Weft laying trolley of warp knitting machine

A technology of weft laying trolley and warp knitting machine, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of waste, poor frame stability, difficult processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

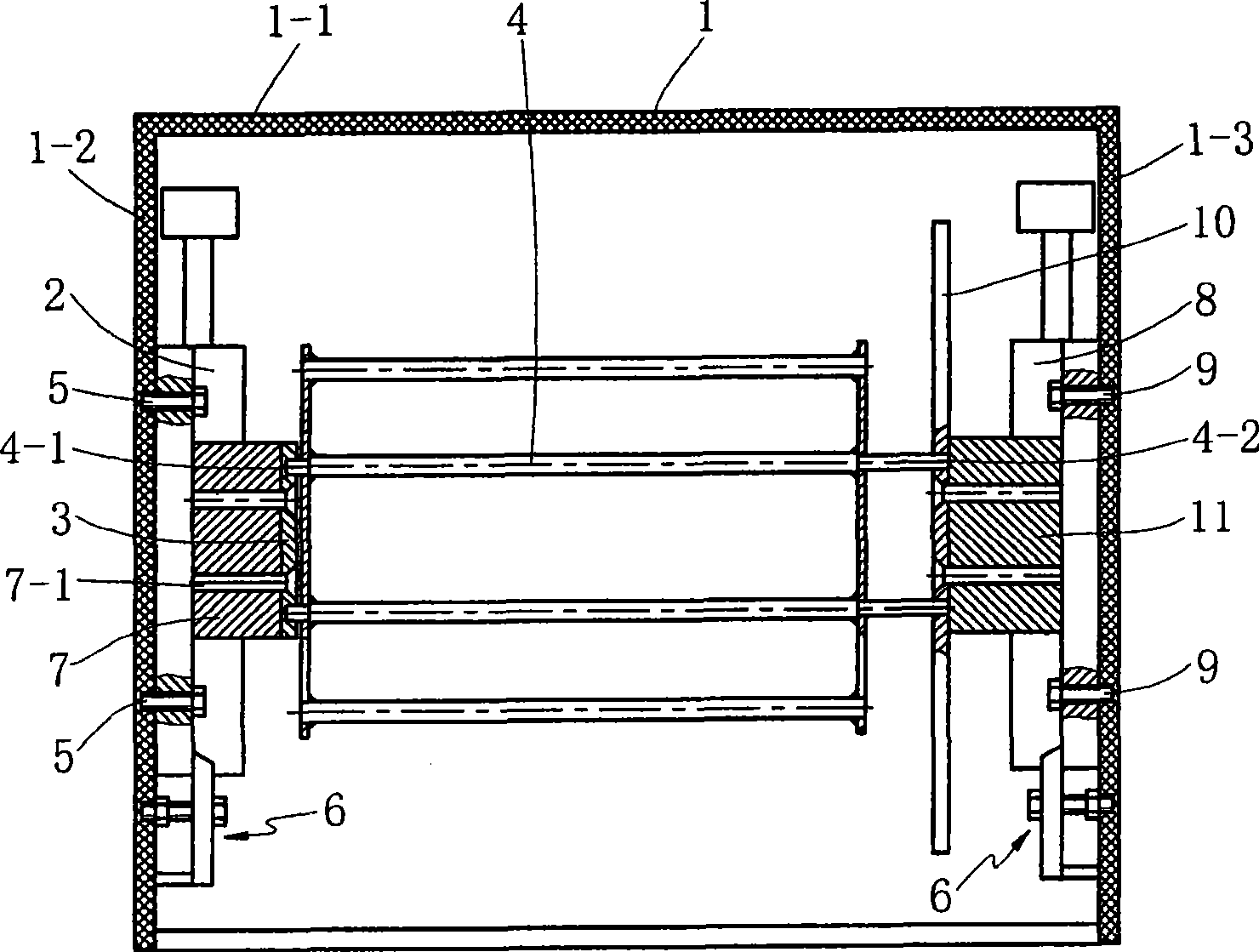

[0013] See Figure 1 to Figure 3 , A warp knitting machine weft laying trolley, comprising a trolley frame 1 composed of a top plate 1-1 and two side plates 1-2, 1-3, a first plate located on one side plate 1-2 of the inner cavity of the trolley frame 1 A guide rod seat 2, a first tension rod seat 3 fixedly connected to the first guide rod seat 2, and a tension rod 4, one end 4-1 of the tension rod 4 is rotatably connected with the first tension rod seat 3 , The first guide rod seat 2 is detachably connected to the side plate 1-2 of the inner cavity of the trolley frame 1.

