Patents

Literature

326results about How to "Reduce load requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

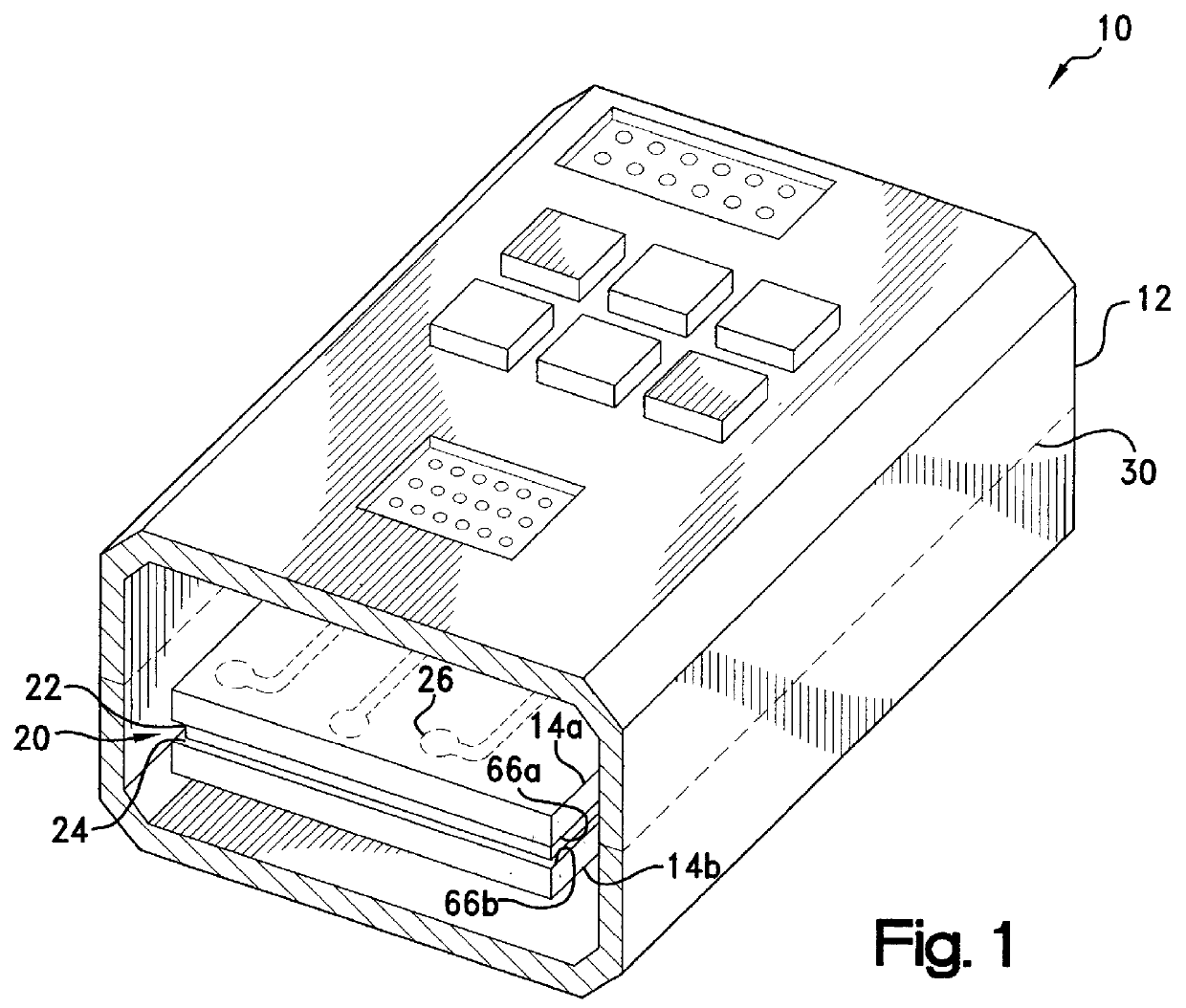

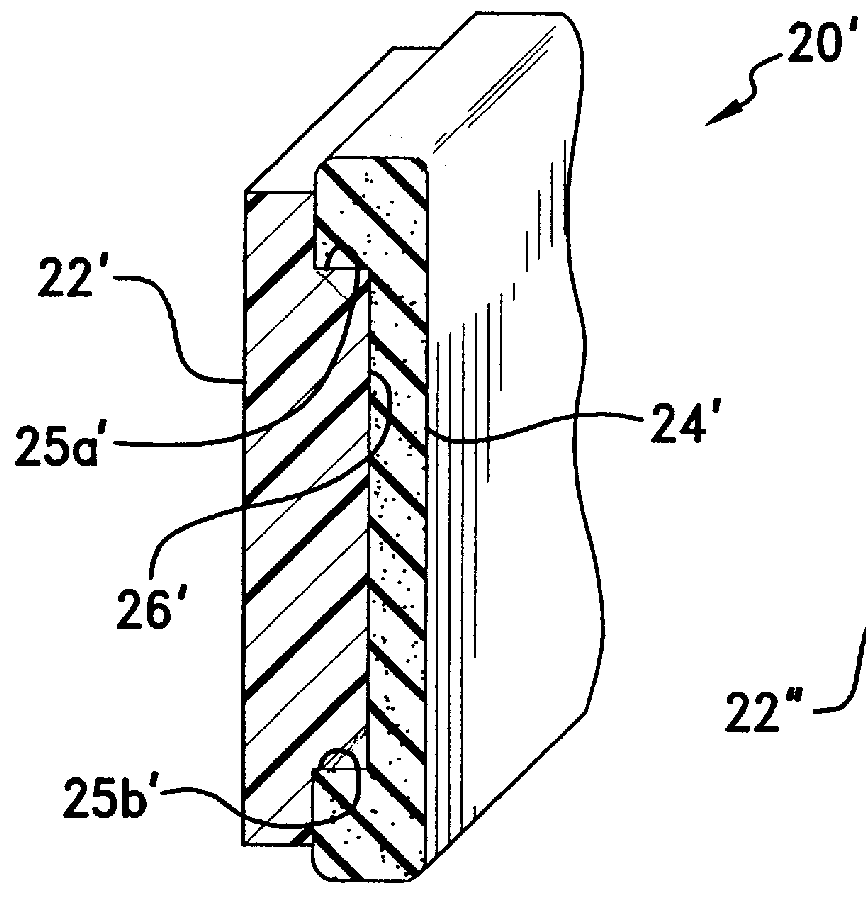

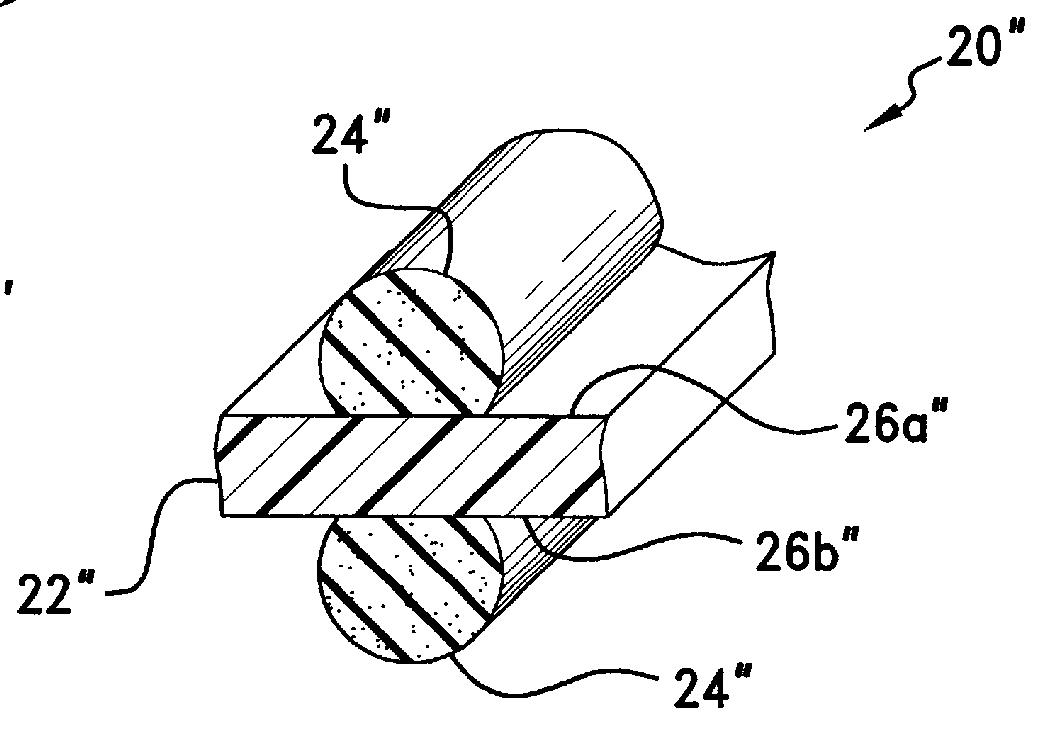

Low closure force EMI shielding spacer gasket

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

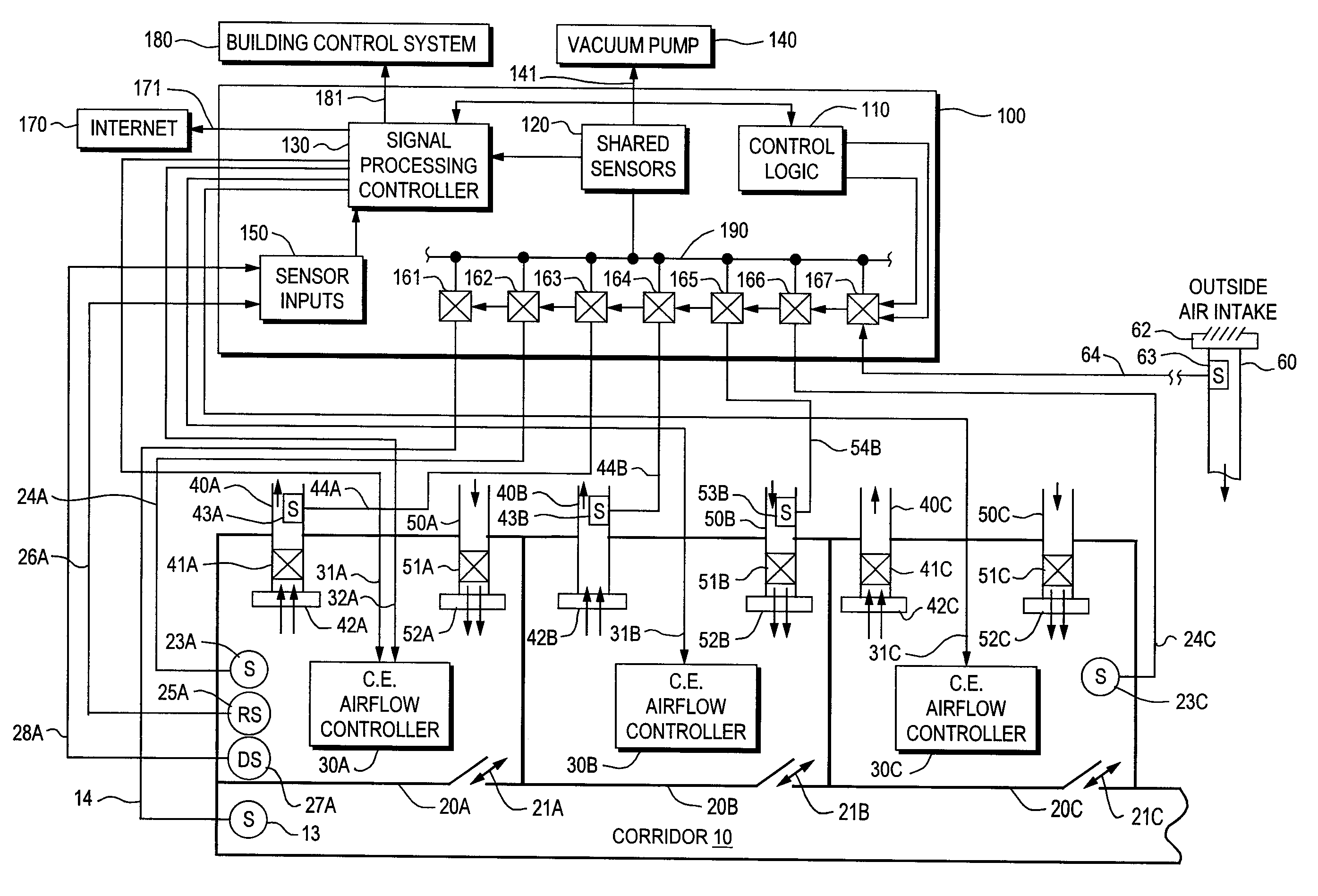

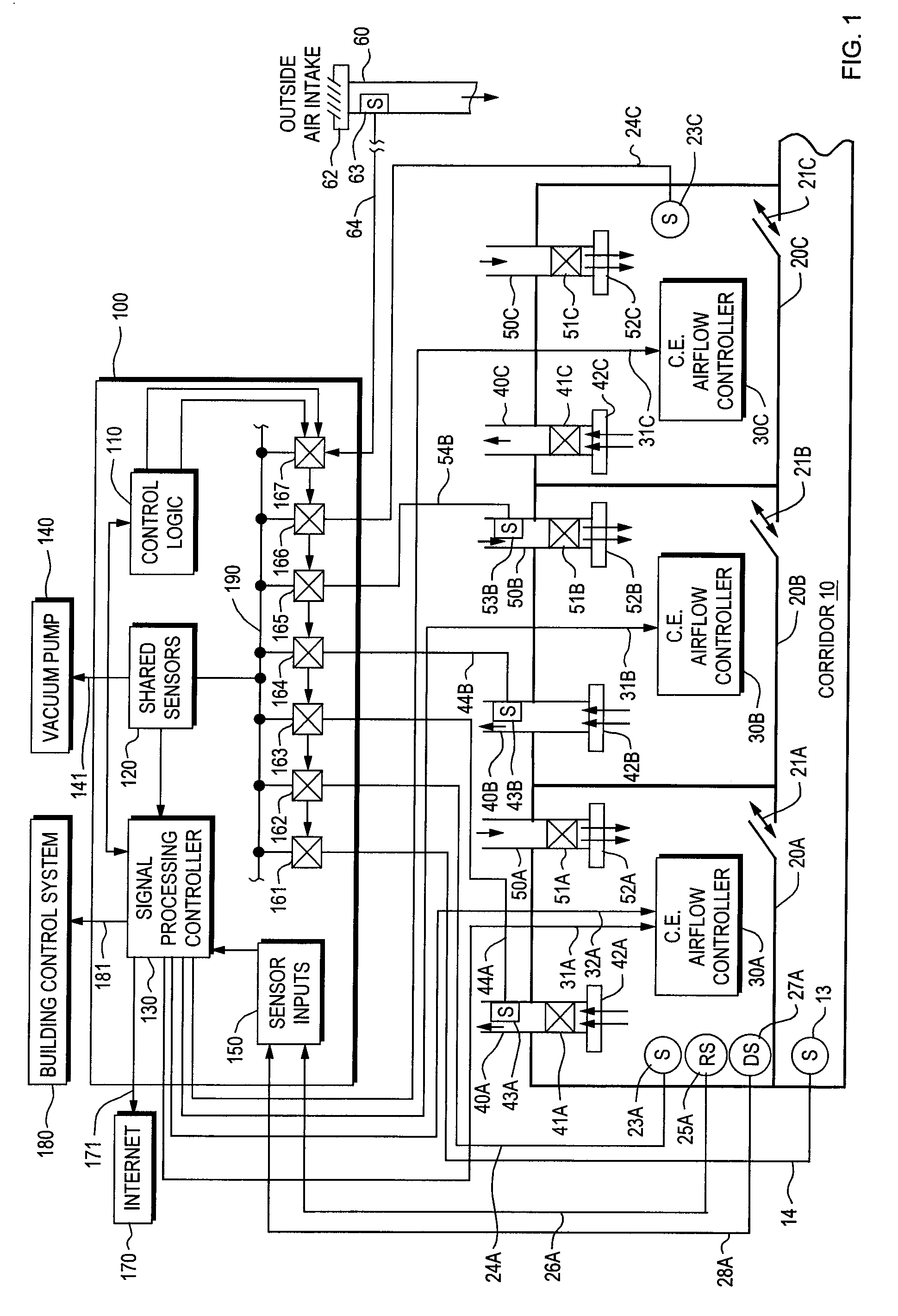

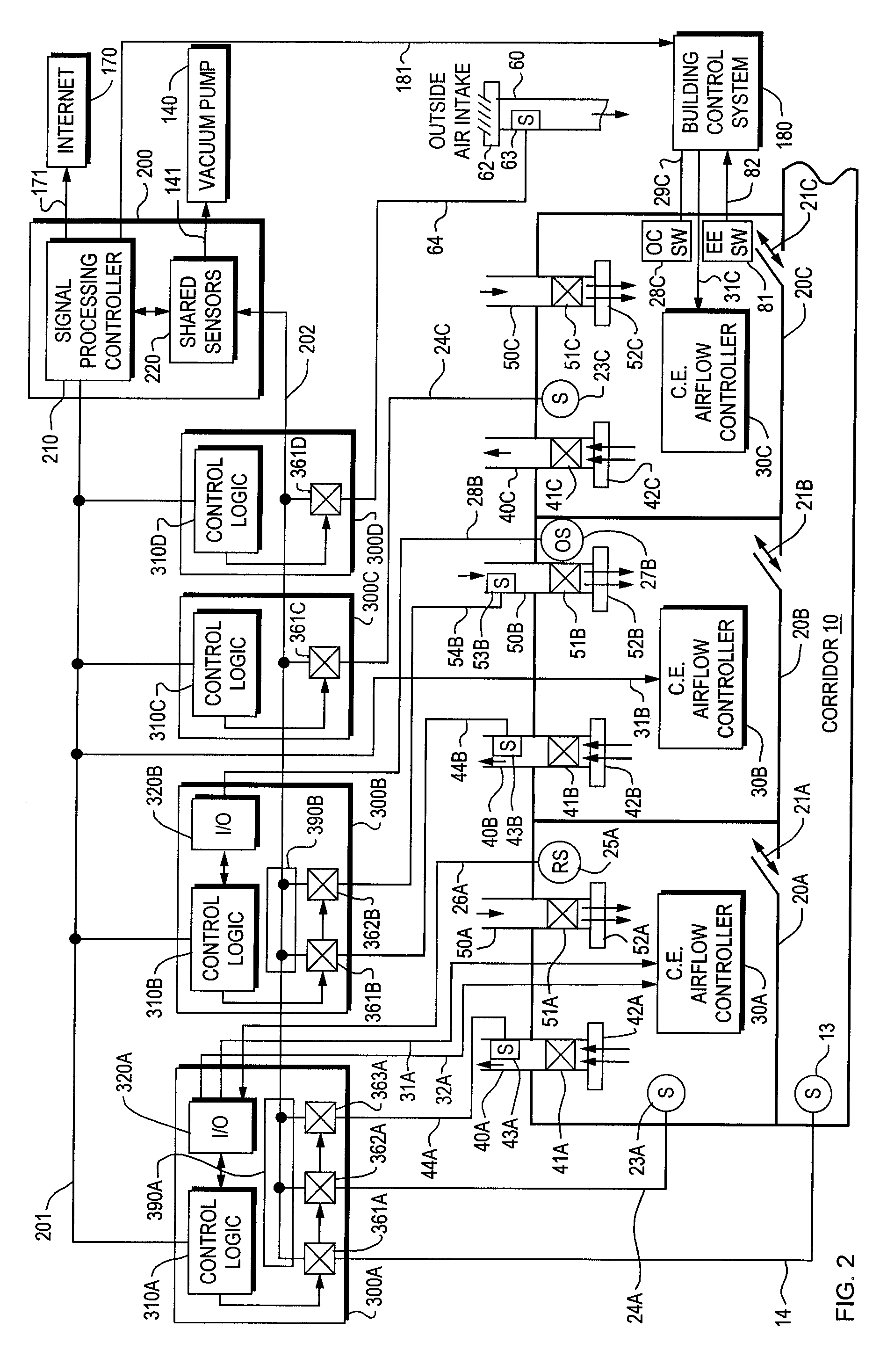

Dynamic control of dilution ventilation in one-pass, critical environments

InactiveUS20070082601A1Quick evacuationIncrease rate of changeDucting arrangementsMechanical apparatusAir contaminantControl system

A dilution ventilation control system for use in a one-pass, critical environments comprising: one or more one-pass, critical environments comprising, a variable source of supply airflow volume, an exhaust for completely exhausting the airflow volume supply from the critical environment and from a building comprising the critical environment through one or more exhaust ducts; and at least one an airflow control device provided in one or more of the ducts to vary the exhaust airflow volume from the critical environment; a facility monitoring system comprising at least one air contaminant sensor for sensing at least one air contaminant of the critical environment; a signal processing controller that generates one or more airflow command signals based at least in part on at least one sensed air contaminant; and a critical environment airflow controller that uses the airflow command signal to at least partially control the critical environment's supply and exhaust airflow volumes.

