Patents

Literature

39results about How to "Won't cut off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

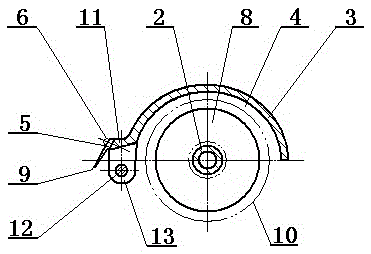

Cold precision forging process for bevel gear and mould thereof

InactiveCN102430692AImprove mechanical propertiesWon't cut offForging/hammering/pressing machinesWheelsHardnessBar stock

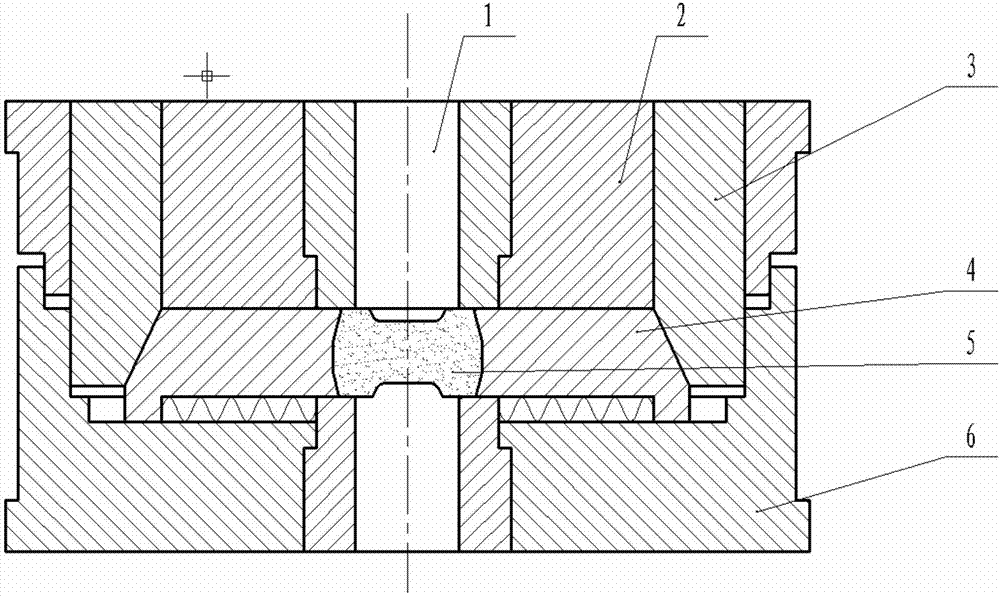

A cold precision forging process for a bevel gear is disclosed, and comprises the steps of: cutting the blanking by cylindrical bars; cutting a conical degree on a segmental length of the blank as segmental pre-form for positioning the blank in a die; performing spheroidization for the machined blank to reduce the hardness, then scouring and descaling, phosphorizing, saponifying and lubricating; the first cold precision forging step comprises: upsetting-extruding segmental tooth form in an extrusion mould to obtain a first extrusion which is used as the blank of the second first cold precision forging step; performing spheroidization again for the first extrusion, then scouring and descaling, phosphorizing, saponifying and lubricating; the second cold precision forging step comprises: upsetting-extruding all tooth forms in the extrusion mould to obtain the coarse material of the bevel gear; machining and shaping the coarse material of the bevel gear and cutting unnecessary materials on the end surface to obtain finished products of the bevel gear. The invention further provides an extrusion mould. The invention has higher production efficiency, reduces the material waste, lowers the cost and improves the mechanical property.

Owner:ZHEJIANG UNIV OF TECH

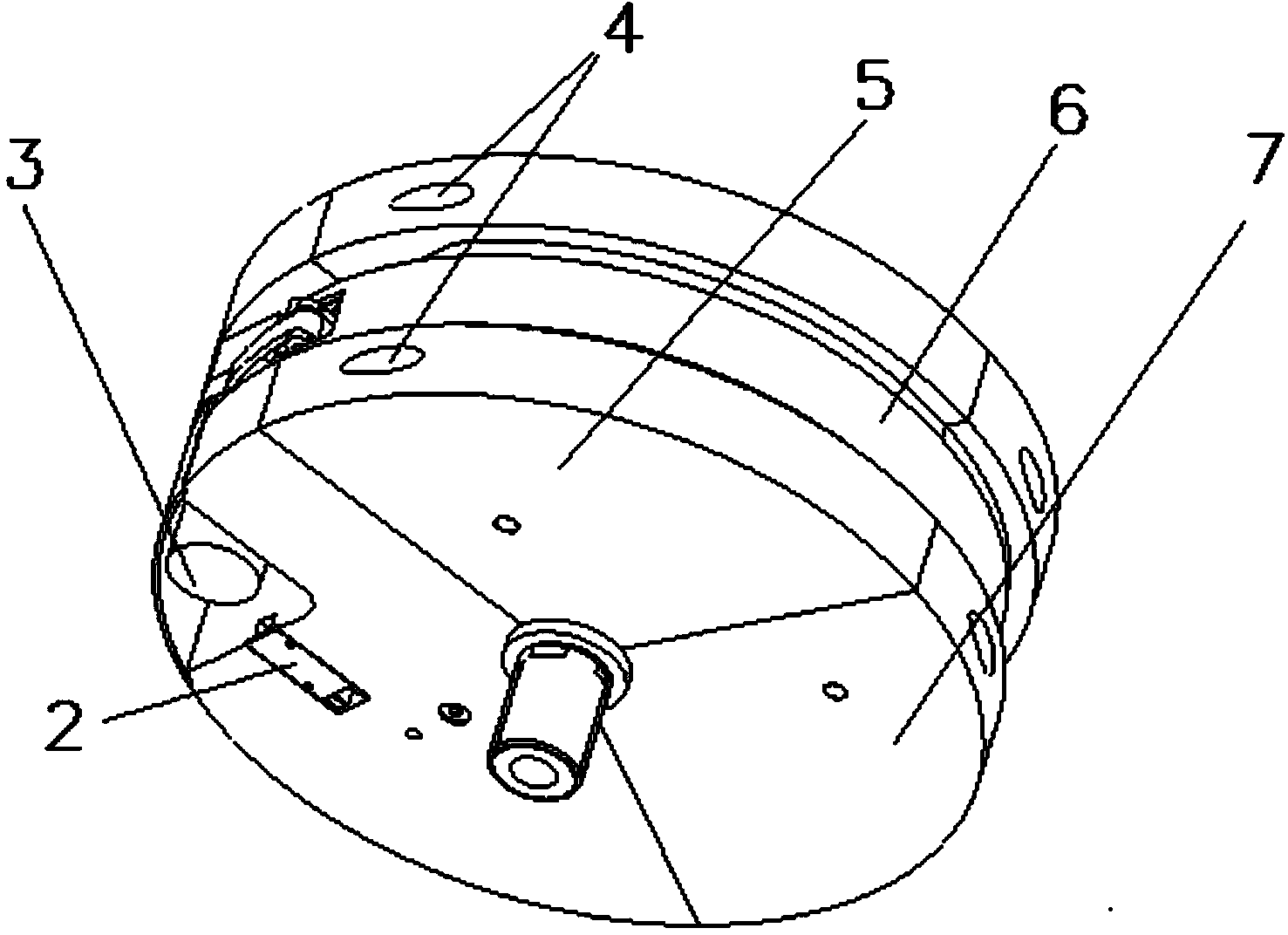

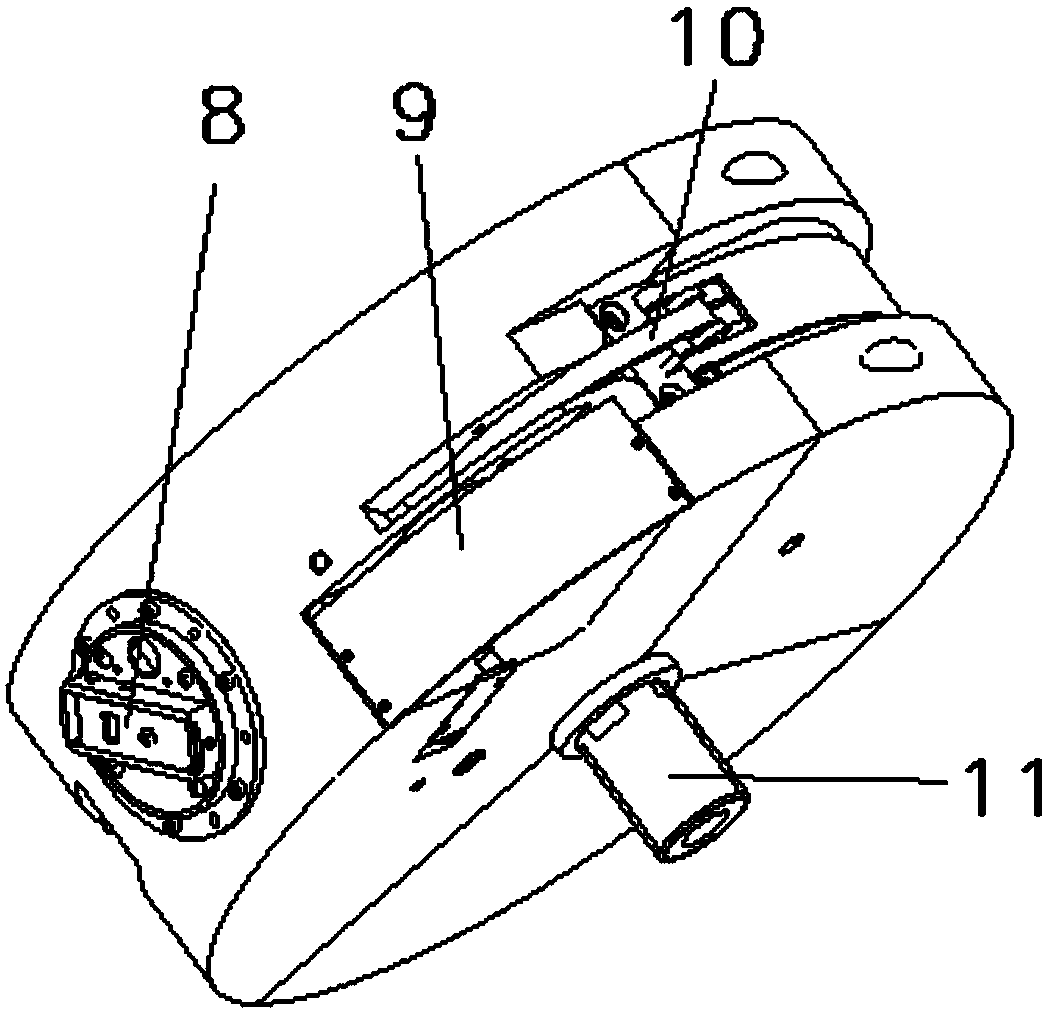

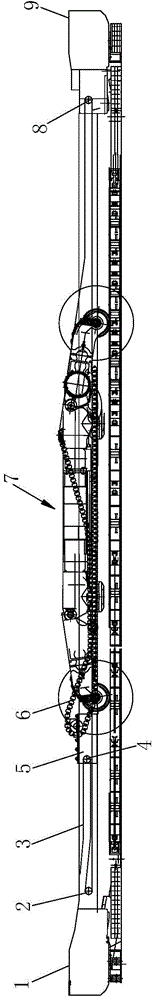

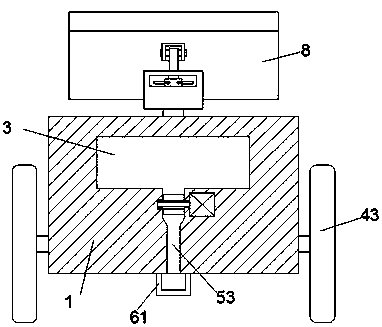

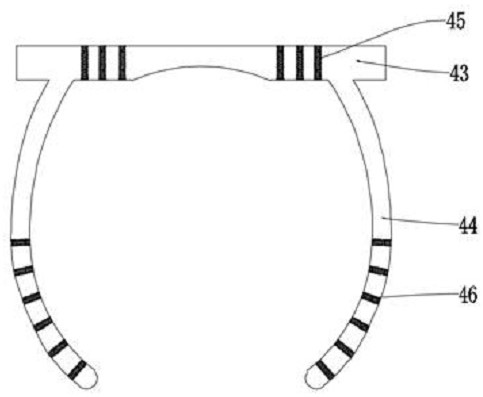

Underwater external self-releasing posture adjusting device

InactiveCN103863536AAttitude adjustment needs are metEasy to operateUnderwater vesselsUnderwater equipmentPetroleum engineeringUnmanned underwater vehicle

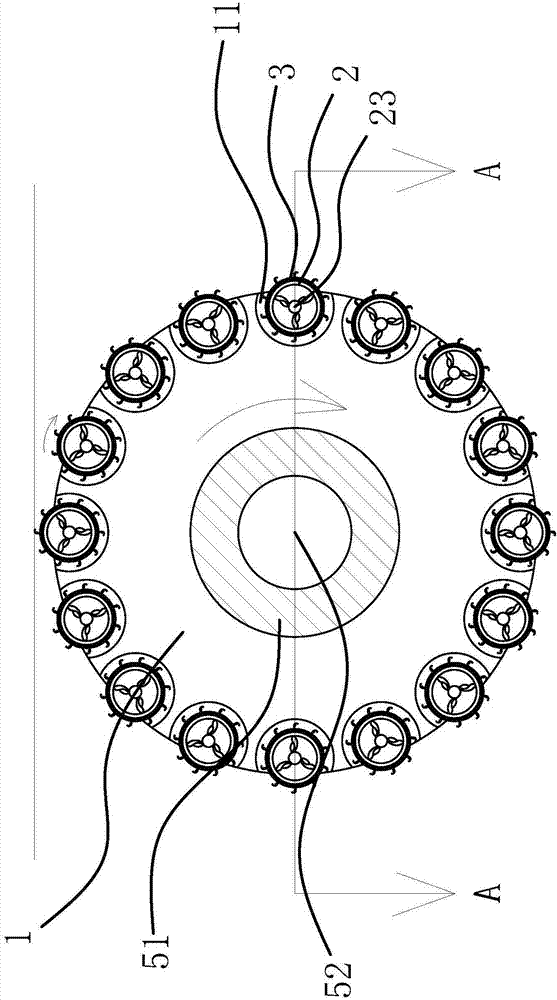

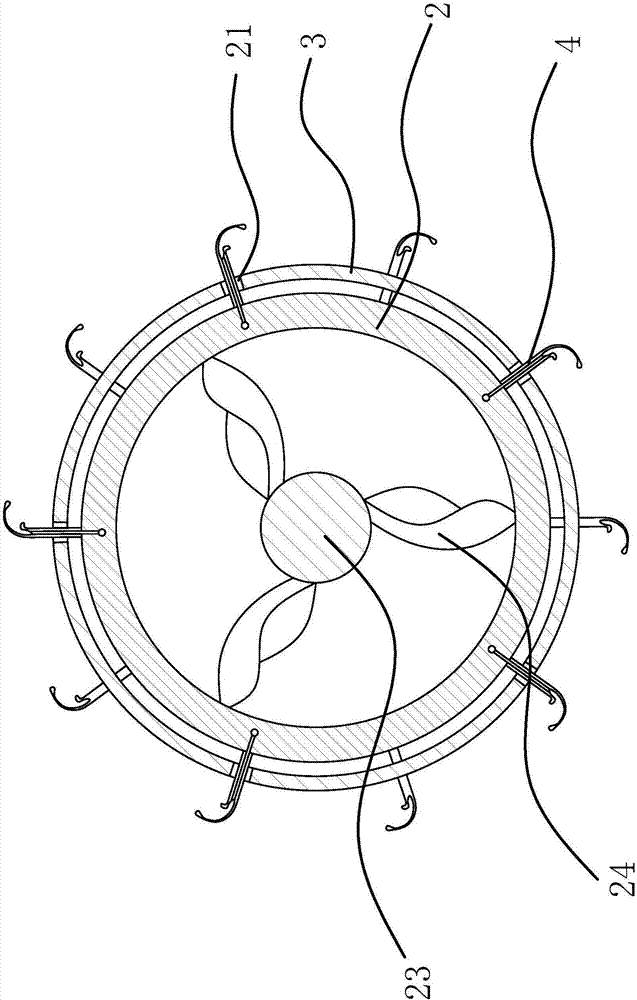

The invention discloses an underwater external self-releasing posture adjusting device adapting to posture adjustment of equipment carried by a UUV (Unmanned Underwater Vehicle). The underwater external self-releasing posture adjusting device is divided into a base body, a movement mechanism, a separating mechanism, a rotating prevention mechanism, an adjusting mechanism and the like according to functions. The underwater external self-releasing posture adjusting device is arranged on the equipment which is needed to be carried by the UUV, the equipment which is equipped with the posture adjusting device automatically moves in water after the UUV arrives to a scheduled place and is released, the posture adjusting device is automatically separated from the equipment after the equipment arrives to a scheduled depth, the follow-up working process of the equipment cannot be affected, and a mission is completed by the posture adjusting device. The underwater external self-releasing posture adjusting device disclosed by the invention has the advantages that the releasing reliability is high, the structural combination is simple and compact, the operation is convenient, the use is flexible, and the like.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

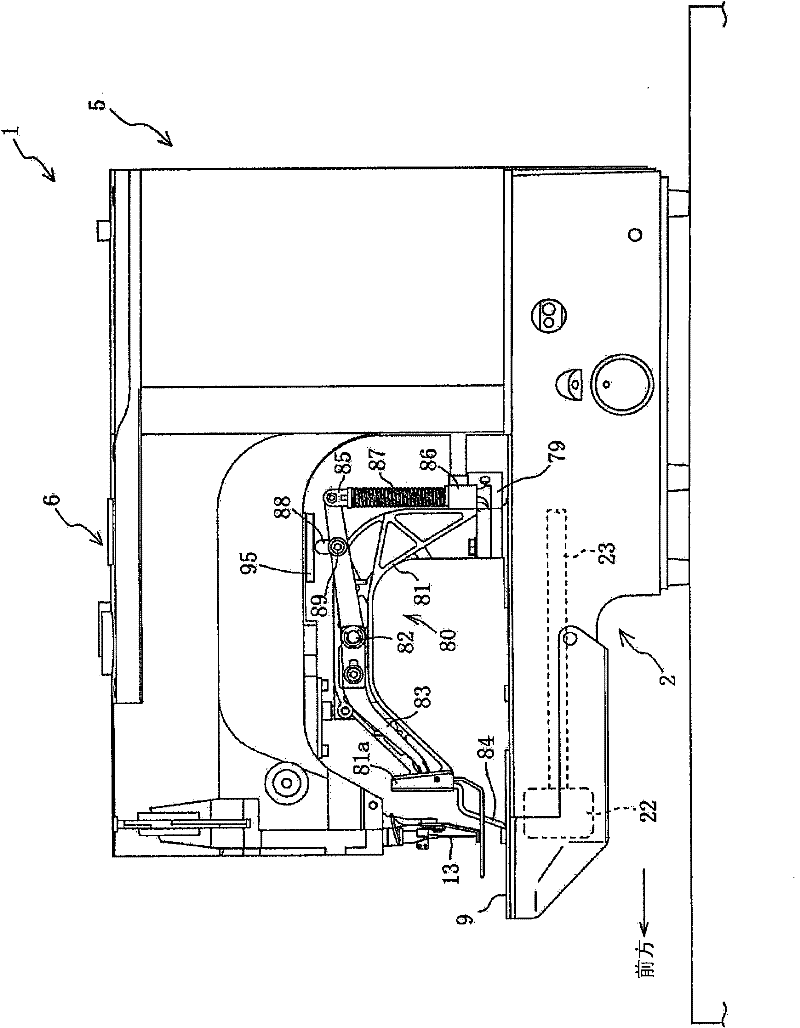

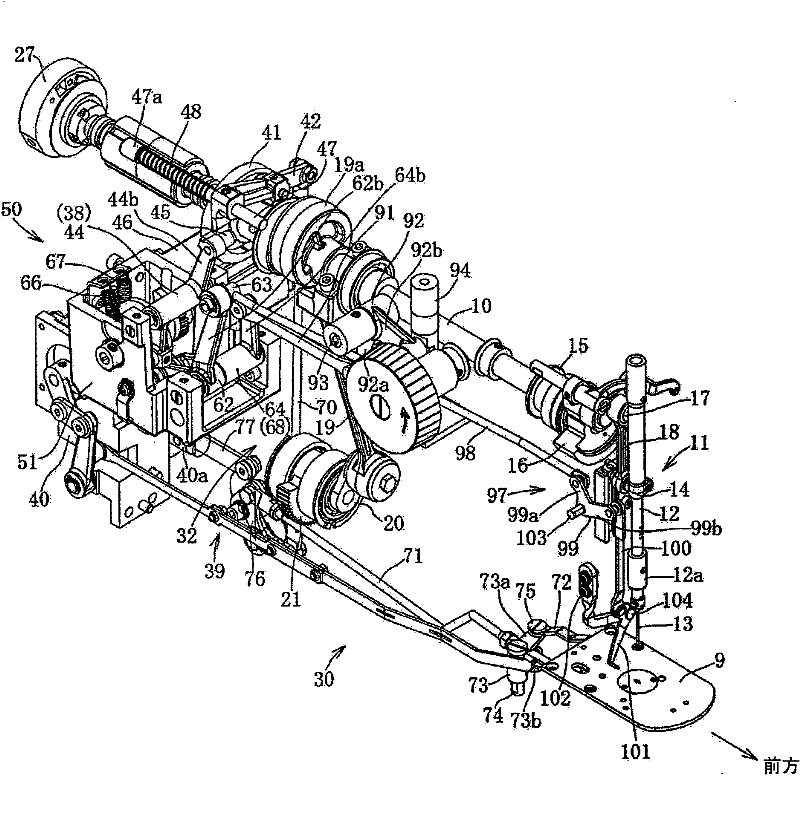

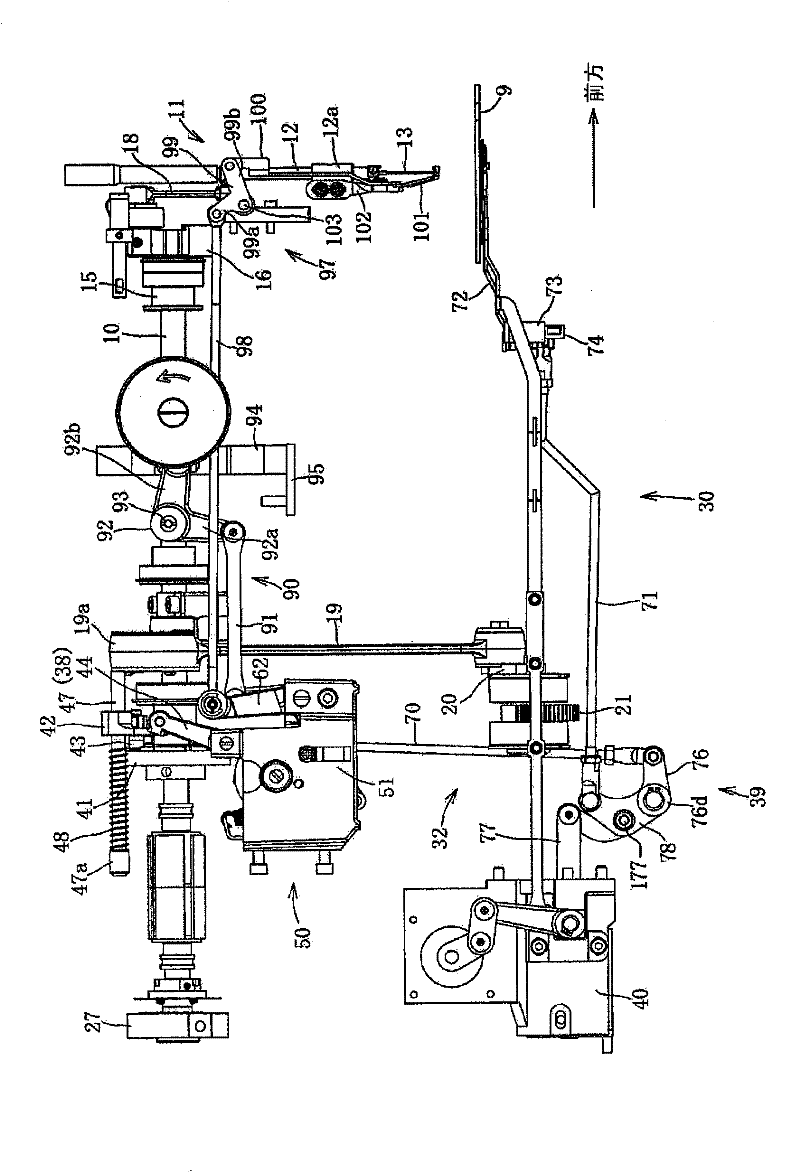

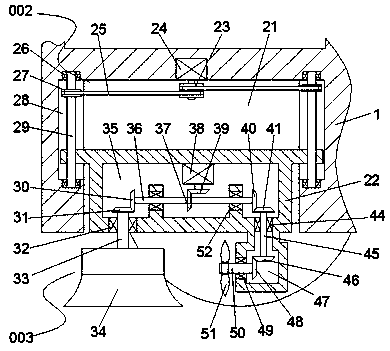

Sewing machine

The invention provides a sewing machine, comprising a thread cutting mechanism. The thread cutting mechanism is provided with a thread cutting cam and a roller component. The roller component clamps with the thread cutting cam plate. The thread cutting cam plate is fixed at the mains haft of the sewing machine. The roller component is disposed at a driving rod, the driving rod moves between a clamping position and a preventing position, at the clamping position, the roller member clamps with the thread cutting cam plate, at the preventing position, the roller component deviates from the thread cutting cam plate. The driving rod moves between the clamping position and the preventing under the effect of an oscillating force generating mechanism. The driving rod oscillates at the clamping position via movement of the roller member. Oscillation of the driving rod is transmitted to a moveable knife via a thread cutting collecting rod mechanism. The moveable knife is in a reciprocating rotation, and stopped when approaching to a fixed knife. The oscillating force generating mechanism and a cloth pressing member upper-lower driving mechanism driving a cloth-pressing piece are driving by a driving pulse motor. The driving pulse motor, the cloth pressing member upper-lower driving mechanism, and the oscillating generating mechanism are configured in a vertical column part of the sewingmachine. The main shaft of the sewing machine is driven by a motor of the sewing machine.

