Patents

Literature

36 results about "Visual servoing system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

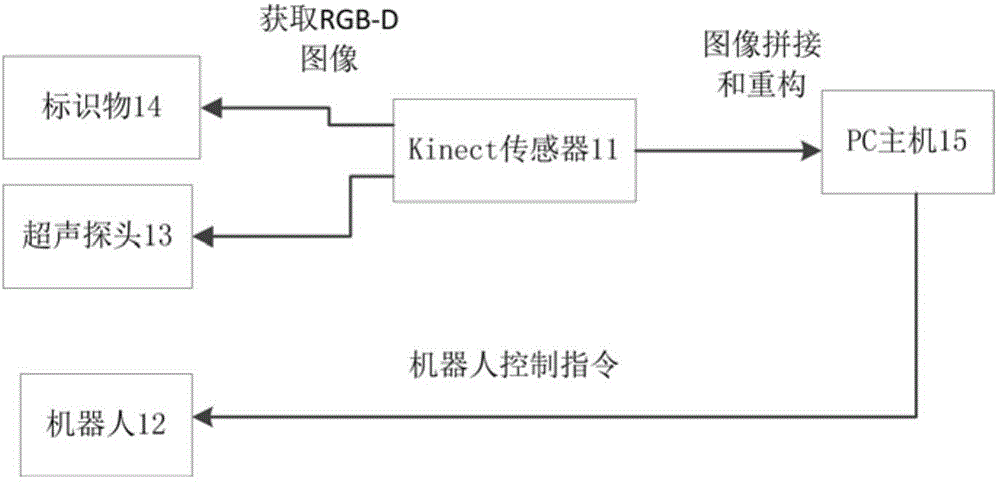

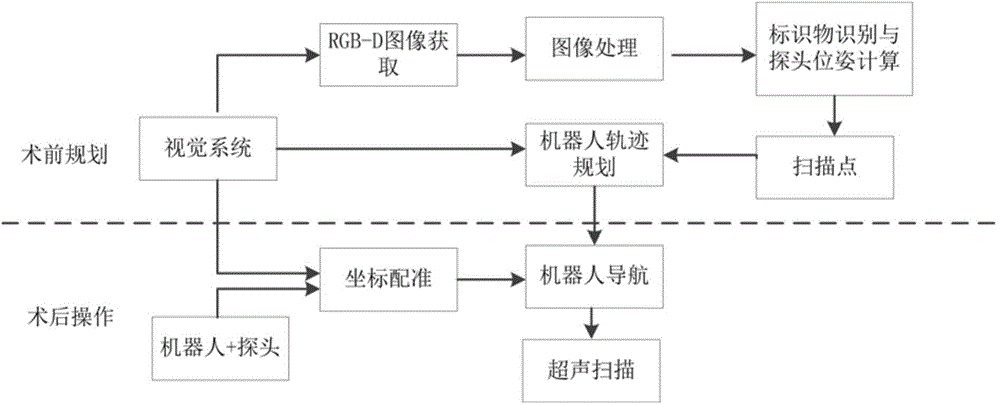

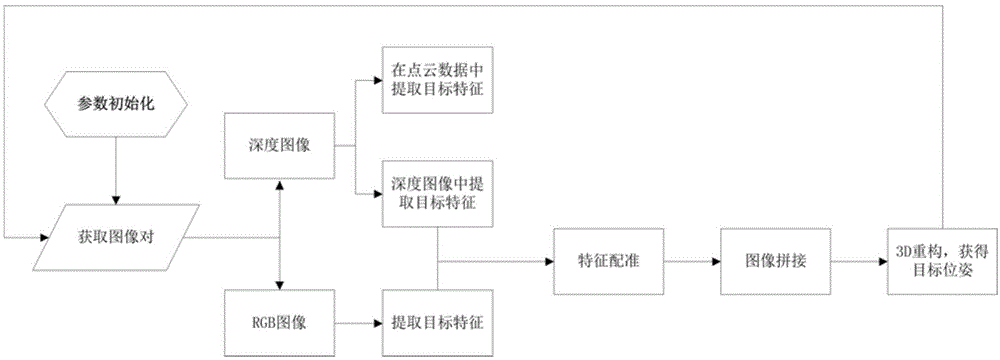

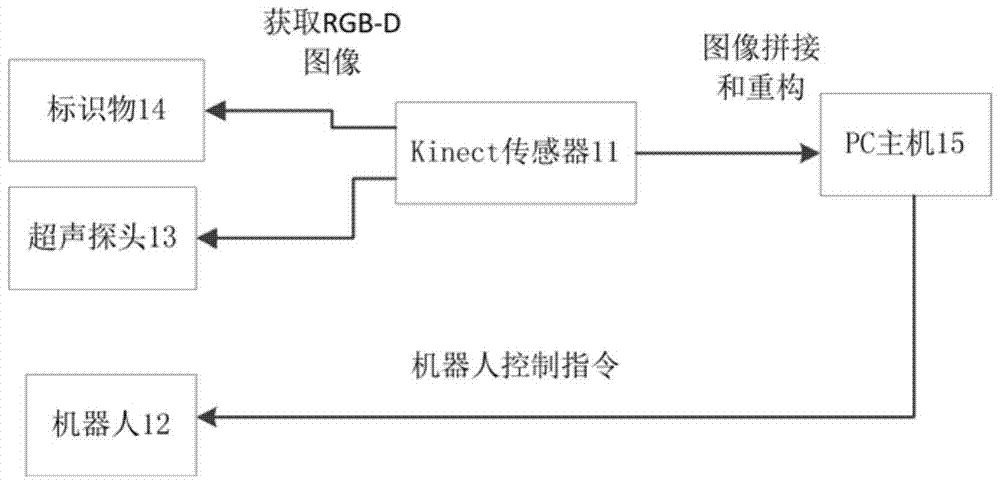

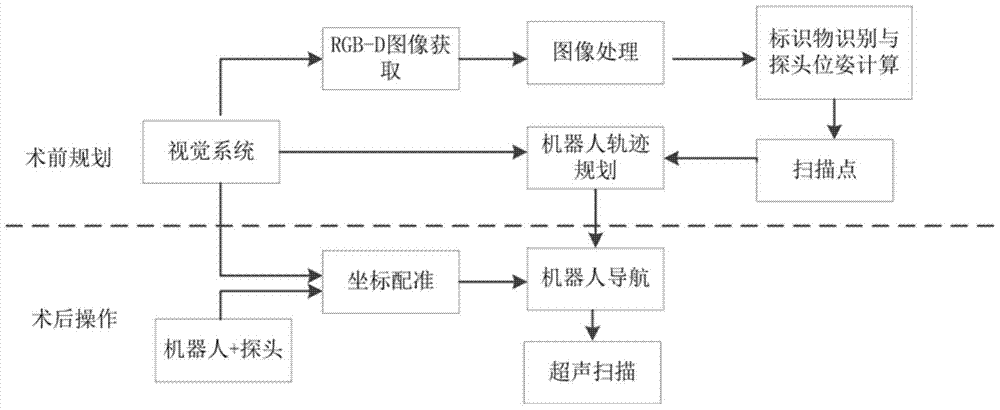

Auxiliary ultrasonic scanning system of robot based on RGB-D sensor

ActiveCN104856720AReasonable structureImprove performanceUltrasonic/sonic/infrasonic diagnosticsSurgeryVisual servoing systemColor image

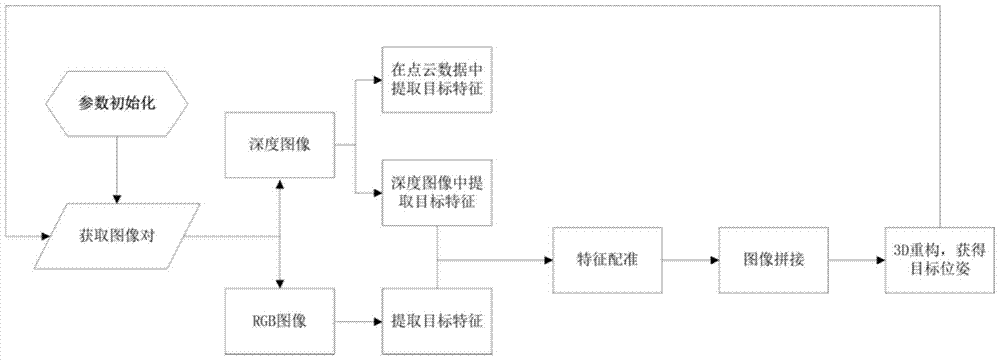

Provided is an auxiliary ultrasonic scanning system of a robot based on an RGB-D sensor. The auxiliary ultrasonic scanning system comprises a Kinect sensor, the robot, an ultrasonic probe, a marker and a host and is characterized in that the Kinect sensor serves as a visual servo system of the robot; the ultrasonic probe is clamped on a mechanical arm of the robot; the marker is fixed onto the ultrasonic probe; the visual servo system of the robot is utilized for synchronously acquiring an RGB color image and a depth image and sending images to the host; the host finishes following processes such as image stitching operation and image three-dimensional reconstruction; according to image pairs acquired by the visual servo system, the marker fixed onto the ultrasonic probe is recognized and positioned by the host; according to a recognition-based positioning result, the position and the posture of the ultrasonic probe are calculated; and the host is used for sending a control instruction to the robot so that the mechanical arm of the robot is controlled to reach at the specified position for carrying out ultrasonic scanning operation. The auxiliary ultrasonic scanning system of the robot based on the RGB-D sensor is advantaged by being reasonable in design, reliable in performance, high in automated degree and detection efficiency and low in cost.

Owner:NORTHEAST DIANLI UNIVERSITY

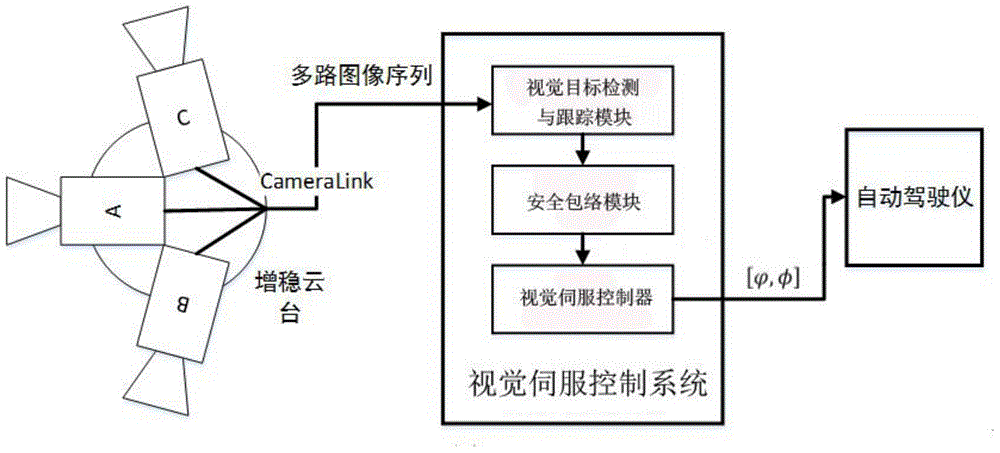

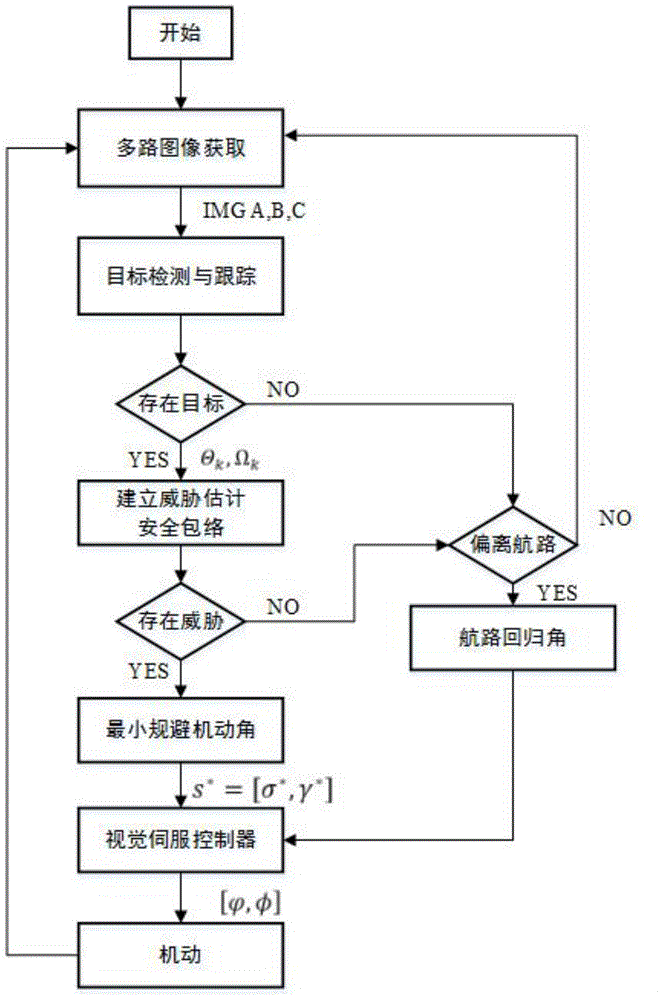

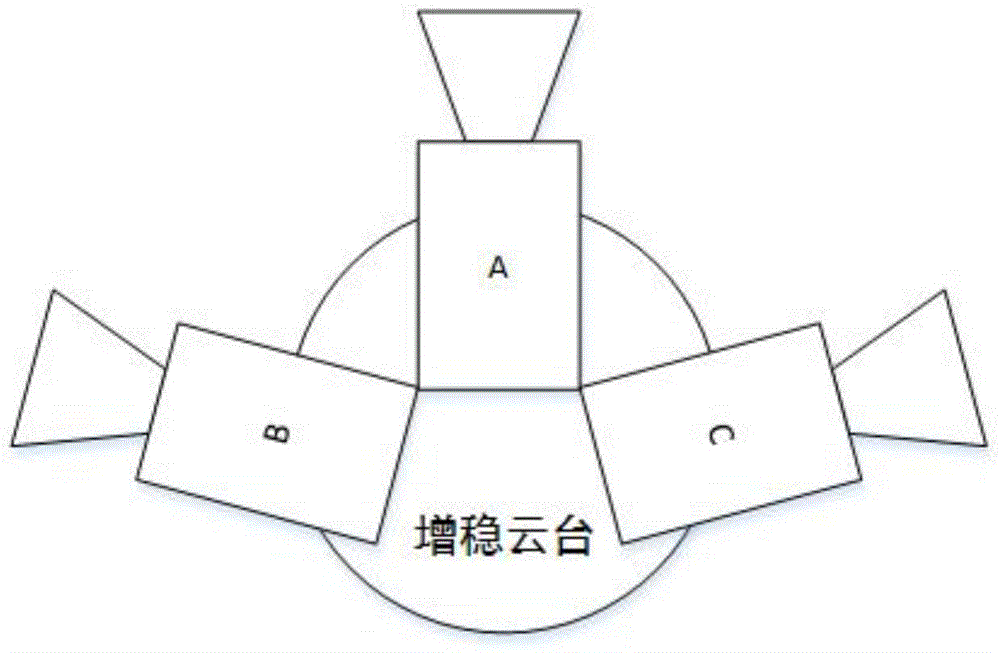

Visual servo-based sense-and-avoid method and system

ActiveCN104102218AFast perceptionImprove airspace flight safety capabilitiesPosition/course control in two dimensionsVisual servoing systemFlight safety

The invention provides a visual servo-based sense-and-avoid system. The visual servo-based sense-and-avoid system includes an unmanned aerial vehicle, an image acquisition system, a visual servo control system and a navigation positioning system; the visual servo system includes a visual target detection and tracking module, a security envelope module and a visual servo controller. The invention also provides a visual servo-based sense-and-avoid method. With the visual servo-based sense-and-avoid method and system of the invention adopted, rapid sensing for surrounding airspace environment can be realized; avoidance maneuvering for space flight targets can be completed independently and autonomously without intervention and operation of ground operation personnel required under a situation that no distance measuring sensor is installed. The visual servo-based sense-and-avoid method and system of the invention have the advantages of low load requirements, high control precision and high intelligence, and can improve the airspace flight safety capacity of the unmanned aerial vehicle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

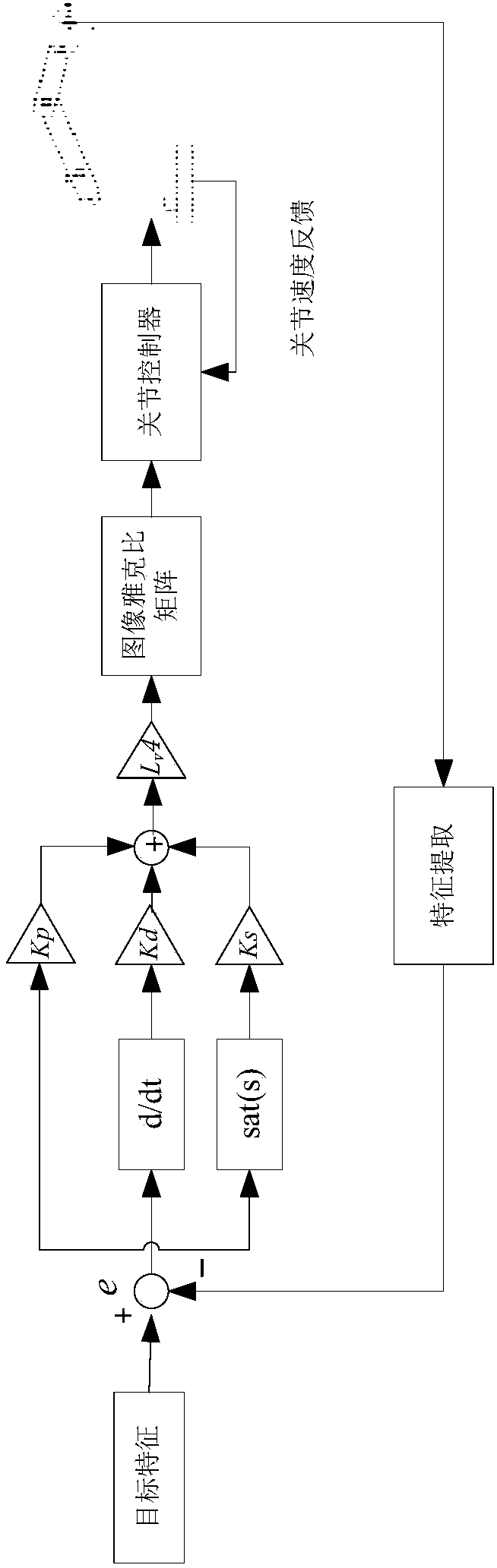

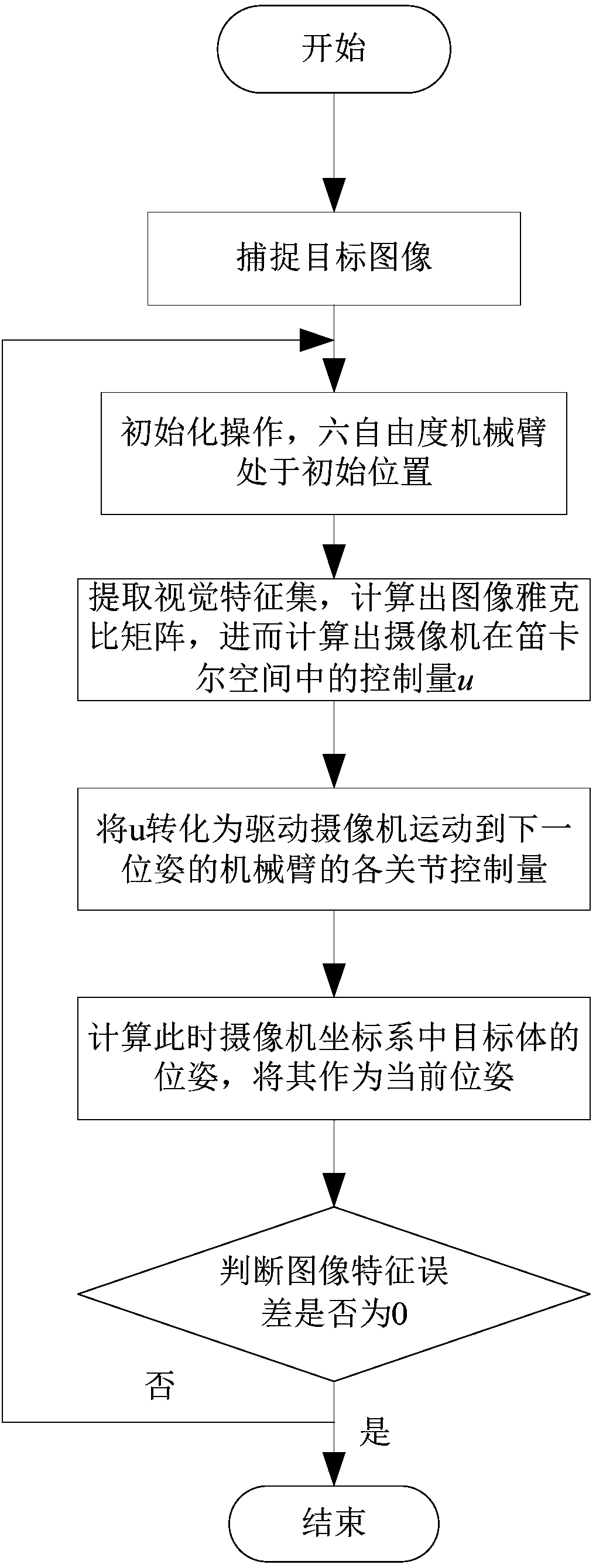

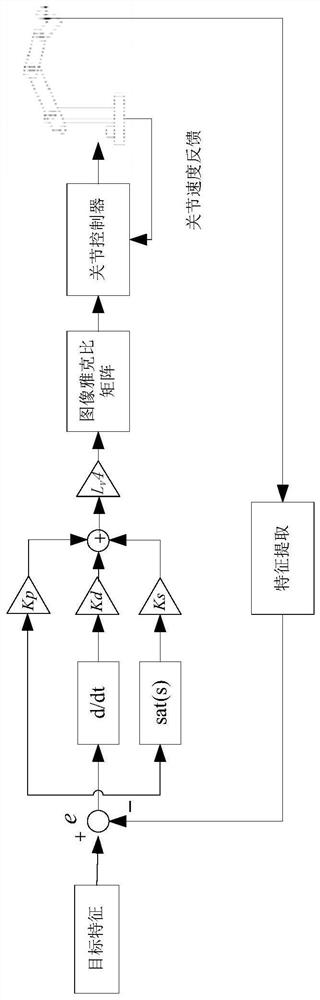

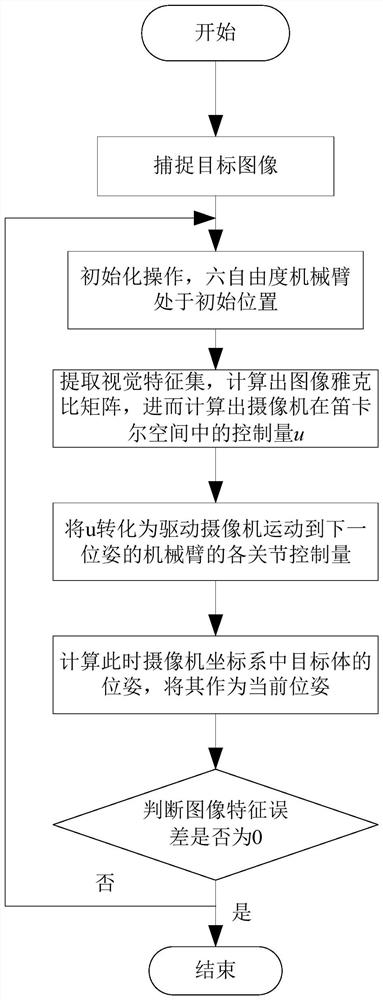

PD-SMC control method of visual servo system based on eye-on-hand structure

ActiveCN107627303AGuaranteed availabilityDealing with uncertaintyProgramme-controlled manipulatorAdaptive controlVisual servoing systemProportional control

The invention relates to the field of visual servo systems, in particular to a PD-SMC control method of a visual servo system based on an eye-on-hand structure so as to solve the problems of uncertainty and large computation amount existing in an existing visual servo system control method. The method comprises the steps of (1) setting an expected image and collecting feature points of the expected image as an expected visual feature set; (2) conducting projection transformation on a target expected image with the current state of the relative poses of a camera and a target body to obtain a current image of the camera; (3) adopting the PD-SMC method for a visual servo controller part and adopting a proportional control method for a joint controller part; (4) extracting a visual feature setfrom the current image, computing a jacobian matrix of the image and then computing the controlled quantity u of the camera in a Cartesian space; and (5) computing the pose of the target body in a camera coordinate system, and repeating the operations with the pose as the current pose until the error is zero. The PD-SMC control method can be applied to target grabbing equipment.