Owner:DESROCHERS ERIC M +1

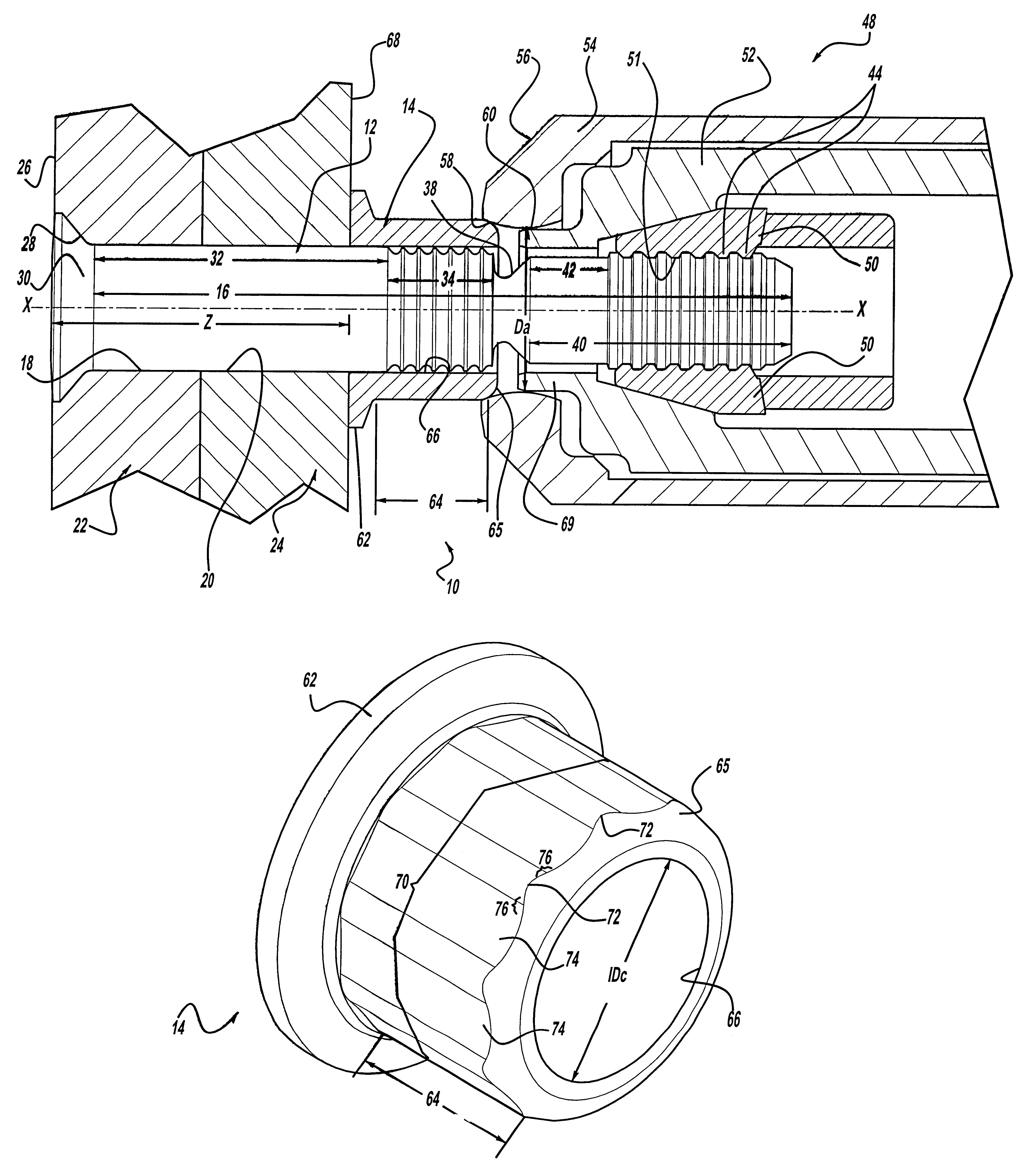

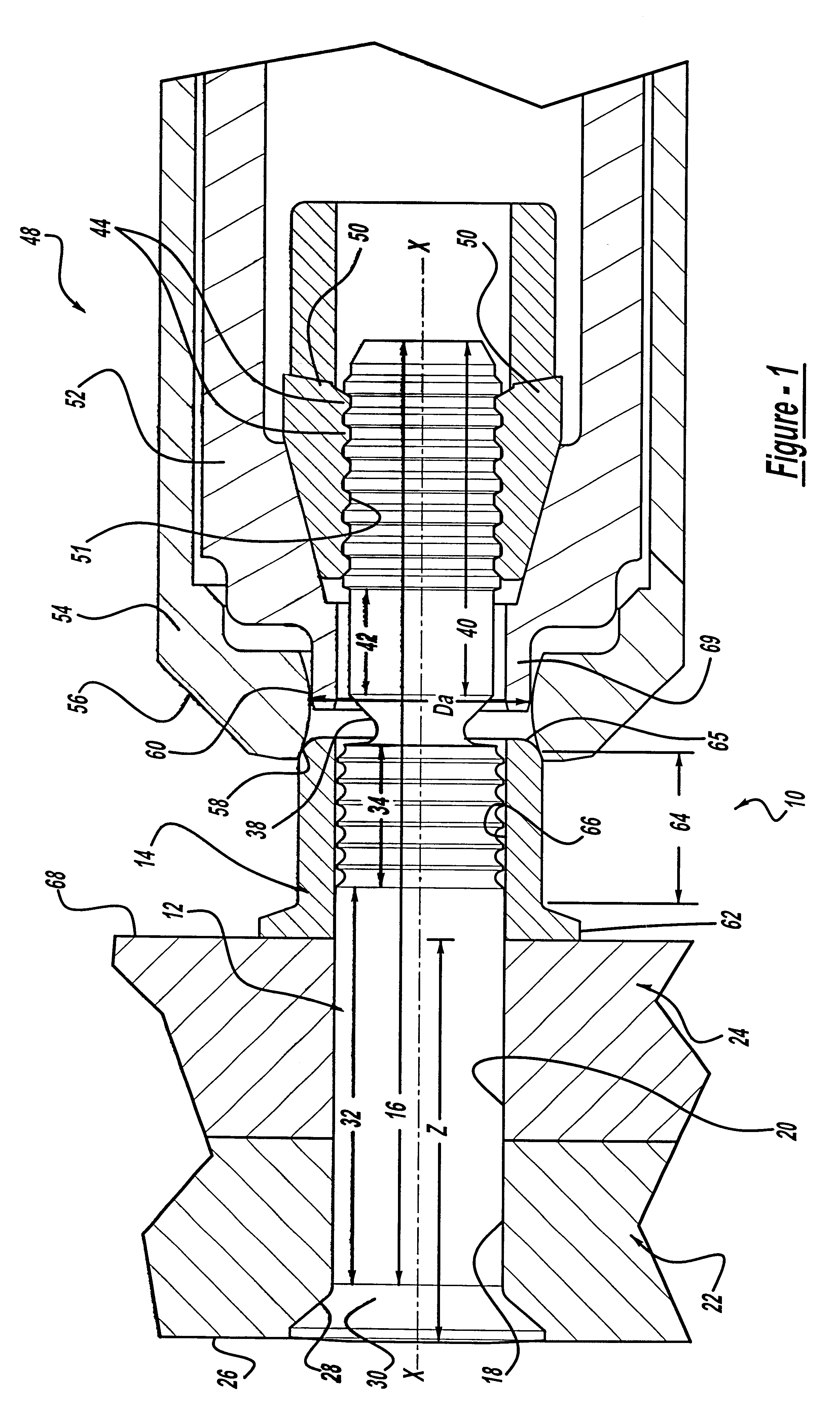

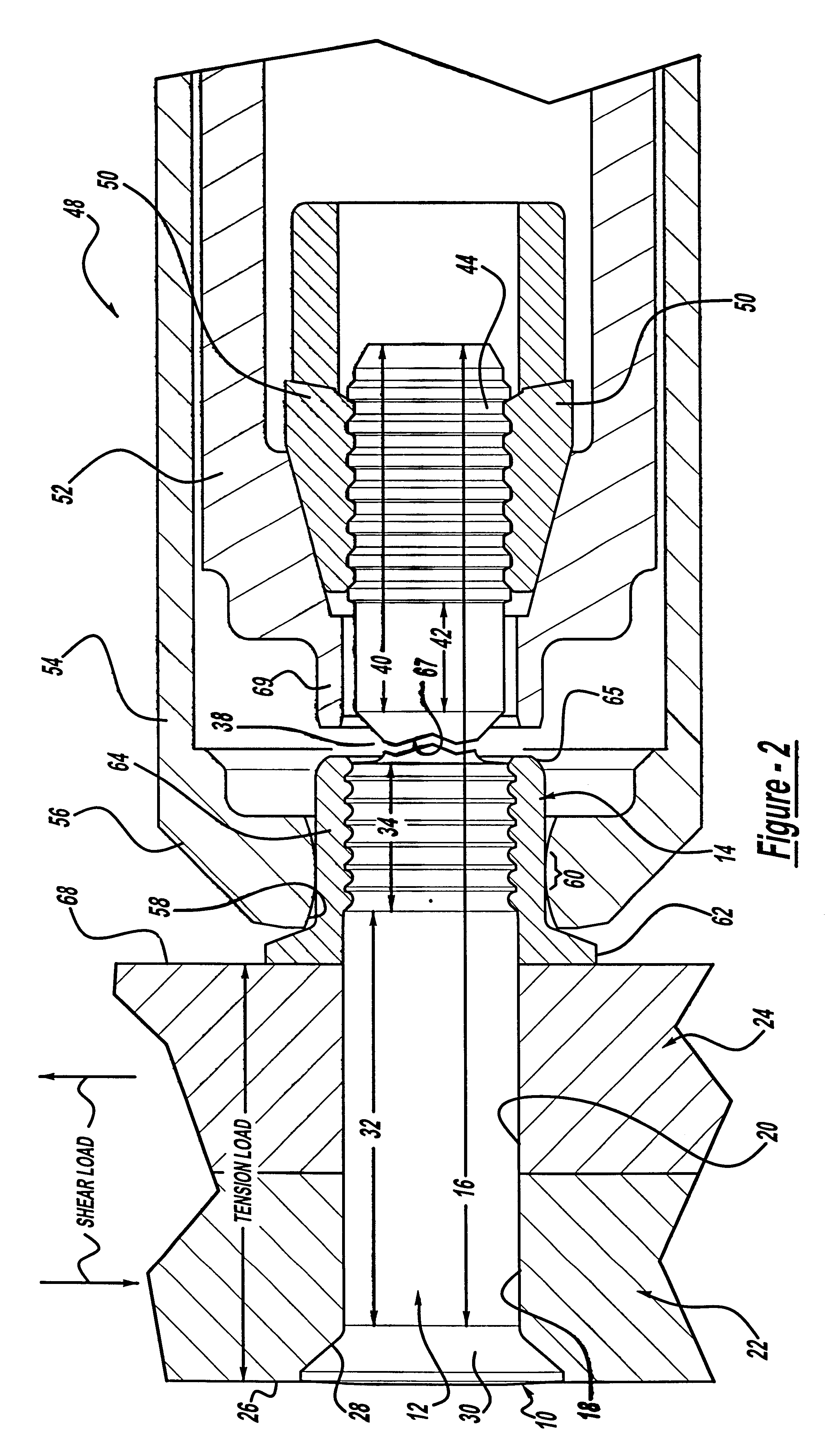

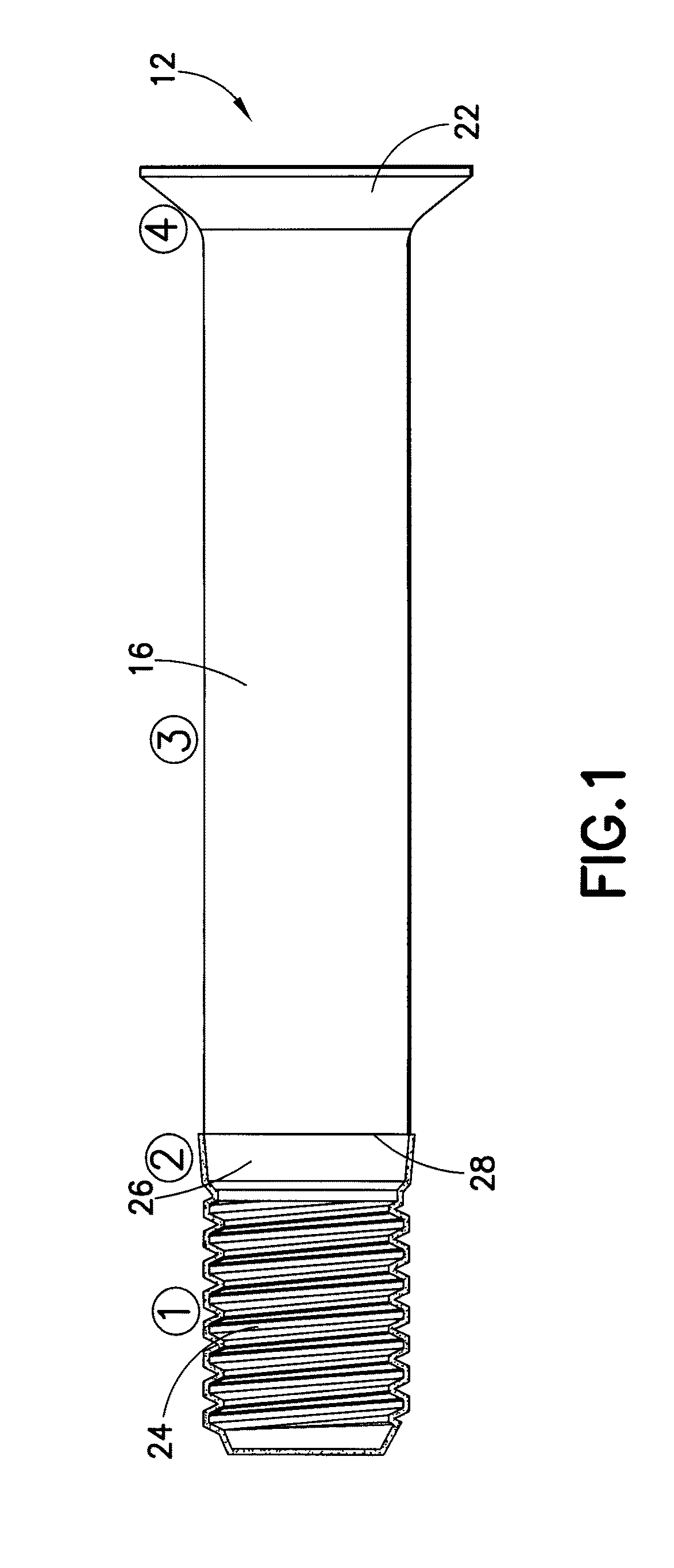

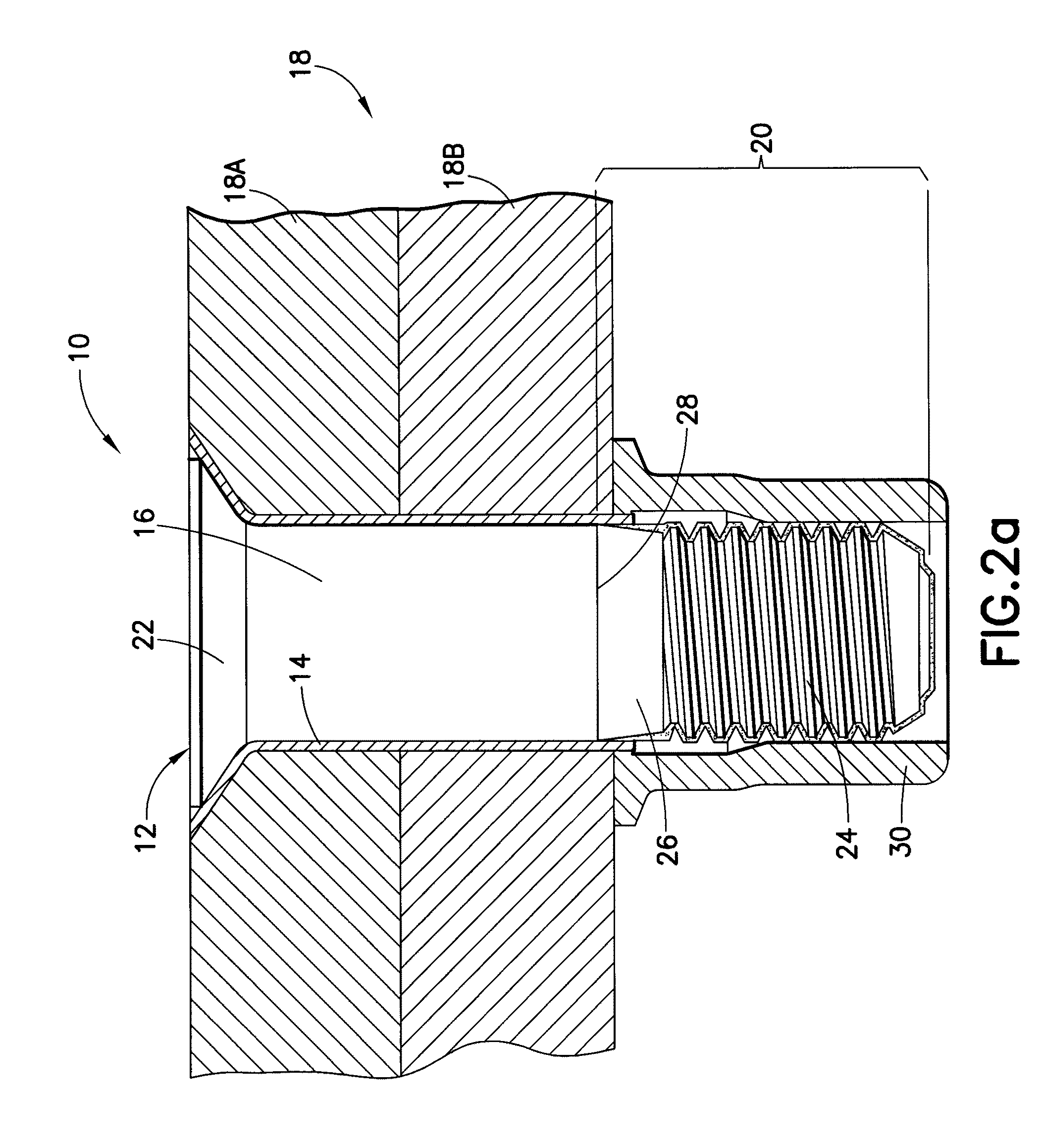

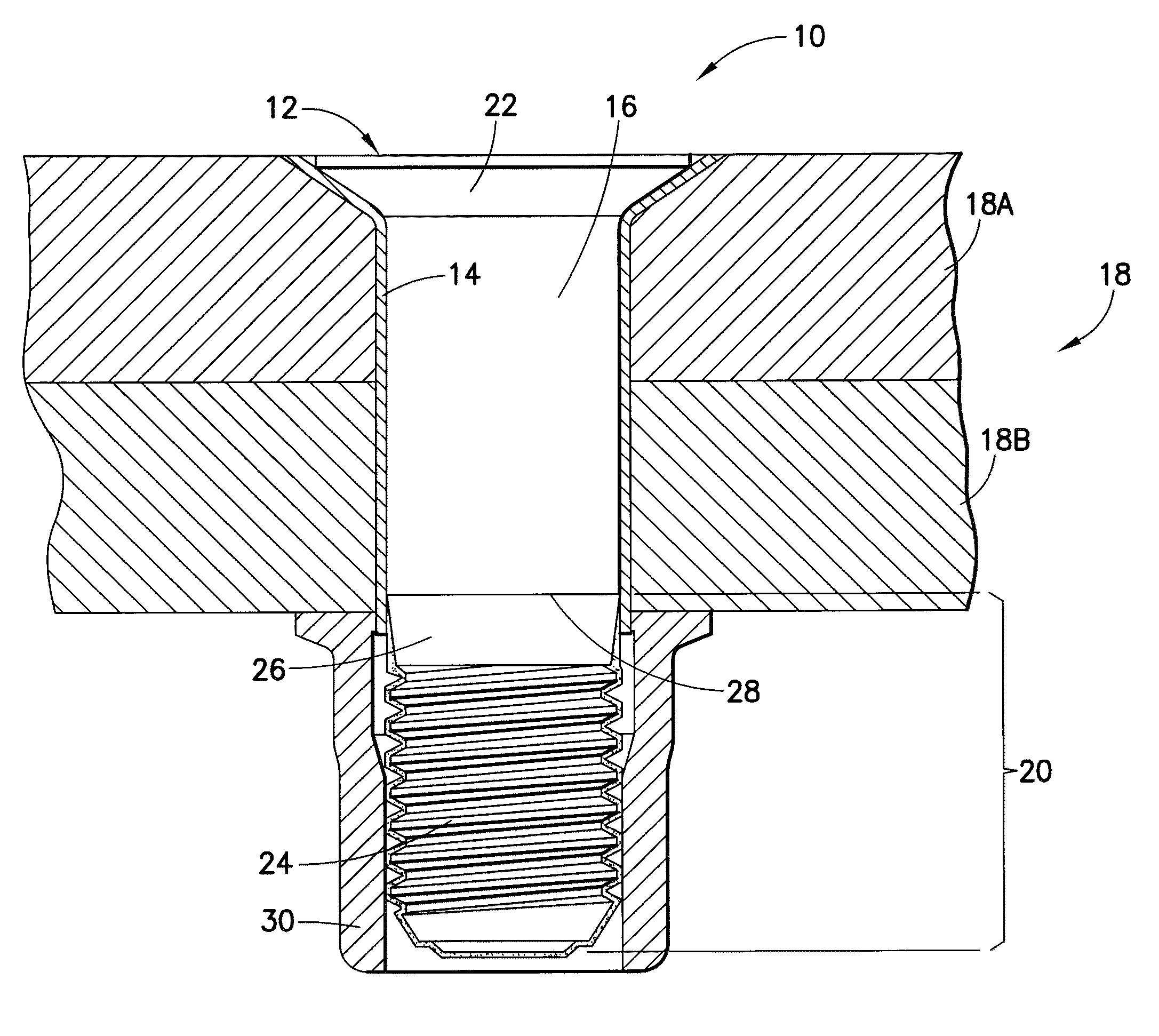

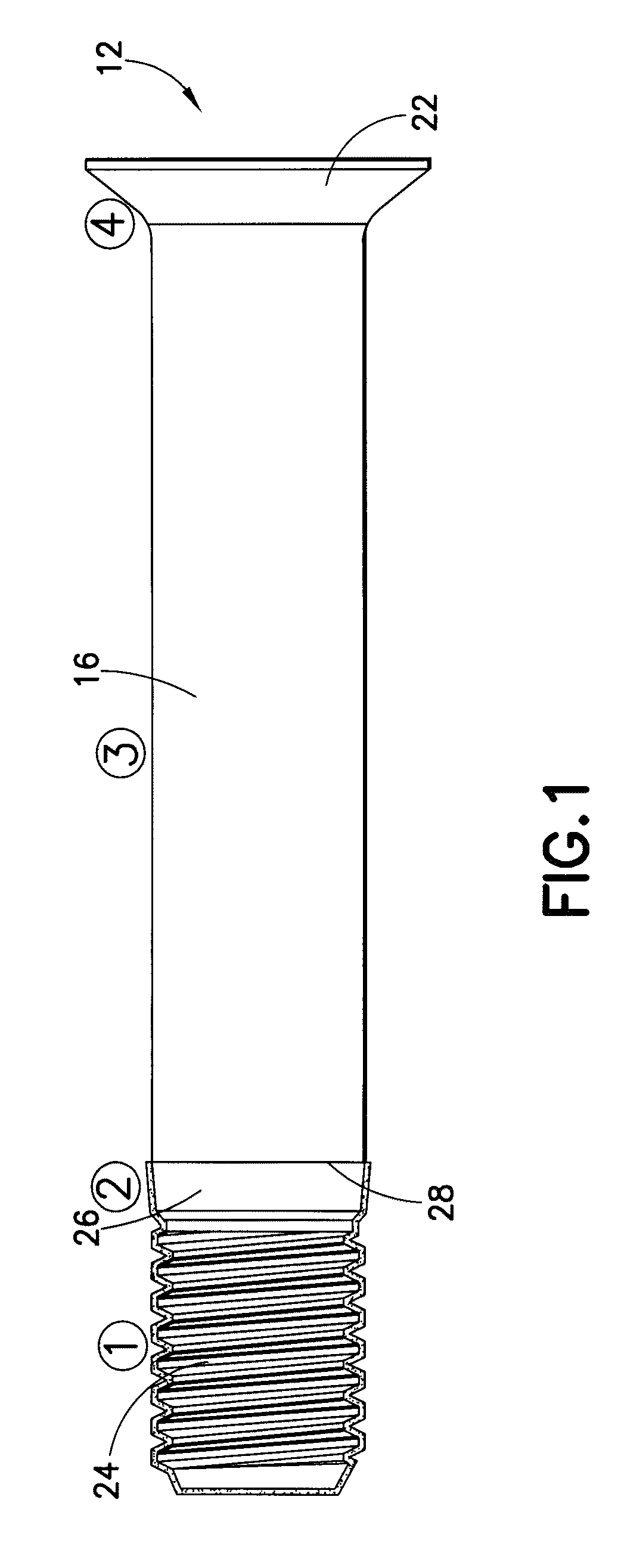

Swage type fastener with low swage load

InactiveUS6325582B1Reduce loadMinimized installation weightRivetsScrewsEngineeringUltimate tensile strength

A two piece fastener system for including a pin member and a collar having an optimized strength with the materials of the pin member and collar having a predetermined shear strength ratio; the collar has a preselected excess volume to provide a desired "overpacking' condition and is of a size whereby after swage it will define a minimum wall thickness; the collar has an outer surface with a contour which in combination with a preselected excess volume results in a reduction in load required to swage the collar and with a pull type fastener providing a breakneck groove of reduced strength whereby severance of the pintail will occur at a reduced load resulting in a reduction in shock or ghost load applied to workpieces including those of a plastic or composite material.

Owner:HUCK INT INC

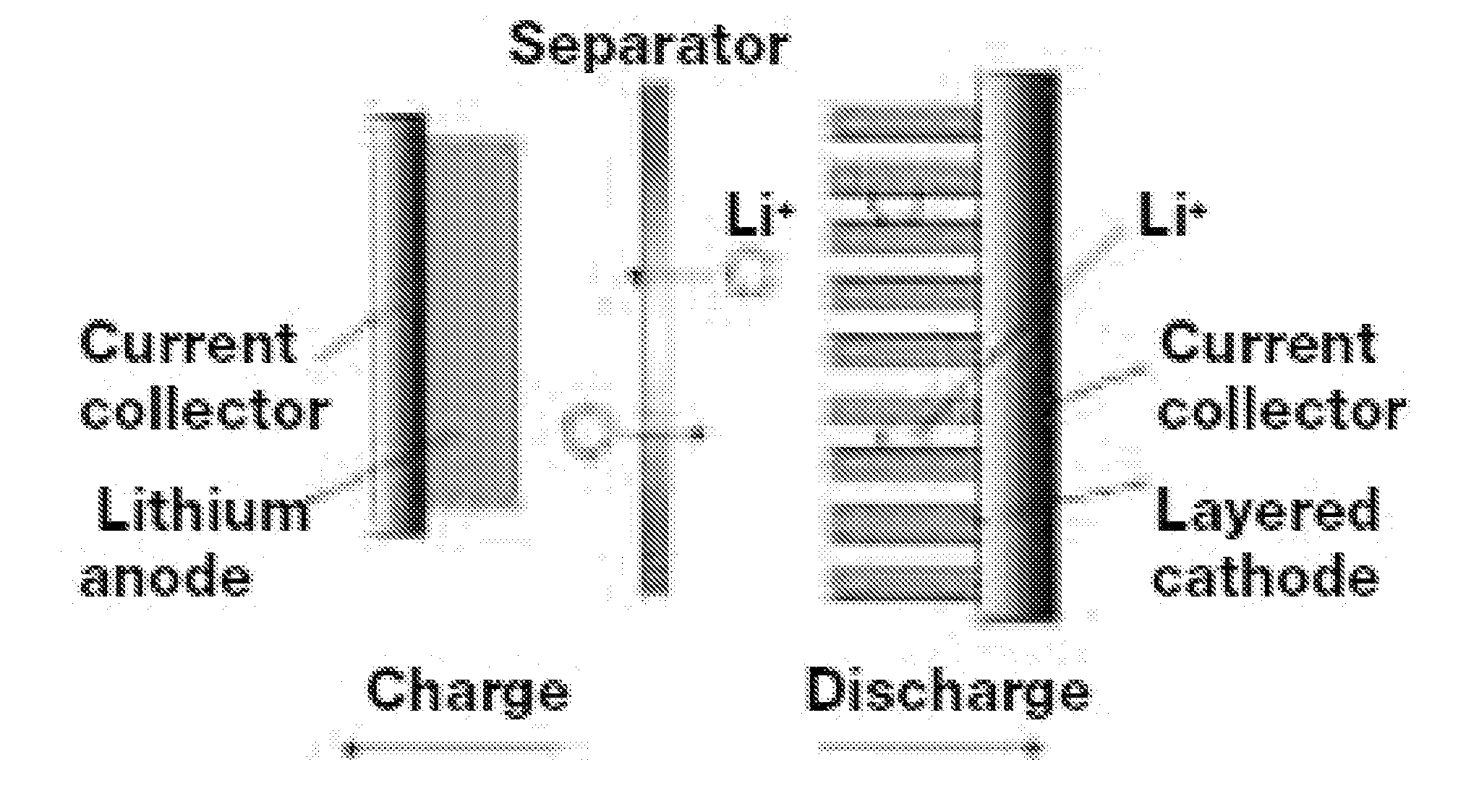

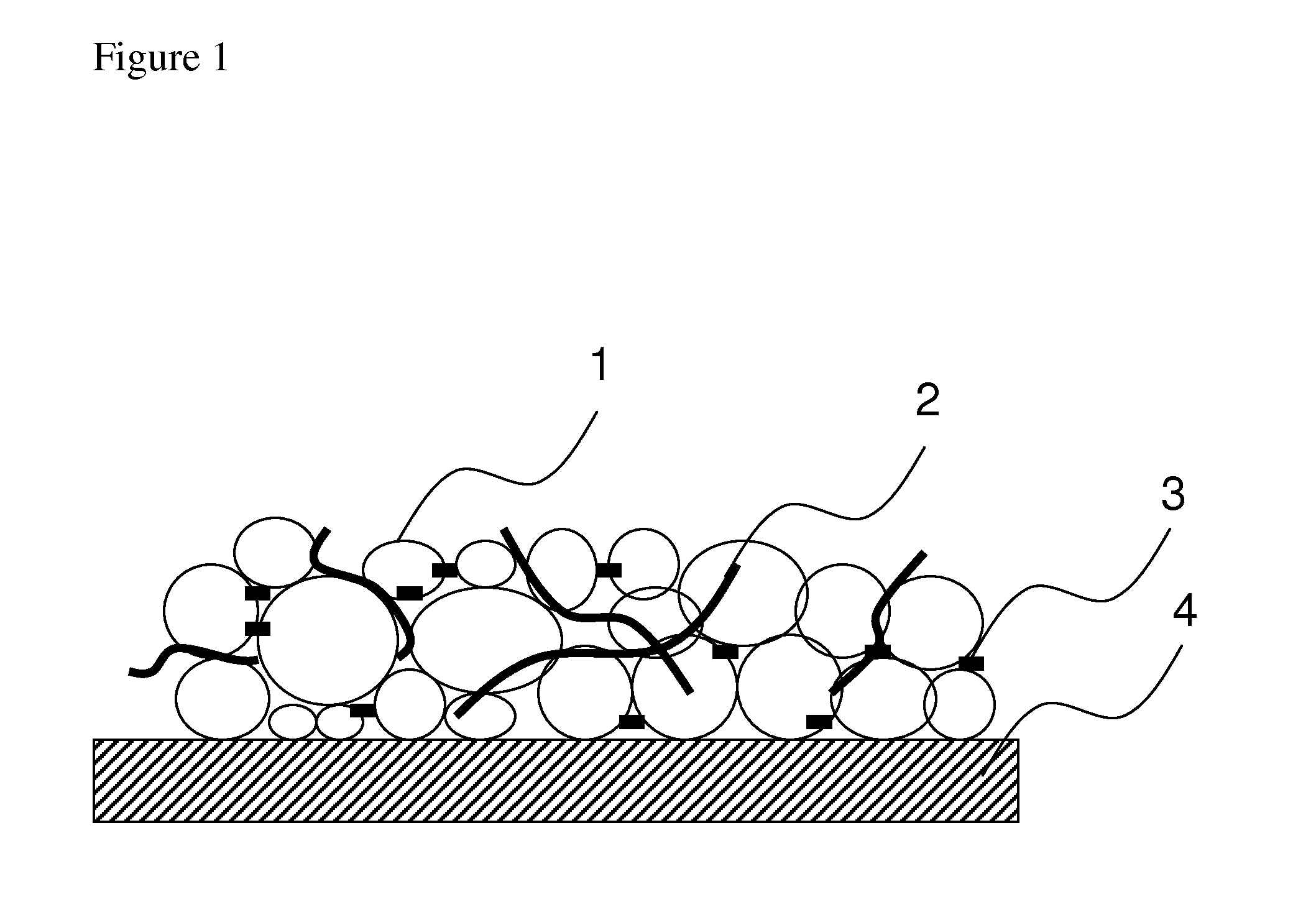

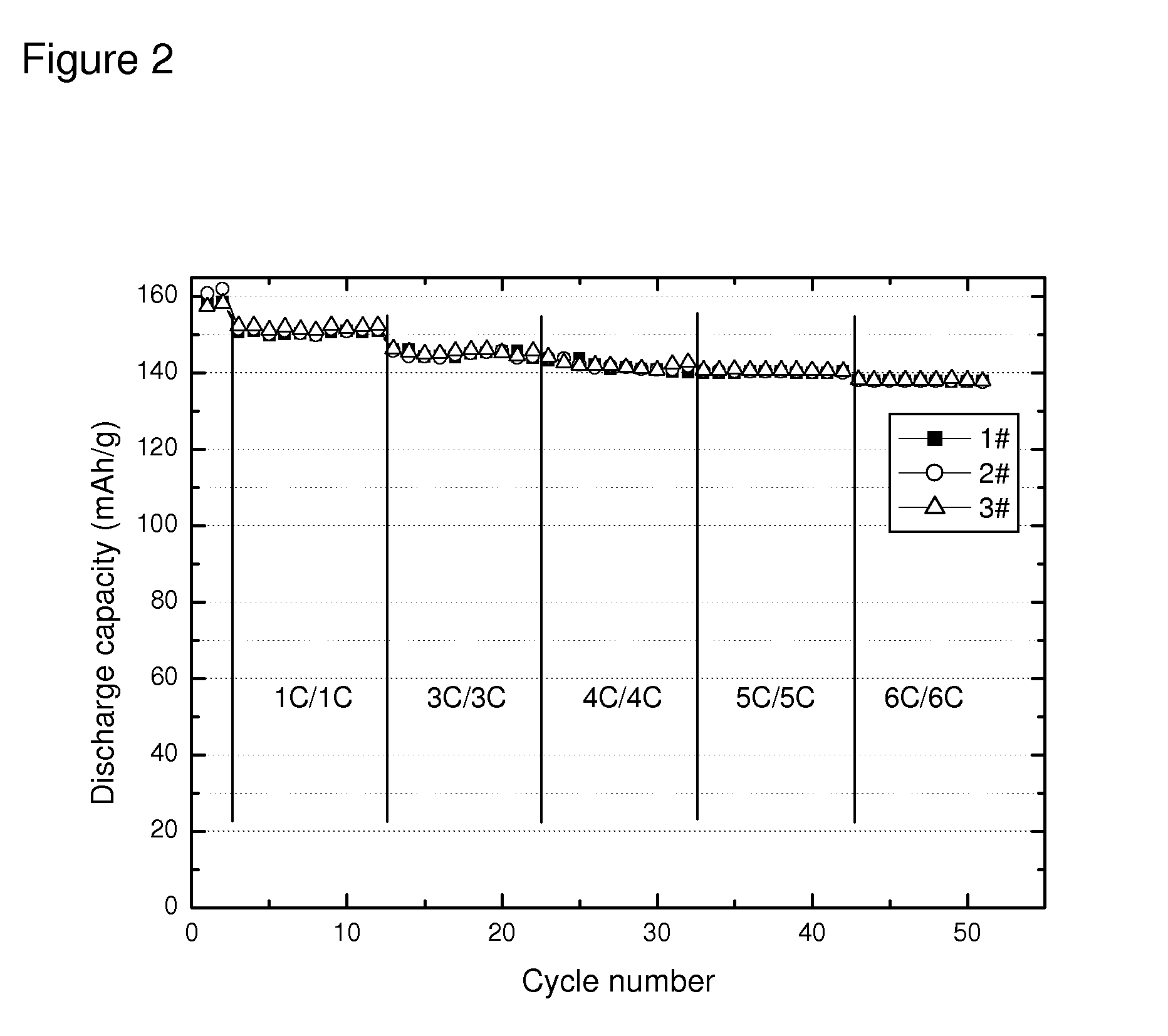

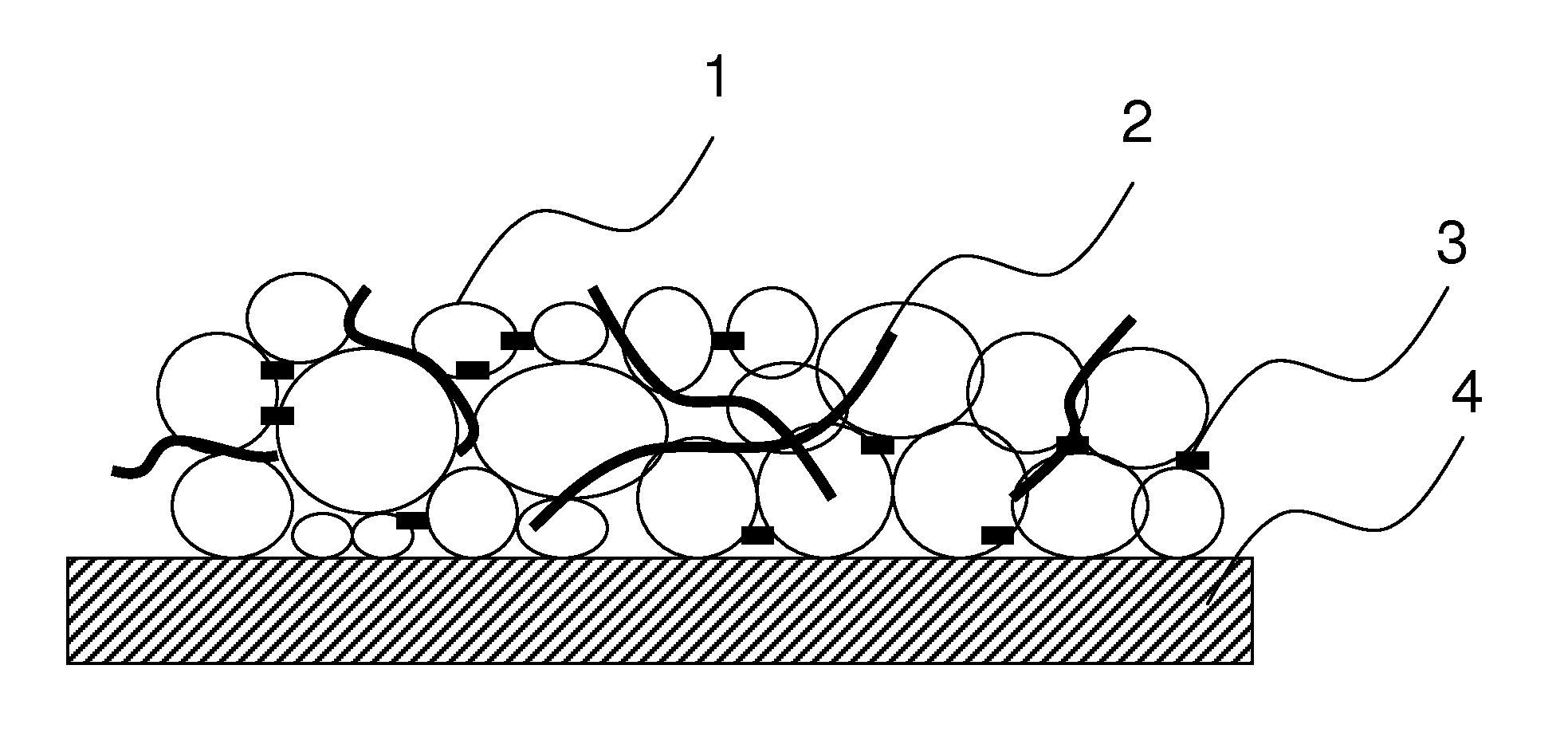

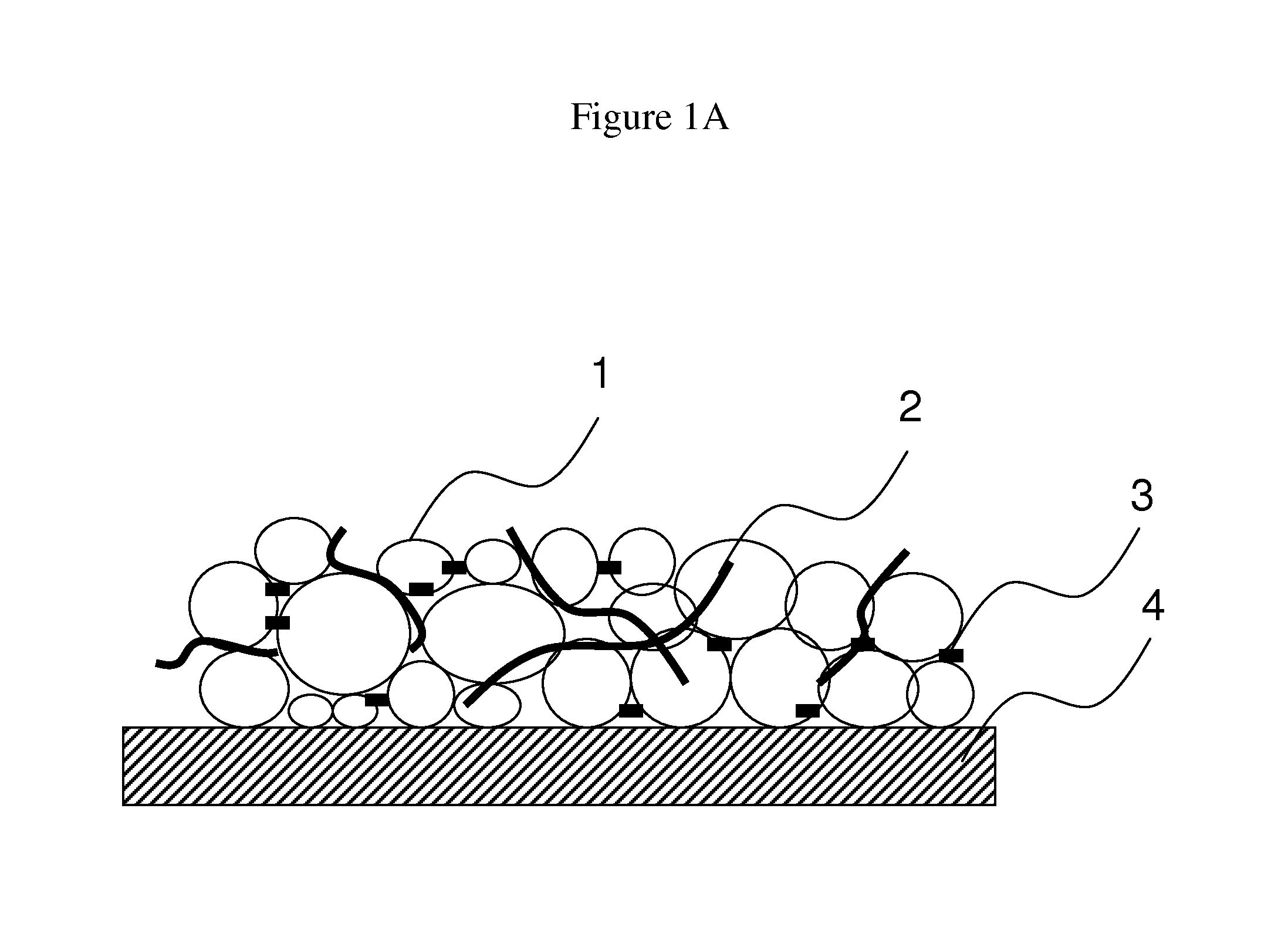

Enhanced Electrode Composition for Li ion Battery

InactiveUS20110171371A1Less filler loadingLess loadNon-metal conductorsMaterial nanotechnologyCarbon nanotubeLithium-ion battery

Carbon nanotube-based compositions and methods of making an electrode for a Li ion battery are disclosed. It is an objective of the instant invention to disclose a composition for preparing an electrode of a lithium ion battery with incorporation of carbon nanotubes with more active material by having less conductive filler loading and less binder loading such that battery performance is enhanced.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

