Safety nosing components and manufacturing methods

a technology of safety components and manufacturing methods, applied in the field of safety components, can solve problems such as lack of orientation, physical injury, and risk, and achieve the effect of avoiding accidents, avoiding accidents, and avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

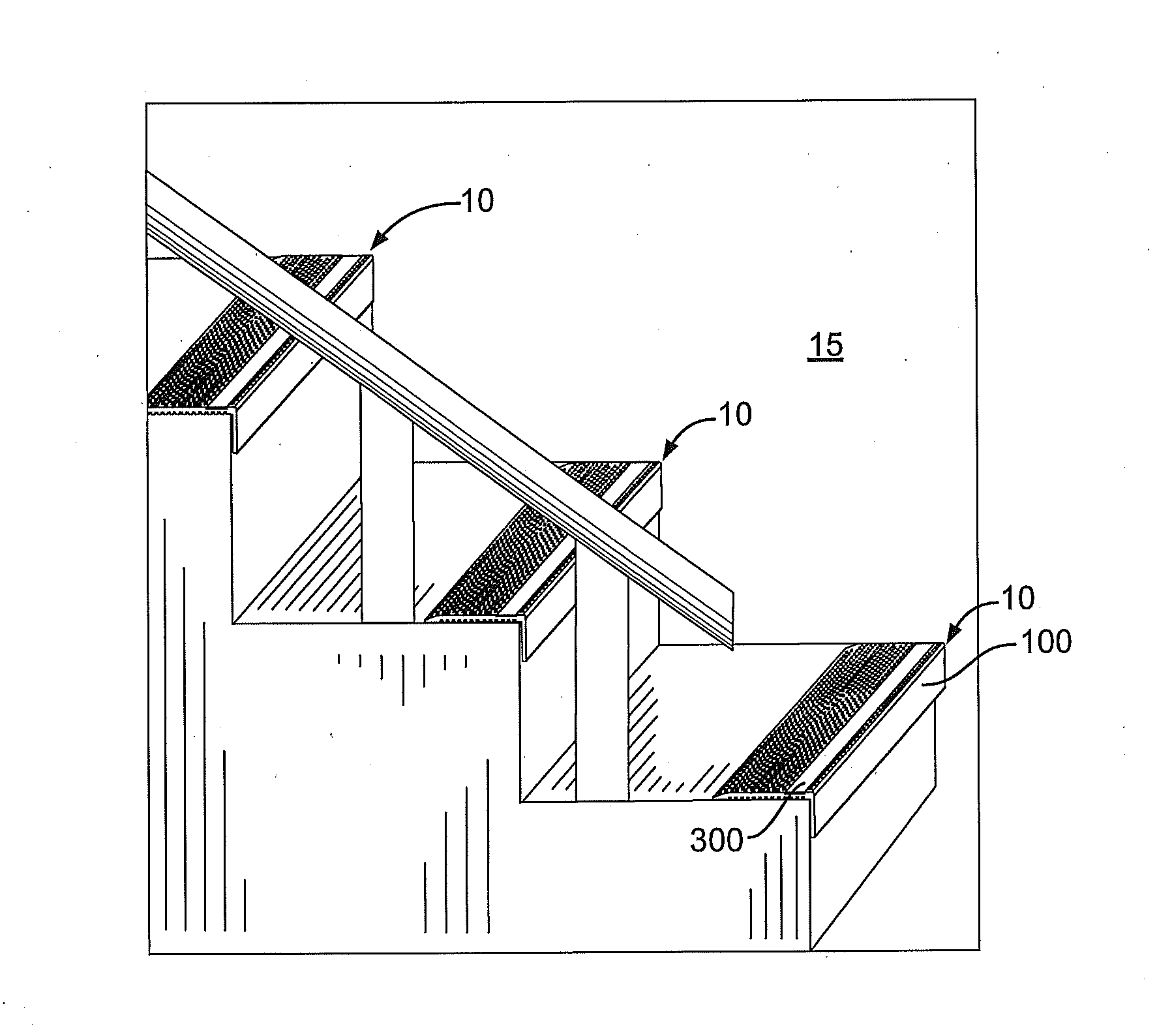

[0063]Preferred embodiments of a protective flooring device according to the present invention are generally shown by referring to the accompanying drawings.