Owner:HARBIN ENG UNIV +3

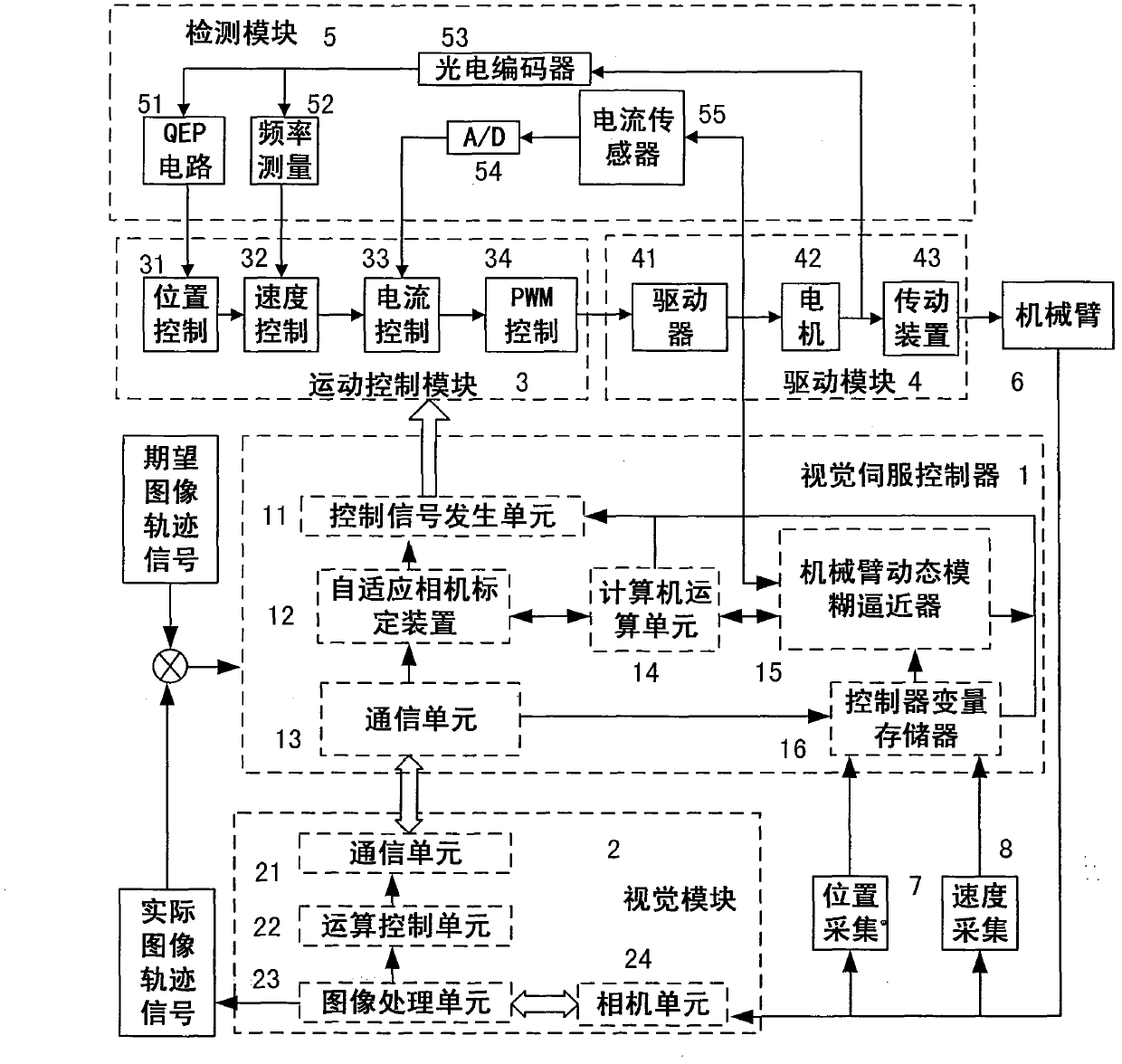

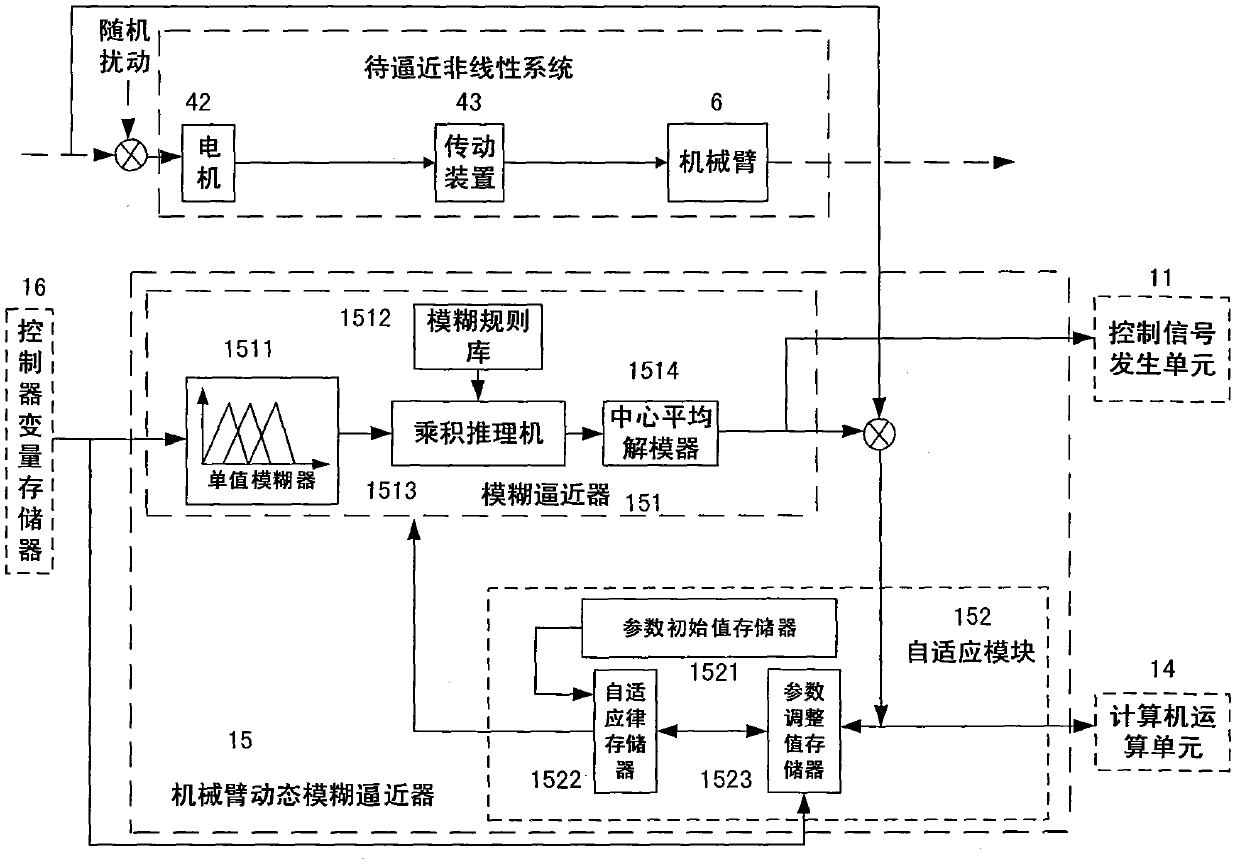

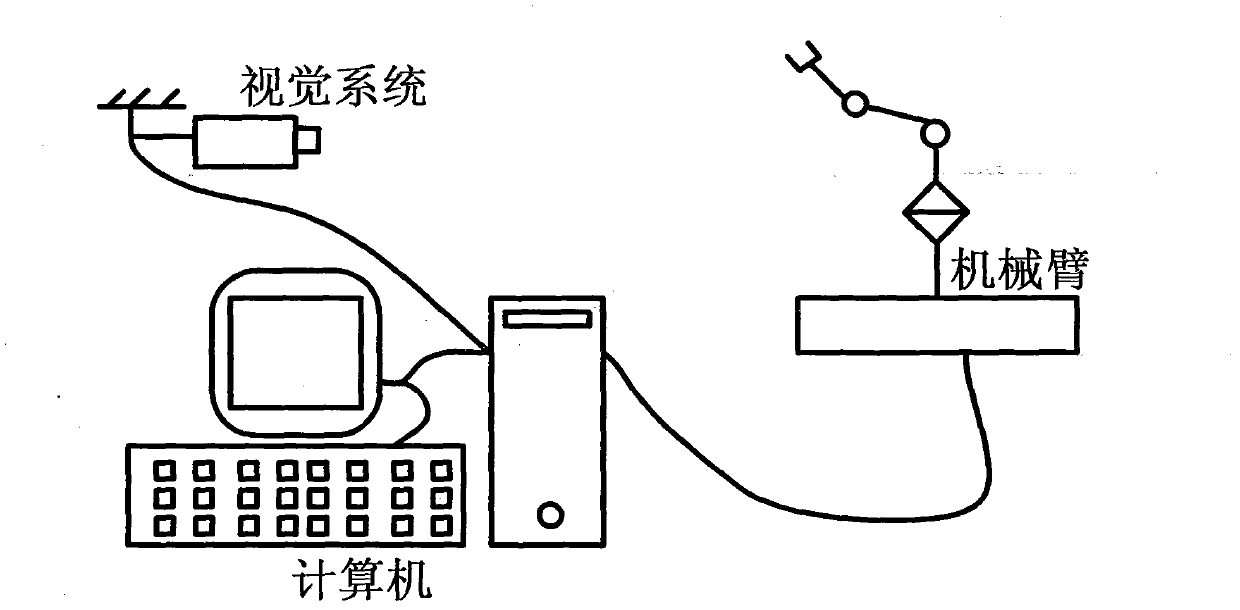

Mechanical arm dynamic fuzzy approximator based on visual servo system

InactiveCN104942809AGuaranteed performanceEffective approximationProgramme-controlled manipulatorAdaptive controlVisual servoingVision based

The invention relates to a mechanical arm dynamic fuzzy approximator based on a visual servo system. The visual servo mechanical arm system is composed of a visual servo controller, a visual module, a motion control module, a driving module, a mechanical arm module, a speed and position collecting module and a detecting module; the mechanical arm dynamic fuzzy approximator in the visual servo controller is used for approximating the unknown mechanical arm dynamic state which is subjected to random disturbance; the approximator comprises a fuzzy approximator body and a self-adaption module, the self-adaption module regulates parameters in the fuzzy approximator body on line to enable the error between the output of the fuzzy approximator body and the mechanical arm system to be approximated to always keep within the bounded errors, and the error tends to zero along with time; on the condition that the mechanical arm dynamic characteristics are unknown and are subjected to random disturbance, the stability of the system is guaranteed, and the trajectory tracking precision on an image plane is improved.

Owner:GUANGDONG UNIV OF TECH

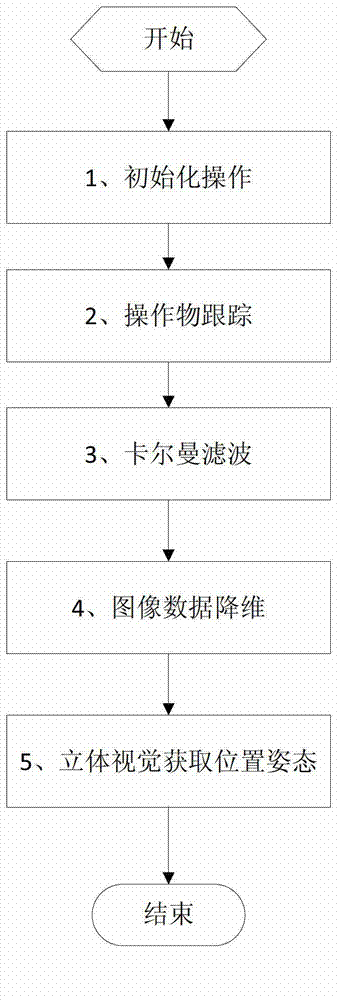

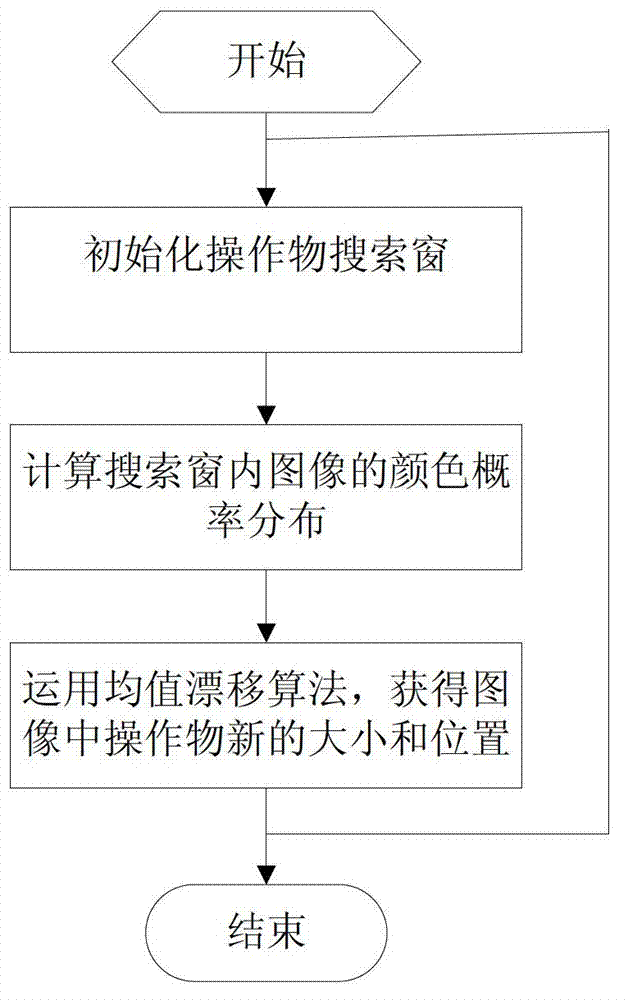

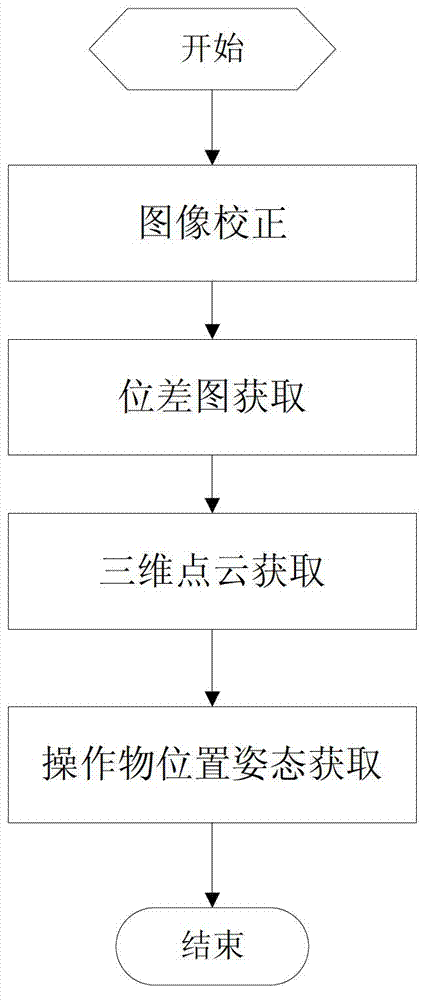

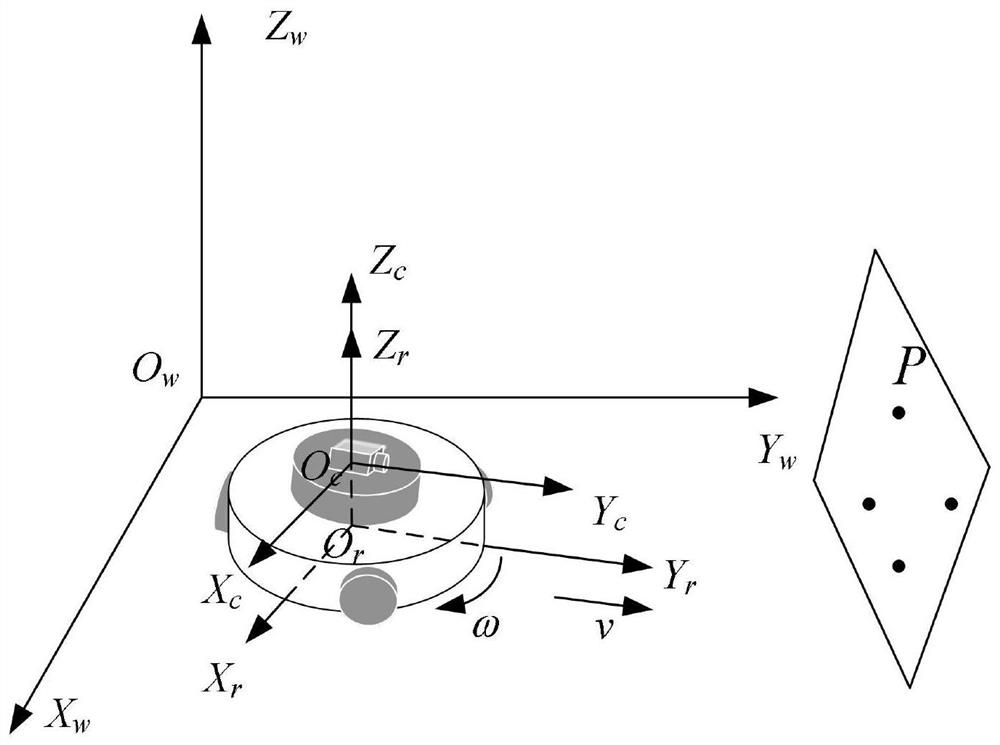

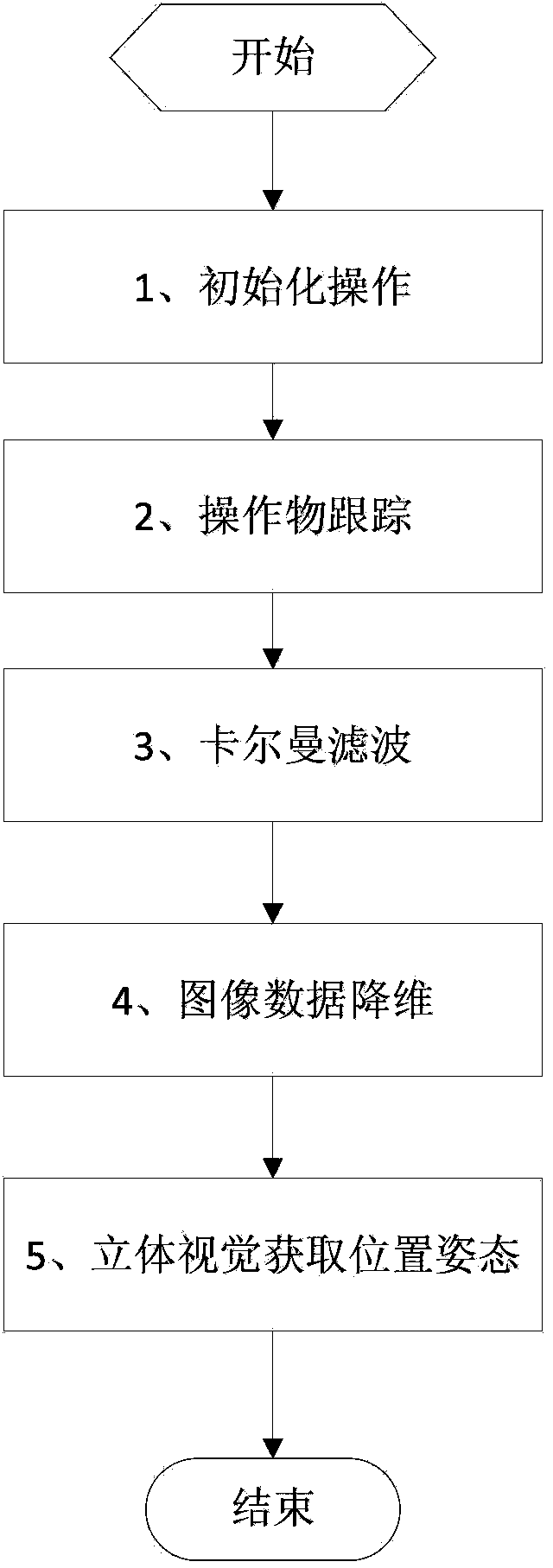

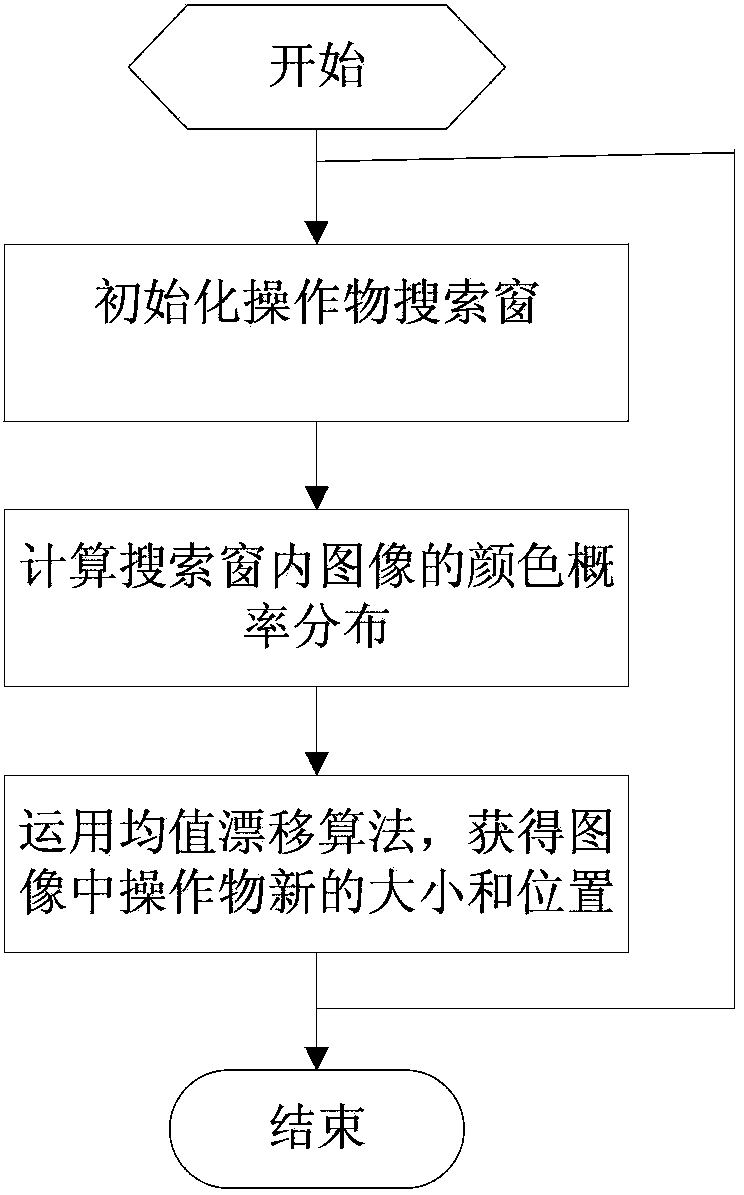

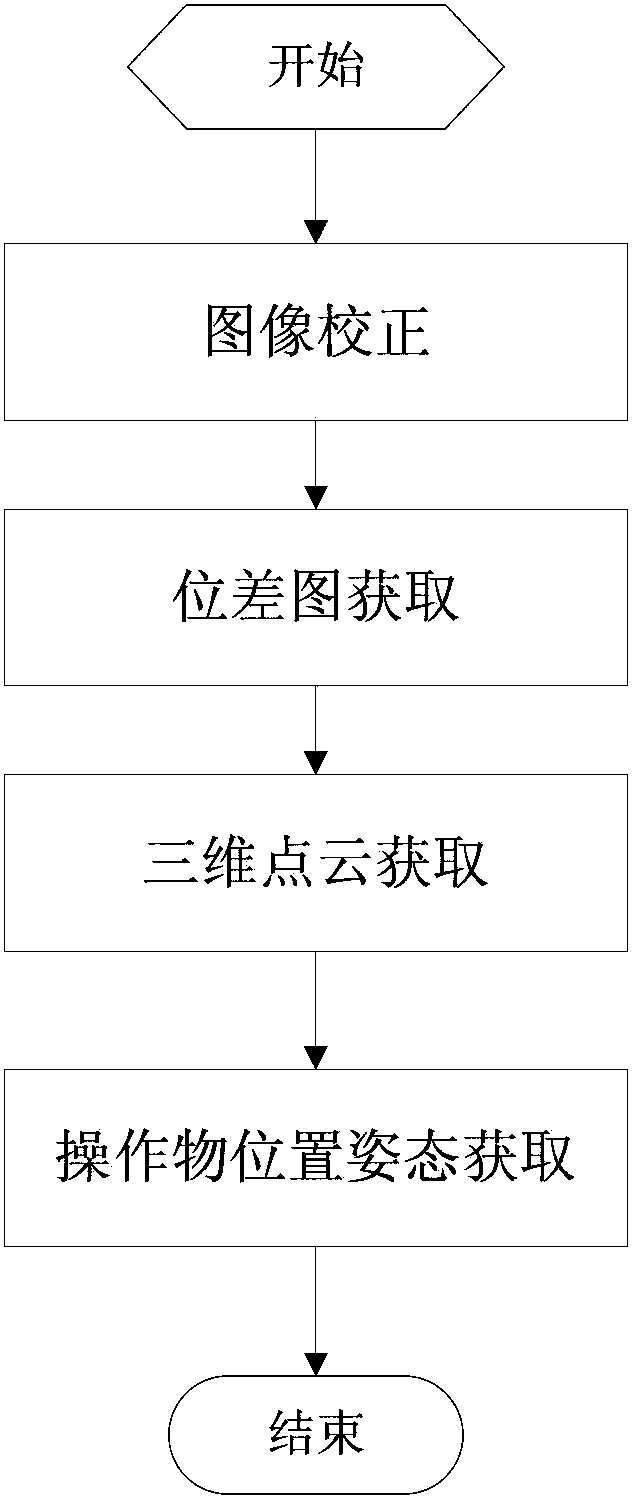

Operating object position and posture recognition method applicable to industrial robot