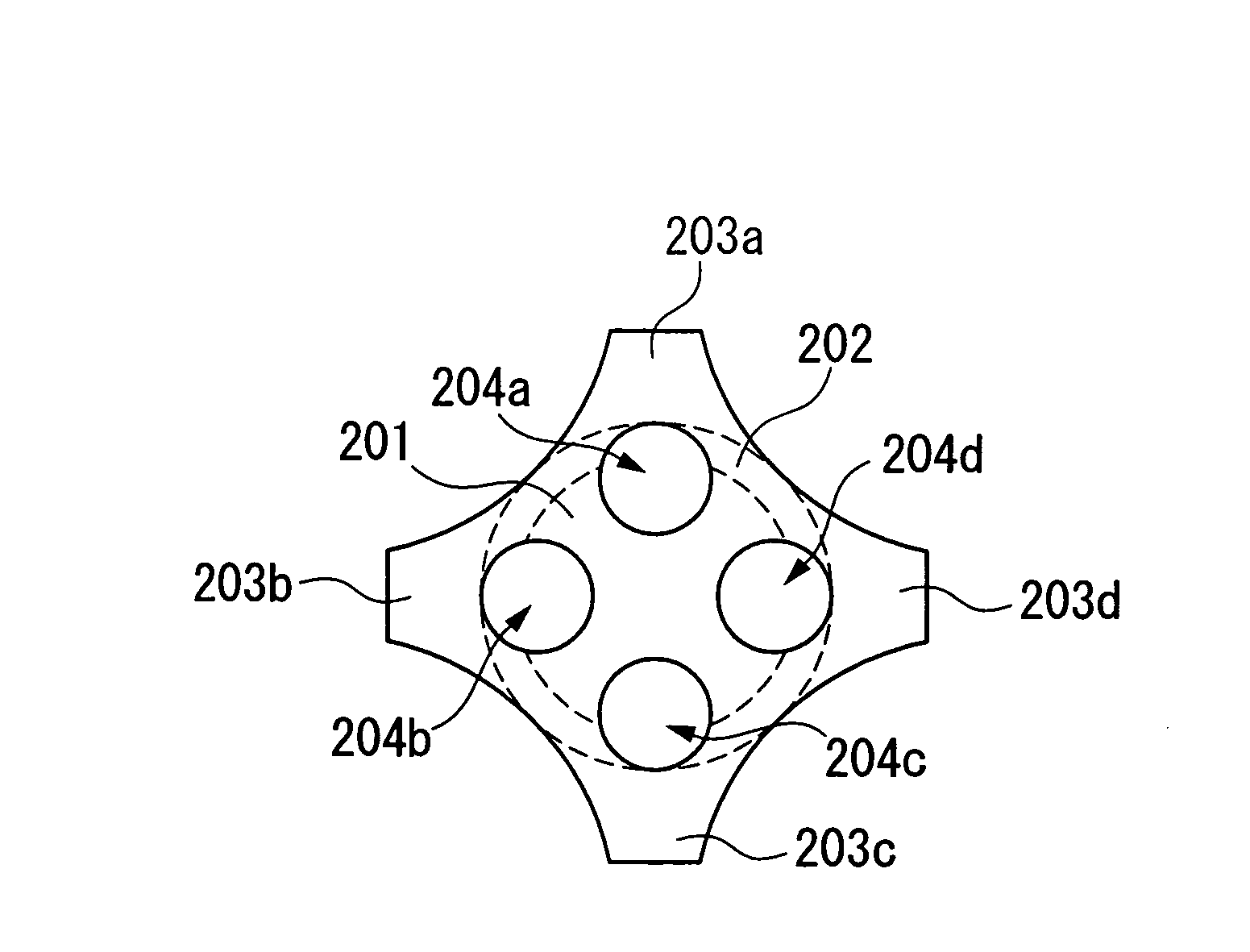

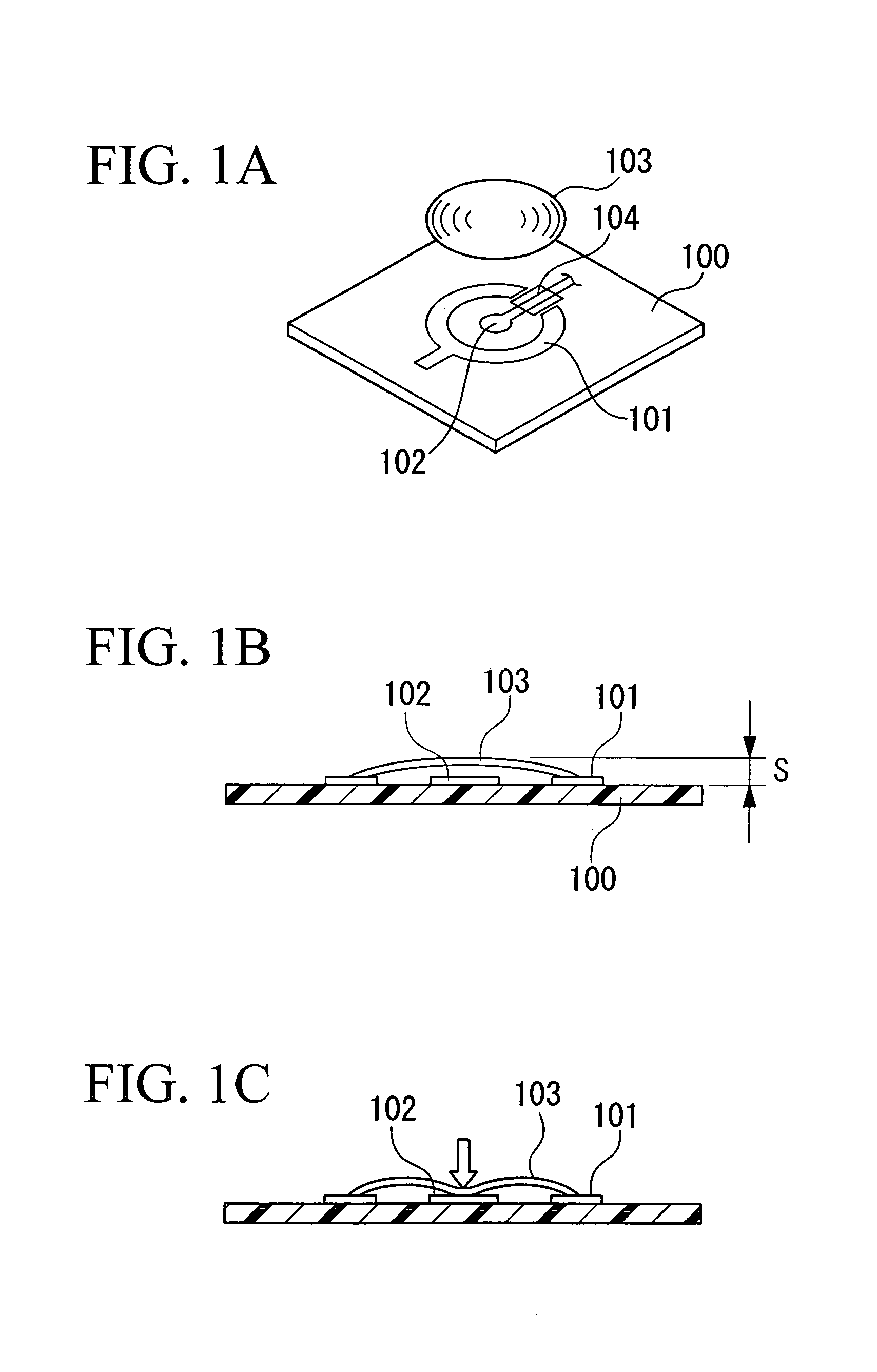

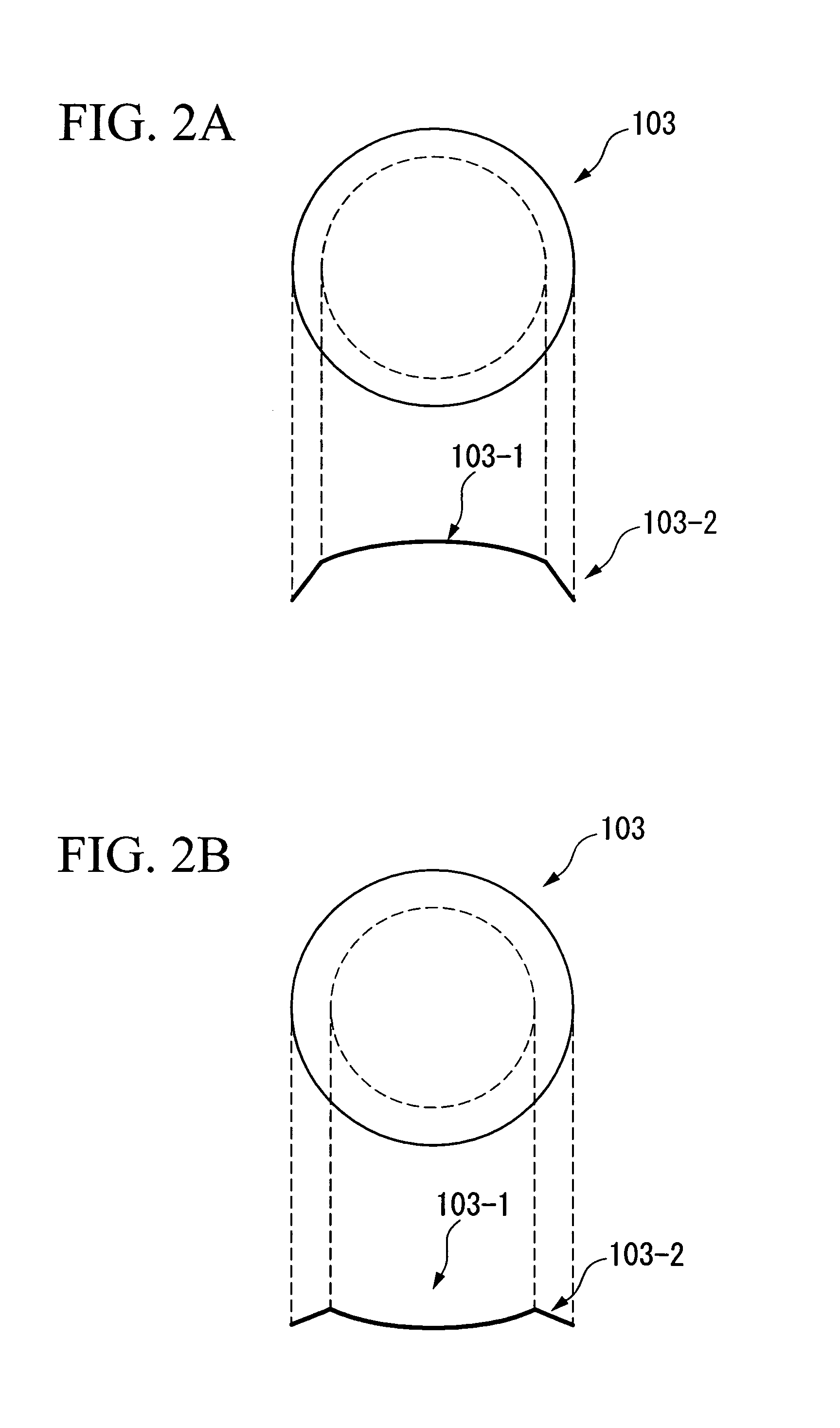

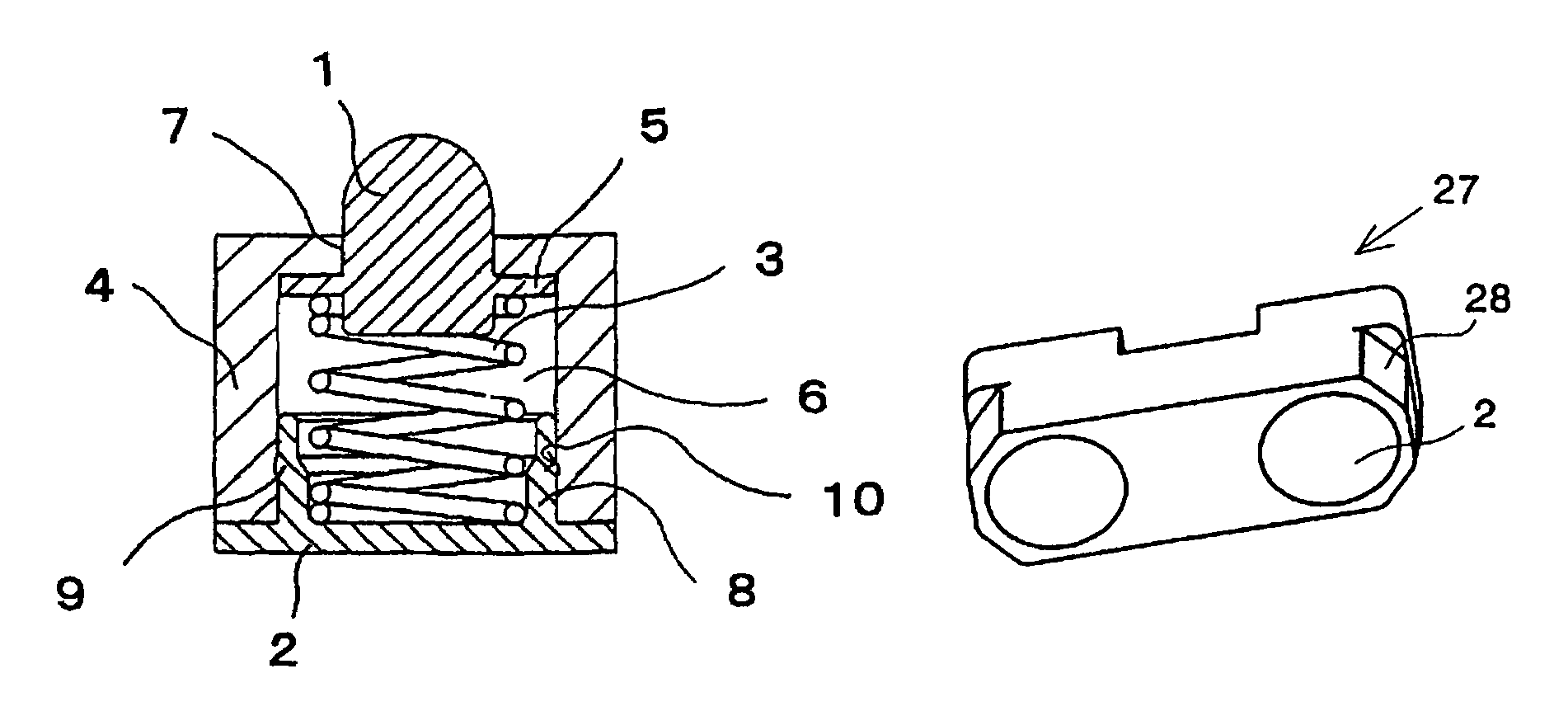

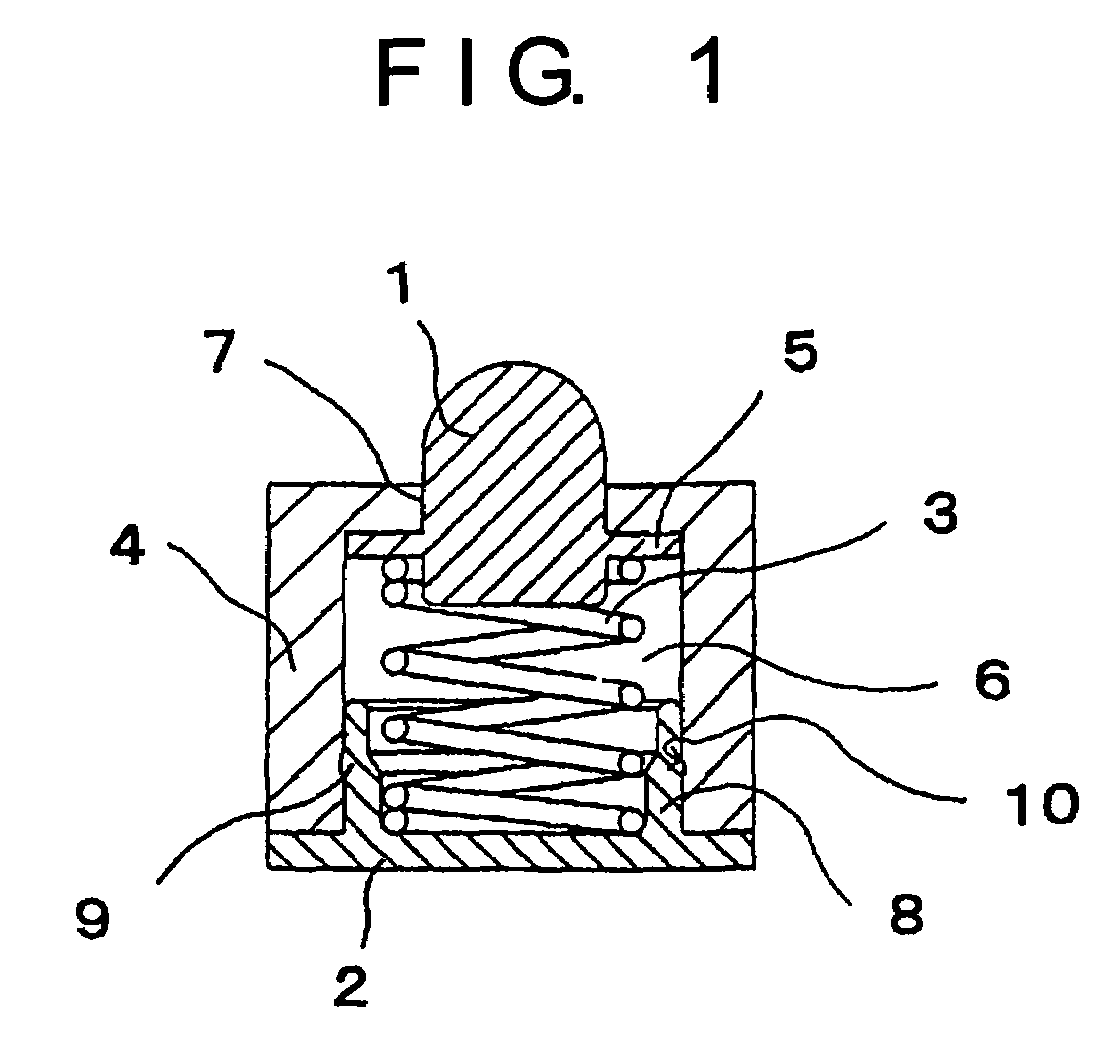

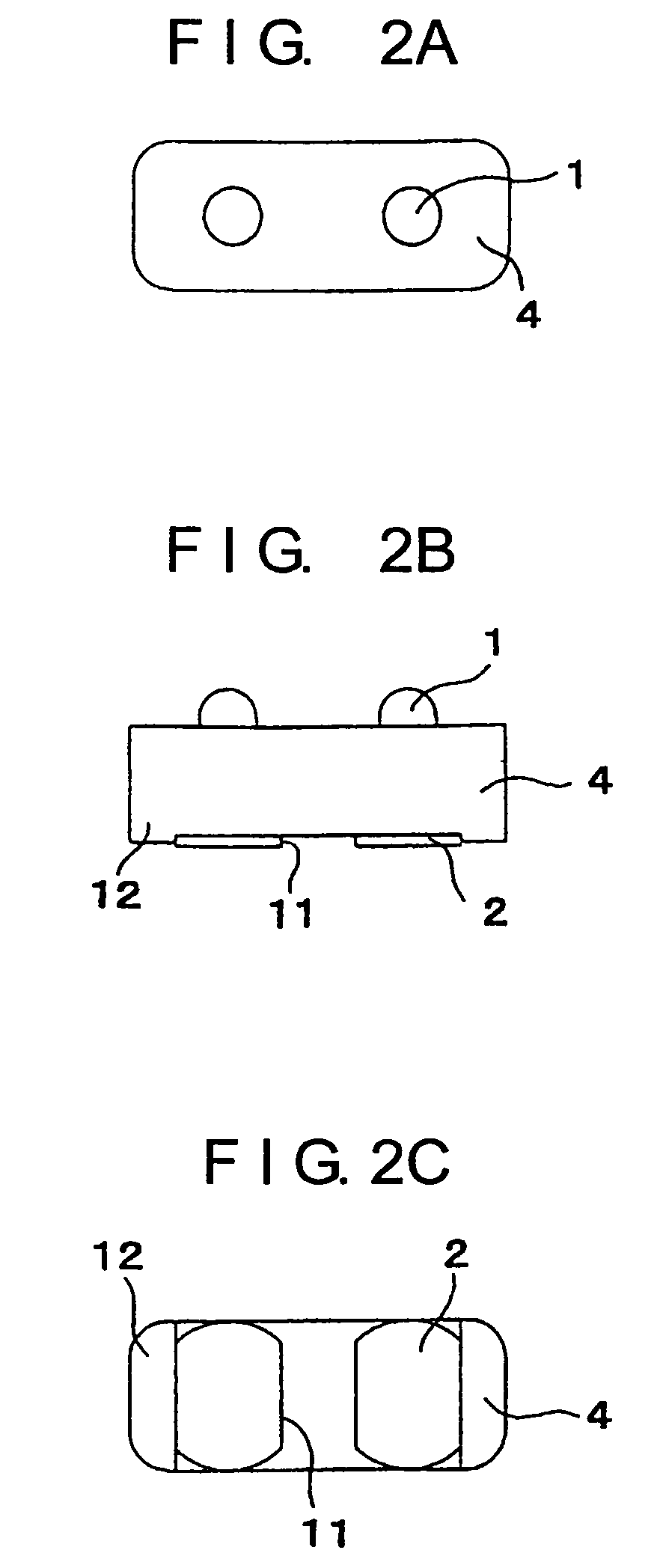

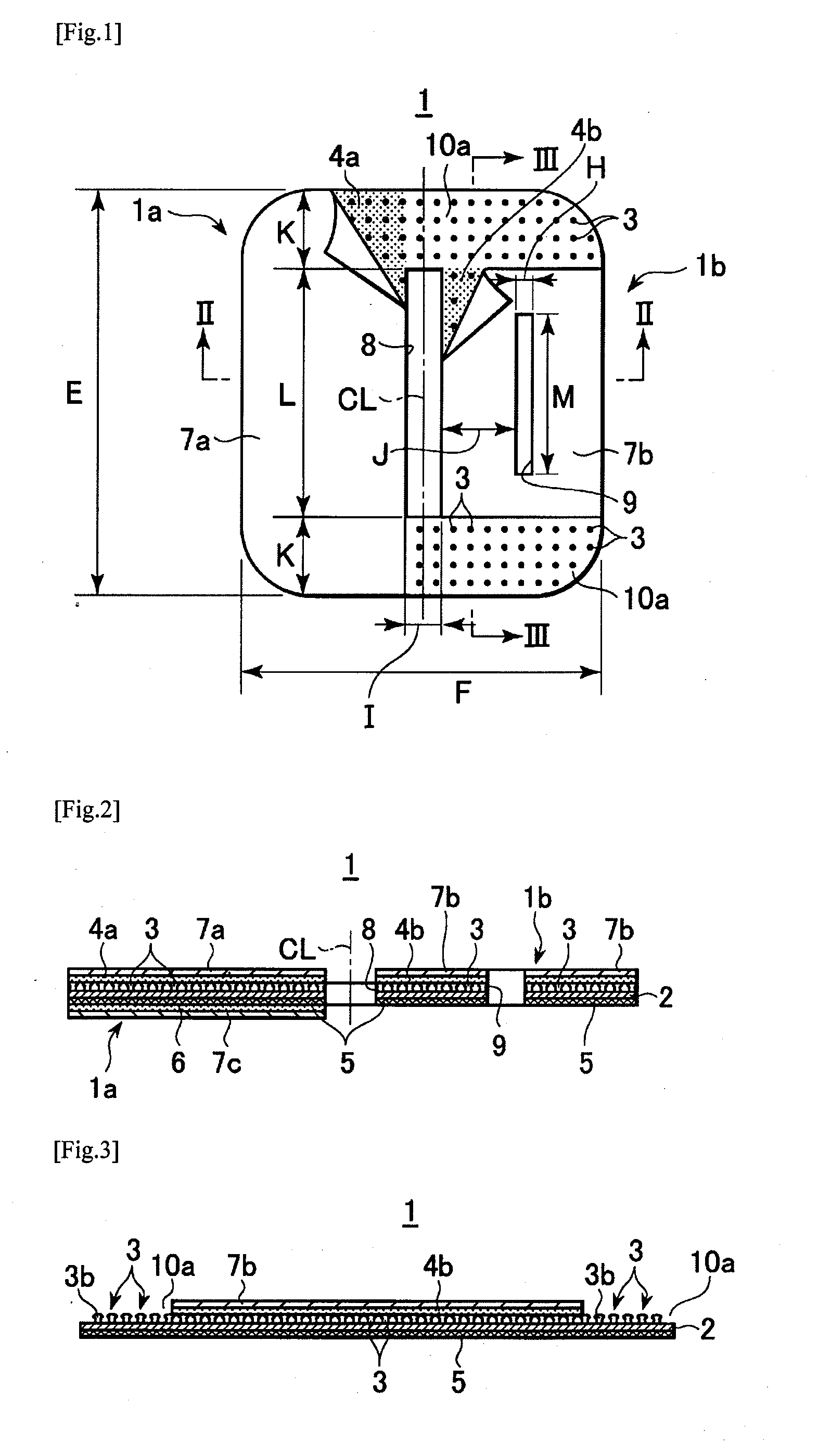

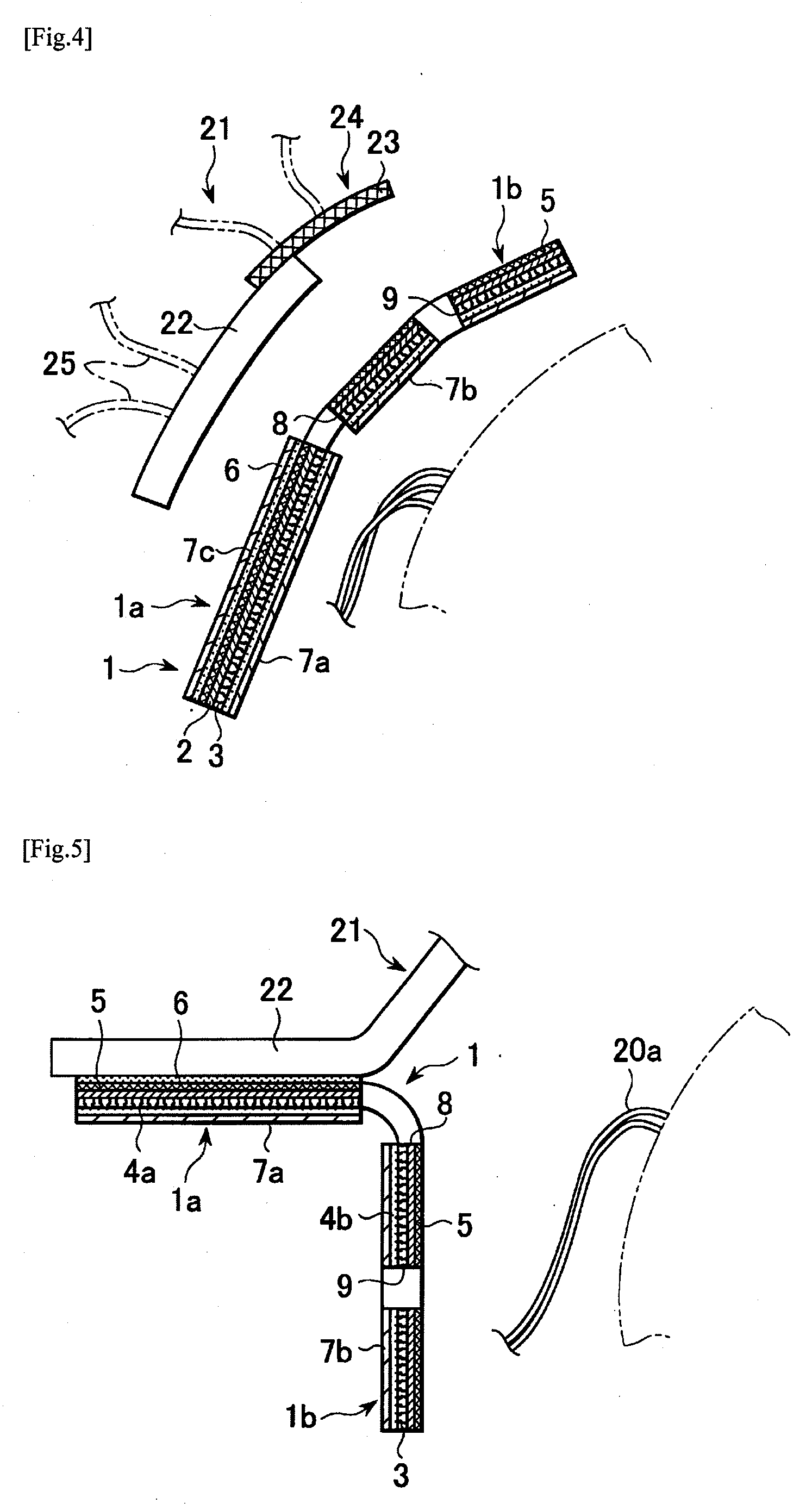

Diaphragm for use in switch, method for manufacturing thereof, membrane switch, and input device

InactiveUS7301113B2Reduce load requirementsReduce deformation areaContact surface shape/structureSnap-action arrangementsMembrane switchMechanical engineering

Owner:THE FUJIKURA CABLE WORKS LTD

Enhanced Electrode Composition For Li ion Battery

InactiveUS20130004657A1Increase storage capacityLess filler loadingMaterial nanotechnologyNon-metal conductorsBi modalCarbon nanotube

Carbon nanotube-based compositions and methods of making an electrode for a Li ion battery are disclosed. It is an objective of the instant invention to disclose a composition for preparing an electrode of battery, optionally a lithium ion battery, with incorporation of a bi-modal diameter distributed carbon nanotubes with more active material by having less total conductive filler loading, less binder loading, and better electrical contact between conductive filler with active battery materials such that battery performance is enhanced.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

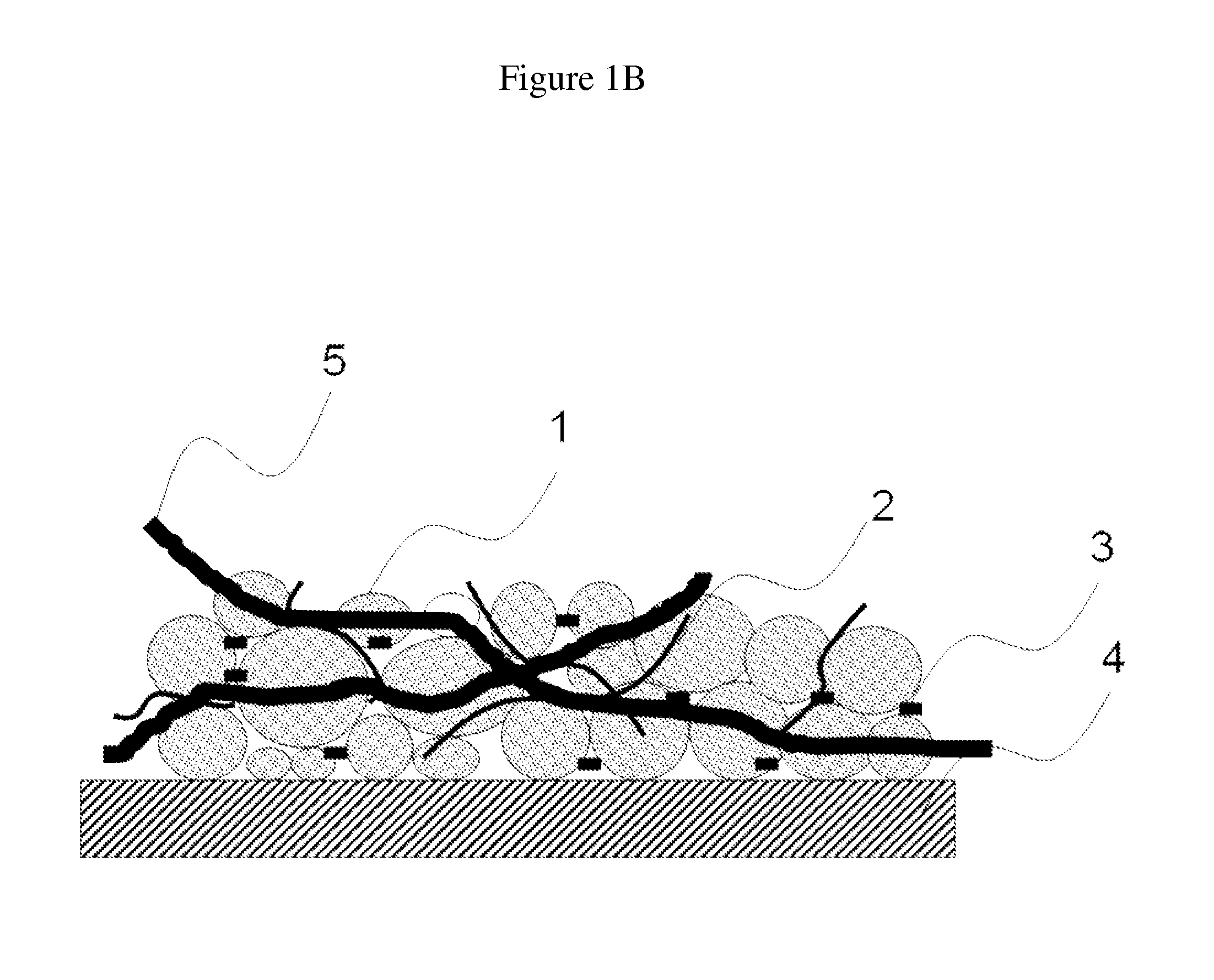

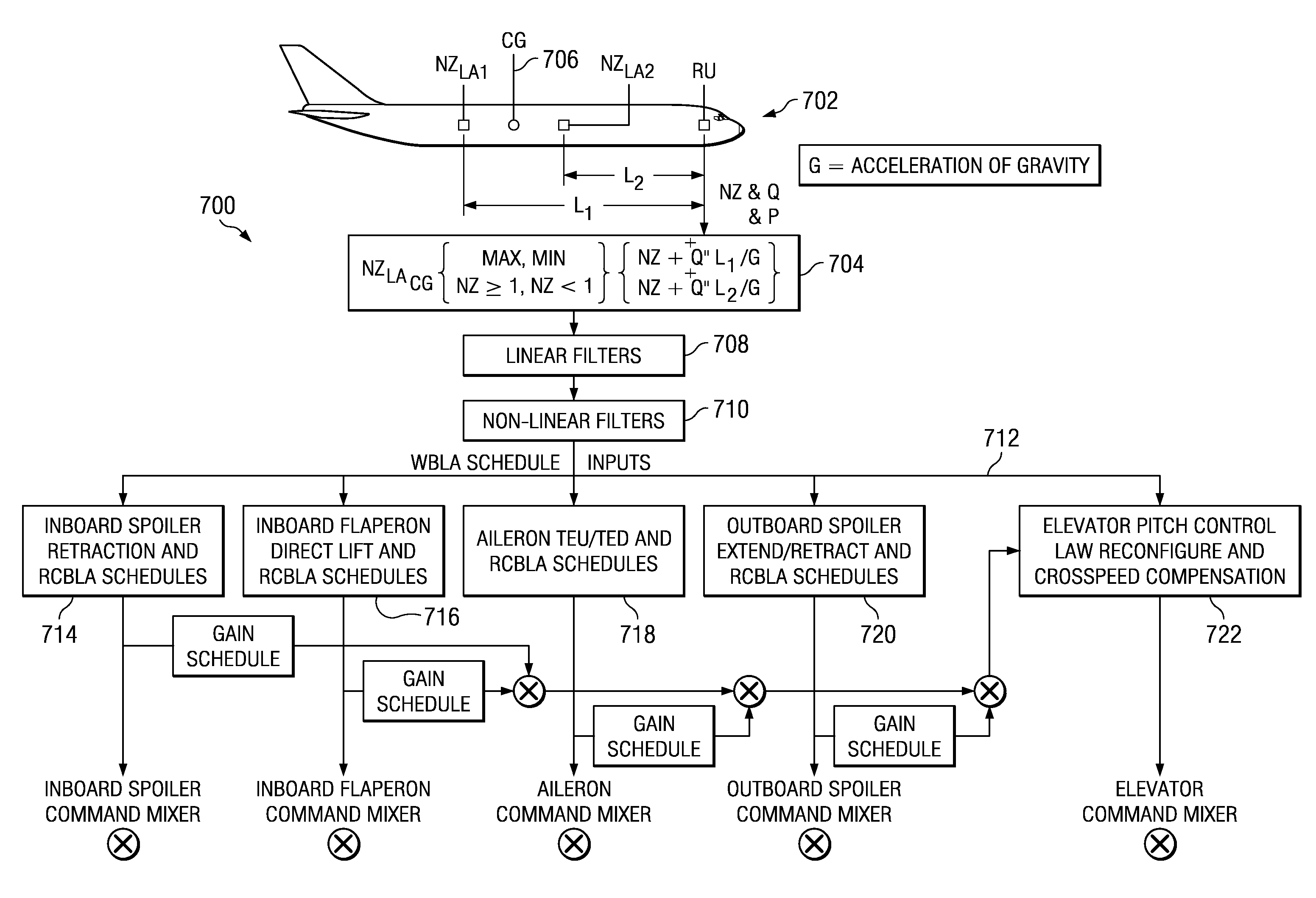

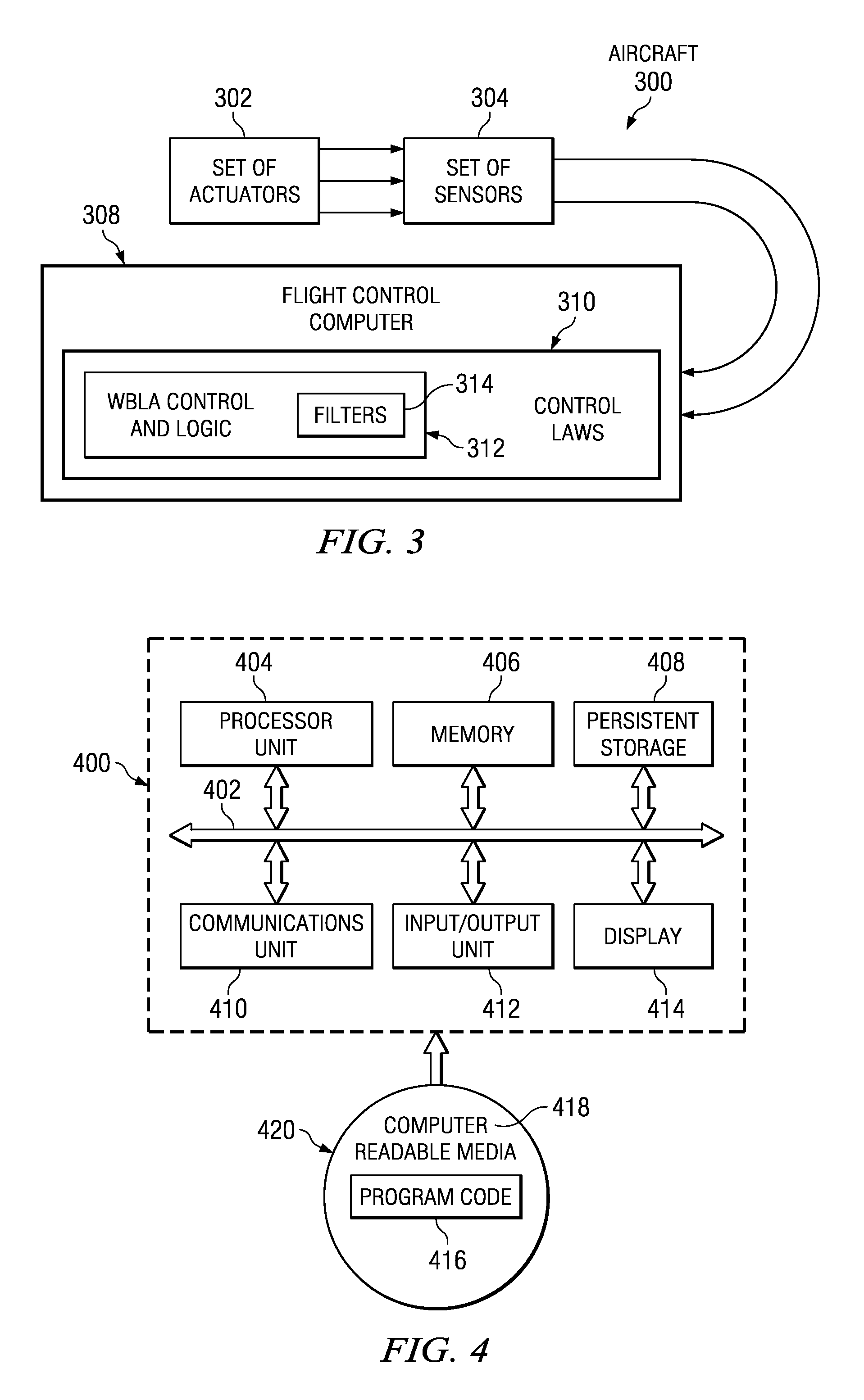

Wing-body load alleviation for aircraft

ActiveUS20090292405A1Reduce load requirementsReduce design loadAircraft stabilisationDigital data processing detailsNonlinear filterFlight control surfaces

A computer implemented method, apparatus, and computer usable program product for symmetric and anti-symmetric control of aircraft flight control surfaces to reduce wing-body loads. Commands are sent to symmetrically deploy outboard control surfaces to shift wing air-loads inboard based on airplane state and speed brake deployment. Surface rate retraction on a wing with peak loads is limited to reduce maximum loads due to wheel checkback accompanied by utilization of opposite wing control surfaces to retain roll characteristics. Airloads are shifted inboard on a swept wing to move the center of pressure forward, thereby reducing the tail load required to perform a positive gravity maneuver. In a negative gravity maneuver, speed brakes are retracted, thereby reducing the positive tail load and reducing the aft body design loads. High gain feedback commands are filtered from wing structural modes above one hertz by a set of linear and non-linear filters.

