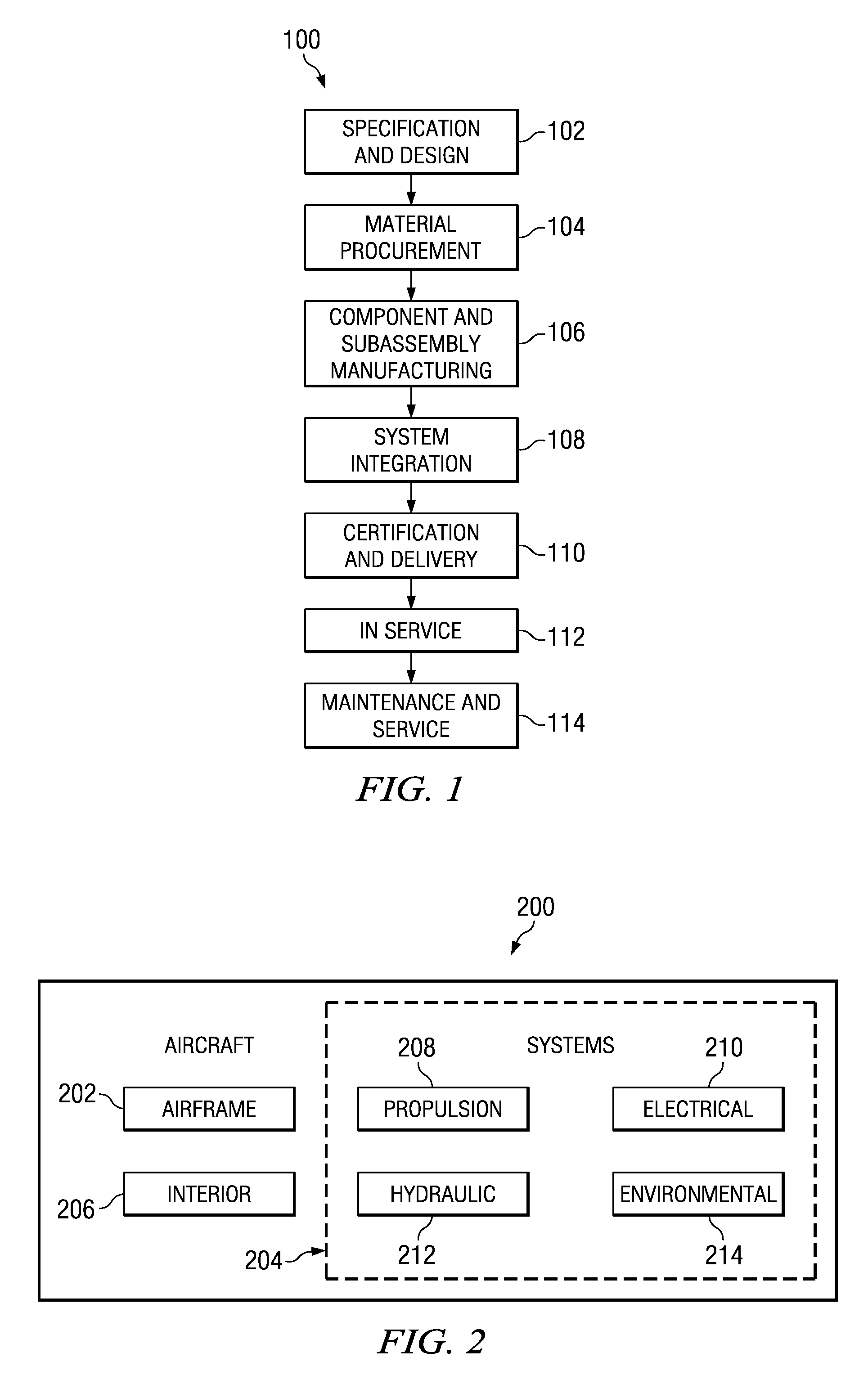

Patents

Literature

62results about How to "Reduce design load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