ActiveCN103112015AAchieve acquisitionImprove intelligenceManipulatorVisual servoing systemImaging data

The invention relates to an operating object position and posture recognition method applicable to an industrial robot. The operating object position and posture recognition method applicable to the industrial robot can be applied to a visual servo system based on positions, timely provides positions and posture information of an operating object for the visual servo system, is short in operation time and high in precision, can adapt to different illumination conditions indoor and outdoor and the like, and provides technical support for usage of the industrial robot in unstructured environments. The operating object position and posture recognition method applicable to the industrial robot comprises the following steps: step1, an initialization operation, calibrating initialization of a left camera, a right camera and the operating object, and then using the left camera and the right camera to obtain image data; step2, following the moving operating object by using a front frame image and a back frame image in the process of image capture; step3, smoothing changes of an operating object following window of the front frame image and the back frame image through kalman filtering; step4, using an image data dimension reduction mode to reduce dimension of data processing; and step5, calculating three-dimensional positions and posture of the operating object, and feeding back data to a servo control system of the industrial robot so as to achieve servo control.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

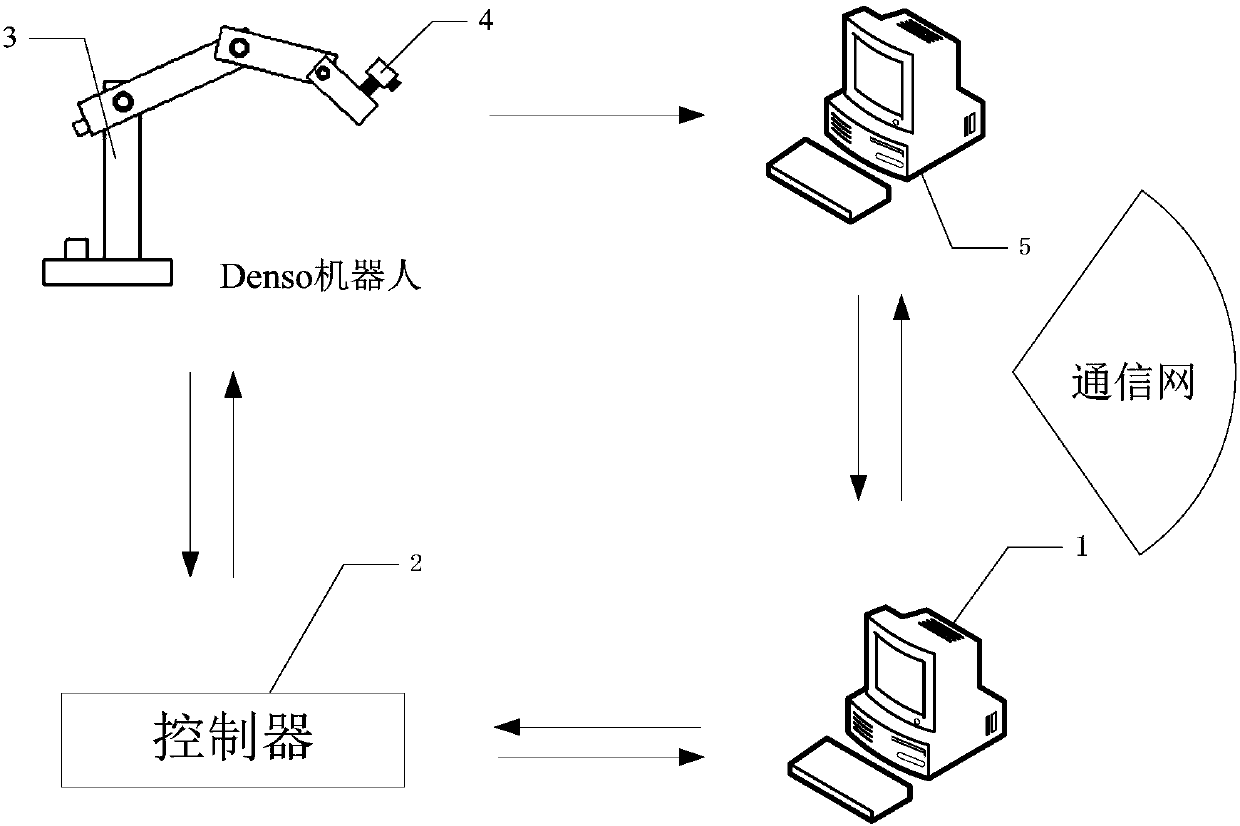

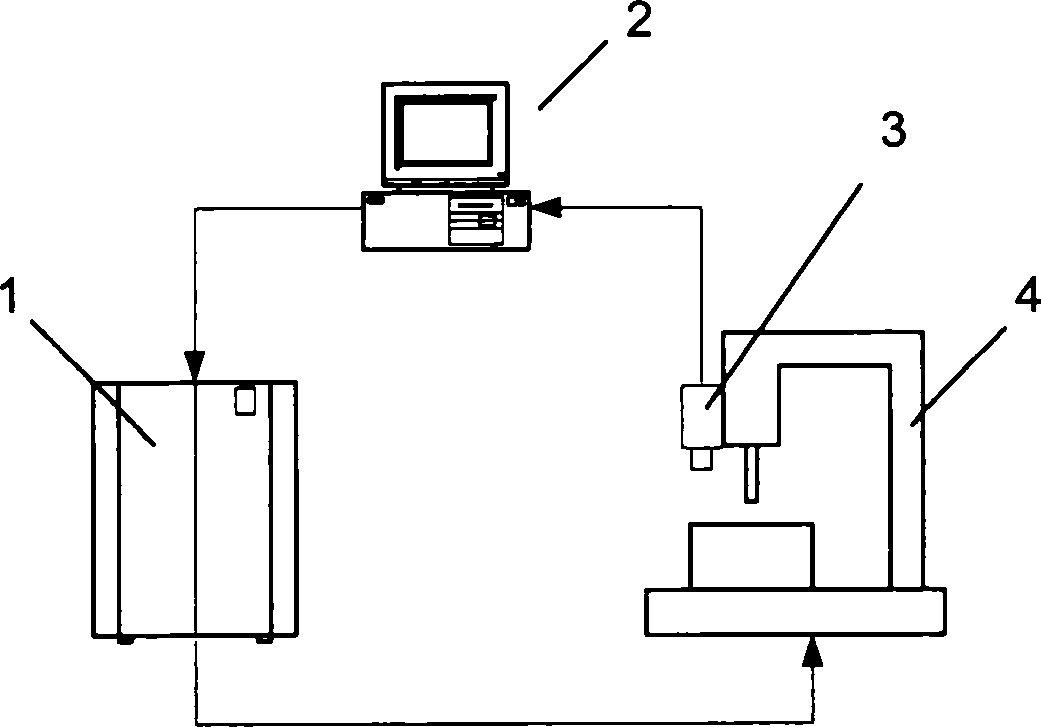

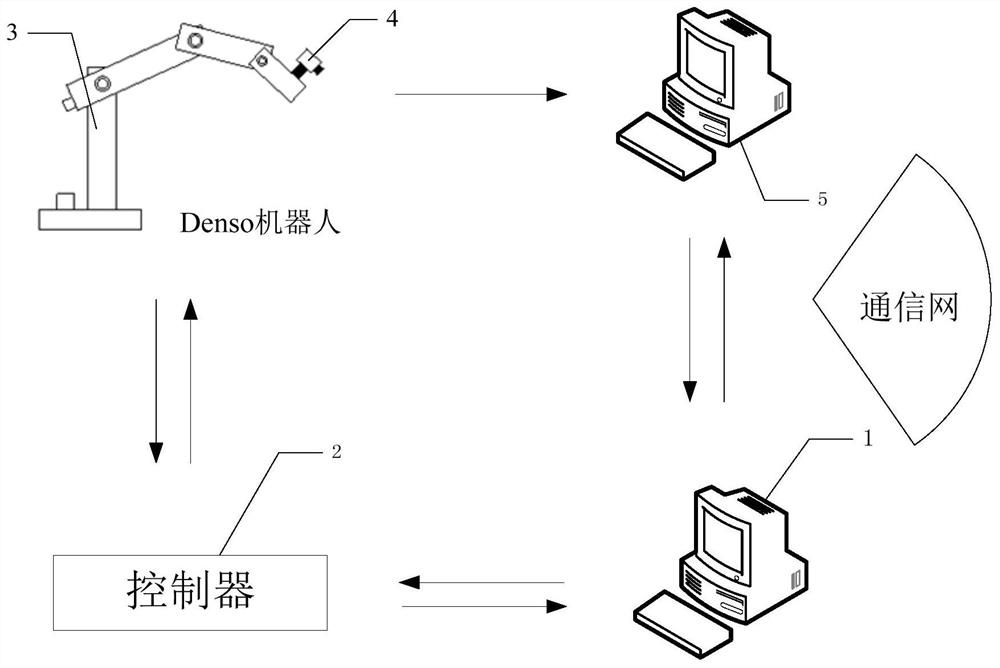

Vision servo system and method for automatic leakage detection platform for sealed radioactive source

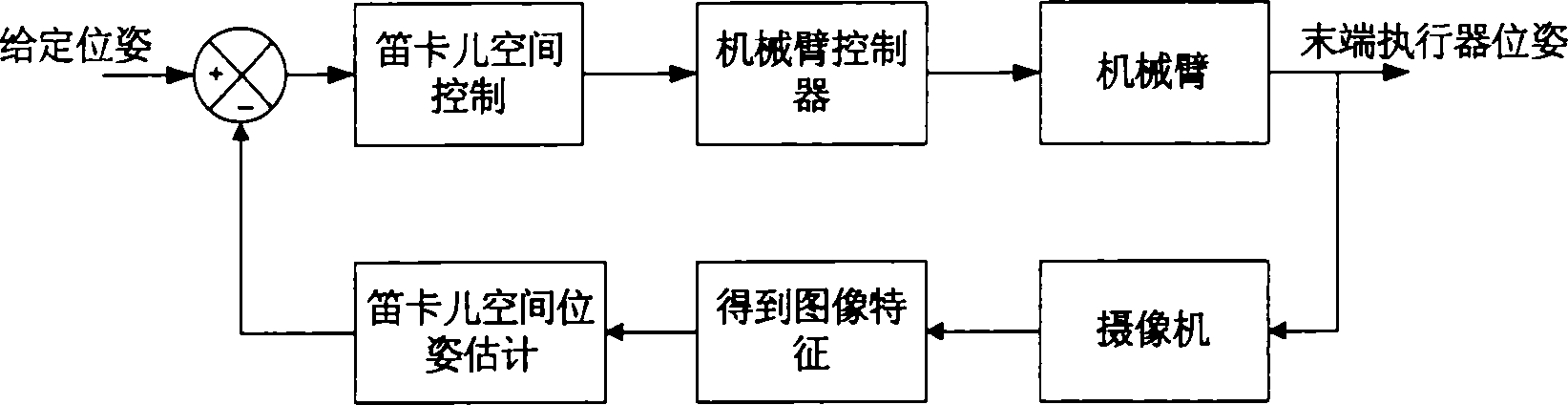

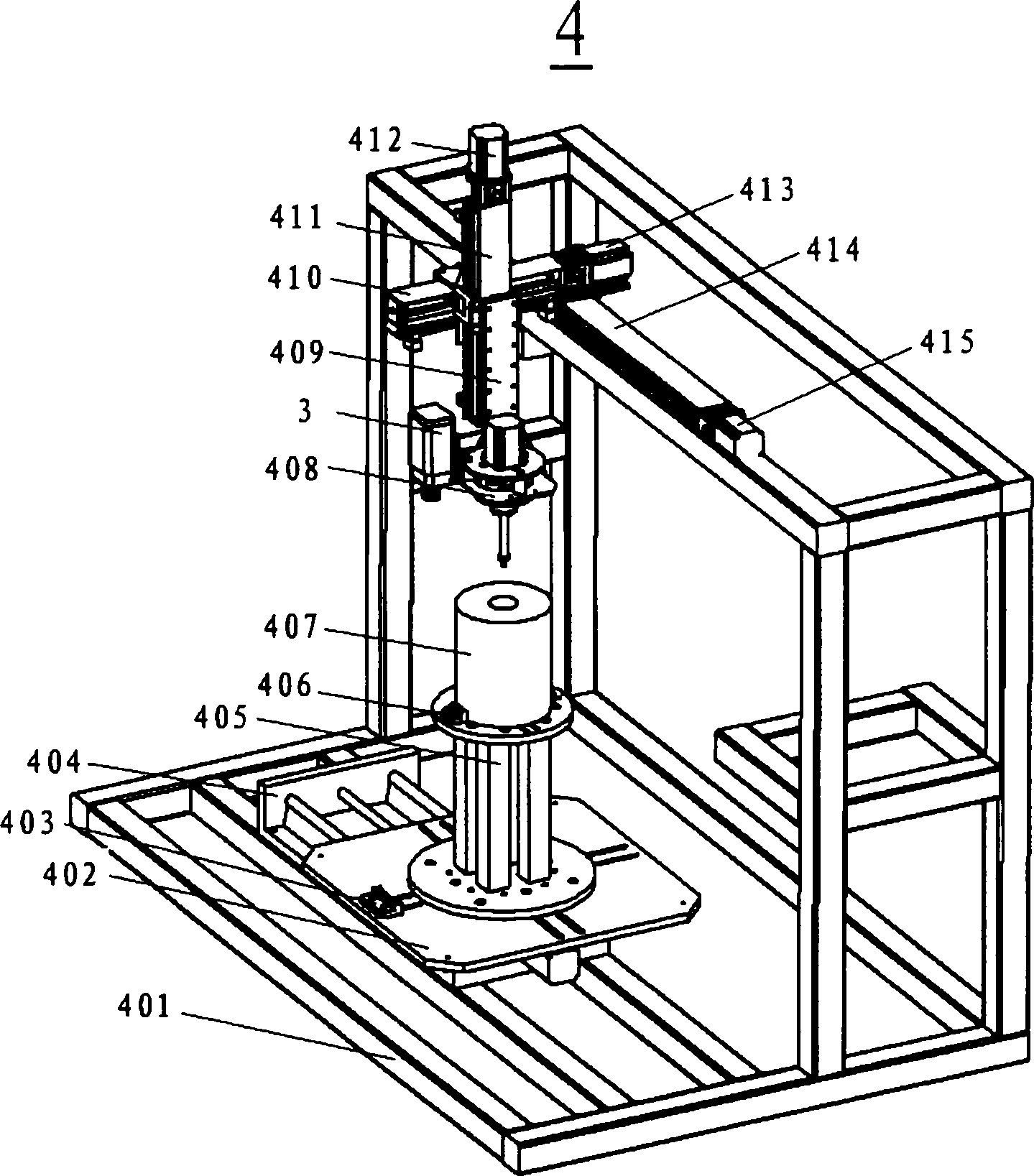

InactiveCN1885064AAchieve positioningX/gamma/cosmic radiation measurmentVisual servoing systemRadioactive waste

The invention relates to a sealing radioactive source leakage detecting technique, especially providing a visual servo system of sealing radioactive source leakage automatic testing platform, and relative method, wherein said system comprises: a computer (2), a camera (3), an executer (4), an executer controller and special altitude estimate visual algorism. And the method comprises: S1, converting colorful image into gray image or collecting gray image; S2, using Canny edge algorism to process the gray image to obtain edge image; S3, using edge fine technique to fine the edge into single pixel connecting edge with eight nearby regions; S4, removing noise; S5, building the model of upper surface geometric character of radioactive source work piece; S6, building the homography matrix between image plane and upper surface of work piece; S7, transmitting the calculated result to the mechanical arm controller.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

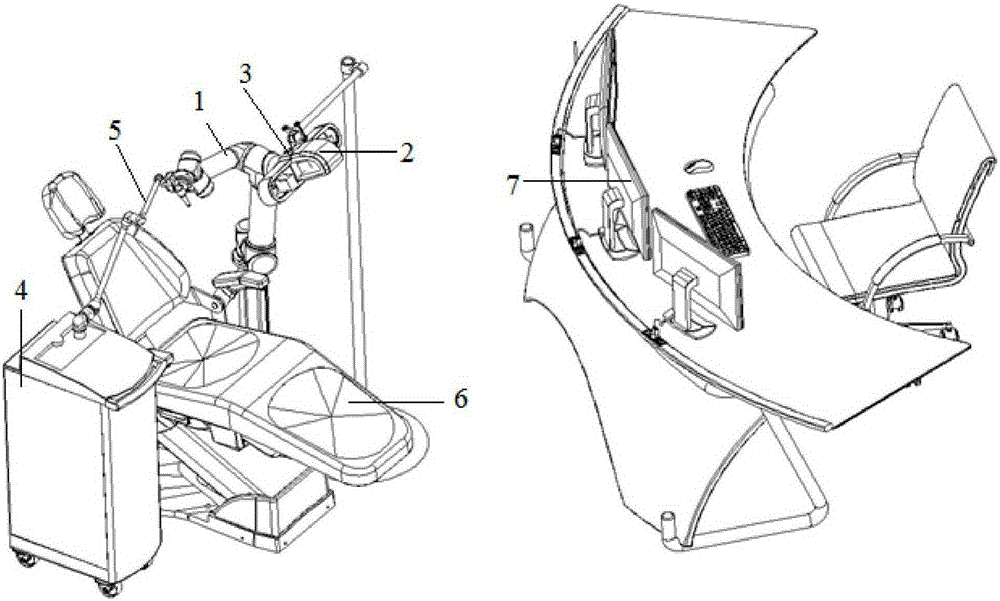

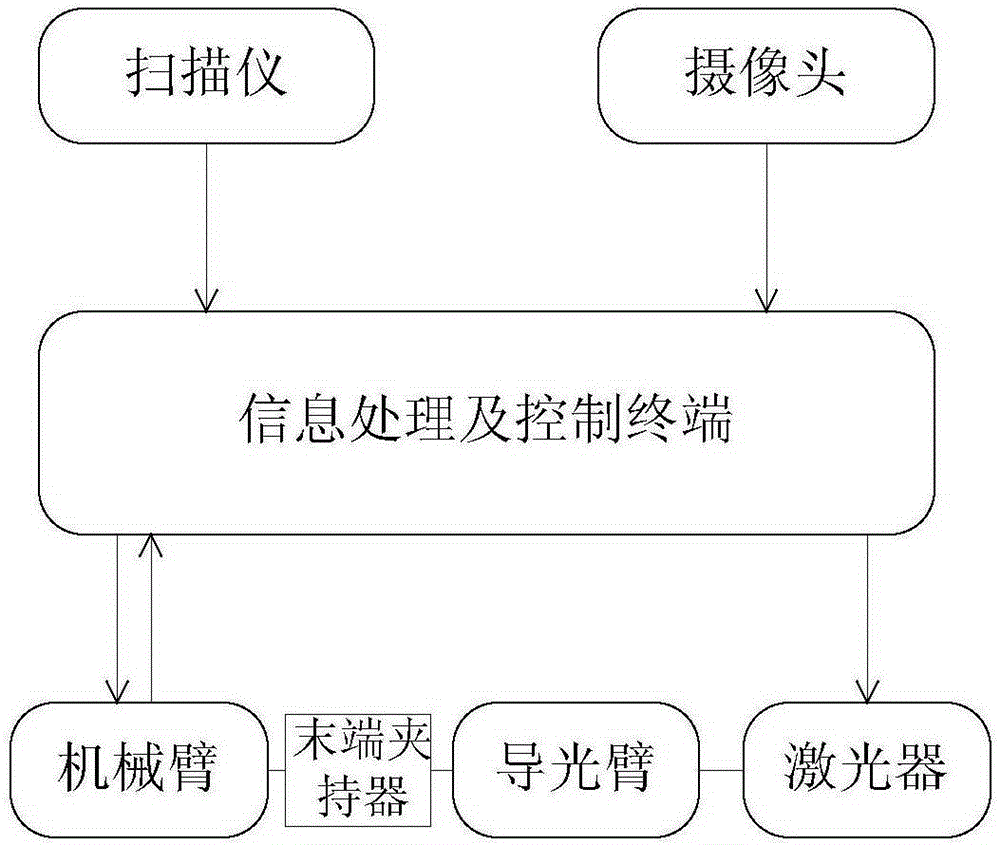

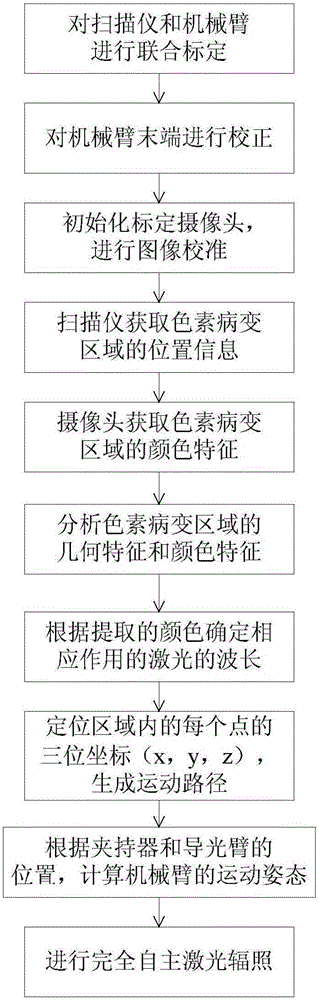

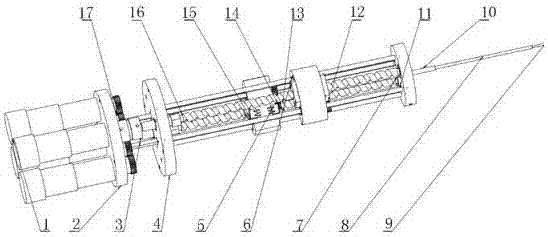

Imaging guided intelligentialized laser minimally invasive surgery system and control method thereof

InactiveCN105169570AStrong expandabilityAutonomousDiagnostic recording/measuringSensorsInformation processingVisual servoing system

The present invention discloses an imaging guided intelligentialized laser minimally invasive surgery system and a control method thereof. The intelligentialized laser minimally invasive surgery system includes a mechanical arm, a scanner, a video camera, a laser, a guiding light arm, a patient movable bed, and an information processing and control terminal. The imaging guided intelligentialized laser minimally invasive surgery system on the basis of the three-dimensional image information can precisely recognize the pigmented lesion region, strictly control the laser dose and irradiate laser on the pigmented lesion region so that the laser minimally invasive surgery is efficient, precious and safe, and the laser minimally invasive surgery system can automatically complete the surgery after acquiring sufficient patient information. The intelligentialized laser minimally invasive surgery system acts on human body surfaces, can be applied to the pigmented lesion laser minimally invasive surgery, is equipped with a visual servo system and a six-freedom light type mechanical arm, has the autonomy, and realizes the full automation. In addition, the intelligentialized laser minimally invasive surgery system has the strong expandability and can be applied to many minimally invasive surgeries based on human body surfaces, such as HIFU (high-intensity focused ultrasound) face-lift and wrinkle-remove surgery.

