Paper cutting device for printing

A technology of cutting device and printing paper, which is applied in metal processing and other directions, can solve the problems of not being able to manually adjust the length and width of cutting and cutting a large amount of paper at the same time, etc., and achieve the effects of long service life, not easy to deform, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

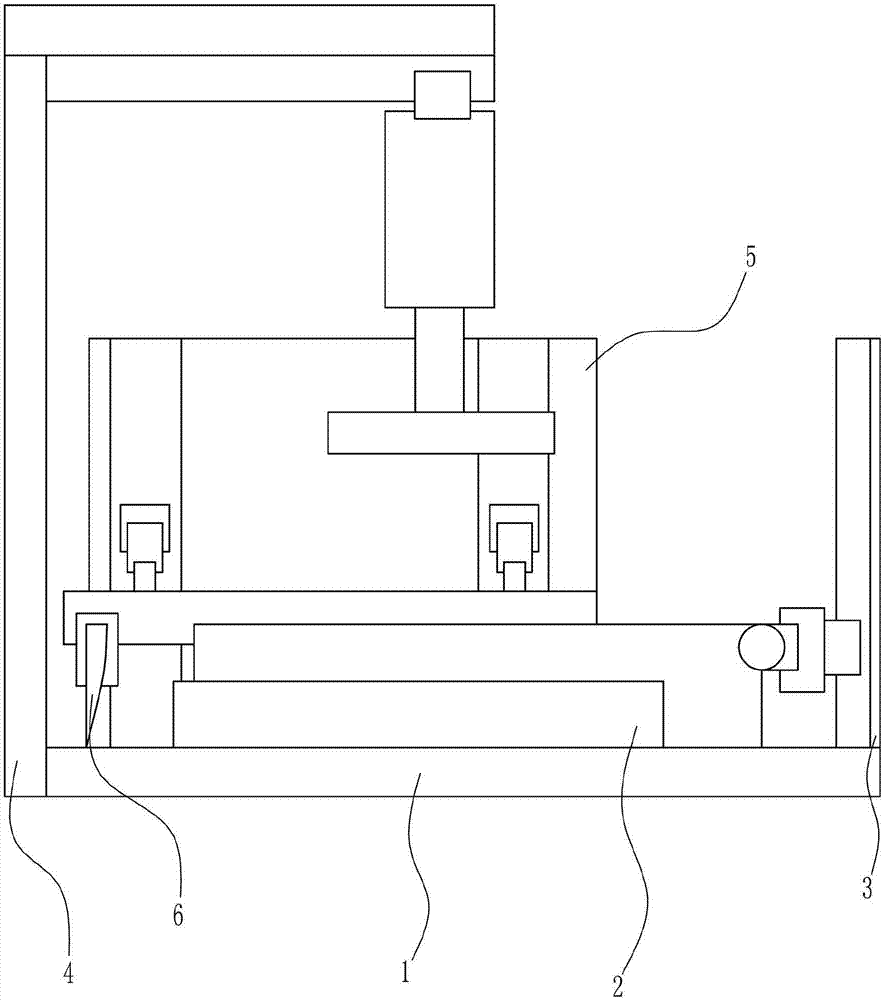

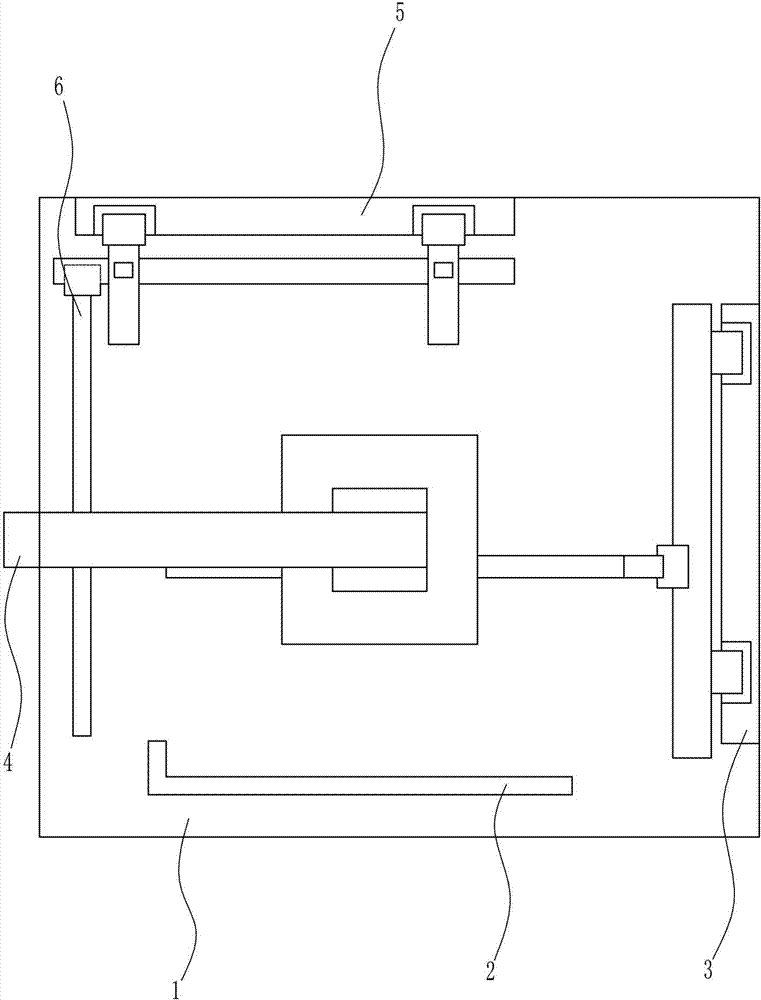

[0031] A printing paper cutting device, such as Figure 1-6 As shown, it includes a bottom plate 1, a baffle plate 2, a fixed plate 3, a pressing mechanism 4, a supporting plate 5 and a cutting mechanism 6, the middle part of the left wall of the bottom plate 1 is connected with a pressing mechanism 4, and the front side of the top of the bottom plate 1 is connected with a baffle plate 2. A fixing plate 3 is connected to the right side of the top of the bottom plate 1 , a supporting plate 5 is connected to the rear side of the top of the bottom plate 1 , and a cutting mechanism 6 is arranged between the supporting plate 5 and the fixing plate 3 .

Embodiment 2

[0033] A printing paper cutting device, such as Figure 1-6 As shown, it includes a bottom plate 1, a baffle plate 2, a fixed plate 3, a pressing mechanism 4, a supporting plate 5 and a cutting mechanism 6, the middle part of the left wall of the bottom plate 1 is connected with a pressing mechanism 4, and the front side of the top of the bottom plate 1 is connected with a baffle plate 2. A fixing plate 3 is connected to the right side of the top of the bottom plate 1 , a supporting plate 5 is connected to the rear side of the top of the bottom plate 1 , and a cutting mechanism 6 is arranged between the supporting plate 5 and the fixing plate 3 .