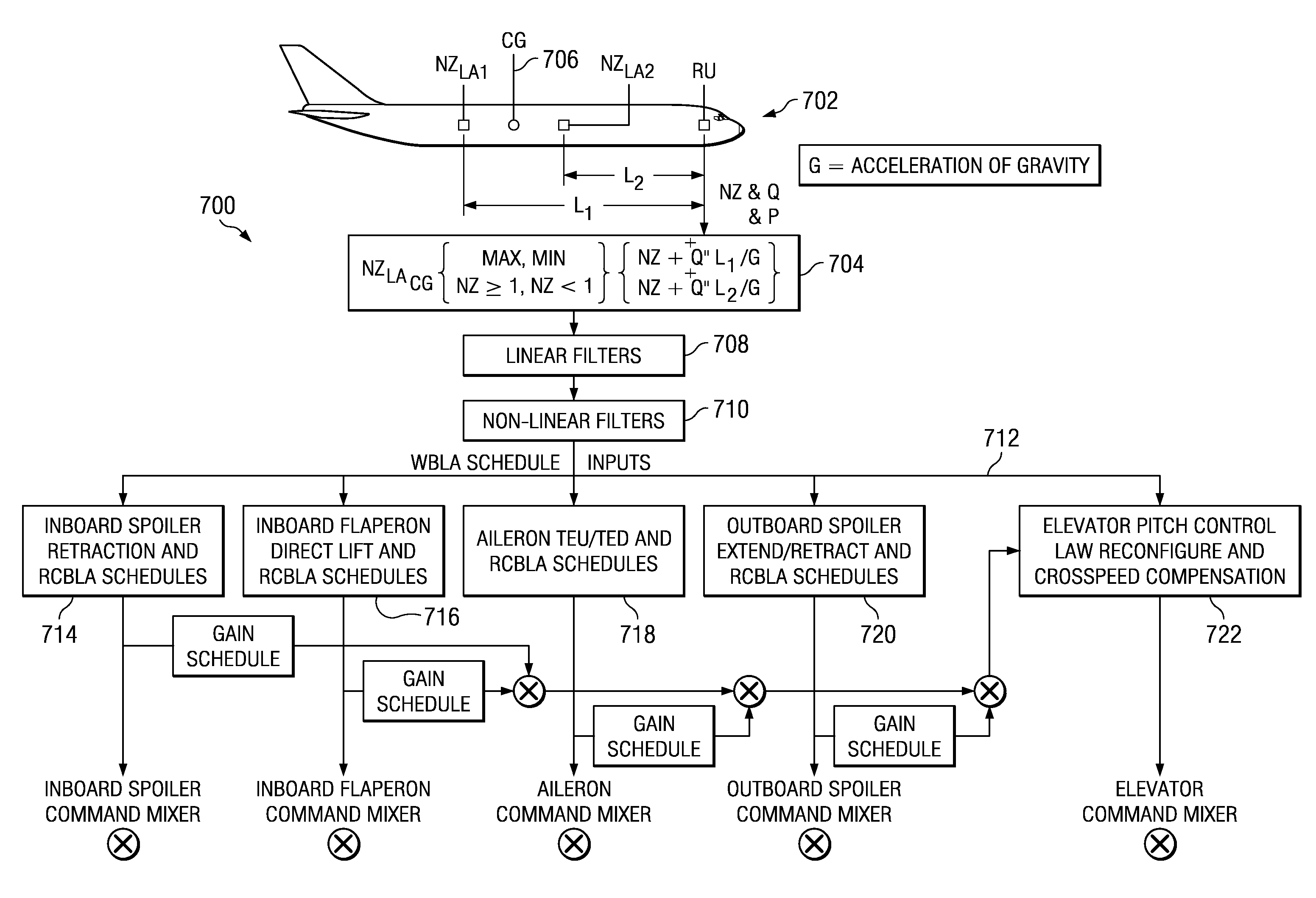

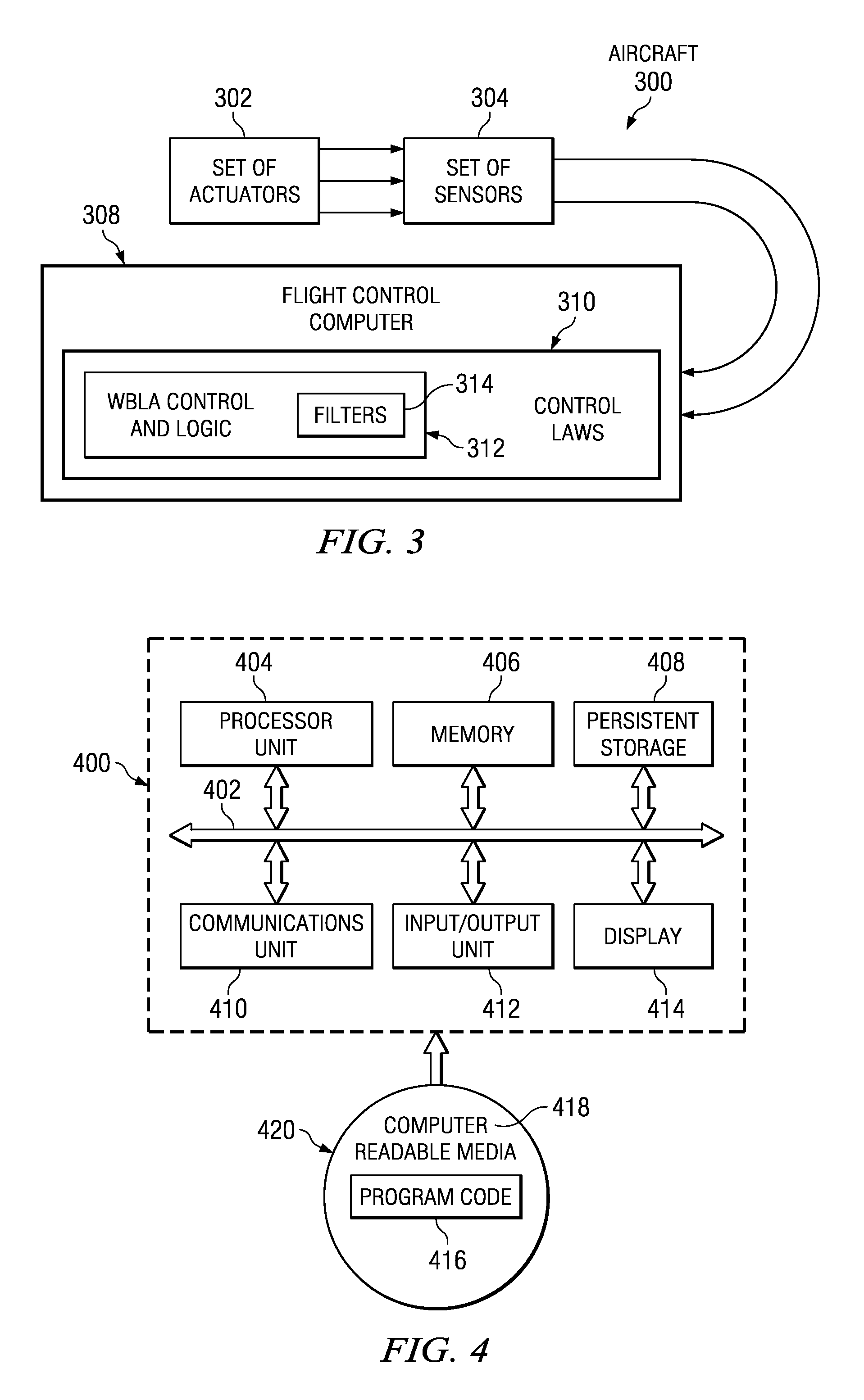

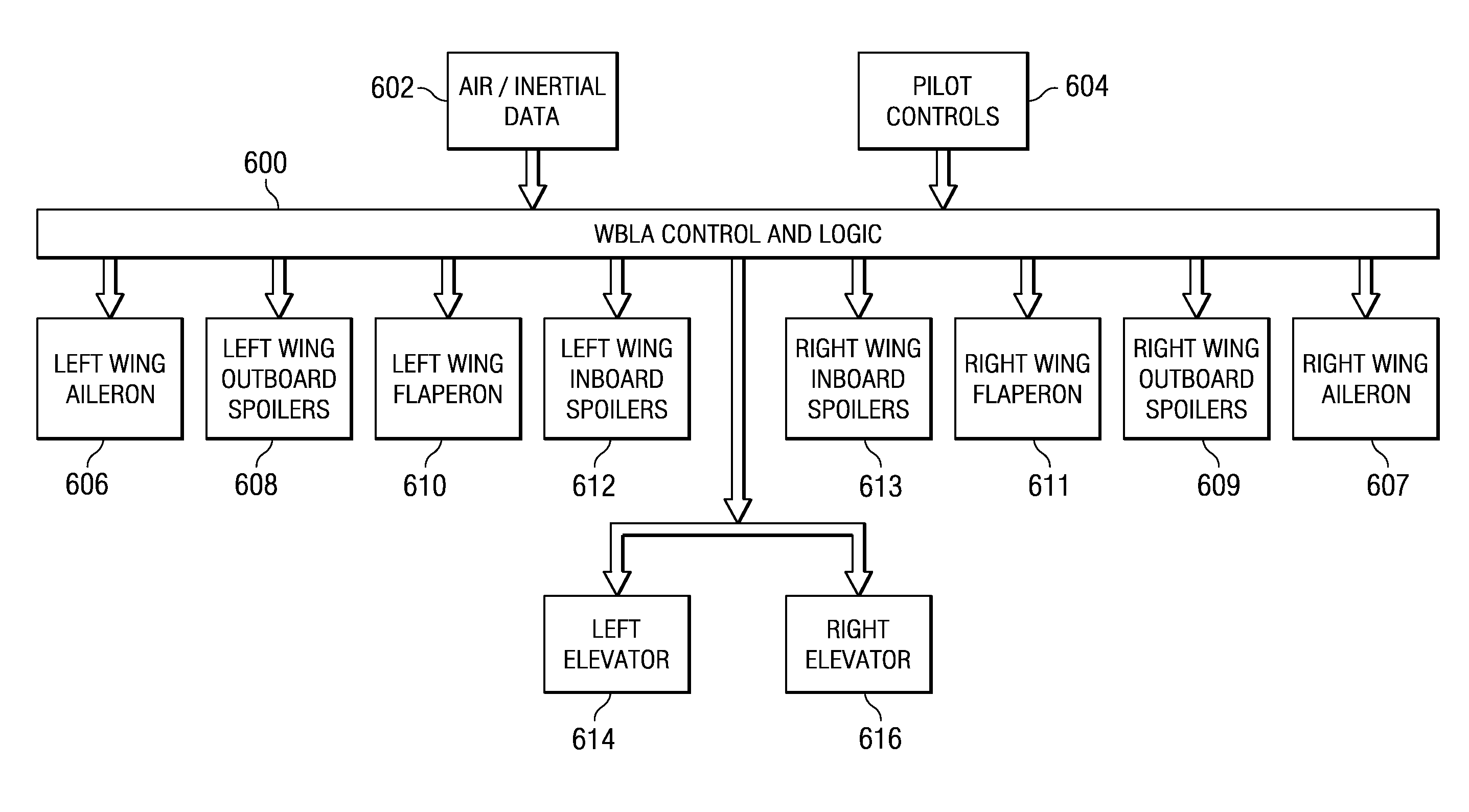

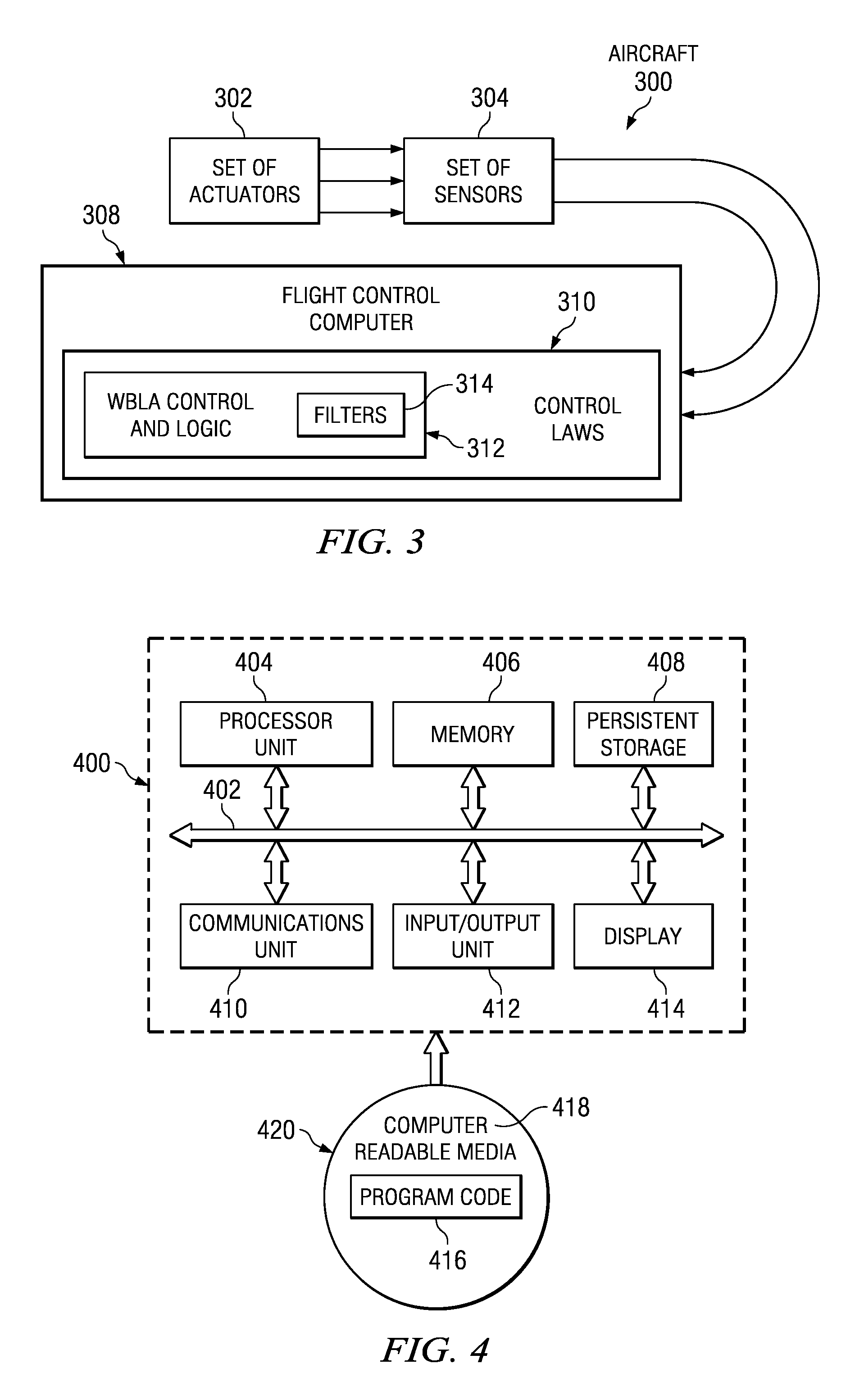

Wing-body load alleviation for aircraft

ActiveUS20090292405A1Reduce load requirementsReduce design loadAircraft stabilisationDigital data processing detailsNonlinear filterFlight control surfaces

A computer implemented method, apparatus, and computer usable program product for symmetric and anti-symmetric control of aircraft flight control surfaces to reduce wing-body loads. Commands are sent to symmetrically deploy outboard control surfaces to shift wing air-loads inboard based on airplane state and speed brake deployment. Surface rate retraction on a wing with peak loads is limited to reduce maximum loads due to wheel checkback accompanied by utilization of opposite wing control surfaces to retain roll characteristics. Airloads are shifted inboard on a swept wing to move the center of pressure forward, thereby reducing the tail load required to perform a positive gravity maneuver. In a negative gravity maneuver, speed brakes are retracted, thereby reducing the positive tail load and reducing the aft body design loads. High gain feedback commands are filtered from wing structural modes above one hertz by a set of linear and non-linear filters.