Owner:BROTHER KOGYO KK

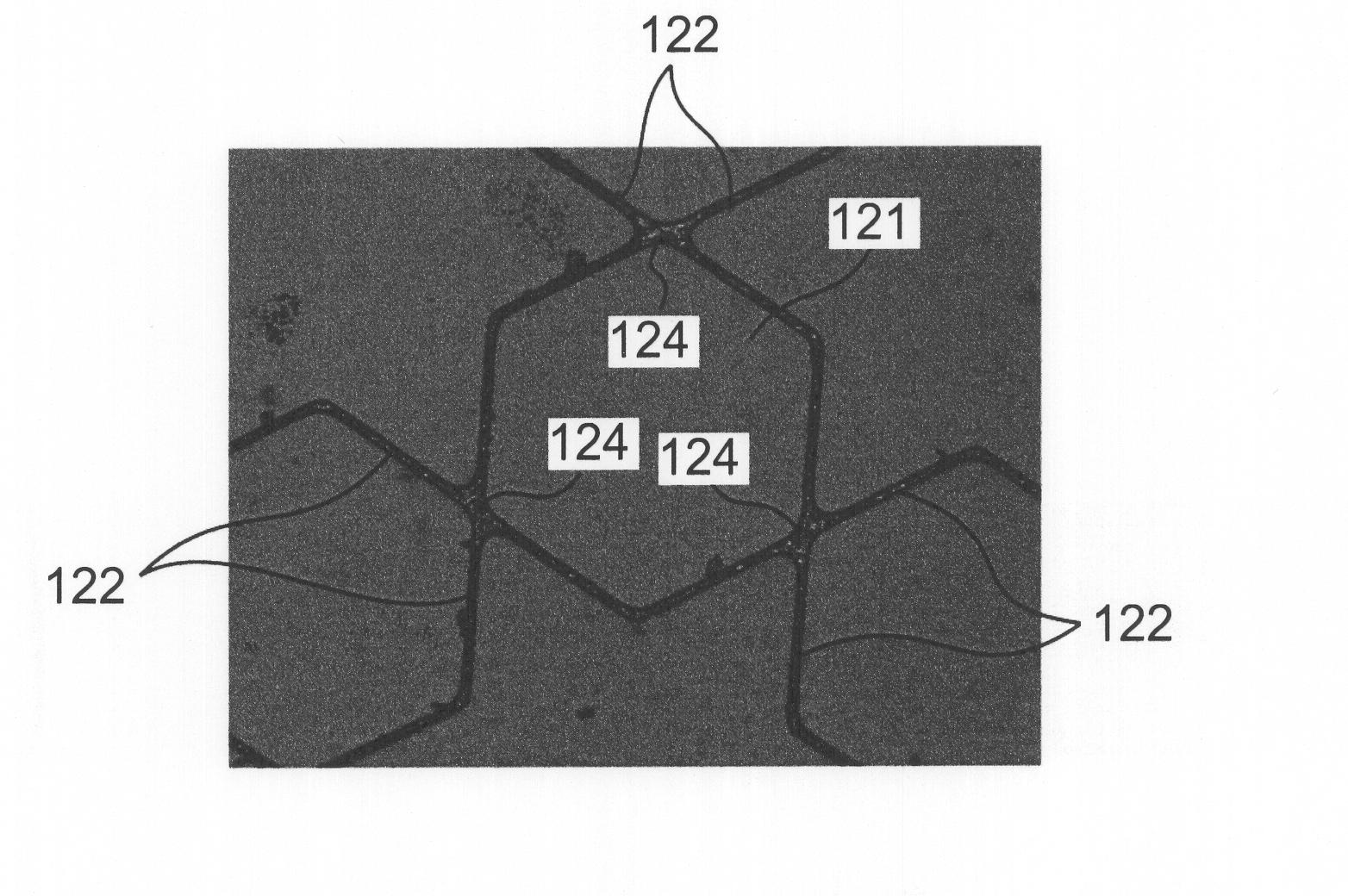

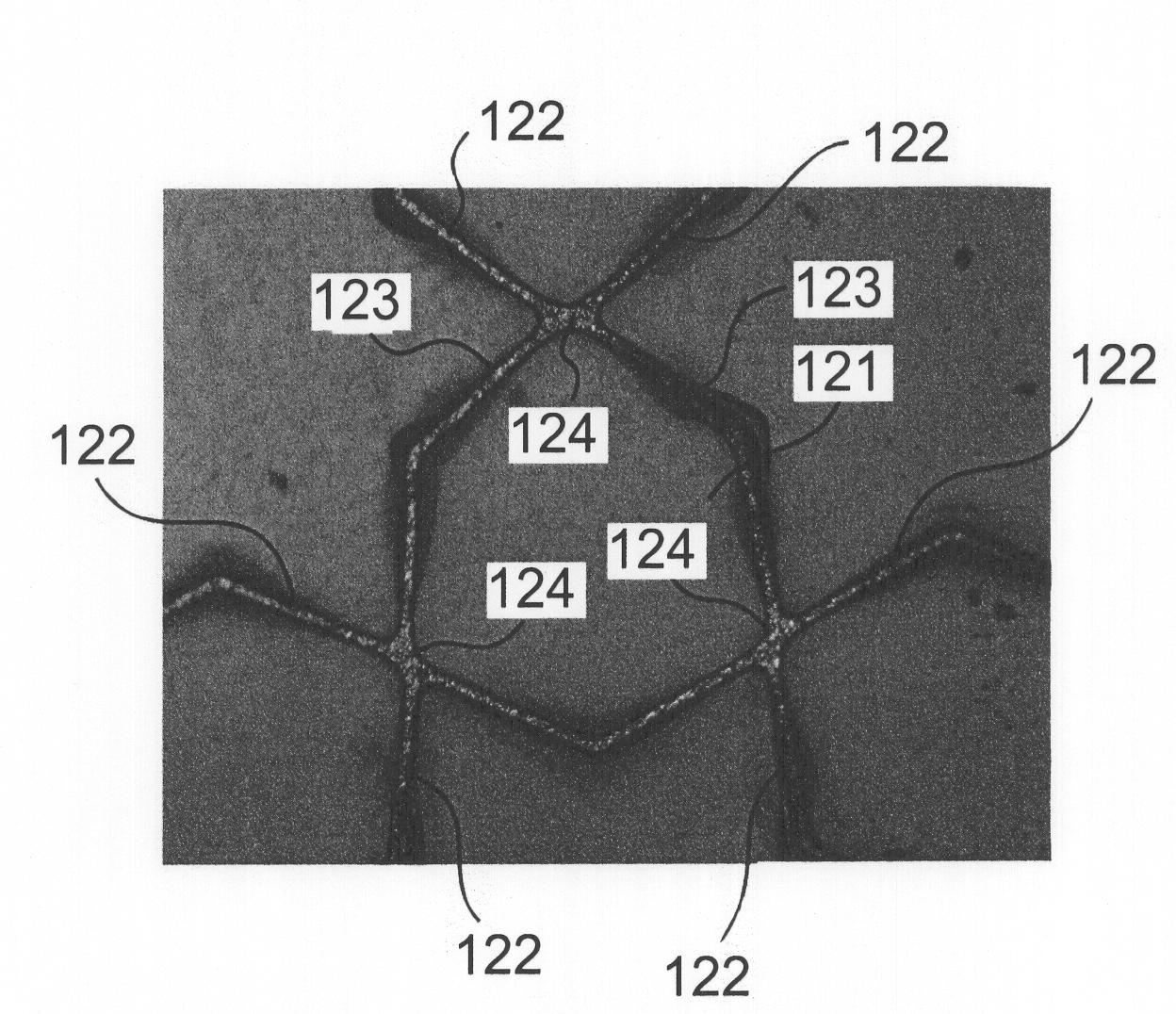

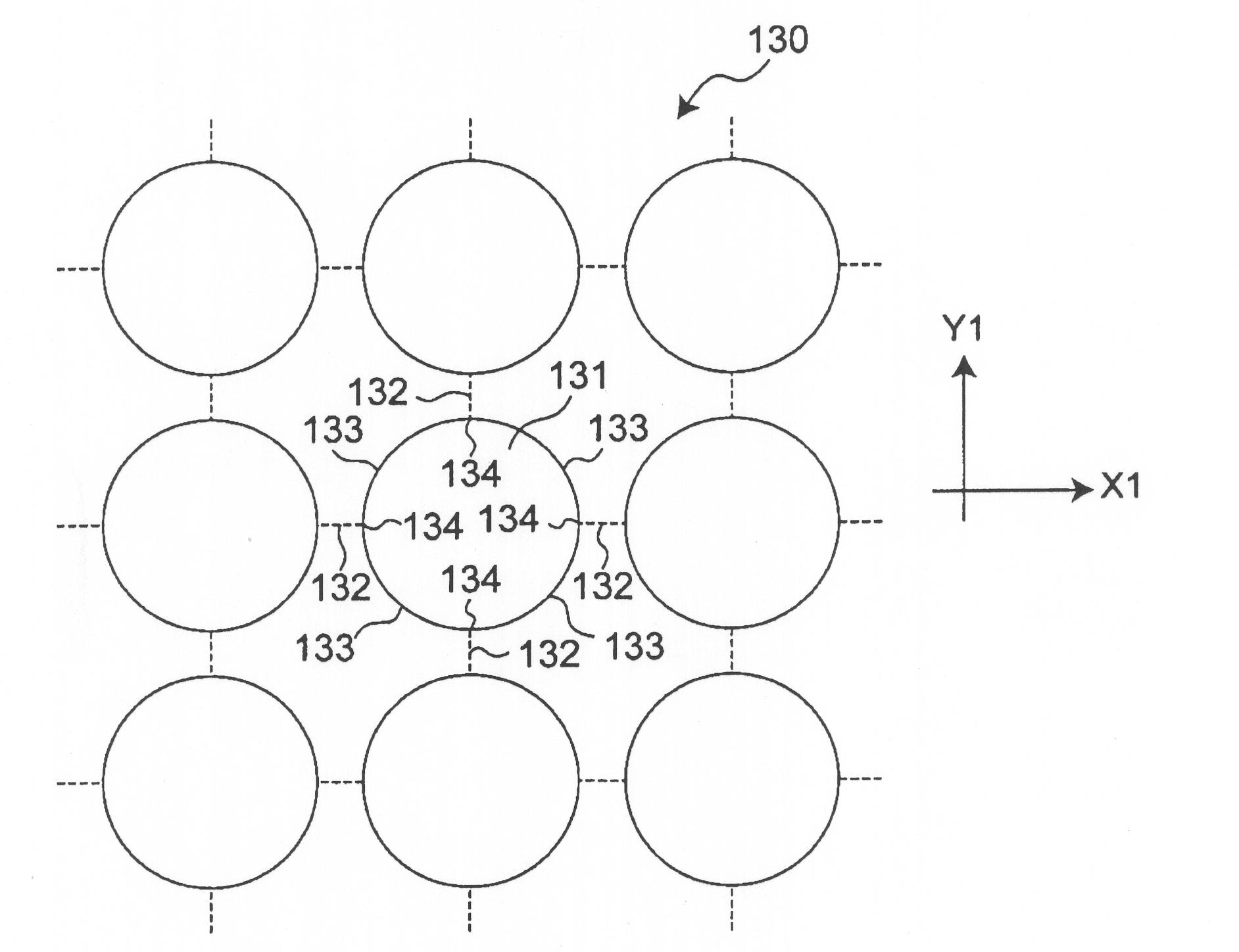

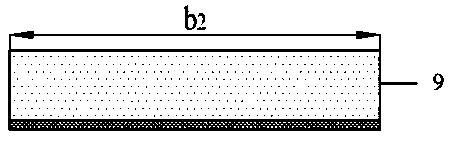

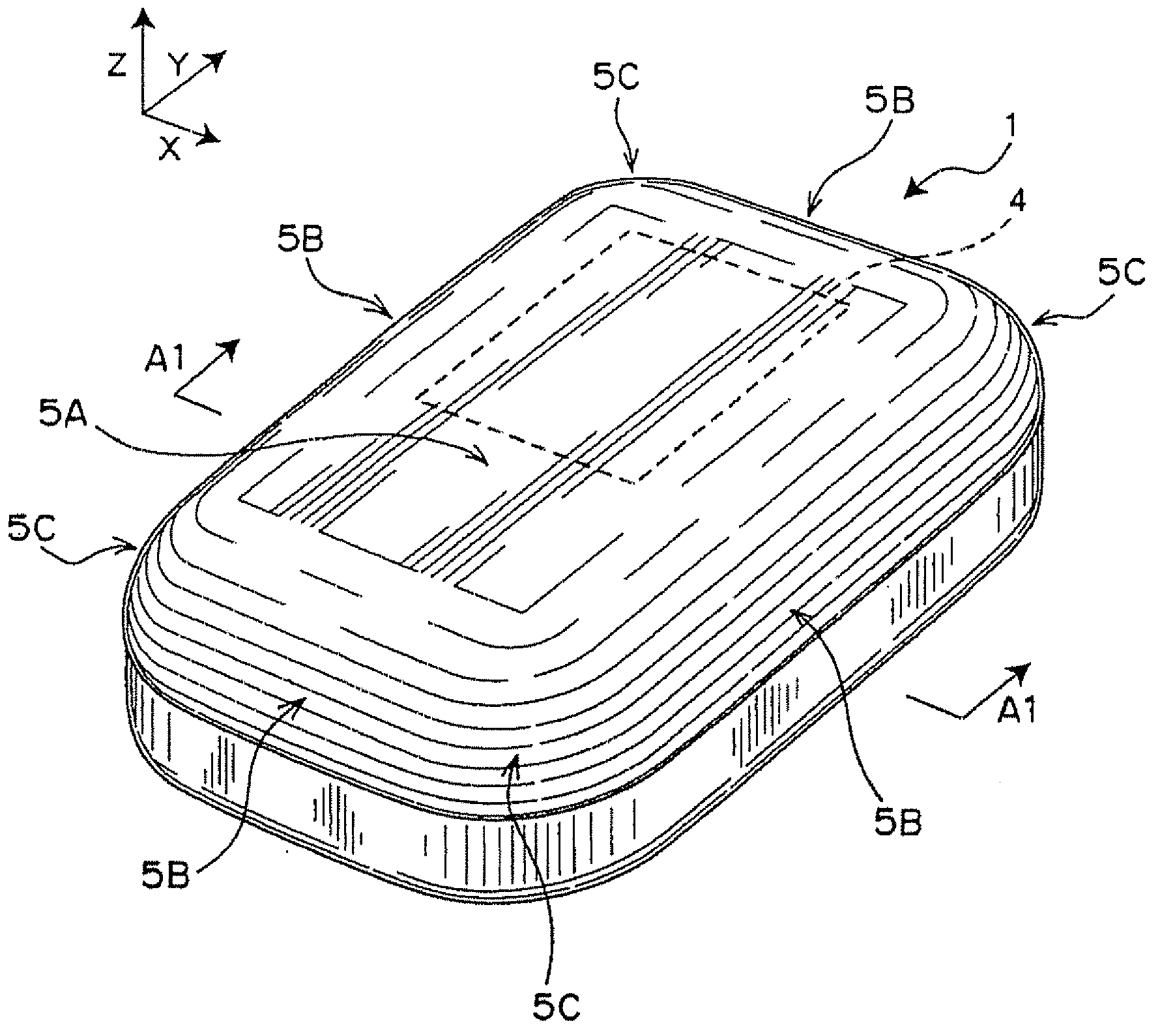

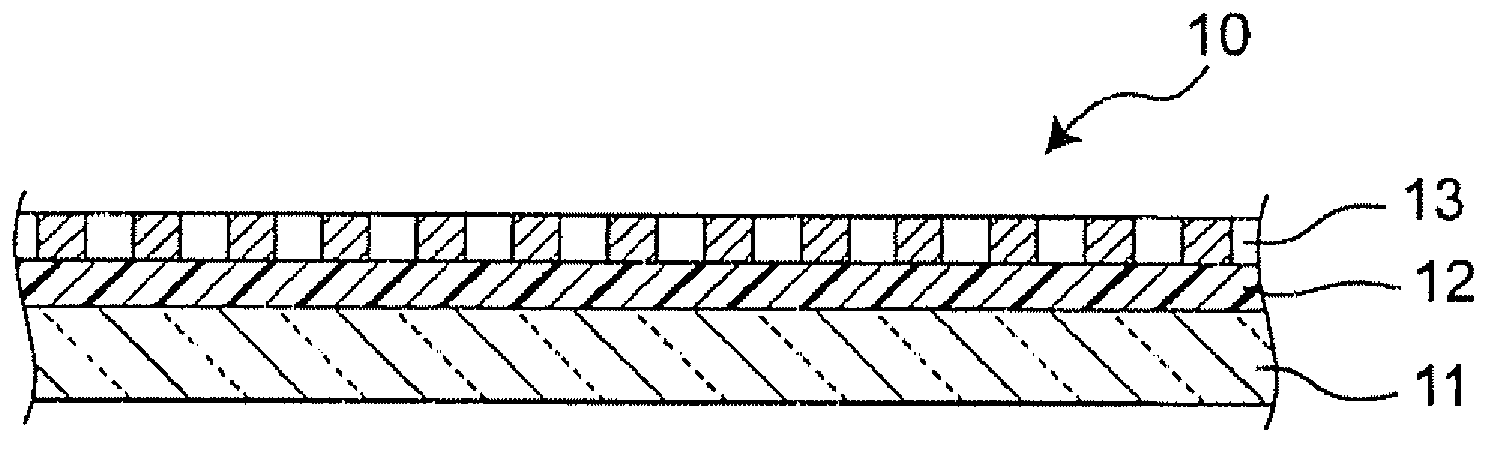

Mesh sheet and housing for electronic devices

ActiveCN101952115AAvoid disconnectionReduce bendingAntenna supports/mountingsSynthetic resin layered productsEngineeringElectron

Disclosed is a mesh sheet wherein a metal mesh composed of metal bands is layered on the surface of a support substrate, and which is used by way of being adhesively attached to the surface of any component having a curved section. The metal mesh is structured such that the narrow bands located between the contact points of adjacent narrow bands have portions formed from curves, so that the mesh can absorb the stress of deformation and follow the shape of highly curved sections without breaking.