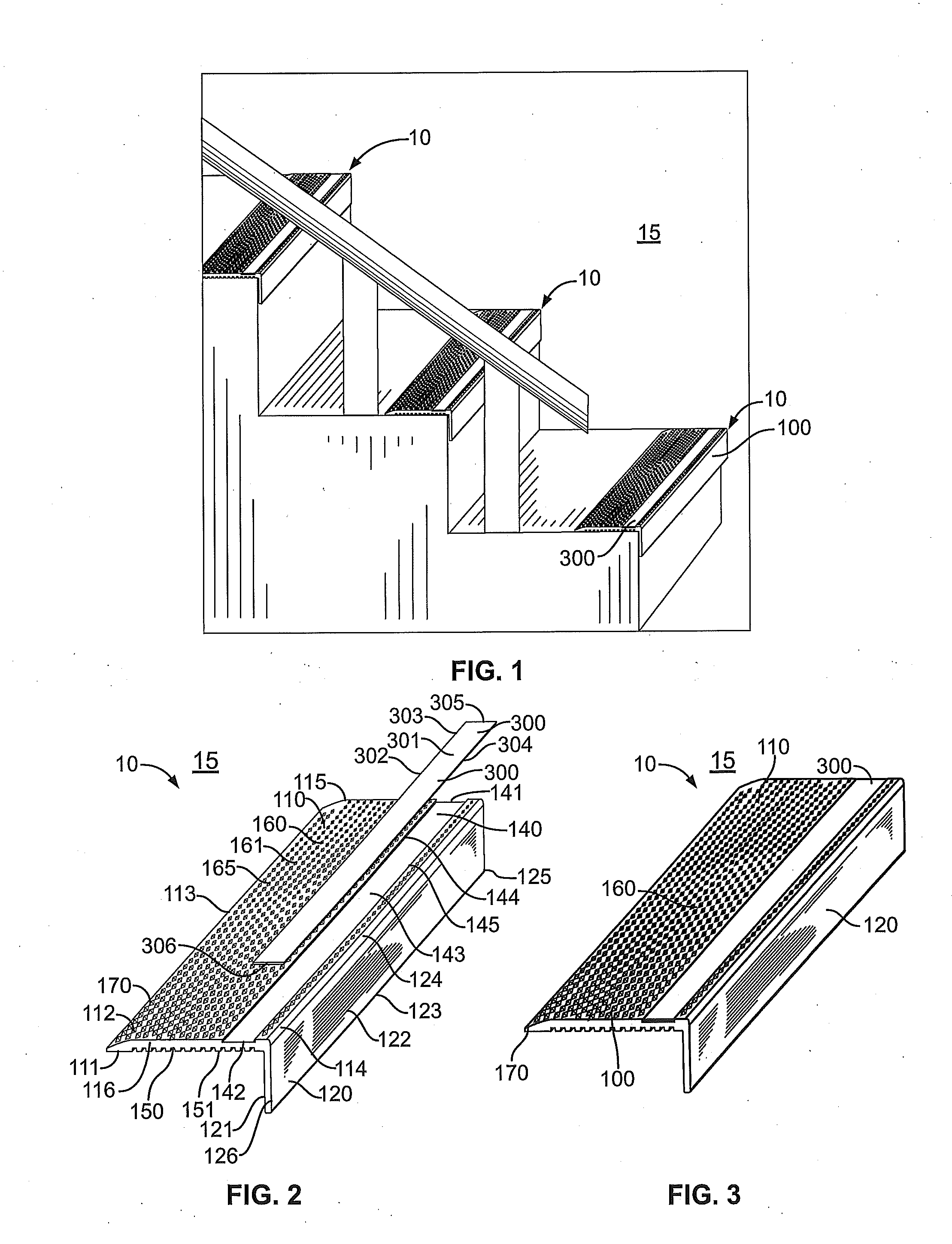

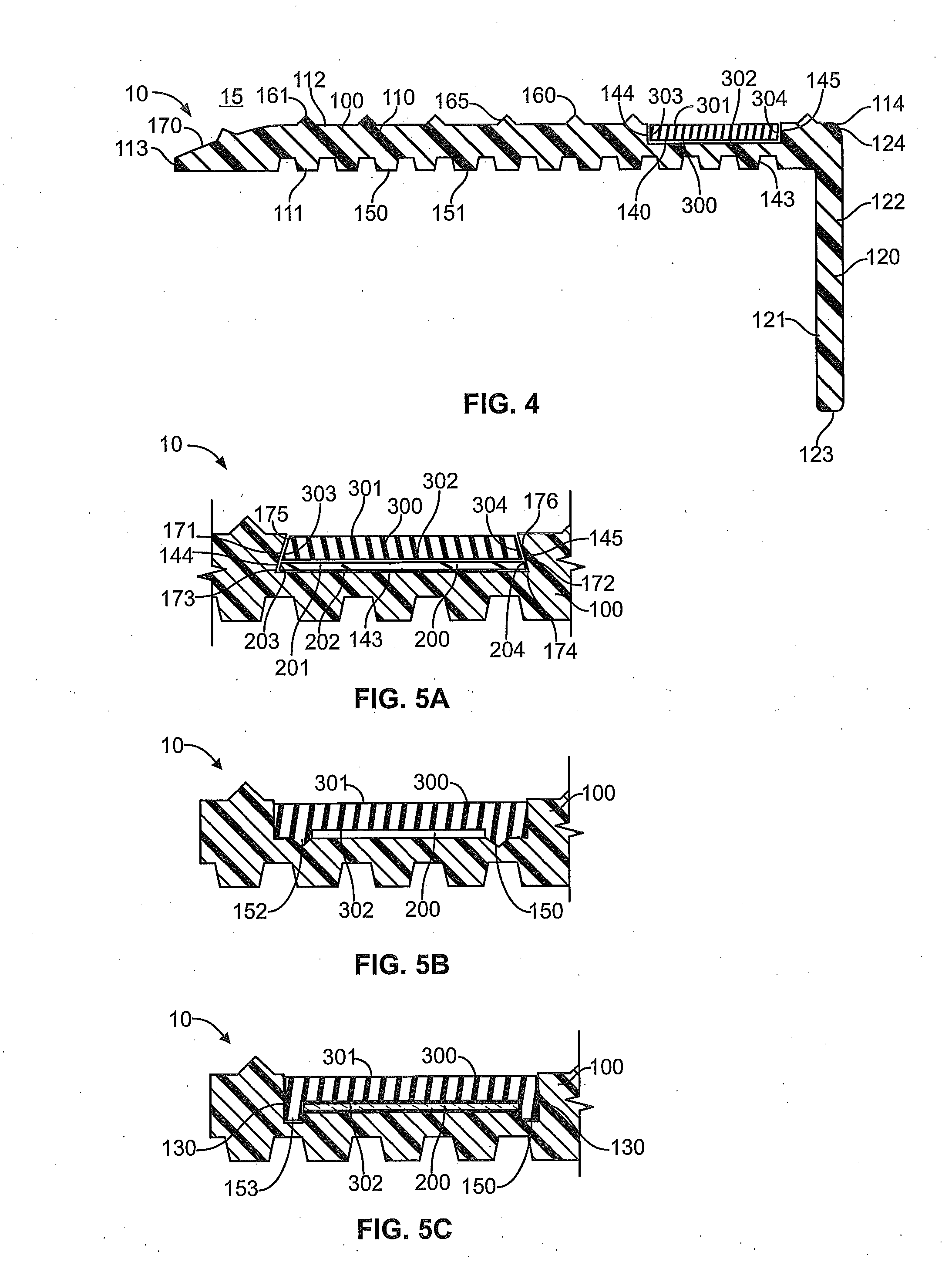

[0064]A safety nosing component 10 is shown in FIG. 1 as stair nosing component 15 in accordance with one embodiment of the present invention. As shown in FIG. 1, FIG. 2, FIG. 3 and FIG. 4, the stair nosing component 15 according to the present invention includes a base element 100 and light emission element 300. Additional embodiments may further include a substrate element 200 as shown in FIG. 5A, FIG. 5B and FIG. 5C.

[0065]In FIG. 1, FIG. 2, FIG. 3 and FIG. 4, the base element 100 includes a main member 110 with an inside surface 111, outside surface 112, first edge 113, second edge 114, third edge 115 and fourth edge 116.

[0066]In this embodiment, the base element 100 includes a main member 110 as described above as well as a support member 120. The support member 120 includes an interior surface 121, exterior surface 122, fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com