Owner:THE BOEING CO

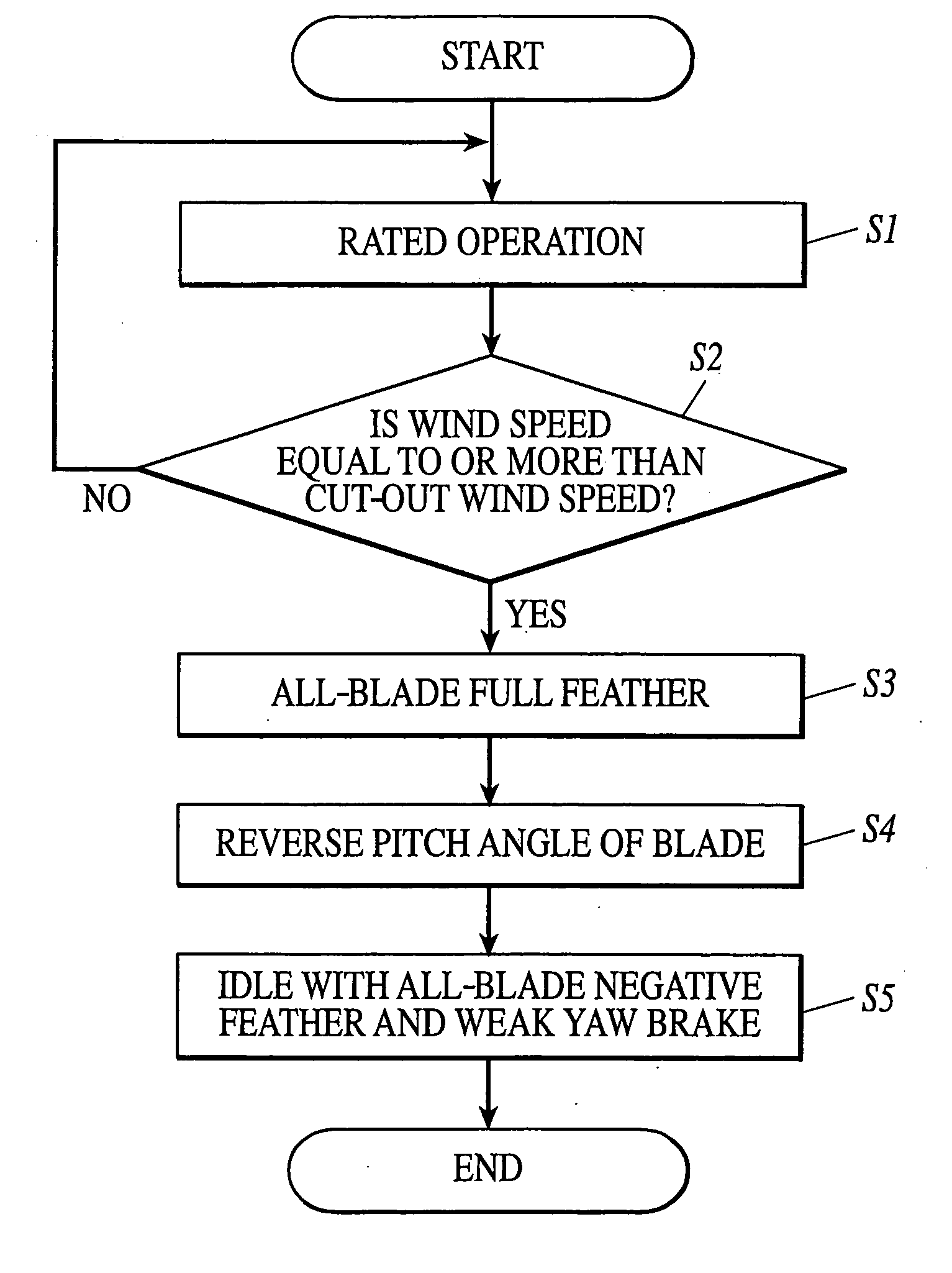

