Manufacturing method for similar-disc cross-section forge piece with height-diameter ratio smaller than 0.3

A manufacturing method and a technology of height-to-diameter ratio, applied in the field of forging, can solve problems such as long manufacturing cycle, low material utilization rate, and large forging size, so as to save equipment investment and equipment loss, improve service life and comprehensive performance, and material utilization rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

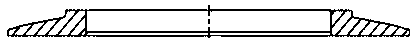

[0015] A method for manufacturing a disc-like section forging with an aspect ratio less than 0.3, the steps are as follows:

[0016] First, the alloy ingot is heated to 1150-1180°C, and then the rolled billet is manufactured through upsetting, punching and hole-enlarging processes, and then the rolled billet is heated to 1150-1180°C in the furnace, and the rolled billet is taken out and placed on the On the ring rolling machine, put the main roller bushing and the core roller bushing on the main roller and the core roller respectively, start the ring rolling machine, start to rotate under the drive of the main roller and the core roller, and the tapered roller presses on the end surface of the billet to start After rolling, after the size is in place, close the ring rolling machine to obtain the special-shaped ring after the ring is rolled, and then process it with a small allowance after heat treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com