A c50 grade marine high performance concrete

A high-performance concrete and marine technology, applied in the field of concrete, can solve the problems of poor resistance to seawater erosion and low service life, and achieve the effects of improving durability, improving material composition, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

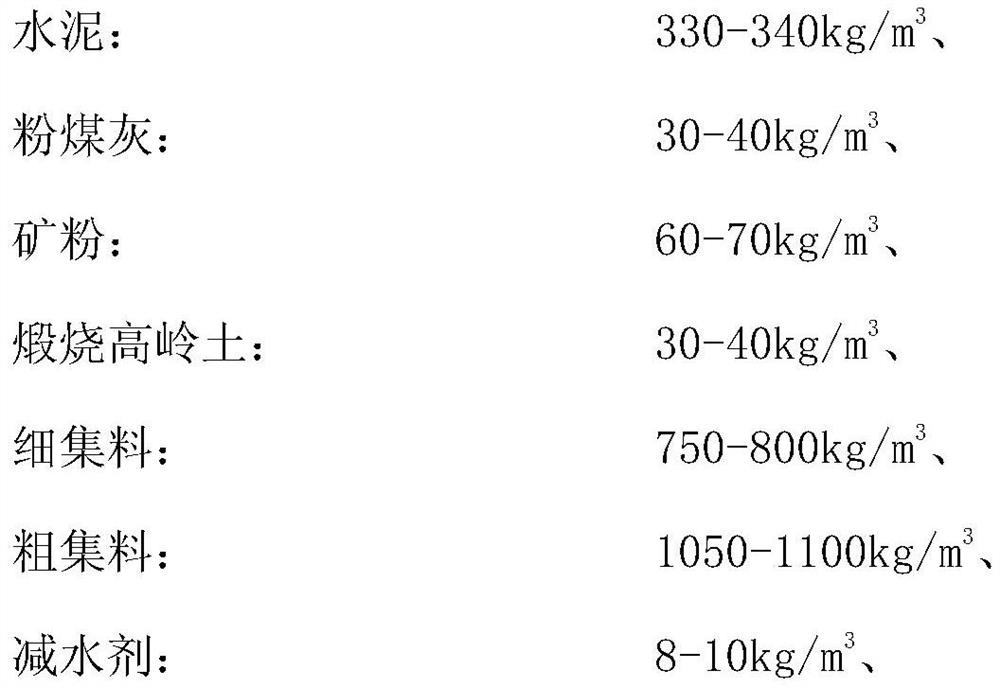

Method used

Image

Examples

Embodiment 1

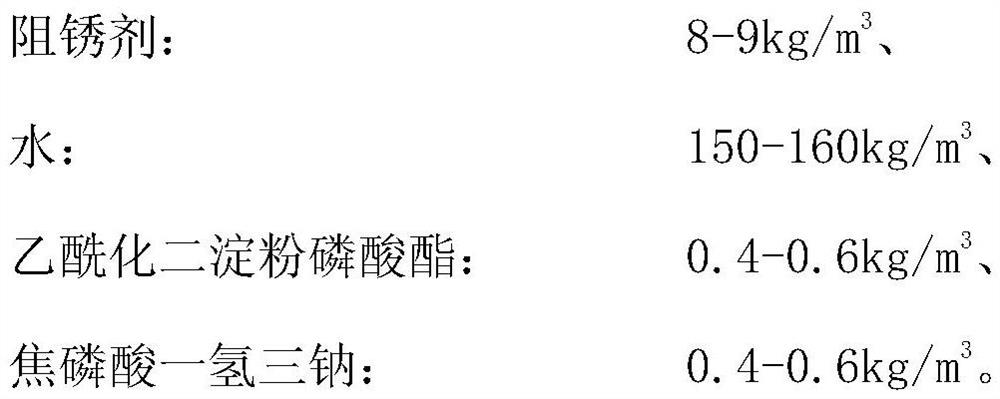

[0040] A C50 grade marine high performance concrete:

[0041] Table 1: Mix ratio unit of C50 grade marine high performance concrete: kg / m 3

[0042]

[0043] According to the above mixing ratio, the cement is 52.5 grade P·O ordinary Portland cement;

[0044] The fly ash is F class II grade fly ash, the slag powder is S95 grade granulated blast furnace slag powder, and the calcined kaolin is calcined secondary kaolin used in the rubber industry;

[0045] The fine aggregate is river sand, the fineness modulus of the fine aggregate is 2.8, the mud content is 0.9%, and the mud block content is 0.2%;

[0046] The coarse aggregate is 5-25mm continuous gradation, its crushing index is 9%, the content of needle-like particles is 4.5%, the content of mud is 0.2%, and the content of mud block is 0%;

[0047] The water-reducing agent is a retarded polycarboxylic acid-based high-performance water-reducing agent;

[0048] Described rust inhibitor is infiltration type containing amin...

Embodiment 2

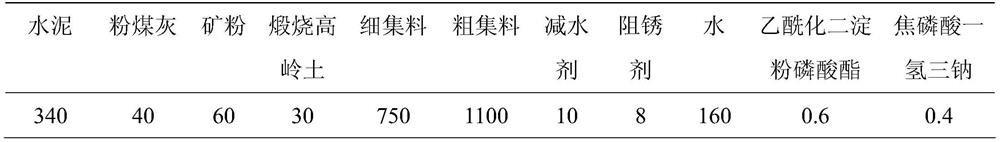

[0054] A C50 grade marine high performance concrete:

[0055] Table 2: Mix ratio unit of C50 grade marine high performance concrete: kg / m 3

[0056]

[0057] According to the above mixing ratio, the cement is 52.5 grade P·O ordinary Portland cement;

[0058] The fly ash is Class I fly ash, the slag powder is S105 grade granulated blast furnace slag powder, and the calcined kaolin is calcined first-grade kaolin for rubber industry;

[0059] The fine aggregate is river sand, the fineness modulus of the fine aggregate is 2.7, the mud content is 1.1%, and the mud block content is 0.2%;

[0060] The coarse aggregate is 5-25mm continuous gradation, its crushing index is 10%, the content of needle-like particles is 3.9%, the content of mud is 0.2%, and the content of mud block is 0.1%;

[0061] The water-reducing agent is a retarded polycarboxylic acid-based high-performance water-reducing agent;

[0062] Described rust inhibitor is infiltration type containing amino alcohol r...

Embodiment 3

[0068] A C50 grade marine high performance concrete:

[0069] Table 3: Mix ratio unit of C50 marine high performance concrete: kg / m 3

[0070]

[0071] According to the above mixing ratio, the cement is 52.5 grade P·O ordinary Portland cement;

[0072] The fly ash is F class II grade fly ash, the slag powder is S95 grade granulated blast furnace slag powder, and the calcined kaolin is calcined secondary kaolin used in the rubber industry;

[0073] The fine aggregate is river sand, the fineness modulus of the fine aggregate is 2.9, the mud content is 1.4%, and the mud block content is 0.5%;

[0074] The coarse aggregate is 5-25mm continuous gradation, its crushing index is 9%, the content of needle-like particles is 4.5%, the content of mud is 0.4%, and the content of mud block is 0.2%;

[0075] The water-reducing agent is a retarded polycarboxylic acid-based high-performance water-reducing agent;

[0076] Described rust inhibitor is infiltration type containing amino al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com