Installing hanging assembly of veneer materials

A technology for facing materials and suspension components, applied in covering/lining, construction, building construction, etc., can solve the problems of high production cost, high consumption of steel, easy to fall off, etc., and achieve reduced thickness requirements, lighten load-bearing requirements, The effect of reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

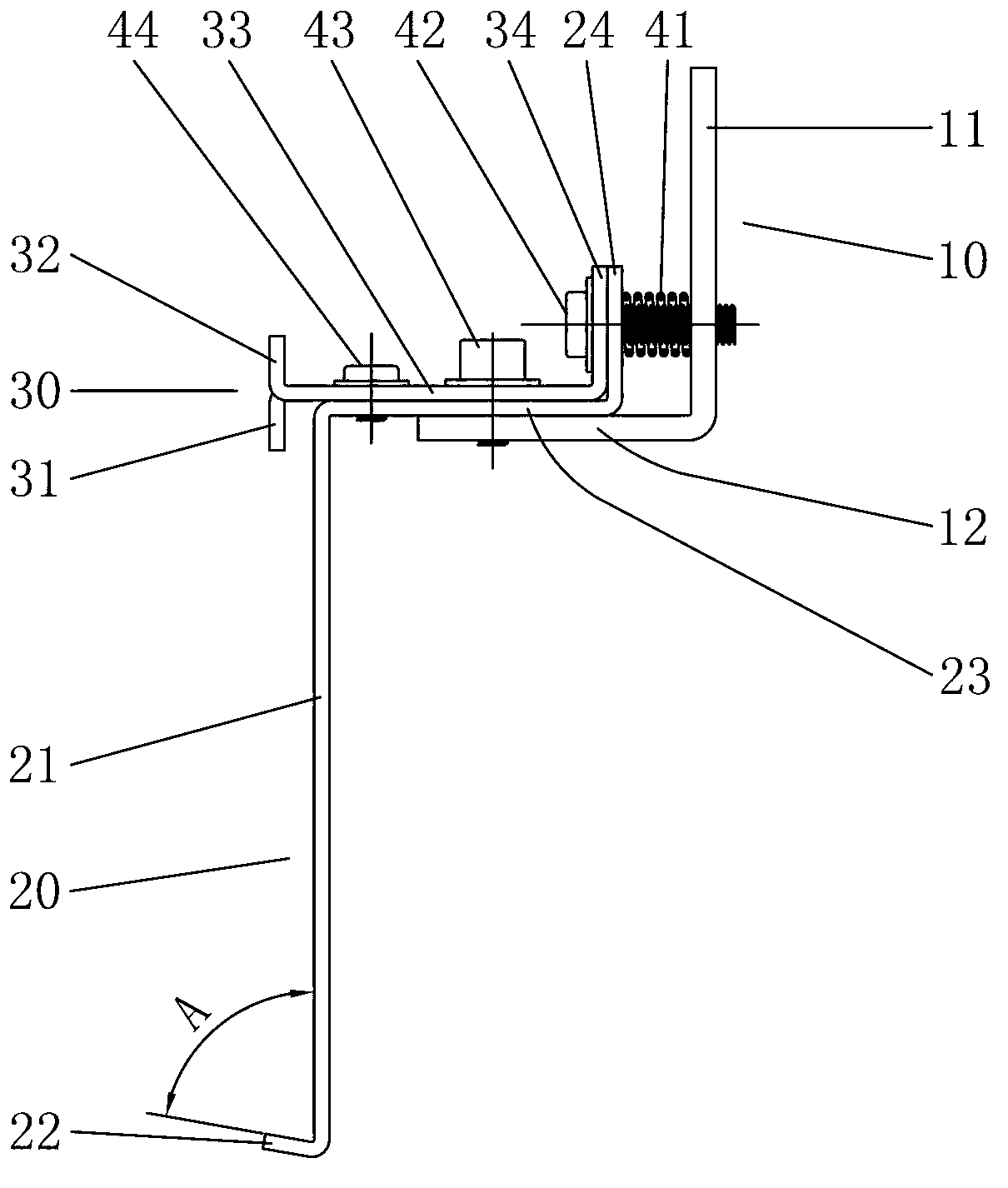

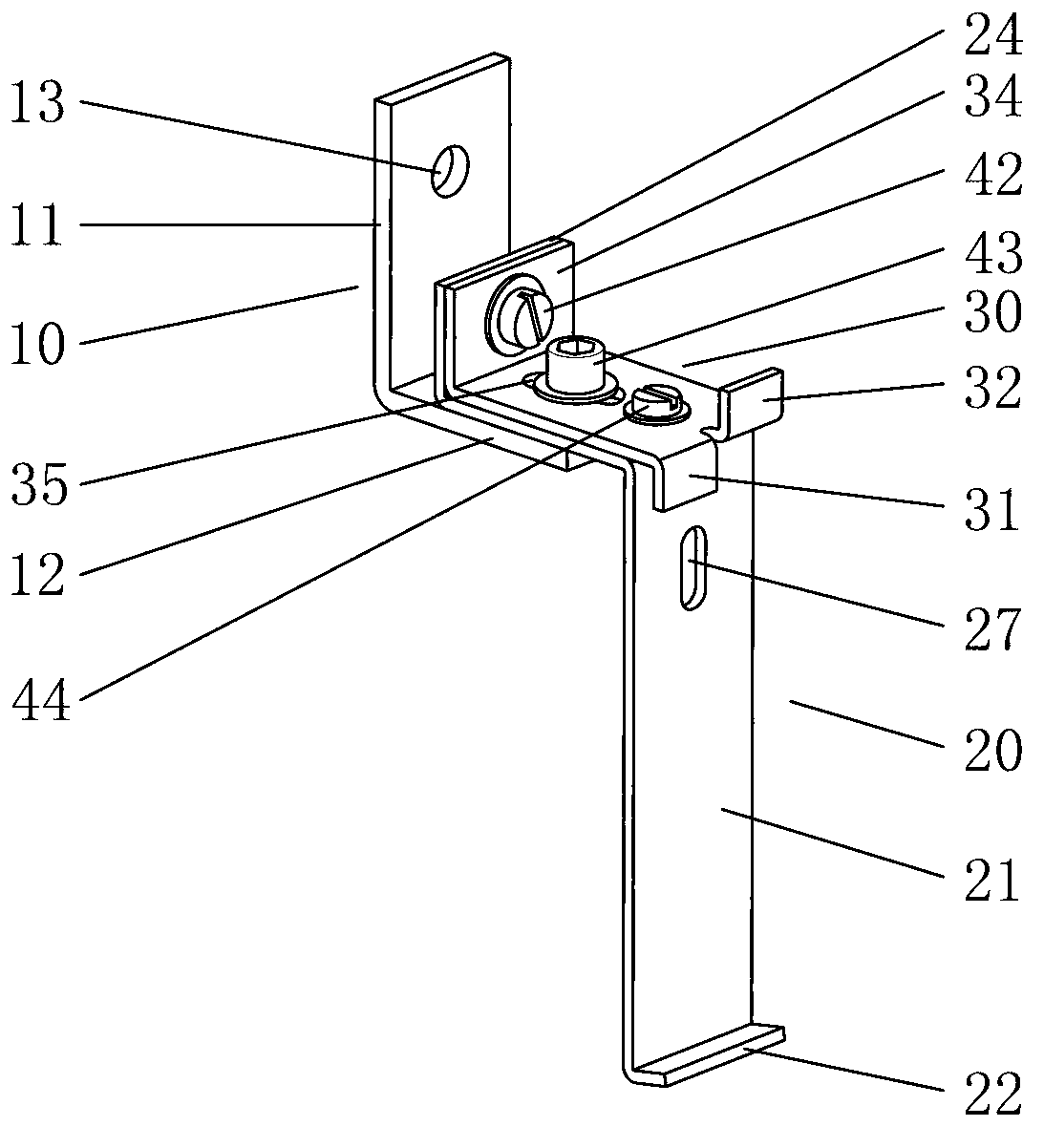

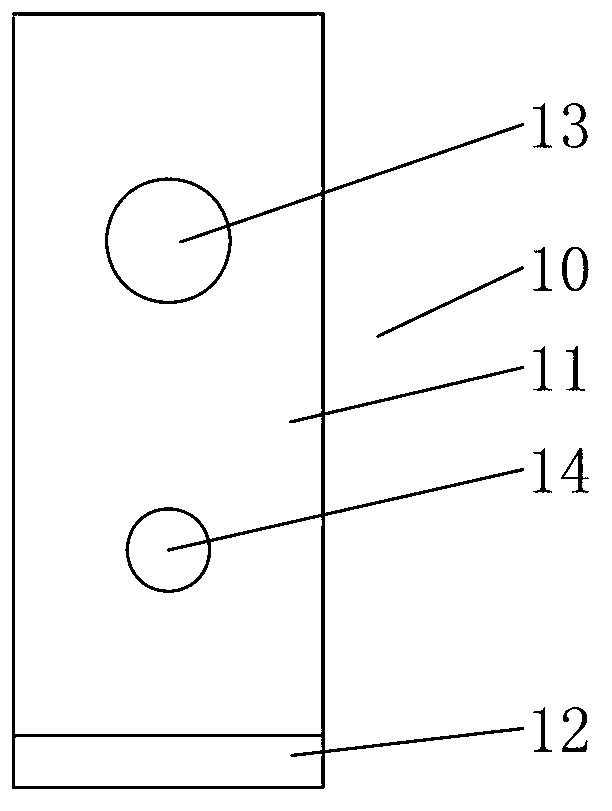

[0035] Example 1, see figure 1 — Figure 7 and Figure 17 :

[0036] The installation and suspension assembly of the facing material includes an L-shaped pendant 10 that can be installed on the wall, a pendant 2 20 that can be installed on the inner surface of the facing material 60 and hang on the horizontal part 12 of the pendant 10, and connects On the upper end of the pendant two 20 and the pendant three 30 on the pendant one 10, the upper end of the pendant three 30 and the pendant two 20 is fixedly connected with the screw rod 44 and then connected with the bending part 11 inside the pendant one 10 and connected with the horizontal part of the pendant one 10 12 The positioning connection of the width can be selected. The outer side of the second pendant 20 extends downwards with a bent part 21 and a hook that can be hung on the facing material 60 is provided at the lower end of the bent part 21. The outer end of the pendant three 30 is provided with a To locate or con...

Embodiment 2

[0043] Example 2, see Figure 8 — Figure 16 ,as well as figure 1 —7, Figure 18 :

[0044]The structure of embodiment 2 is basically similar to the structure of embodiment 1, the difference is that: the above-mentioned bending part 34 at the outer end of the third pendant 30 is formed by making a right-angled flange 38 upwards at the outer end of the transverse part 33 of the pendant three 30, so The above-mentioned bending part 34 is positioned at the inner side of the bending part 21 of the pendant two 20, and is provided with a pendant four 50 having an outer flange 54 at the upper end of the vertical plate, the bending part 51 of the pendant four 50 and the outer flange 54 Angle ≤ 90 degrees, more than one positioning hole 52, 53 is provided on the bending part 51 of the pendant four 50, one of the positioning holes 52 is a strip hole, and the lower side of the pendant four 50 is attached to the pendant two 20 The outer surface of the upper end face of the pendant thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com