Drum stress test device and method thereof

A stress testing and reeling technology, applied in the direction of hoisting device, using stable tension/pressure test material strength, spring mechanism, etc., can solve the problems of high test cost and high energy consumption, and achieve the test energy consumption The effect of fixing, reducing energy consumption and reducing subsequent procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

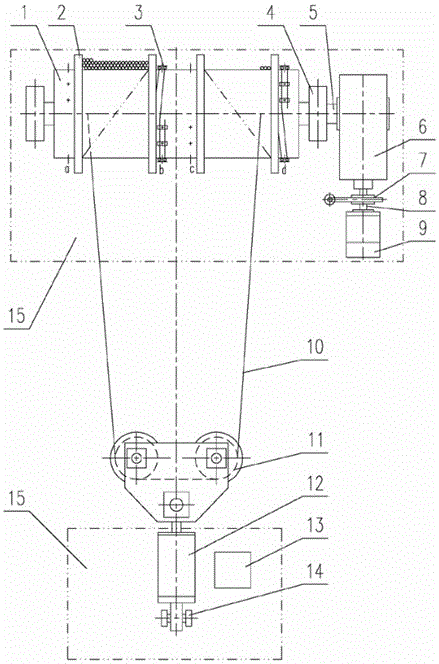

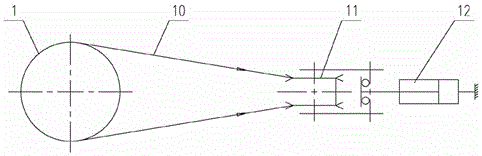

[0029] As a preferred embodiment of the present invention, refer to the accompanying figure 1 and 2 , this embodiment discloses:

[0030] A reel stress testing device includes a double reel assembly, a wire rope 10, a drive assembly and an installation frame 15, the double reel assembly includes a double reel 1; the testing device further includes a loading assembly, the loading The assembly includes a pulley block 11, a hydraulic cylinder 12 and a hydraulic pump station 13; the hydraulic pump station 13 is used to adjust the expansion and contraction of the hydraulic cylinder 12, the piston rod head of the hydraulic cylinder 12 is connected to the pulley block 11, and the hydraulic cylinder 12 passes through the support 14. The shaft is connected to the installation frame 15, and the pulley block 11 is free to rotate around the axis of the hydraulic cylinder 12; , and the other end is wound around the other end of the double drum 1 through the pulley block 11 ; the pulley b...

Embodiment 2

[0032] As another preferred embodiment of the present invention, refer to the accompanying figure 1 and 2 , this embodiment discloses:

[0033] A reel stress testing device includes a double reel assembly, a wire rope 10, a drive assembly and an installation frame 15, the double reel assembly includes a double reel 1; the testing device further includes a loading assembly, the loading The assembly includes a pulley block 11, a hydraulic cylinder 12 and a hydraulic pump station 13; the hydraulic pump station 13 is used to adjust the expansion and contraction of the hydraulic cylinder 12, the piston rod head of the hydraulic cylinder 12 is connected to the pulley block 11, and the hydraulic cylinder 12 passes through the support 14. The shaft is connected to the installation frame 15, and the pulley block 11 is free to rotate around the axis of the hydraulic cylinder 12; , the other end is wound around the other end of the double drum 1 through the pulley block 11; the pulley ...

Embodiment 3

[0035] As another preferred embodiment of the present invention, refer to the accompanying figure 1 and 2 , this embodiment discloses:

[0036] A reel stress testing device includes a double reel assembly, a wire rope 10, a drive assembly and an installation frame 15, the double reel assembly includes a double reel 1; the testing device further includes a loading assembly, the loading The assembly includes a pulley block 11, a hydraulic cylinder 12 and a hydraulic pump station 13; the hydraulic pump station 13 is used to adjust the expansion and contraction of the hydraulic cylinder 12, the piston rod head of the hydraulic cylinder 12 is connected to the pulley block 11, and the hydraulic cylinder 12 passes through the support 14. The shaft is connected to the installation frame 15, and the pulley block 11 is free to rotate around the axis of the hydraulic cylinder 12; , the other end is wound around the other end of the double drum 1 through the pulley block 11; the pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com