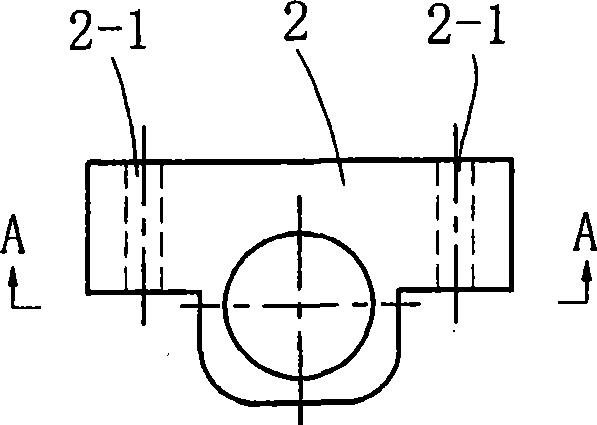

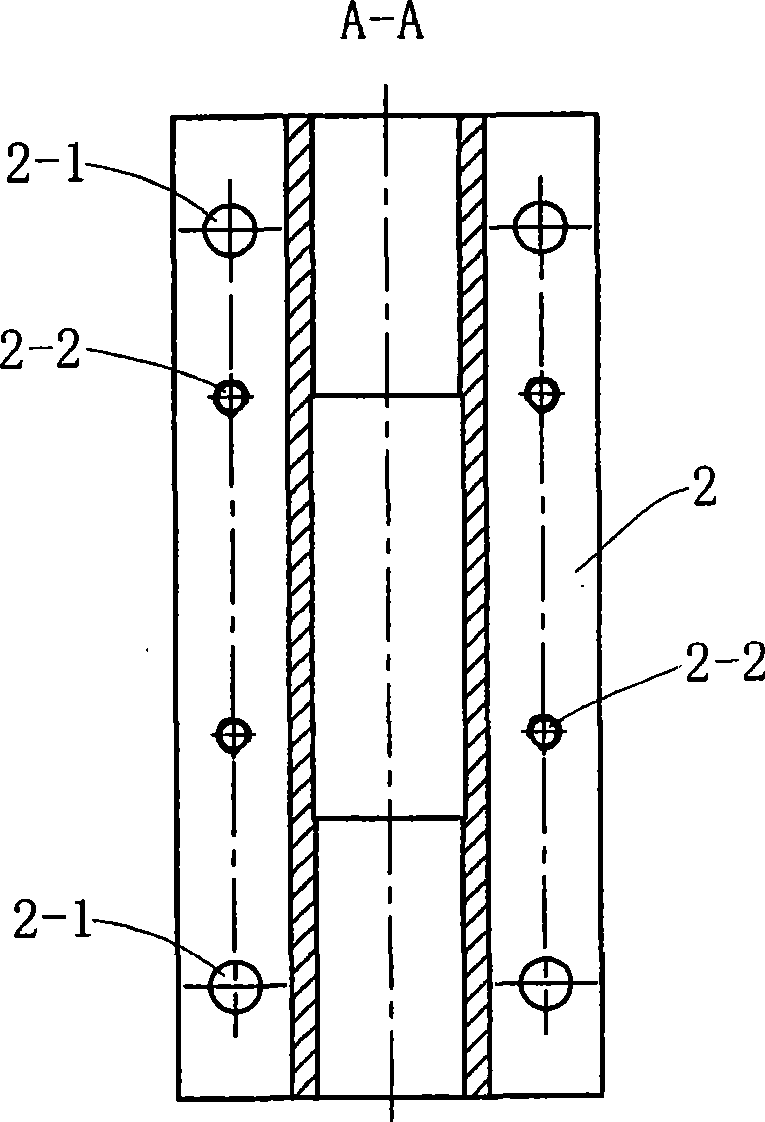

[0014] The first guide rod seat 2 penetrates the bolt 5 through its hole 2-1 or through the plate bolt mechanism 6 provided at the upper and lower parts of the first guide rod seat 2 and the inner cavity side plate 1- of the trolley frame 1 2 constitute a detachable connection.

[0015] In order to simplify the structure of the first guide rod seat 2 and facilitate the connection between the first tension rod s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com