Owner:THE BOEING CO

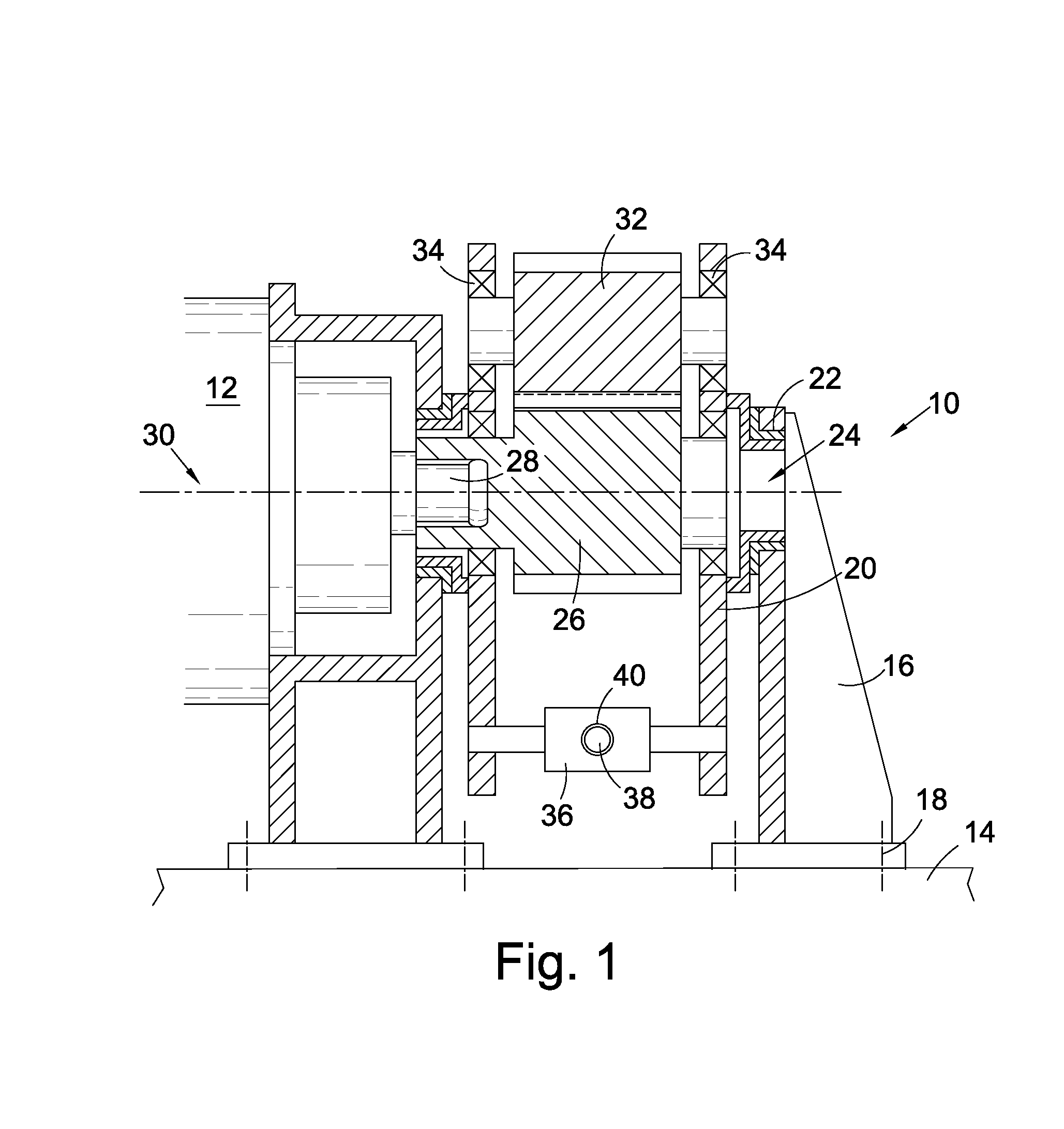

Apparatus and method for rotating a shaft

ActiveUS20100095791A1Facilitate selective engagementReducing structural loading requirementGearingMachines/enginesRotational axisGear wheel

Turning gear apparatus for rotating a shaft comprises a rotary drive arrangement and a transmission system including a pivot arm. The rotary drive arrangement is fixed, for example to a vessel hull, and the pivot arm is pivotable between a first, shaft-disengaged, position and a second, shaft-engaged position where the rotary drive arrangement is operably coupled to the shaft, thereby permitting control over rotation of the shaft by the rotary drive arrangement.

Owner:GALLOWAY ERIC

Pressure contact holding-type connector

A pressure contact holding-type connector in accordance with the present invention is configured to be interposed between opposing electrodes. A conductive pin is located in at least one end portion of each through-hole of an insulating housing having a through-hole oriented in a thickness direction. A flange section provided on the conductive pin is mated with a small-diameter section provided in one end portion of the through-hole to maintain at least part of the conductive pin in a state of accommodation inside the through-hole. And, a conductive coil spring having one end thereof mated with the flange section provided on the conductive pin and pushing the conductive pin with a snap to an exterior of the through-hole is installed inside the through-hole. The conductive pin can be disposed at both ends of the coil spring.

Owner:SHIN-ETSU POLYMER CO LTD

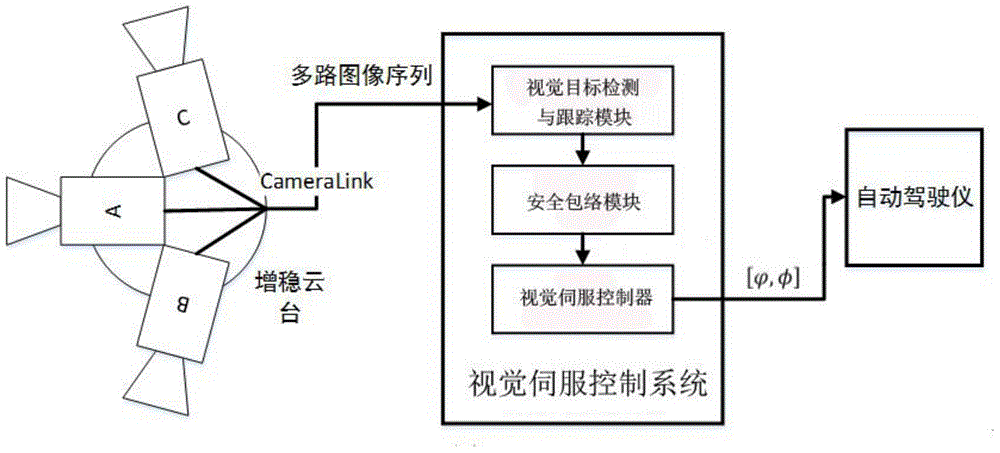

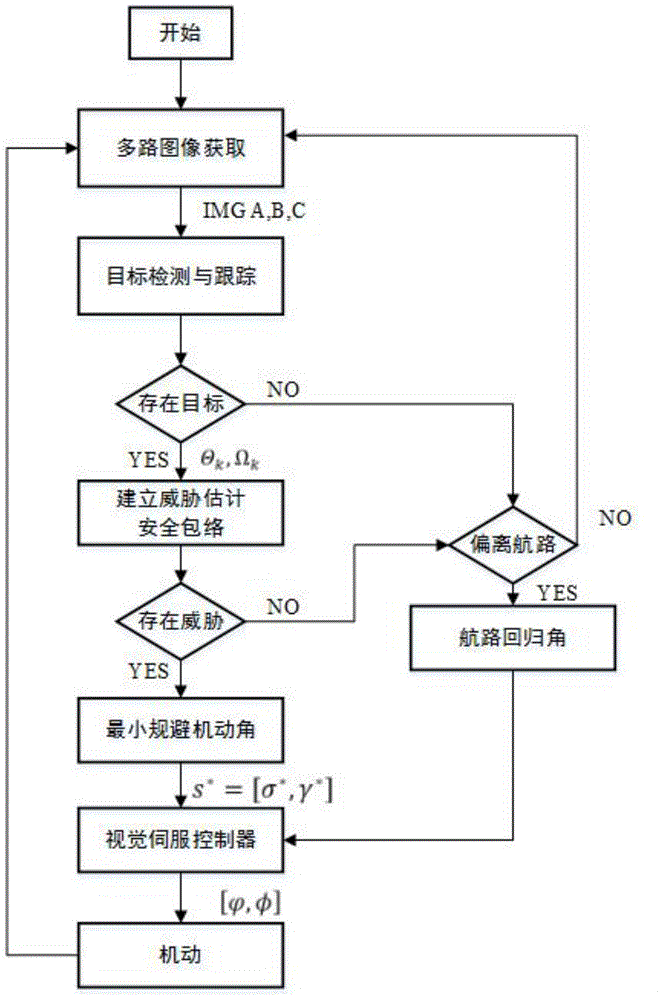

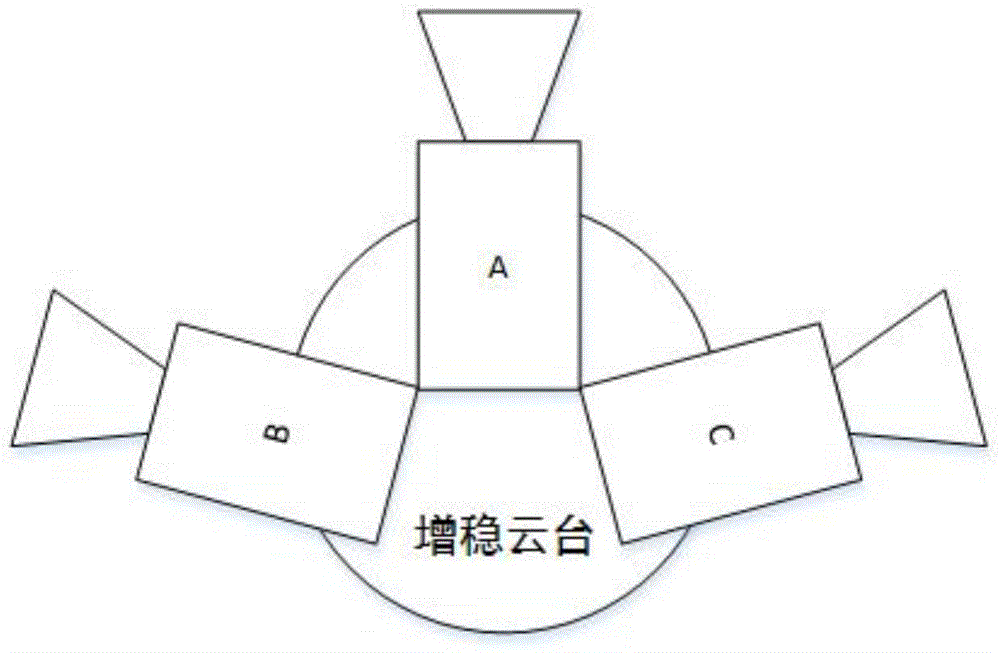

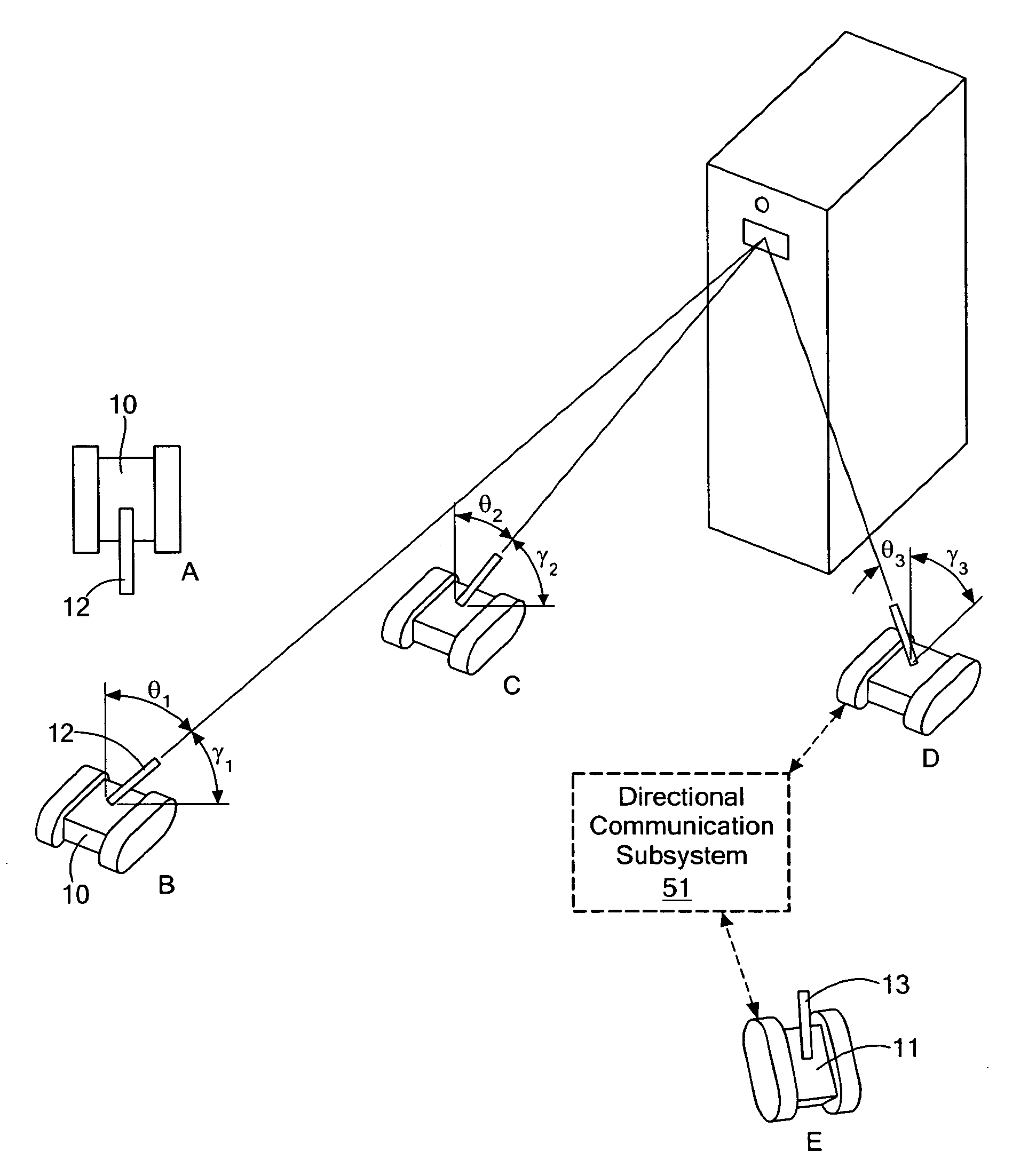

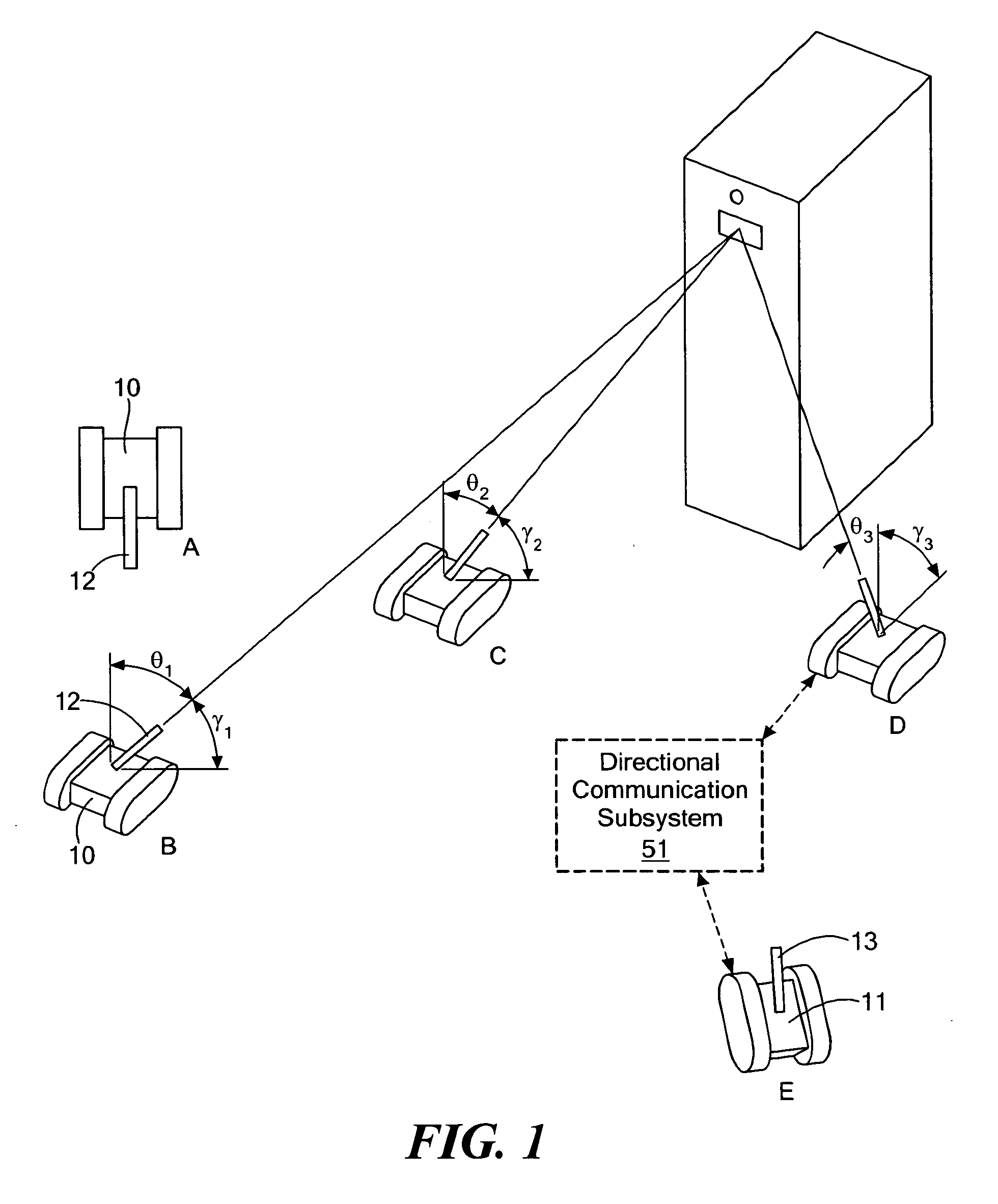

Visual servo-based sense-and-avoid method and system

ActiveCN104102218AFast perceptionImprove airspace flight safety capabilitiesPosition/course control in two dimensionsVisual servoing systemFlight safety

The invention provides a visual servo-based sense-and-avoid system. The visual servo-based sense-and-avoid system includes an unmanned aerial vehicle, an image acquisition system, a visual servo control system and a navigation positioning system; the visual servo system includes a visual target detection and tracking module, a security envelope module and a visual servo controller. The invention also provides a visual servo-based sense-and-avoid method. With the visual servo-based sense-and-avoid method and system of the invention adopted, rapid sensing for surrounding airspace environment can be realized; avoidance maneuvering for space flight targets can be completed independently and autonomously without intervention and operation of ground operation personnel required under a situation that no distance measuring sensor is installed. The visual servo-based sense-and-avoid method and system of the invention have the advantages of low load requirements, high control precision and high intelligence, and can improve the airspace flight safety capacity of the unmanned aerial vehicle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

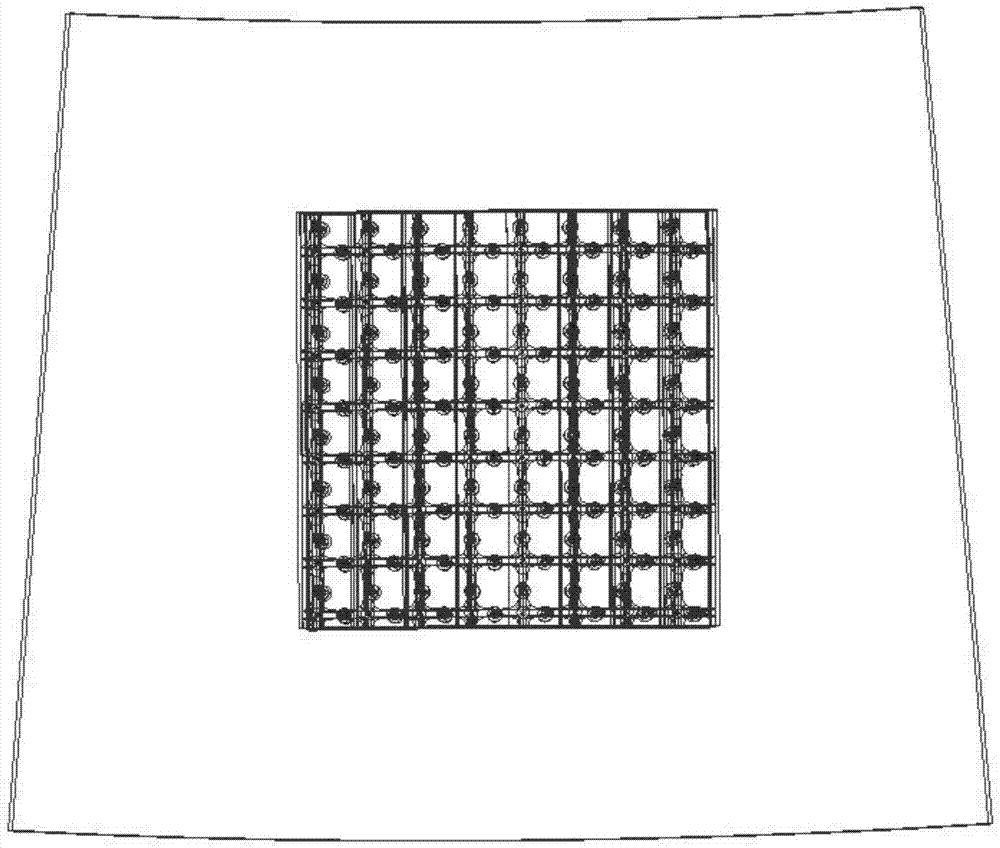

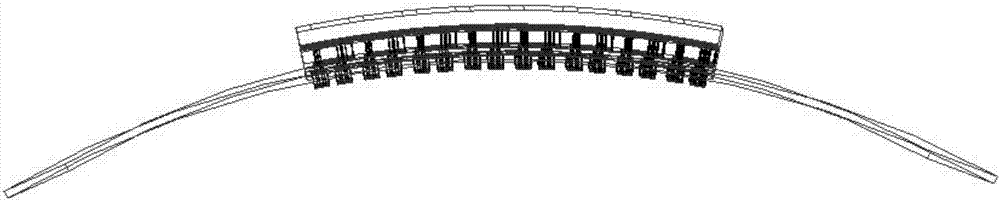

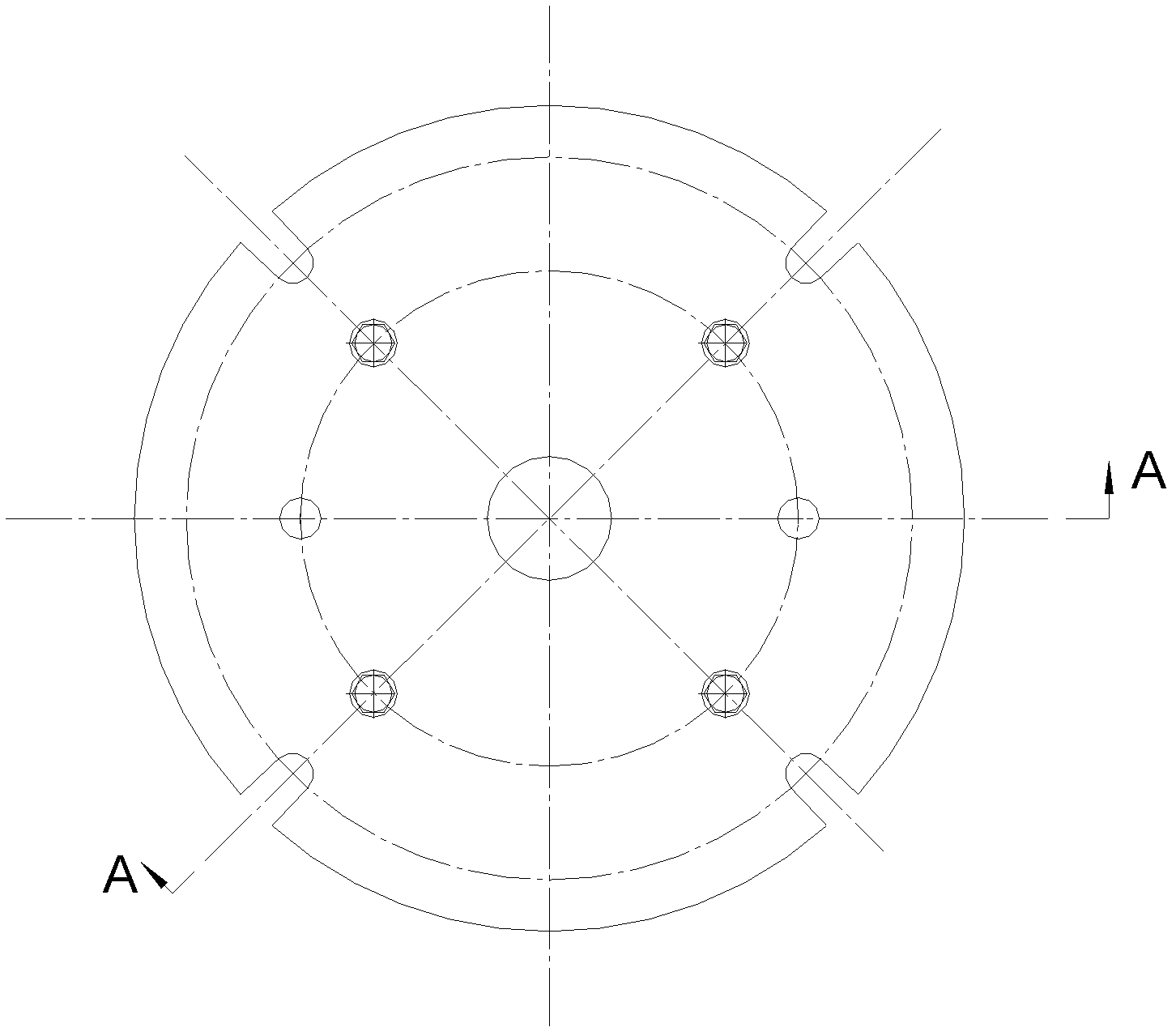

Strong mutual-coupling ultra-wideband wide-angle scanning dual-polarized conformal phased-array antenna

ActiveCN107342457ARealize scanningReduce weightSimultaneous aerial operationsRadiating elements structural formsUltra-widebandDielectric substrate

The invention belongs to the technical field of antenna engineering, and discloses a strong mutual-coupling ultra-wideband wide-angle scanning dual-polarized conformal phased-array antenna. The strong mutual-coupling ultra-wideband wide-angle scanning dual-polarized conformal phased-array antenna comprises a conformal dielectric substrate, conformal dipole units, a circular metal patch, a conformal dielectric layer, a conformal dielectric impedance matching layer, a metal ground matching layer, an unbalance feeding structure, five grounding metallized through holes, a microwave coaxial cable and a metallized frustum-shaped carrier, wherein the conformal dipole units are printed on an upper layer of the conformal dielectric substrate, and placed in a vertical intersection way; the circular metal patch is printed on a lower layer of the conformal dielectric substrate; the conformal dielectric layer is positioned below the conformal dielectric substrate, and subjected to hole digging treatment; the conformal dielectric impedance matching layer is positioned above the conformal dielectric substrate; and the microwave coaxial cable is used for feeding the unbalance feeding structure. The weight of the novel antenna is only 70 percent that of a conventional phased array, so that the requirement on the load carrying of a carrier is lowered greatly. The metal ground matching layer is used, so that an original complex matching circuit is omitted; the machining difficulty is lowered greatly; and the machining cost of the antenna on engineering applications is lowered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

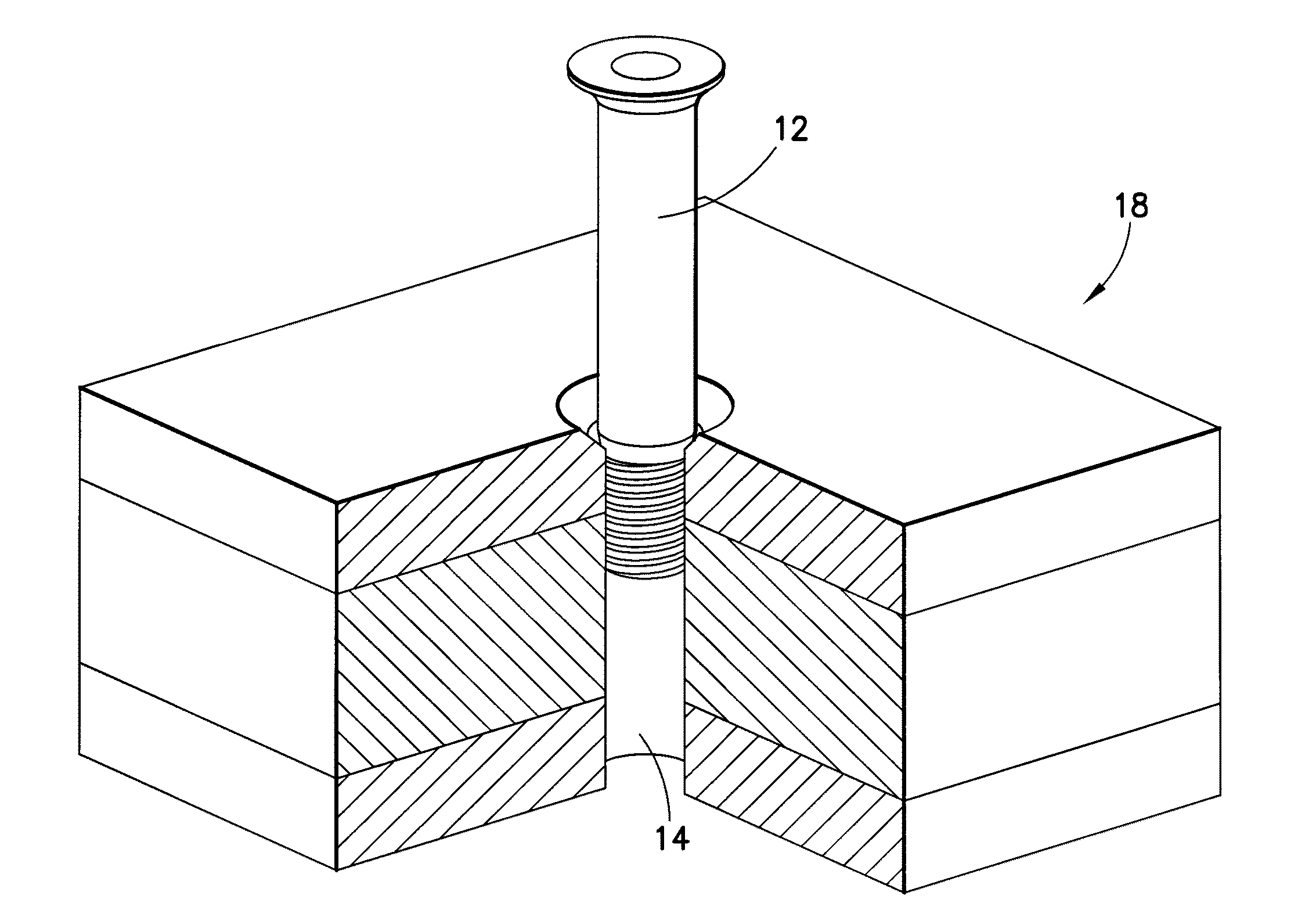

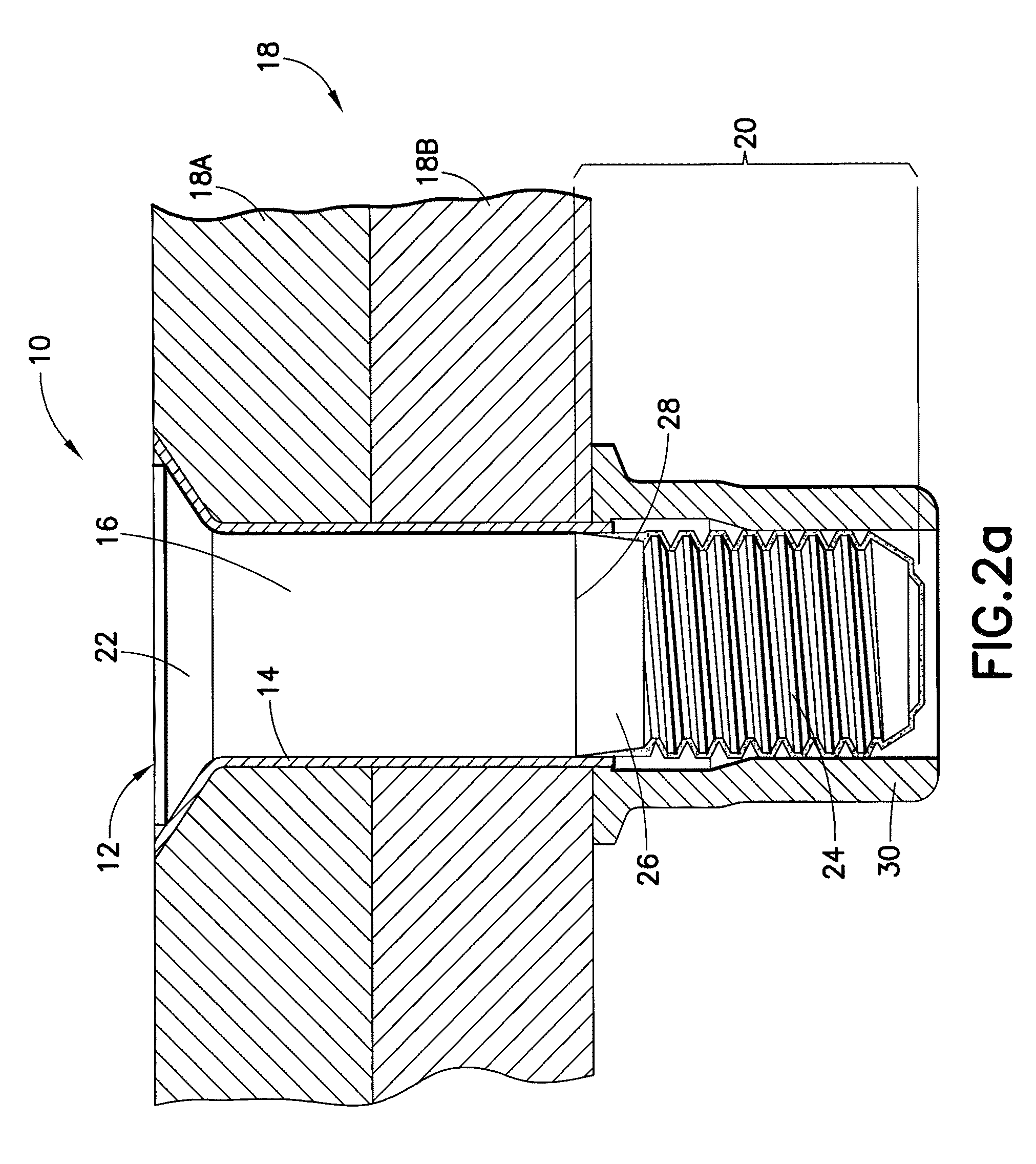

Enhanced conductivity sleeved fastener and method for making same

A sleeve interference fastener adapted to be installed in a hole of a structure includes a sleeve; a pin member, wherein the pin member has a transition zone between a shank portion and a locking portion and wherein a portion of the pin member comprises a low friction dielectric coating; a locking member; wherein, in the installed position, a first interface between the shank portion of the pin member and the sleeve is substantially free from the low friction dielectric coating, and wherein, in the installed position, the transition zone of the pin member and a second interface between the locking portion of the pin member and the locking member are substantially covered with the low friction dielectric coating.

