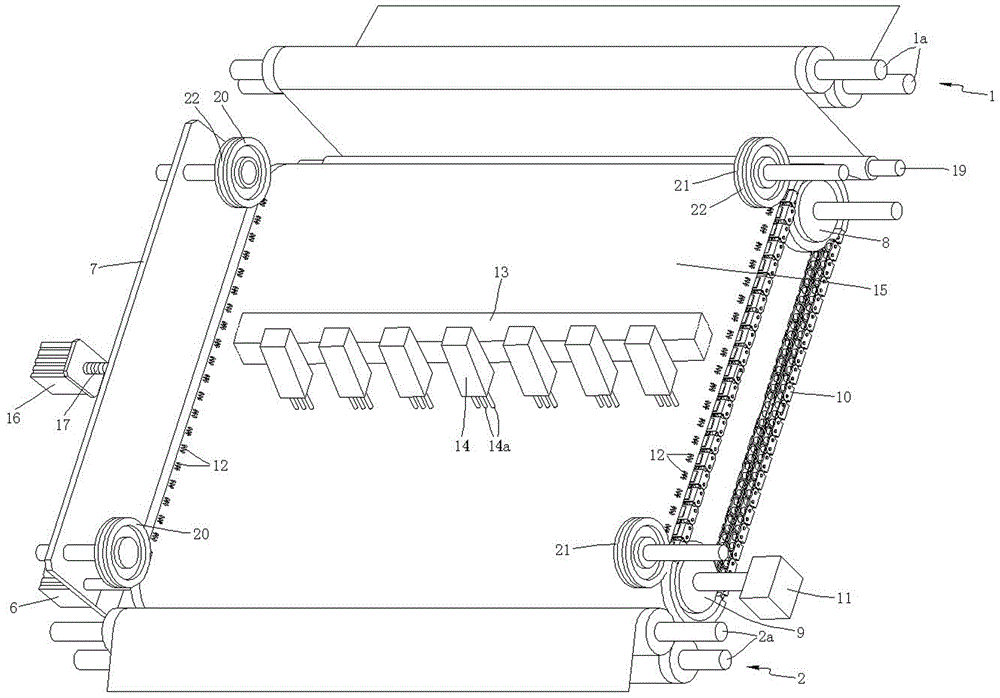

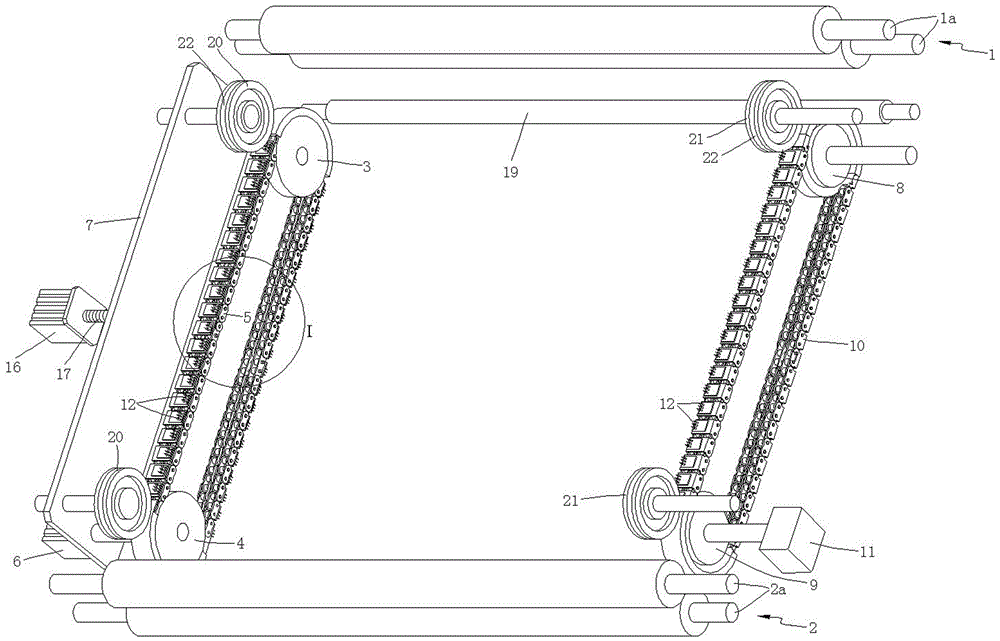

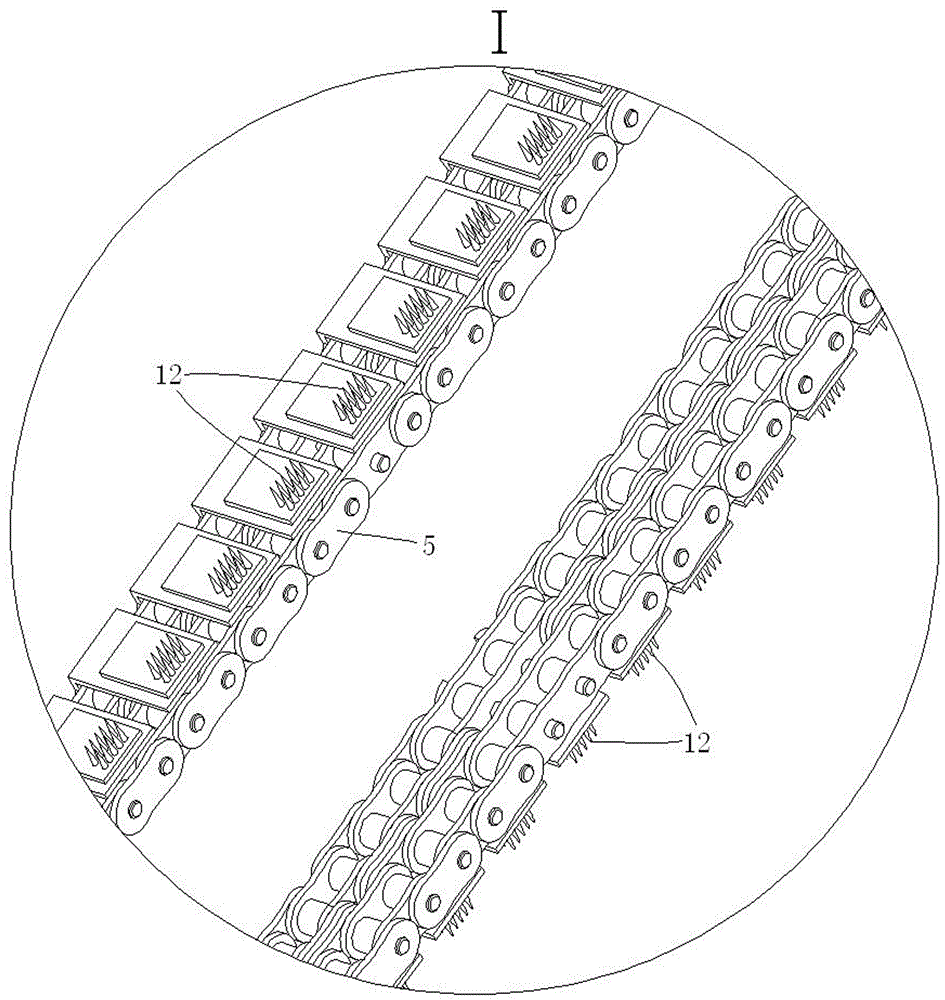

[0019] see Figure 1 to Figure 4 Shown is a cloth feeding mechanism of an embroidery machine, the embroidery machine includes a machine head 14 fixedly installed on the crossbeam 13 of the embroidery machine, and a plurality of embroidery needles 14a for embroidery are installed at the bottom of the machine head 14. The cloth feeding mechanism includes a front clamping roller set 1 and a rear clamping roller set 2 respectively arranged on the front and rear sides of the machine head 14. The front cloth clamping rollers 1a arranged in pairs, the rear cloth clamping roller group 2 includes the rear cloth clamping rollers 2a which are rotatably installed on the embroidery machine frame through bearings and arranged in pairs up and down, the embroidery machine frame is not shown in the figure . During work, the embroidery needle 14a on the machine head 14 embroiders the cloth 15 sent between the front clamping roller group 1 and the rear clamping roller group 2, and the cloth fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com