Owner:PEKING UNIV

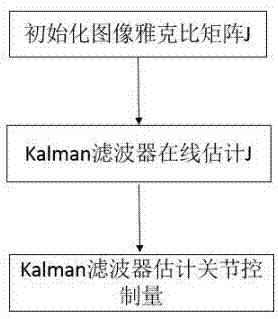

Visual servo based concentric-tube-robot precise motion control method

InactiveCN107097231AProgramme controlProgramme-controlled manipulatorVisual servoing systemSurgical operation

The invention discloses a visual servo based concentric-tube-robot precise motion control method. The method includes: establishing an eye-in-hand visual servo system on the basis of images with an aim to extract features of the images without calibration of a camera and completing extraction of controlled quantity through mapping of image Jacobian matrix; completing online estimation of the image Jacobian matrix by the aid of a Kalman filter, taking feature variation of the images as the measurement vector and taking the image Jacobian matrix as the state vector; taking the estimated value of the image Jacobian matrix as the measurement matrix of the Kalman filter, taking the joint angle error as the state vector, and taking the image error as the measurement vector, and acquiring the controlled quantity of the joint angle through filter estimation; when the image error approaches zero, completing position of target points. Motion control is fed back by relying on reliable image information, and the tiny and vibrating target points during surgical operation are finally accurately positioned, so that surgical operation is completed.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

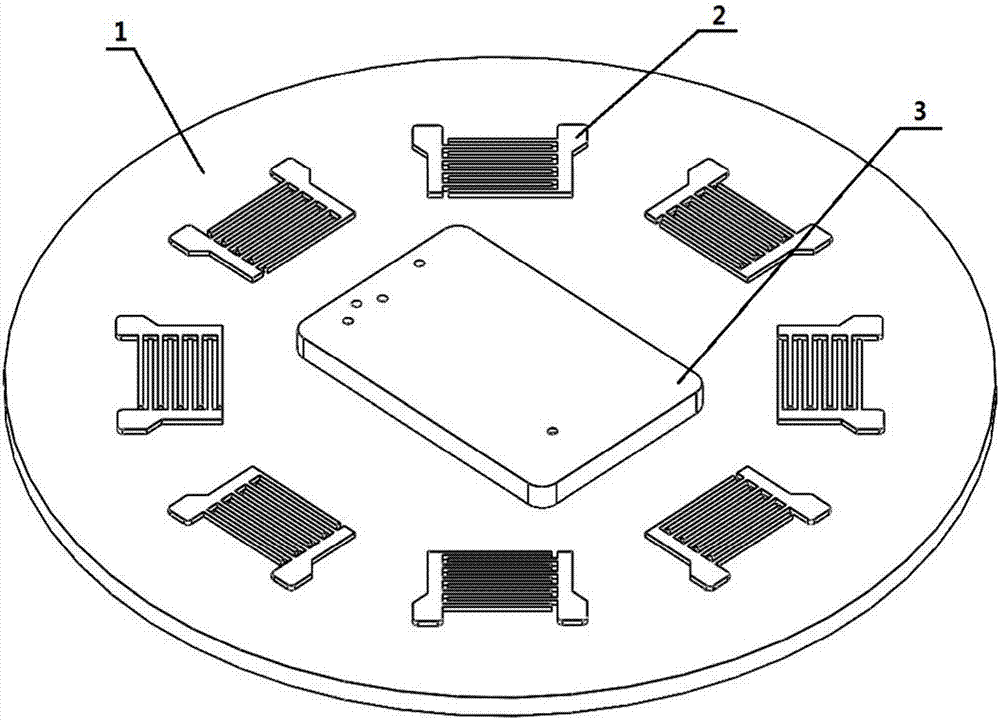

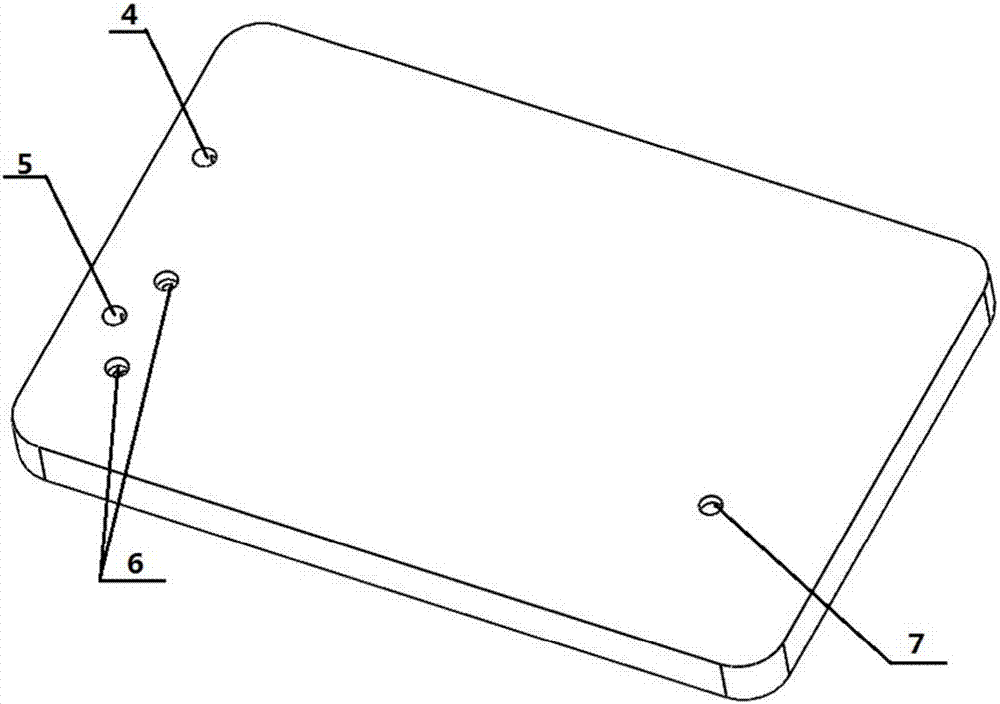

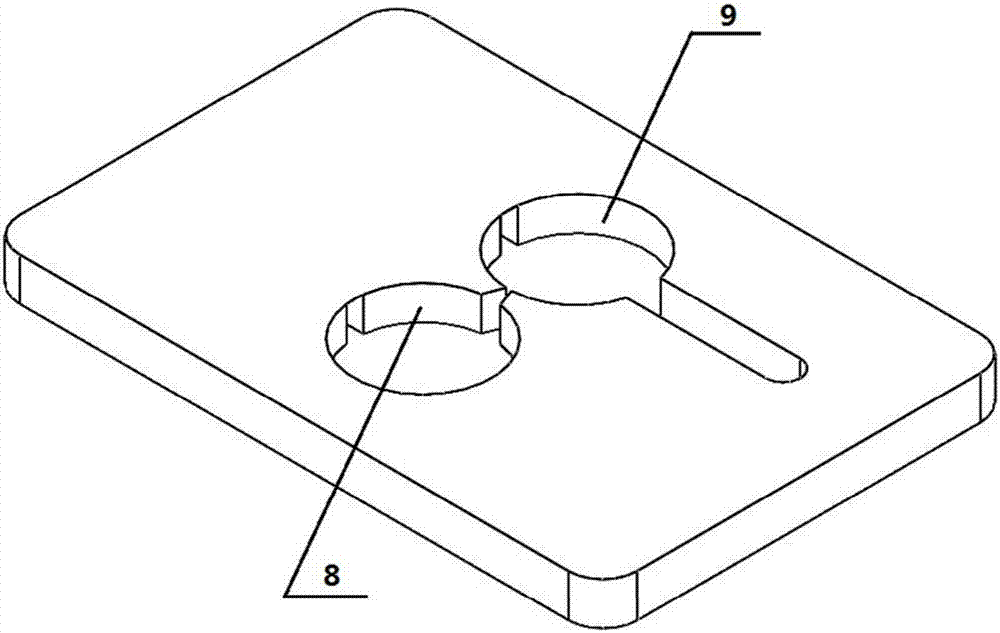

Cell adhesion force measuring instrument and cell adhesion force measuring method based on acoustic surface waves

ActiveCN107238556ALess distracting factorsAvoid destructionBioreactor/fermenter combinationsBiological substance pretreatmentsVisual servoing systemCell adhesion

The invention discloses a cell adhesion force measuring instrument and measuring method based on acoustic surface waves. The cell adhesion force measuring instrument comprises a lithium niobate crystal plate, a silver interdigitatal electrode annular array, a PDMS (polydimethylsiloxane) micro-channel and a micro-vision servo system, the micro-vision servo system comprises an upper computer system based on a PXI (peripheral component interconnect) bus, a multi-path signal generating system and a micro-vision monitoring system, the silver interdigitatal electrode annular array is arranged on the upper periphery of the lithium niobate crystal plate, the lithium niobate crystal plate and the silver interdigitatal electrode annular array form an interdigital transducer, and the silver interdigitatal electrode annular array is connected with the multi-path signal generating system. According to the measuring instrument, an expected sound field is synthesized in a PDMS micro-channel cavity by the aid of the interdigital transducer and the micro-vision servo system, cells are operated by the aid of radiation force of the acoustic surface waves, cell adhesion force is measured, and the measuring instrument has the advantages of simplicity and easiness in operation, fewer interference factors and the like.

Owner:ZHEJIANG UNIV

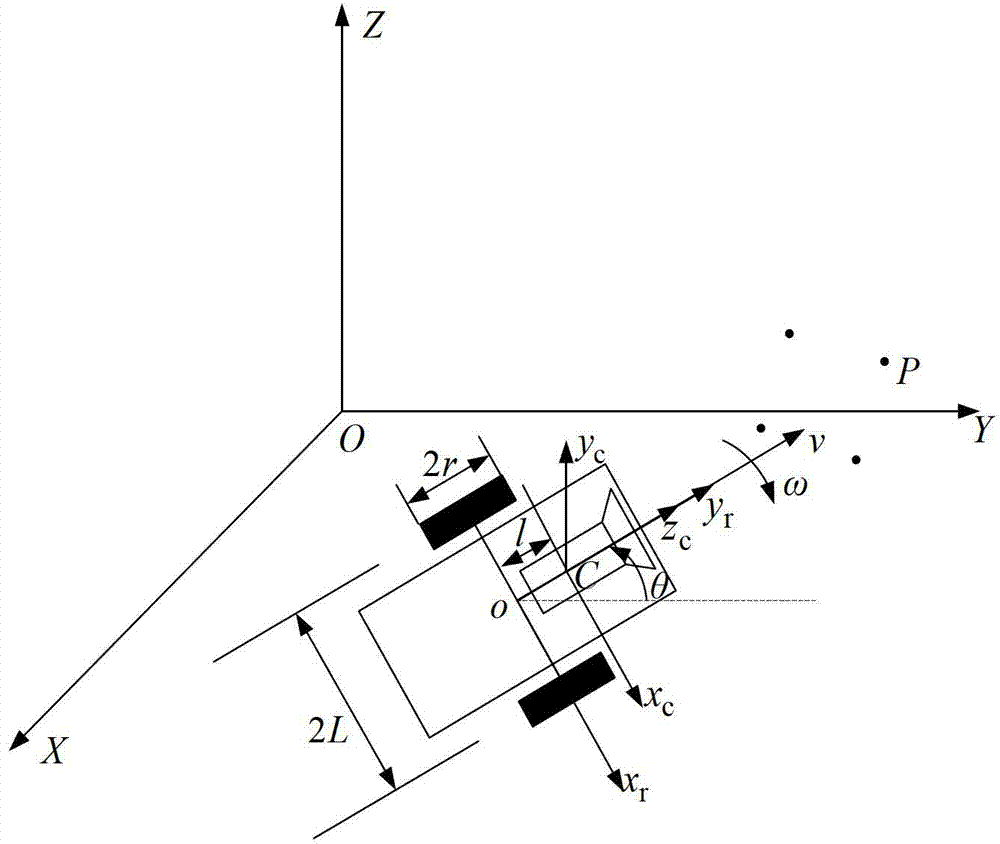

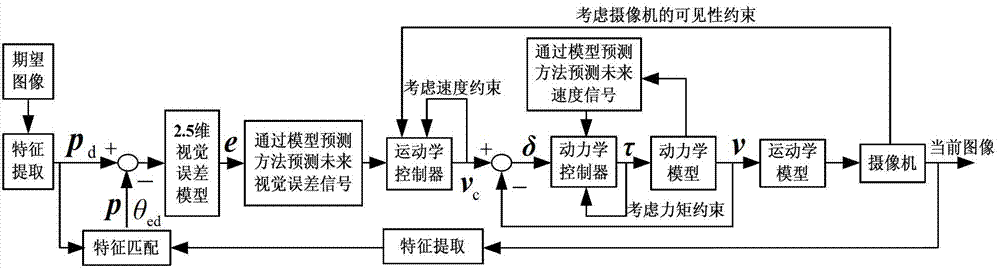

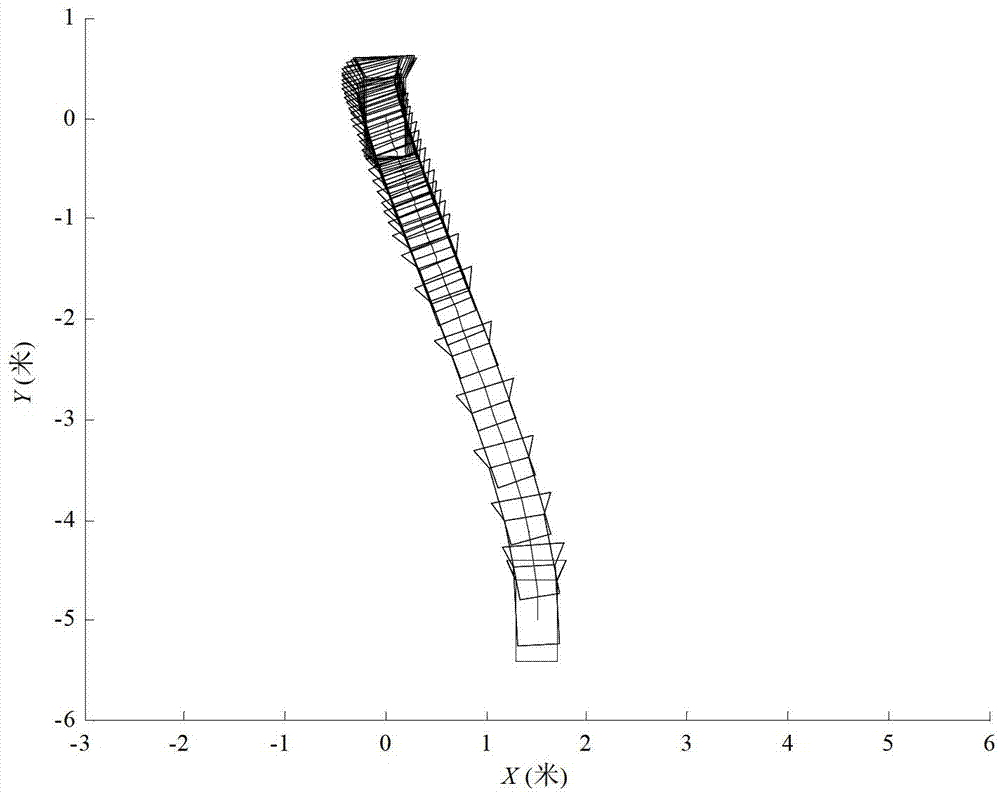

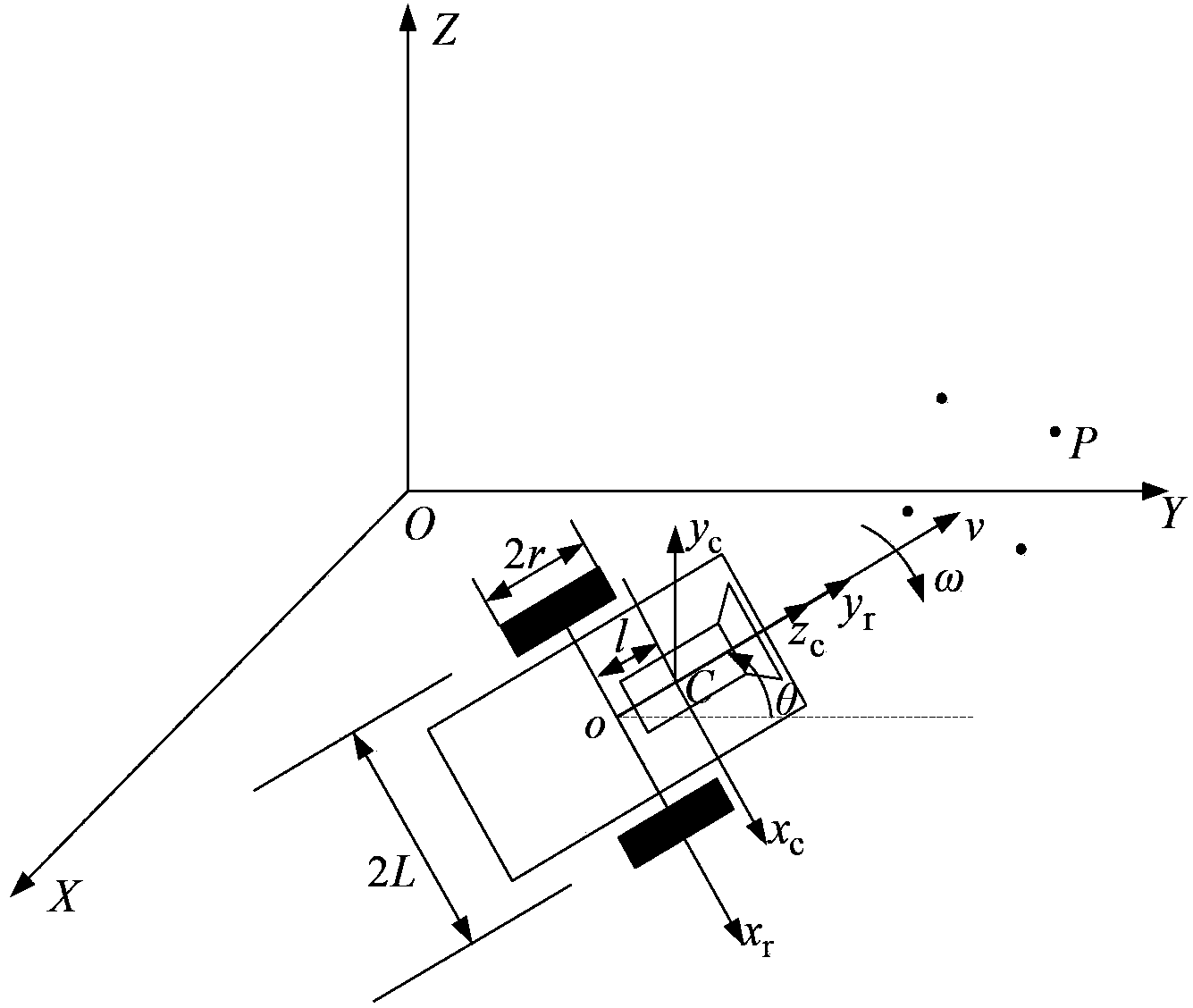

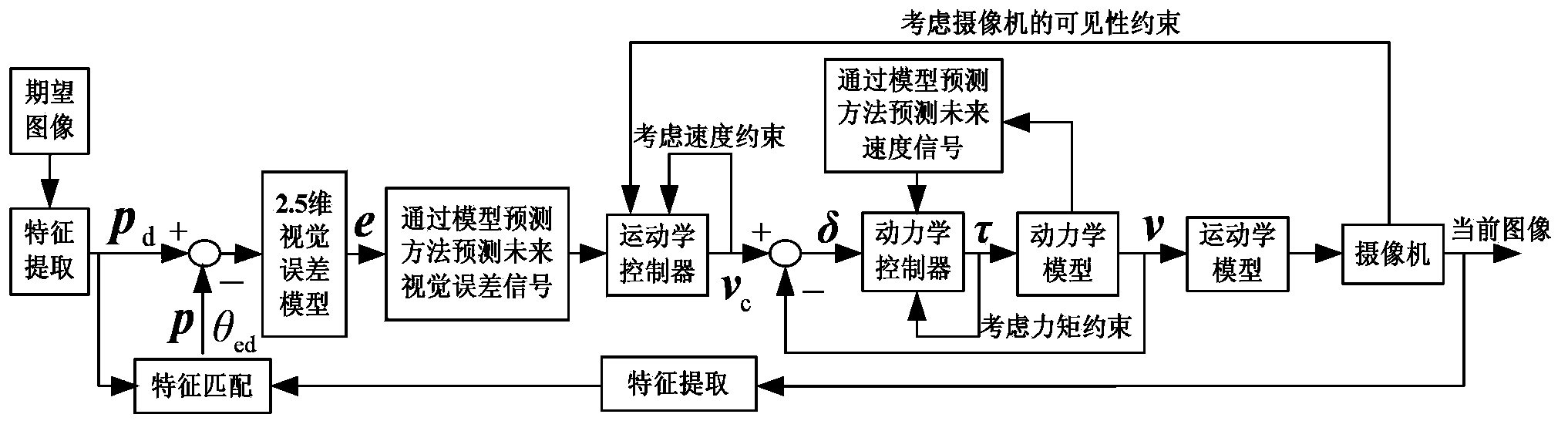

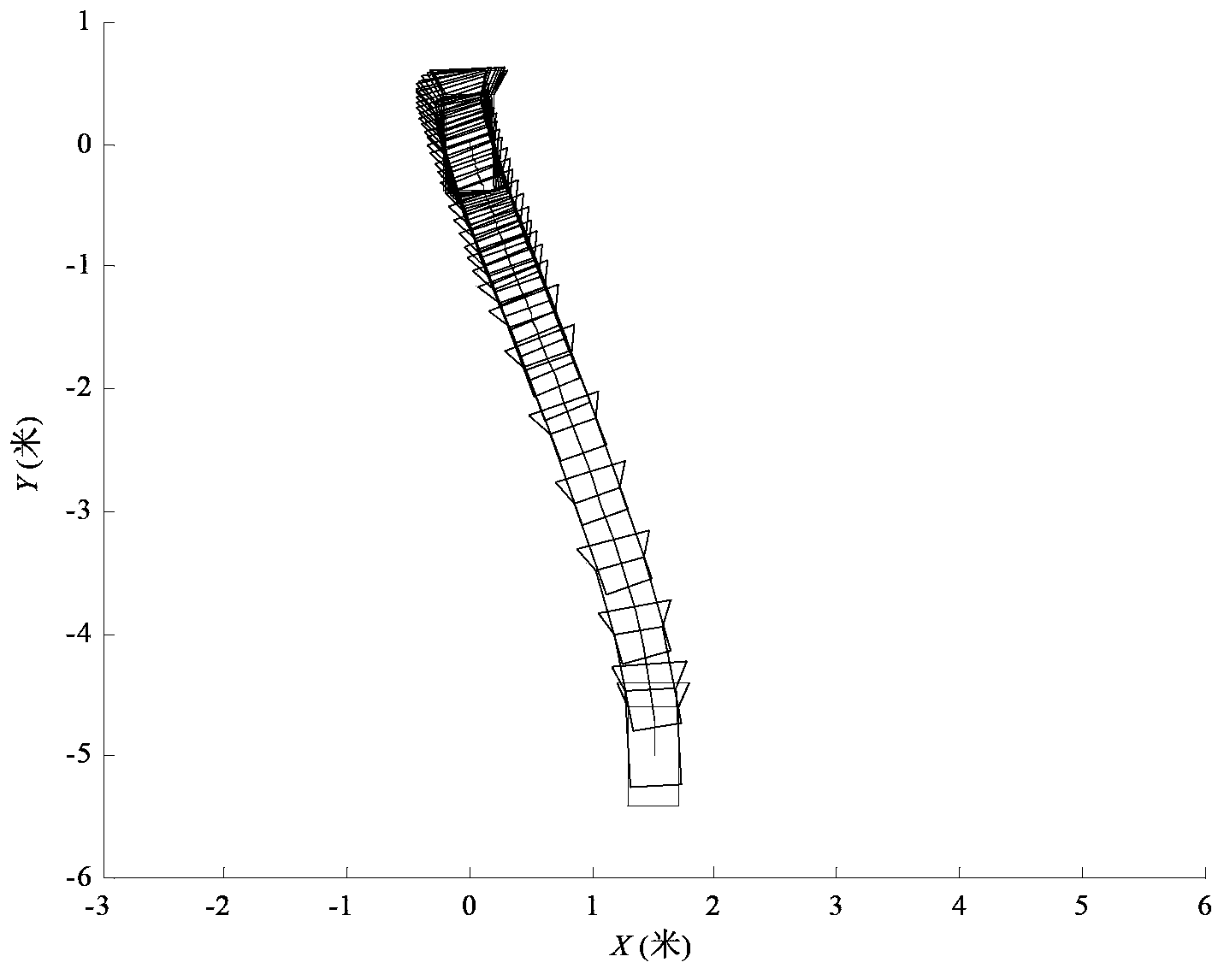

Intelligent trolley 2.5-dimensional visual servo control method based on nonlinear model prediction

InactiveCN102880062AImprove reliabilityImprove securitySimulator controlPosition/course control in two dimensionsVisual servoing systemNon linear model predictive control

The invention discloses an intelligent trolley 2.5-dimensional visual servo control method based on nonlinear model prediction. The intelligent trolley 2.5-dimensional visual servo control method comprises the steps as follows: firstly, obtaining a current image and an expected image of a reference target respectively through a video camera at a current pose and an expected pose; secondly, extracting the characteristic points of the reference target and the pose information of the trolley, organically combining a two-dimensional image signal with a three-dimensional pose signal through coordinate conversion, and building a 2.5-dimensional visual error model; and lastly, aiming at the 2.5-dimensional visual error model, designing a multilevel visual predication controller by utilizing a nonlinear model prediction control method. According to the intelligent trolley 2.5-dimensional visual servo control method, the problem that velocity and torque constraint of a motion performing system and visibility constraint of the video camera cannot be processed by the conventional 2.5-dimensional visual servo control method is solved, the reference target can be guaranteed to remain visible all the time in the servo process, and the reliability and the safety of a visual servo system are greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