Owner:NISSHA PRINTING COMPANY

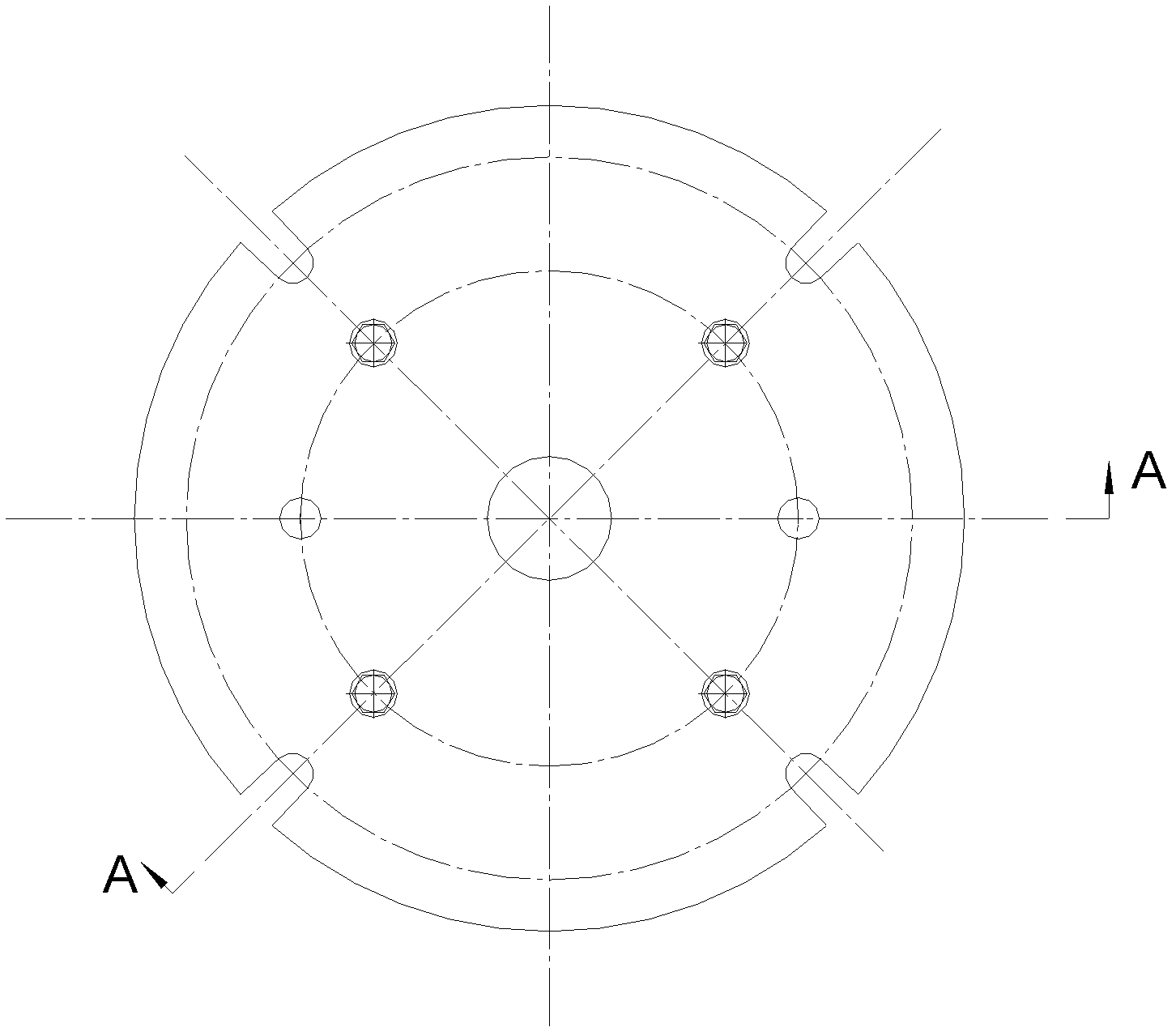

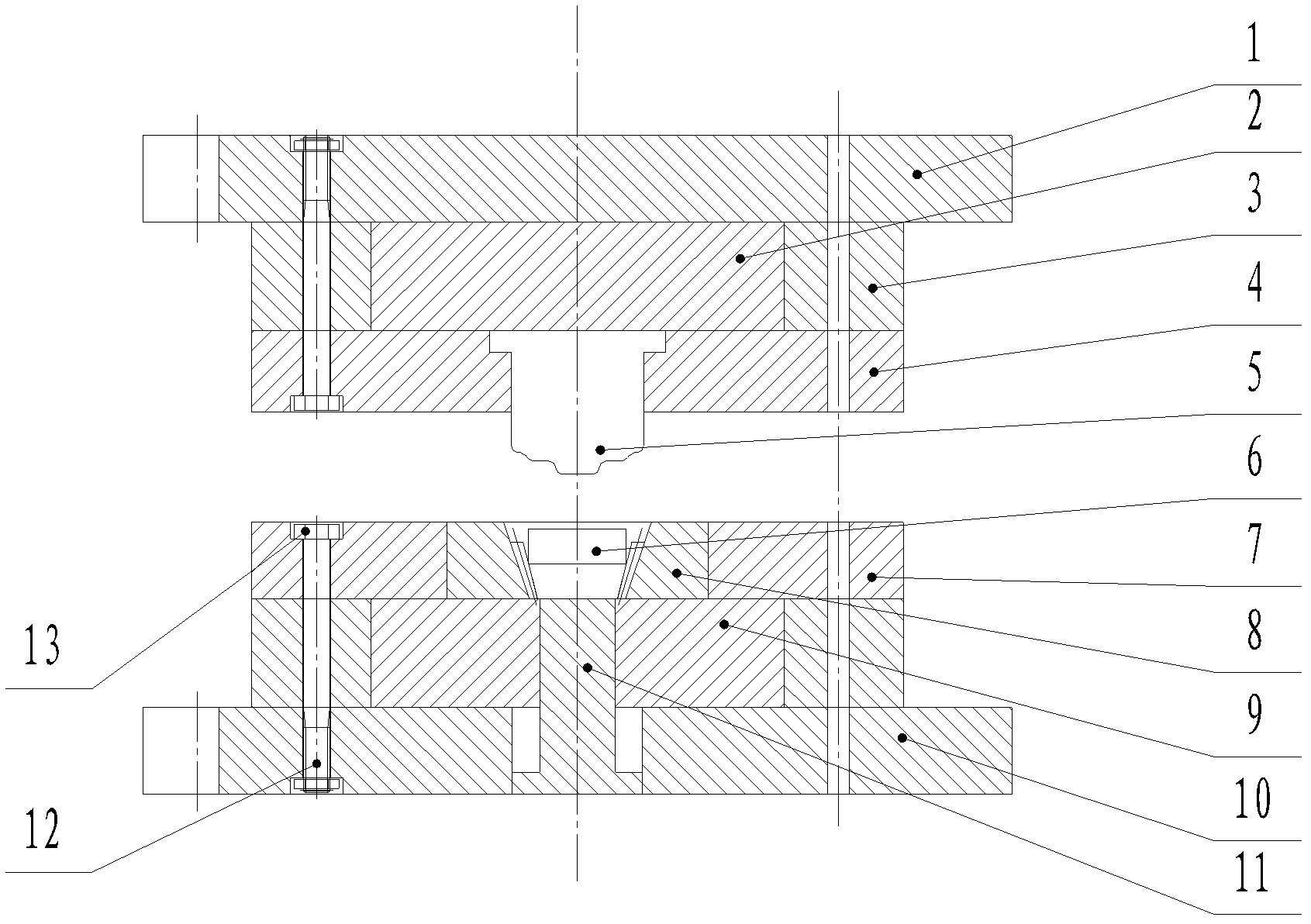

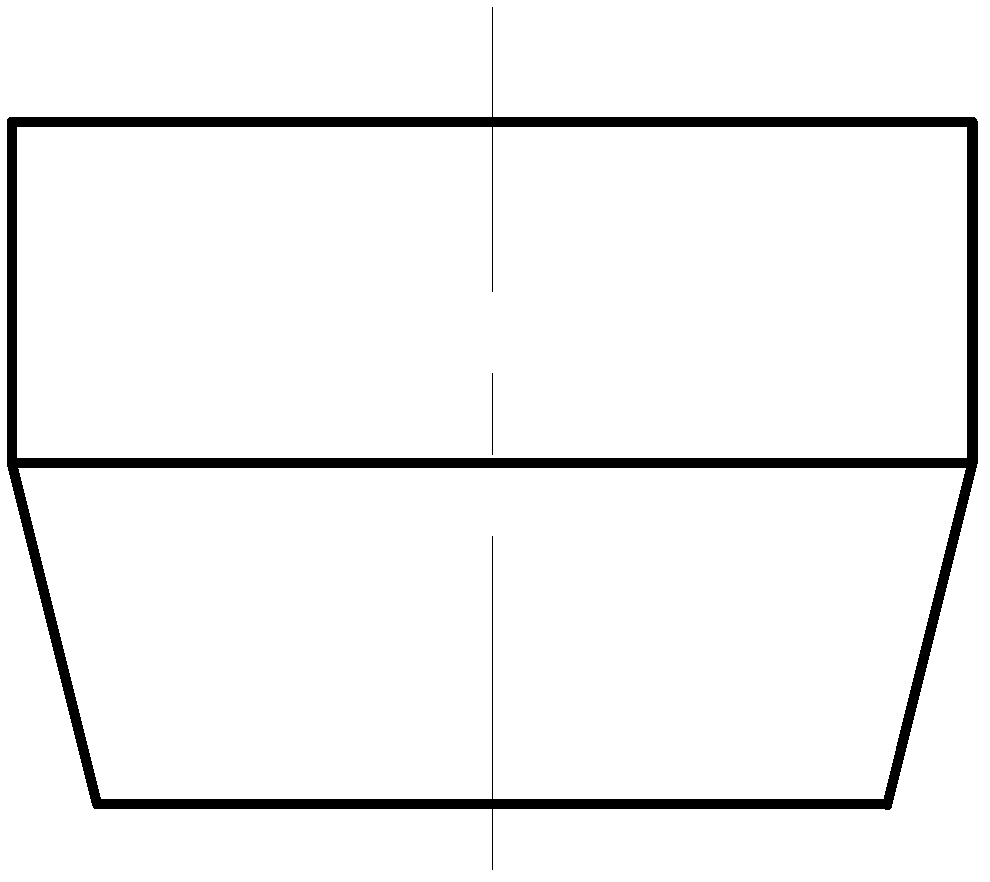

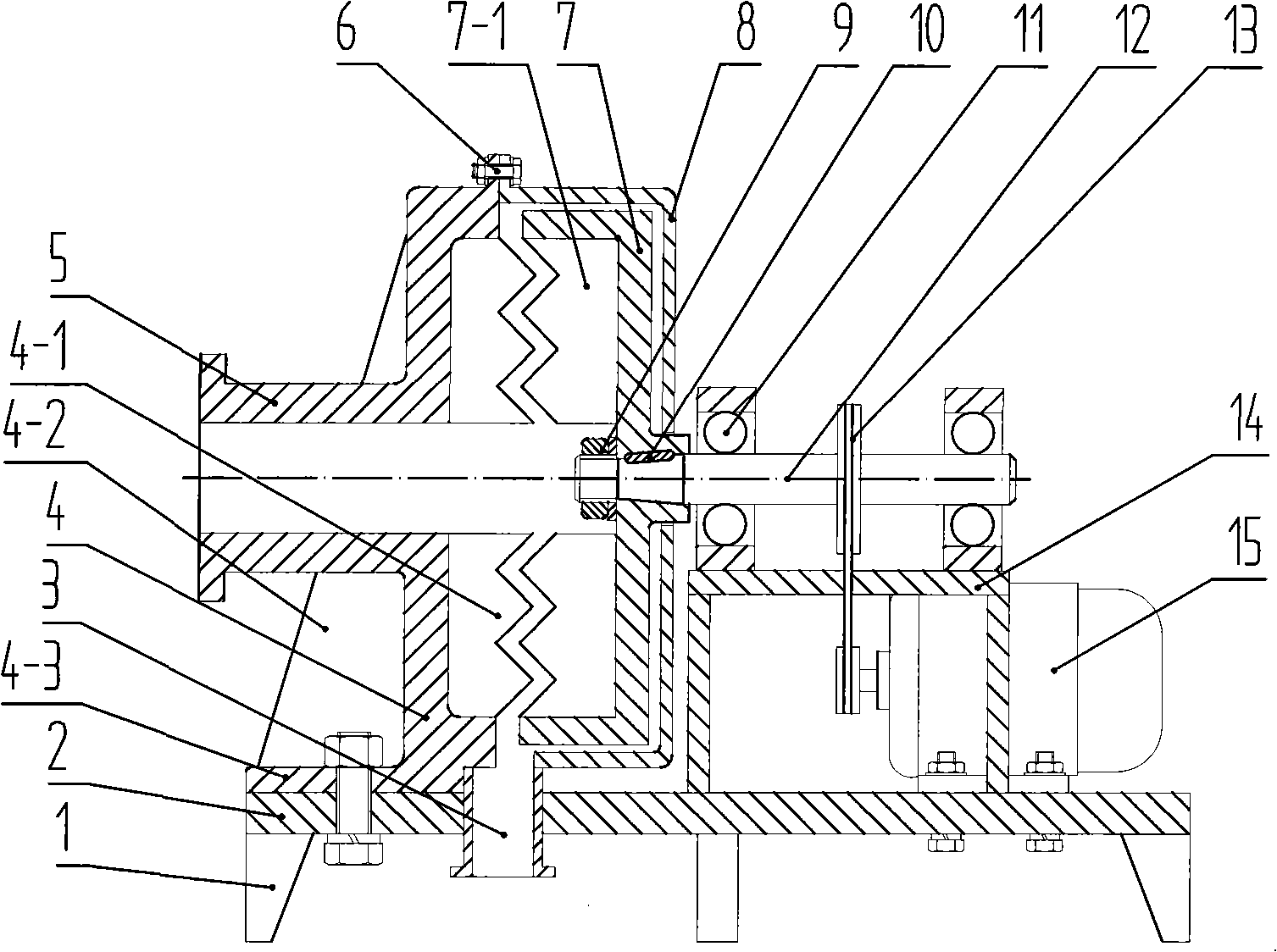

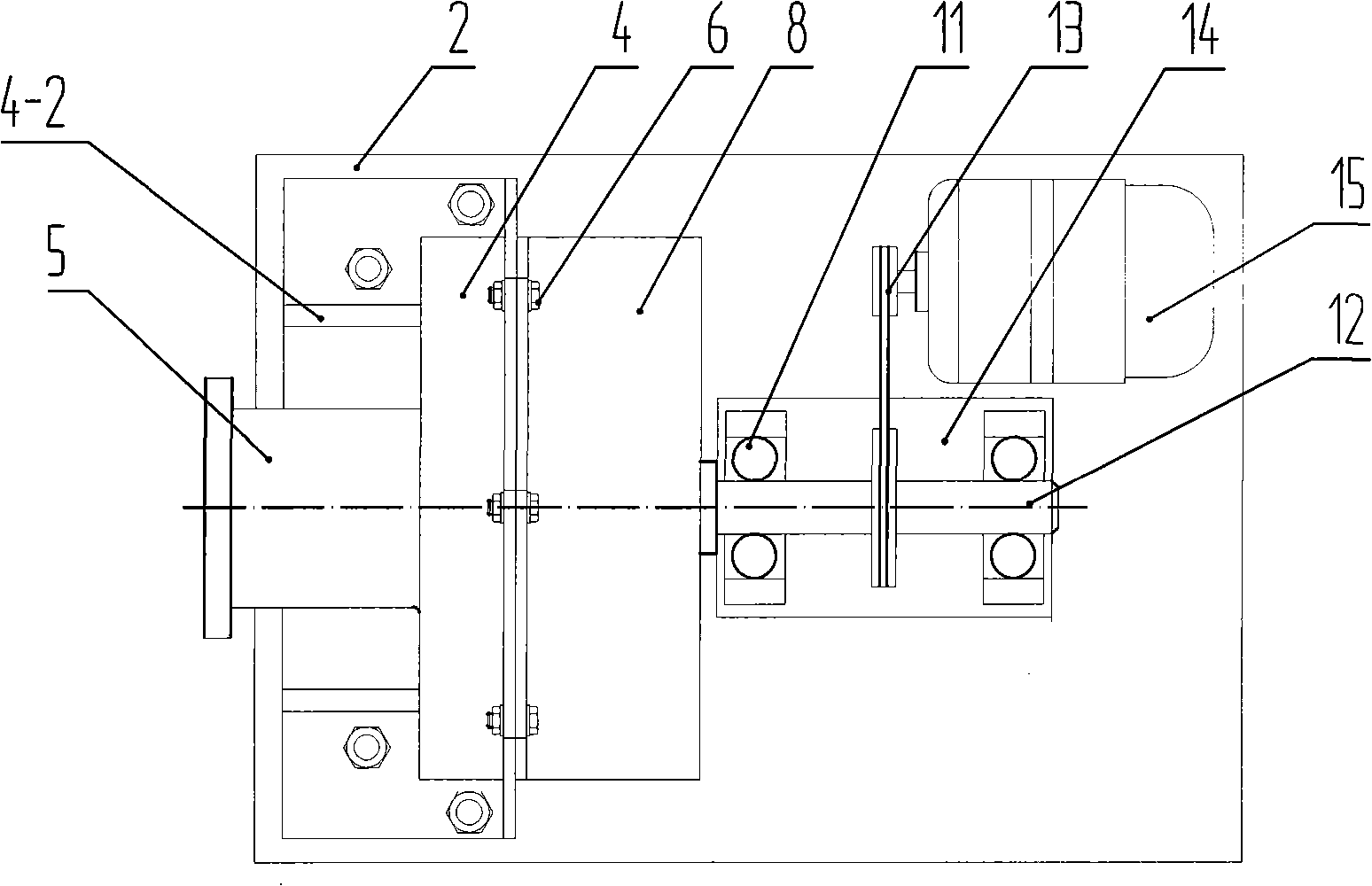

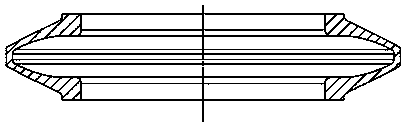

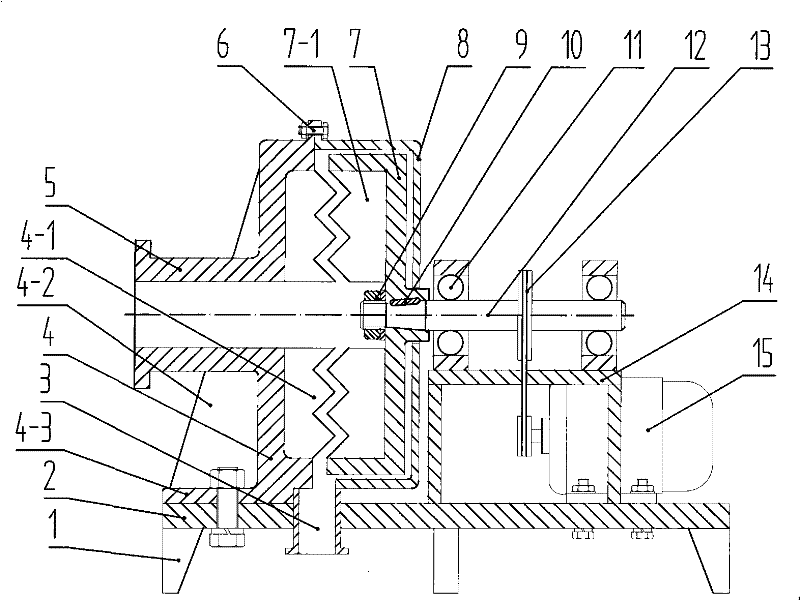

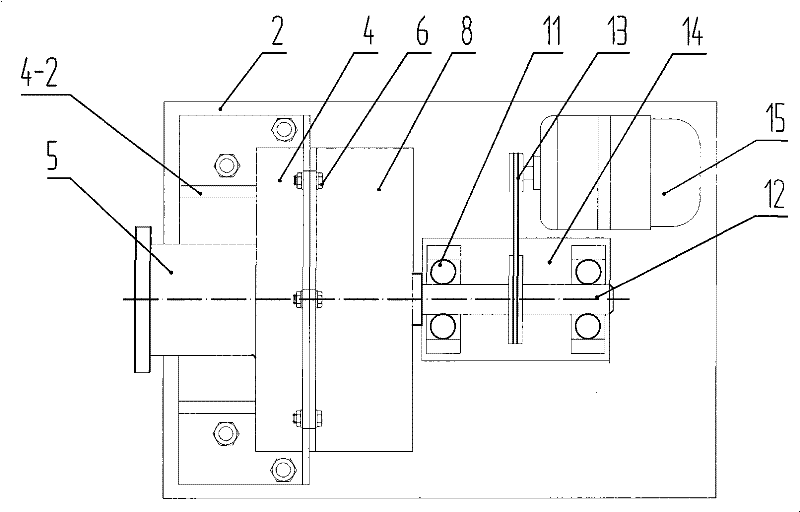

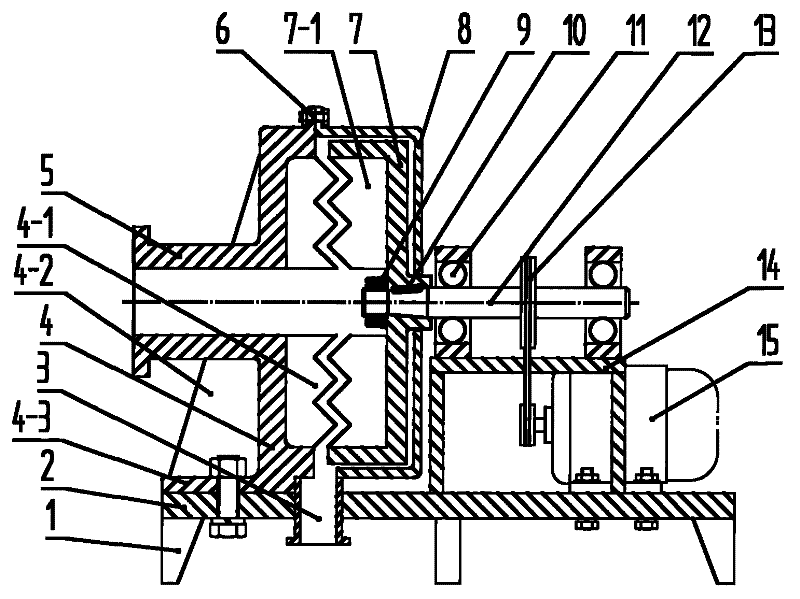

Forming die and machining technology of oblique channel forge piece

PendingCN107537966AReduce the amount of machiningReduce processForging/hammering/pressing machinesEngineeringMachining process

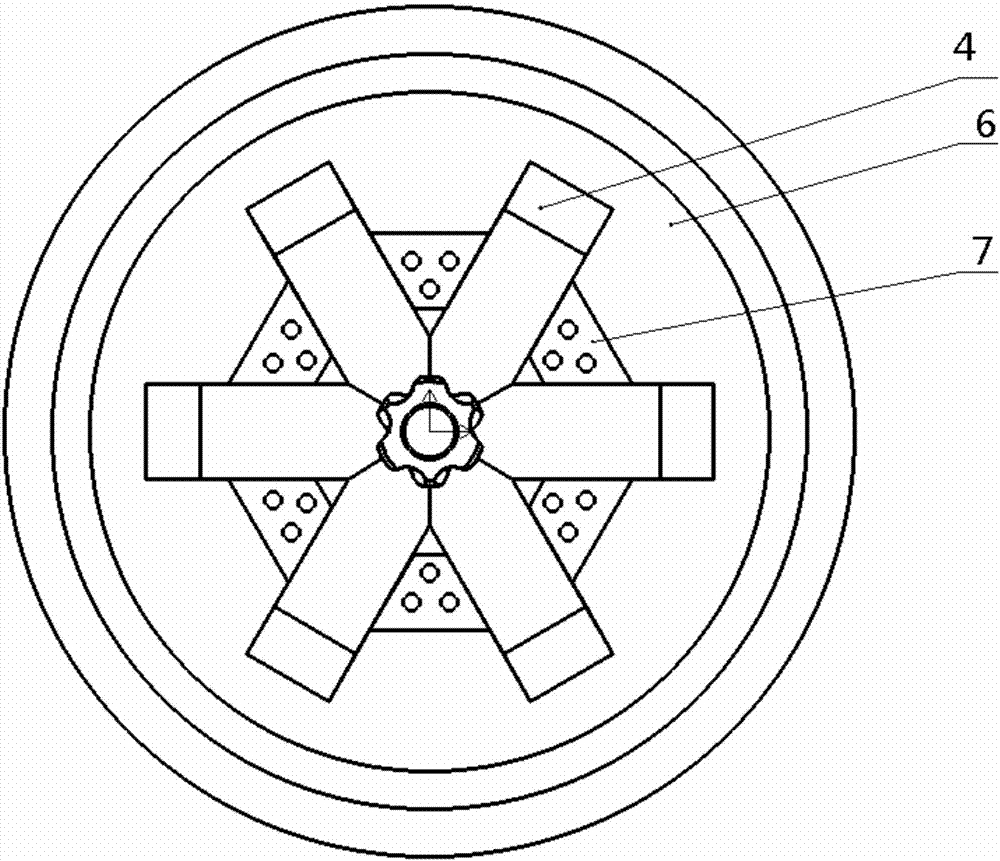

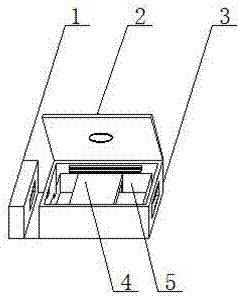

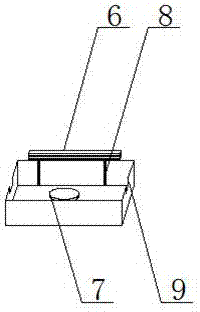

The invention discloses a forming die and machining technology of an oblique channel forge piece. The forming die and the machining technology of the oblique channel forge piece are characterized in that the forming die of the oblique channel forge piece comprises a punch, an upper die body, a segmental die pressing block, a lower die body, a positioning block and a radial extruding segmental diebody; the segmental die pressing block is divided into six equal parts to be fixed to the upper die body; an oblique surface is arranged on the inner side of the lower end of the segmental die pressing block; the radial extruding segmental die body is divided into six equal parts to be horizontally placed on the lower die body; the tail end of the radial extruding segmental die body is provided with an oblique surface with the same angle as the oblique surface at the lower end of the segmental die pressing block; a spring is arranged on a lower die main body of the radial extruding segmental die body, and the radial extruding segmental die body is positioned through the positioning block; and the positioning block is fixed to the lower die body through two positioning pins and a screw. According to the forming die and machining technology of the oblique channel forge piece, oblique channel parts are machined through a forging method, the cutting machining quantity is greatly reduced, materials are saved, the technology process is reduced, occupied equipment is little, and the cost is reduced.