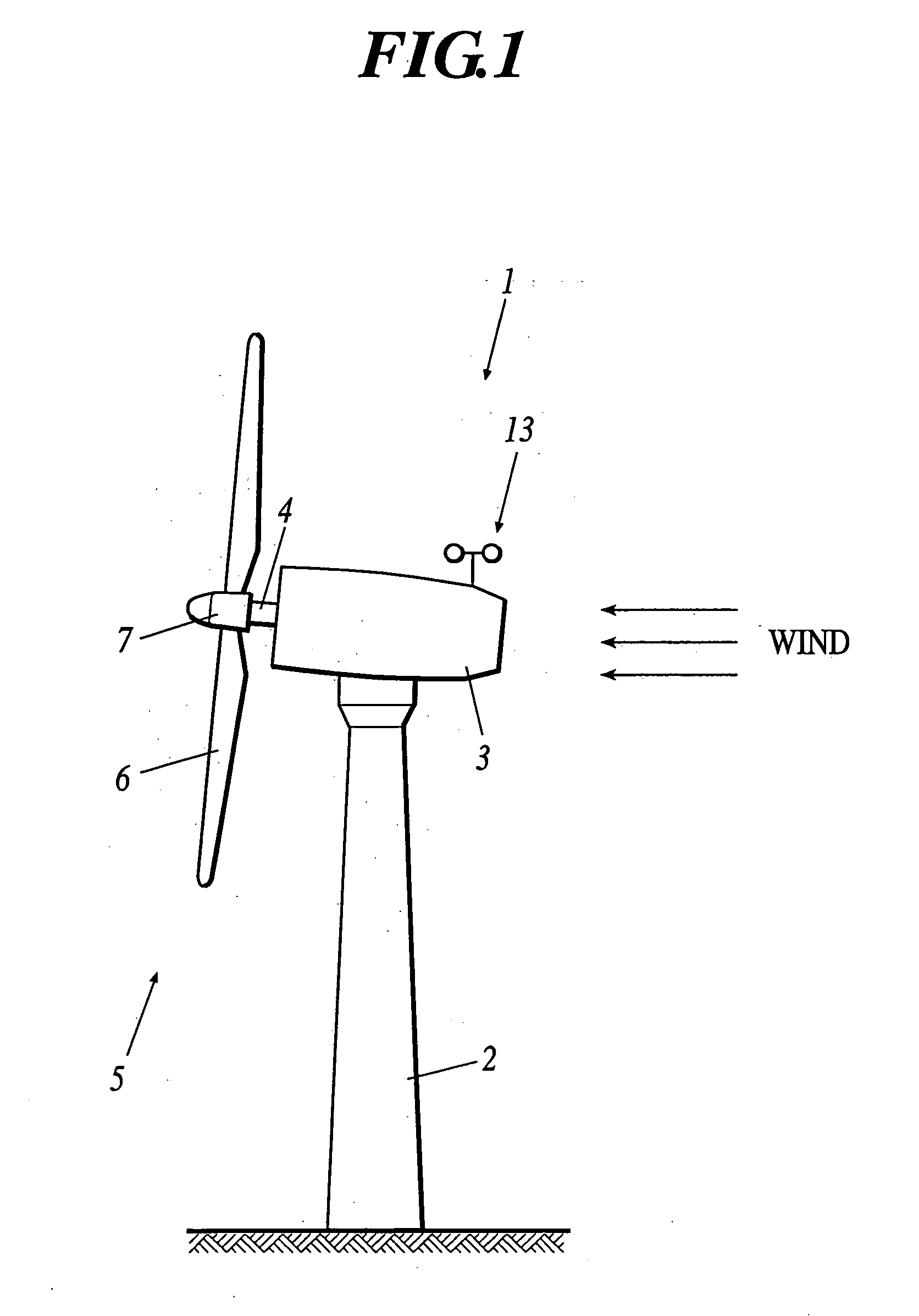

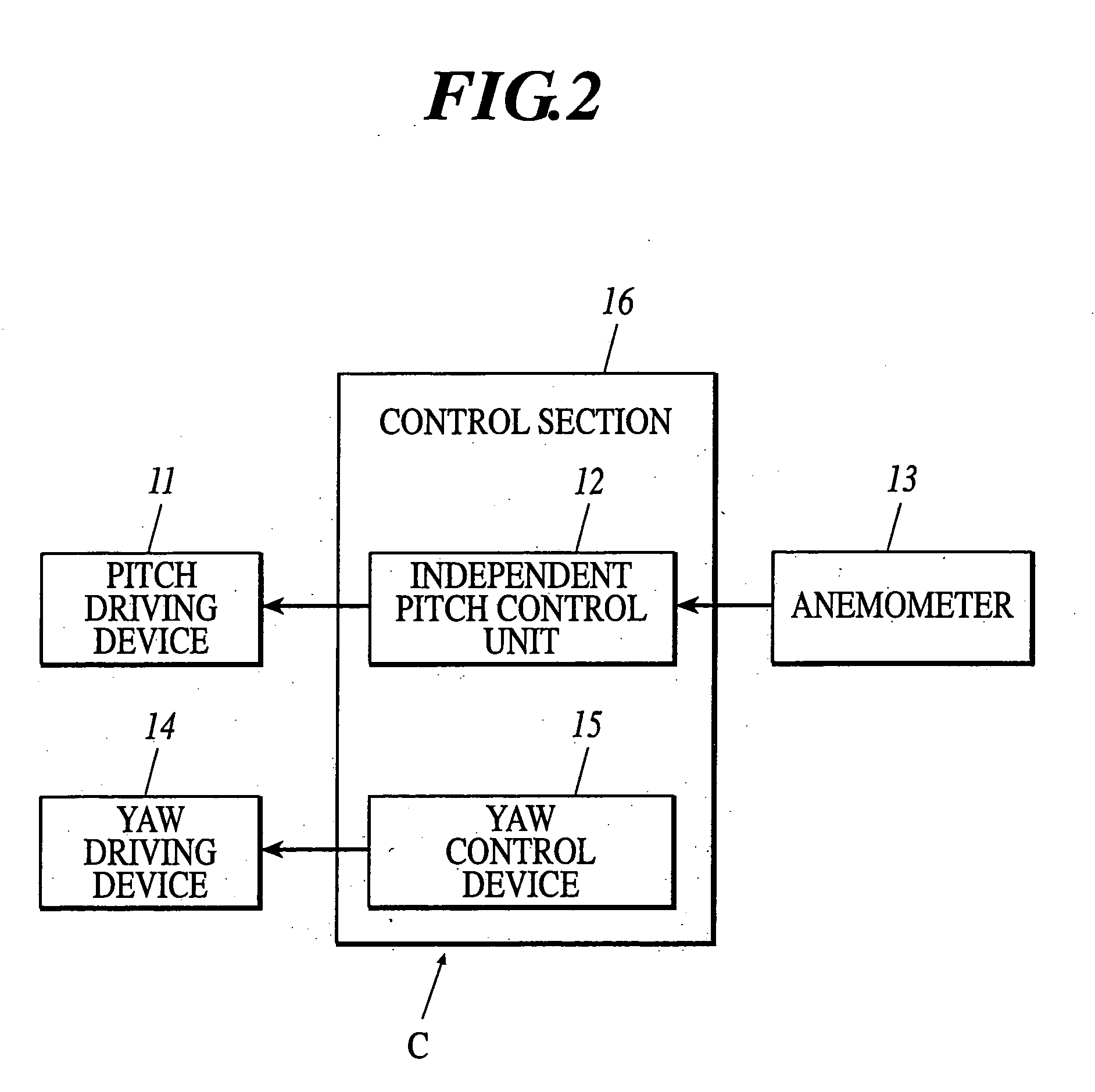

