Microvision servo-system of platinum aurum fiber drawing bushing nozzle arc welding robot and the method thereof

A technology of microscopic vision and wire drawing bushings, applied in arc welding equipment, instruments, manipulators, etc., can solve the problems of poor welding quality consistency, low mechanical strength, narrow mold space, etc., to meet the requirements of welding seam tracking accuracy, The positioning process is simple and fast, and the effect of precise positioning is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

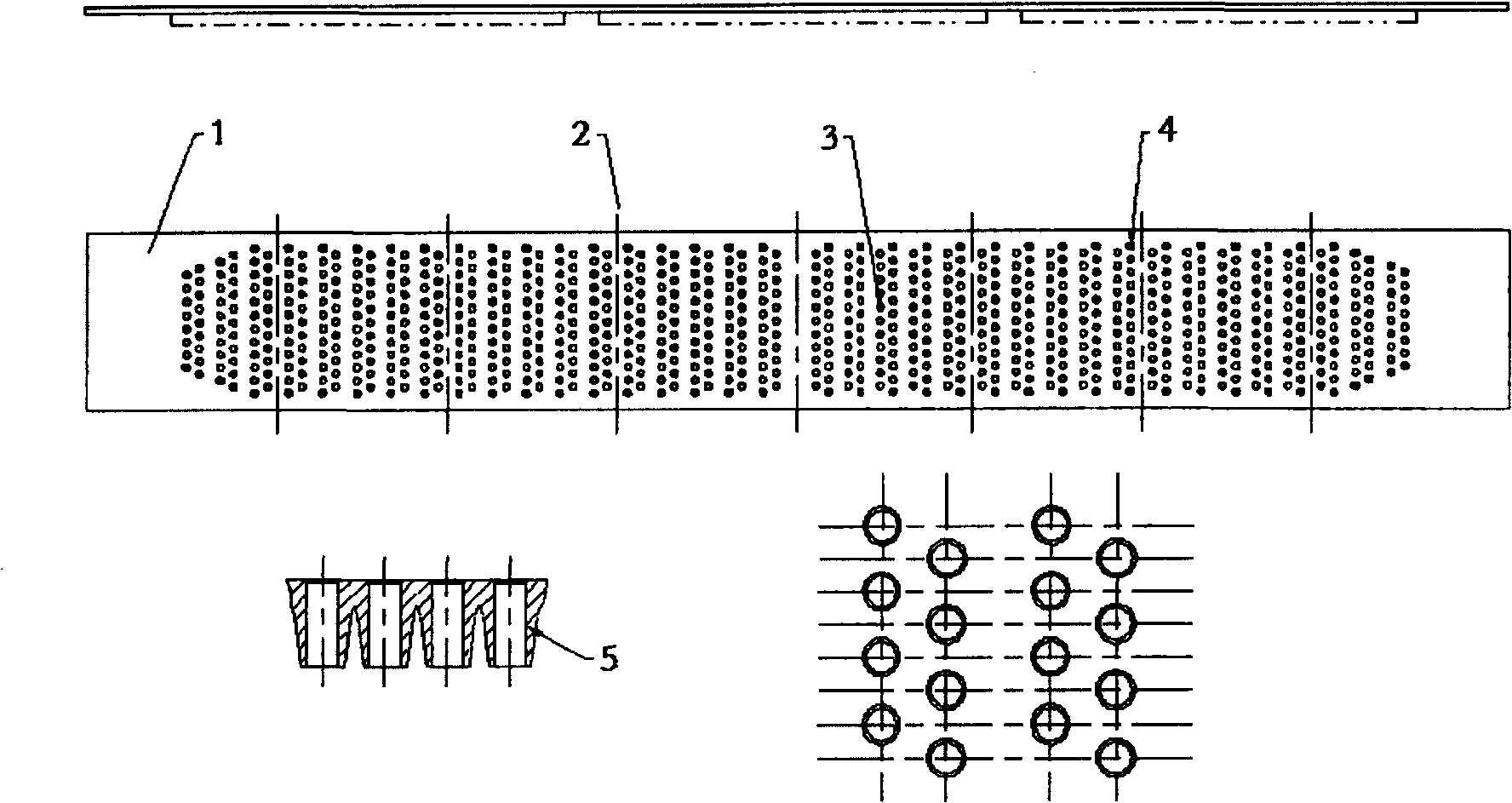

[0044] figure 1 It is the layout of the nozzle of the 800-hole platinum brushed leak plate.