Owner:江苏大洋精锻有限公司

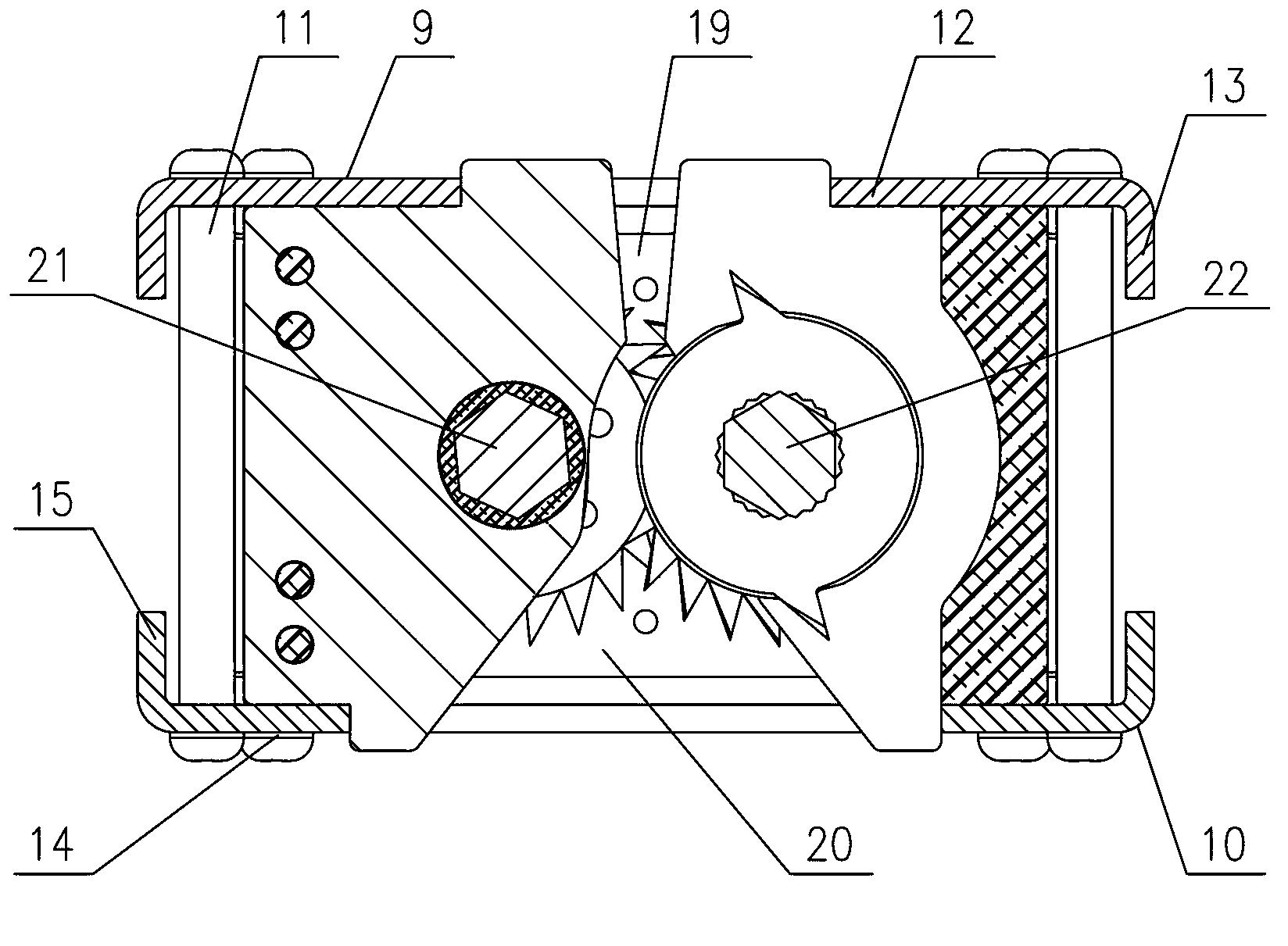

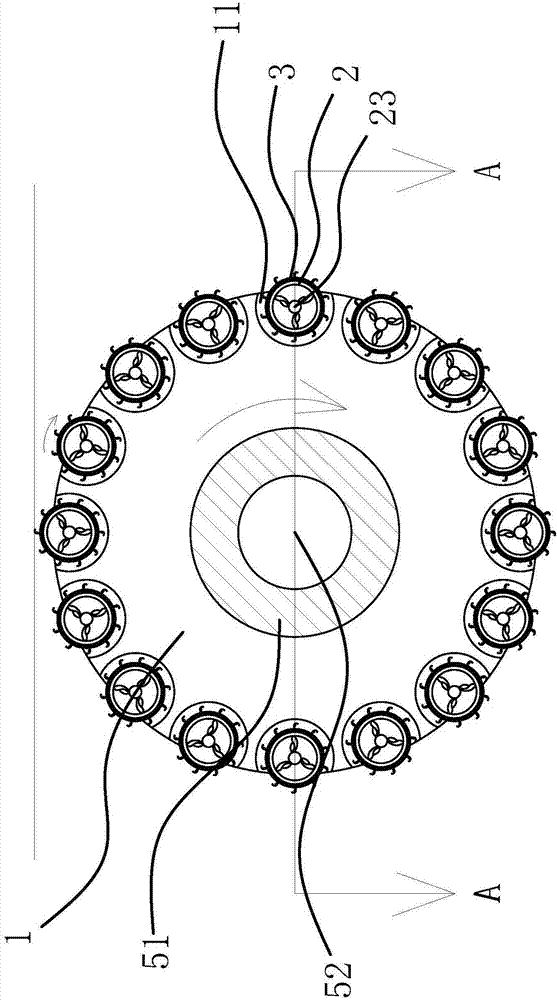

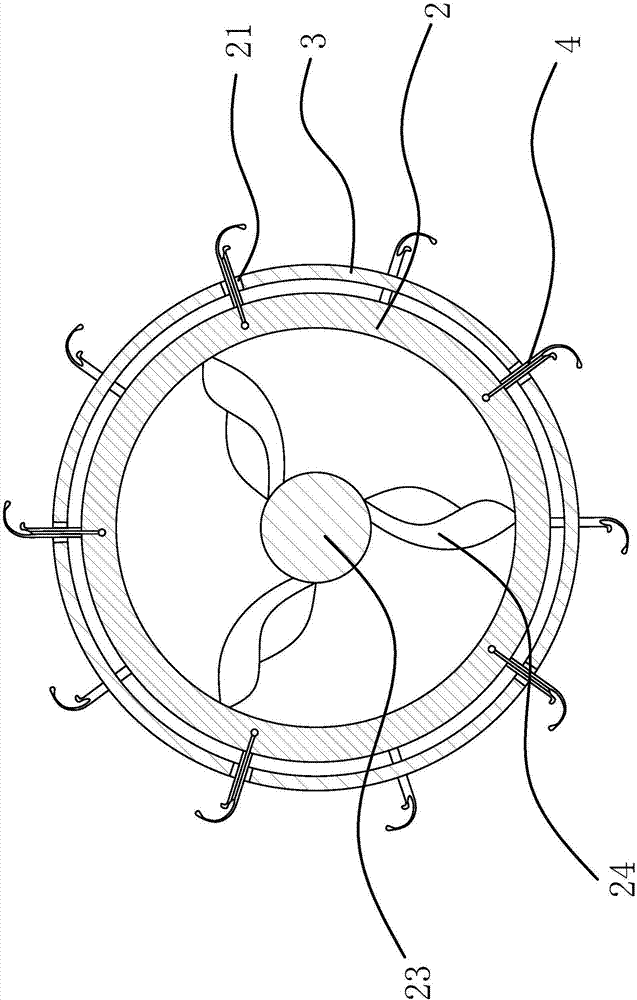

Car seat cover fabric fluffing machine

The invention provides a car seat cover fabric fluffing machine and belongs to the technical field of weaving. The car seat cover fabric fluffing machine solves the technical problem that the existing fluffing machine has low fluffing efficiency. The fluffing machine comprises a main roller, a plurality of fluffing rollers, guide sleeves corresponding to the fluffing rollers and a blower. The main roller is provided with avoiding ports corresponding to the fluffing rollers one by one. The fluffing rollers are arranged in the corresponding avoiding ports. A part of each one of the fluffing rollers stretches out of the avoiding port. The fluffing roller is uniformly provided with fluffing needles. A guide sleeve is provided with multiple guide grooves on the peripheral surface of the guide sleeve. The guide grooves are arranged in a corrugate way. The guide sleeve is fixedly connected to the main roller. The fluffing needles are inserted into the guide grooves. A ventilation chamber is arranged in each one of the fluffing rollers. The ventilation chamber is provided with a rotation shaft. The rotation shaft is fixedly provided with an impeller. The impeller is fixedly connected to the interior of the fluffing roller. The rotation shaft is rotatablely connected to the main roller. The car seat cover fabric fluffing machine has high fluffing efficiency.

Owner:李梦颖

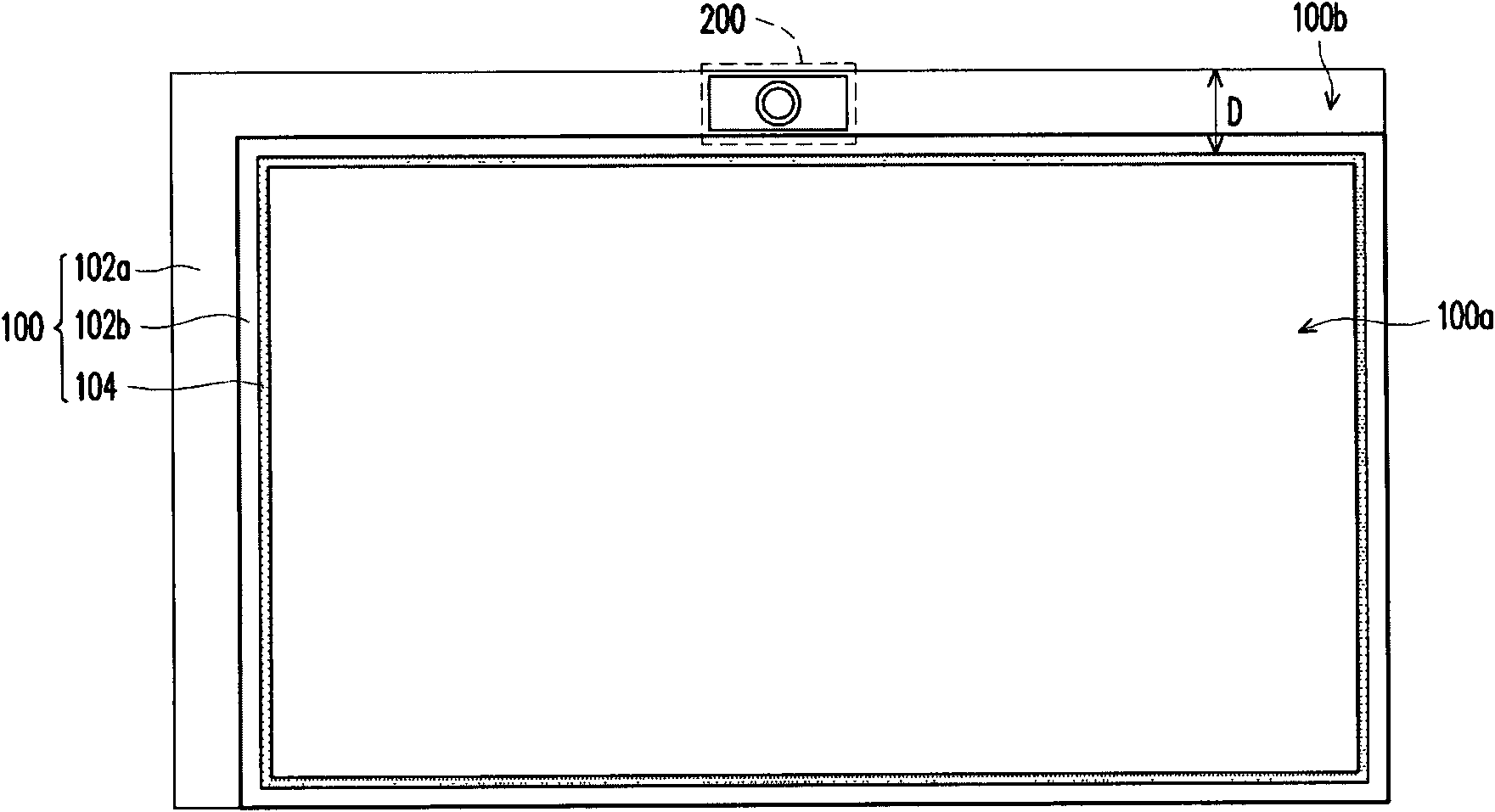

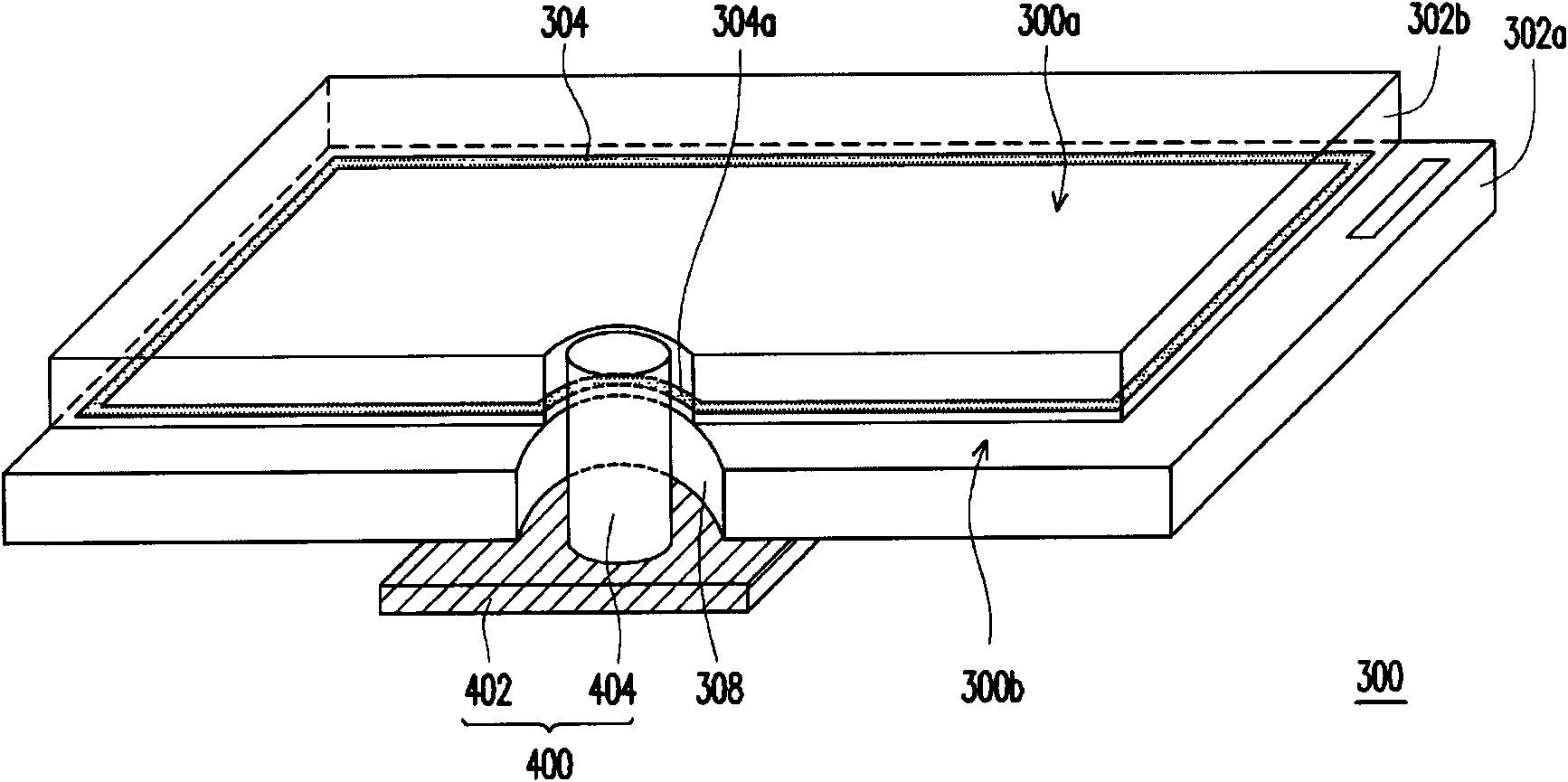

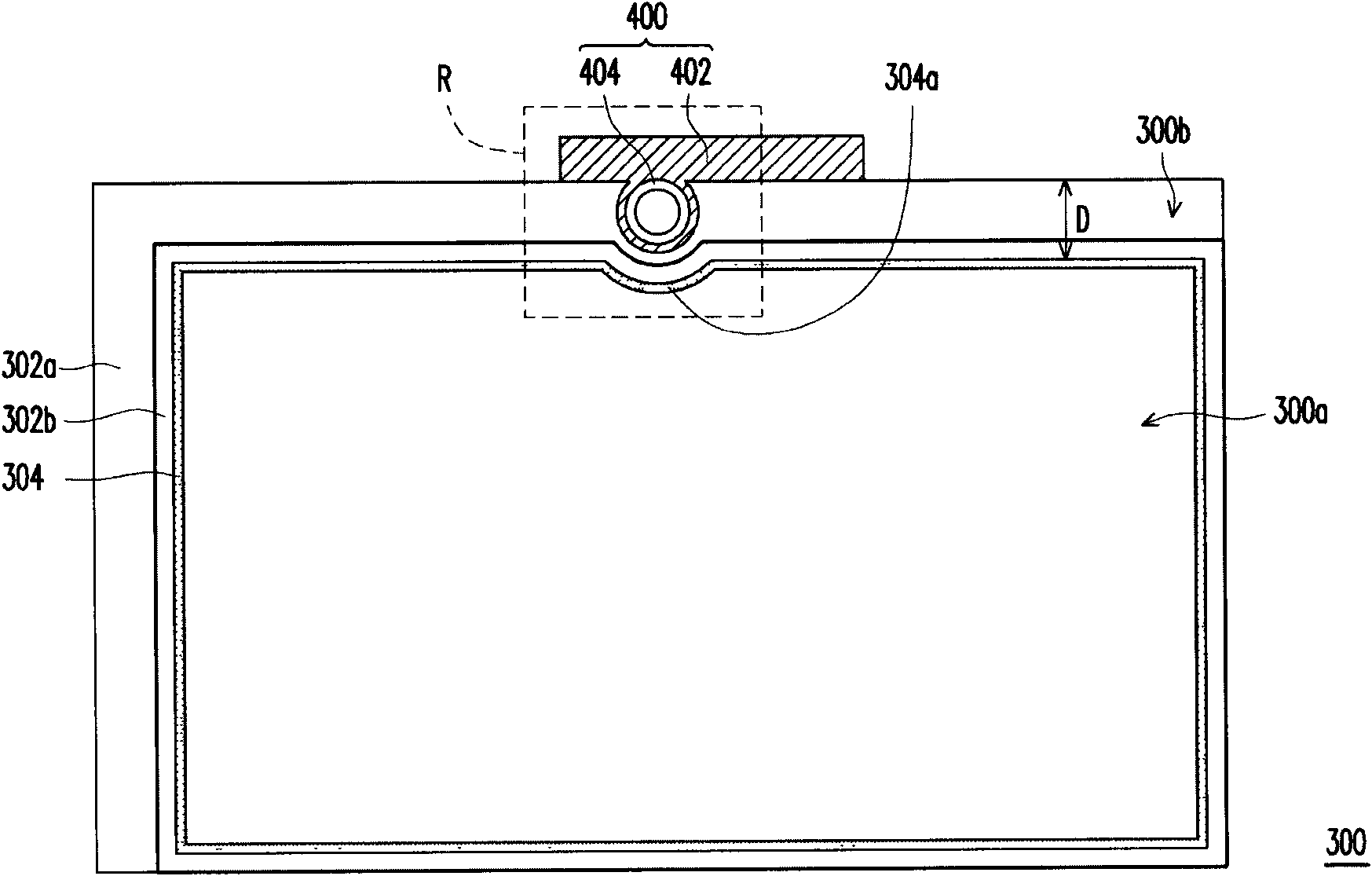

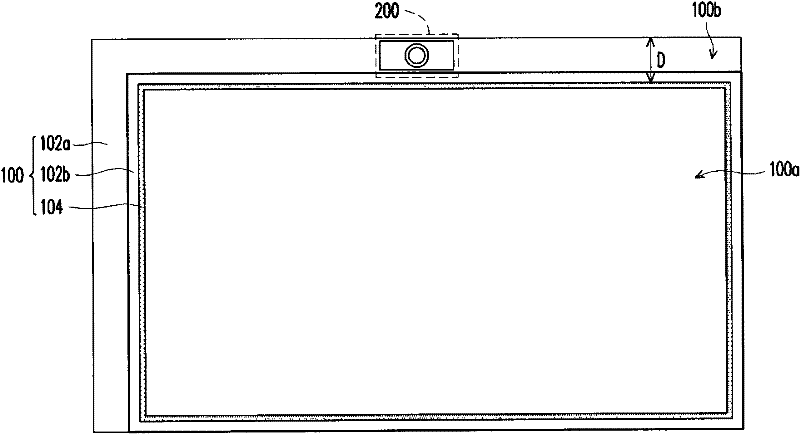

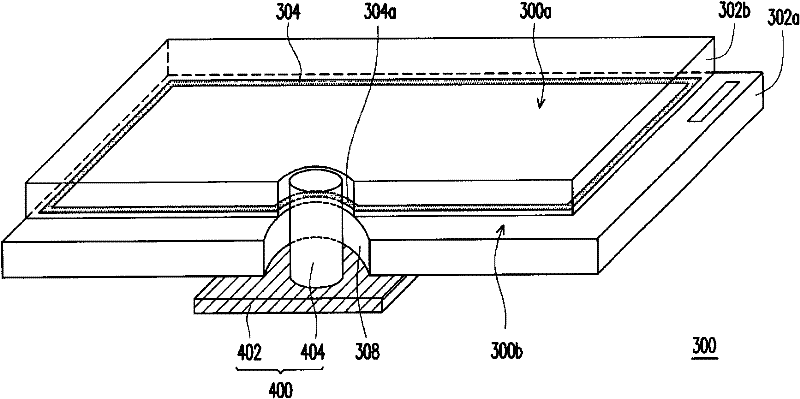

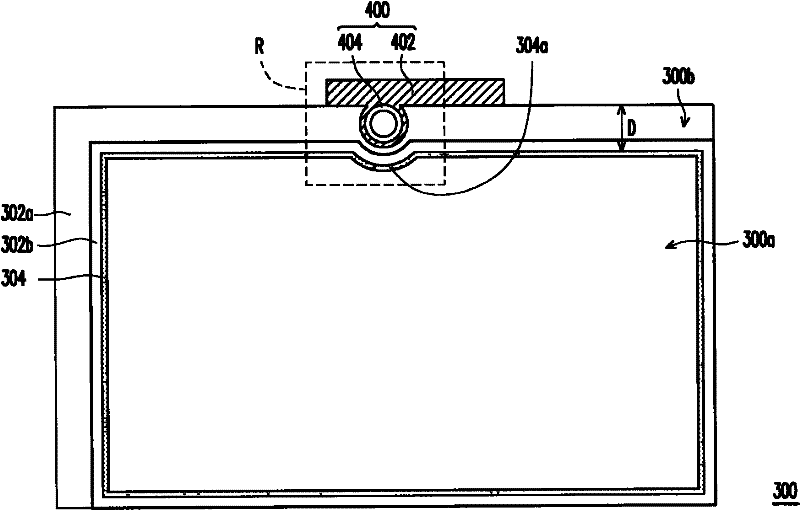

Display

The invention discloses a display, which comprises a display panel and an image acquisition device, wherein the display panel is provided with a display area, a peripheral area enclosing the display area and a through hole positioned in the peripheral area; the image acquisition device is assembled on the display panel, and comprises a signal transmission element and an image acquisition element positioned in the through hole; and the image acquisition element is connected with the signal transmission element.

Owner:AU OPTRONICS CORP

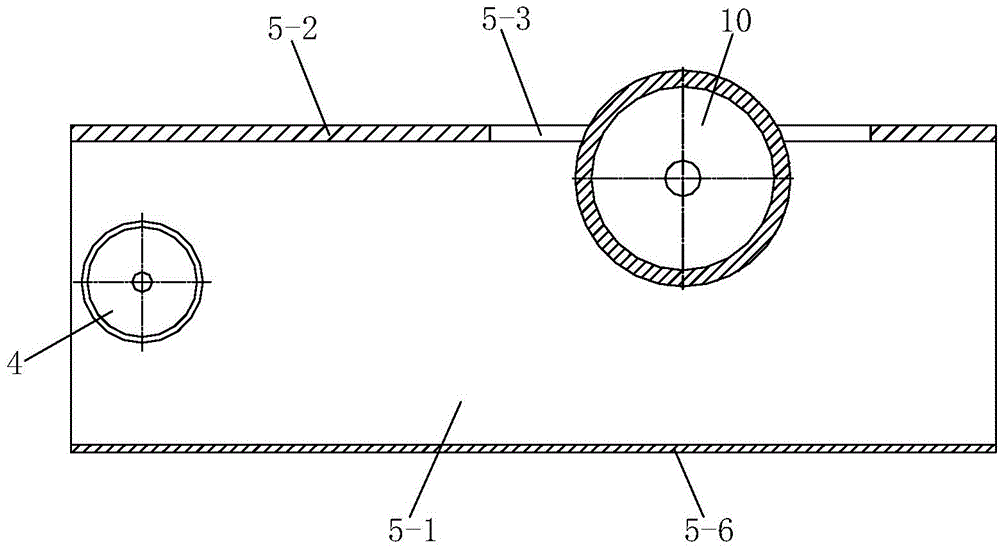

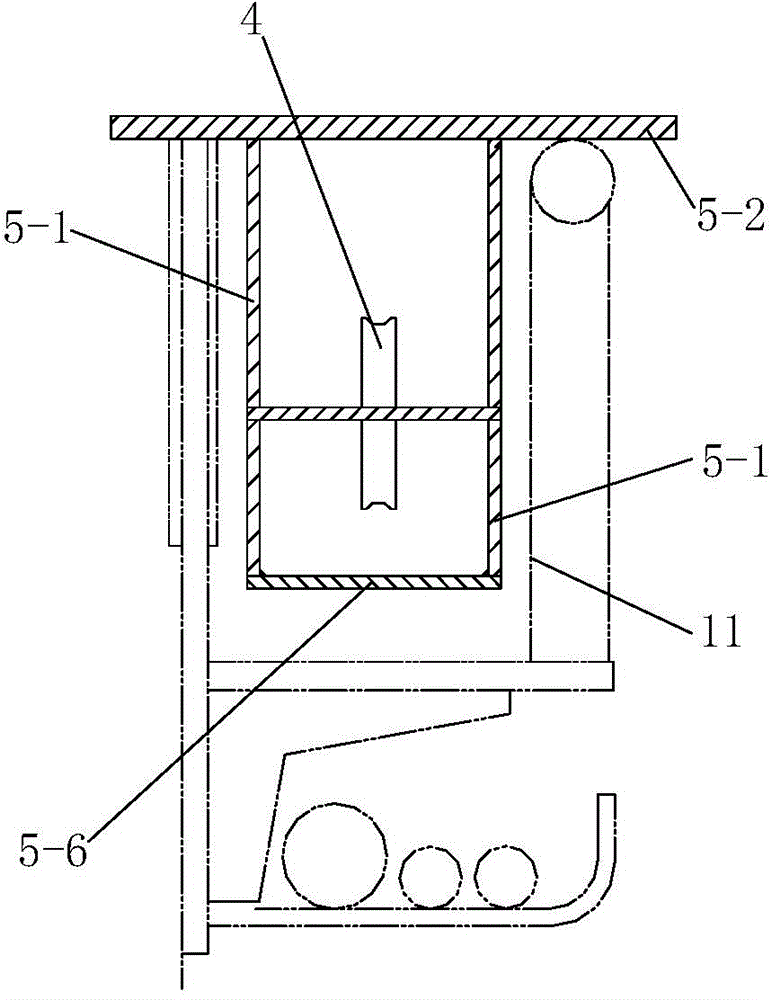

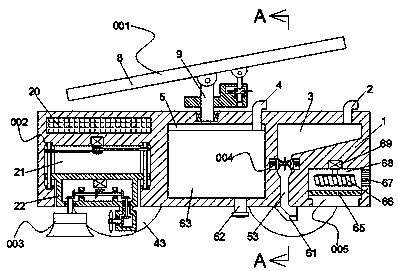

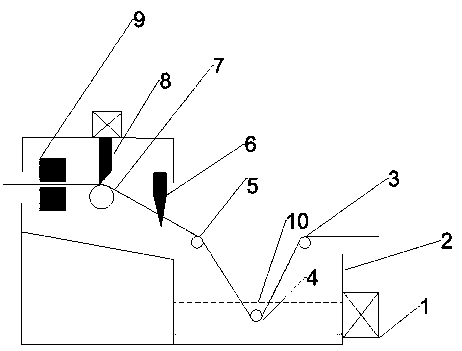

Automatic towing device and method for coal mining machine

ActiveCN104682313ASimple structureIngenious designCable arrangements between relatively-moving partsEngineeringPulley

The invention discloses an automatic towing device for a coal mining machine. The automatic towing device comprises a first fixed pulley, a second fixed pulley, a pulling rope and a mobile towing rack, wherein a movable pulley is mounted on the mobile towing rack; a guide roller is arranged on the mobile towing rack; a cable clamping plate of the coal mining machine goes around the guide roller and is connected to the coal mining machine; one end of the pulling rope is fixed on a conveyor head, while the other end of the pulling rope goes around the movable pulley, the first fixed pulley and the second fixed pulley, and is fixed on the coal mining machine. The automatic towing device can avoid the multi-layer stacking problem of the cable clamping plate of the coal mining machine. The invention further discloses an automatic towing method for a coal mining machine. The automatic towing method comprises the following steps: when the coal mining machine moves from a conveyor tail to the conveyor head, the coal mining machine pulls the pulling rope, the pulling rope pulls the mobile towing rack to move toward the conveyor head along a conveyor cable groove. The automatic towing method is simple in operation and convenient for promotion and application.