Owner:HOWMET AEROSPACE INC

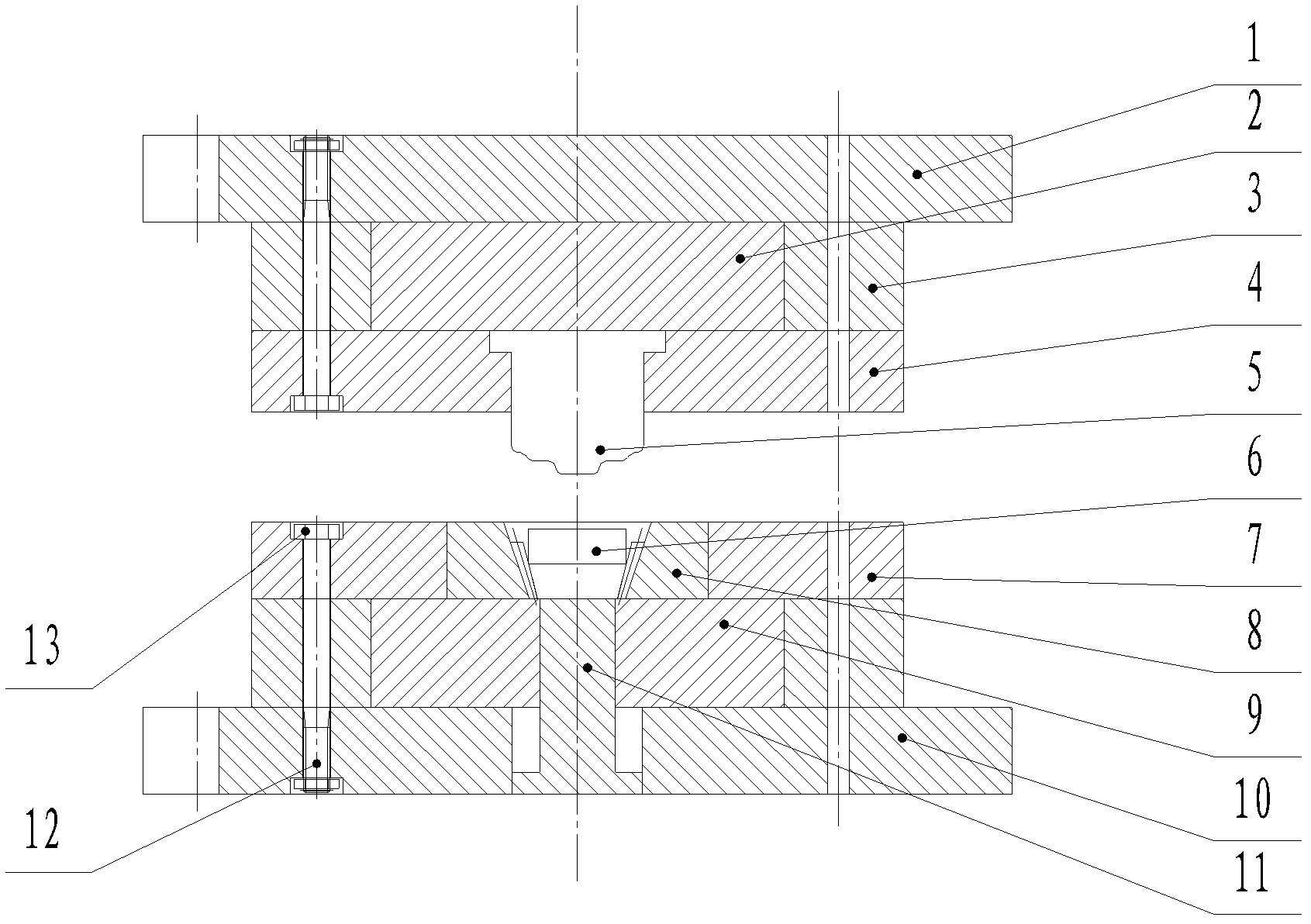

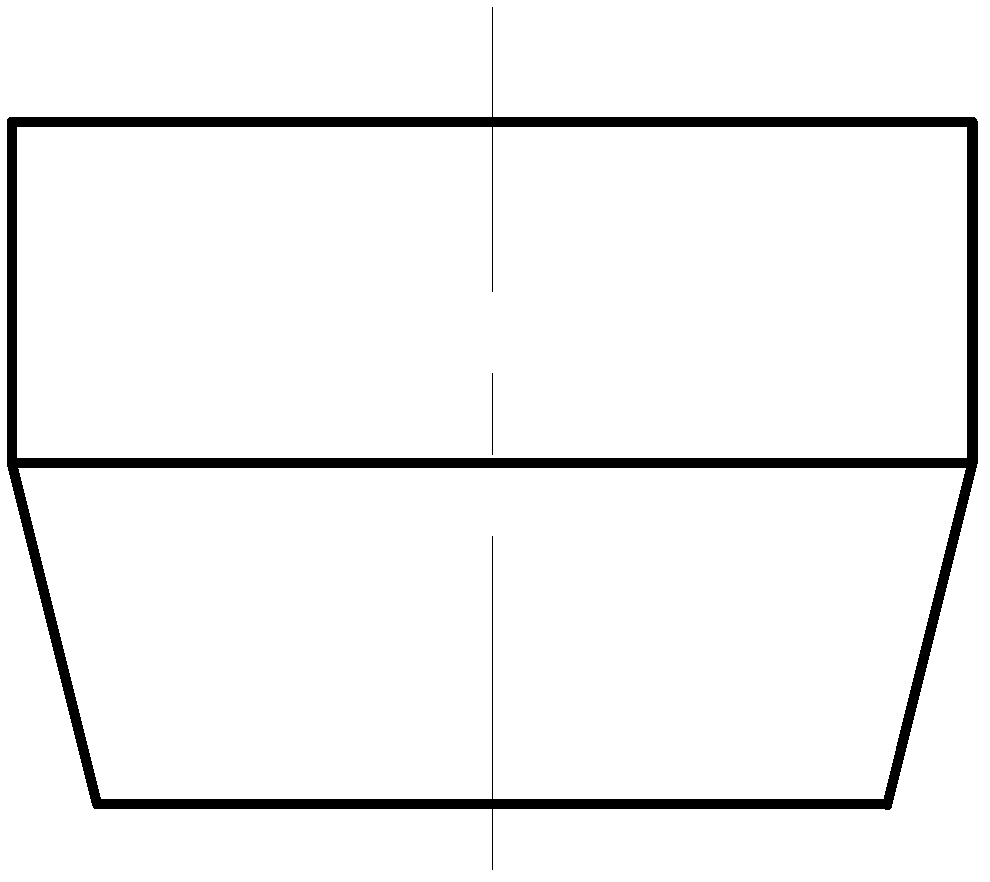

Cold precision forging process for bevel gear and mould thereof

InactiveCN102430692AImprove mechanical propertiesWon't cut offForging/hammering/pressing machinesWheelsHardnessBar stock

A cold precision forging process for a bevel gear is disclosed, and comprises the steps of: cutting the blanking by cylindrical bars; cutting a conical degree on a segmental length of the blank as segmental pre-form for positioning the blank in a die; performing spheroidization for the machined blank to reduce the hardness, then scouring and descaling, phosphorizing, saponifying and lubricating; the first cold precision forging step comprises: upsetting-extruding segmental tooth form in an extrusion mould to obtain a first extrusion which is used as the blank of the second first cold precision forging step; performing spheroidization again for the first extrusion, then scouring and descaling, phosphorizing, saponifying and lubricating; the second cold precision forging step comprises: upsetting-extruding all tooth forms in the extrusion mould to obtain the coarse material of the bevel gear; machining and shaping the coarse material of the bevel gear and cutting unnecessary materials on the end surface to obtain finished products of the bevel gear. The invention further provides an extrusion mould. The invention has higher production efficiency, reduces the material waste, lowers the cost and improves the mechanical property.

Owner:ZHEJIANG UNIV OF TECH

Enhanced conductivity sleeved fastener and method for making same

ActiveUS8475102B2Low densityReduce resistanceNutsAircraft lighting protectorsEngineeringLow friction

A sleeve interference fastener adapted to be installed in a hole of a structure includes a sleeve; a pin member, wherein the pin member has a transition zone between a shank portion and a locking portion and wherein a portion of the pin member comprises a low friction dielectric coating; a locking member; wherein, in the installed position, a first interface between the shank portion of the pin member and the sleeve is substantially free from the low friction dielectric coating, and wherein, in the installed position, the transition zone of the pin member and a second interface between the locking portion of the pin member and the locking member are substantially covered with the low friction dielectric coating.

Owner:HOWMET AEROSPACE INC

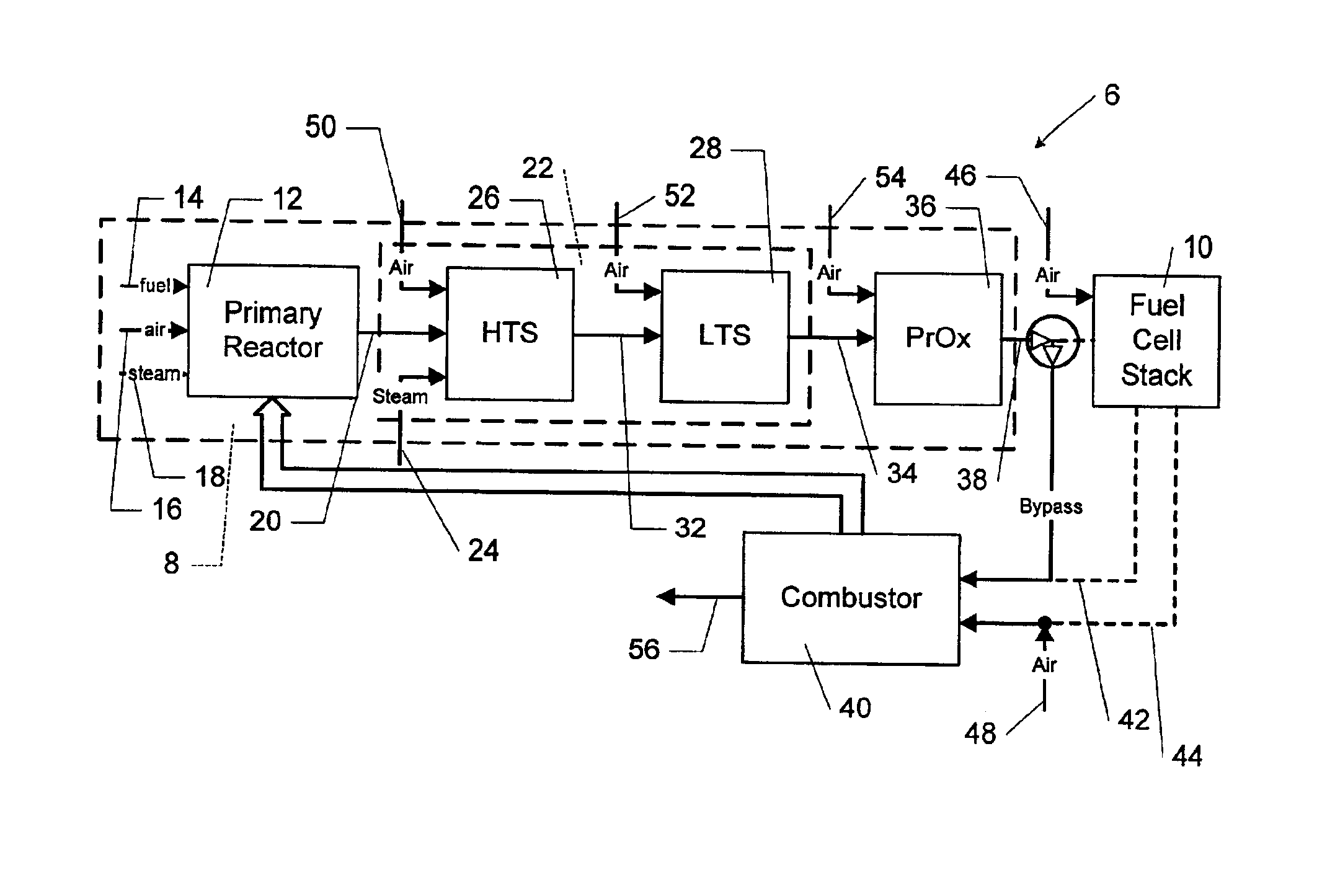

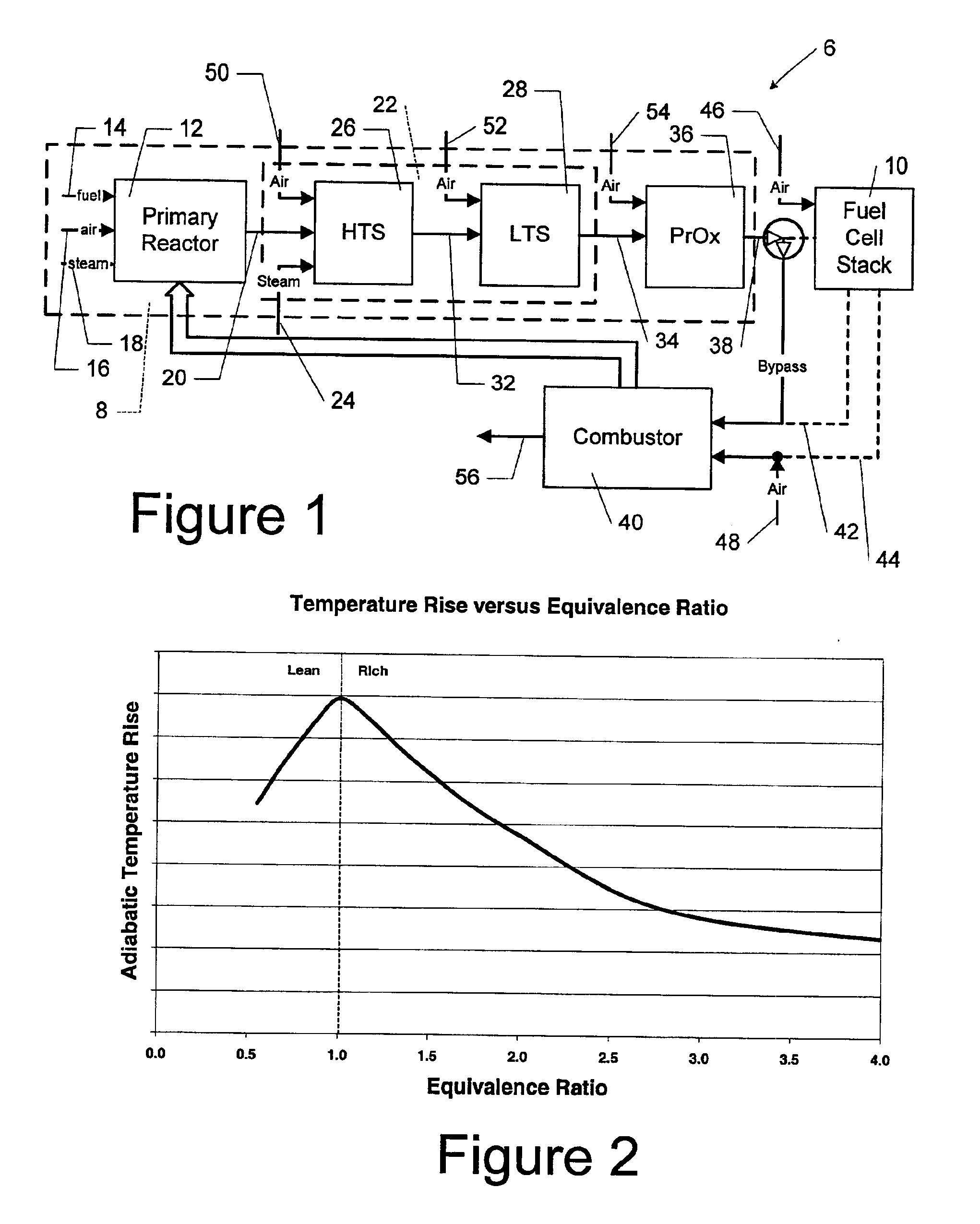

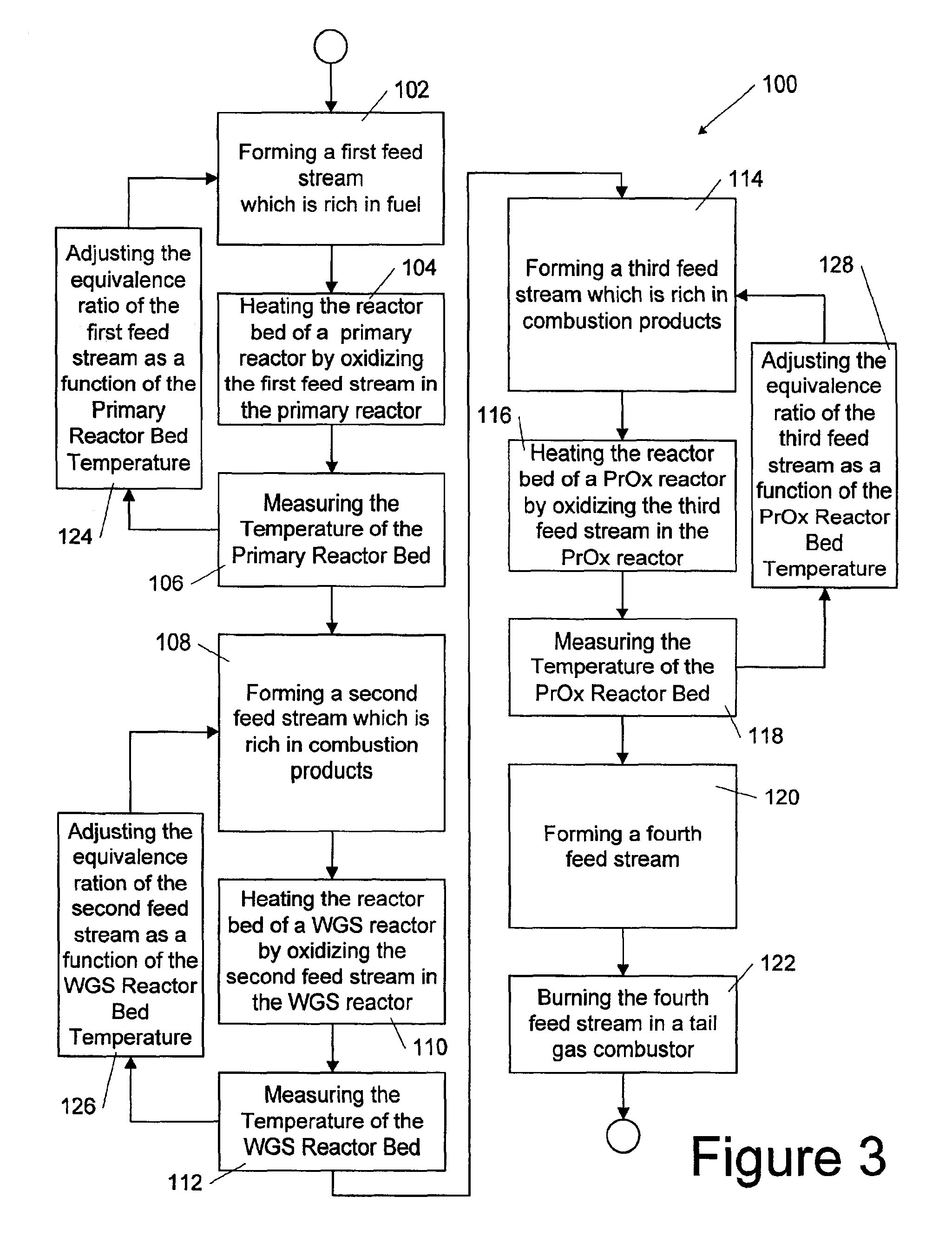

Method for quick start-up of a fuel processing system using controlled staged oxidation

InactiveUS6846585B2Improve performanceAdverse effect of be avoidHydrogenFuel cells groupingOperating temperatureProcess engineering

The present invention relates to controlled staged rich combustion throughout a fuel processing system in order to improve start up performance. Multiple stages of air injection are used to burn rich combustion products within each component to provide direct heating thereof. During the start up cycle, the fluid temperature entering each reactor is increased and each component is heated to its operating temperature in parallel. The controlled staged rich combustion eliminates the load imposed upon a combustor within the system during the start up cycle. Thus, each of the components within the fuel processing system may be optimized for an operational mode rather than a start up mode.

Owner:GENERAL MOTORS CORP

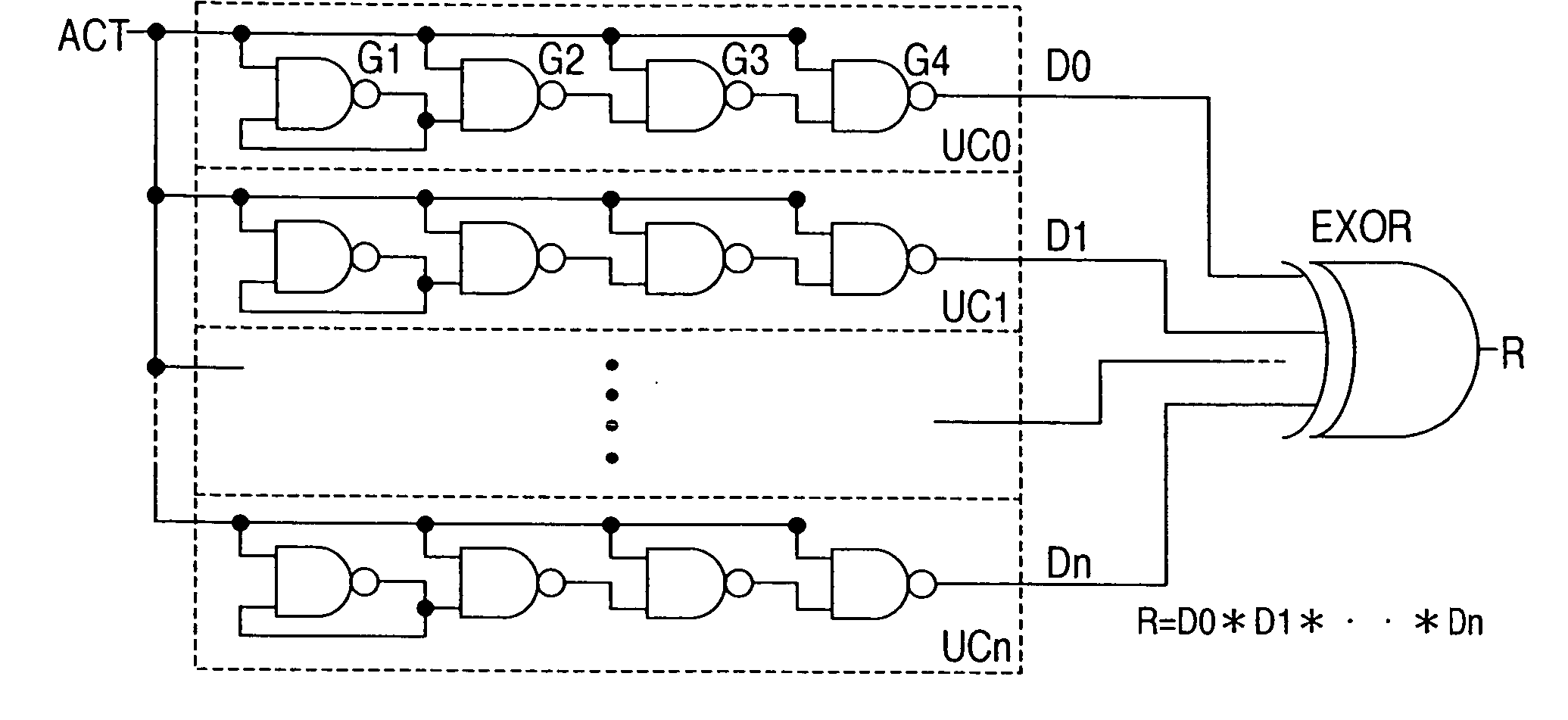

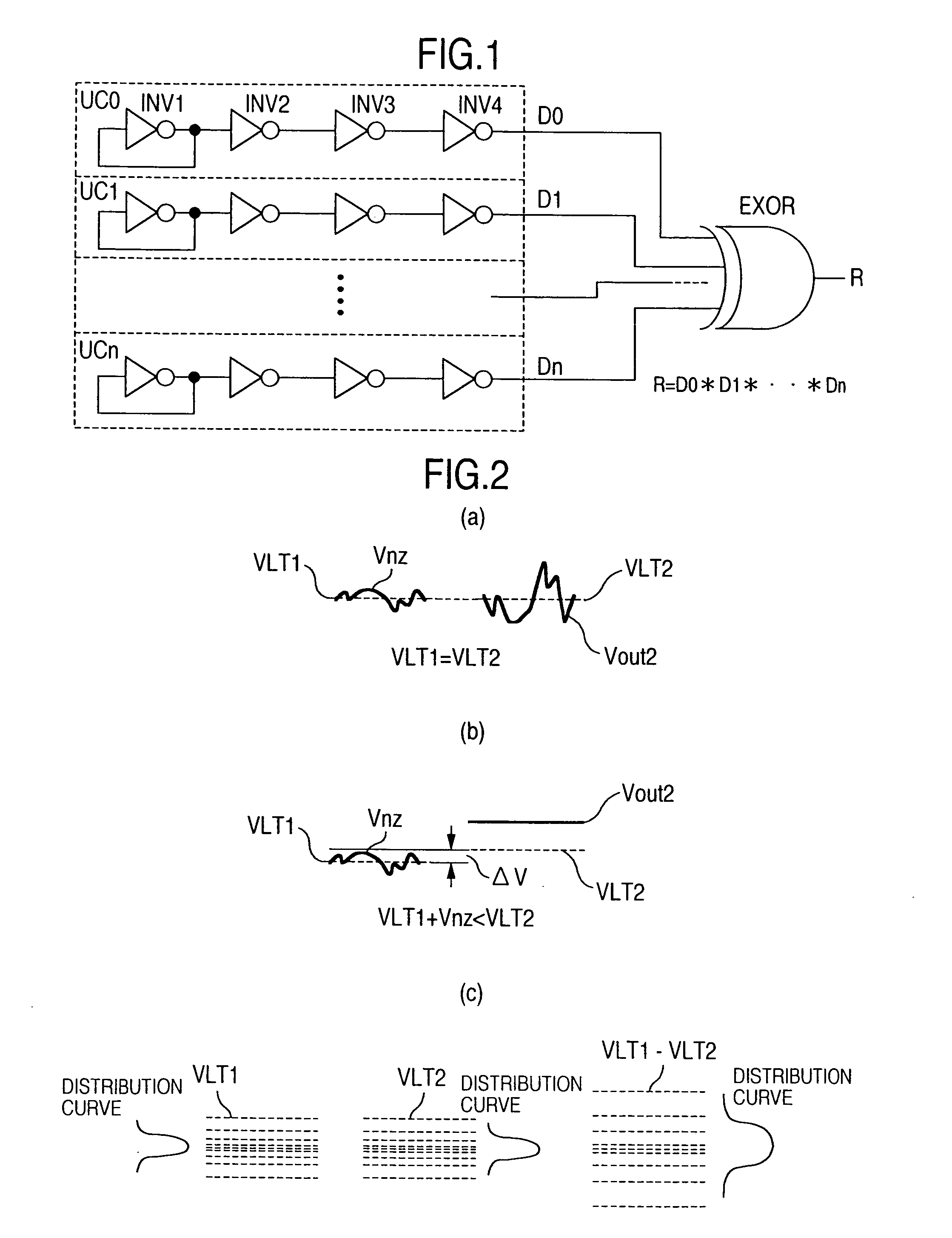

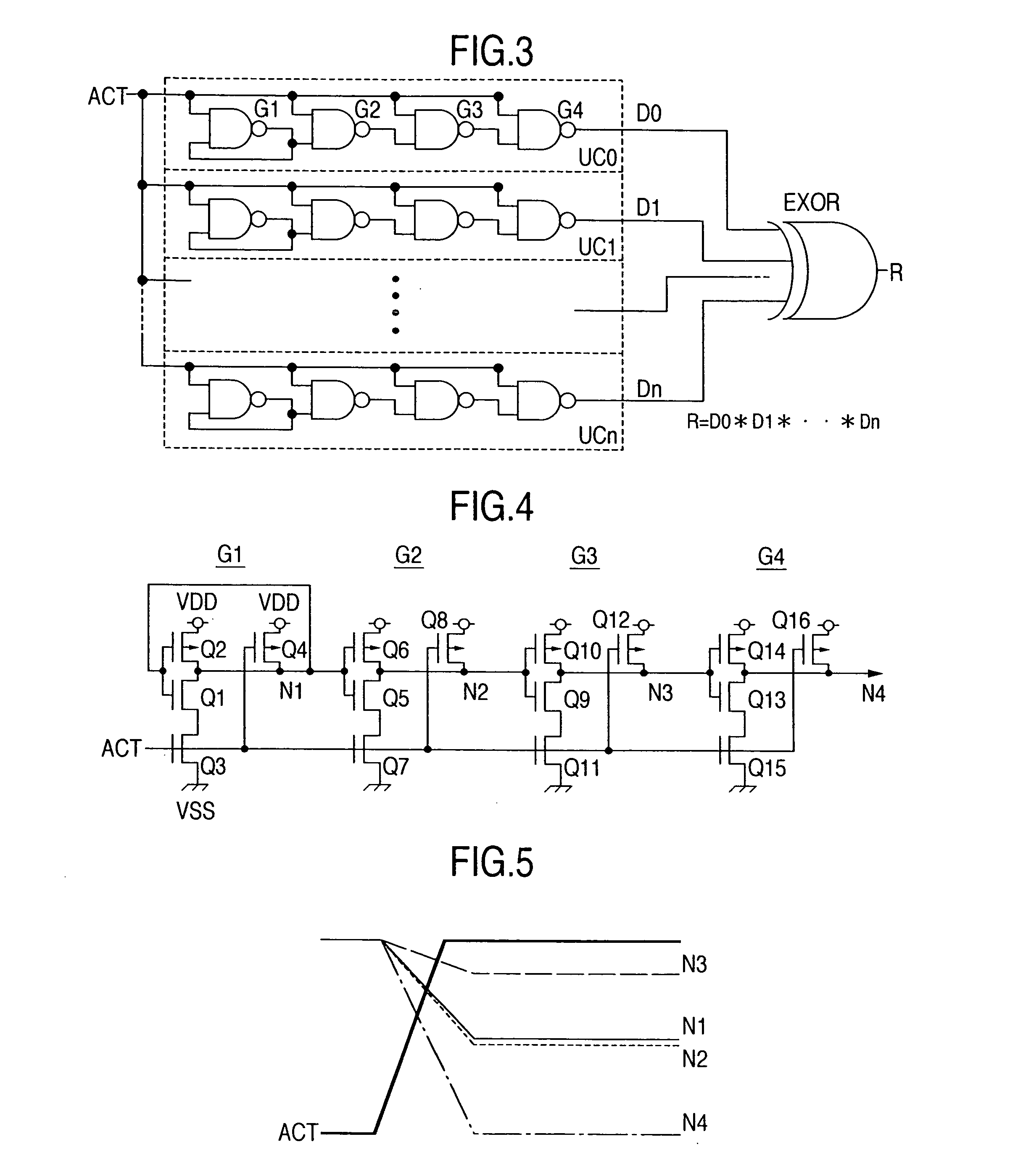

Random number generating method and semiconductor integrated circuit device

InactiveUS20070143384A1High qualityReduce load requirementsRandom number generatorsEncryption apparatus with shift registers/memoriesIntegrated circuitVoltage

A random number generating method uses: a plurality of unit circuits each having a first and a second logic circuit formed into an identical shape through an identical fabrication process and an amplifier circuit for forming a binary signal by amplifying a noise superposed on the differential voltage of threshold voltages of the first and the second logic circuits; and a signal variation detecting circuit for forming an output signal in response to variation in any of a plurality of binary signals outputted from the plurality of unit circuits, wherein a plurality of binary signals outputted from the signal variation detecting circuit are combined to generate a random number.

Owner:HITACHI ULSI SYST

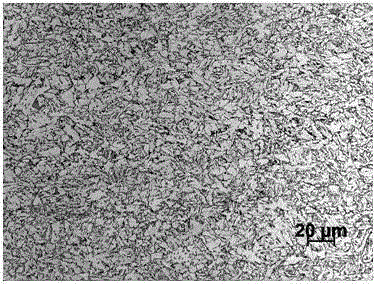

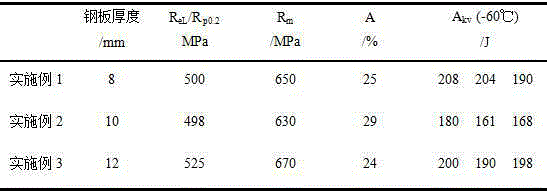

Method for producing thin-specification and high-strength atmosphere corrosion resistance structural steel plate

InactiveCN105256246AHigh strengthImprove toughness and plasticityLaminar coolingUltimate tensile strength

The invention discloses a method for producing a thin-specification and high-strength atmosphere corrosion resistance structural steel plate. The heating temperature of a continuous casting before rolling ranges from 1,150 DEG C to 1,250 DEG C; the finishing temperature of rough rolling ranges from 1,020 DEG C to 1,080 DEG C, and the accumulated rolling reduction of rough rolling is larger than or equal to 60%; the thickness of a hold-temperature blank is larger than or equal to 3.0 h, the fine rolling finishing temperature is larger than or equal to 830 DEG C, and the reduction rate of fine rolling tail pass is smaller than or equal to 12.5%; after fine rolling is finished, high-speed steel throwing is carried out, the steel throwing speed is 4 m / s, and it is guaranteed that the water entry temperature of a rolled piece is larger than or equal to 770 DEG C; and laminar cooling is carried out, the finished cooling temperature ranges from 550 DEG C to 650 DEG C, and the cooling speed ranges from 5 DEG C / s to 30 DEG C / s. The steel is delivered in the hot rolling state; and by means of the low-carbon and alloy components, it is guaranteed that the atmosphere corrosion resistance index I of the steel is larger than or equal to 6.5, the yield strength of the steel is larger than or equal to 450 MPa, the tensile strength of the steel is larger than or equal to 550 MPa, the yield ratio of the steel is smaller than or equal to 0.85, the ductility of the steel is larger than or equal to 20%, and the ballistic work of the steel at the temperature being minus 60 DEG C is larger than or equal to 100 J.

