Flocked yarn gluing equipment and gluing method

A technology of yarn and velvet yarn, which is applied in flocking yarn gluing equipment and gluing field, which can solve the problems affecting flocking product feel, flexibility, flocking fastness, easy to remove fluff, etc., to meet the technical requirements The effect of production demand, guaranteed gluing quality and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the following examples further describe the present invention in detail.

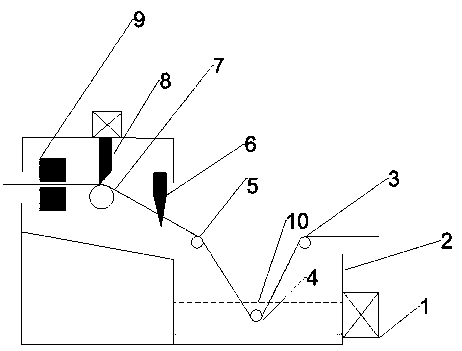

[0023] A gluing equipment for flocking yarn, including an ultrasonic micro-nano bubble generating device 1, a glue tank 2, a first roller 3, a second roller 4, a third roller 5, a low-pressure nozzle 6, and a fourth roller 7. Pneumatic lifting scraper 8 and adjustable width Teflon foam material 9. Among them: the first roller 3 and the third roller 5 are located above the glue 10, directly contacting the yarn, the second roller 4 is immersed in the glue 10, and the fourth roller 7 is provided with a pneumatic lifting scraper 8, which can be used by the pressure of the scraper. To strengthen the penetration of the glue on the material, the low-pressure nozzle 6 is set between the third roller 5 and the fourth roller 7. There are two nozzles in total, which are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com