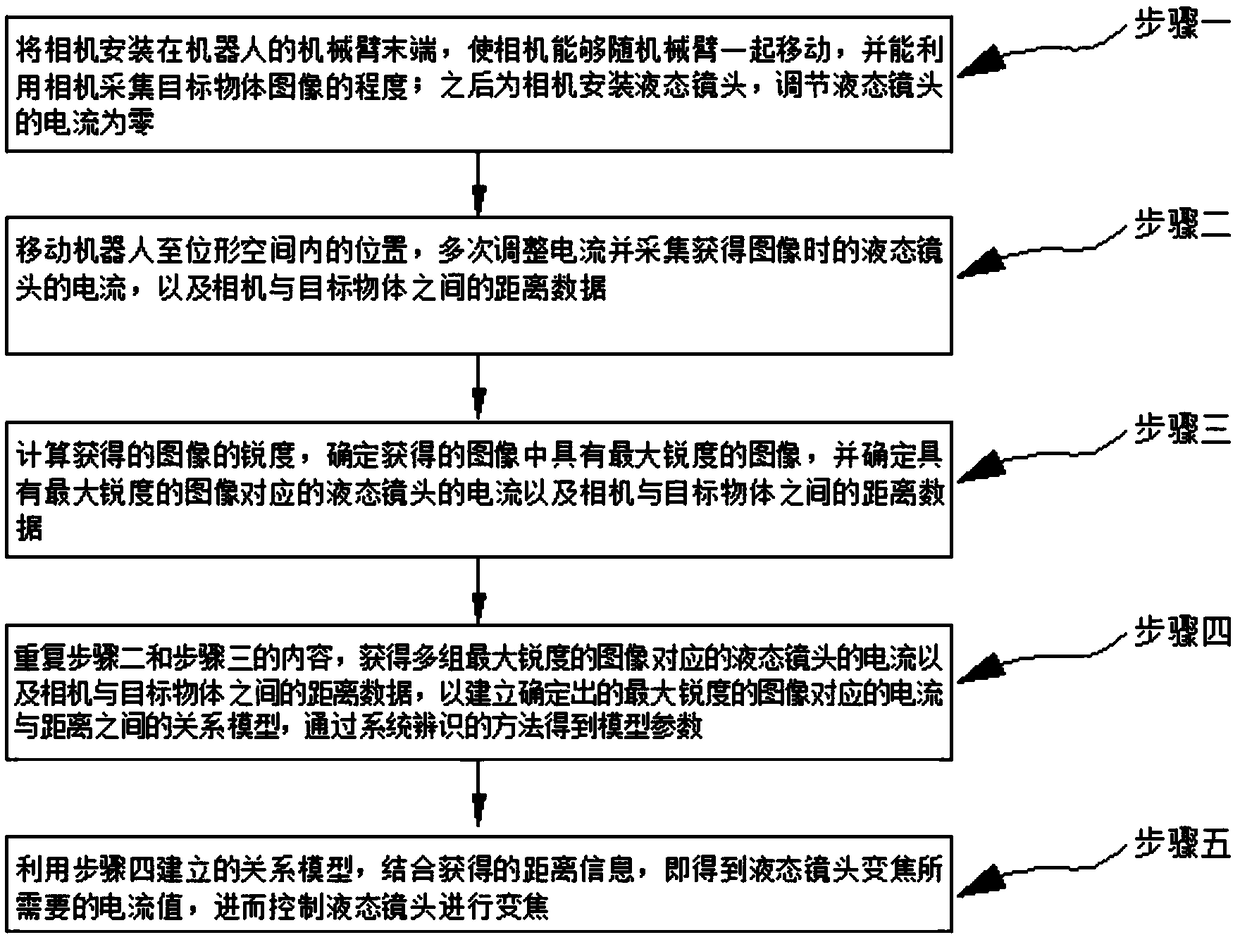

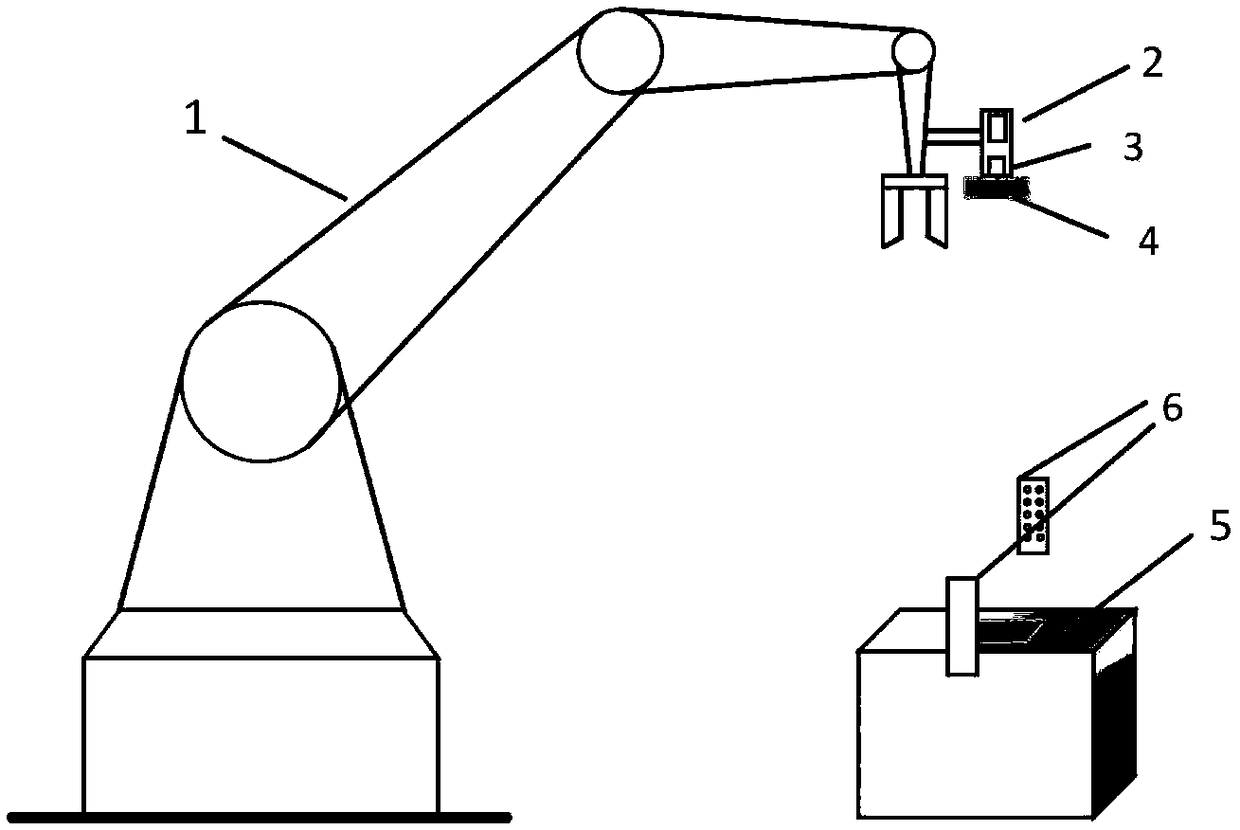

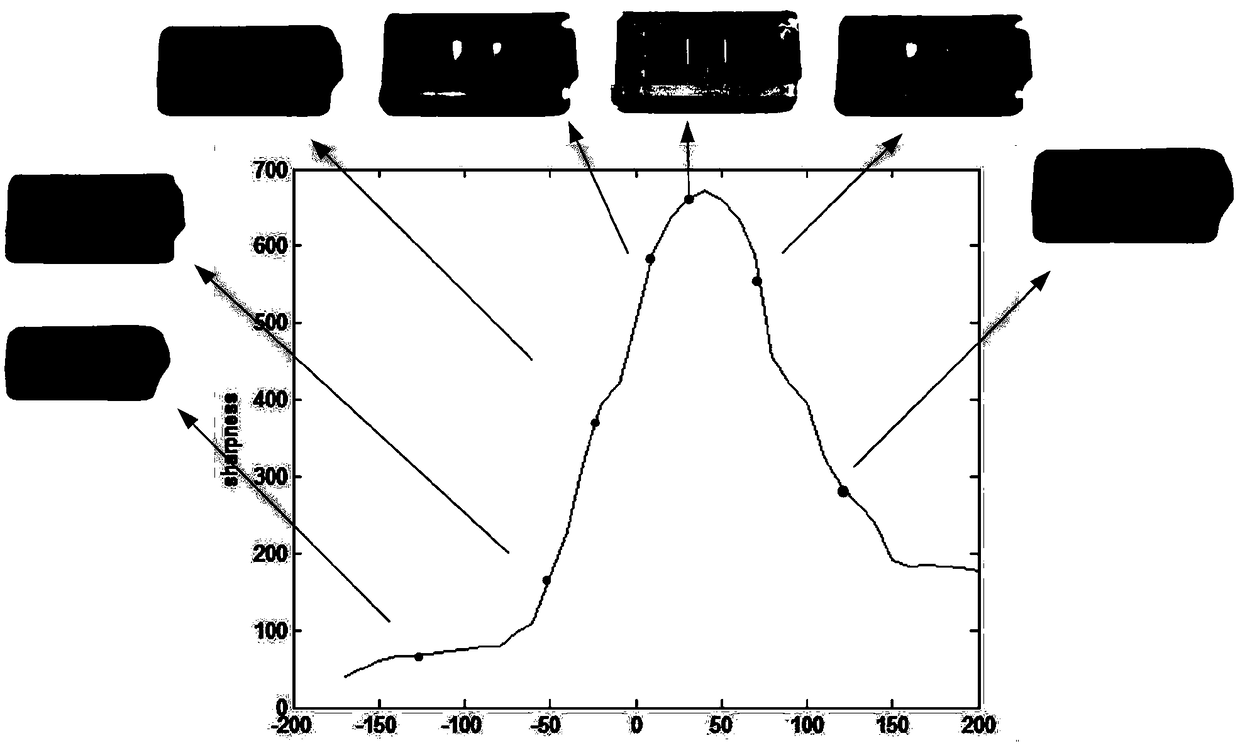

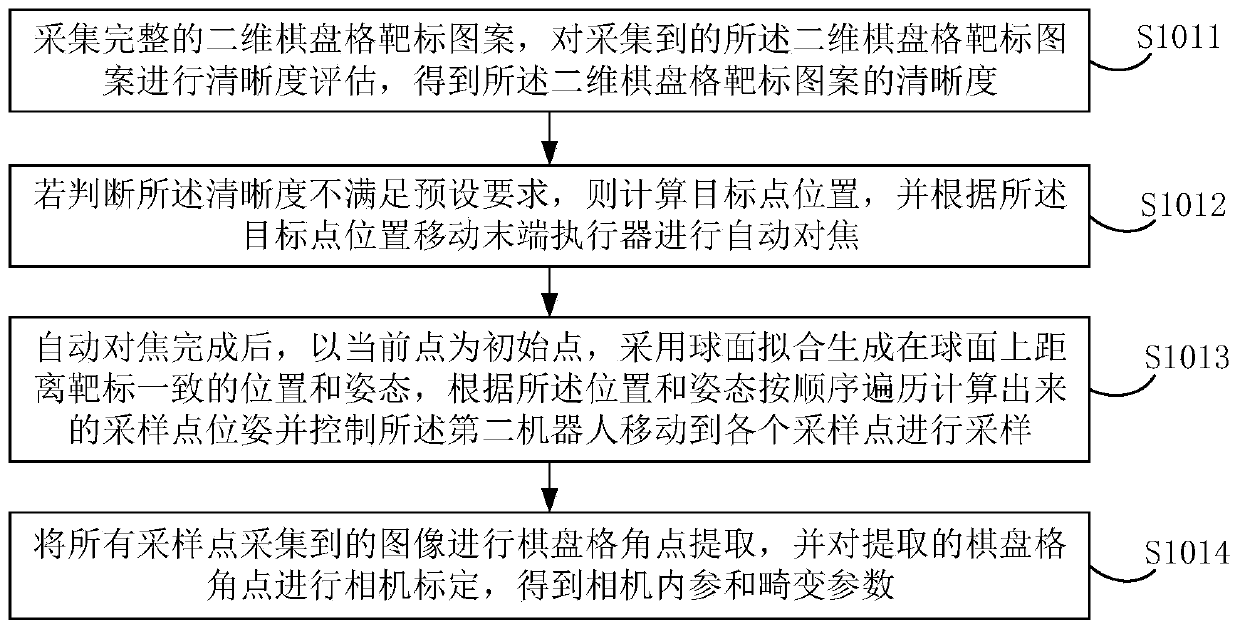

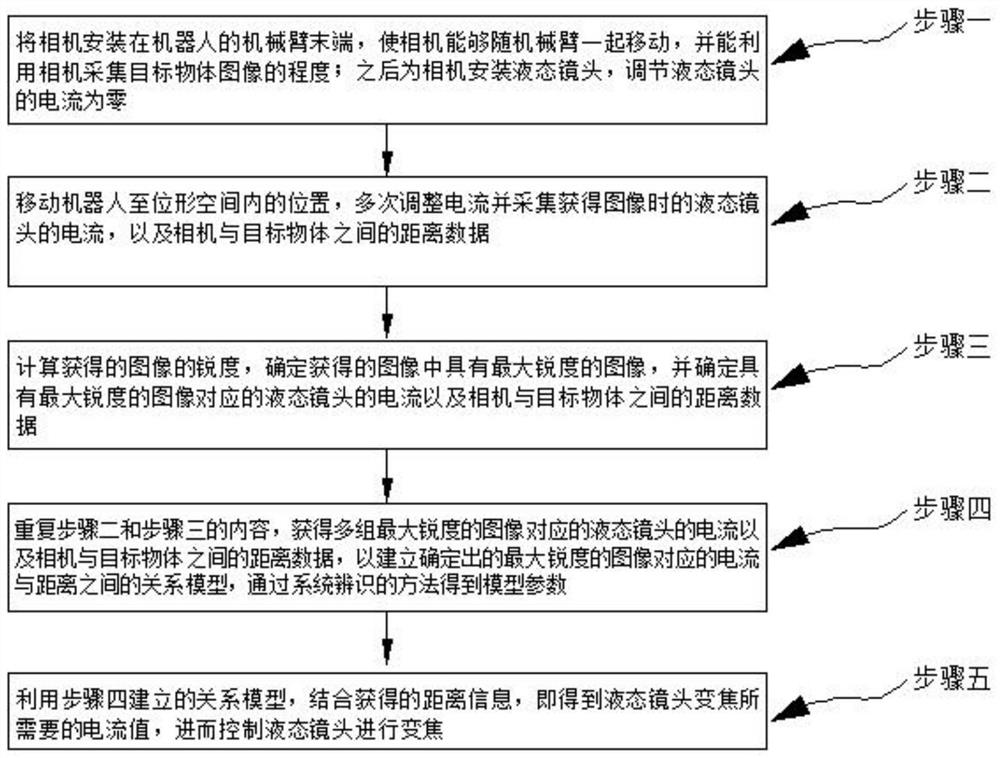

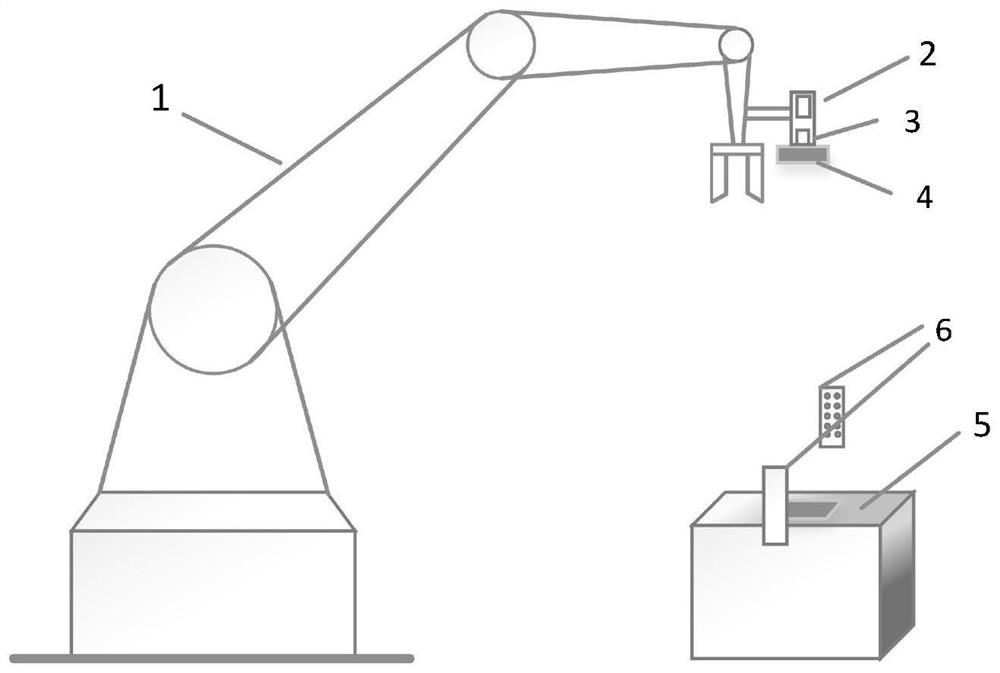

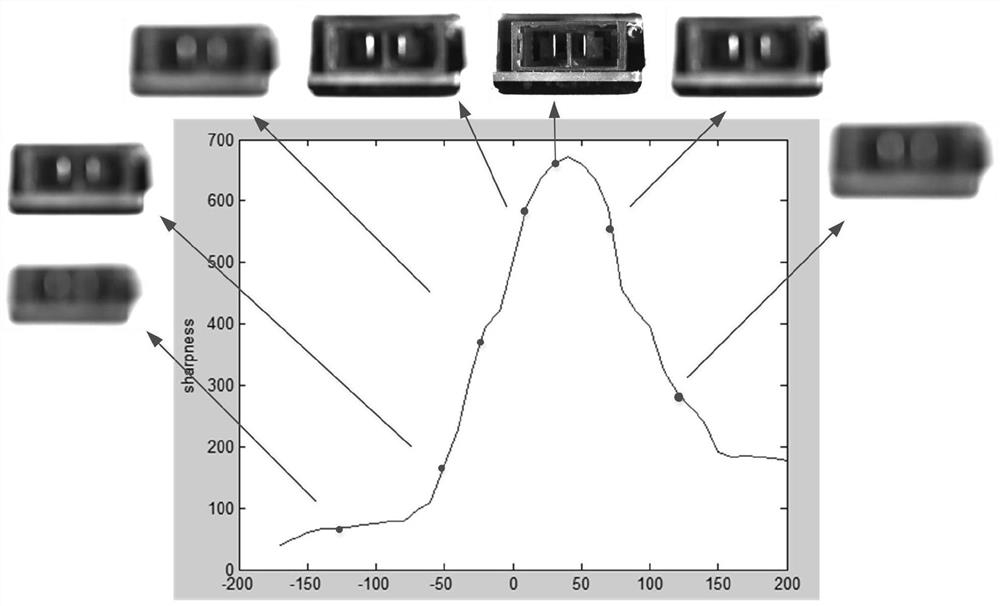

Rapid focusing method of visual servo system of robot

ActiveCN109318235AQuick focusGuaranteed clarityProgramme-controlled manipulatorMountingsCamera lensVisual servoing system

The invention discloses a rapid focusing method of a visual servo system of a robot, and belongs to the field of image processing. An existing mechanical focusing technology has the problems that thezooming capability is poor and the speed is low, and the real-time requirement of visual servo is difficult to meet. According to the method, a liquid lens is installed at a camera arranged at the tail end of a mechanical arm of the robot; the current of the liquid lens when the image is acquired and the distance data between the camera and a target object are collected for multiple times; the image with the maximum sharpness, the current of the corresponding liquid lens and the distance data between the camera and the target object are determined; the above content is repeated to obtain a plurality of sets of current and distance data with the maximum sharpness, a relation model between the current and the distance of the maximum sharpness is established, and model parameters are obtainedthrough a system identification method; the established relation model is utilized, a current value required by the liquid lens zooming is obtained by combining the distance information, and then theliquid lens is controlled to perform zooming. According to the method, the rapid focusing of the visual servo system and the imaging definition of the target object are ensured.

Owner:HARBIN INST OF TECH

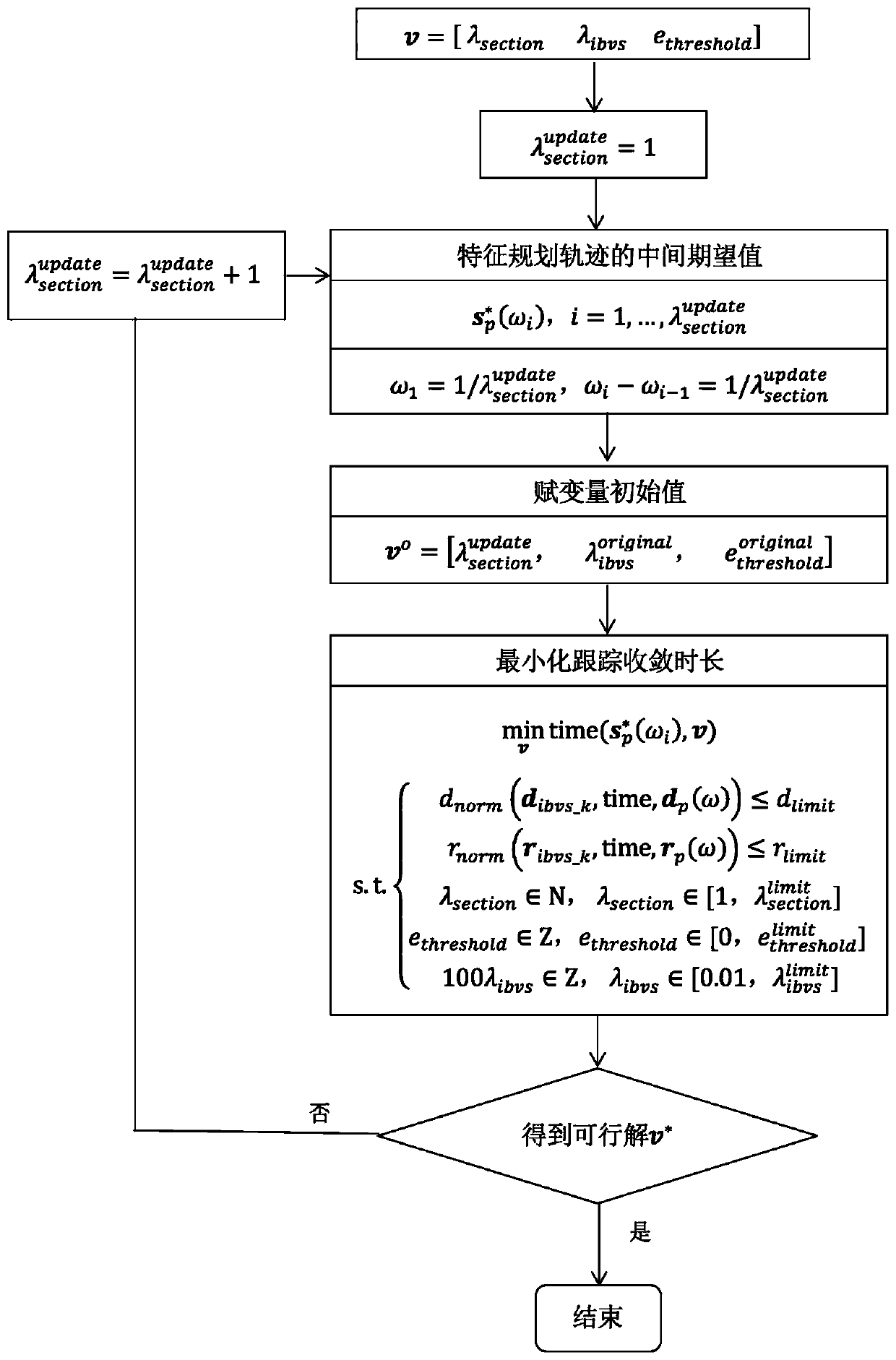

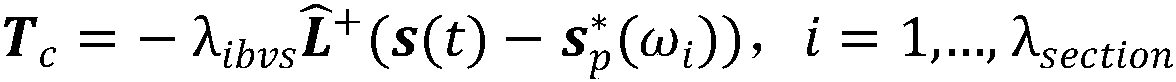

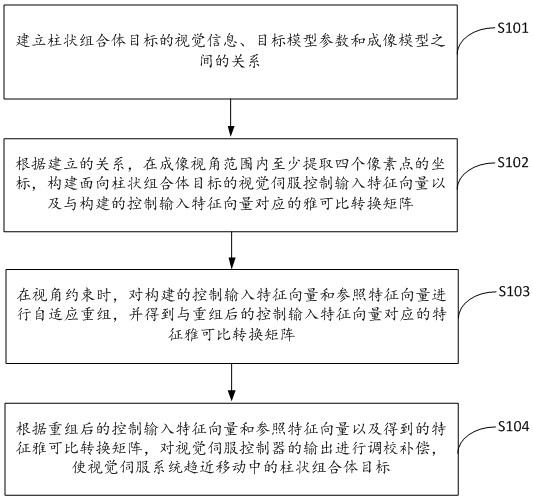

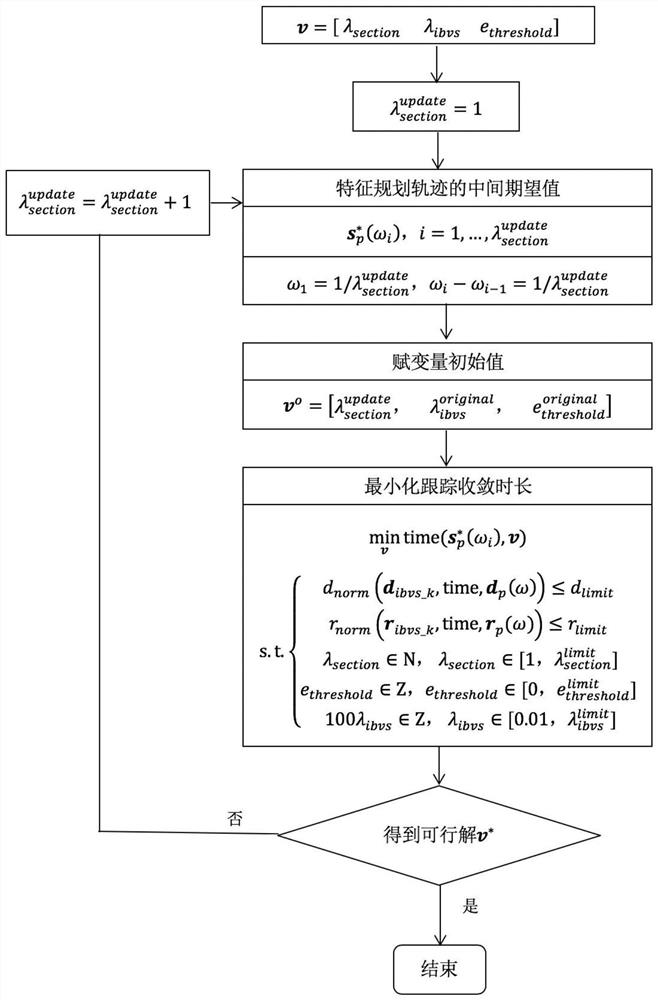

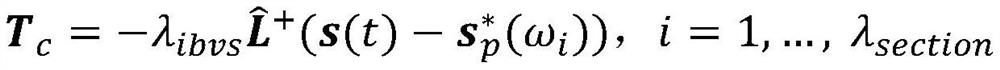

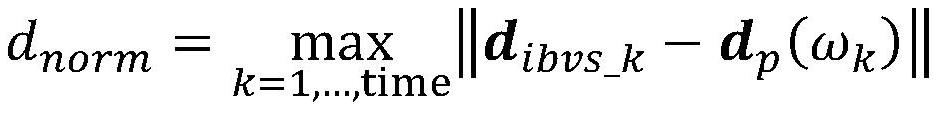

Servo tracking accelerated convergence method for robot visual feature planning track

ActiveCN111283683AImprove adaptabilityEnsure global convergenceProgramme-controlled manipulatorVisual servoing systemComputer vision

The invention discloses a servo tracking accelerated convergence method for a robot visual feature planning track. The method comprises the following steps of S101, building a visual feature track planning model, and obtaining a specific planning track; S102, uniformly segmenting the characteristic track parameter, and carrying out segmented visual servo tracking; S103, defining a maximum displacement error and a maximum rotation error generated by tracking; and S104, minimizing the tracking convergence time under the constraint of a specific tracking error. According to the method, the tracking error is defined, the track interpolation is set, and multi-parameter optimization is carried out, the tracking convergence duration is shortened as much as possible while the tight tracking is achieved to obtain the global convergence, and the adaptive capacity of a visual servo system to a dynamic target and the environment is improved.

