Movement of paper shredder

A paper shredder and machine core technology, applied in grain processing, etc., can solve the problems of paper guide plate wear, paper jam, and the gap between the hob and the paper guide plate become larger, so as to achieve small motor power, reduce production costs, and good wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

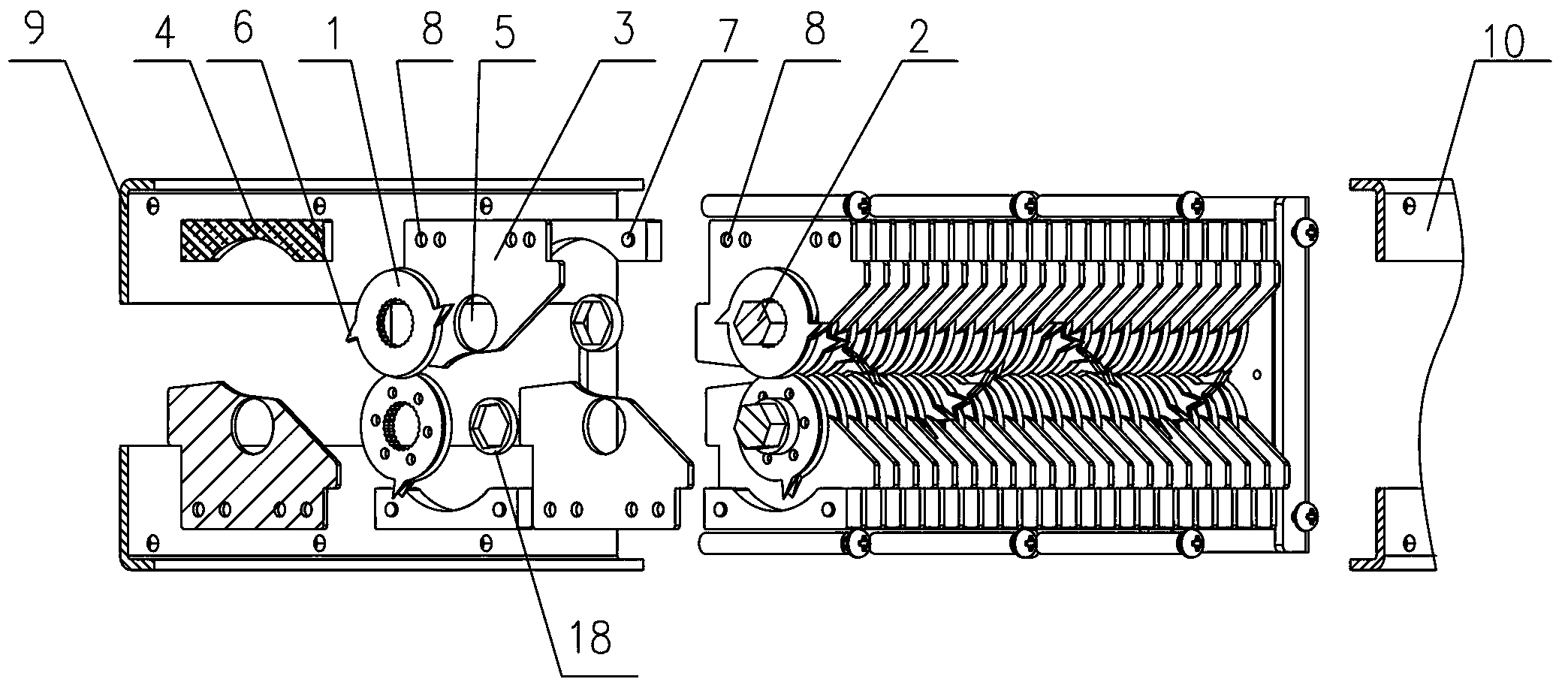

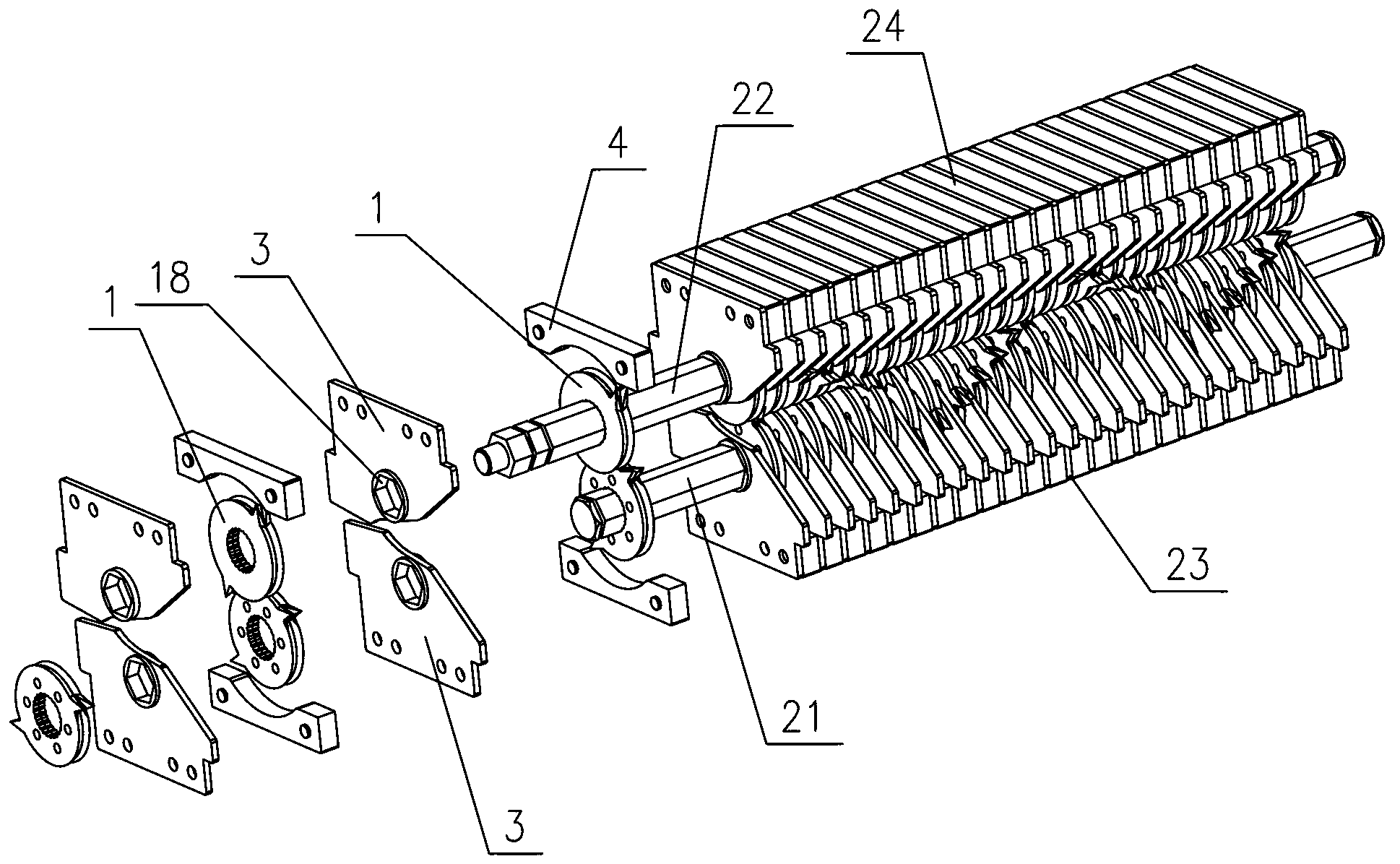