Owner:XIAN COAL MINING MACHINERY

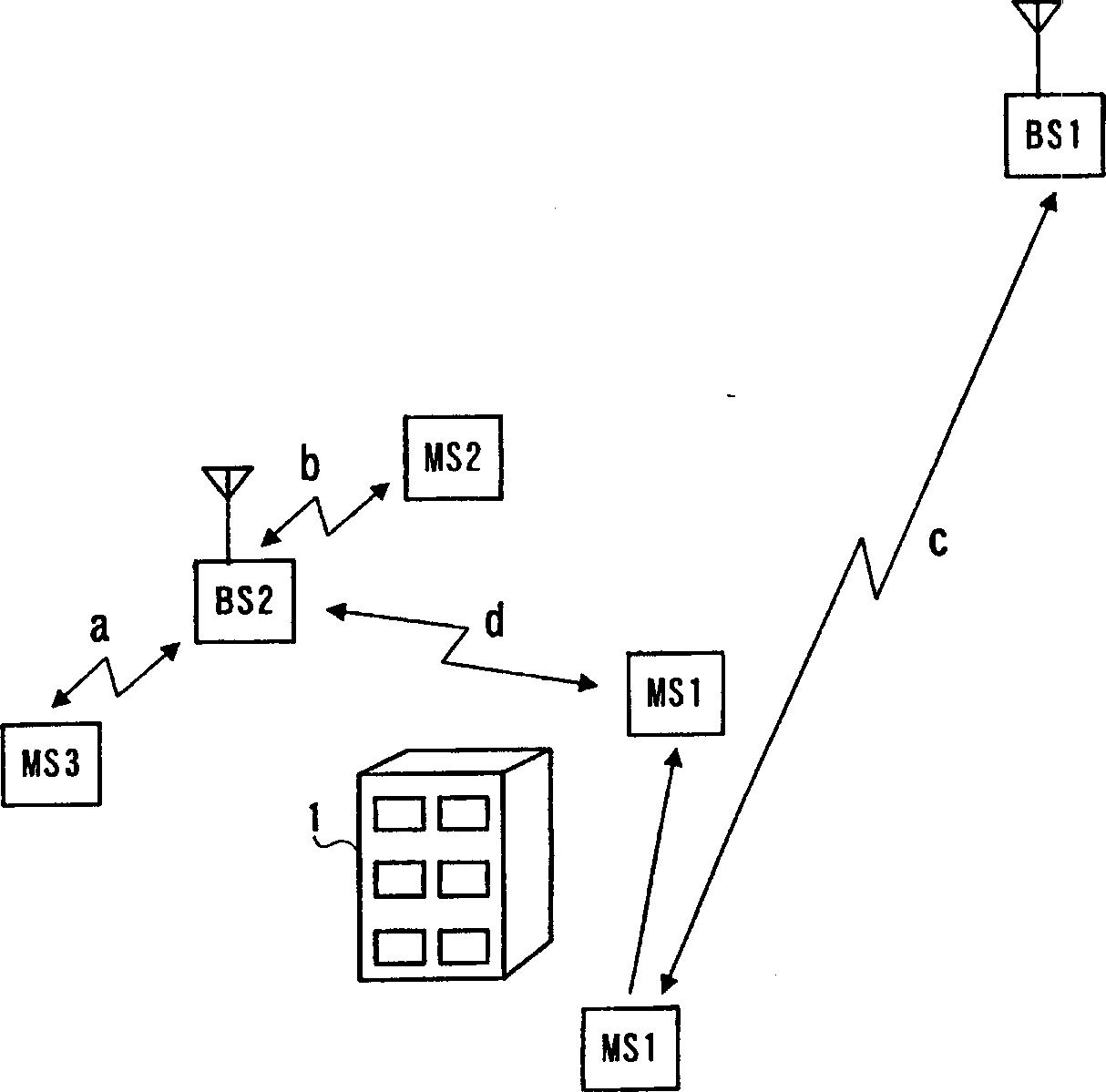

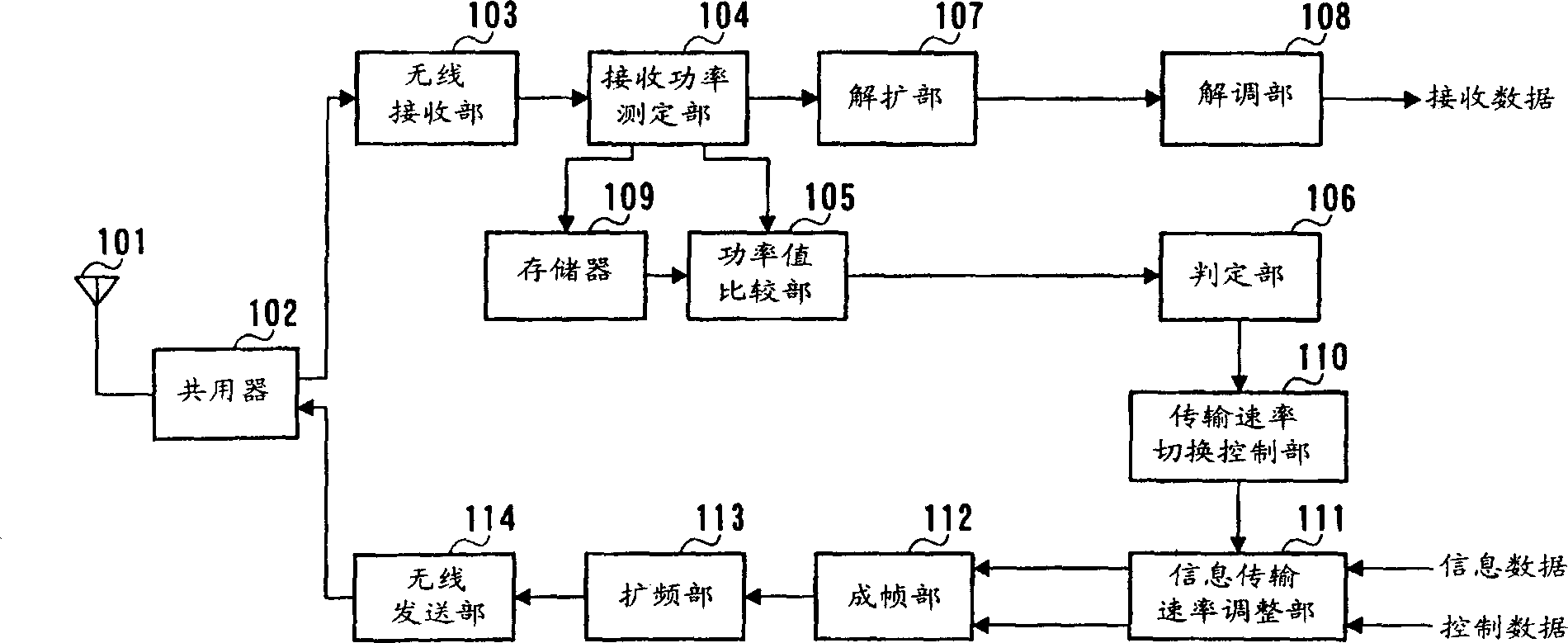

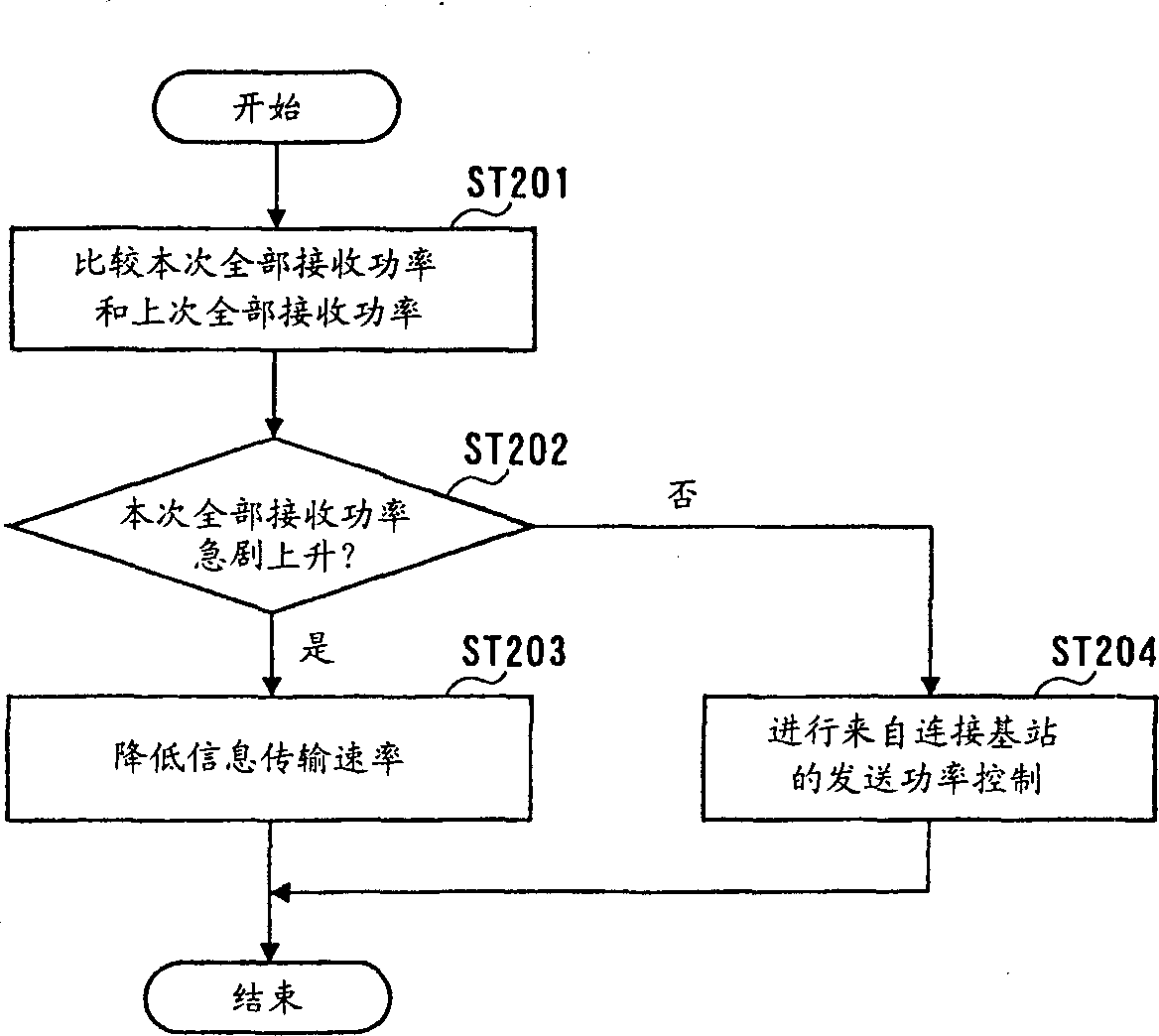

Communication terminal device and method of prevention of excessive interference

InactiveCN1304623ANo reduction in transfer rateReduce distractionsPower managementEnergy efficient ICTTerminal equipmentControl data

The presence of a need for a handover operation is checked in the case of the rapid increase in the power values of received signals at a mobile communication terminal. Thereafter, if required, transmission rates of control data necessary for a handover operation, and of signals required for link maintenance are controlled not to be reduced, and a transmission rate of information data is controlled to rapidly be reduced. And if not needed, the transmission power is controlled to be reduced without changing the transmission rate.

Owner:PANASONIC CORP

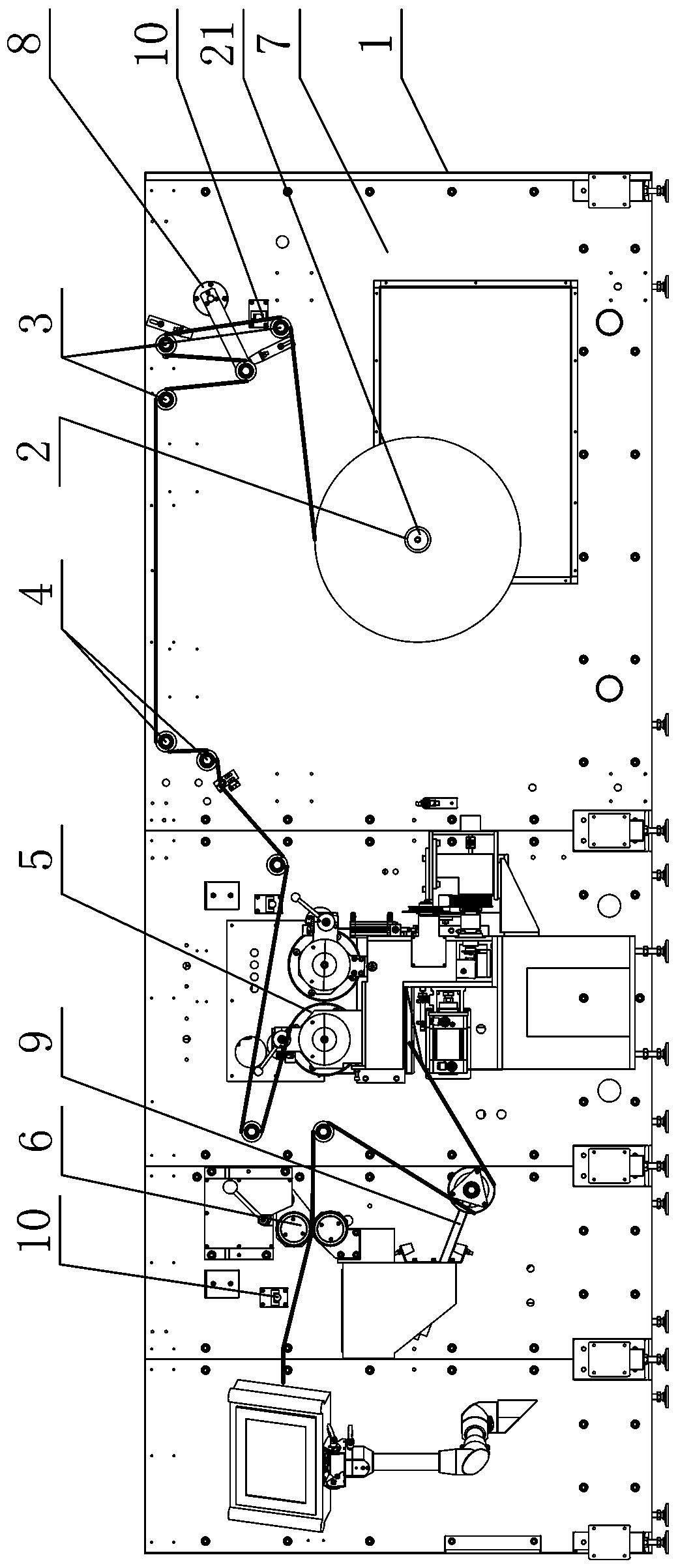

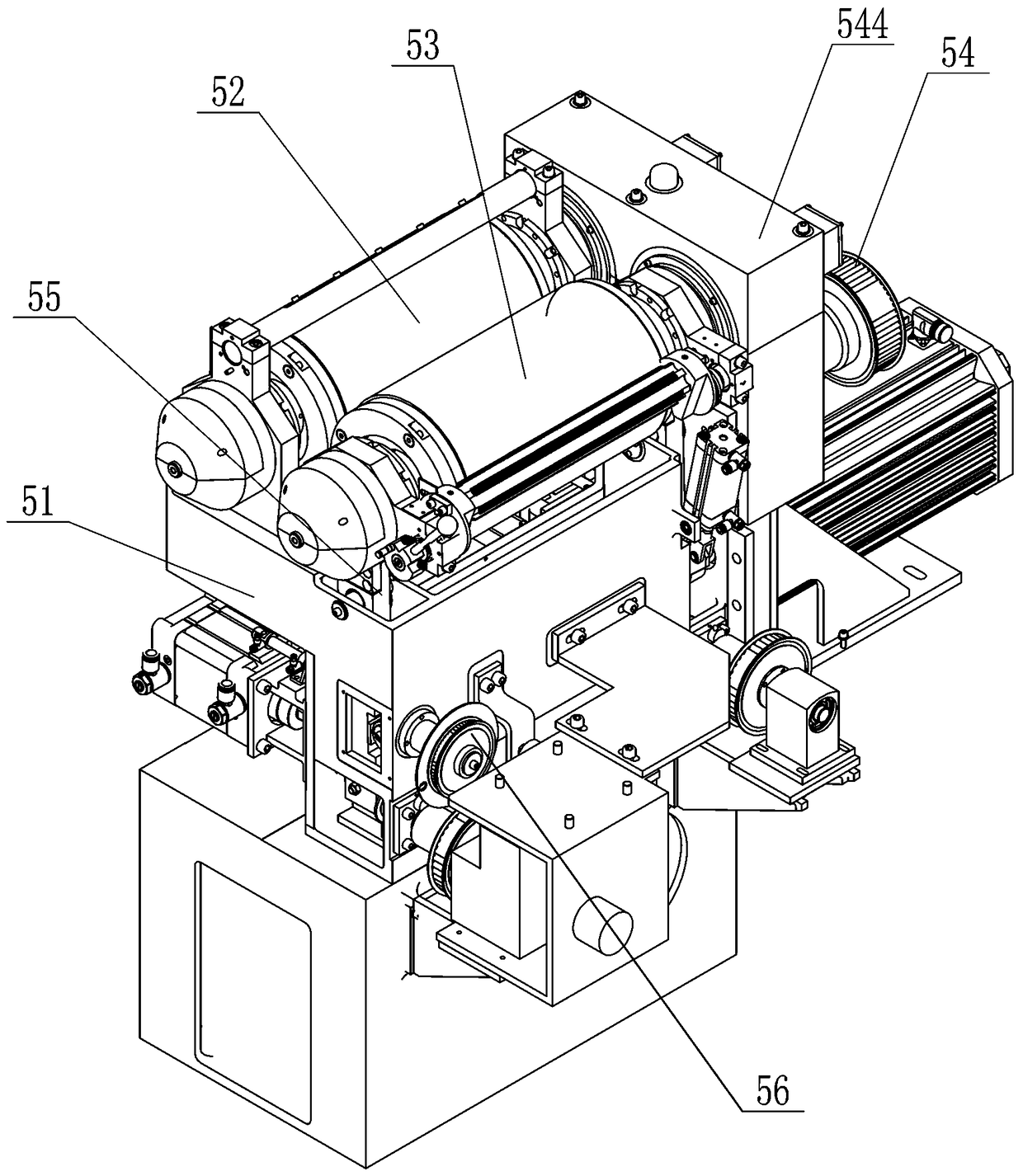

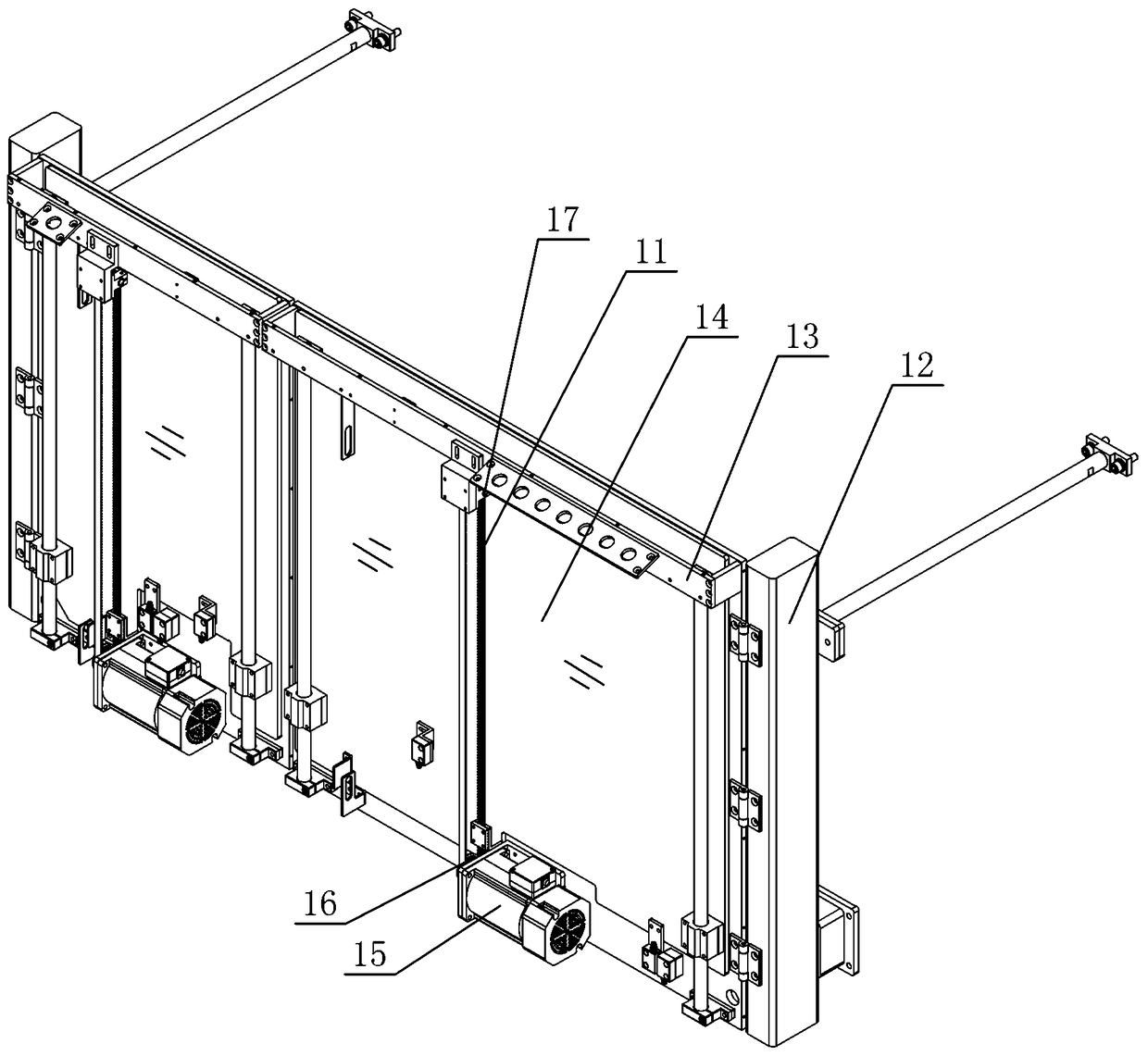

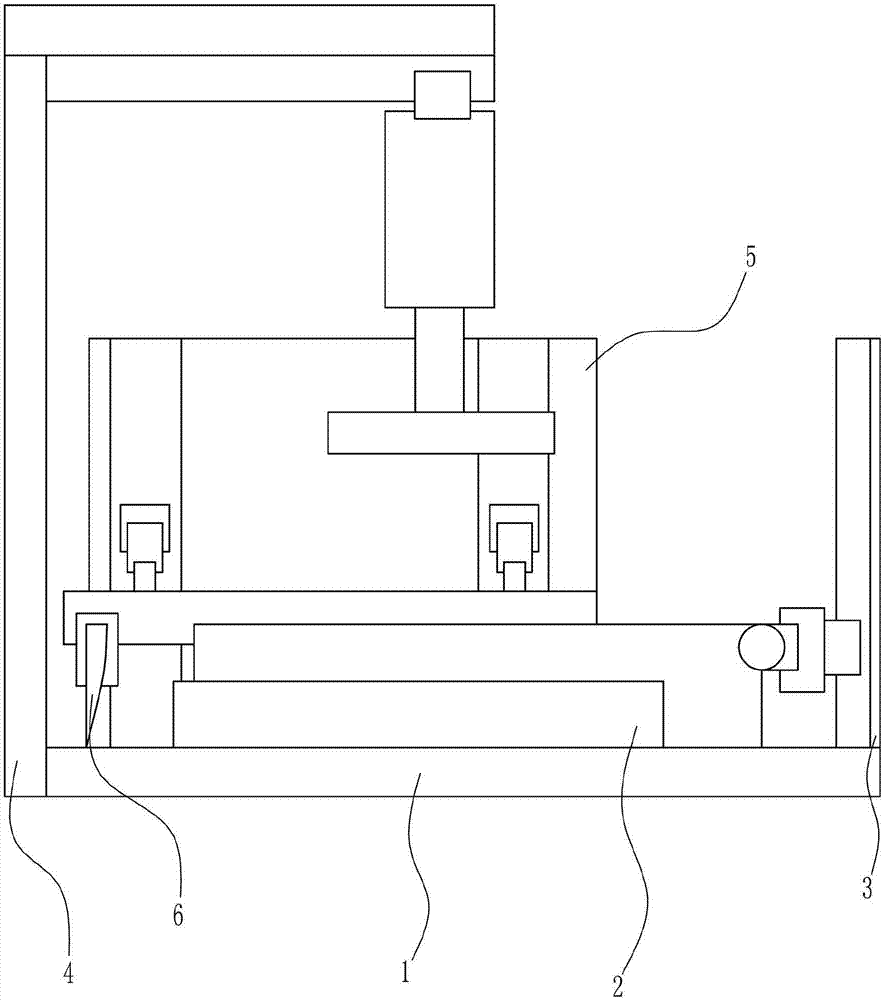

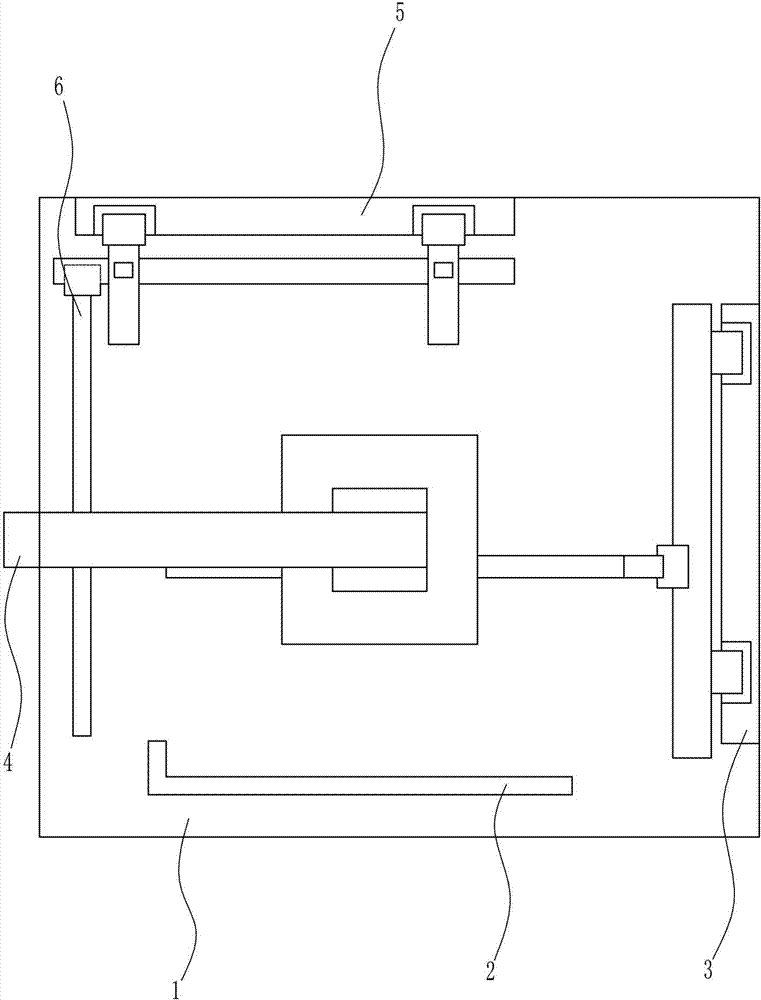

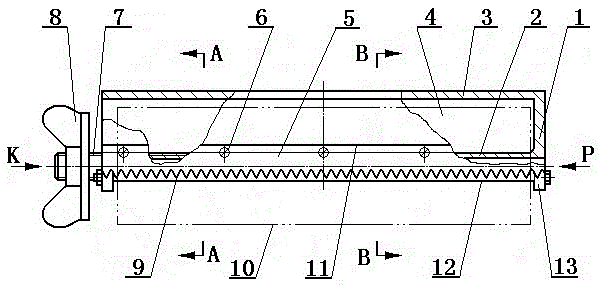

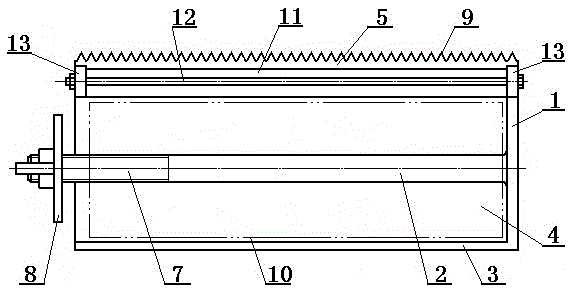

Sheet PLA composite press cutting machine

ActiveCN108657852AMeet the needs of the cooling sectionWon't cut offTobacco smoke filtersElectrostatic chargesCombustionCoil procedure