Owner:HUNAN NORMAL UNIVERSITY

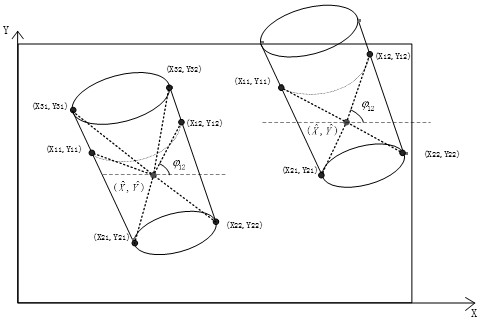

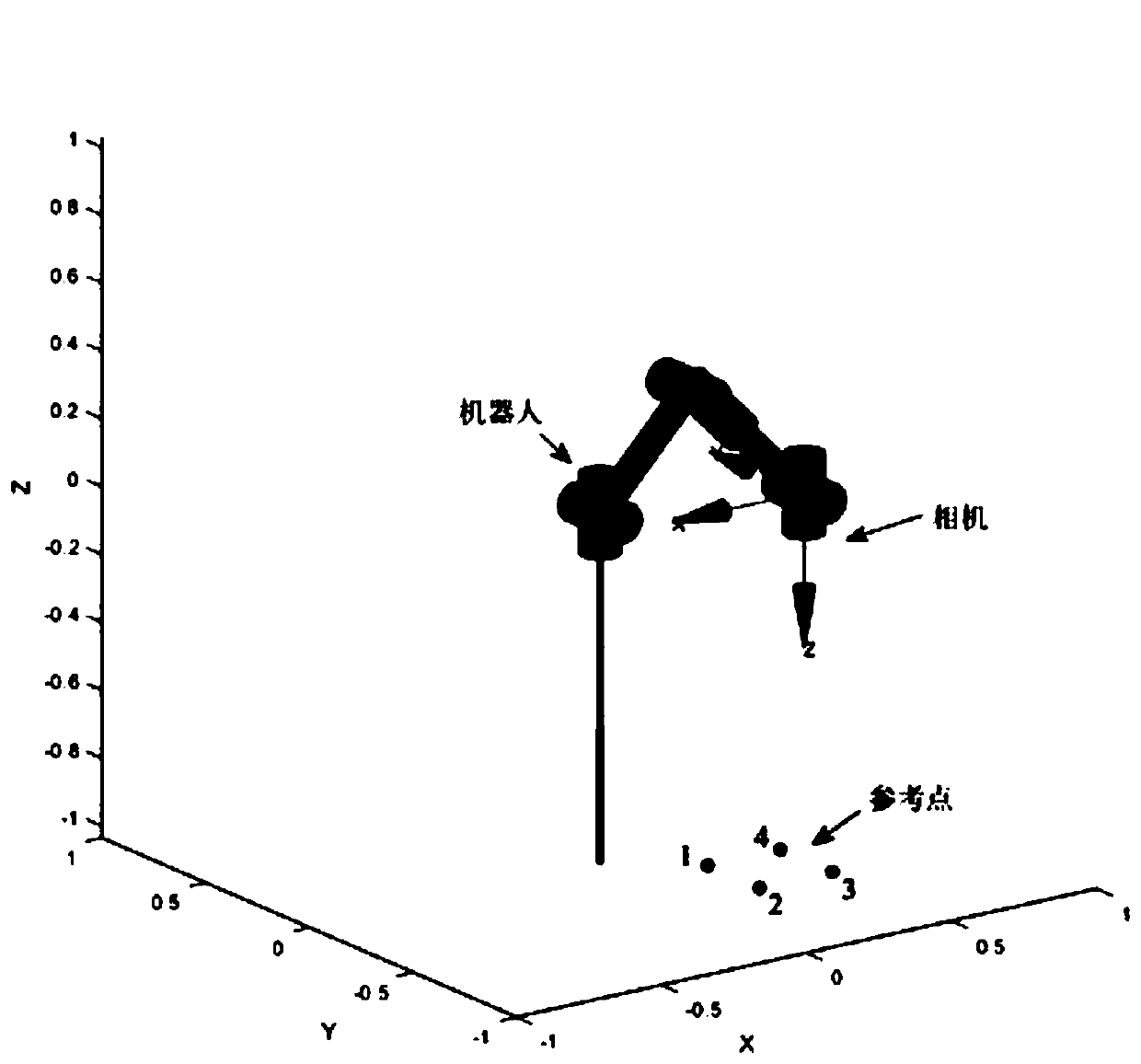

Robot stereo visual servo system construction method

InactiveCN108062777AProcess balanceSatisfy Servo CycleImage analysisVisual servoing systemInformation transmission

The invention discloses a robot stereo visual servo system construction method. The method includes the following steps of: the first step, robot stereo visual servo system structure and stereo visualsystem model establishment; the second step, target detection and positioning research; the third step, moving object tracking and prediction research; the fourth step, robot stereo visual servo system parallel processing research; and the fifth step, robot real-time stereo visual servo system demonstration experiment. According to the robot stereo visual servo system construction method of the invention, the tracking and capturing of moving objects of images are researched; a stereo visual servo system is adopted to realize the collection, processing, recognition, tracking and positioning ofvideo information; and the tracking and capturing of the moving targets are realized through a position-based robot visual control method; and information transmission is realized through using a network.

Owner:HARBIN INST OF TECH GENIUS INTELLIGENTTECH

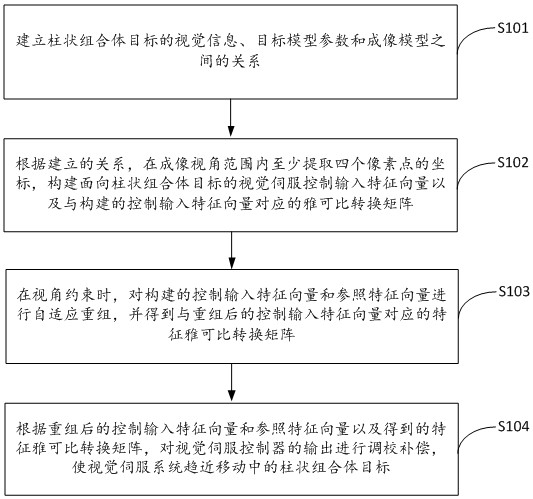

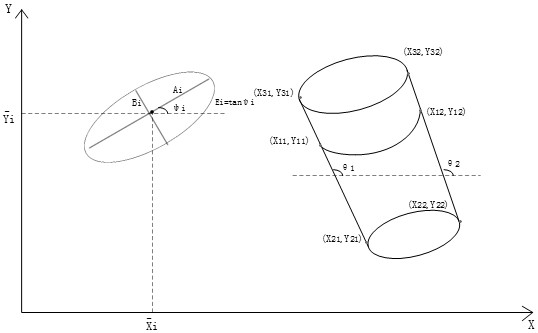

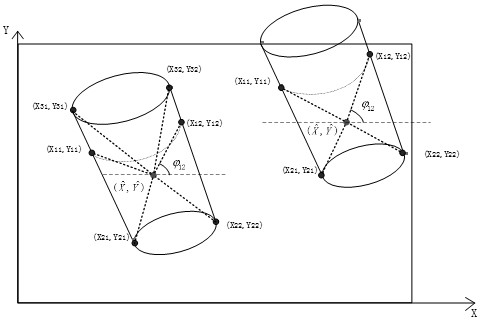

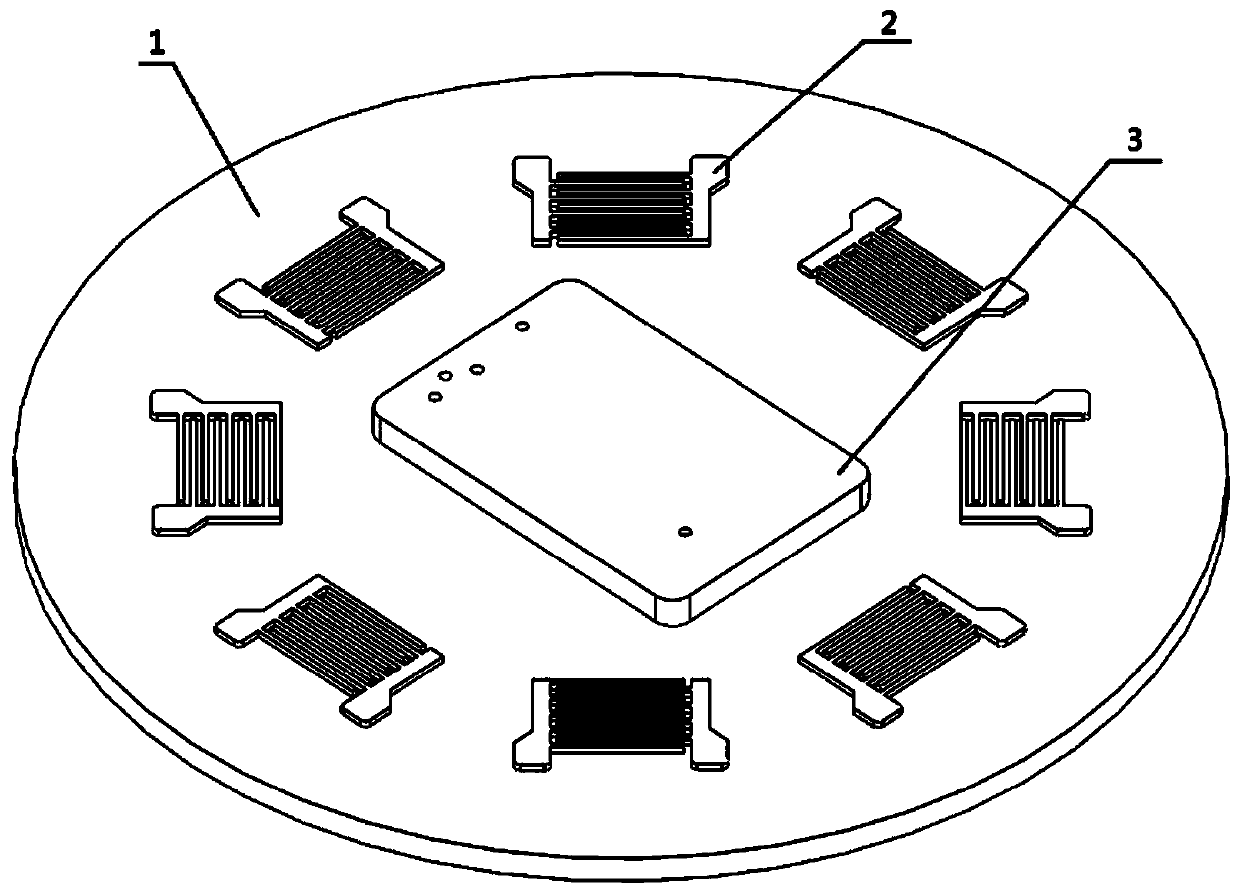

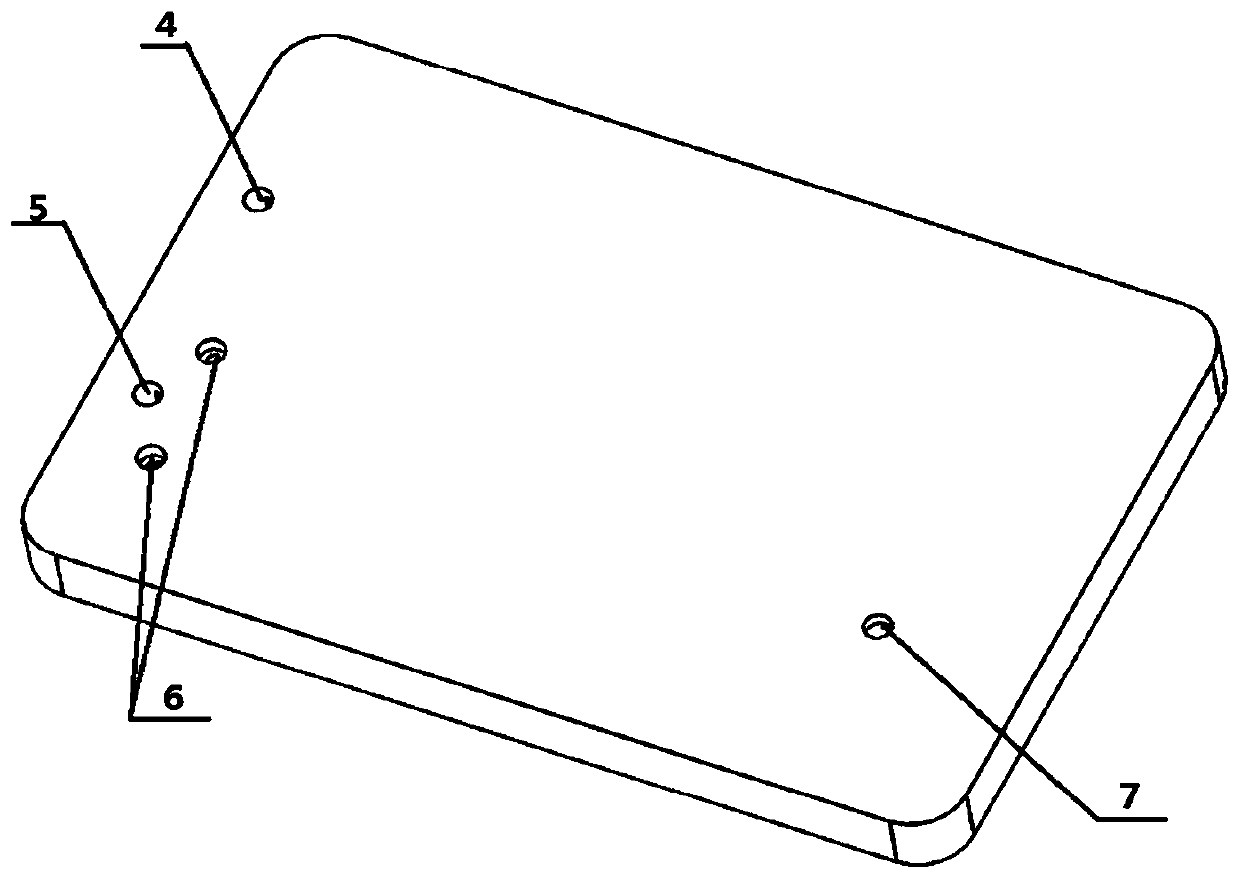

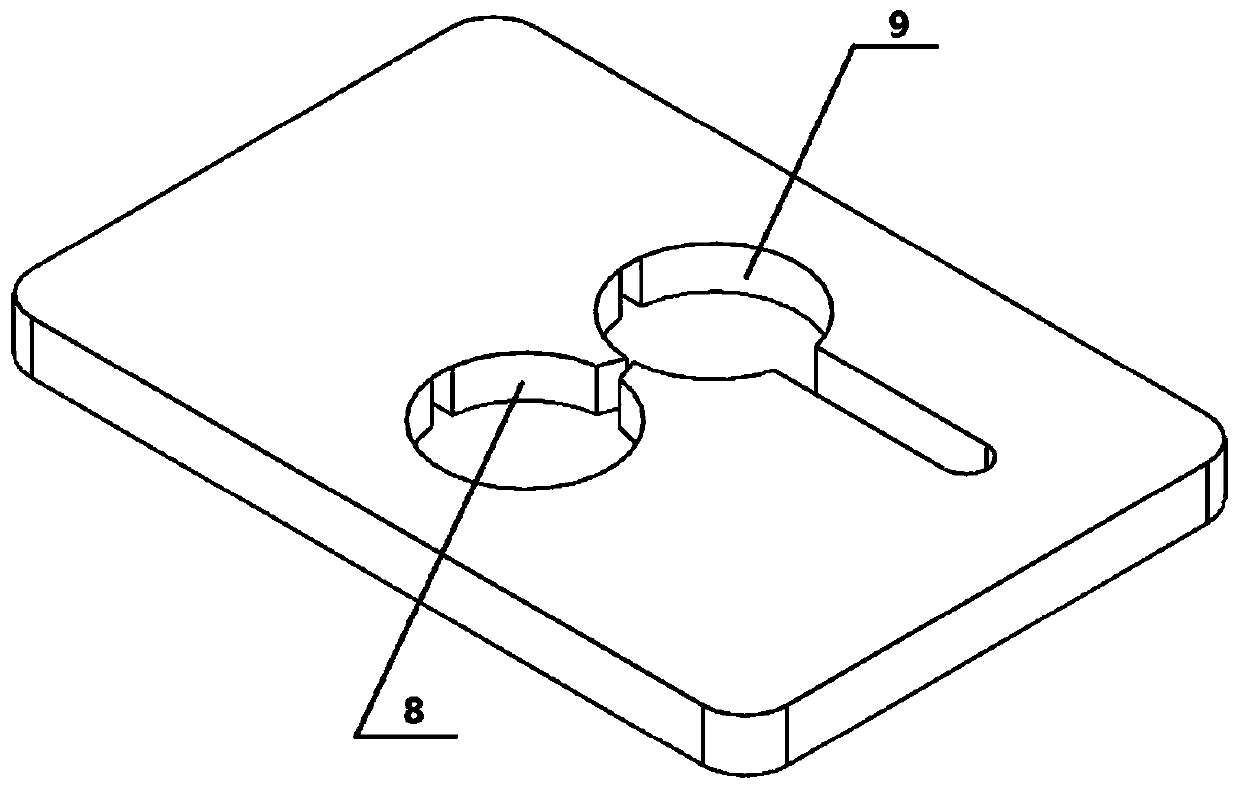

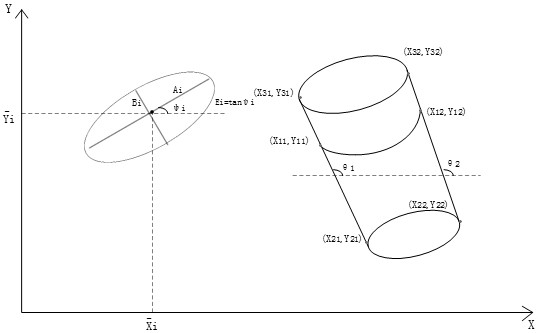

Visual servo approaching method for mobile columnar assembly

ActiveCN111931387AImprove robustnessImprove global convergenceProgramme-controlled manipulatorDesign optimisation/simulationVisual servoing systemEngineering

The invention discloses a visual servo approaching method for a mobile columnar assembly. The method comprises the following steps: establishing a relationship among visual information of a columnar assembly target, target model parameters and an imaging model; extracting coordinates of at least four pixel points in an imaging visual angle range, and constructing a visual servo control input feature vector for the columnar assembly target and a Jacobi transformation matrix corresponding to the visual servo control input feature vector; in view angle constraint, performing adaptive recombination on the constructed control input feature vector and the reference feature vector, and obtaining a feature Jacobi conversion matrix corresponding thereto; and adjusting and compensating for the output of a visual servo controller, so that the visual servo system approaches the mobile columnar assembly target. In this way, redundant visual information of columnar assembly target imaging is fully utilized, the robustness of a servo system for image noise, the adaptability for view angle constraint and the applicability for columnar assembly movement can be improved, and global convergence of visual servo control for a moving target is promoted.

Owner:HUNAN NORMAL UNIVERSITY

A robot-assisted ultrasound scanning system based on rgb‑d sensors

ActiveCN104856720BReasonable structureImprove performanceUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsVisual servoing systemColor image

Provided is an auxiliary ultrasonic scanning system of a robot based on an RGB-D sensor. The auxiliary ultrasonic scanning system comprises a Kinect sensor, the robot, an ultrasonic probe, a marker and a host and is characterized in that the Kinect sensor serves as a visual servo system of the robot; the ultrasonic probe is clamped on a mechanical arm of the robot; the marker is fixed onto the ultrasonic probe; the visual servo system of the robot is utilized for synchronously acquiring an RGB color image and a depth image and sending images to the host; the host finishes following processes such as image stitching operation and image three-dimensional reconstruction; according to image pairs acquired by the visual servo system, the marker fixed onto the ultrasonic probe is recognized and positioned by the host; according to a recognition-based positioning result, the position and the posture of the ultrasonic probe are calculated; and the host is used for sending a control instruction to the robot so that the mechanical arm of the robot is controlled to reach at the specified position for carrying out ultrasonic scanning operation. The auxiliary ultrasonic scanning system of the robot based on the RGB-D sensor is advantaged by being reasonable in design, reliable in performance, high in automated degree and detection efficiency and low in cost.

Owner:NORTHEAST DIANLI UNIVERSITY

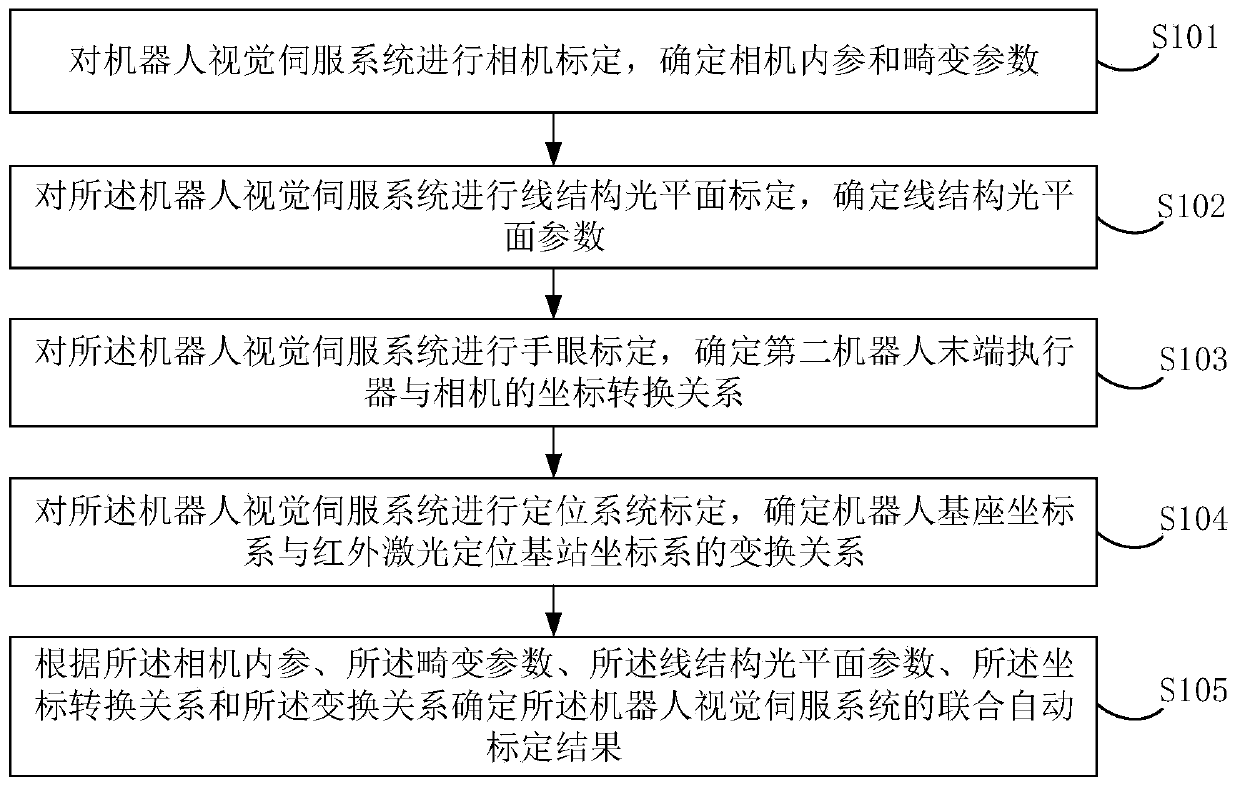

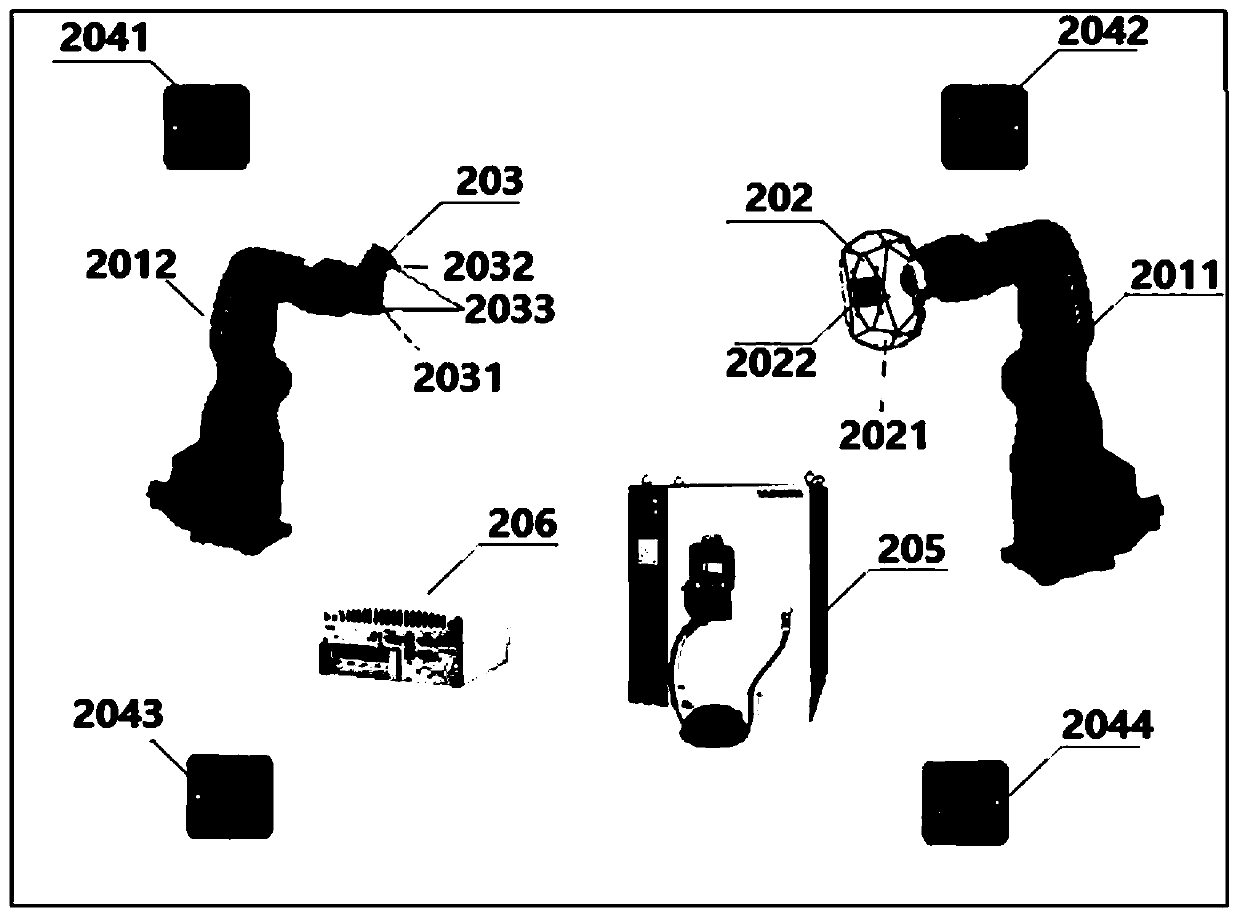

A joint automatic calibration method and device for a robot visual servo system

ActiveCN110136208BFully automatedAchieve global optimizationImage analysisVisual servoing systemIr laser