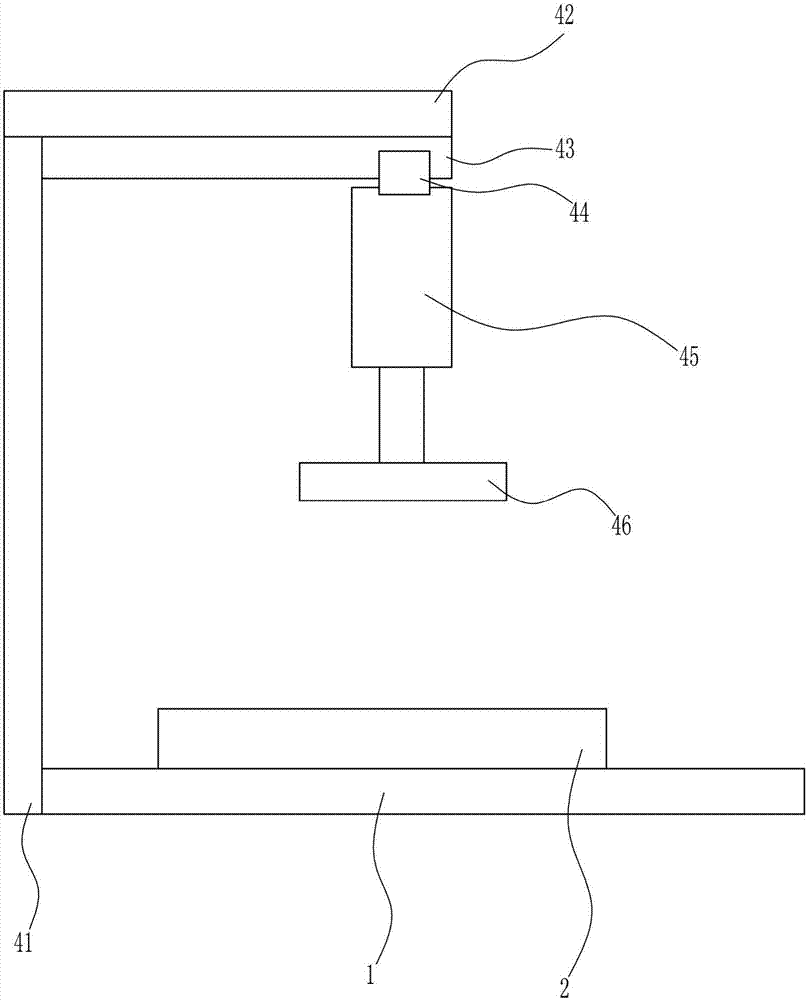

[0034] The pressing mechanism 4 includes a bracket 41, a first connecting rod 42, a first slide rail 43, a first slider 44, an electric push rod 45 and a pressure plate 46. A bracket 41 is connected to the middle of the left wall of the bottom plate 1, and a bracket 41 is connected to the top of the bracket 41. A first connecting ro...

Embodiment 3

[0036] A printing paper cutting device, such as Figure 1-6 As shown, it includes a bottom plate 1, a baffle plate 2, a fixed plate 3, a pressing mechanism 4, a supporting plate 5 and a cutting mechanism 6, the middle part of the left wall of the bottom plate 1 is connected with a pressing mechanism 4, and the front side of the top of the bottom plate 1 is connected with a baffle plate 2. A fixing plate 3 is connected to the right side of the top of the bottom plate 1 , a supporting plate 5 is connected to the rear side of the top of the bottom plate 1 , and a cutting mechanism 6 is arranged between the supporting plate 5 and the fixing plate 3 .

[0037] The pressing mechanism 4 includes a bracket 41, a first connecting rod 42, a first slide rail 43, a first slider 44, an electric push rod 45 and a pressure plate 46. A bracket 41 is connected to the middle of the left wall of the bottom plate 1, and a bracket 41 is connected to the top of the bracket 41. A first connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com