Antibacterial floor film and processing method thereof

A floor and raw material technology, applied in the field of antibacterial floor film and its processing, can solve the problems of poor antibacterial performance, achieve the effect of enhanced antibacterial performance, good antibacterial performance, and improved material composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An antibacterial floor film, comprising the following raw materials in parts by weight: high K value PVC powder; 100 parts, MBS resin: 4 parts, ACR: 3.0 parts, plasticizer: 2 parts, heat stabilizer: 3 parts, Epoxidized soybean oil: 1.2 parts, nanoscale filler: 12 parts, lubricant: 1.35 parts, pigment: 13 parts, antibacterial material: 1.3 parts.

[0024] The lubricant is glyceryl stearate or epoxidized soybean oil. In this embodiment, the lubricant is glyceryl stearate. The heat stabilizer is KSR organic rare earth composite stabilizer. The nano filler is modified titanium dioxide.

Embodiment 2

[0026] An antibacterial floor film, comprising the following raw materials in parts by weight: high K value PVC powder; 90 parts, MBS resin: 3.6 parts, ACR: 2.52 parts, plasticizer: 1.8 parts, heat stabilizer: 2.7 parts, Epoxidized soybean oil: 1.08 parts, nanoscale filler: 10.8 parts, lubricant: 1.215 parts, pigment: 11.7 parts, antibacterial material: 1.17 parts.

[0027] The lubricant is glyceryl stearate or epoxidized soybean oil. In this embodiment, the lubricant is glyceryl stearate. The heat stabilizer is KSR organic rare earth composite stabilizer. The nano filler is modified titanium dioxide.

Embodiment 3

[0029] An antibacterial floor film, comprising the following raw materials in parts by weight: high K value PVC powder; 80 parts, MBS resin: 3.2 parts, ACR: 2.24 parts, plasticizer: 1.6 parts, heat stabilizer: 2.4 parts, Epoxidized soybean oil: 0.96 parts, nanoscale filler: 9.6 parts, lubricant: 1.08 parts, pigment: 10.4 parts, antibacterial material: 1.04 parts.

[0030] The lubricant is glyceryl stearate or epoxidized soybean oil. In this embodiment, the lubricant is glyceryl stearate. The heat stabilizer is KSR organic rare earth composite stabilizer. The nano filler is modified titanium dioxide.

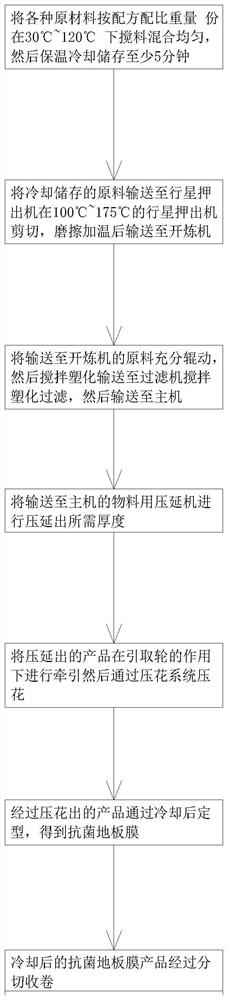

[0031] The present invention proposes a kind of processing method of antibacterial floor film, comprises the following steps:

[0032] (1) Stir and mix various raw materials according to the proportion of the formula at 30° C. to 120° C., and then store them for at least 5 minutes under heat preservation and cooling; in this embodiment, they were stored under heat preservation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com