Owner:北京无远弗届科技有限公司

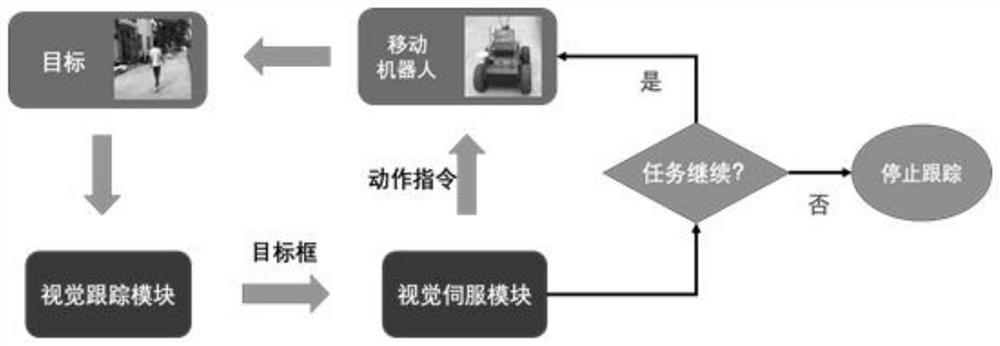

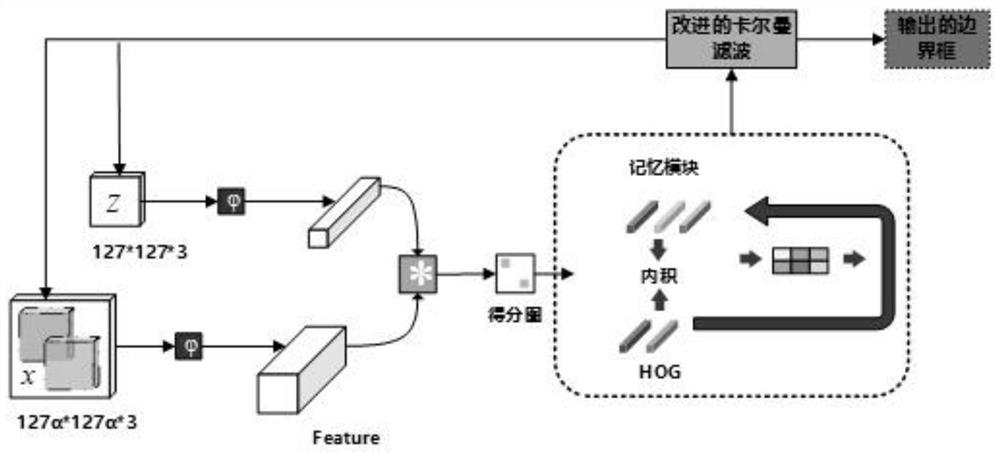

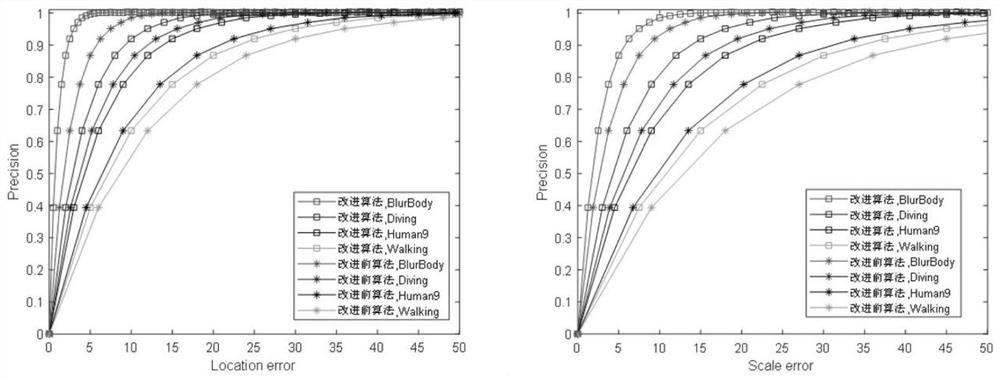

Visual tracking method for mobile robot

PendingCN112507859AReduce wasteAccurate predictionCharacter and pattern recognitionVisual servoing systemComputer graphics (images)

The invention discloses a visual tracking method for a mobile robot. According to the method, a full-connection twin network tracking algorithm based on HOG feature similarity calculation and Kalman filtering feedback is used, HOG features based on color statistics are used as an appearance model, a plurality of similar targets in a scene are further distinguished, and identity jump of the targetsis reduced. Meanwhile, a Kalman filtering motion model is adopted, so that accurate prediction of the motion trail of the target is realized, the boundary frame is refined, the search area is reduced, the target shielding problem in the target tracking process is solved, and the calculated amount is reduced. And finally, the bounding box position information of the tracking target is transmittedto a visual servo system for controlling the robot. According to the method, the waste of computing resources caused by searching useless areas is effectively reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

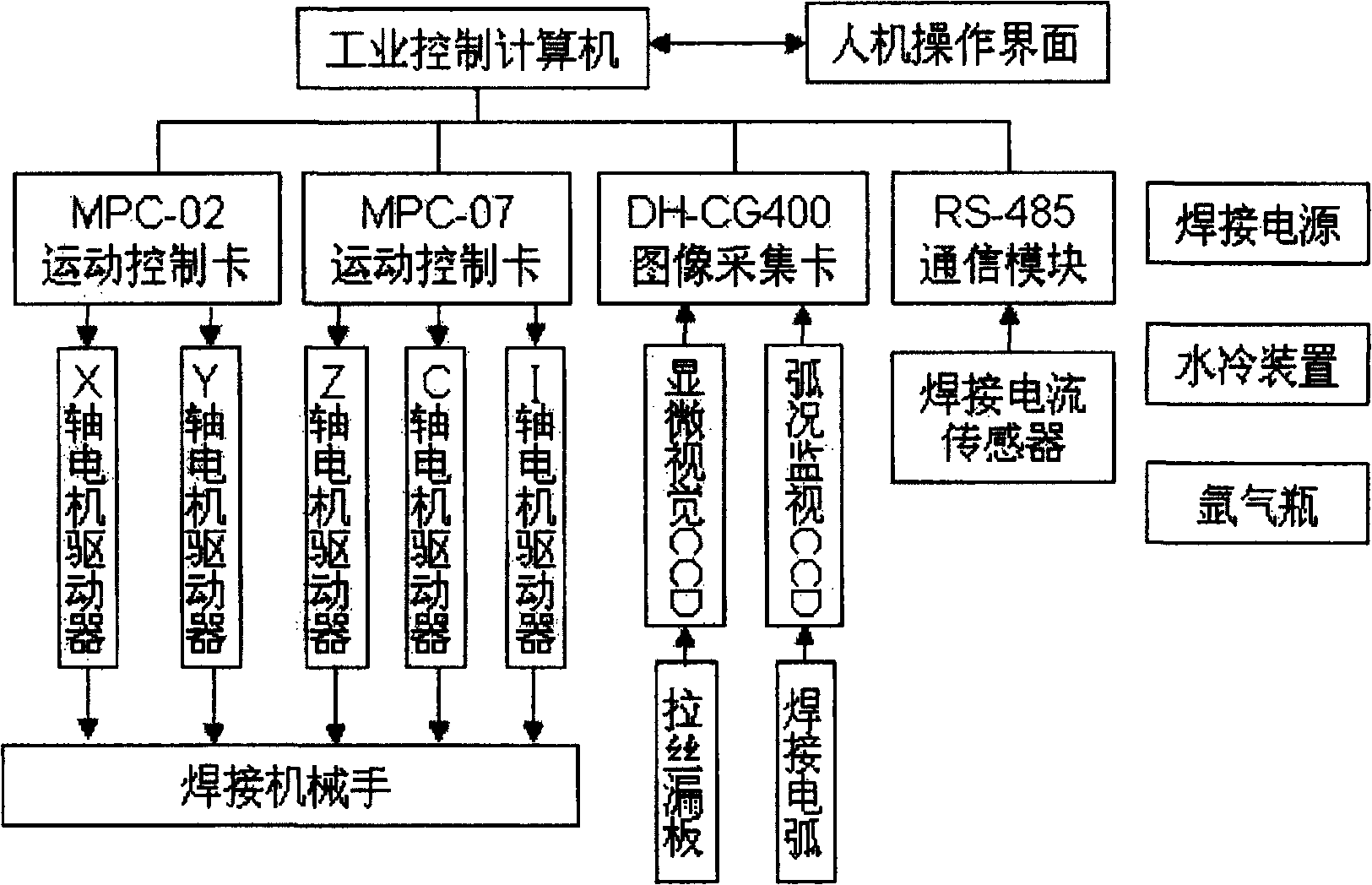

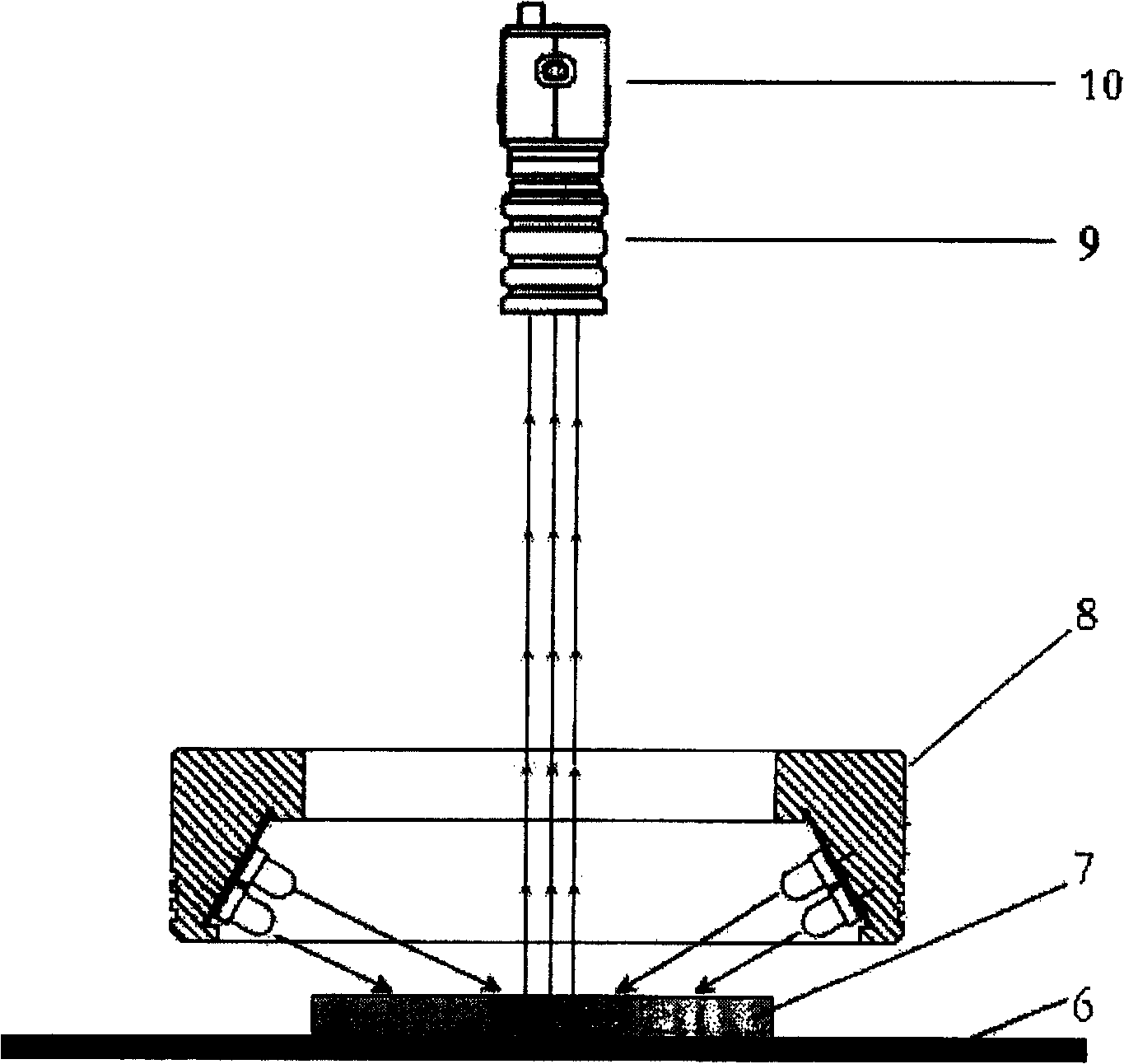

Microvision servo-system of platinum aurum fiber drawing bushing nozzle arc welding robot and the method thereof

InactiveCN100457357CRapid positioningPrecise Seam TrackingArc welding apparatusCharacter and pattern recognitionVisual servoing systemEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

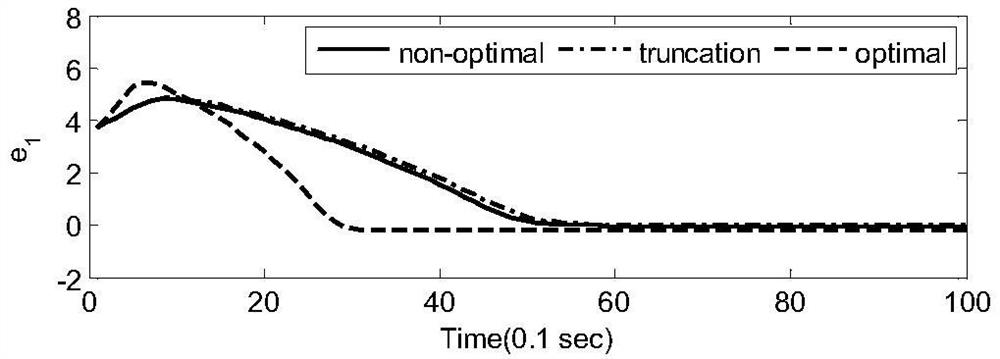

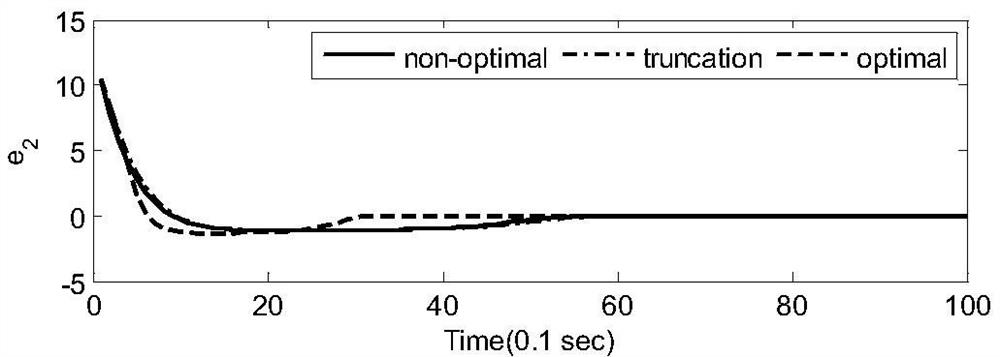

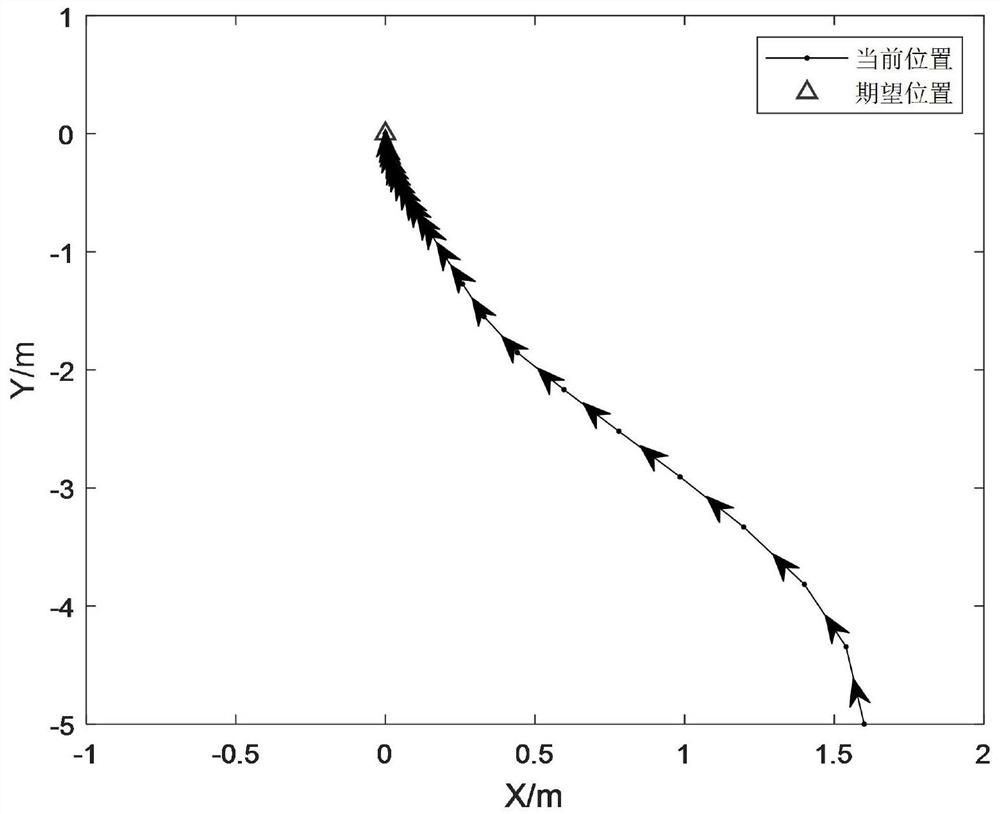

Mobile robot visual servo control method based on a Lyapunov function

ActiveCN113031590ADesign optimisation/simulationSpecial data processing applicationsVisual servoing systemEngineering

The invention discloses a mobile robot visual servo control method based on a Lyapunov function. According to the method, a series of explicit stable control laws are designed by adopting discrete time CLF of a visual servo system, and then a group of optimal parameters of the control laws are calculated by off-line solving and considering an optimal control problem of visible constraints and actuator constraints. According to the invention, simulation results show that the algorithm is feasible and effective in the visual servo control of the incomplete mobile robot.