The invention provides a sheet PLA composite press cutting machine comprising a box, a safety door, an uncoiling device, a conveying roller group, a reversing roller group, a forming device and an outputting roller group. Continuous uncoiling action of a sheet PLA composite is achieved through the uncoiling device. The sheet PLA composite is conveyed to the forming device through the conveying roller group. The forming device cuts the sheet PLA composite into strips which are apparently separated but actually connected, or the forming device presses strip-shaped indentations on the sheet PLA composite, or the forming device wrinkles the sheet PLA composite to be zigzag; and the sheet PLA composite is made to meet the demand of a cooling section of a cigarette free of combustion at low temperature. The formed sheet PLA composite is output through the outputting roller group, and conditions are provided for follow-up coiling procedure.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD +2

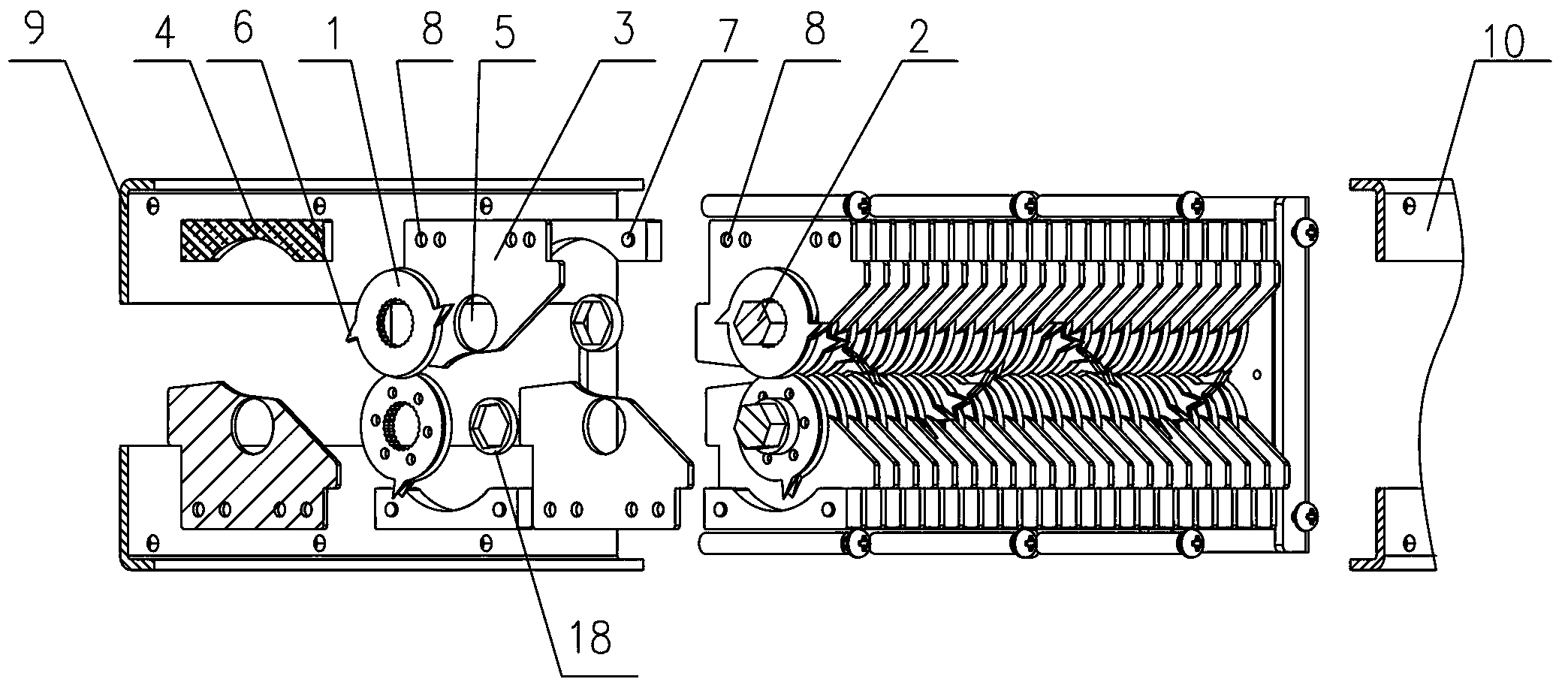

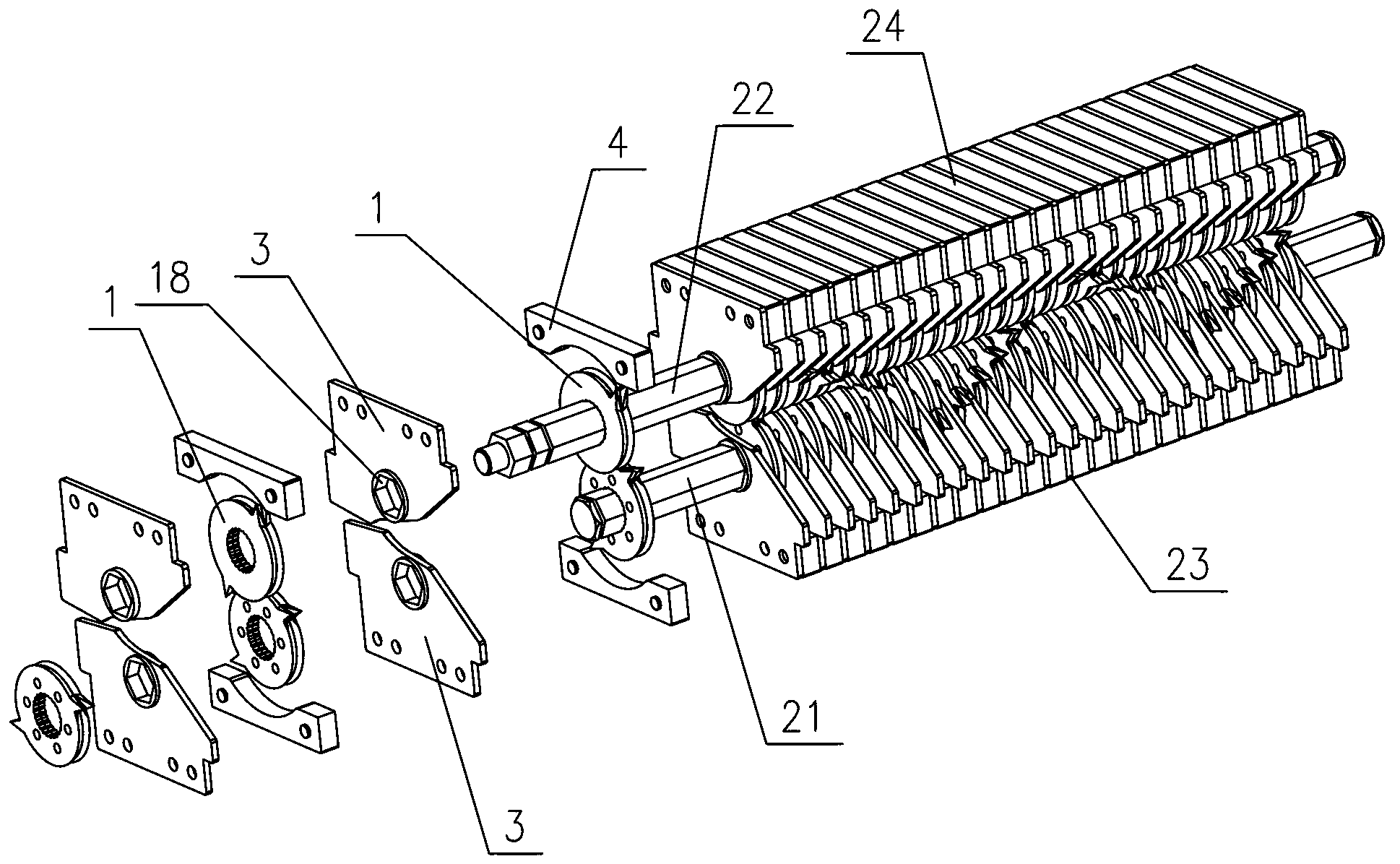

Movement of paper shredder

ActiveCN102698846AImprove wear resistanceWon't wear outGrain treatmentsCardboardPulp and paper industry

The invention discloses a movement of a paper shredder. Each paper deflector group comprises a plurality of metal paper deflectors which are arranged side by side at intervals; a baffle plate is arranged between each two metal paper deflectors; a shaft hole is formed in each metal paper deflector; a hob shaft sequentially penetrates the shaft holes of all the metal paper deflectors in the row; and a section cutting blade is integrally arranged on each hob, and is matched with a metal paper deflector opposite to the section cutting blade to cut paper into sections. The metal paper deflectors and the hobs on the hob shaft are matched with each other to cut the paper into sections smoothly, so that the phenomena of paper jamming, paper carrying, paper clamping and the like are avoided. As the metal paper deflectors have higher abrasion resistance than plastic paper deflectors, when the metal paper deflectors and the section cutting blades are matched with each other to cut the paper into sections for a long time, the metal paper deflectors cannot be abraded by paper, and the clearances between the metal paper deflectors and the section cutting blades cannot be enlarged, which ensures smooth section cutting of the paper.

Owner:宁波王兴工艺品有限公司

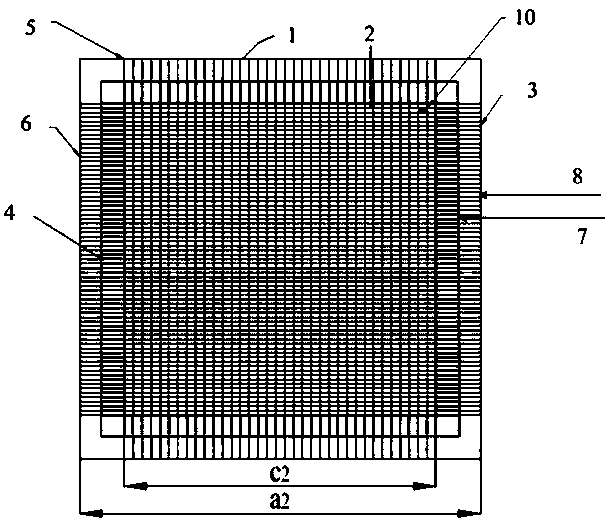

Ceramic component block and cutting method thereof

PendingCN109494079AEasy to separateWon't cut offStacked capacitorsWorking accessoriesMaterials science

The invention discloses a ceramic component block and a cutting method thereof. The ceramic component block comprises a block body, the block body comprises a chip area and an edge material area arranged around the chip area, the edge material area is provided with four cutting identification lines configured to identify cutting locations, the four cutting identification lines are connected end toend in order to form an area around the chip area, and the area is concentric with the chip area. Through arrangement of the four cutting identification lines, when the block body is cut, the edge material area cannot be completely cut off so as to rapidly separate the chip area from the edge material area to obtain a qualified chip.

Owner:广东微容电子科技有限公司

Mesh sheet and housing for electronic devices

ActiveCN103252940AReduce bendingWon't cut offSynthetic resin layered productsCellulosic plastic layered productsEngineeringMechanical engineering

A mesh sheet of the present invention is a mesh sheet in which a metal mesh comprising fine bands is laminated on a surface of a base substrate, the mesh sheet being used and adhered along a surface of an arbitrary member having a curved surface portion. The metal mesh has a part in which the fine band positioned between connection points of the fine bands which are adjacent to each other is a curved line so as to absorb stress relative to deformation to be placed along the curved surface portion with a large curvature without destructing the metal mesh.

Owner:NISSHA PRINTING COMPANY

Manufacturing method for similar-disc cross-section forge piece with height-diameter ratio smaller than 0.3

The invention discloses a manufacturing method for a similar-disc cross-section forge piece with the height-diameter ratio smaller than 0.3. The manufacturing method includes the steps that an alloy ingot is heated to 1,150 DEG C to 1,180 DEG C, and through upsetting, the punching and chambering processes, a rolled blank is manufactured; the rolled blank is put into a furnace and heated to 1,150 DEG C to 1,180 DEG C, the obtained rolled blank is taken out and put on a ring rolling machine, a main roller bushing and a core roller bushing sleeve a main roller and a core roller respectively, thering rolling machine is started, and starts to rotate under driving of the main roller and the core roller, a conical roller is pressed on the end face of the blank, rolling is started, the size is inplace, and then the ring rolling machine is closed; an abnormal-shape ring piece after ring rolling is obtained, a small balance amount of machining is carried out after heat treatment, and the similar-disc cross-section forge piece can be obtained. According to the manufacturing method, the material utilization rate is greatly increased, metal filters cannot be cut off through a small balance amount of machining, the service life of a product is prolonged, the comprehensive performance of the product is improved, and the manufacturing period is short; through the technical advantages of thelocal, continuous and the small deformation amount of ring rolling, if a large-tonnage hydraulic machine is manufactured through small-tonnage equipment, the forge piece can be manufactured, and the equipment cost and loss are greatly reduced.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

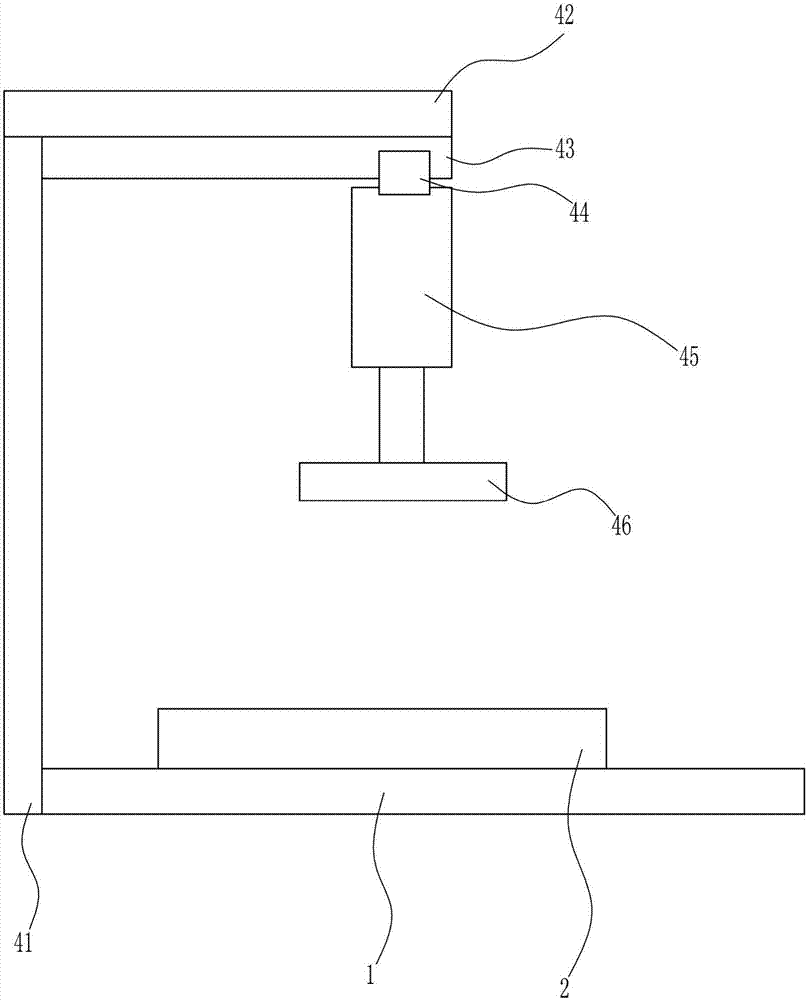

Paper cutting device for printing

InactiveCN107471303AEffective and stable up and down movementWon't cut offMetal working apparatusPulp and paper industryLeft wall

The invention relates to a cutting device, in particular to a paper cutting device for printing. According to the technical purpose to be achieved, the paper cutting device for printing is provided, wherein the length and width cutting degree can be manually adjusted at will, and a large number of pieces of paper can be cut at the same time. In order to achieve the above technical purpose, the paper cutting device for printing is provided and comprises a bottom plate and the like. A pressure applying mechanism is connected to the middle portion of the left wall of the bottom plate; a baffle is connected to the front side of the top of the bottom plate; a fixing plate is connected to the right side of the top of the bottom plate; a supporting plate is connected to the rear side of the top of the bottom plate; and a cutting mechanism is arranged between the supporting plate and the fixing plate. The paper cutting device for printing is designed, an electric push rod can effectively and stably drive the pressing plate to vertically move, and a user can also conveniently conduct pressure applying control over the position needing to be subjected to pressure applying due to left-right movement of the pressing plate.

