Method for processing electrolytic residue

A disposal method and waste residue technology, applied in the direction of solid waste removal, etc., can solve the problems of inconvenient operation and management, large initial engineering volume, and large floor area, and achieve the effects of saving infrastructure investment, small engineering volume, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

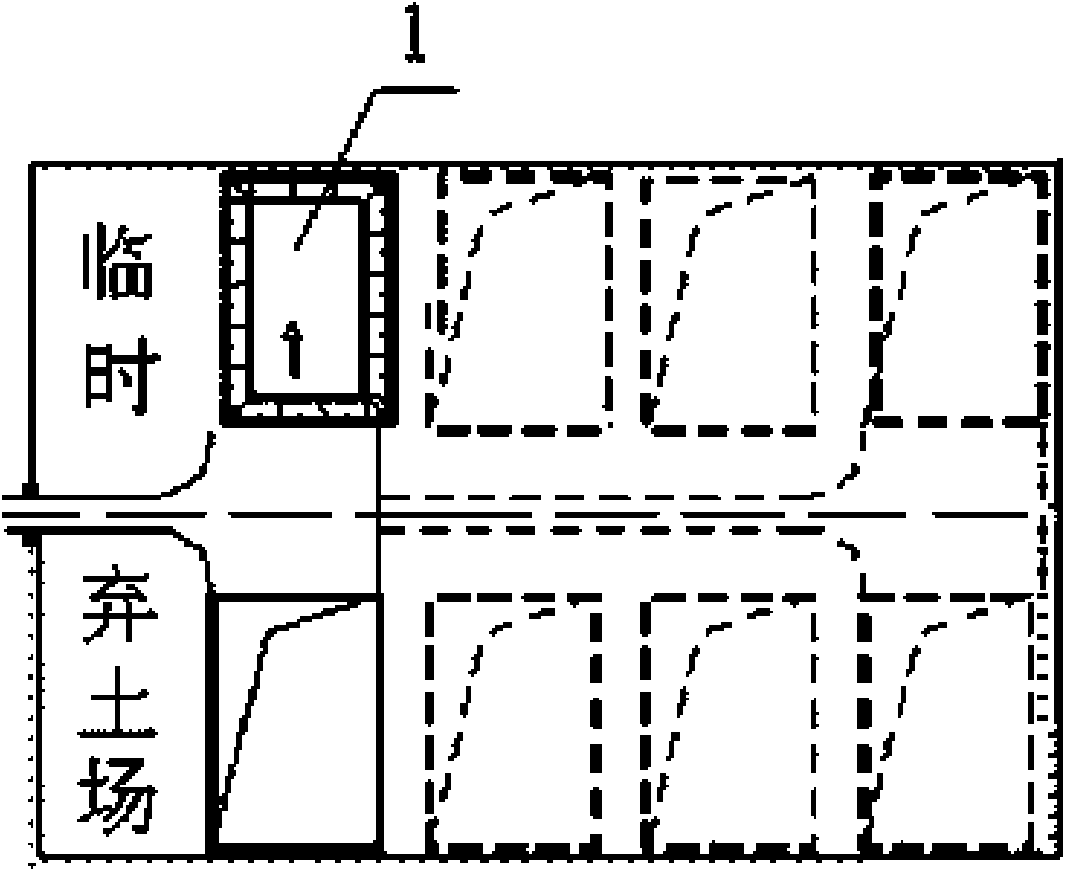

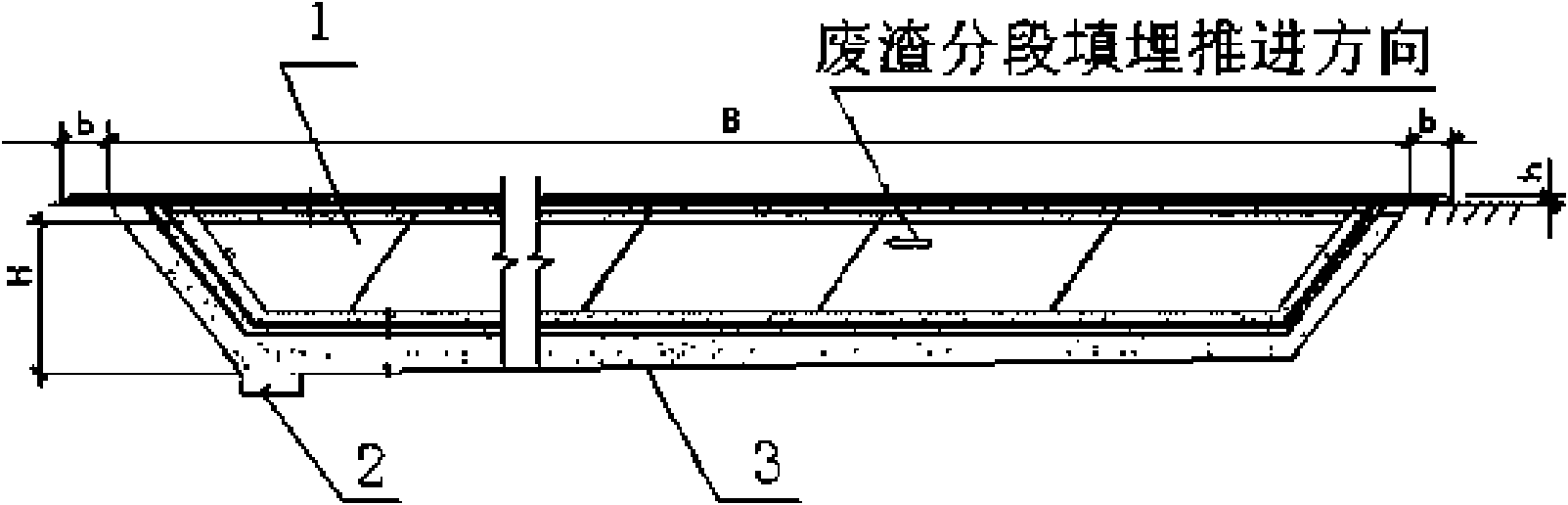

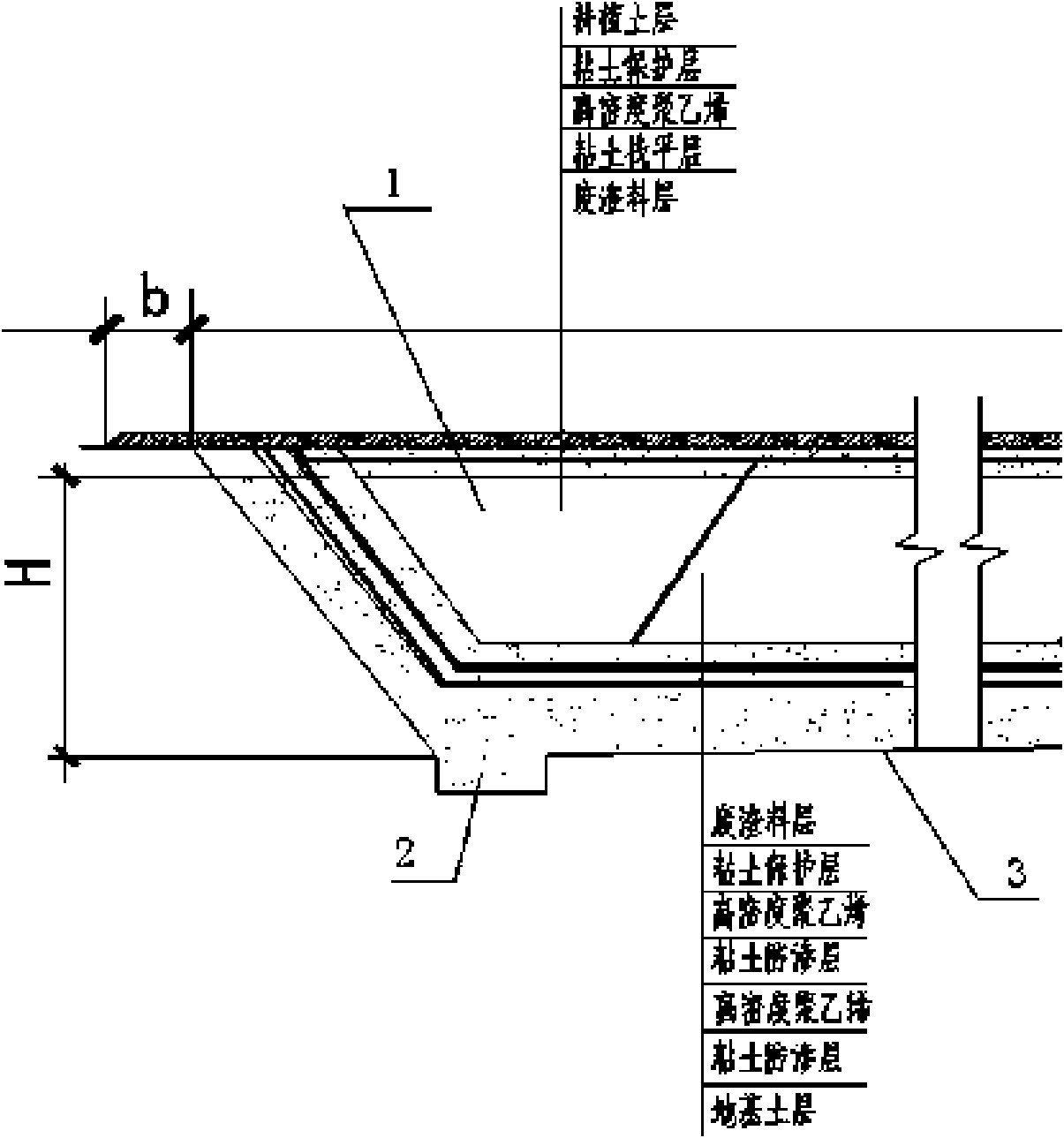

[0020] Embodiments of the present invention: it comprises the following processes: the first, the slag site is planned as several landfill pits 1, and the temporary spoil site is reserved simultaneously, see figure 1 ; The volume of each landfill pit can meet the amount of waste residues stored for 1-2 years. The bottom 3 of the landfill pit is set in a slope shape with a slope ≥ 0.5%, and a sump 2 is set at the lowest point of the pit bottom; Dig landfill pits, excavate in stages, and only excavate one landfill pit each time; third, carry out anti-seepage treatment on the excavated landfill pits, and the anti-seepage treatment from bottom to top is as follows: foundation soil layer, Clay anti-seepage course, high-density polyethylene course, clay anti-seepage course, high-density polyethylene course, clay protective course, see image 3 ; Fourth, pile up waste residues in the landfill pit, and gradually stack them in sections from high to low. (approximately 15-20m), after f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com