Owner:NANJING IRON & STEEL CO LTD

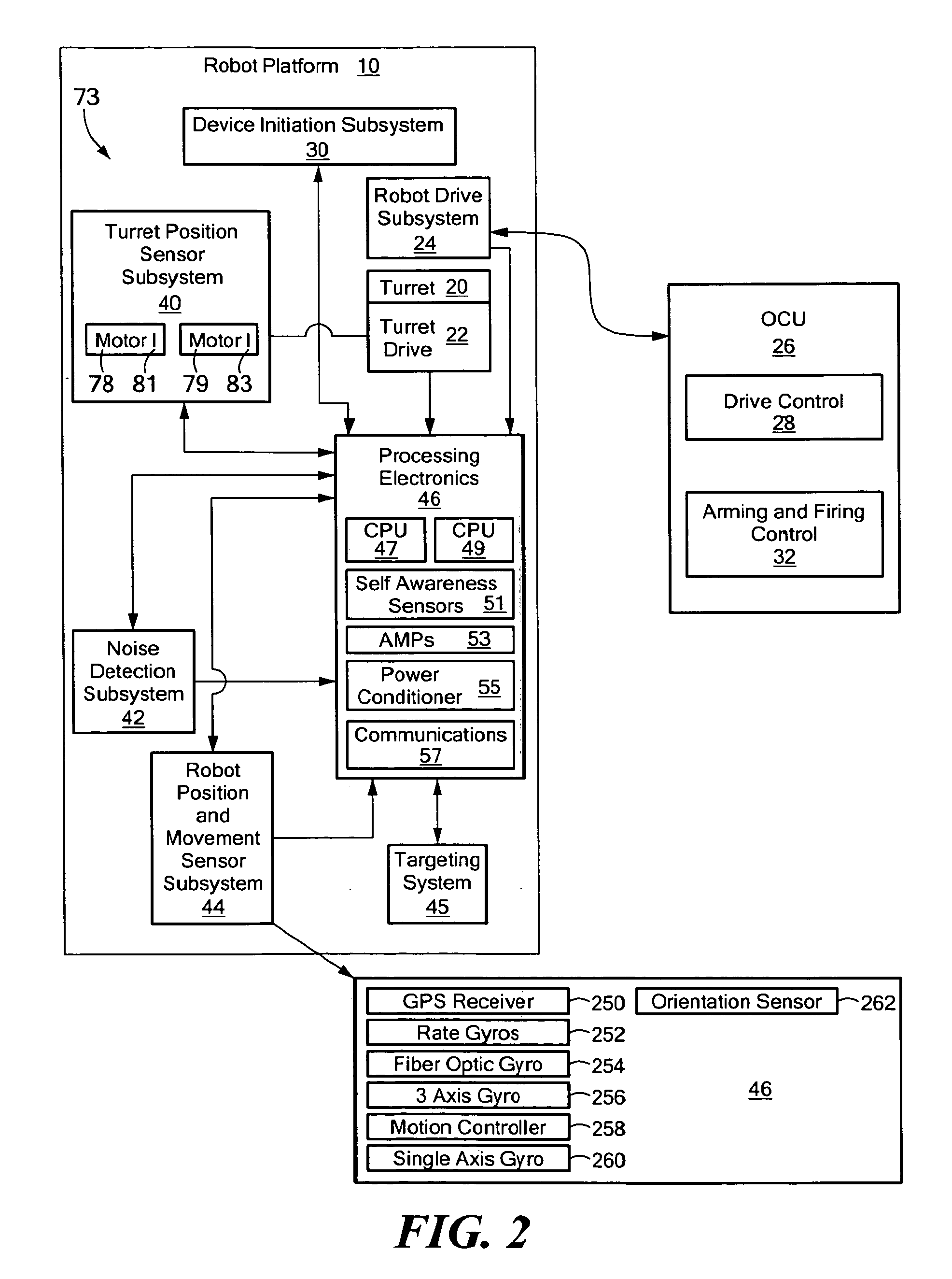

Gunshot detection stabilized turret robot

ActiveUS20090281660A1Suffer damageReduce load requirementsProgramme controlDefence devicesTeleoperated robotNoise detection

A mobile, remotely controlled robot comprising a robot drive subsystem for maneuvering the robot, a turret on the robot, a turret drive for moving the turret, a noise detection subsystem for detecting the probable origin of a noise, a robot position and movement sensor subsystem, a turret position sensor subsystem, and one or more processors, responsive to the noise detection subsystem, the robot position and movement sensor subsystem. The turret position sensor subsystem is configured to control the turret drive to orient the turret to aim a device mounted thereto at the origin of the noise and to maintain said aim as the robot moves.

Owner:FOSTER-MILLER

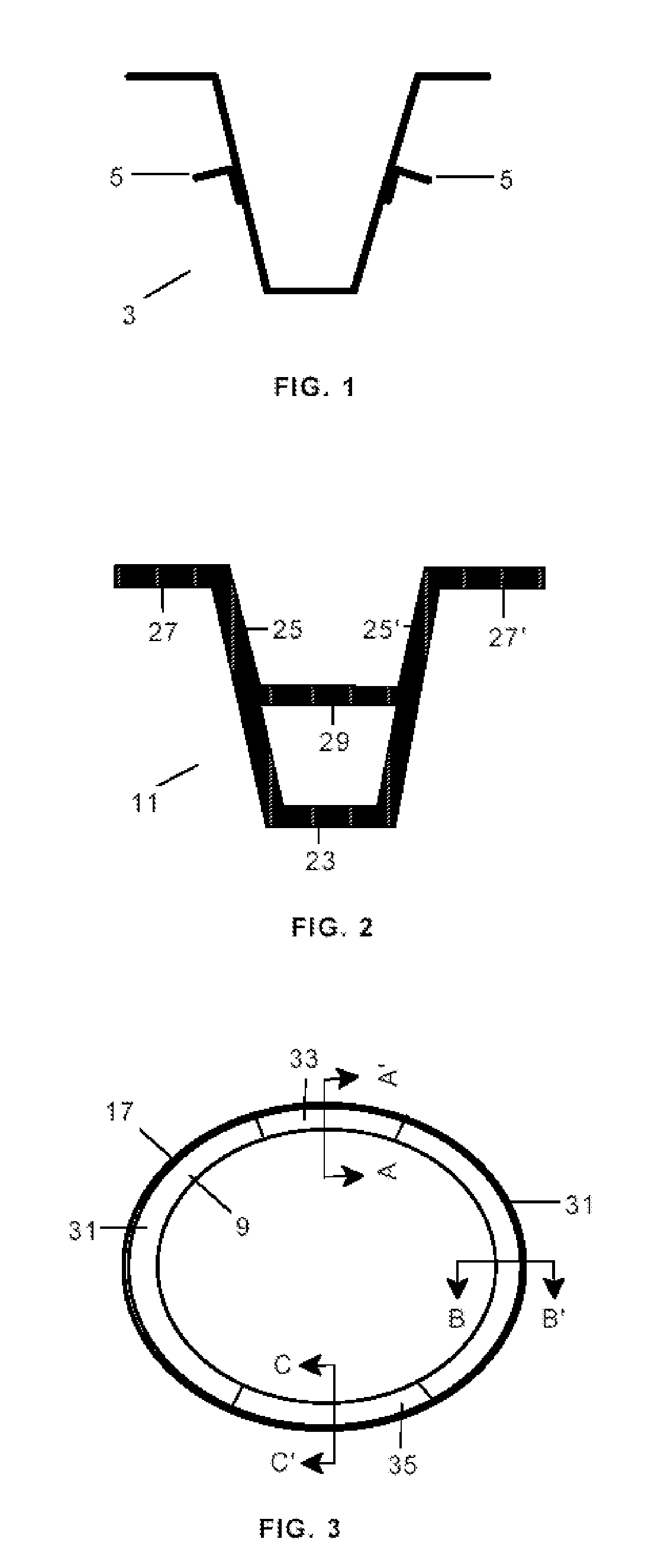

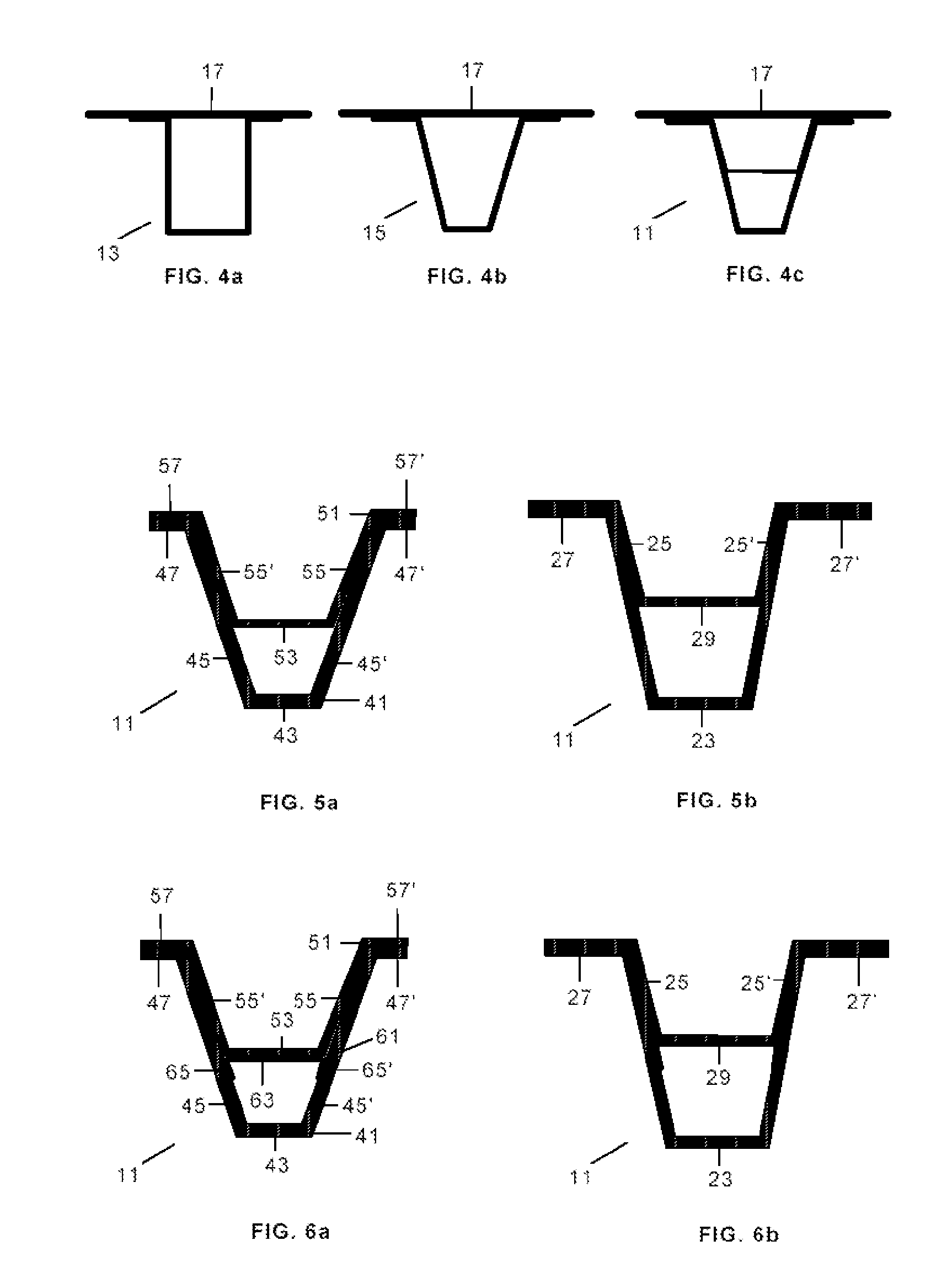

Aircraft fuselage frame in composite material with stabilized web

InactiveUS20110159242A1Easy to manufactureReduce load requirementsFuselage framesLayered productsEngineeringOmega

Aircraft fuselage frame (9) in composite material with stabilized web whose omega-shaped cross section (11) in at least a first segment (31) is formed by one head (23), two webs (25, 25′), two feet (27, 27′) with a stiffening element (29) between the two webs (25, 25′). The invention also refers to a manufacturing procedure for the first segment (31) comprising steps to: a) provide an external element (41) with an omega-shaped cross section formed by one head (43), two webs (45, 45′) and two feet (47, 47′), and an internal element (51) with omega-shaped section formed by one head (53), two webs (55, 55′) and two feet (57, 57′), with their respective webs (45, 55; 45′, 45′) and feet (47, 57; 47′, 57′) oriented in parallel; b) join the internal element (51) to the external element (41).

Owner:AIRBUS OPERATIONS SL

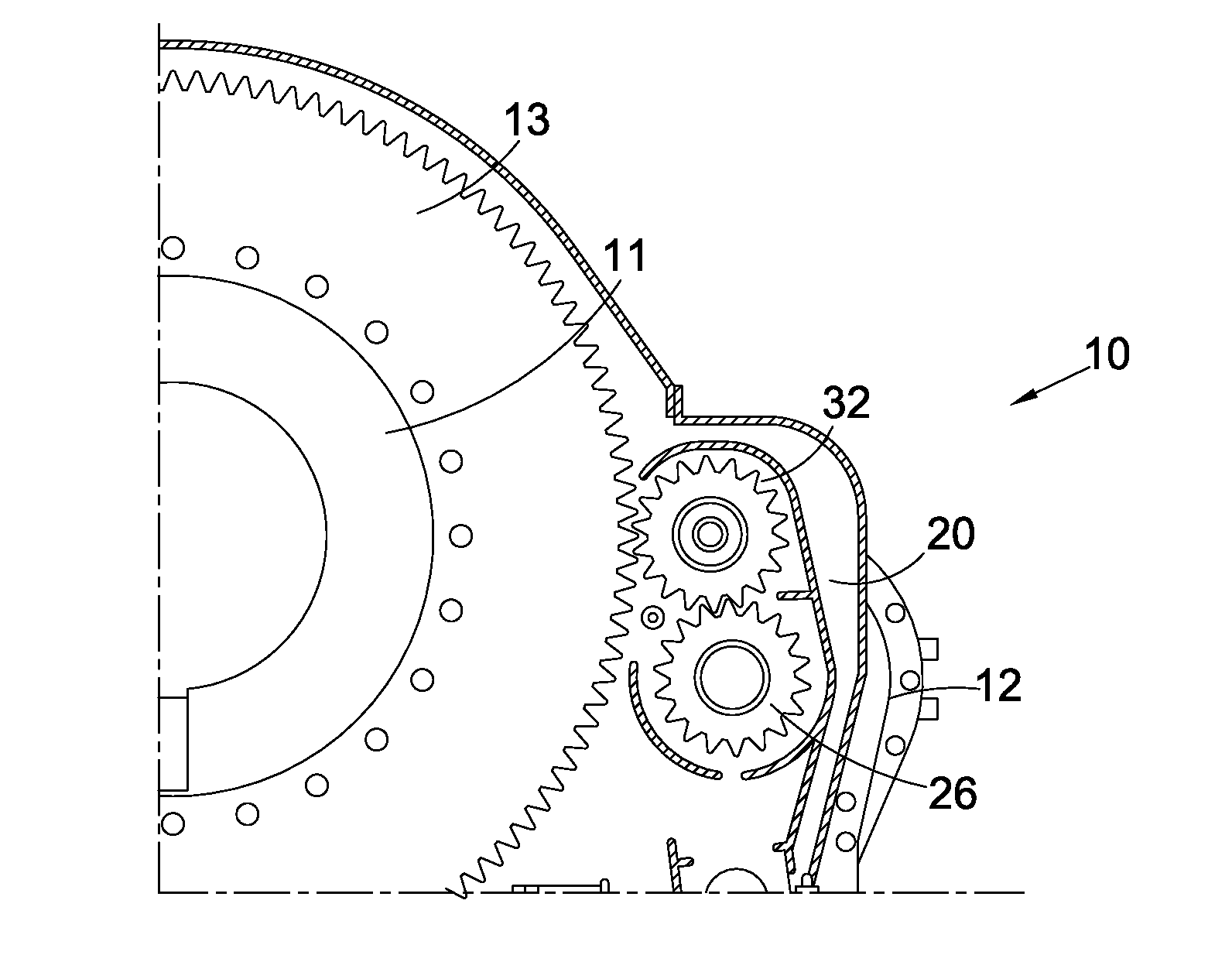

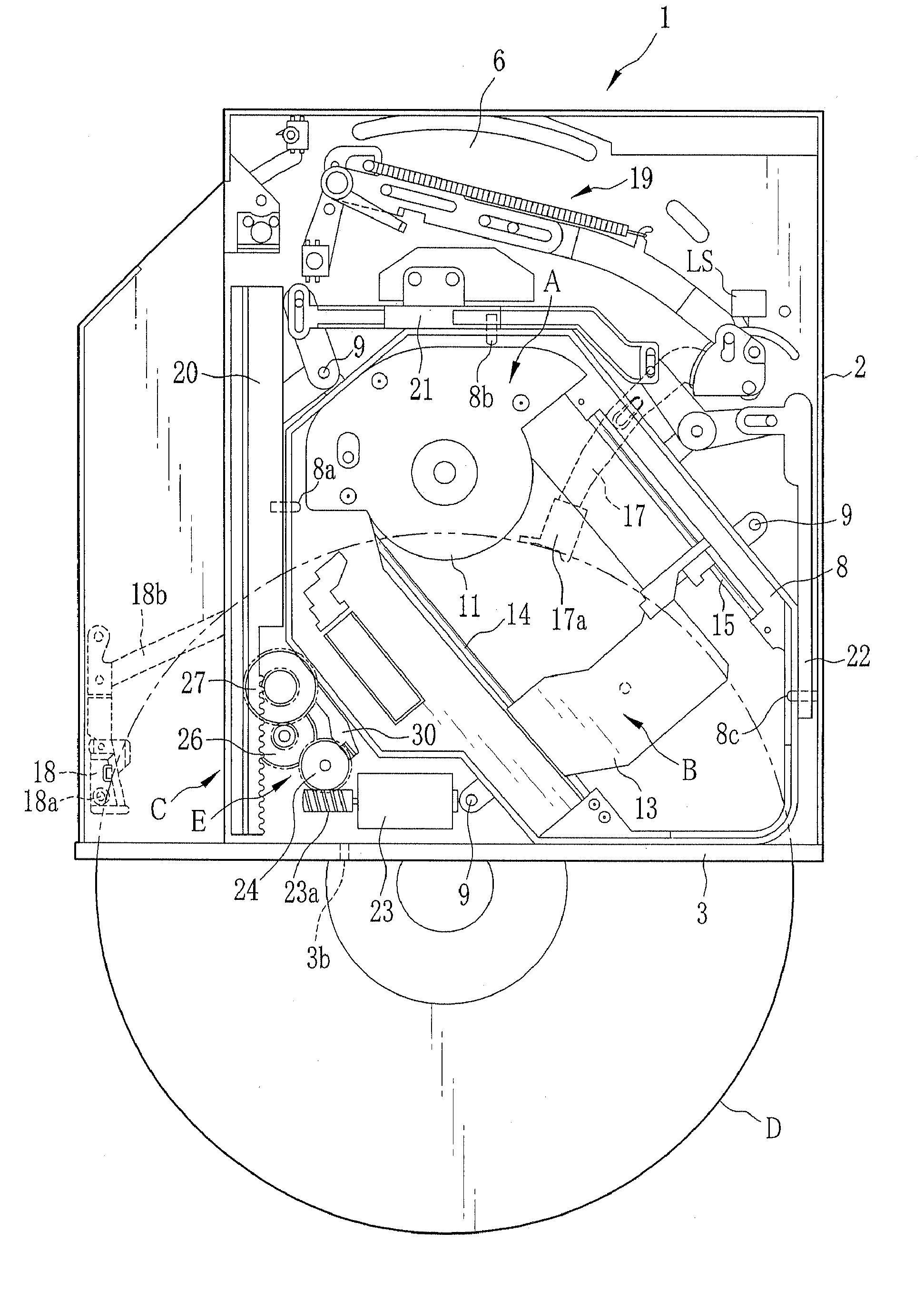

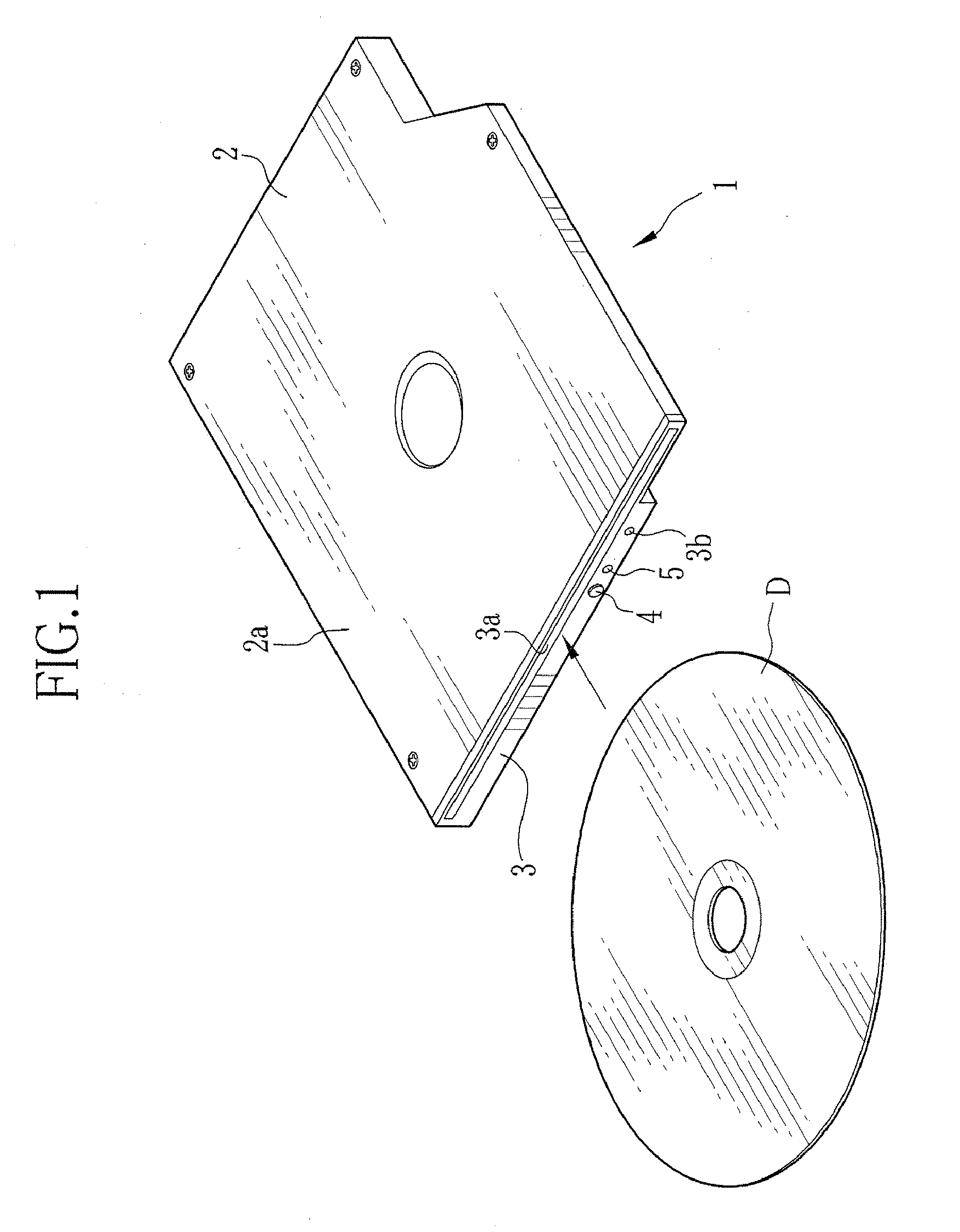

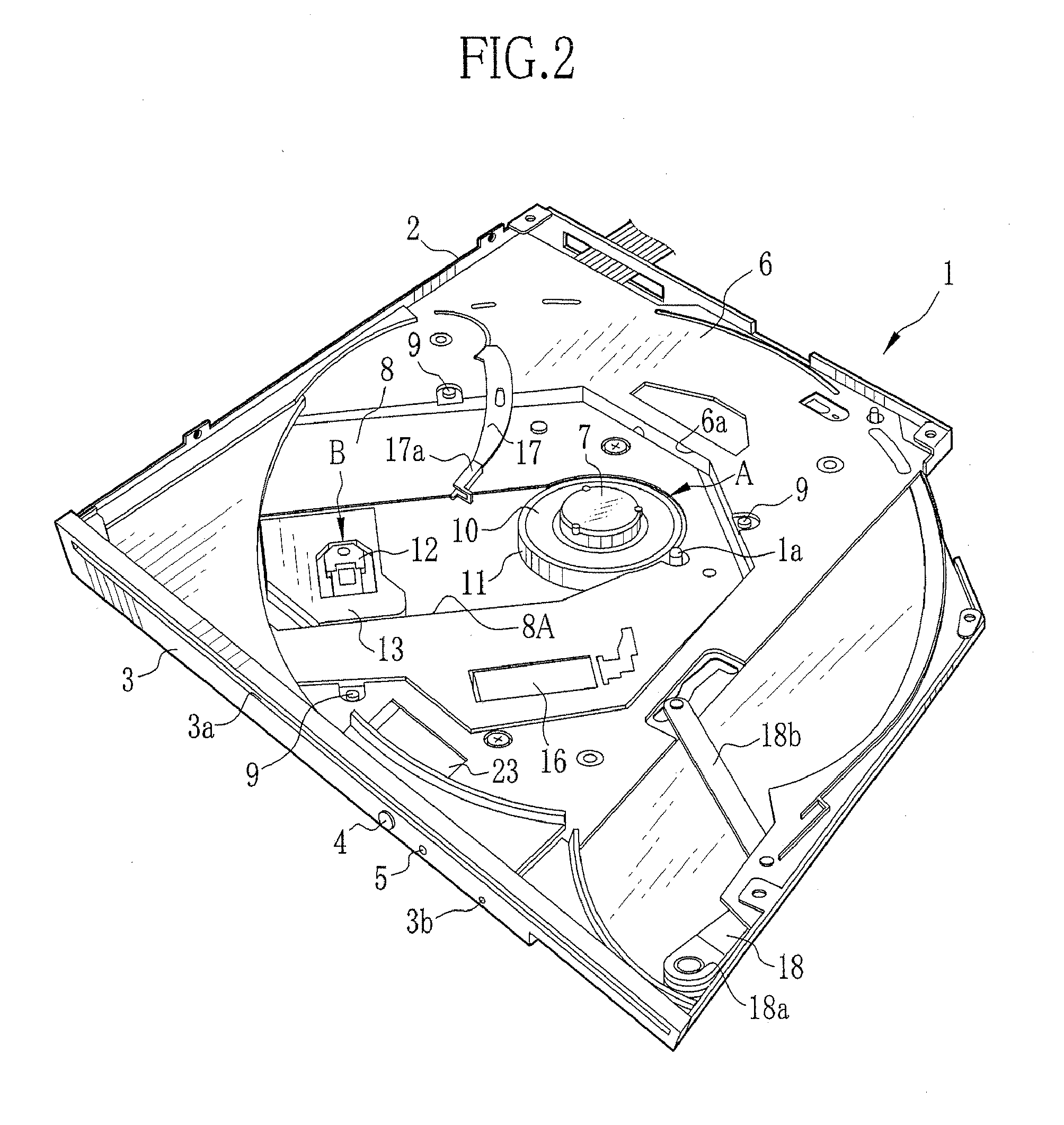

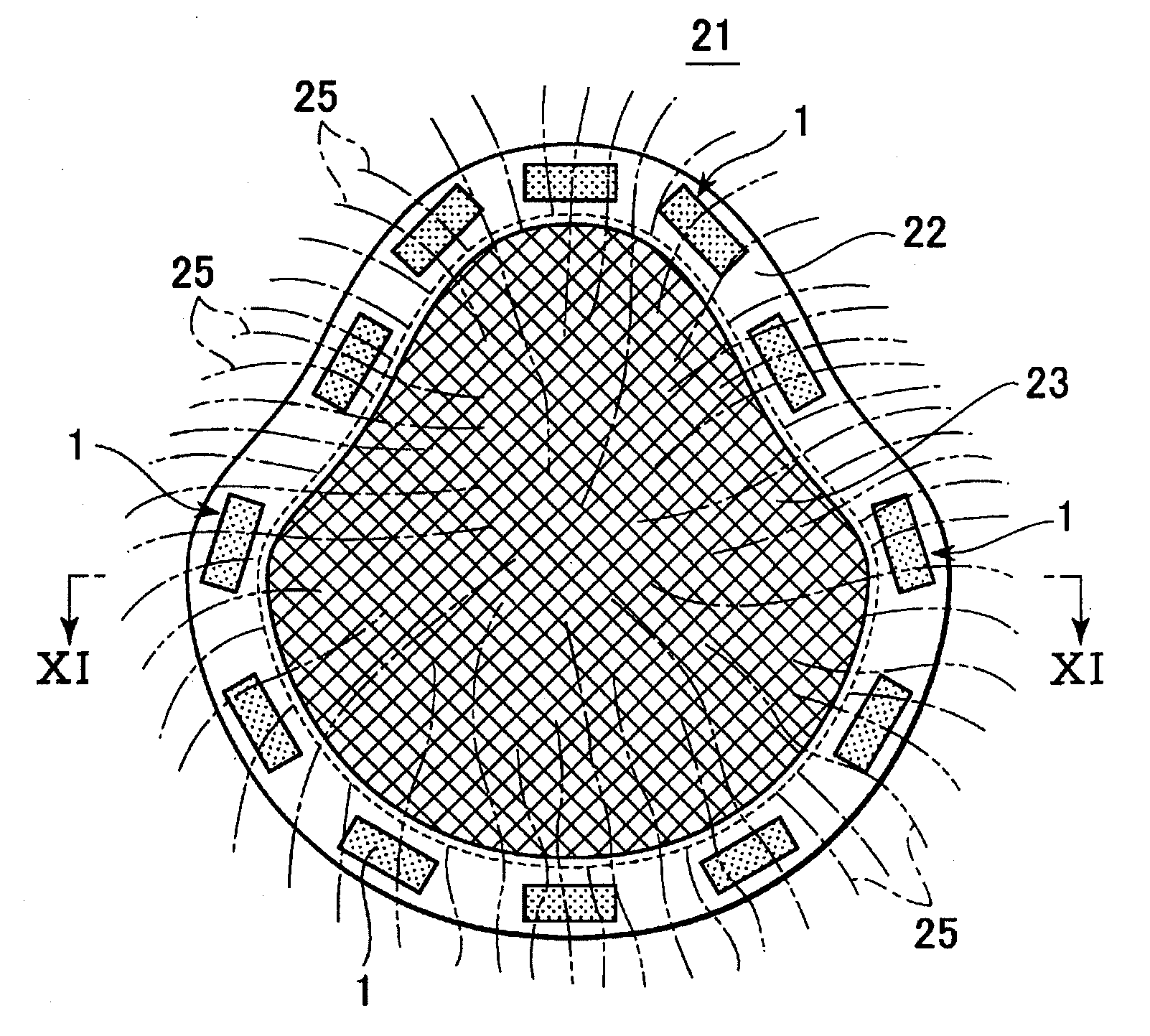

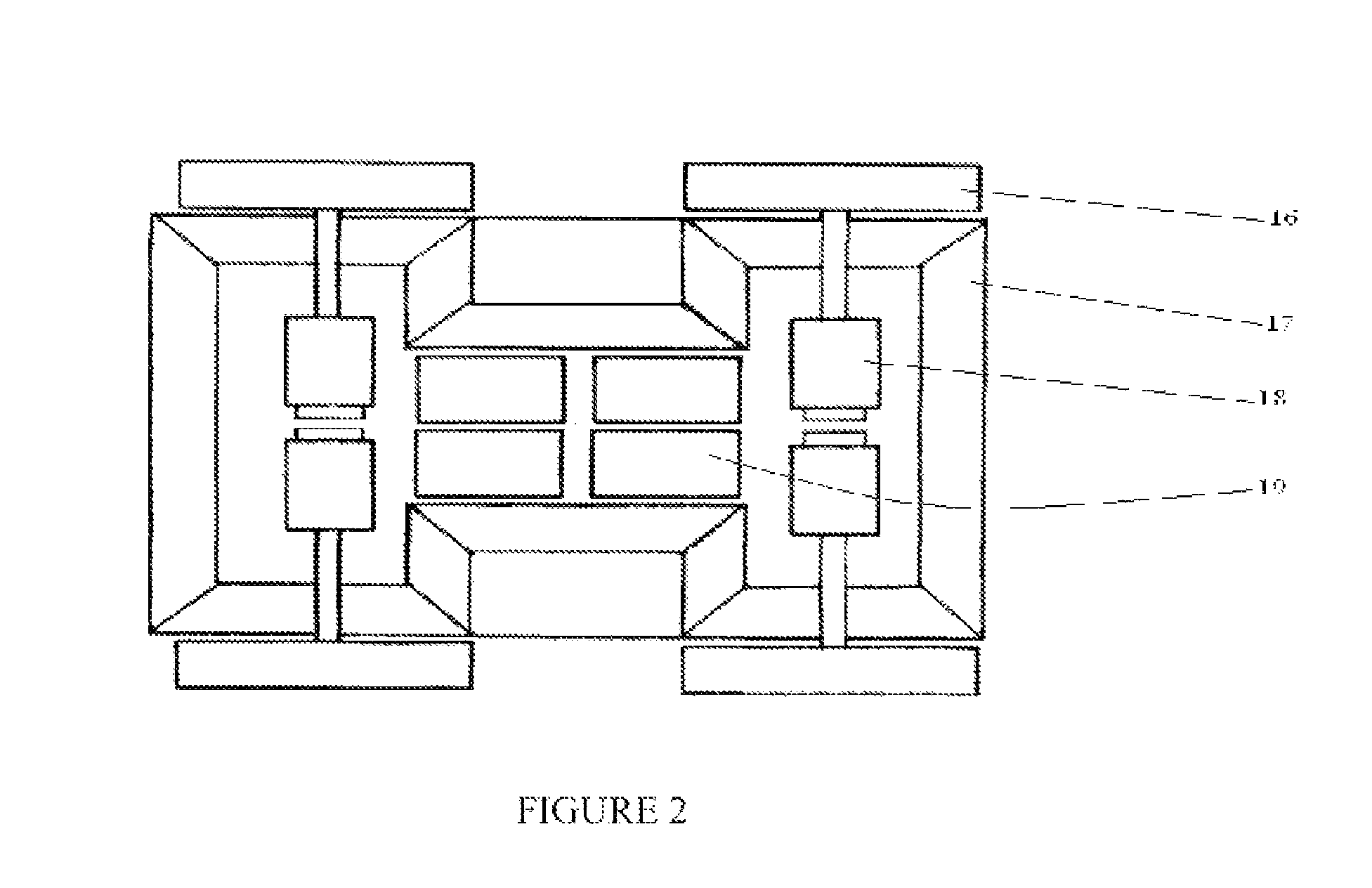

Disk device

InactiveUS20080010650A1Manually operable with great easeReduce load requirementsRecord information storageMotor driveGear wheel

A disk transport mechanism in a disk drive is connected with a transmission gear mechanism. A loading motor drives the disk transport mechanism. When the loading motor rotates forwards, an optical disk is carried by the disk transport mechanism to a chuck position. When the loading motor rotates backwards, the optical disk is moved back to an ejection position. In failure of the loading motor, an emergency pin is pushed to actuate an emergency disk ejector. A first gear wheel in the transmission gear mechanism is disengaged by the emergency disk ejector to separate the transmission gear mechanism into a disk transport mechanism side and a motor. A second gear wheel on the disk transport mechanism side is rotated to actuate the disk transport mechanism. The emergency pin is pushed repeatedly to cause the disk transport mechanism to move back the optical disk to the ejection position.