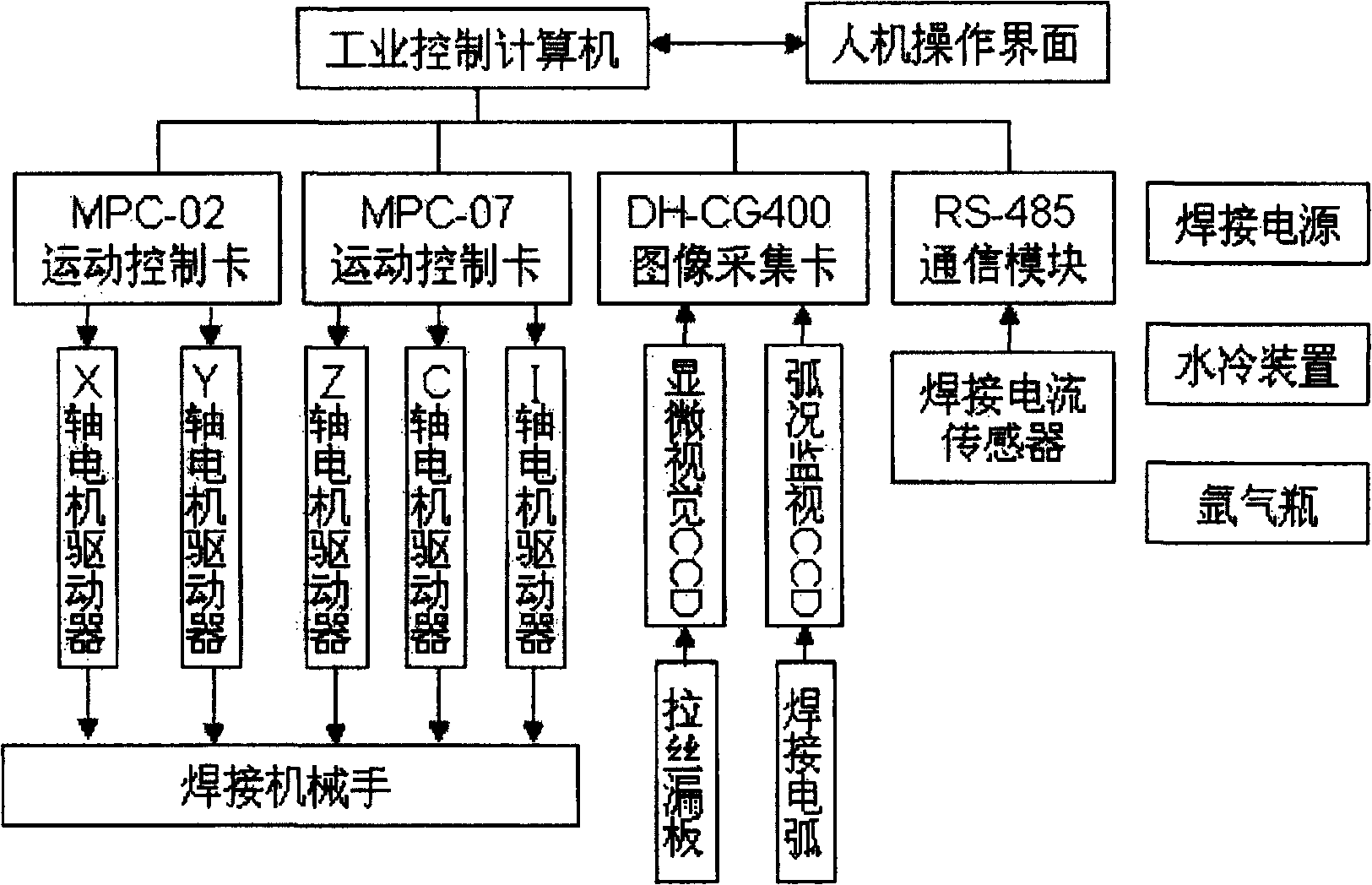

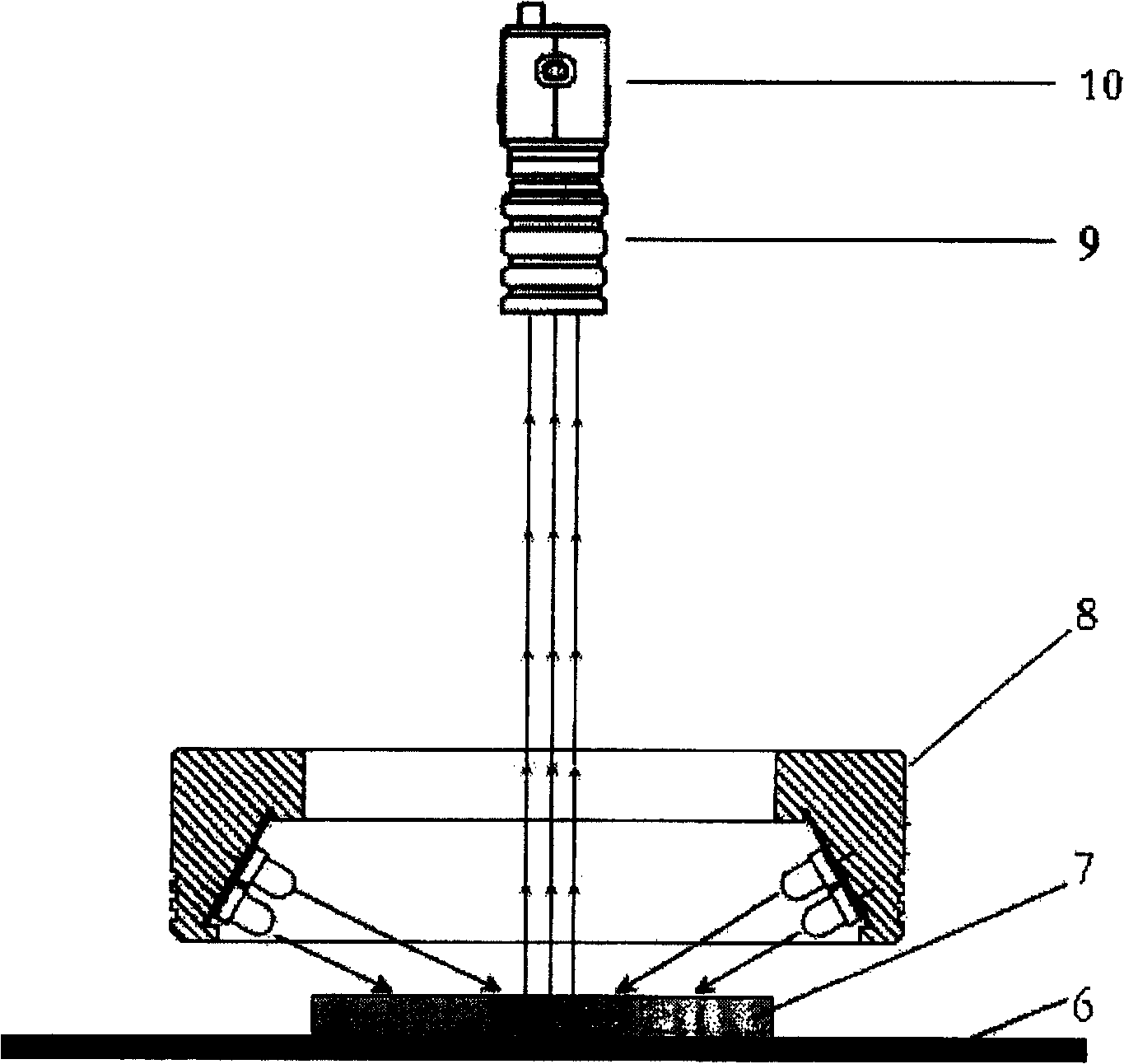

[0045] according to figure 2 As shown, the glass fiber pool kiln platinum wire drawing drain plate nozzle arc welding robot consists of industrial control computer, welding manipulator, motion control system, micro vision system, arc condition monitoring system, welding current detection system, welding power supply, water cooling device, Argon cylinder composition. Among them, through the analysis of the visual function of the human eye during the arc welding connection process of the platinum wire drawing bushing plate nozzle, it can be found that the robot that realizes the automatic arc welding connection of the platinum wire drawing bushing plate nozzle must have the following machine vision functions: 1) Large size The common machine vision function in the range is used to judge whether the arc is successful, measure the arc length, and judge whether the arc is accidentally e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com