Automatic towing device and method for coal mining machine

A coal mining machine, automatic technology, applied in the direction of cable layout, cable installation, electrical components, etc. between relative moving parts, can solve problems such as falling off, cable clamps superimposed, cable clamps overturned on the conveyor, etc., to achieve mobile The effect of fast speed, avoiding multi-layer superposition, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

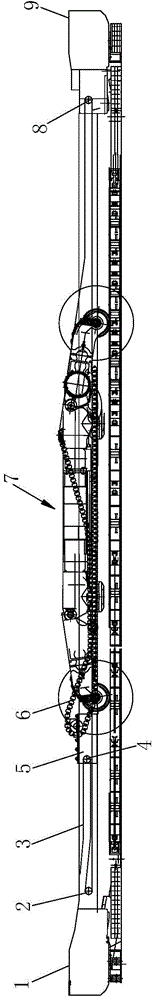

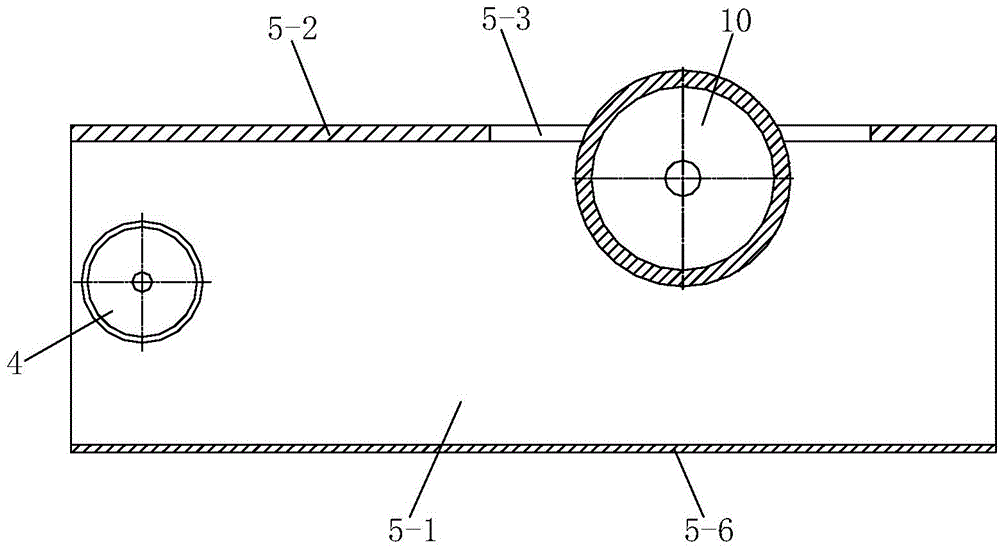

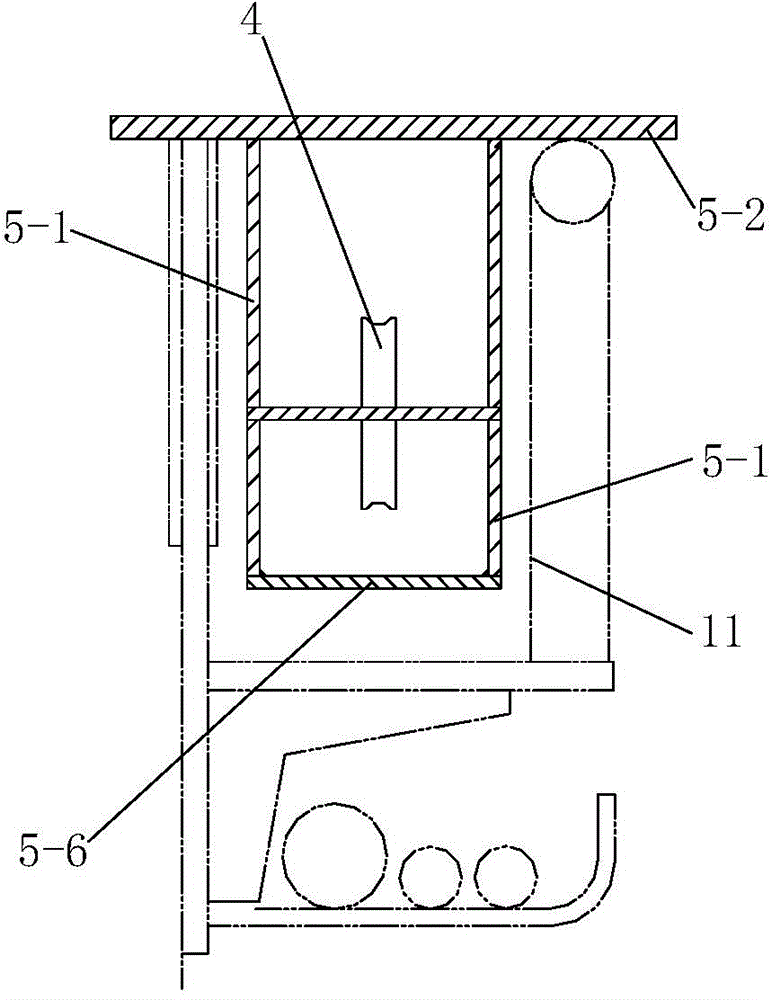

[0034] Such as figure 1 A coal shearer automatic towing cable device shown includes a first fixed pulley 2, a second fixed pulley 8, a pull rope 3 and a moving cable frame 5 for moving along the conveyor cable trough 11, the first The fixed pulley 2 is installed on the conveyor nose 1, the second fixed pulley 8 is installed on the conveyor tail 9, and the moving cable frame 5 is arranged between the first fixed pulley 2 and the shearer 7. A movable pulley 4 is installed on the mobile tow cable frame 5, and a guide roller 10 for guiding the cable splint 6 of the coal mining machine is arranged on the mobile tow cable frame 5, and the cable splint 6 of the coal shearer bypasses the guide roller 10 is connected to the coal shearer 7, one end of the pulling rope 3 is fixed on the conveyor nose 1, and the other end of the pulling rope 3 bypasses the movable pulley 4, the first fixed pulley 2 and the The second fixed pulley 8 is also fixed on the shearer 7 . In this embodiment, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com