Method for detecting bottom outline of contact plug

A detection method and technology for contact plugs, which are used in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as inability to obtain photos and inability to obtain contact plug bottom contour detection results, etc. Achieve the effect of reducing charge trapping effect, good test environment and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0042] reference Figure 5A , First provide a wafer; the wafer includes: a semiconductor substrate 21 formed with an active region 22; a first dielectric layer 23 on the semiconductor substrate 21; penetrating through the first dielectric layer 23 and with the The contact plug 24 electrically connected to the source region 22; the second dielectric layer 25 formed on the first dielectric layer 23 and the contact plug 24; and the second dielectric layer 25 penetrates the second dielectric layer 25 and is in contact with the The metal layer 26 to which the plug 24 is electrically connected.

[0043] Wherein, the material of the first dielectric layer 23 and the second dielectric layer 25 is one or a combination of silicon oxide or silicon nitride, and the material of the contact plug 24 is tungsten, copper, or aluminum. The contact plug 24 may be a trapezoidal plug.

[0044] reference Figure 5B , The metal layer 26 and the second dielectric layer 25 are removed by chemical mechanic...

no. 2 example

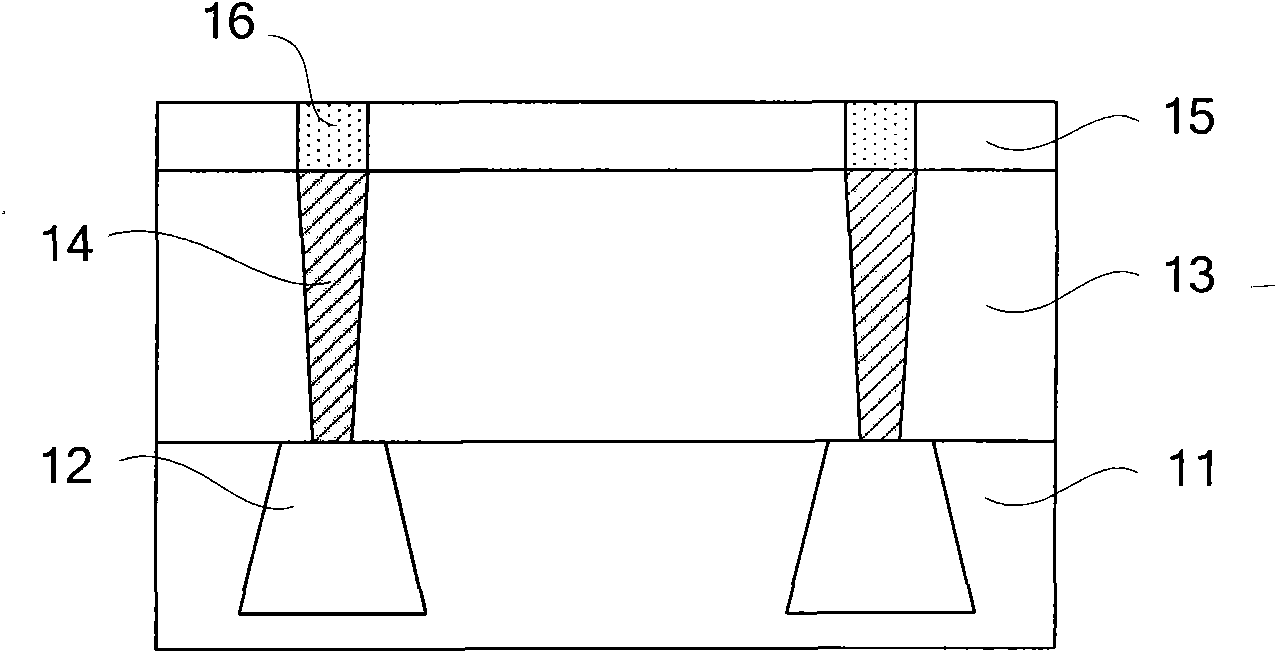

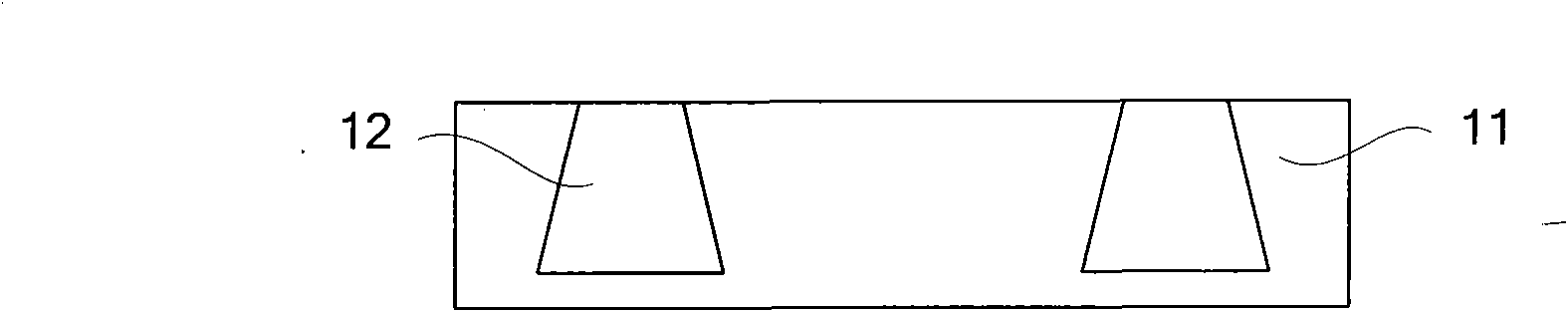

[0054] reference Figure 6A , First provide a wafer; the wafer includes: a semiconductor substrate 31 formed with an active region 32; a first dielectric layer 33 on the semiconductor substrate 31; penetrating the first dielectric layer 33 and interacting with the A contact plug 34 electrically connected to the source region 32; a second dielectric layer 35 formed on the first dielectric layer 33; and a second dielectric layer 35 that penetrates the second dielectric layer 35 and is electrically connected to the contact plug 34 The metal layer 36.

