Cloth clamping device of embroidery machine

An embroidery machine and cloth clamping technology, which is applied in the textile field, can solve the problems of affecting the quality of embroidery, affecting the quality of cloth processing, and shaking of cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

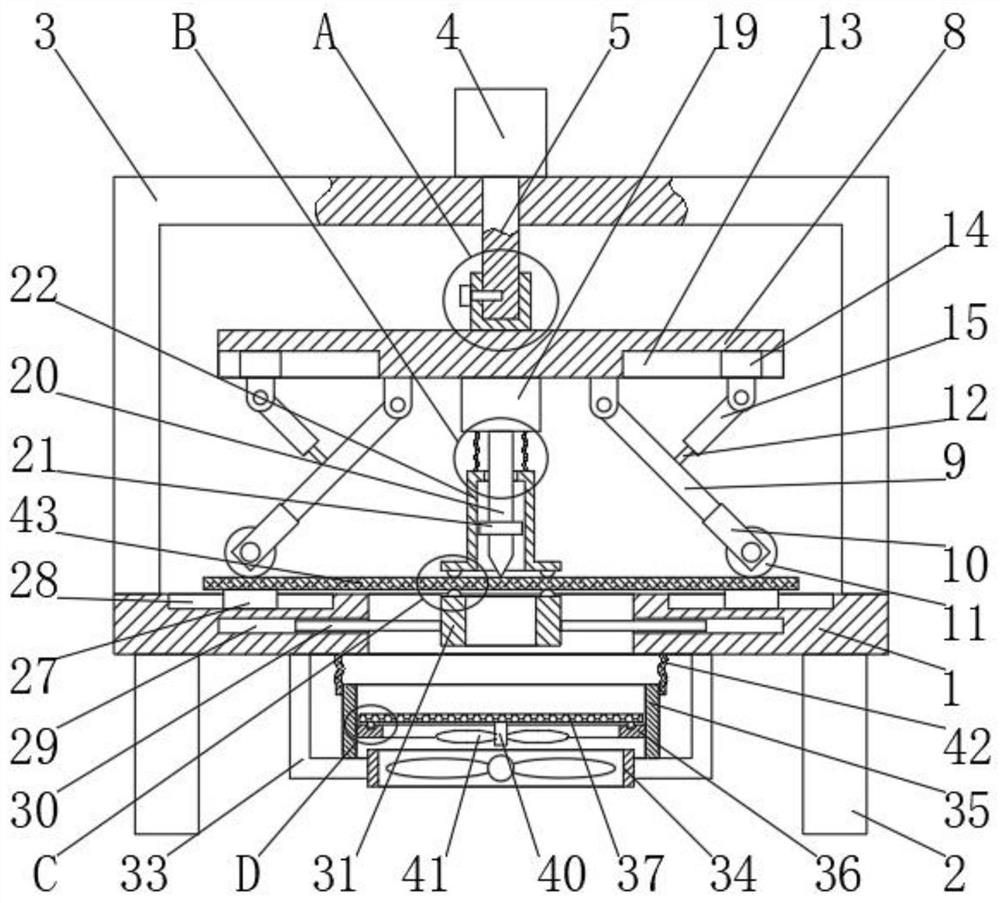

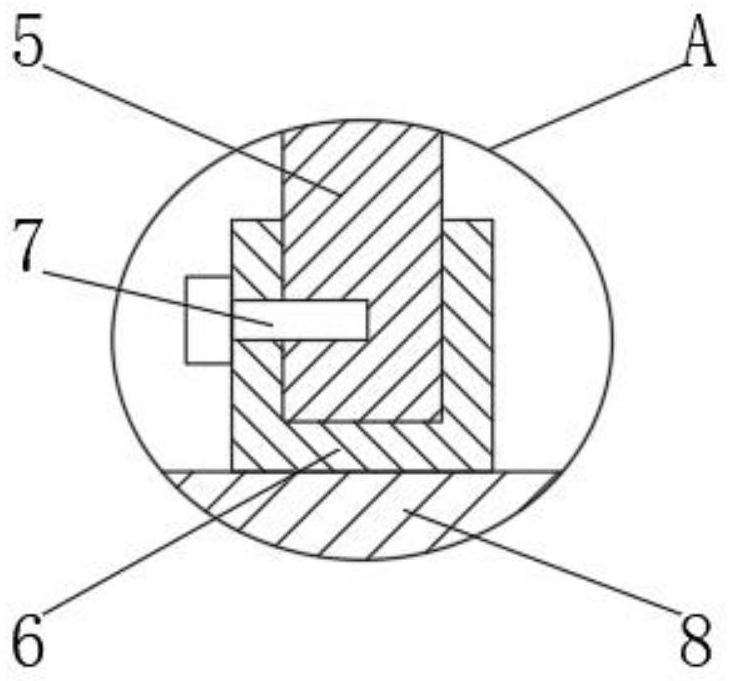

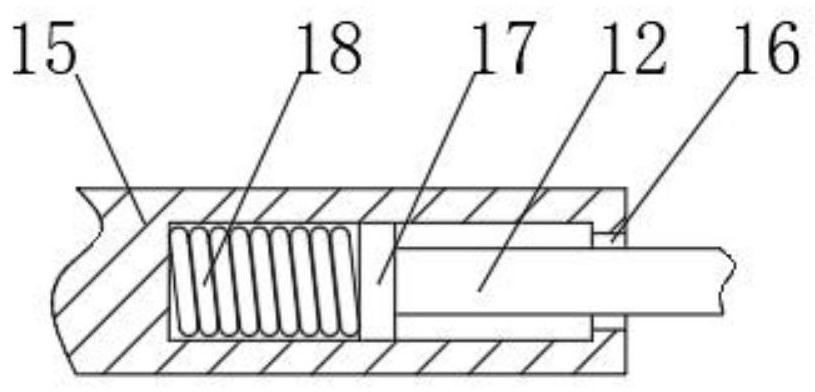

[0027] A cloth clamping device for an embroidery machine, comprising a bottom plate 1, on which a leg 2 is welded, a frame 3 is welded on one end of the bottom plate 1 away from the leg 2, and a cylinder is fixedly installed at one end of the frame 3 away from the bottom plate 1 4. One end of the cylinder 4 close to the bottom plate 1 is provided with a cylinder rod 5, a cylinder rod 5 is slidably sleeved in the frame 3, and a connecting sleeve 6 is sleeved outside the end of the cylinder rod 5 away from the cylinder 4. One end of the connecting sleeve 6 away from the cylinder 4 is welded with a support plate 8, and one end of the support plate 8 away from the cylinder 4 is hinged with two connecting rods 9, and the two connecting rods 9 are symmetrically distributed on the support plate 8, each of which is A mounting frame 10 is welded to the end of the connecting rod 9 , the mounting frame 10 is provided with a pressing roller 11 , and the outer sides of the two pressing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com