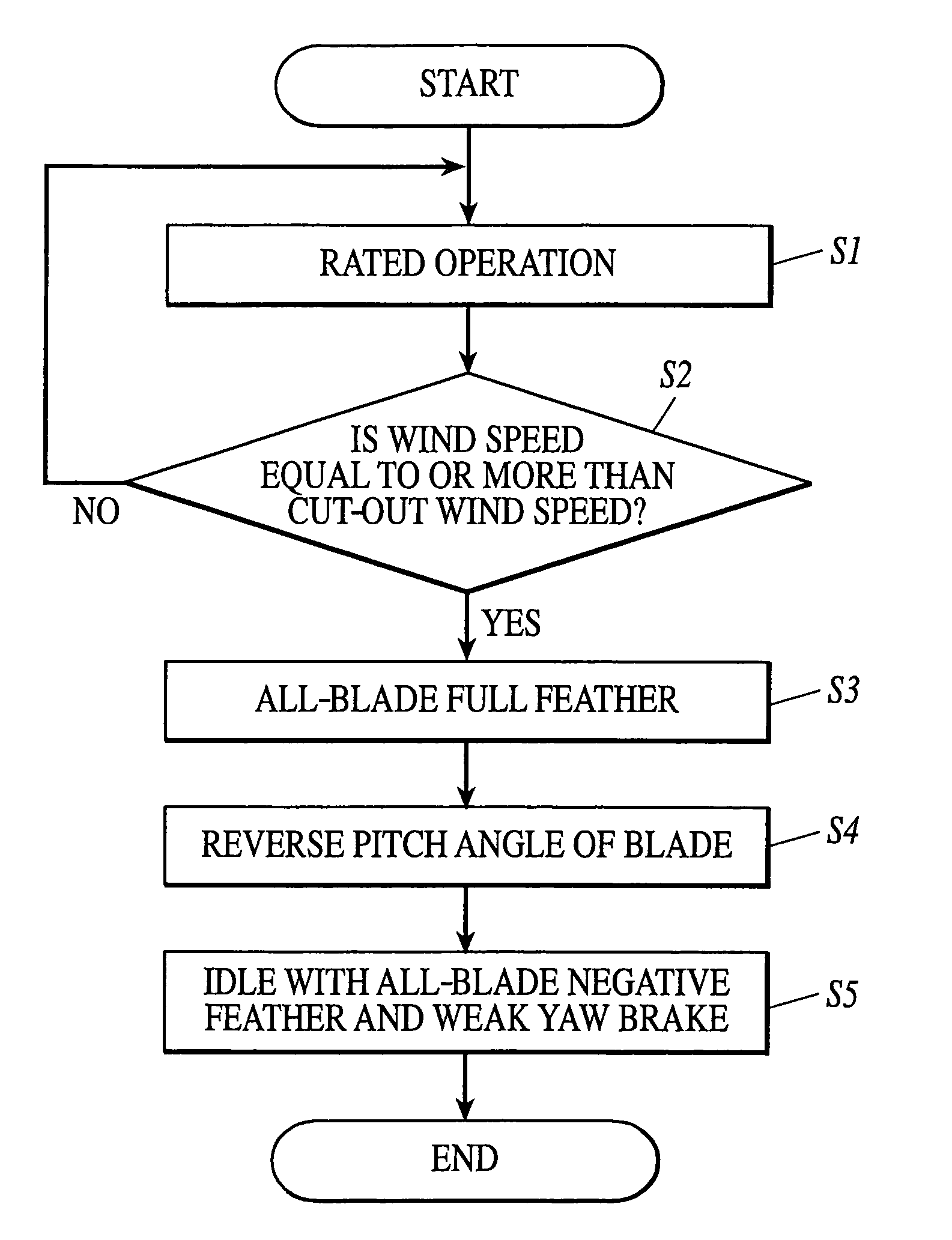

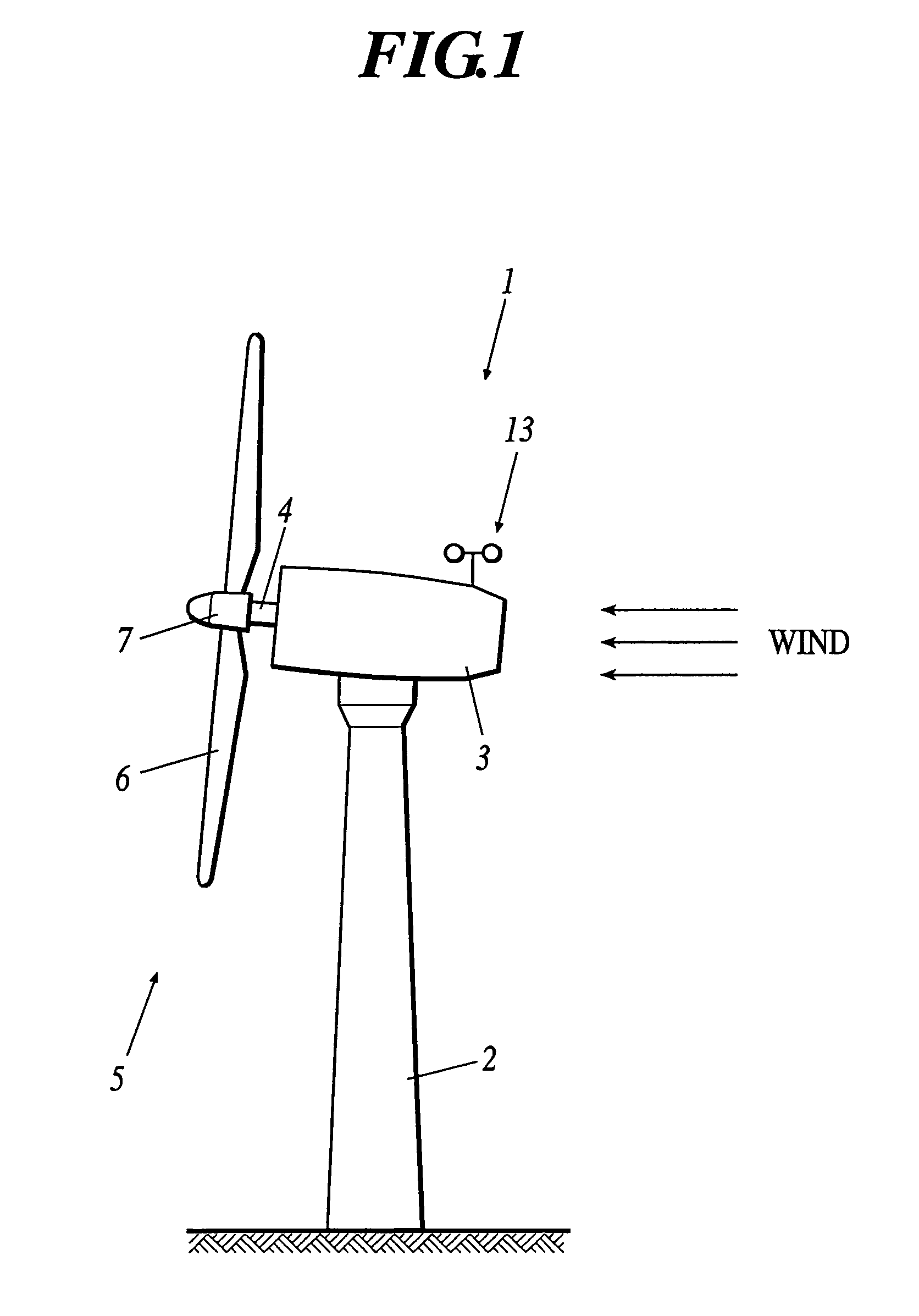