[0055] In order to reduce the contact resistance, the wafer further includes a metal silicide layer 37 formed in the active region 32, and the contact plug 34 is electrically connected to the active region 32 through the metal silicide layer 37. The material of the metal silicide layer 37 may be cobalt silicide, titanium silicide or platinum silicide.

[0056] reference Figure 6B , The metal layer 36 and the second dielectric layer 35...

no. 3 example

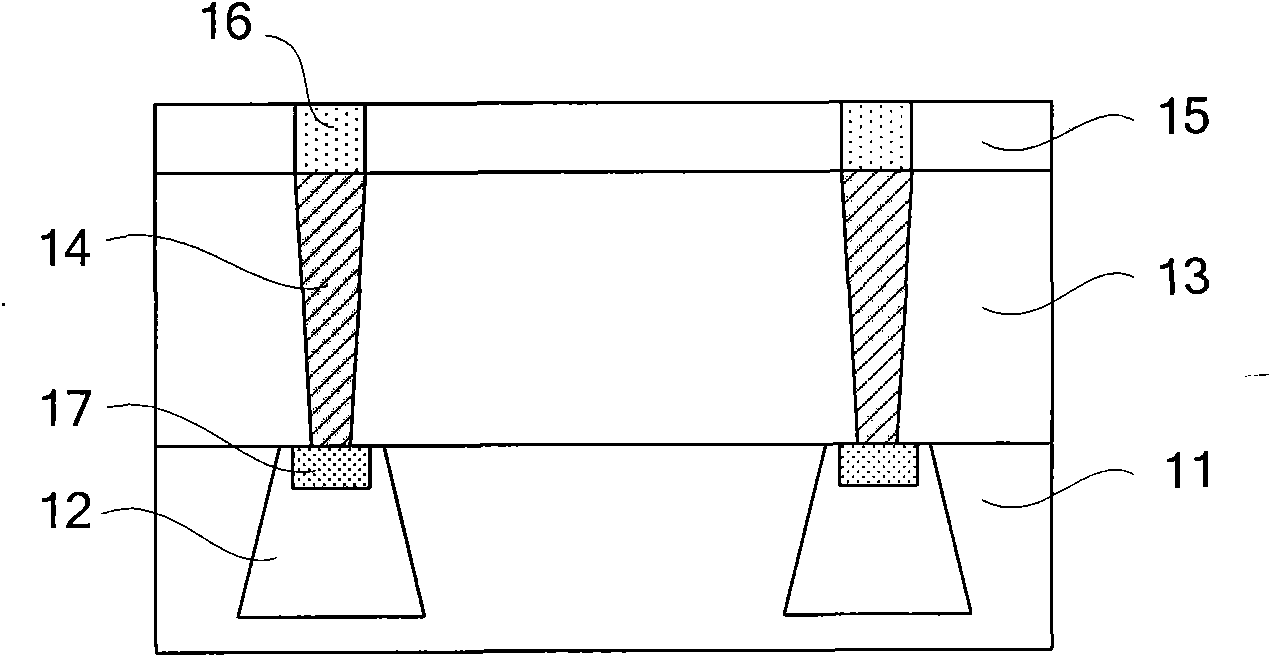

[0063] reference Figure 7A , First provide a wafer; the wafer includes: a semiconductor substrate 41 formed with an active region 42; a first dielectric layer 43 on the semiconductor substrate 41; penetrating the first dielectric layer 43 and interacting with the A contact plug 44 electrically connected to the source region 42; a second dielectric layer 45 formed on the first dielectric layer 43; and a second dielectric layer 45 penetrating through the second dielectric layer 45 and electrically connected to the contact plug 44 The metal layer 46.

[0064] In order to reduce the contact resistance, the wafer may also include a doped region 47 formed in the active region 42. The contact plug 44 is partially located in the active region 42 and passes through the doped region 47 and the doped region 47. The active region 42 is electrically connected, wherein the doped region 47 can be formed by ion implantation.

[0065] reference Figure 7B , The metal layer 46 and the second diele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com