Owner:TEAC CORP

Apparatus for fixing a wig and method for fixing a wig using the apparatus

ActiveUS20100170527A1Keeping tangling stateGood conditionSnap fastenersHair accessoriesEngineeringMechanical engineering

An apparatus for fixing a wig to head of a user, including a flexible plane sheet including a first opening and a second opening, a plurality of monofilaments each including a swollen head and protrusively provided on a first side of the flexible plane sheet, a first adhesive layer provided so as to cover the monofilaments, a net member provided on a second side of the flexible plane sheet, and a second adhesive layer provided on the net member of a first half area, the flexible plane sheet being divided into the first half area and a second half area by a line bisecting the flexible plane sheet is provided. The first opening is provided on the line bisecting the flexible plane sheet while having a thin and long shape so that a part of natural hair of the user passes through the first opening, and the second opening is provided at a predetermined position on the second half area so that other part of the natural hair of the user passes through the second opening.

Owner:ADERANS HLDG CO LTD

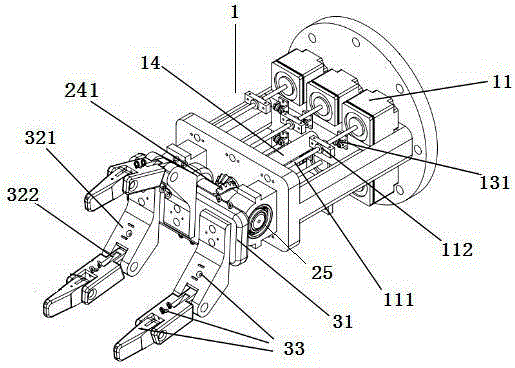

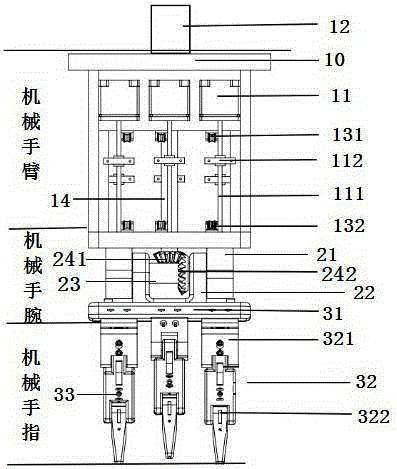

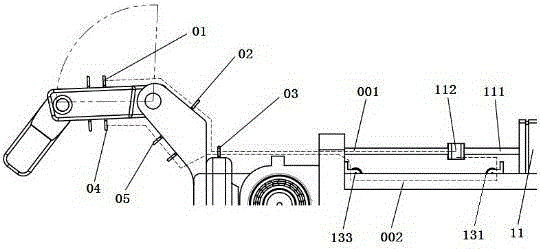

Flexible bionic manipulator

ActiveCN105291134AHigh degree of flexibilityImprove the quality of useProgramme-controlled manipulatorJointsRobotic armFinger joint

The invention discloses a flexible bionic manipulator and relates to the technical field of mechanical devices. The flexible bionic manipulator comprises a mechanical arm, a mechanical wrist and a mechanical finger component. The mechanical arm comprises an arm support, first motors and a second motor, and the first motors and the second motor are connected with screw rods through rotating shafts. Nuts are mounted on the screw rods through threaded fit. The mechanical finger component comprises a mounting base, finger units are arranged on the mounting base, and each finger unit comprises three finger knuckles which are connected through two finger joints. The finger joints are connected to the nuts of the screw rods through steel wires respectively. According to the mechanical wrist, a connecting shaft connects a first rotating seat on the arm support and a second rotating seat on the finger mounting base, and the mechanical wrist further comprises a gear set in meshing transmission, wherein a first bevel gear is synchronous with a rotary shaft of the second motor, and a second bevel gear is fixedly connected to the connecting shaft in a sleeving mode. The flexible bionic manipulator is high in bionic degree, the grabbing force and grabbing postures can be autonomously adjusted, the ratio between the grabbing force and the dead weight is high, and the requirement for loads of an industrial robot body is lowered.

Owner:FOSHAN GUANGDONG TECH UNIV CNC EQUIP TECH DEV +1

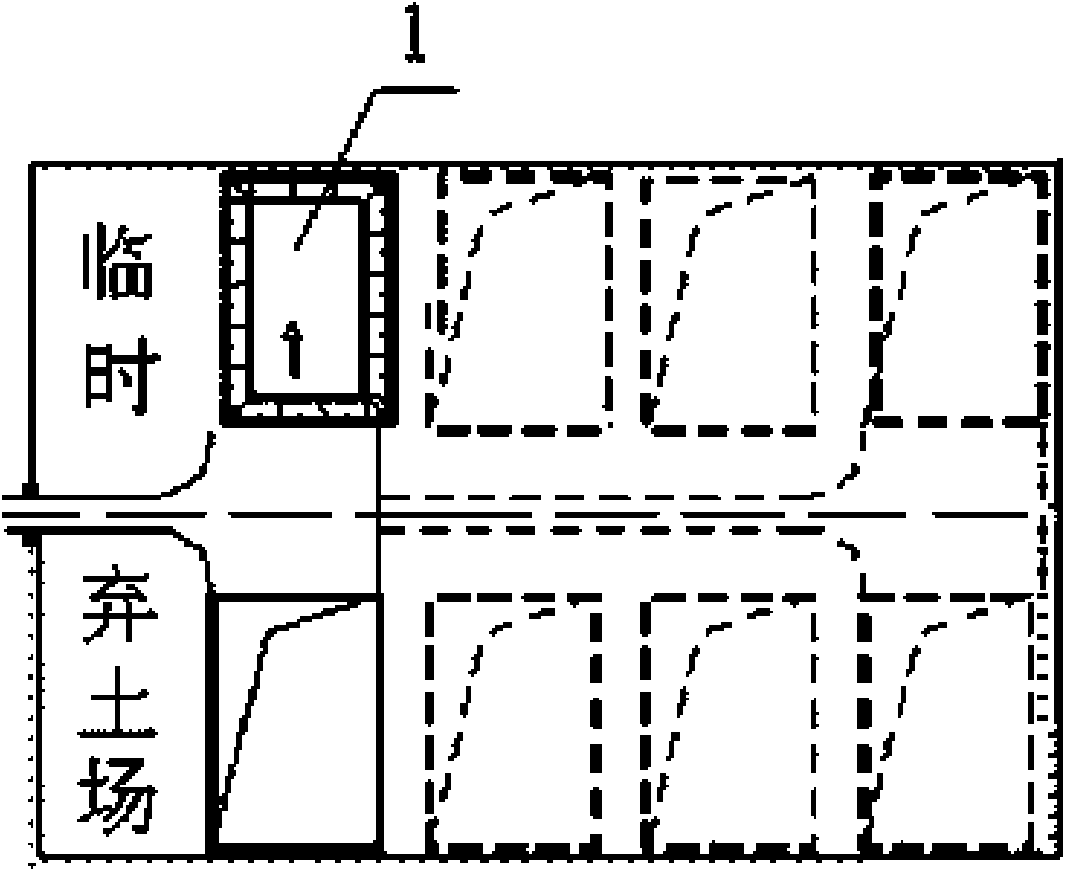

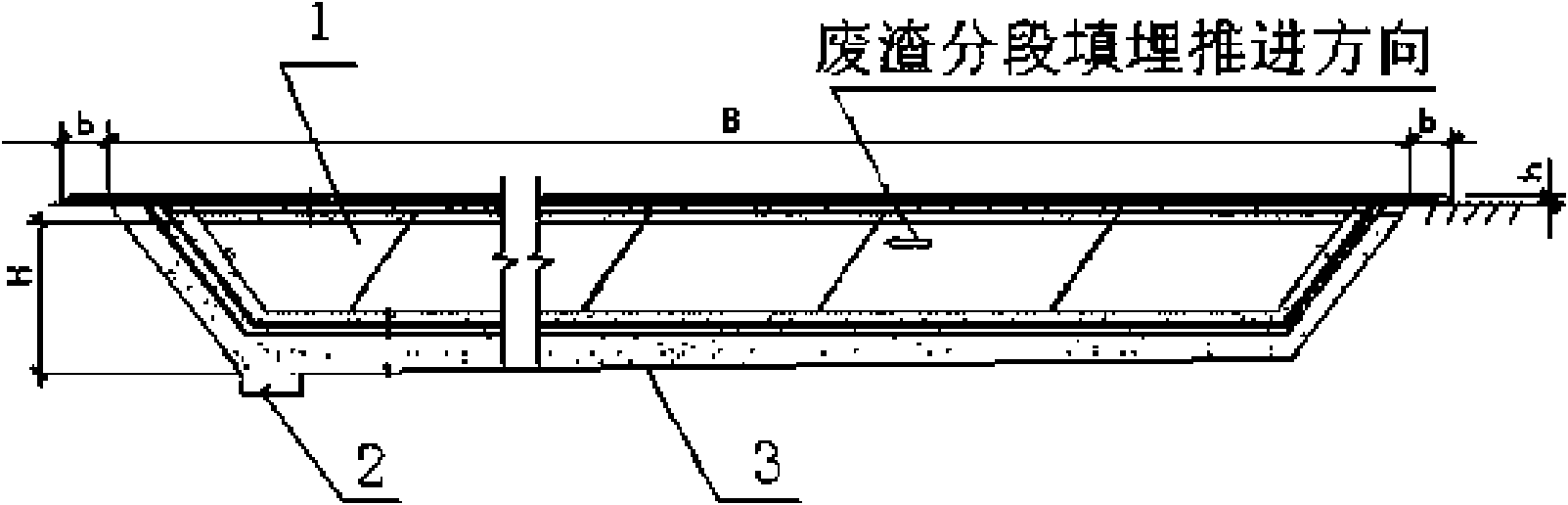

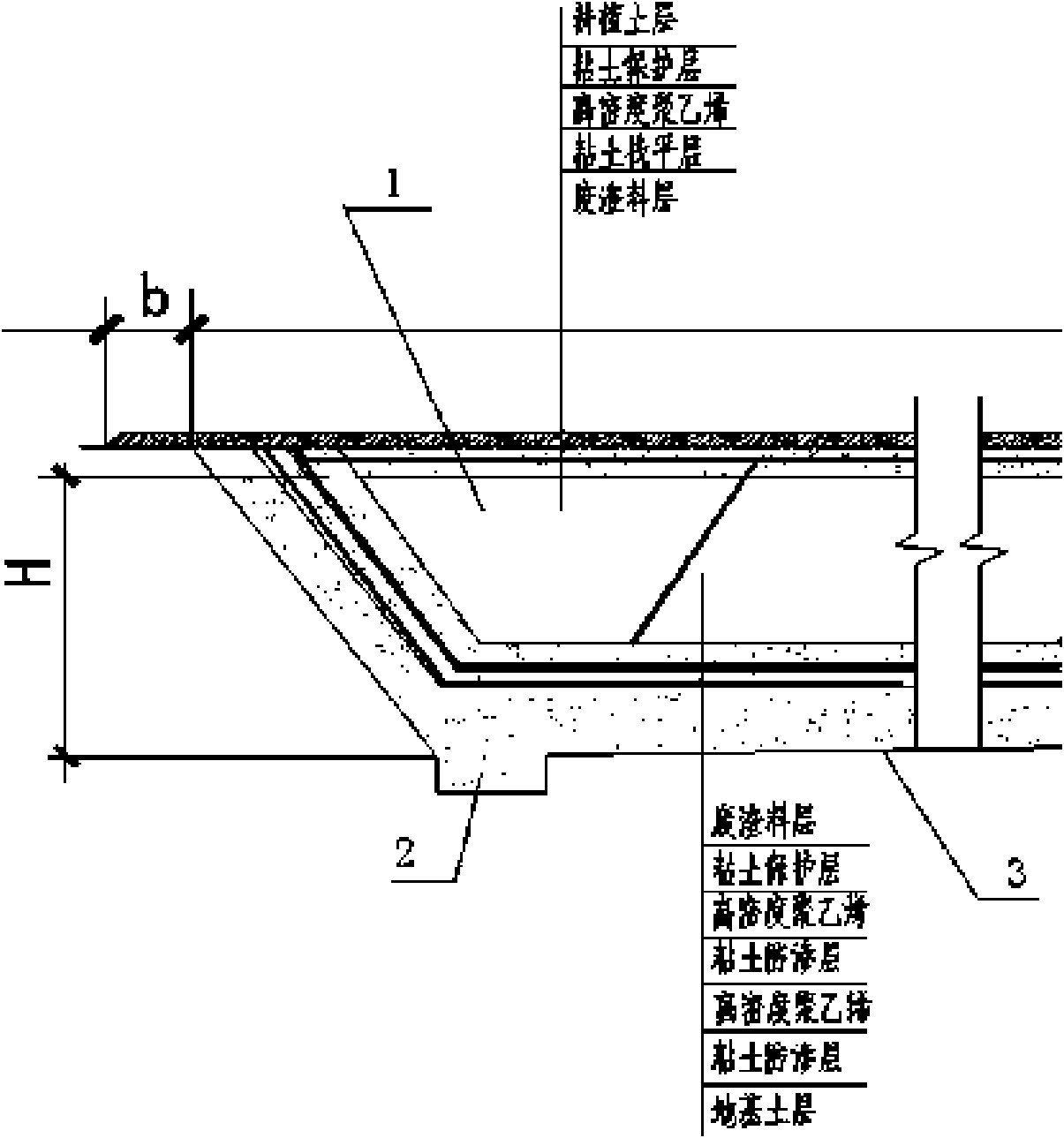

Method for processing electrolytic residue

InactiveCN101612626AFlexible site selectionEasy site selectionSolid waste disposalEngineeringGreening

The invention discloses a method for processing electrolytic residue. The method comprises the following steps: firstly, planning a residue dump area into a plurality of filling pits (1) with slope bottoms and respectively arranging water-depositing pits in the lowest positions of the pit bottoms; secondly, respectively digging the filling pits (1) and digging one filling pit (1) once; thirdly, processing the dug filling pits (1) for resisting seepage; fourthly, piling the residue in the filling pits (1) in a direction from top to bottom by segments; covering the surface after leveling and compacting or piling up, compacting and leveling at a higher segment of each pit before leveling and forming a slope with earth dug from each pit, wherein the layer is covered to thickness covering bulkprotrusions in the residue; then, laying a plastic waterproof layer and covering the plastic waterproof layer with the dug earth; and finally, planting herbaceous plants or undershrubs on the surfacecovering layer for greening. The invention is suitable for use in various electrolytic residue dumps.

Owner:GUIYANG AL-MG DESIGN & RES INST

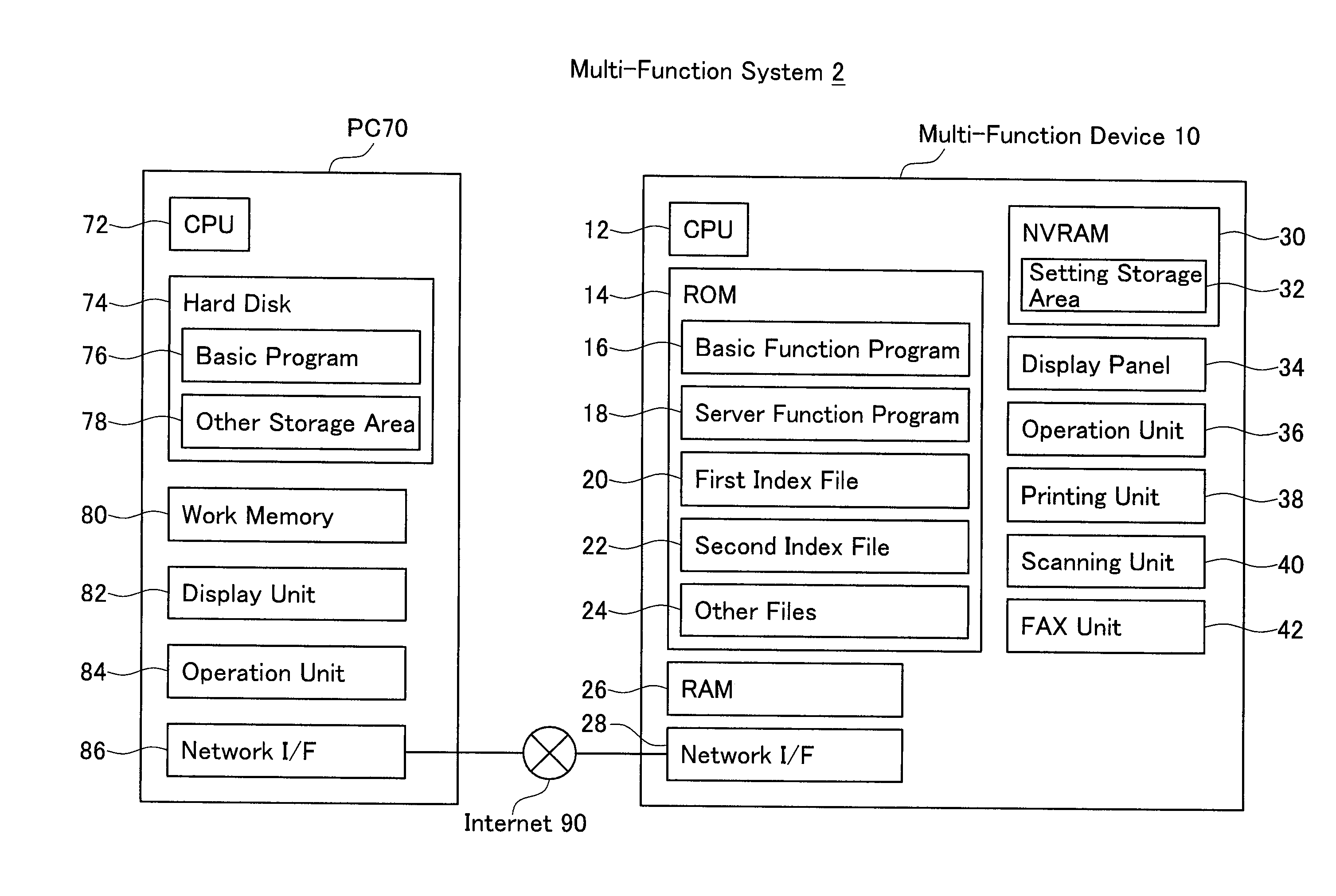

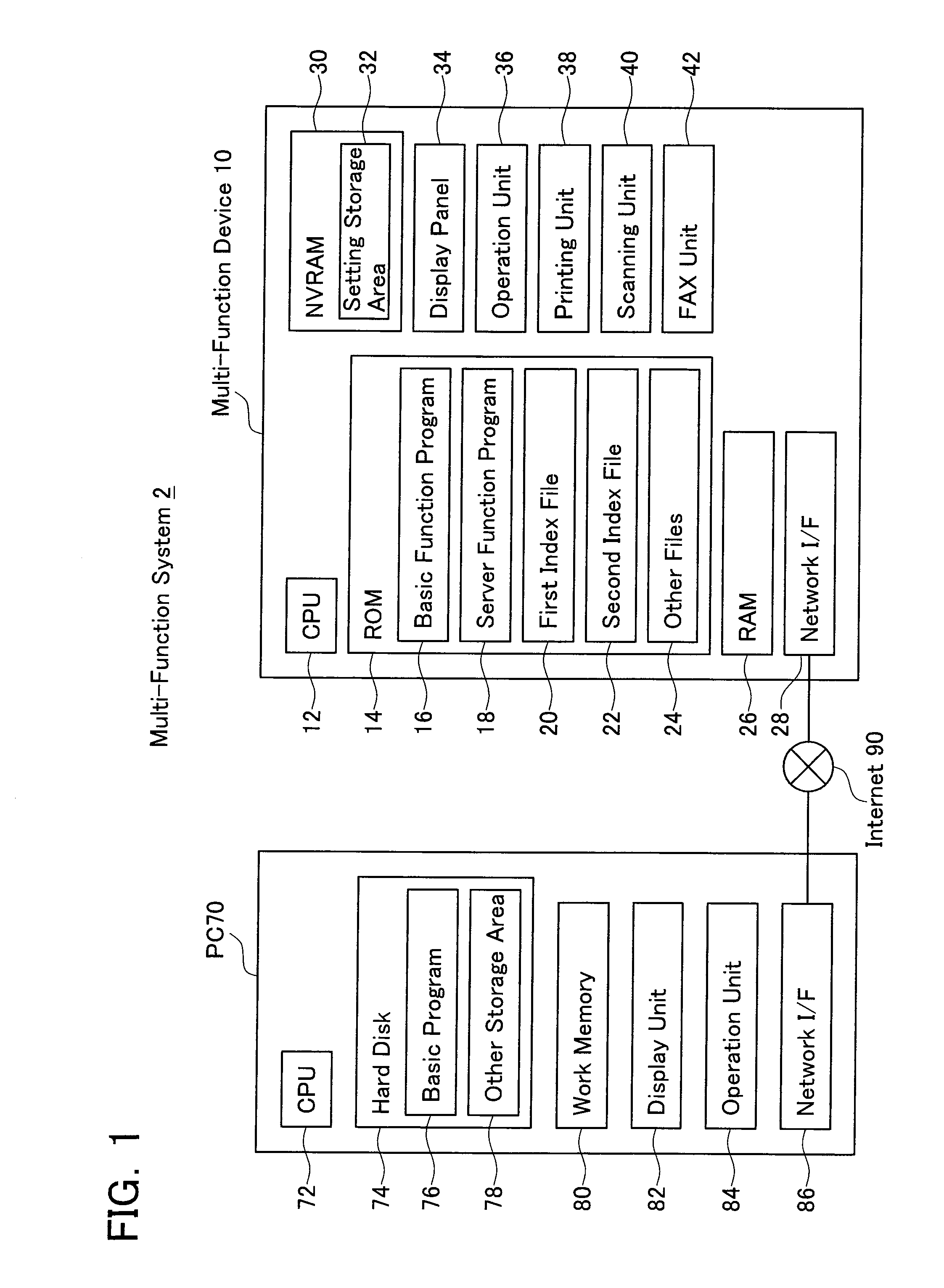

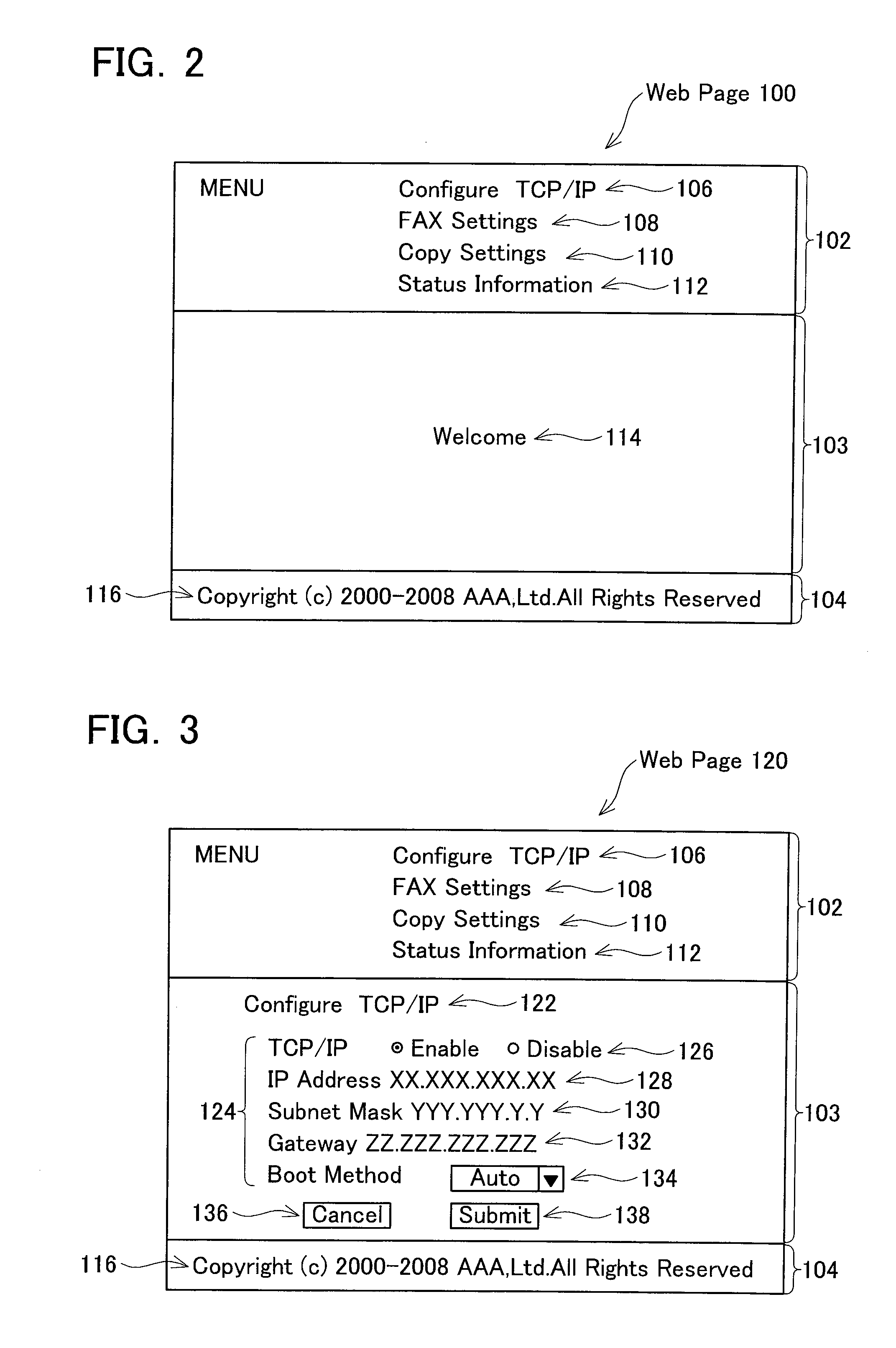

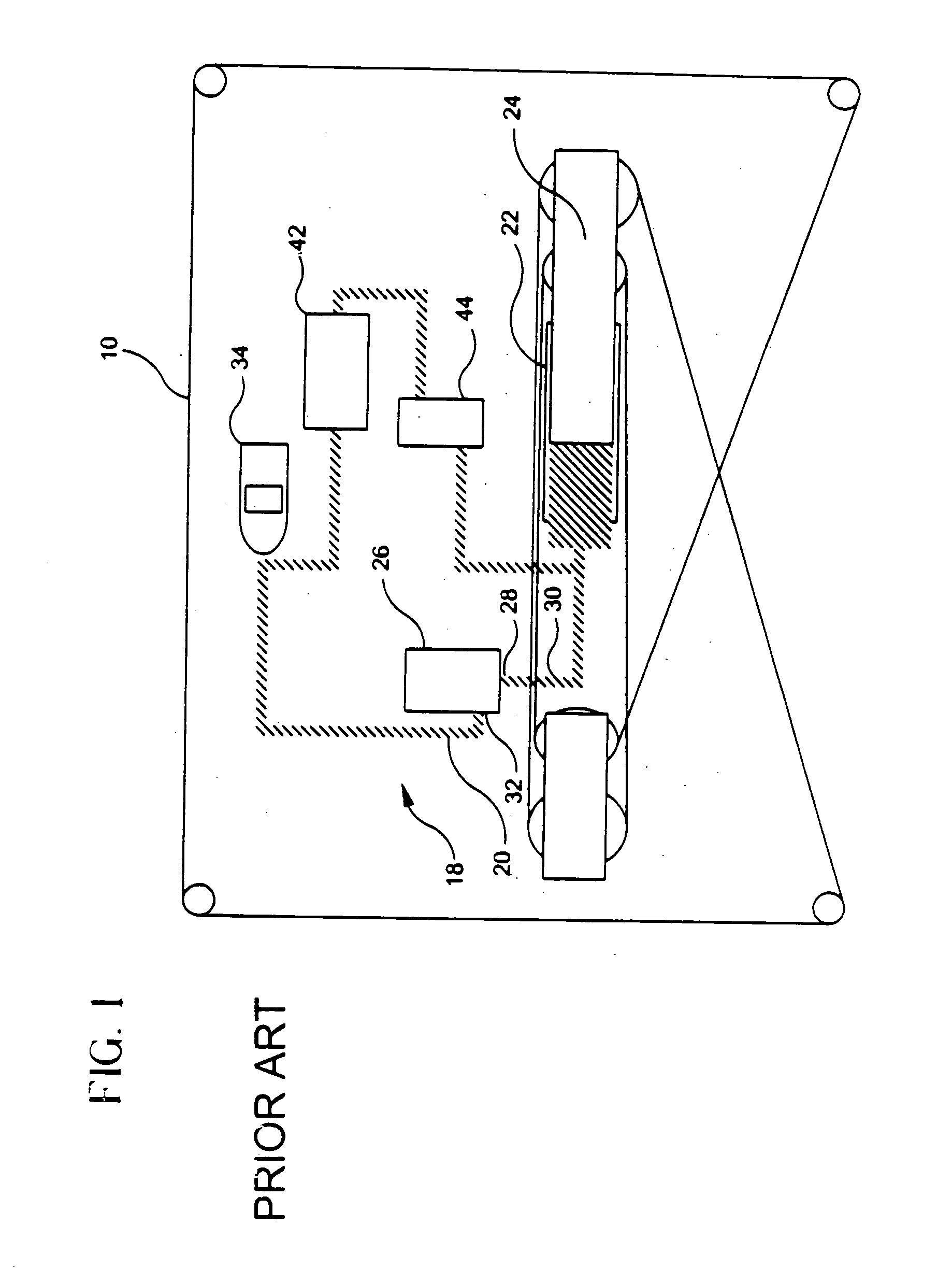

Printer Having Web Server Function

ActiveUS20100079804A1Reduce loadReduce load requirementsNatural language data processingTransmissionData displayWeb service

A printer may comprise a command file storage unit, a receiving unit, a command file sending unit, and a first data sending unit. The command file storage unit may store a command file including a first command, a second command, and a third command. The first command is a command for sending a request for first data. The second command includes design data, and is a command for converting the first data into second data in accordance with the design data. The third command is a command for displaying a web page in accordance with the second data. The receiving unit may receive a request. The command file sending unit may send a response including the command file when a request for the command file is received. The first data sending unit may send a response including the first data when the request for the first data is received.

Owner:BROTHER KOGYO KK

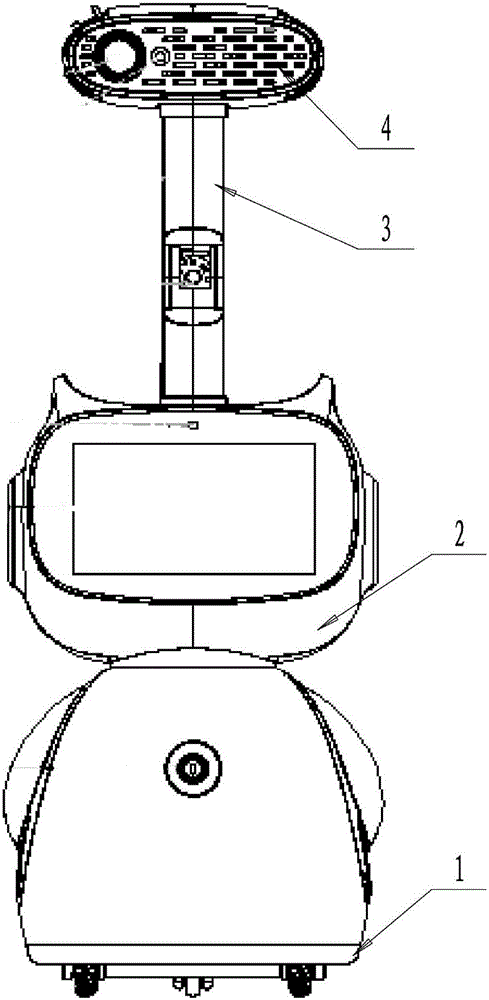

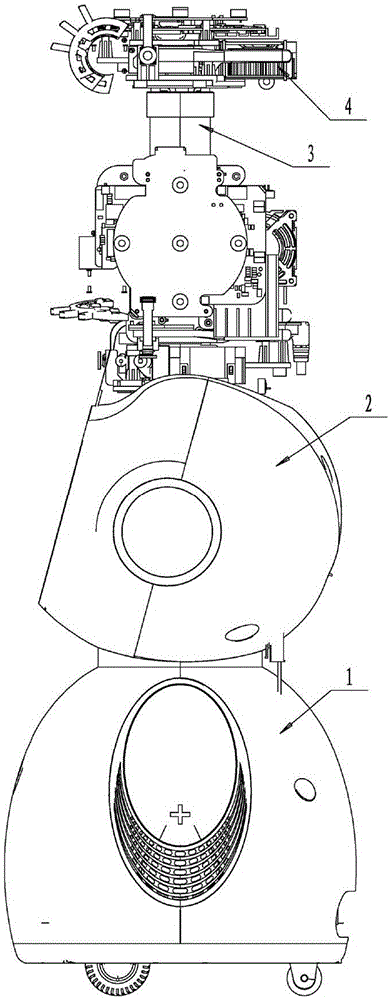

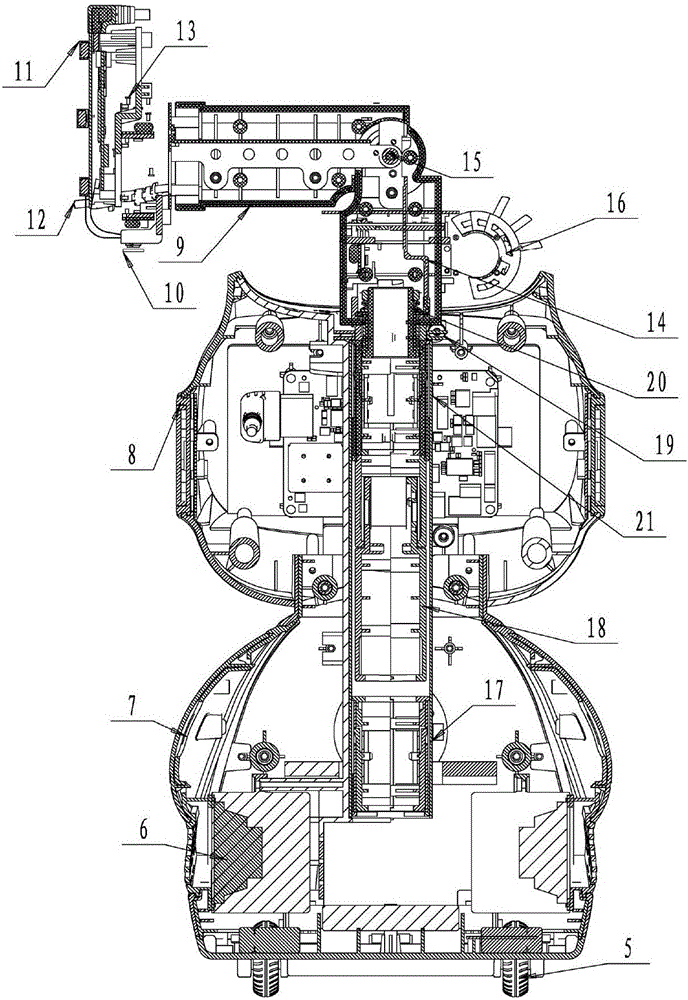

Projection robot and projection method thereof

PendingCN106406313AReasonable designLow costPosition/course control in two dimensionsVehiclesEngineeringMotor drive

The invention relates to a projection robot and a projection method thereof. The projection robot comprises a pedestal, a main body arranged above the pedestal, a neck part arranged at the upper end of the main body in a rotatable stretching mode, a head arranged on the neck part, motor-driven wheels arranged under the pedestal, a BOX horn arranged on the pedestal, a touch volume adjusting switch being arranged on a pedestal housing and being connected with the BOX horn electrically, a charging wake-up breathing lamp arranged on the main body, and a processor and a battery module, wherein the processor and the battery module are arranged in the main body. According to the invention, the projection robot has advantages of reasonable design, compact structure, and convenient usage.