Owner:刘慎柱

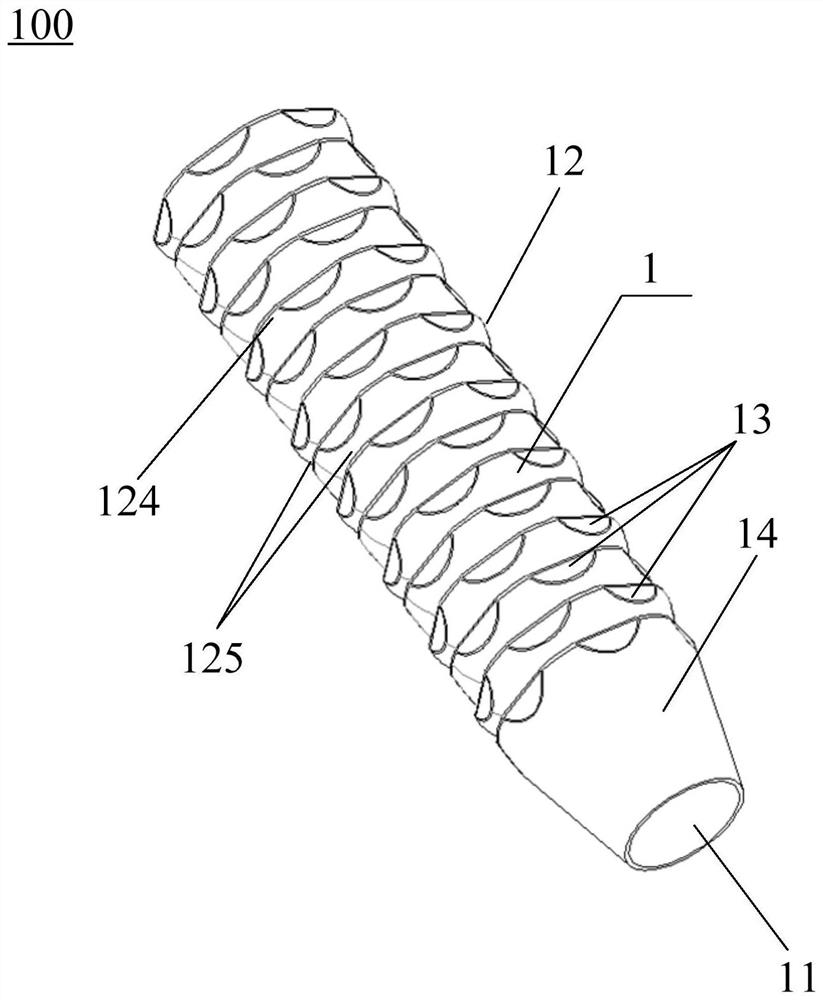

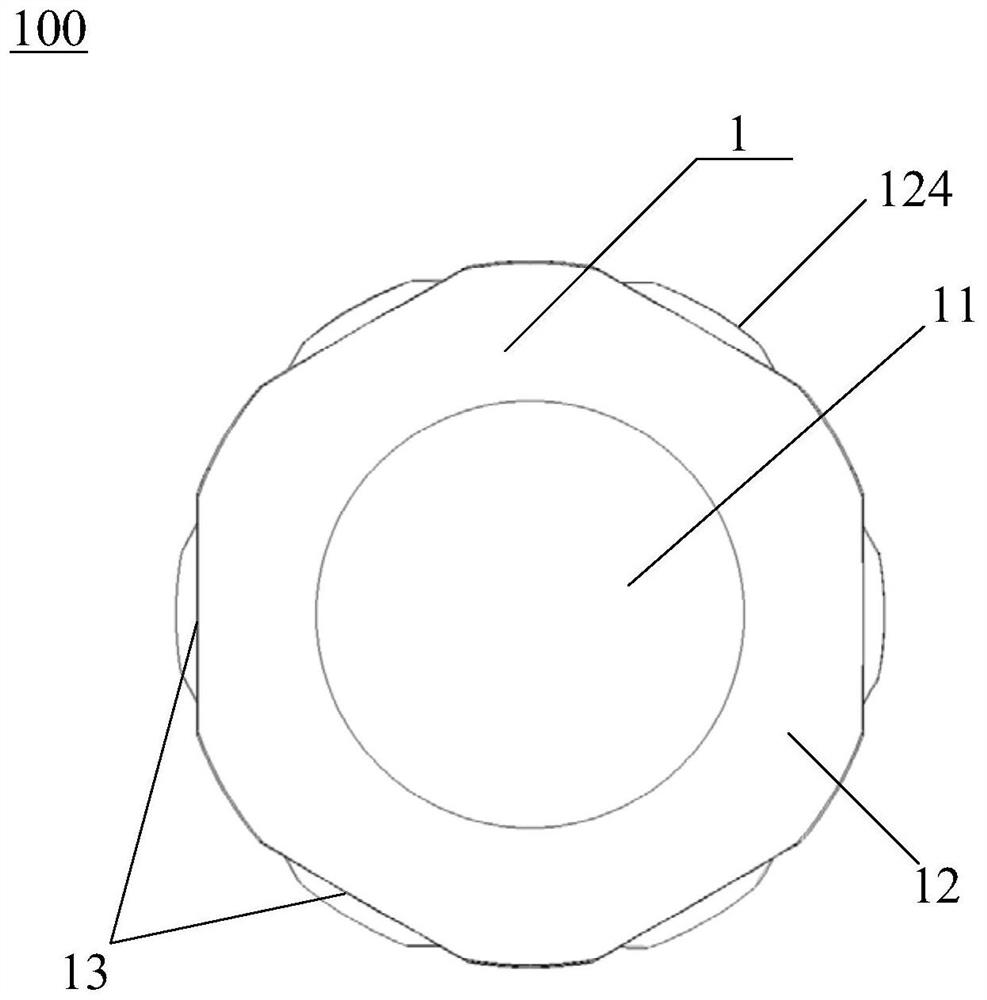

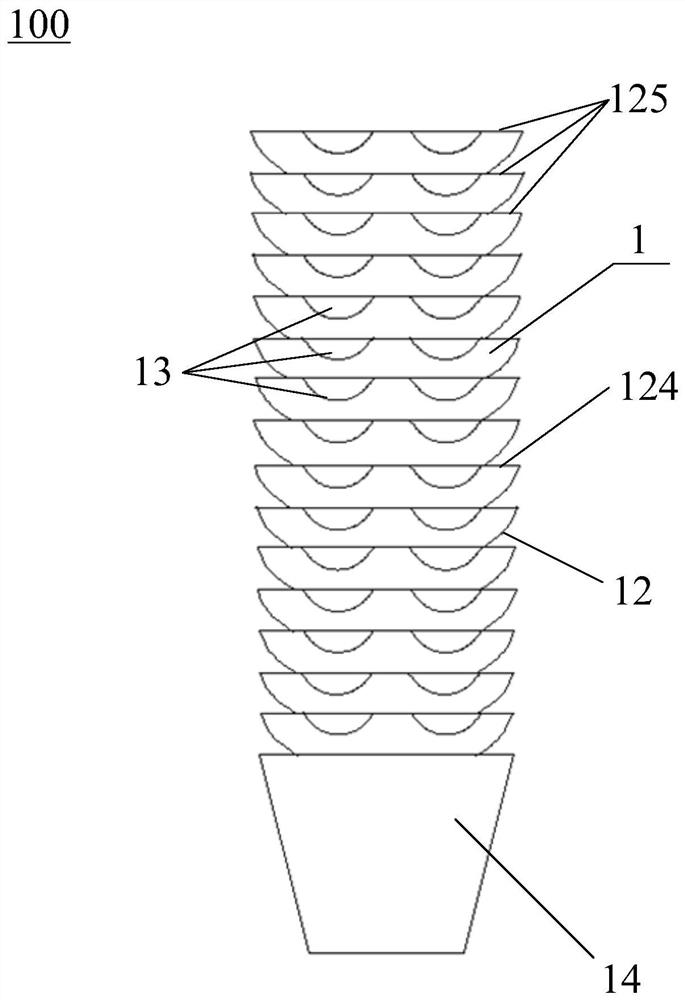

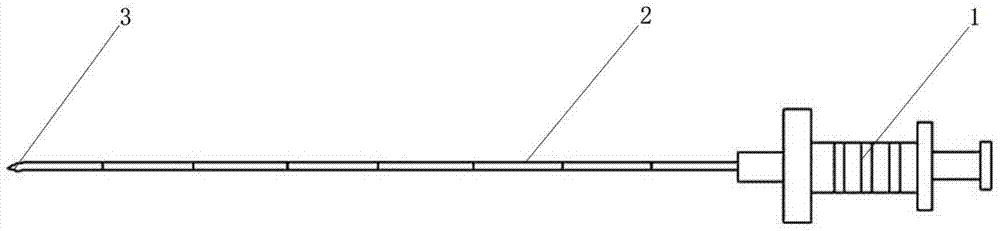

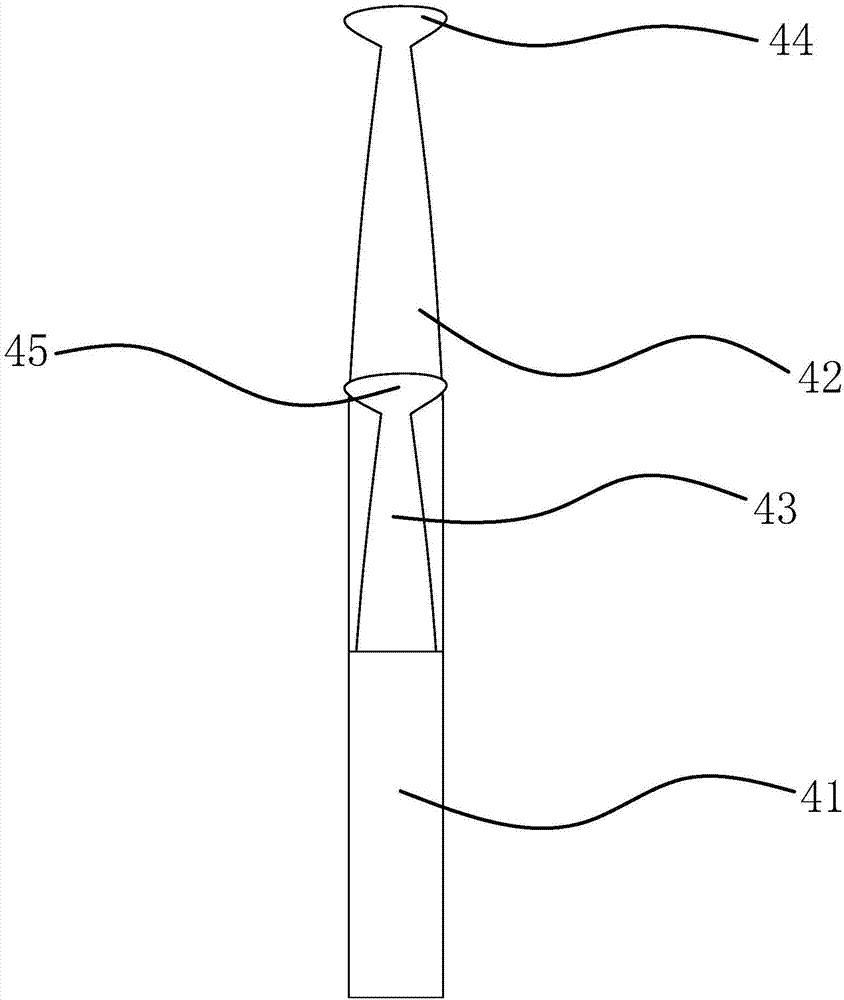

Knotting-free anchor and anchor implantation instrument

ActiveCN112494089AImprove the fixed effectGuaranteed StrengthStaplesNailsBiomedical engineeringSurgery

The invention belongs to the technical field of medical instruments, and discloses a knotting-free anchor and an anchor implantation instrument. The knotting-free anchor comprises an anchor body, an axial center hole axially penetrating through the anchor body is formed in the anchor body, and the anchor body comprises a threaded connection section. At least one notch is formed in the edge of theexternal thread of the threaded connection section. The knotting-free anchor has the advantages that sutures can be prevented from being cut off by the knotting-free anchor, and accordingly the fixingeffect of the knotting-free anchor is improved.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

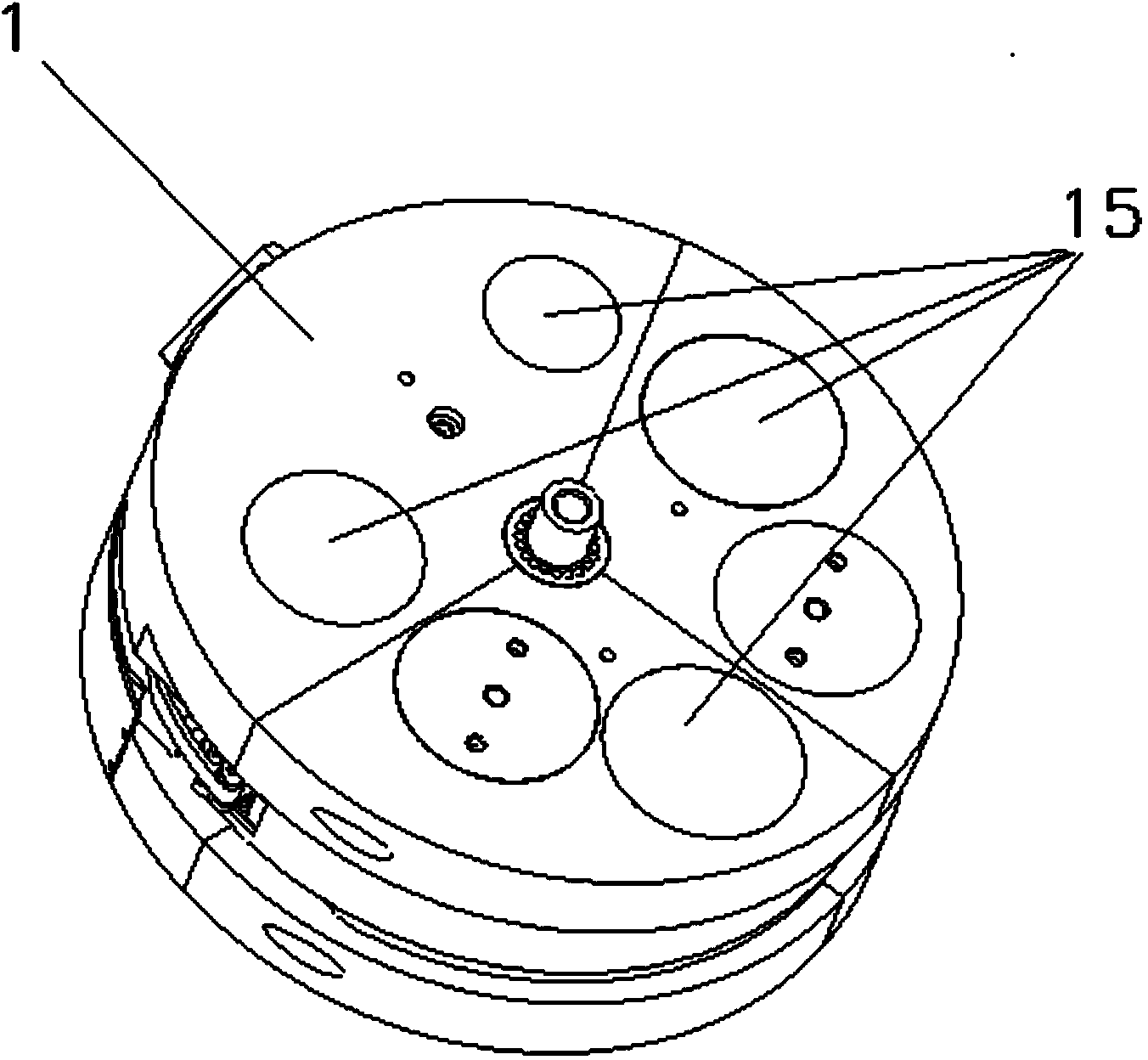

Down kneading machine

The invention discloses a down softening machine, comprising a stationary toothed disc which is arranged on a bottom plate, a moving toothed disc and a motor driving the moving toothed disc to rotate; one end of the stationary toothed disc manufactures a ring stationary toothed surface and the other end thereof is connected with a feed inlet; one end of the moving toothed disc manufactures a ring moving toothed surface and the other end thereof is connected with the motor by a moving disc shaft, a bearing seat, a bracket and a belt driving pair; a casing of a moving disc is sheathed on the moving toothed disc. A large piece of feather is kneaded to be soft by the mutual movement with high speed between the ring stationary toothed surface and the ring moving toothed surface so as to lead the feather to have good bulk and good softness. The obtained feather can be used as the fillings of down products such as a seat pad and a backrest, etc., can improve the use value of the feather and is beneficial to environment protection. The invention has good economic benefit and social benefit.

Owner:徐州腾宇羽绒制品设备有限公司

Paper cutting device for rolled-up sketching paper/vegetable parchment

The invention discloses a paper cutting device for rolled-up sketching paper / vegetable parchment. The paper cutting device is mainly characterized in that a fan-shaped shaft seat plate is arranged at the right end of a handle; a hollow shaft for being sleeved with and inserted in cylinder core inner holes of rolled-up sketching paper / vegetable parchment is arranged on the inner end face of the fan-shaped shaft seat plate; the axis of the hollow shaft, the left horizontal central axis of a semicircular inner hole of the handle and the right horizontal central axis of the semicircular inner hole of the handle coincide together; an external thread connected with a butterfly nut is arranged at the left end of the hollow shaft; a horizontal boss protruding forwards is arranged at the front end of the handle in the left-right direction; a lug base is arranged at the left end of the horizontal boss, and a lug base is arranged at the right end of the horizontal boss; a pull rod is arranged between the lug bases at the left end and the right end; the pull rod is fastened on the lug bases at the left end and the right end through nuts; a cutter used for cutting off sketching paper / vegetable parchment is arranged on the front end inclined face of the horizontal boss; and zigzag sharp edges evenly distributed are arranged on the lower portion of the cutter in the left-right length direction. The paper cutting device can rapidly cut off sketching paper / vegetable parchment, and is convenient to use. The work efficiency is remarkably improved.

Owner:罗云

Rolling forming method of C-shaped section forge piece

A rolling forming method of a C-shaped section forge piece includes the following steps that an alloy ingot is heated to 1150-1180 DEG C, and then the alloy ingot is subjected to upsetting and drawingto improve a cast-state structure of the alloy ingot; then punching, hole expanding and rounding procedures are carried out to manufacture a prefabricated blank; the prefabricated blank is heated to1150-1180 DEG C in a furnace, and the prefabricated blank is taken out and placed on a ring rolling mill; a main roller bush sleeves a main roller, and a core roller bush sleeves a core roller; the ring rolling mill is started and starts to rotate under the driving of the main roller and the core roller, a conical roller a and a conical roller b are pressed on the two end faces of the prefabricated blank respectively, rolling is started, and after the required size is achieved, the ring rolling mill is shut down to obtain the C-shaped forged piece obtained after ring rolling. By the adoption of the method, the material utilization rate is greatly improved, only small allowance machining is needed after heat treatment, and metal fiber cannot be cut off, so that the service life of a productis prolonged, the comprehensive performance of the product is improved, and the manufacturing period is short.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Solar-powered road line drawing machine

InactiveCN111206485AAvoid destructionImprove bindingPhotovoltaic supportsSolar heating energyEngineeringRoad surface

The invention discloses a solar-powered road line drawing machine. The machine comprises a device body of a solar cell panel device capable of tracking the sun irradiation direction by adjusting is arranged on the top end surface of the machine; a lifting cavity is formed in the position, close to the left side, in the bottom end face of the device body, a cleaning box capable of moving up and down is arranged in the lifting cavity, and a cleaning device capable of cleaning a road surface needing paint spraying in advance is arranged in the cleaning box. According to the invention, an angle-adjustable solar cell panel is arranged, the power source is cleaner, by arranging the cleaning device capable of cleaning the road surface needing to be drawn in advance in the left end of the device body, it is guaranteed that line drawing of the line drawing machine on the road surface is not separated by sundries on the ground, meanwhile, the cleaned road surface is more beneficial to combination of paint and the road surface, and the paint surface is not prone to falling off.

Owner:SANMEN QIULAN SPRAYER TECH CO LTD

Flocked yarn gluing equipment and gluing method

InactiveCN110947574APrecise thickness controlImprove breathabilityPretreated surfacesCoatingsYarnAdhesive glue

The invention discloses flocked yarn gluing equipment. The flocked yarn gluing equipment comprises a first roller, a second roller, a third roller, a fourth roller, a glue containing tank, a low-pressure nozzle, a pneumatic lifting scraper, a width-adjustable Teflon foam material and an ultrasonic micro-nano bubble generating device; the pneumatic lifting scraper utilizes scraper pressure to reinforce the soaking of a materials by glue; the low-pressure nozzle is used for blowing off redundant glue on the surface of a yarn; the width-adjustable Teflon foam material is used for adjusting the width of a gap between the upper layer and lower layer of the foam material so as to control the thickness of a glue material layer; and the ultrasonic micro-nano bubble generating device is used for generating micro-nano bubbles in the glue. The invention further discloses a gluing method of the flocked yarn gluing equipment. With the flocked yarn gluing equipment and the gluing method of the invention adopted, accurate control over the thickness of the glue material layer in a gluing process and control over the size of air holes in the glue material layer can be achieved, and therefore, it isguaranteed that a flocked product has good air permeability, hand feeling and high flexibility; and the flocked product manufactured in subsequent processes can be used as a high-grade fabric.

Owner:浙江久大纺织科技有限公司

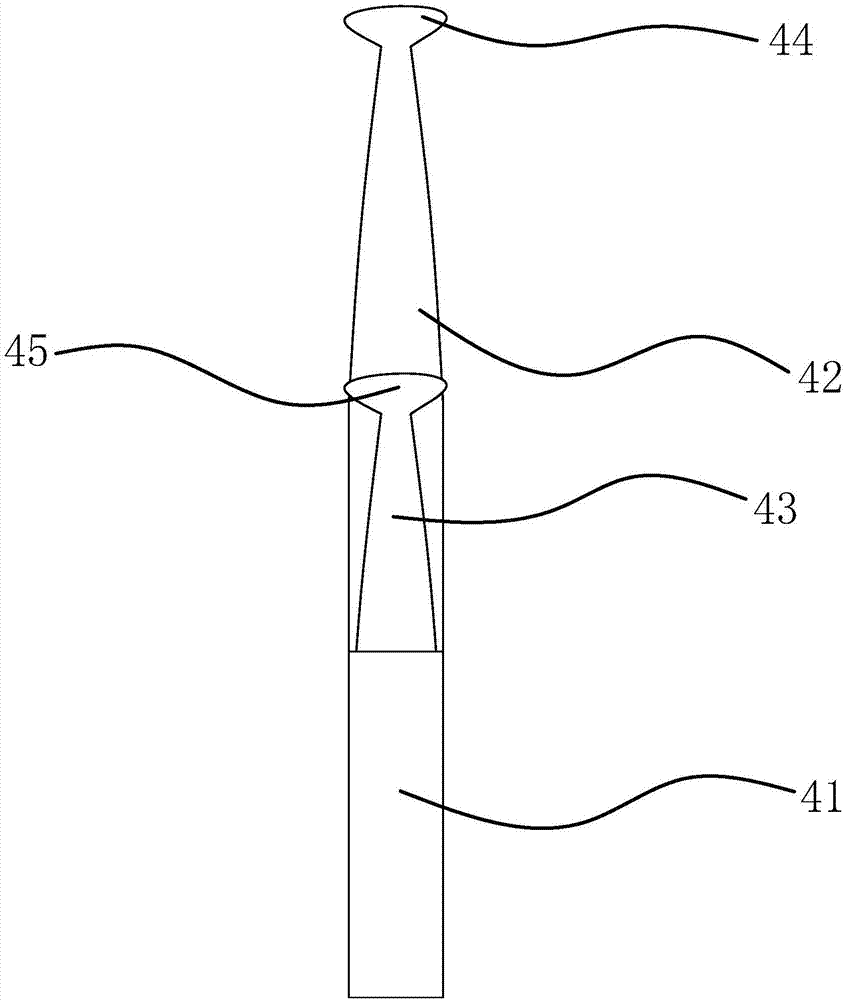

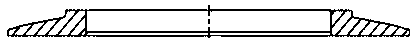

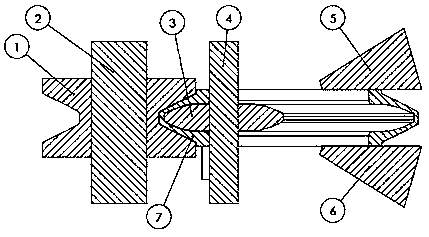

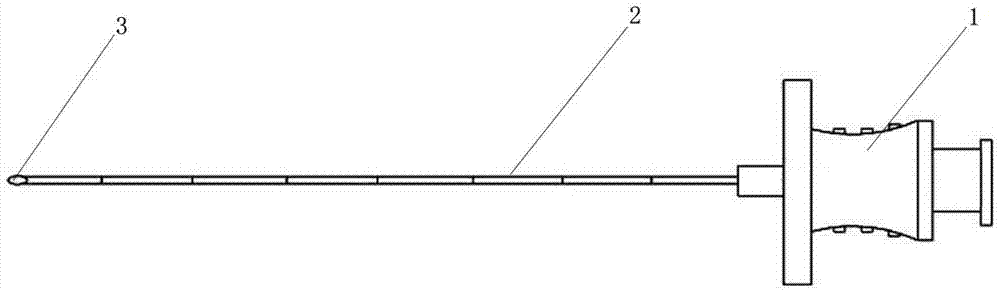

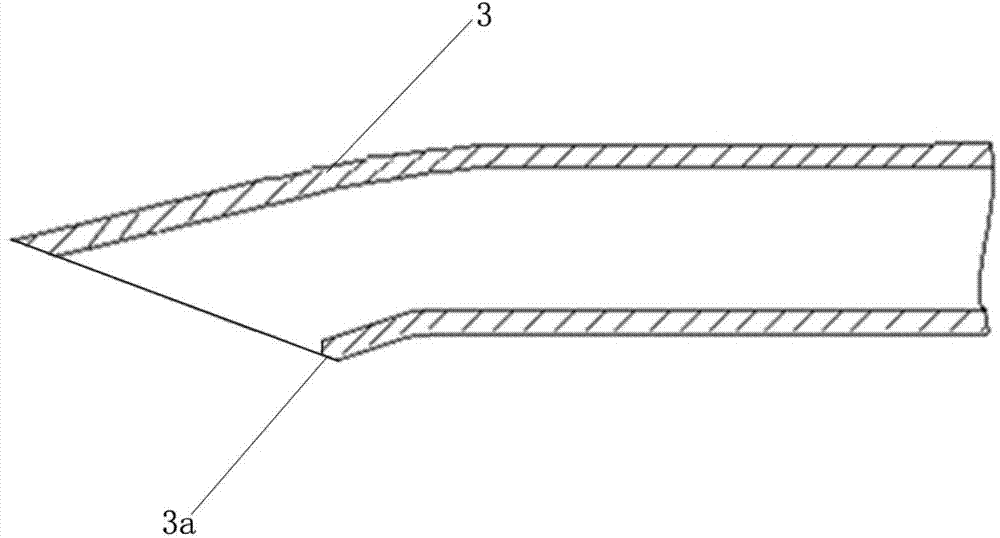

Epidural puncture needle preventing epidural catheter from being cut off

The invention provides an epidural puncture needle preventing an epidural catheter from being cut off, and the epidural puncture needle can prevent the catheter from being cut off in an intraspinal anesthesia operation. The epidural puncture needle preventing the epidural catheter from being cut off aims to overcome the defect that the epidural catheter is prone to being cut off by an existing epidural puncture needle, and the epidural catheter is not cut by the end face at the opening position of a needle tube. The epidural puncture needle comprises a needle seat and a needle body, the needle body is of a tubular structure, and the head of the needle body is a spoon-shaped needle point used for puncturing; the tail of the needle body is fixed to the needle seat; the open position of the inner wall of the needle point is of an obtuse structure and cannot cut the epidural catheter when making contact with the epidural catheter. Compared with an existing epidural puncture needle, the epidural puncture needle has the advantages that the epidural catheter is prevented from being cut off, and the epidural puncture needle is safe and convenient to use for puncturing.

Owner:蓝志坚

Colored spun yarn fiber dyeing device

PendingCN107338594AFiber runs smoothlyAvoid scratchesTextile treatment containersTextile treatment machine arrangementsCartridge heaterRight triangle

The invention discloses a color spinning fiber dyeing device, which includes a cleaning box, an upper cover, a heat preservation shell, a lower pressing plate, a dye box, a warm air box, a resistance plate, a movable groove, a limit groove, a scraper, an observation mirror, a housing Slots, imports and exports. The beneficial effects of the invention are: the observation mirror is a concave lens structure, which can enlarge the dyeing condition of the fiber to the human eye, so that the dyeing effect can be observed accurately; Avoid being scraped off; the scraper is a right-angled triangle structure with a right angle on the right side, which ensures that the dye is hung when going out, so that the fiber will not be cut when the dye is scraped off; the insulation shell is electrically connected to the lower pressure plate, the resistance plate and the heater box. All parts are easy to be controlled uniformly; the bottom of the scraper, the limit groove, the inlet and the outlet are located at the same vertical height, so that the fiber running process is smooth.

Owner:响水文昊纺织品有限公司

Napping needle on car seat cover fabric wool pile-making machine

The invention provides a napping needle on a car seat cover fabric wool pile-making machine, and belongs to the technical field of textile manufacturing. The napping needle solves technical problems that a napping needle can not play the combing effect on wools. The napping needle on the car seat cover fabric wool pile-making machine comprises a main roller, a plurality of napping rollers, guide sleeves corresponding to the napping rollers and an air blower, and the main roller is provided with avoiding openings corresponding to the napping rollers, the napping rollers are arranged in the corresponding avoiding openings, the napping rollers extend out of the avoiding openings partly, each napping roller is evenly provided with a plurality of napping needles, the napping needles are in a Y shape, each napping needle comprises a needle body, a fuzzing needle and a carding needle, the fuzzing needle and the carding needle are fixedly connected with the needle body, the outer end of the fuzzing needle is provided with a needle head one, the outer end of the carding needle is provided with a needle head two, the fuzzing needle is bent in the direction of the carding needle, and the needle head one is located above the needle head two. The napping needle on the car seat cover fabric wool pile-making machine has the advantage of being able to comb the wools while napping.

