Dynamic control of dilution ventilation in one-pass, critical environments

a technology of dilution ventilation and dynamic control, applied in ventilation systems, heating types, instruments, etc., can solve the problems of wasting resources, creating allergic reactions in individuals, and fresh outdoor air, and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

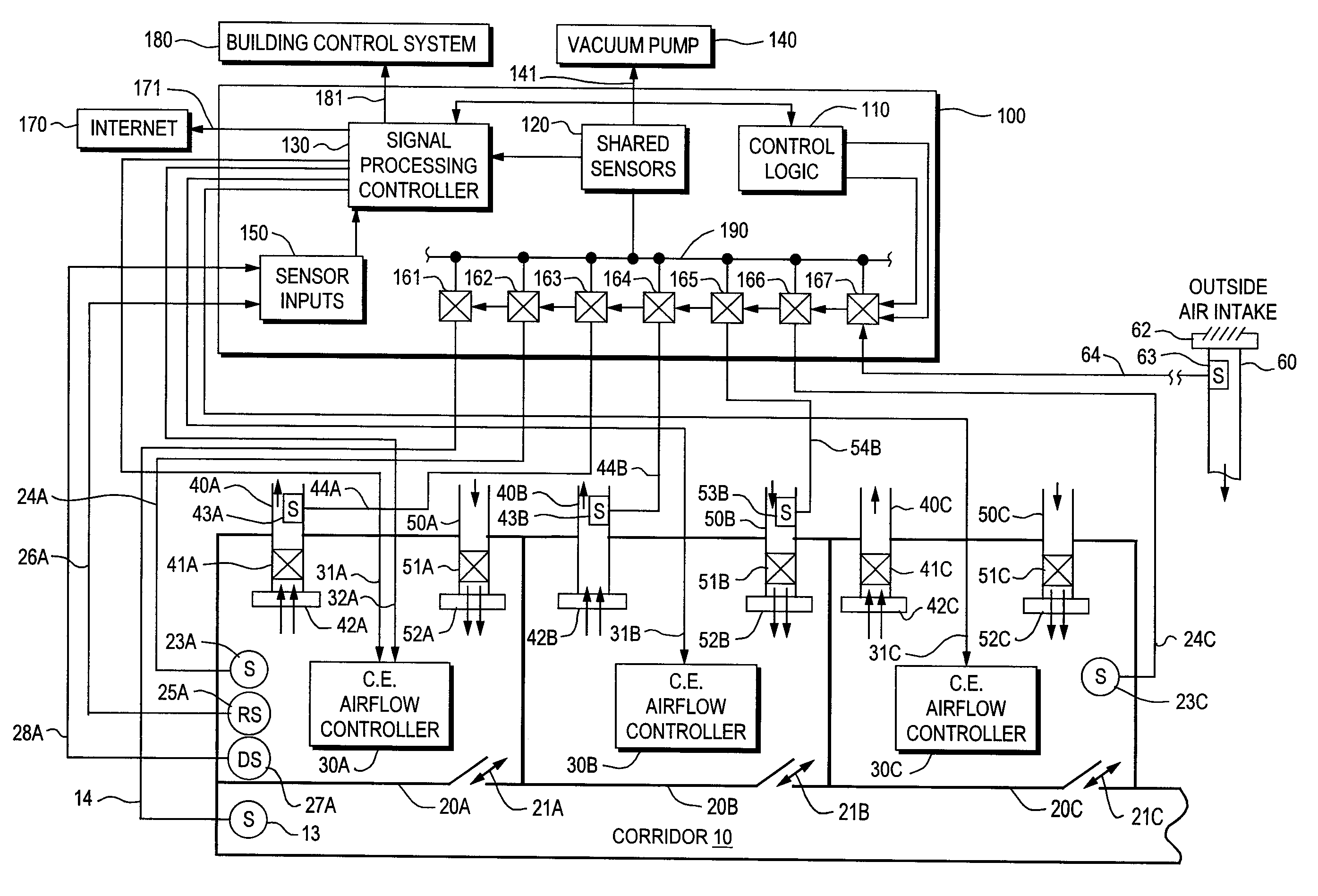

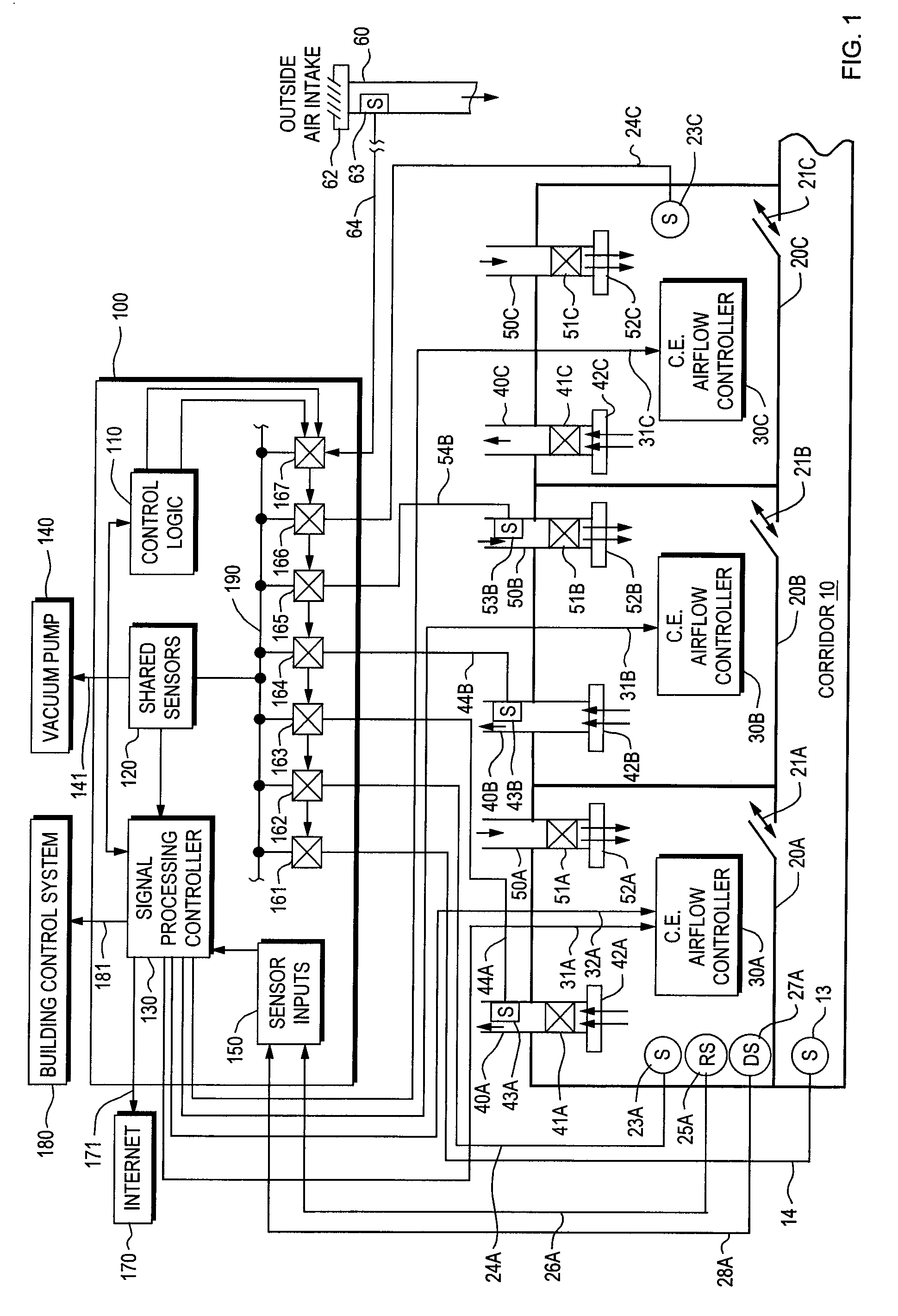

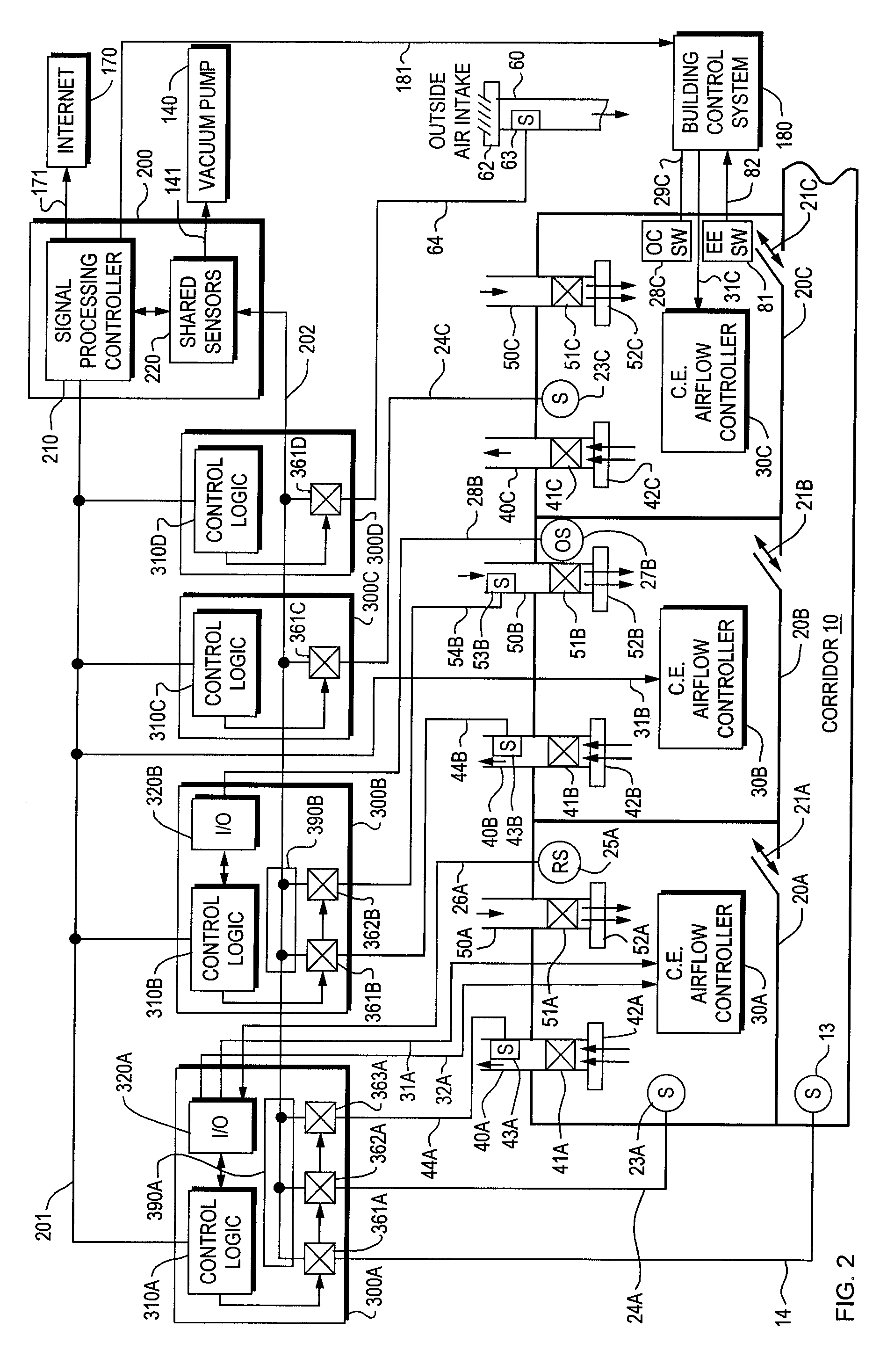

[0052]FIGS. 1, 2 and 6 all show a typical set of monitored critical environments or rooms 20A, 20B, and 20C that have doors entering a corridor 10 that is also being monitored. Due to a positive or negative pressurization of the critical environments, an offset may exist between the critical environment space or area and an adjacent space. An example of this is shown in FIGS. 1, 2 and 6 as offset airflow 21A, 21B, and 21C between the spaces 20A, B, and C and corridor 10. Although the diagrams show three rooms and a corridor, the present invention may be used with any plurality of rooms or spaces including corridors or other adjacent spaces that are also being monitored, such as for example, two or more critical environments, or one corridor plus one or more spaces. Note also that, although the critical environments shown in the Figures are enclosed within walls, critical environments in the context of this invention may also be a section or area of a room having no walls or partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com