Owner:SHENZHEN QIANHAI YYD ROBOT CO LTD

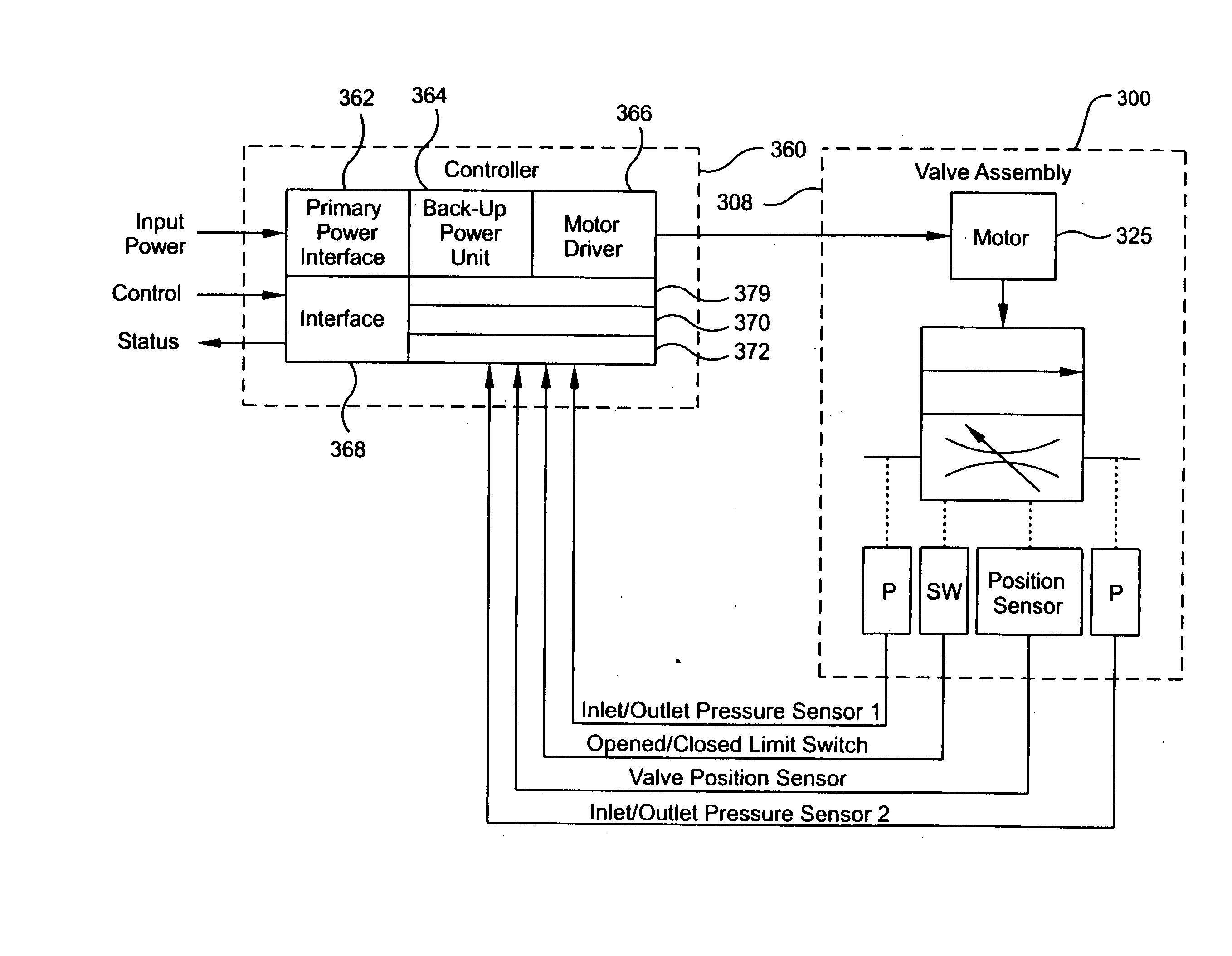

Method and system for controlling the operation of a valve

InactiveUS20050151011A1Minimize forceReduce load requirementsArresting gearAlighting gearControlled releaseEnergy transfer

A speed reduction system for decreasing the speed of a moving craft has a craft engaging device, a control mechanism, and a hydraulic energy transfer system adapted to transmit energy from the craft engaging device to the control mechanism. The control mechanism is adapted to actively control release of energy from the hydraulic energy transfer system during the decrease of the speed of the craft. A method of controlling the operation of a valve includes adjusting the valve during the operation of the valve after comparing a condition to a desired condition determined by a profile. A hydraulic valve has a valve member defining passages arranged to balance the force of the fluid pressure acting on the valve member and an actuator connected to the valve member. A valve control system includes a controller and a driver arranged with the controller. The position of the valve is adjusted during a predetermined cycle to control the operation of the valve.

Owner:MAROTTA SCI CONTROLS

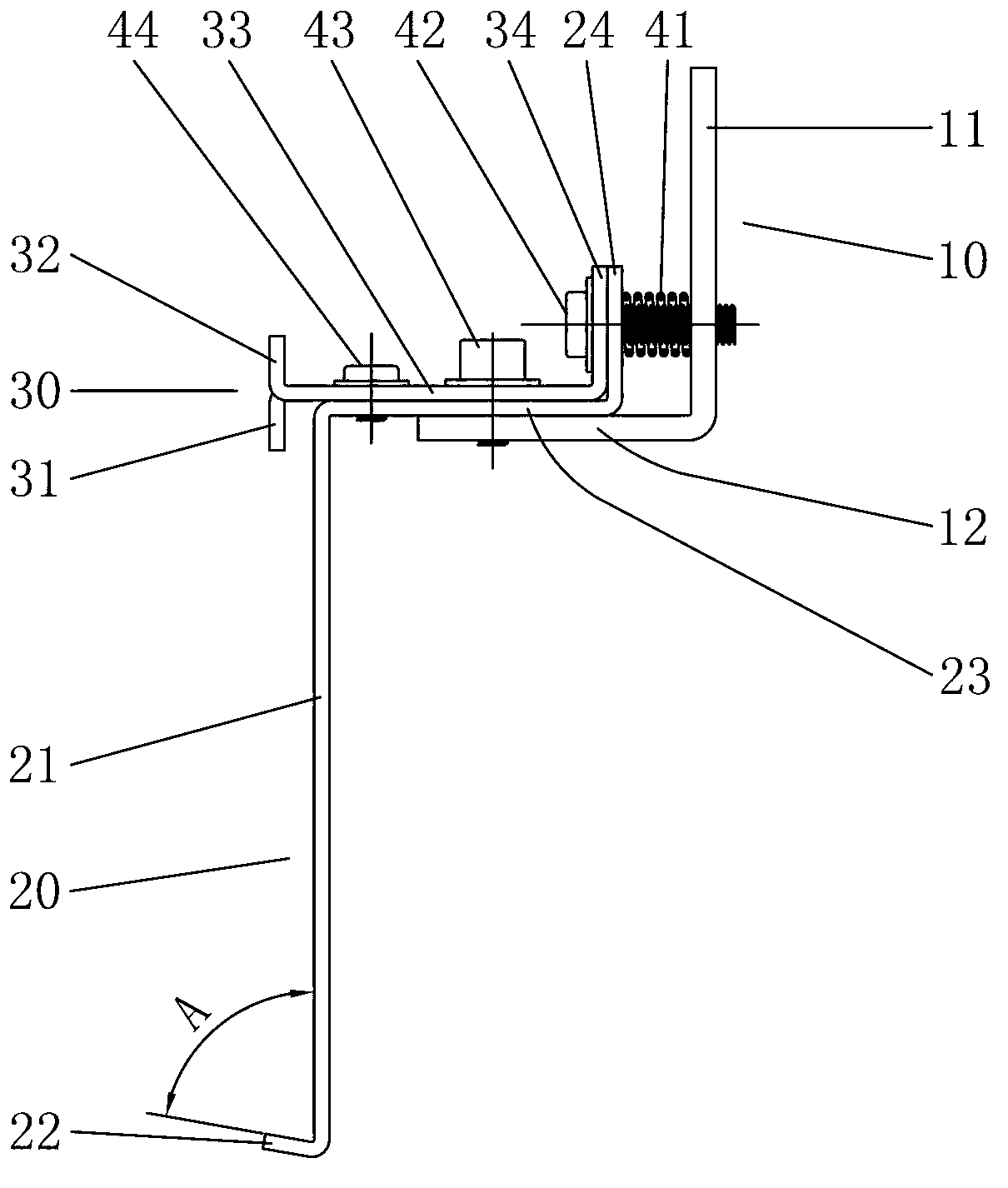

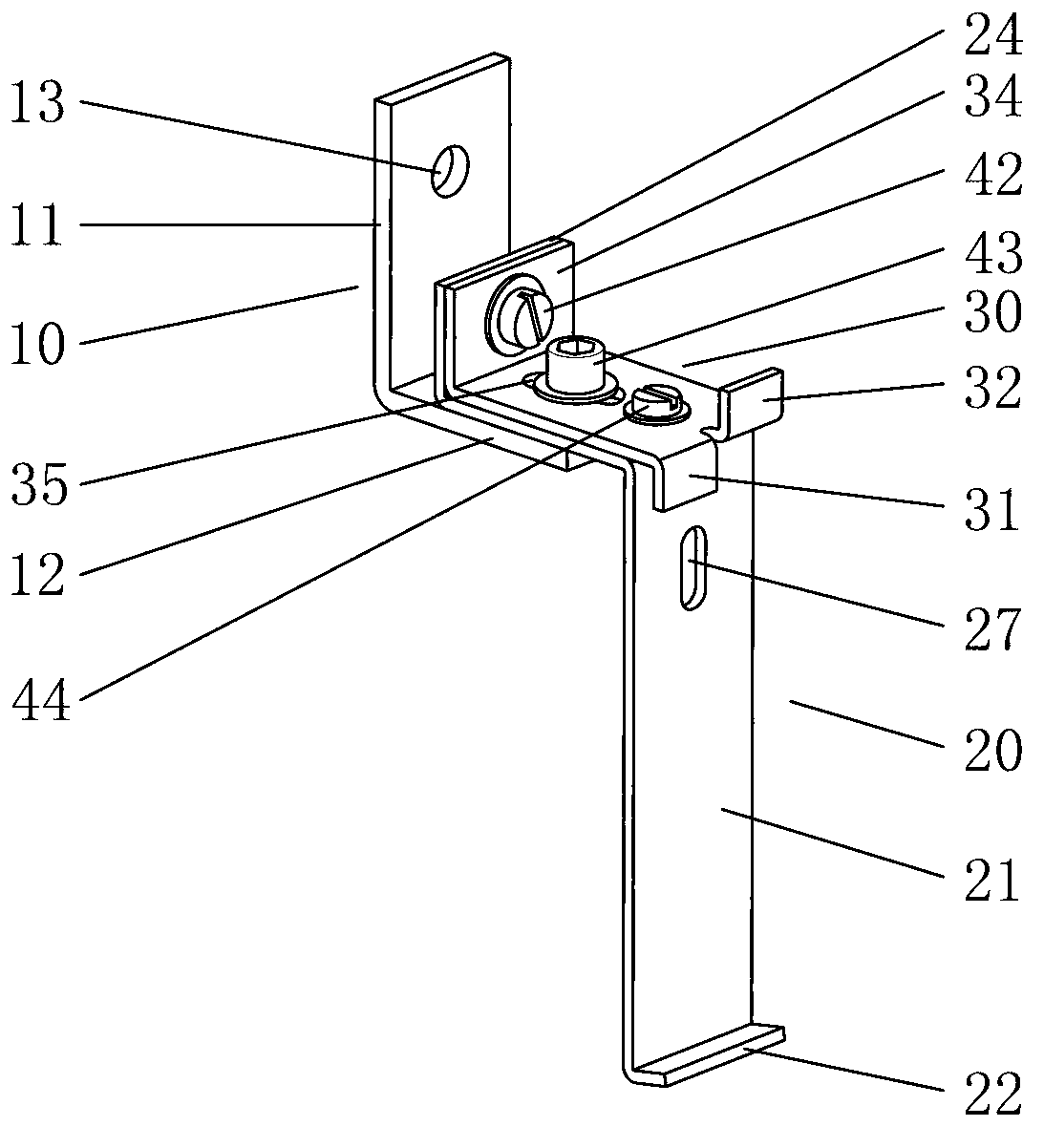

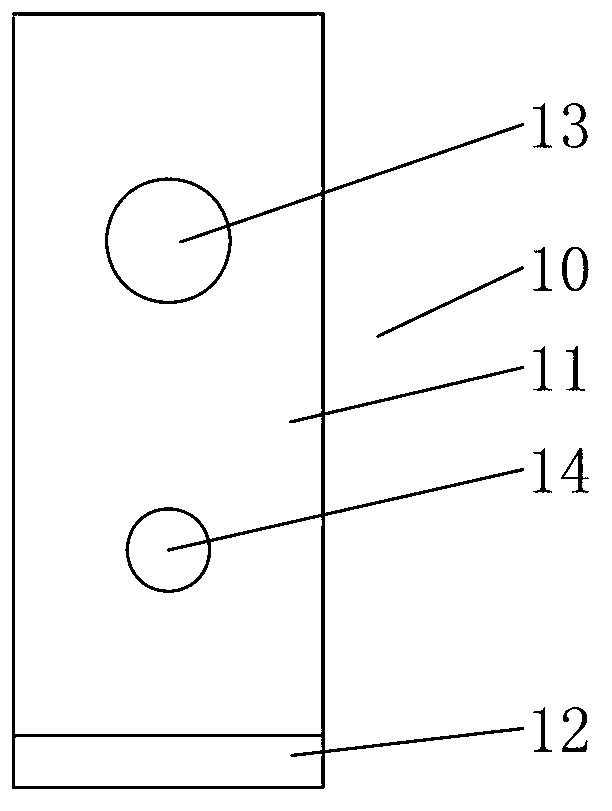

Installing hanging assembly of veneer materials

ActiveCN103291043AOutstanding and Beneficial Technical EffectsSave resourcesCovering/liningsKeelEngineering

The invention belongs to the technical field of wall decoration parts, and relates to an installing hanging assembly of veneer materials. The installing hanging assembly of the veneer materials comprises an L-shaped hanging part I which can be installed on a wall or a kneel or a supporting frame, a hanging part II which can be installed on the inner surface of a veneer and on a cross portion of the hanging part I, and a hanging part III connected with the upper end of the hanging part II and the hanging part I, wherein after the hanging part III is fixedly connected with the upper end of the hanging part II, the hanging part III is in elastic connection with a bending portion of the inner side of the hanging part I, and is in positioning connection with the cross portion of the hanging part I in a selective width mode, the outer side of the hanging part II extends downwards to form a bending portion, a pothook which can be hung on the veneer is arranged at the lower end of the bending portion of the hanging part II, a bending portion used for positioning or connecting the veneer is arranged at the outer end of the hanging part III, and an installation hole is formed in the upper side of the bending portion of the inner side of the hanging part I. The installing hanging assembly of the veneer materials has the advantages of being capable of installing thin veneer materials, high in firmness, simple and rapid in construction, capable of saving materials, low in production cost, flat in wall surface to be decorated, and suitable for being used as hanging parts for the veneer materials on indoor and outdoor walls.

Owner:郑念标 +1

Bottom bonding material used in preservative treatment of chimney and flue

ActiveCN101602927AReduce load requirementsStrong weather resistanceNon-macromolecular adhesive additivesWeather resistanceStrong acids

The invention relates to a bottom bonding material used in preservative treatment of a chimney and a flue. The bottom bonding material is modified silicon rubber (M50), and surface modified polytetrafluoroethylene (DS1) of a surface preservative material is bonded to the inner walls of the chimney and the flue; the modified silicon rubber (M50) is formed by modifying room-temperature vulcanized silicon rubber through nano SiOx and TiO2 additives, and the weight ratio of the room-temperature vulcanized silicon rubber to the nano SiOx to the TiO2 is 100:2-6:1-3; and x in the nano SiOx is 1.2 to 1.6. The bottom bonding material can provide effective bonding for DS1 (surface modified polytetrafluoroethylene board) with temperature resistance and strong corrosion resistance in the preservative treatment of the chimney and the flue so that an integral preservative layer has good temperature resistance, strong adhesive force, super-strong acid resistance, good thermal shock resistance, good weather resistance, strong permeability resistance, strong pollution resistance and good scouring resistance.

Owner:重庆大众防腐股份有限公司

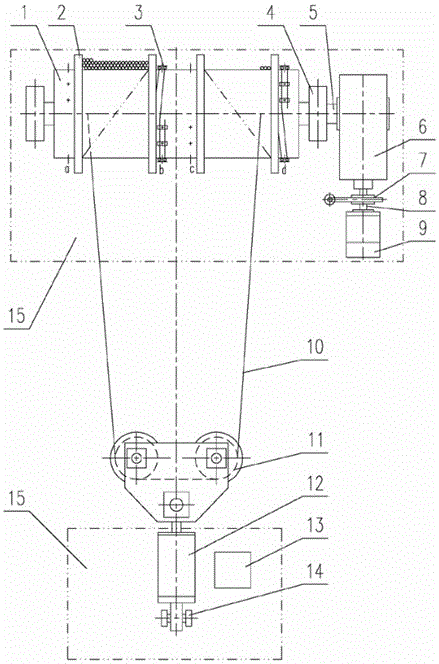

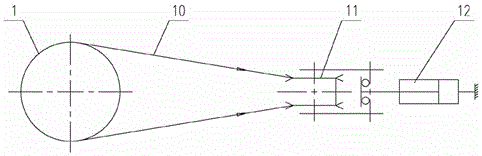

Drum stress test device and method thereof

ActiveCN105043885AReduce purchase quantityReduce test site requirementsMaterial strength using tensile/compressive forcesWinding mechanismsHydraulic pumpEnergy conservation

The invention discloses a drum stress test device and a method thereof and relates to the technical field of crane drum stress tests. The drum stress test device comprises a duplex-drum assembly, a steel wire rope (10), a drive assembly and a mounting rack (15). The duplex-drum assembly comprises a duplex drum (1). The test device further comprises a loading assembly. The loading assembly comprises a pulley set (11), a hydraulic oil cylinder (12) and a hydraulic pump station (13). According to the drum stress test device and the method, only one drive device set is needed, and the drive assembly and the loading assembly can be used as universal pieces to be suitable for different drums; the test cost is lowered, power consumption is lowered, and energy is saved.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

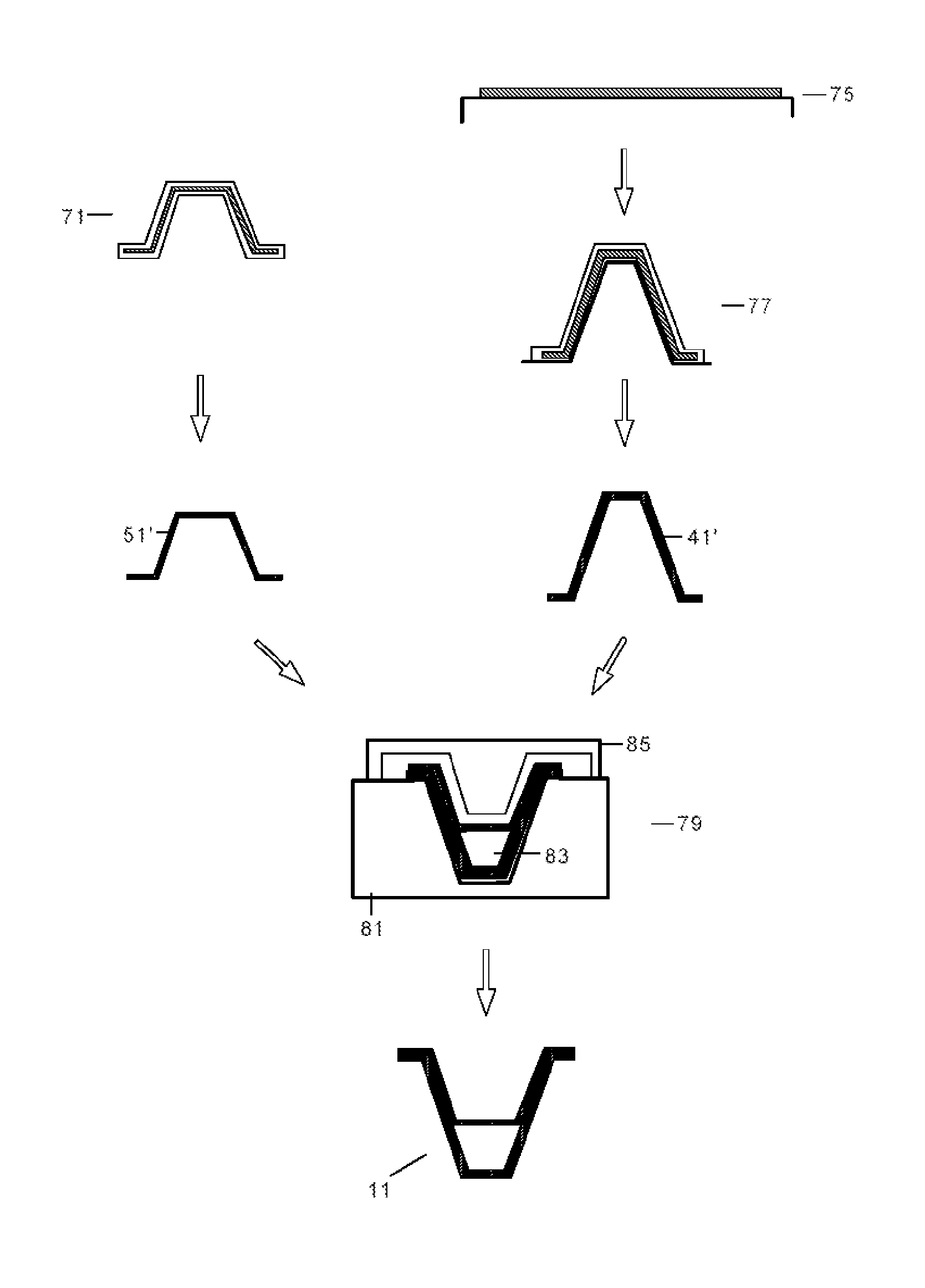

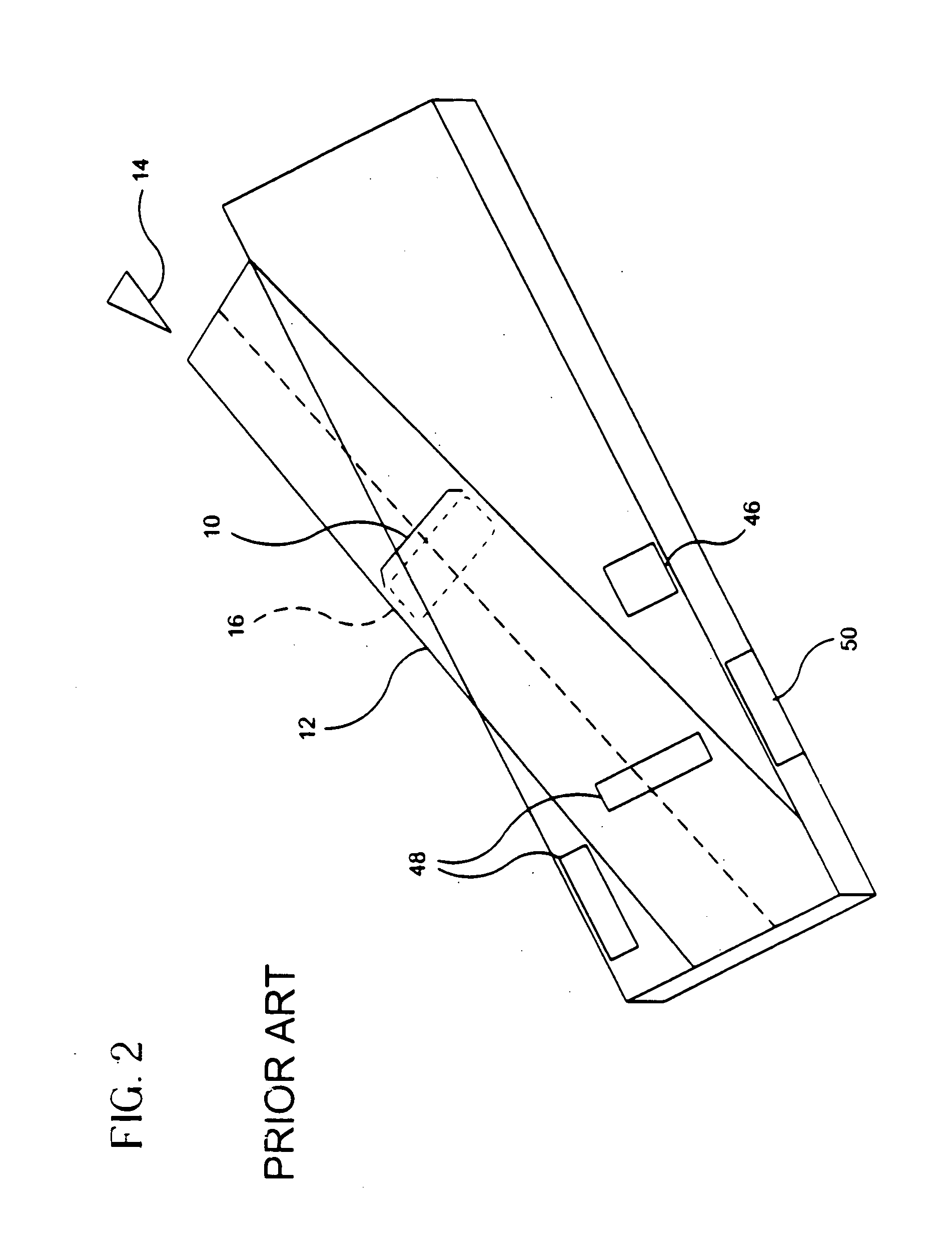

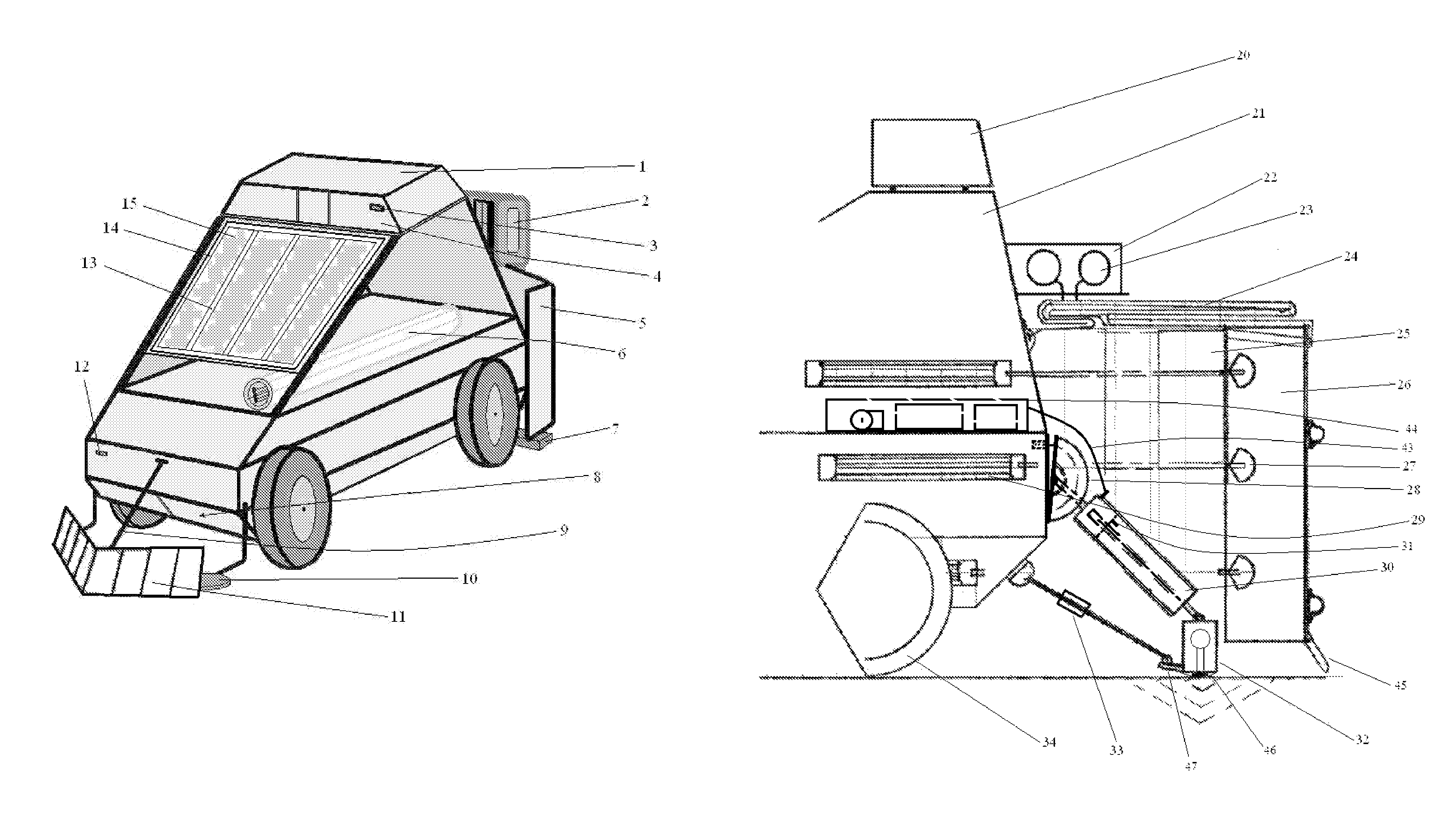

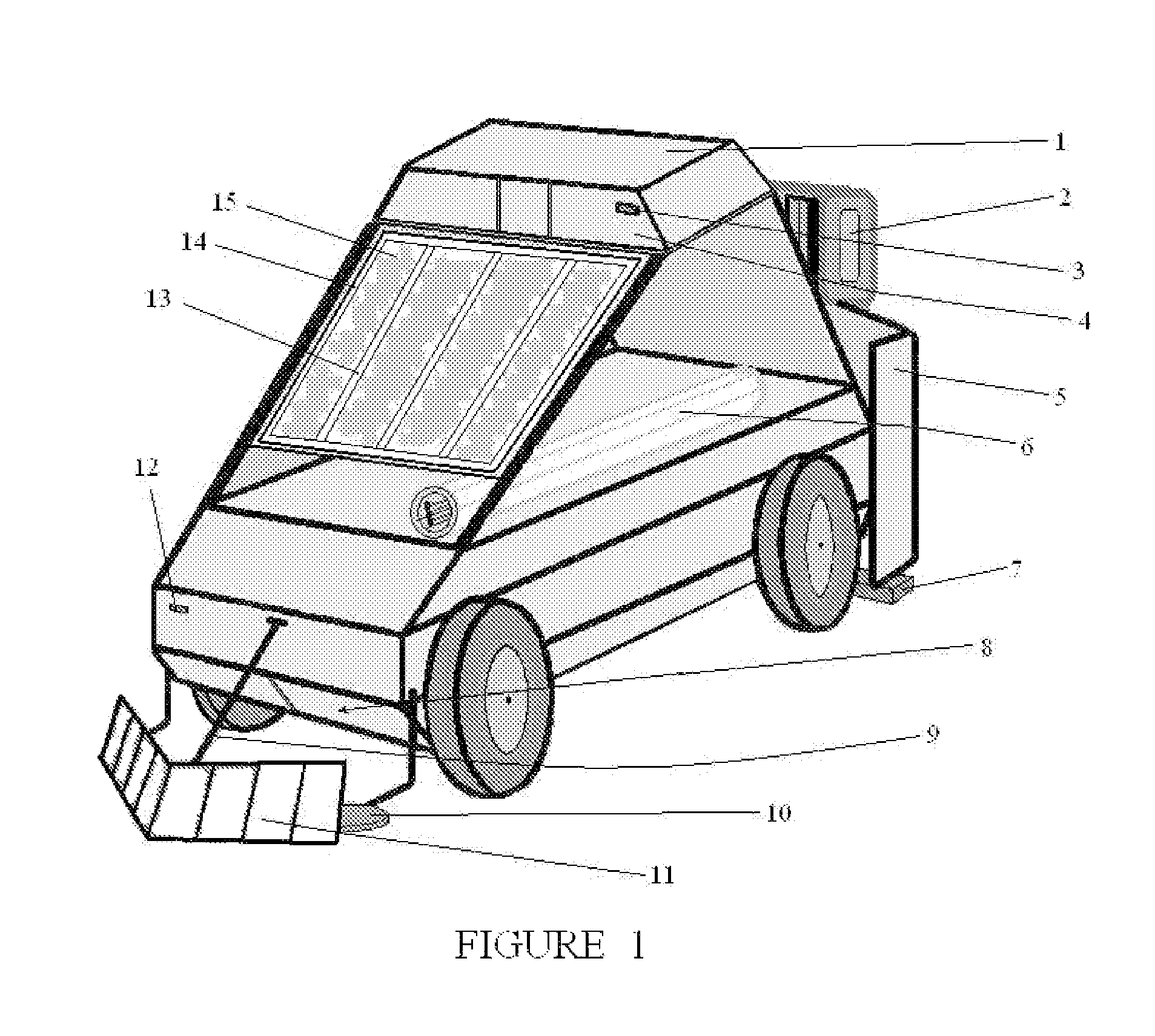

4D simultaneous robotic containment with recoil

A semi-continuous duty, Green Technology, self-charging 14, unmanned electric vehicle providing protection and security from underground mines. A deflector blade 11 follows natural existing contours to maintain straight line paths, while simultaneously carrying a mine detector 10, a vertical reciprocating ram set 30, 32 and 33 that preloads soil while also creating forward motion, followed by an energy dissipation and containment canopy system 22, 24, 26&29. The comprehensive system provides protection from mines on existing pathways in desert environments using a self-sufficient energy source. In addition, the total system utilizes only Green Technology for all modes of operation.

Owner:DIAZ KEVIN MARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com