Owner:安徽迪思自动化设备有限公司

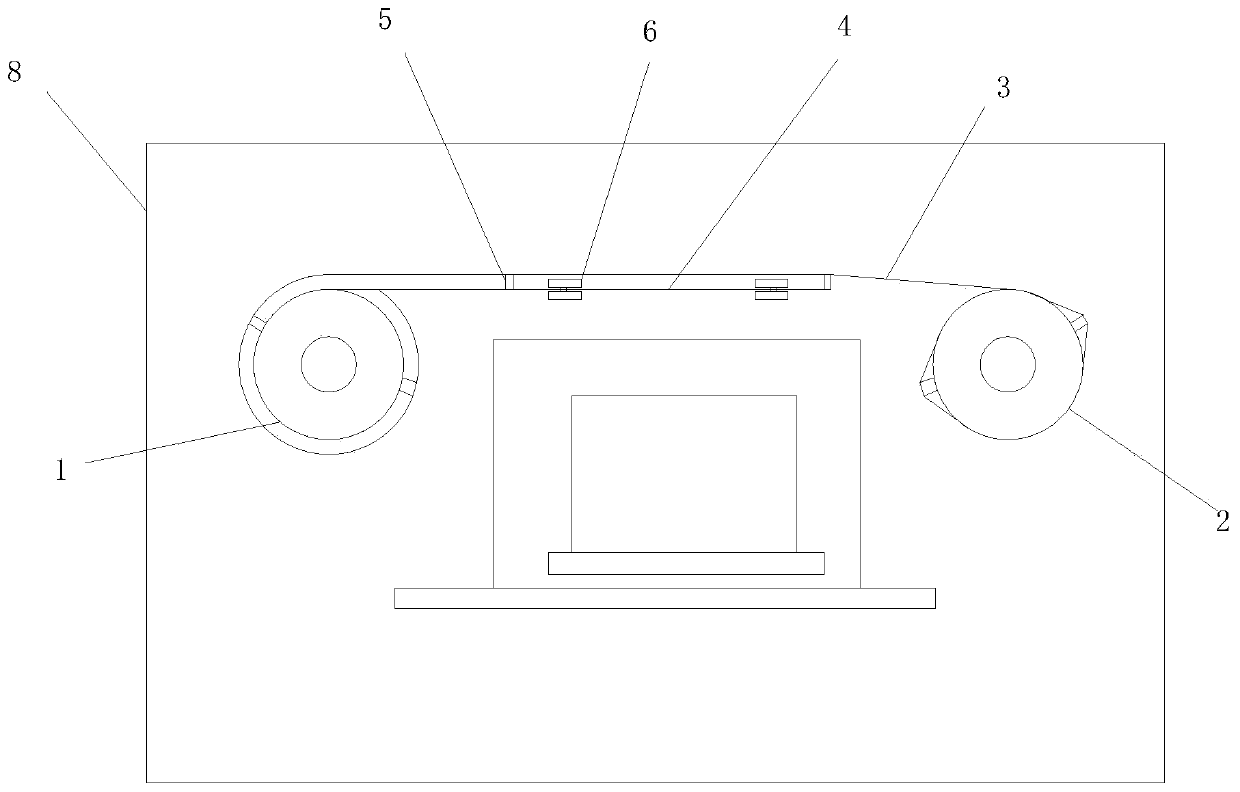

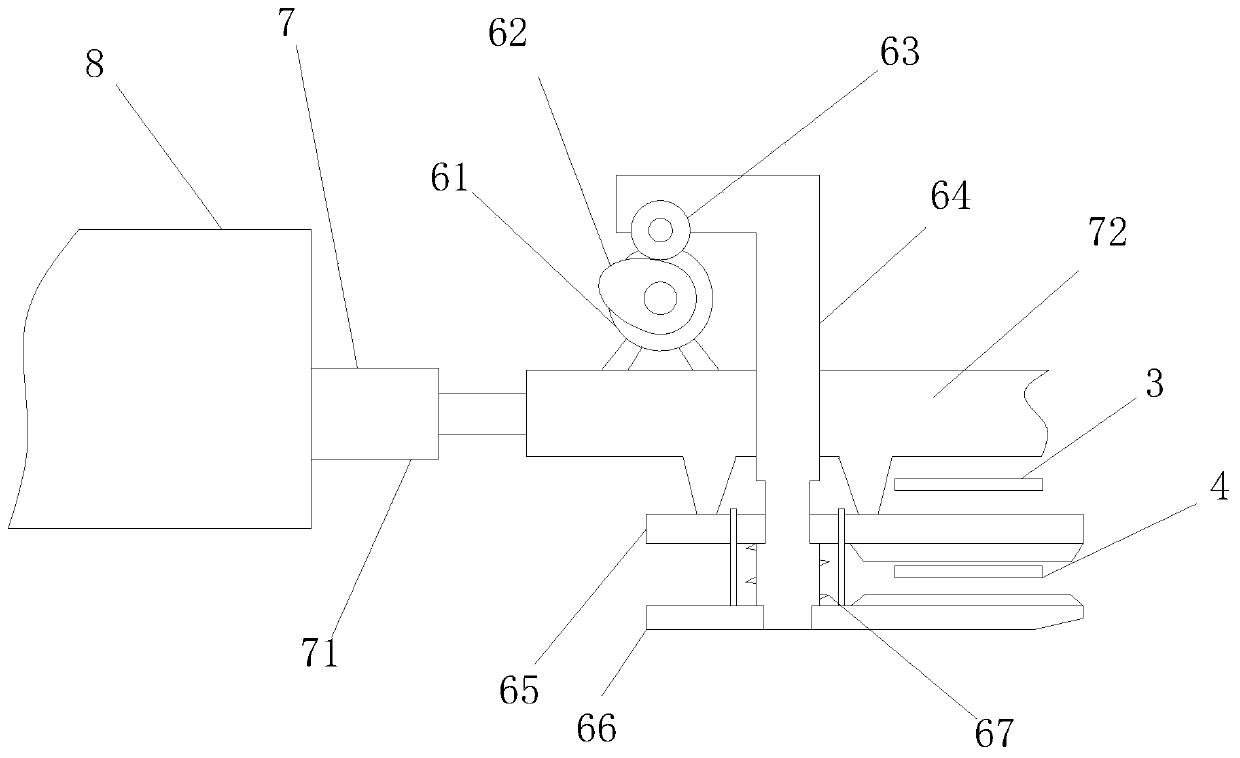

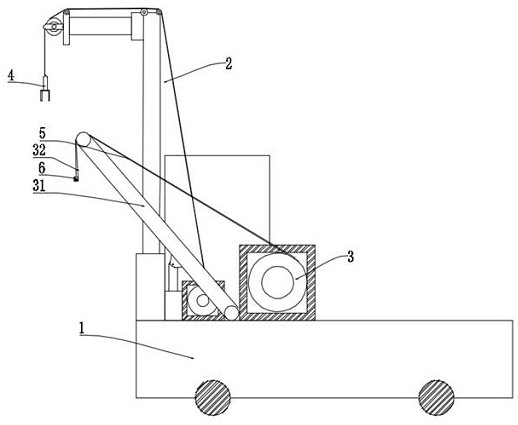

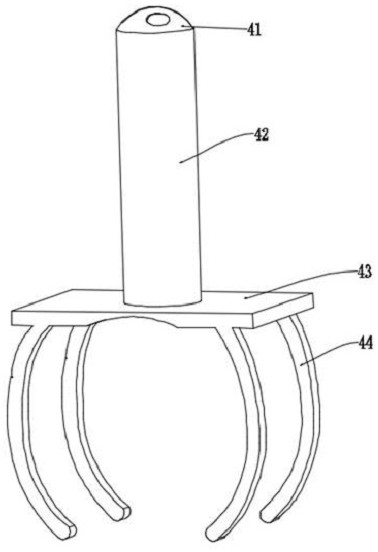

A device for affixing security inspection identification labels

The invention relates to the field of safety inspection equipment, in particular to safety inspection identifying tag gluing equipment. The safety inspection identifying tag gluing equipment comprisesa first wheel, a second wheel, an auxiliary tag, a main tag, nodes, shearing mechanisms, pushing mechanisms and a safety inspection instrument. Each shearing mechanism is provided with a motor, a cam, a rotating wheel, a lifting rod, a first cutter, a second cutter and a spring. Each pushing mechanism comprises an electric push rod and a support. By means of the equipment, tags can be glued to parcels with problems detected by a safety inspection instrument, and identification and extraction by safety inspection staff are convenient.

Owner:江苏铨通印数字印刷有限公司

Heavy pipeline hoisting mechanism for highway engineering construction

ActiveCN114772453AReduce the risk of fallingReduce stepsLoad-engaging elementsCranesHighway engineeringChain link

The invention discloses a heavy pipeline hoisting mechanism for highway engineering construction. The heavy pipeline hoisting mechanism comprises a hoisting vehicle, a first hoisting device, a second hoisting device, an inverted-U-shaped electromagnetic fastening assembly, a bilateral one-way fastening chain and an expansion type chain expander. The first hoisting device is arranged on the hoisting vehicle, the second hoisting device is arranged on the hoisting vehicle, the first hoisting device and the second hoisting device are arranged side by side, the inverted-U-shaped electromagnetic fastening assembly is movably arranged on the first hoisting device, the bilateral one-way fastening chain is movably arranged on the second hoisting device, and the inverted-U-shaped electromagnetic fastening assembly is movably arranged on the second hoisting device. And the expansion type chain expander is movably arranged on the bilateral one-way fastening chain. The invention belongs to the technical field of heavy pipeline hoisting equipment for highway engineering construction, and particularly relates to a heavy pipeline hoisting mechanism for highway engineering construction, which can easily clamp and release pipelines, can support the pipelines, is not easy to bend the pipelines and is convenient to align the pipelines.

Owner:山西路桥智慧交通信息科技有限公司

Display

The invention discloses a display, which comprises a display panel and an image acquisition device, wherein the display panel is provided with a display area, a peripheral area enclosing the display area and a through hole positioned in the peripheral area; the image acquisition device is assembled on the display panel, and comprises a signal transmission element and an image acquisition element positioned in the through hole; and the image acquisition element is connected with the signal transmission element.

Owner:AU OPTRONICS CORP

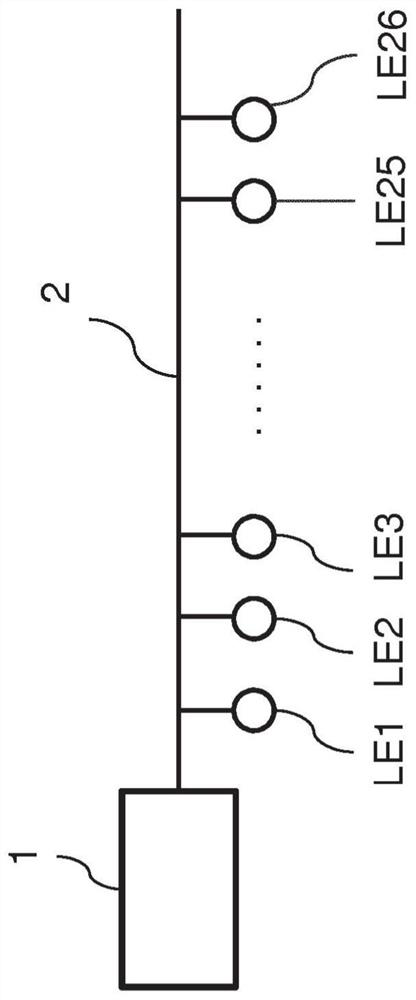

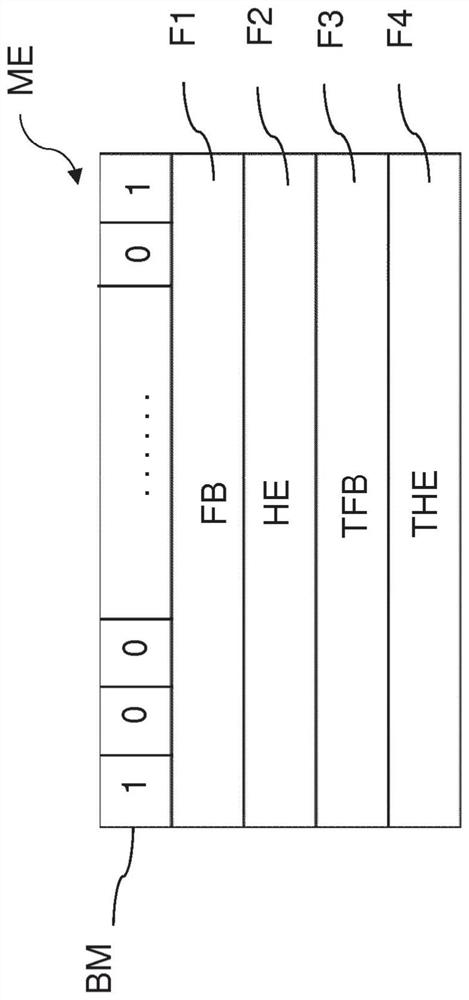

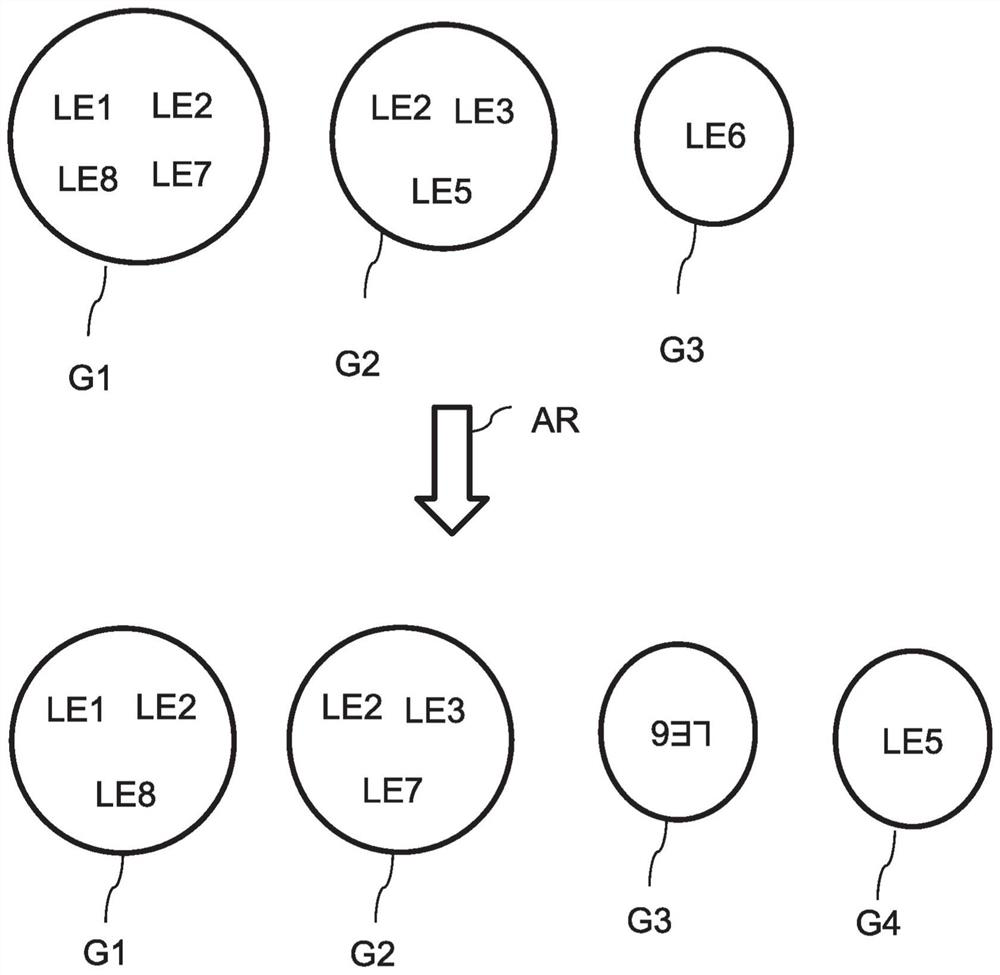

Method for operating lighting device in motor vehicle

PendingCN112041197AAdjust light distributionRaise the possibilityLighting circuitsElectrical apparatusLight equipmentControl cell

The invention relates to a method for operating a lighting device in a motor vehicle, wherein the lighting device comprises a plurality of lighting units (LE1, LE2-LE26), which are connected to a communication bus (2) in the motor vehicle and receive successive messages (ME) from a control unit (1) via the communication bus (2), the lighting units (LE1, LE2-LE26) of the plurality of lighting units(LE1, LE2-LE26) being divided into a plurality of groups (G1, G2, G3, G4), each formed of one or more lighting units (LE1, LE2-LE26), and one group (G1, G2, G3, G4) being associated with each message. Each message (ME) specifies one or more operating parameters (FB, HE, TFB, THE) for an individual lighting unit (LE1, LE2-LE26), and a lighting unit (LE1, LE2-LE26) which is in the associated group(G1, G2, G3, G4) of a received message (ME) performs its operation on the basis of the operating parameter(s) (FB, HE, TFB, THE) from the received message (ME). The method according to the invention is characterised in that the control unit (1) changes the division of the plurality of lighting units (LE1, LE2-LE26) in groups (G1, G2, G3, G4) at least once during the operation of the lighting device.

Owner:BAYERISCHE MOTOREN WERKE AG

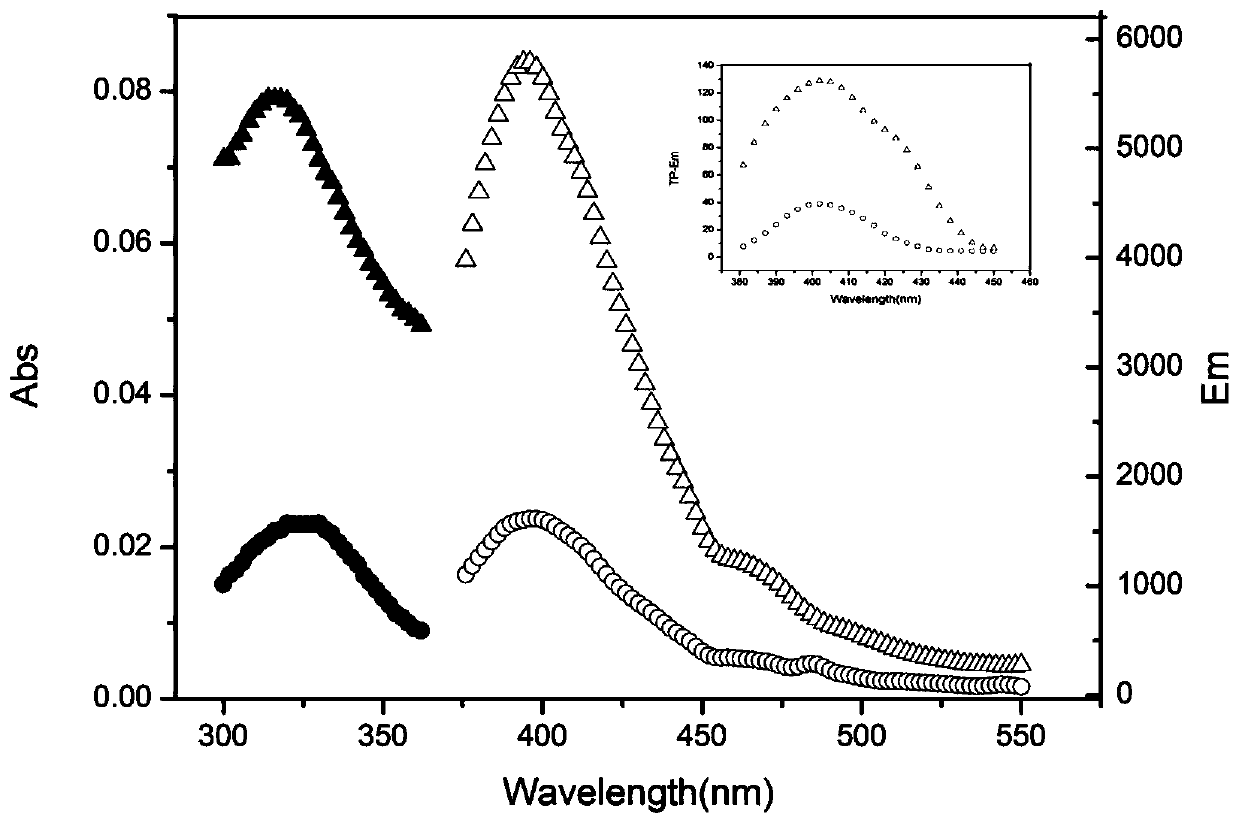

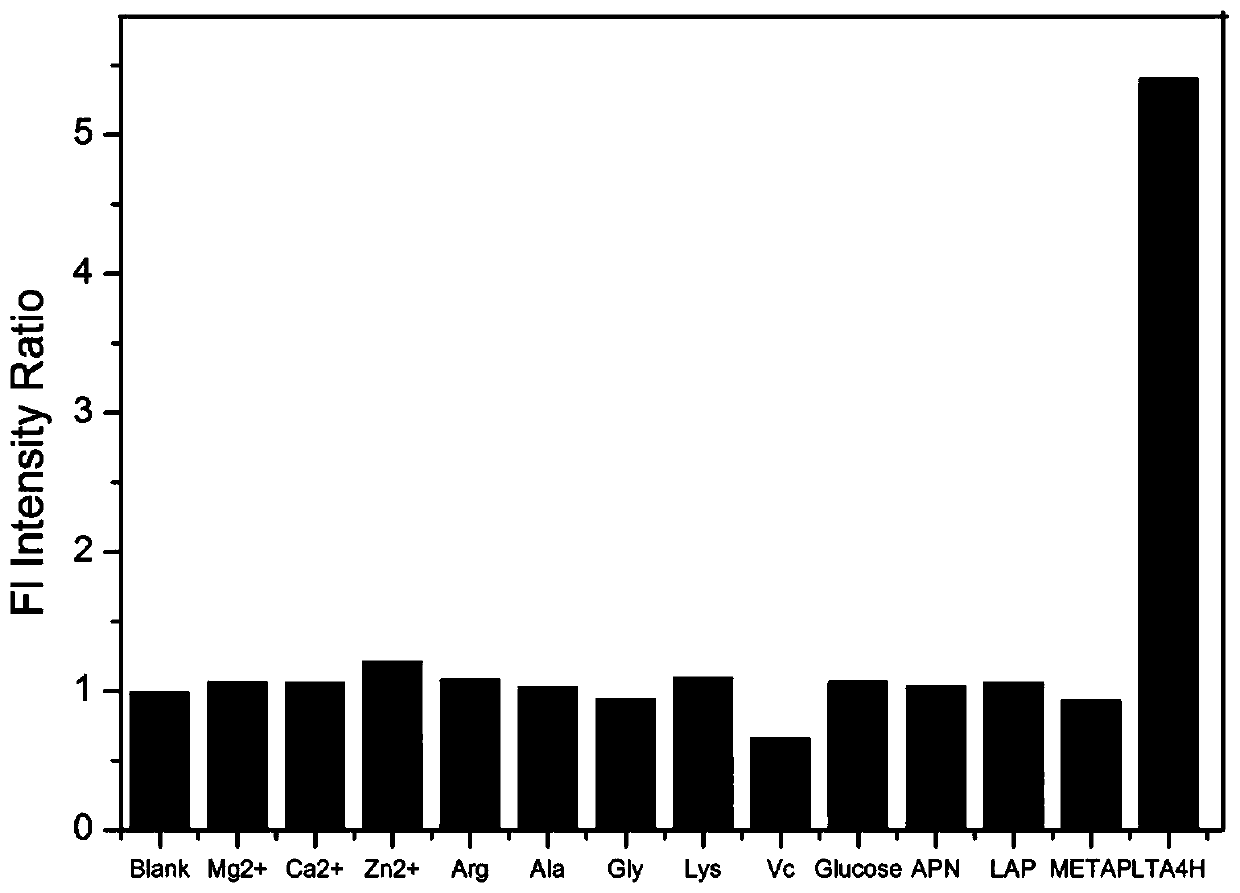

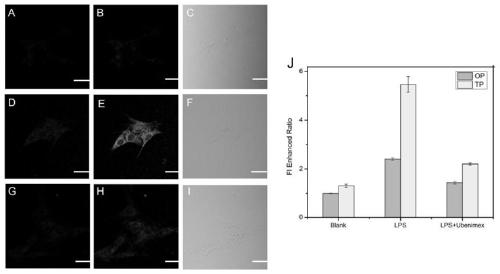

Two-photon fluorescent probe for detecting activity of pneumonia marker and synthesis method

InactiveCN108276991BLarge Stokes shiftReduce self-absorptionOrganic chemistryFluorescence/phosphorescenceFluorescent spectraFluoProbes

The invention discloses a two-photon fluorescent probe for detecting the activity of a pneumonitis marker, and a synthesis method of the two-photon fluorescent probe. The structural formula of the fluorescent probe is described in the description. When the active center of an LTA4H protein recognizes a corresponding substrate part in the probe, an amide bond is cut off, and the fluorescence of theprobe is further enhanced. The probe has good two-photon absorption property, thus having the advantages of deep tissue penetration, small damage to the living cells, and the like. According to a fluorescence spectrum, responding to LTA4H and other biologically relevant components, of the probe, the probe is proved to have high response sensitivity to the LTA4H and good selectivity. The result ofmouse nuclear lung imaging shows that the probe can quickly and accurately detect the activity of the LTA4H in real time, and can realize the detection of pneumonitis. The probe provided by the invention is novel in structure and excellent in photophysical properties.

Owner:SHANDONG NORMAL UNIV

down kneading machine

The invention discloses a feather kneading machine, which comprises a fixed toothed disc, a movable toothed disc and a motor for driving the movable toothed disc to rotate. One end of the fixed tooth disc is made into an annular fixed tooth surface, and the other end is connected with the feed inlet. One end of the movable toothed plate is made with a ring-shaped movable tooth surface, and the other end is connected with the motor through the movable plate shaft, the bearing seat, the bracket, and the transmission width of the belt; the movable plate cover is set on the movable toothed plate. Through the mutual high-speed motion between the annular fixed tooth surface and the annular movable tooth surface, the large feather flakes are kneaded to make them bulky and soft. It can be used as a filling material for down products such as seat cushions and backrests, which improves the use value of feathers and is also conducive to environmental protection. It has good economic and social benefits.

Owner:徐州腾宇羽绒制品设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com