Owner:浙江同筑科技有限公司

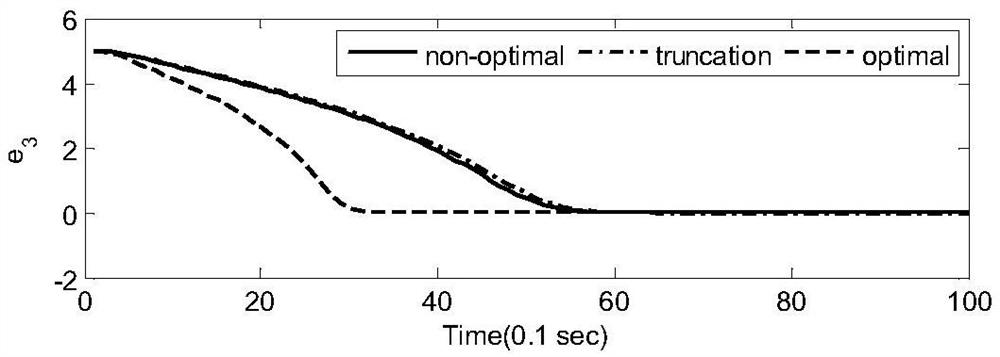

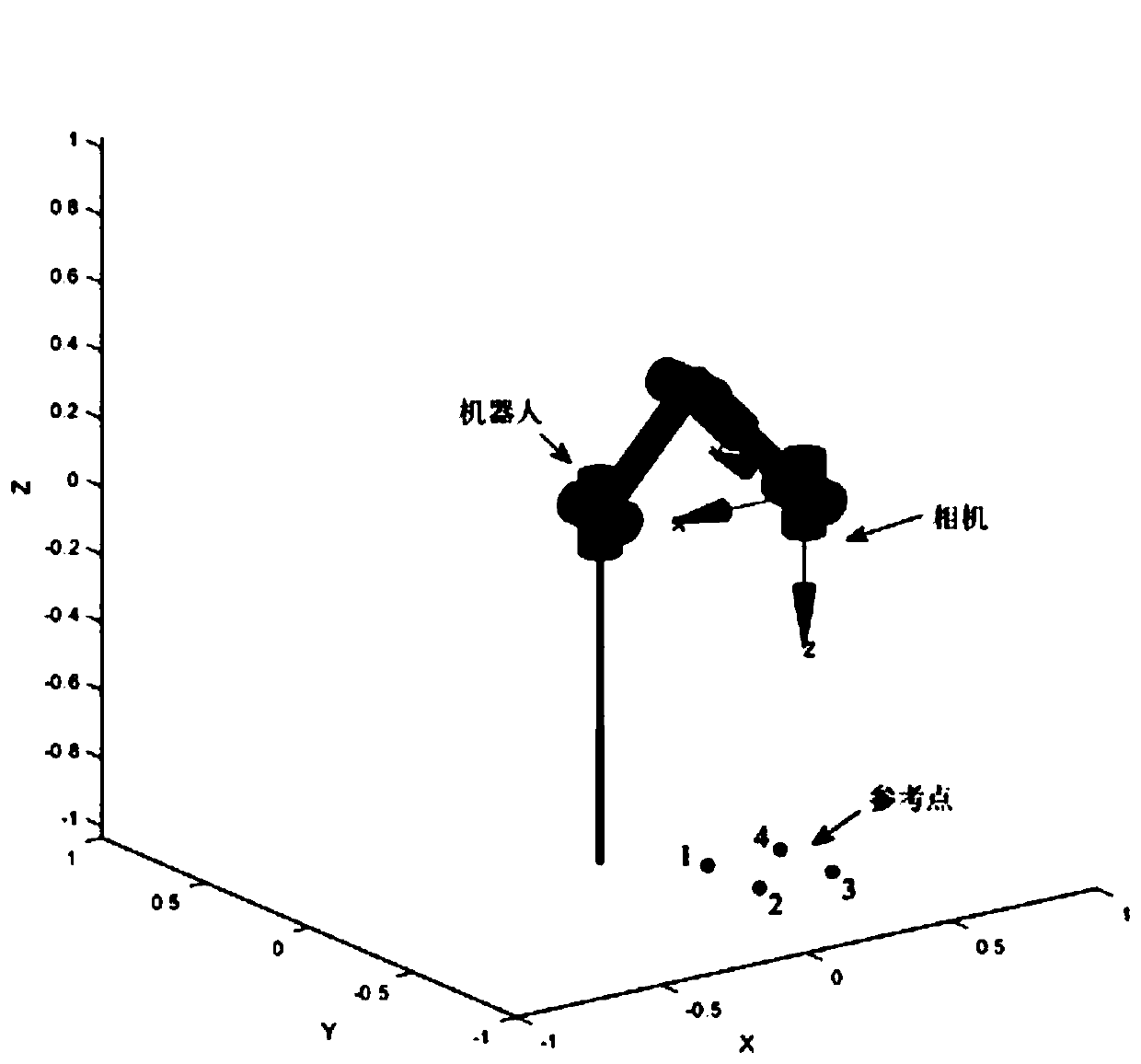

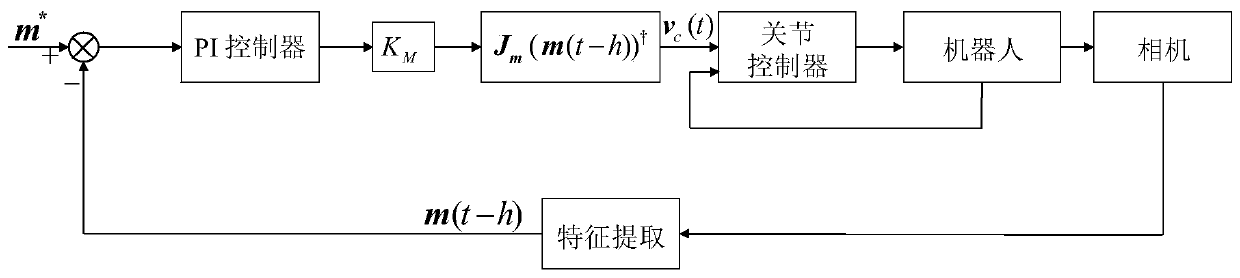

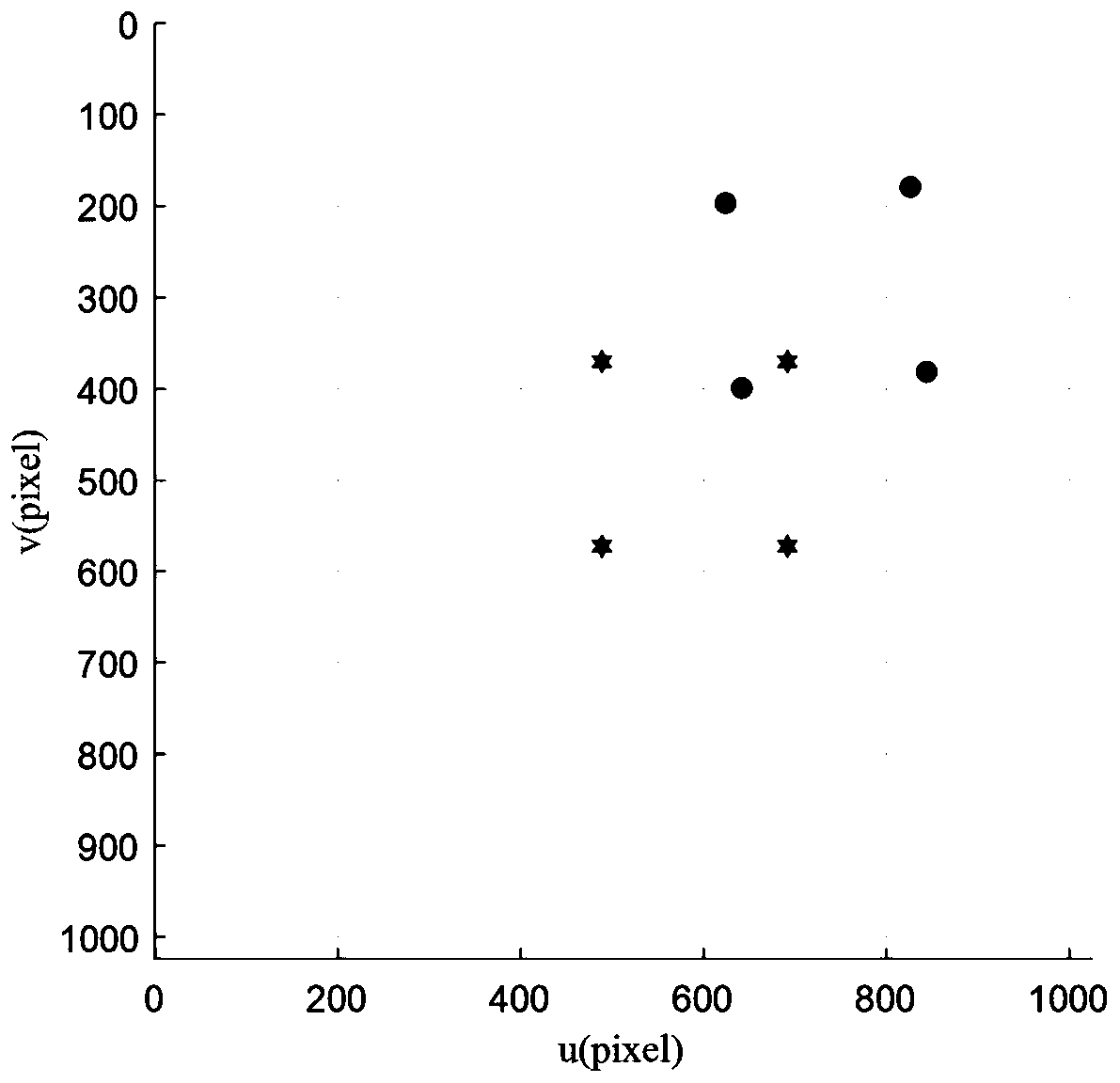

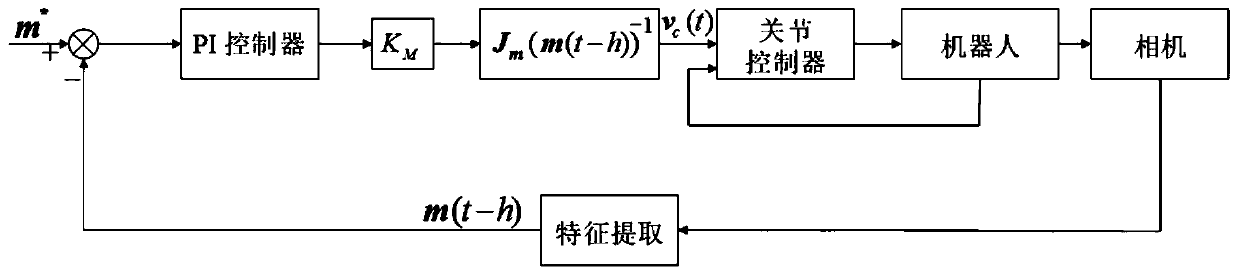

Time-lag visual servo system optimal PI parameter optimization method and system

ActiveCN109799698ASimple designImprove responsivenessControllers with particular characteristicsVisual servoing systemState space

The invention provides a time-lag visual servo system optimal PI parameter optimization method and system. The method includes the steps: determining time lag of a visual servo system; performing kinematical modeling on the visual servo system according to the time lag; performing state space transformation on a kinematical model; calculating a state-transition matrix of a state space equation bya differential quadrature method; changing a parameter of a PI controller in the visual servo system, calculating a maximum value of modules of characteristic values under different parameters; makingthe maximum value of modules of characteristic values of the state-transition matrix to be 1, and calculating a stability boundary of the visual servo system in PI controller parameter space; optimally minimizing the maximum value of the modules of the characteristic values of the state-transition matrix in the stability boundary, and comparing the maximum values of the modules of the characteristic values of the state-transition matrix under different controller parameter conditions to obtain optimized PI controller parameter. According to the method, the response performance of the visual servo system is improved, and the application range of visual servo technologies is widened.

Owner:SHANGHAI JIAO TONG UNIV

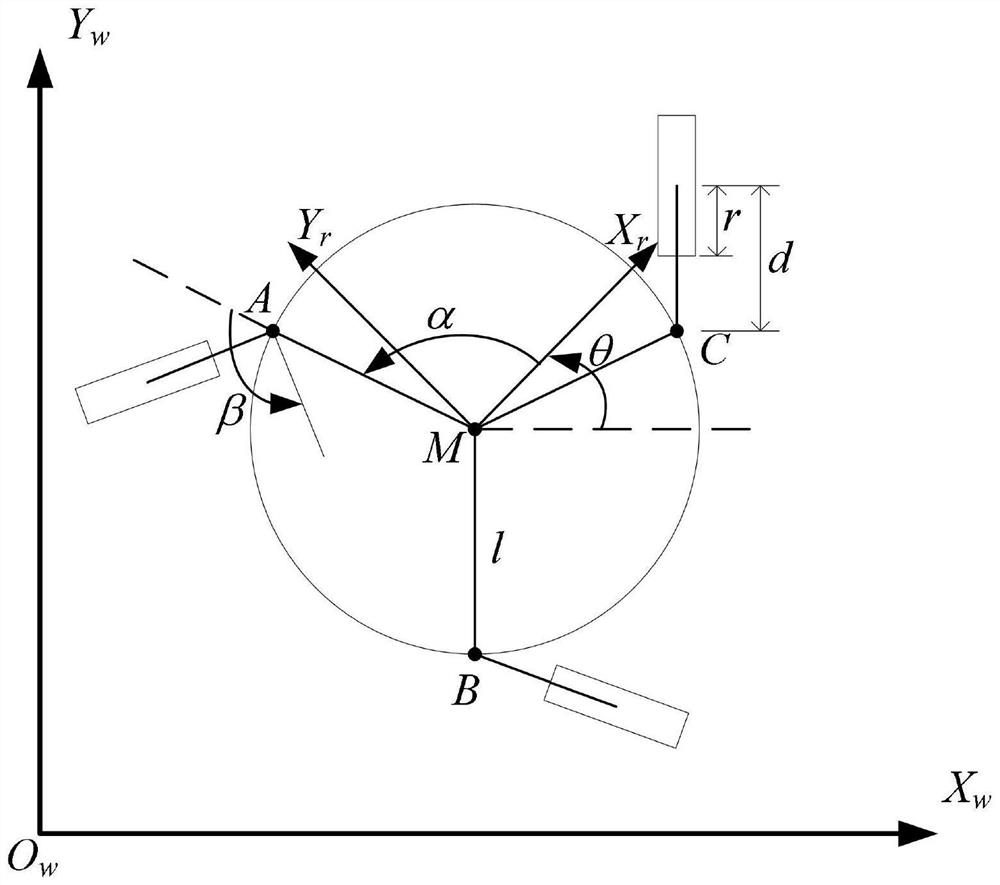

Modeling and control method for visual servo system of omni-directional mobile robot

PendingCN113848908AEasy to handlePosition/course control in two dimensionsVehiclesVisual servoing systemKinematics equations

The invention relates to a modeling and control method for a visual servo system of an omni-directional mobile robot, which considers the problem that an inintegratable speed constraint exists in a nonintegrity mobile robot, and researches the visual servo system of the omni-directional mobile robot consisting of three driving eccentric wheels. The invention provides a visual servo controller based on a model prediction control strategy aiming at the condition that a visual servo system has visual visibility constraint and actuator constraint. The method comprises the following steps: firstly, modeling a visual servo error system of rolling angular velocity and deflection angular velocity of an eccentric direction wheel of the omni-directional mobile robot is performed based on a kinematics equation and a visual servo system error model of the active eccentric wheel omni-directional mobile robot; on the basis, a visual servo prediction model of the omni-directional mobile robot is established in combination with a model prediction control strategy, and then a visual servo prediction control strategy is designed; and the designed controller not only can drive the mobile robot to reach a target point, but also can better process constraint conditions.

Owner:ZHEJIANG UNIV OF TECH

Operating object position and posture recognition method applicable to industrial robot

ActiveCN103112015BAchieve acquisitionImprove intelligenceManipulatorVisual servoing systemImaging data

The invention relates to an operating object position and posture recognition method applicable to an industrial robot. The operating object position and posture recognition method applicable to the industrial robot can be applied to a visual servo system based on positions, timely provides positions and posture information of an operating object for the visual servo system, is short in operation time and high in precision, can adapt to different illumination conditions indoor and outdoor and the like, and provides technical support for usage of the industrial robot in unstructured environments. The operating object position and posture recognition method applicable to the industrial robot comprises the following steps: step1, an initialization operation, calibrating initialization of a left camera, a right camera and the operating object, and then using the left camera and the right camera to obtain image data; step2, following the moving operating object by using a front frame image and a back frame image in the process of image capture; step3, smoothing changes of an operating object following window of the front frame image and the back frame image through kalman filtering; step4, using an image data dimension reduction mode to reduce dimension of data processing; and step5, calculating three-dimensional positions and posture of the operating object, and feeding back data to a servo control system of the industrial robot so as to achieve servo control.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

A Fast Focusing Method for Robot Vision Servo System

ActiveCN109318235BQuick focusGuaranteed clarityProgramme-controlled manipulatorMountingsVisual servoing systemImaging processing

The invention discloses a fast focusing method for a robot visual servo system, which belongs to the field of image processing. The existing mechanical focusing technology has the problems of poor zoom ability and slow speed, and it is difficult to meet the real-time requirements of visual servoing. The method of the present invention installs a liquid lens for the camera at the end of the robotic arm of the robot; the current of the liquid lens when the image is obtained multiple times, and the distance data between the camera and the target object; determines the image with the maximum sharpness and the current of the corresponding liquid lens and The distance data between the camera and the target object; repeat the above content to obtain multiple sets of maximum sharpness current and distance data, establish the relationship model between the maximum sharpness current and distance, and obtain the model parameters through the system identification method; use the established The relationship model, combined with the distance information, obtains the current value required for the liquid lens to zoom, and then controls the liquid lens to zoom. The method of the invention ensures the fast focusing of the visual servo system and the imaging definition of the target object.

Owner:HARBIN INST OF TECH

Intelligent trolley 2.5-dimensional visual servo control method based on nonlinear model prediction

InactiveCN102880062BImprove reliabilityImprove securitySimulator controlPosition/course control in two dimensionsVisual servoing systemControl theory

The invention discloses an intelligent trolley 2.5-dimensional visual servo control method based on nonlinear model prediction. The intelligent trolley 2.5-dimensional visual servo control method comprises the steps as follows: firstly, obtaining a current image and an expected image of a reference target respectively through a video camera at a current pose and an expected pose; secondly, extracting the characteristic points of the reference target and the pose information of the trolley, organically combining a two-dimensional image signal with a three-dimensional pose signal through coordinate conversion, and building a 2.5-dimensional visual error model; and lastly, aiming at the 2.5-dimensional visual error model, designing a multilevel visual predication controller by utilizing a nonlinear model prediction control method. According to the intelligent trolley 2.5-dimensional visual servo control method, the problem that velocity and torque constraint of a motion performing system and visibility constraint of the video camera cannot be processed by the conventional 2.5-dimensional visual servo control method is solved, the reference target can be guaranteed to remain visible all the time in the servo process, and the reliability and the safety of a visual servo system are greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

A surface acoustic wave-based cell adhesion measuring instrument and measuring method

ActiveCN107238556BLess distracting factorsAvoid destructionBioreactor/fermenter combinationsBiological substance pretreatmentsVisual servoing systemCell adhesion

The invention discloses a cell adhesion measuring instrument and a measuring method based on surface acoustic waves. It includes lithium niobate wafer, silver interdigital electrode annular array, PDMS micro-channel and micro visual servo system. The micro visual servo system includes a host computer system based on PXI bus, a multi-channel signal generation system and a micro visual monitoring system. , a lithium niobate wafer is surrounded by a silver interdigital electrode annular array, the lithium niobate wafer and the silver interdigital electrode annular array form an interdigital transducer, the silver interdigital electrode annular array and a multi-channel signal generation system connected. The present invention uses an interdigital transducer and a microscopic visual servo system to synthesize the expected sound field in the PDMS microfluidic cavity, uses surface acoustic wave radiation force to manipulate cells and measures cell adhesion, and has the advantages of simple operation and low interference factors. Advantages of waiting less.

Owner:ZHEJIANG UNIV

A Visual Servo Approach Method for Moving Cylindrical Combinations

ActiveCN111931387BImprove robustnessImprove global convergenceProgramme-controlled manipulatorDesign optimisation/simulationVisual servoing systemControl theory

The invention discloses a visual servo approaching method for a mobile columnar assembly. The method comprises the following steps: establishing a relationship among visual information of a columnar assembly target, target model parameters and an imaging model; extracting coordinates of at least four pixel points in an imaging visual angle range, and constructing a visual servo control input feature vector for the columnar assembly target and a Jacobi transformation matrix corresponding to the visual servo control input feature vector; in view angle constraint, performing adaptive recombination on the constructed control input feature vector and the reference feature vector, and obtaining a feature Jacobi conversion matrix corresponding thereto; and adjusting and compensating for the output of a visual servo controller, so that the visual servo system approaches the mobile columnar assembly target. In this way, redundant visual information of columnar assembly target imaging is fully utilized, the robustness of a servo system for image noise, the adaptability for view angle constraint and the applicability for columnar assembly movement can be improved, and global convergence of visual servo control for a moving target is promoted.

Owner:HUNAN NORMAL UNIVERSITY

A PD-SMC Control Method of Visual Servo System Based on Eye-on-Hand Structure

ActiveCN107627303BGuaranteed availabilityDealing with uncertaintyProgramme-controlled manipulatorAdaptive controlVisual servoing systemFeature set

The invention relates to the field of visual servo systems, in particular to a PD-SMC control method of a visual servo system based on an eye-on-hand structure so as to solve the problems of uncertainty and large computation amount existing in an existing visual servo system control method. The method comprises the steps of (1) setting an expected image and collecting feature points of the expected image as an expected visual feature set; (2) conducting projection transformation on a target expected image with the current state of the relative poses of a camera and a target body to obtain a current image of the camera; (3) adopting the PD-SMC method for a visual servo controller part and adopting a proportional control method for a joint controller part; (4) extracting a visual feature setfrom the current image, computing a jacobian matrix of the image and then computing the controlled quantity u of the camera in a Cartesian space; and (5) computing the pose of the target body in a camera coordinate system, and repeating the operations with the pose as the current pose until the error is zero. The PD-SMC control method can be applied to target grabbing equipment.

Owner:HARBIN ENG UNIV +3

A Servo Tracking Accelerated Convergence Method for Robot Vision Feature Planning Trajectory

ActiveCN111283683BImprove adaptabilityEnsure global convergenceProgramme-controlled manipulatorVisual servoing systemControl engineering

Owner:HUNAN NORMAL UNIVERSITY

Optimal pi parameter optimization method and system for time-delay visual servo system

ActiveCN109799698BSimple designImprove responsivenessControllers with particular characteristicsVisual servoing systemTransition matrices

Owner:上海墨向机械科技有限公司

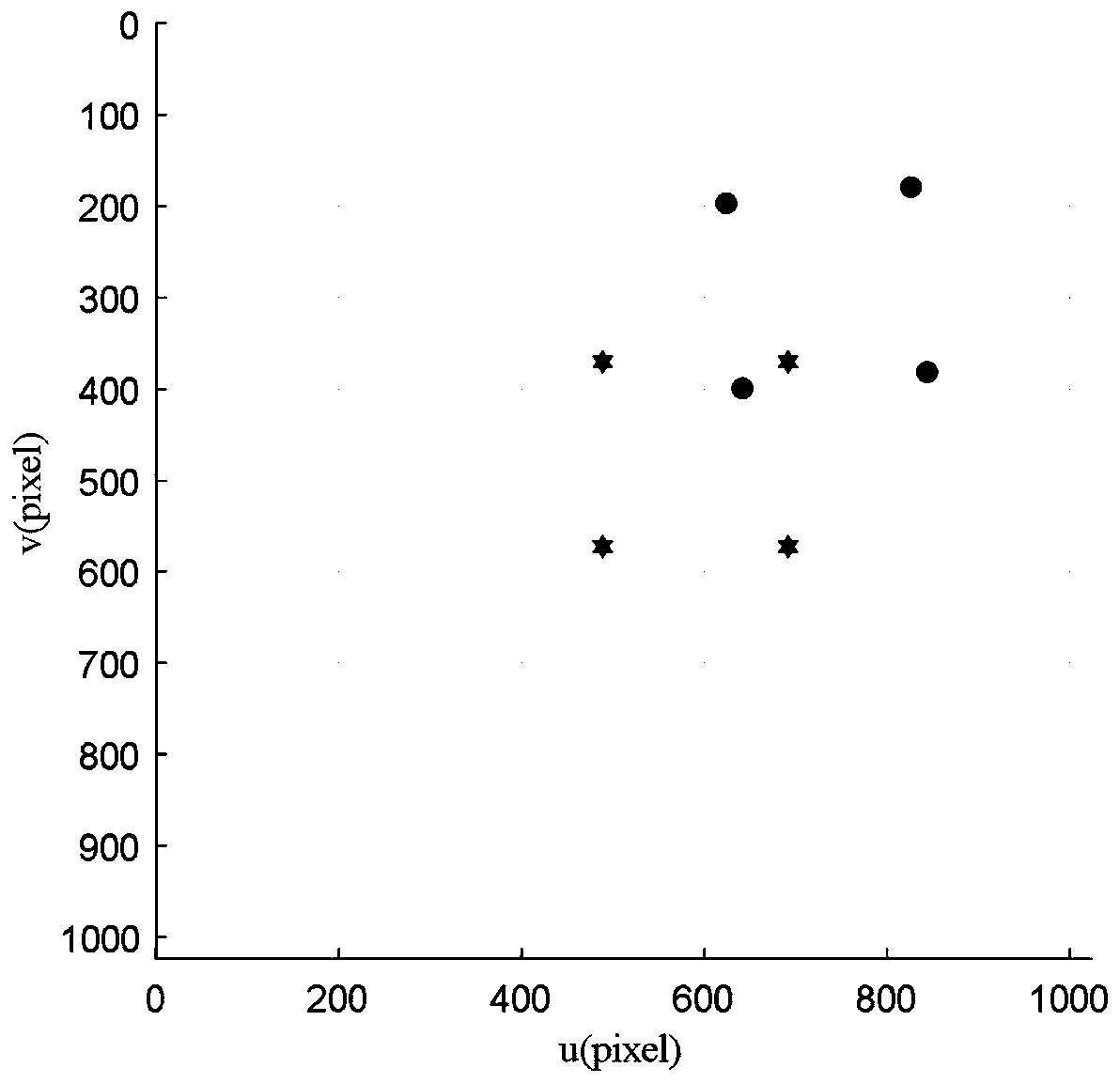

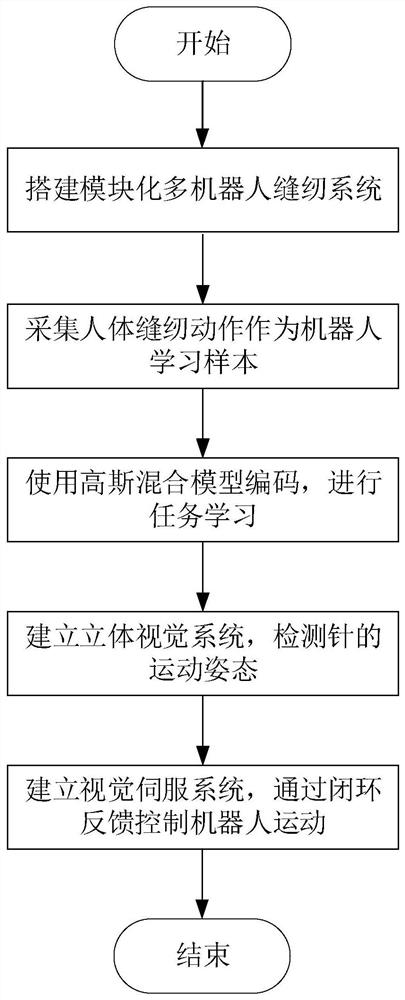

Method for recognizing human body sewing actions by robot

ActiveCN112257655AImprove accuracyGood task learningInput/output for user-computer interactionCharacter and pattern recognitionVisual servoing systemHuman body

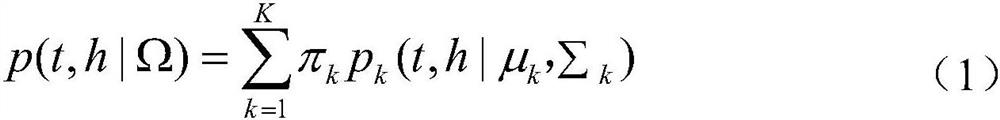

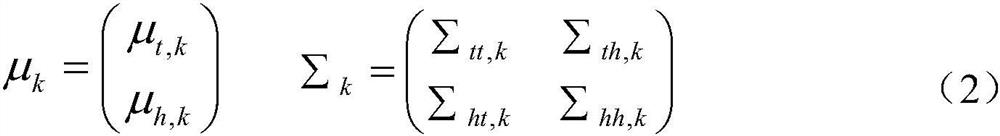

The invention discloses a method for recognizing human body sewing actions by a robot, which comprises the following steps: 1, building a modular multi-robot sewing system which comprises a double-hand sewing system, a stereoscopic vision system and a visual servo system which are connected with one another; 2, human body sewing actions being collected to serve as robot learning samples, and training data being generated; 3, performing task learning on the motion elements obtained by demonstration by using Gaussian mixture model coding; 4, establishing a stereoscopic vision system, and detecting the moving posture of the needle in the task period; and 5, establishing a visual servo system, and guiding and adjusting the movement of the robot through the feedback of closed-loop vision. According to the method, the sewing gesture recognition accuracy is improved, the response speed is increased, and the problem of poor dynamic real-time performance of the current method is solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com