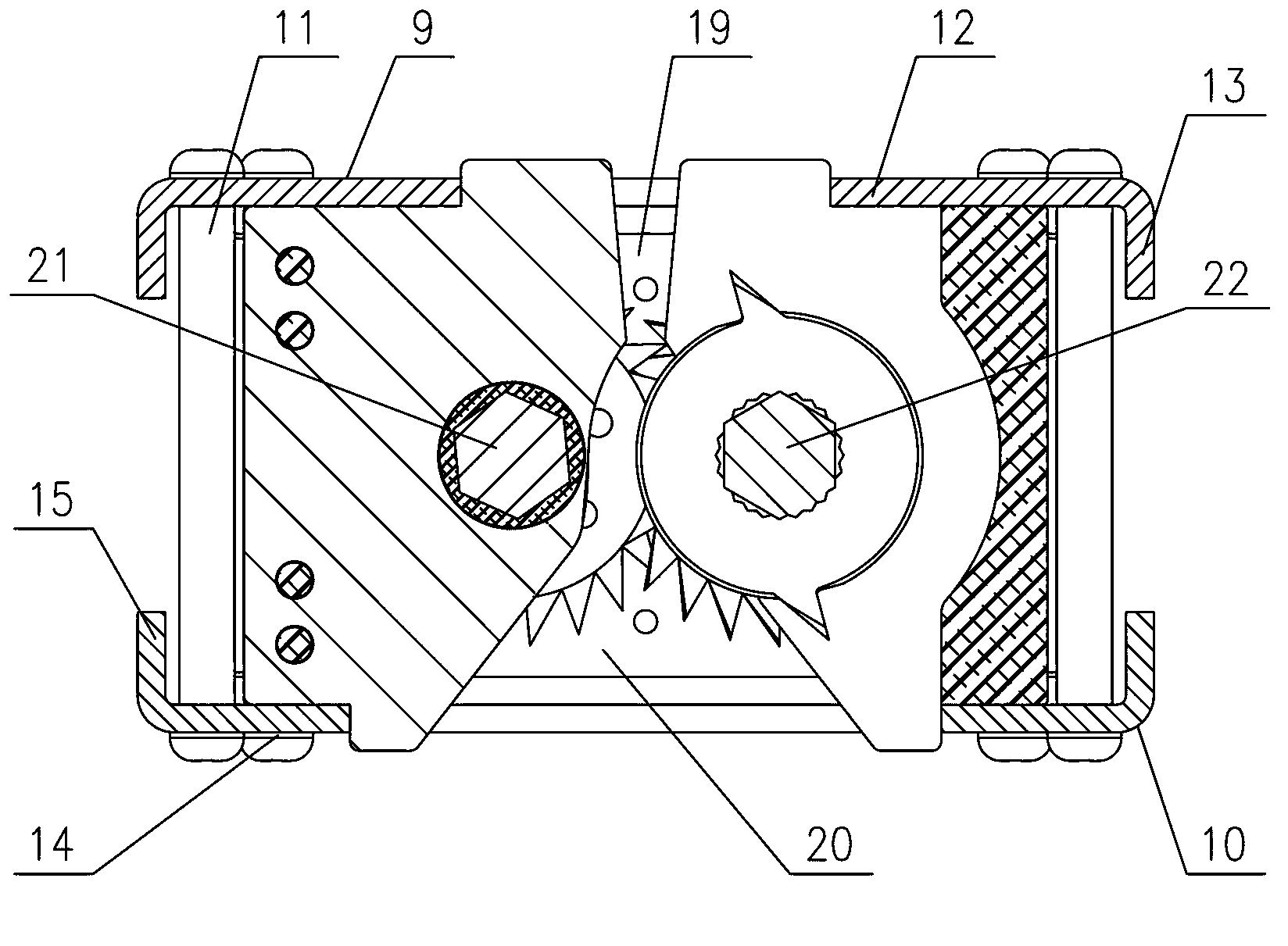

[0019] A core of a paper shredder, comprising a core body and a hob shredder mechanism, the hob shredder mechanism includes two hob shafts 2 provided with a plurality of hobs 1, the core body includes an outer support frame and a paper guide device , the paper guide device includes two paper guide board groups, the two paper guide board groups are fixed by an outer support frame, each paper guide board group is formed by a plurality of metal paper guide boards 3 arranged side by side at intervals, and there is a gap between the two metal paper guide boards 3 The separator 4 and the metal paper guide plate 3 are provided with shaft holes 5, and the hob shaft 2 passes through the shaft holes 5 of all the metal paper guide plates 3 in the row in turn, and the hob 1 is integrally provided with a cutting blade 6, and the cutting blade 6. Cooperate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com