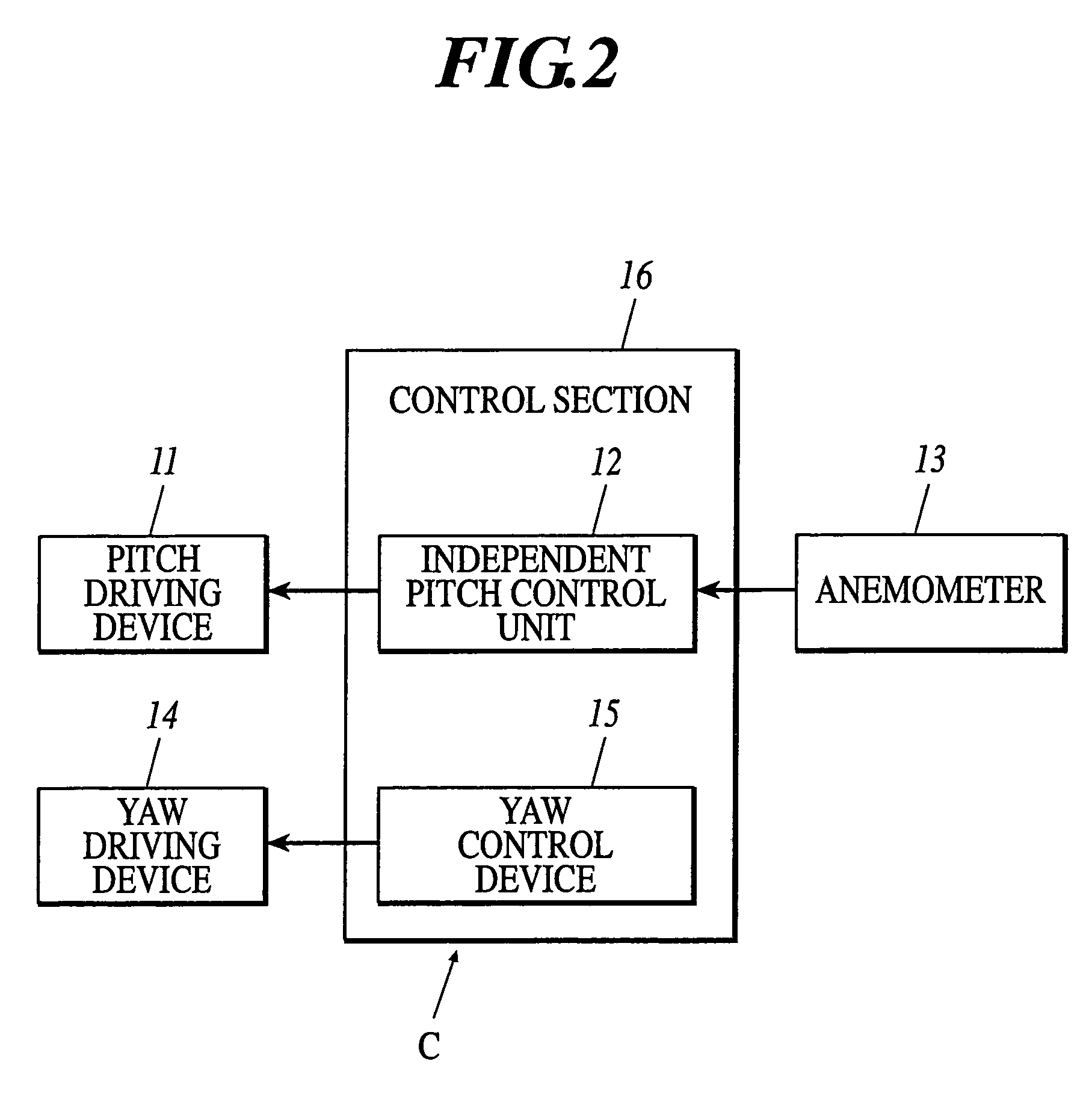

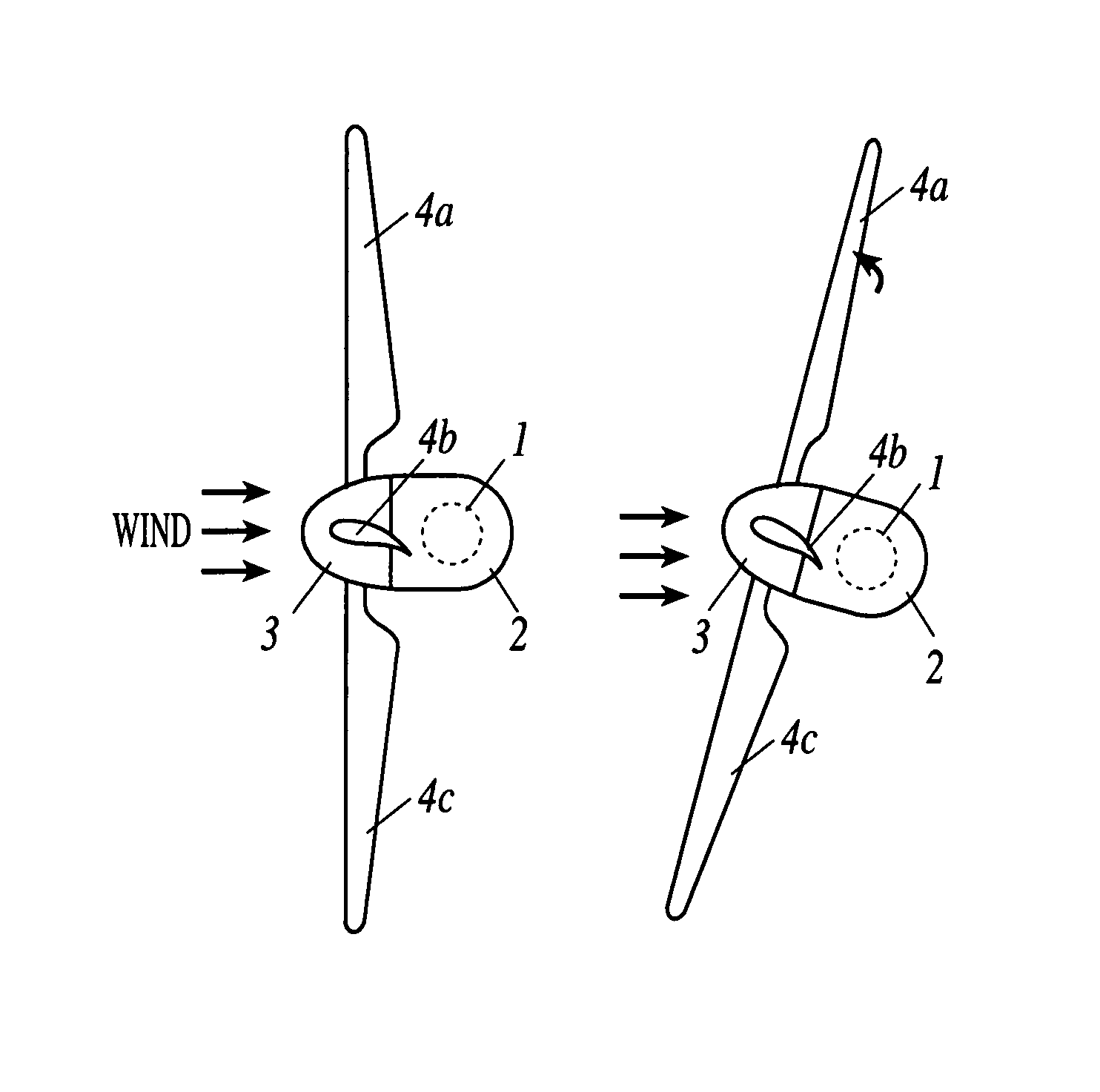

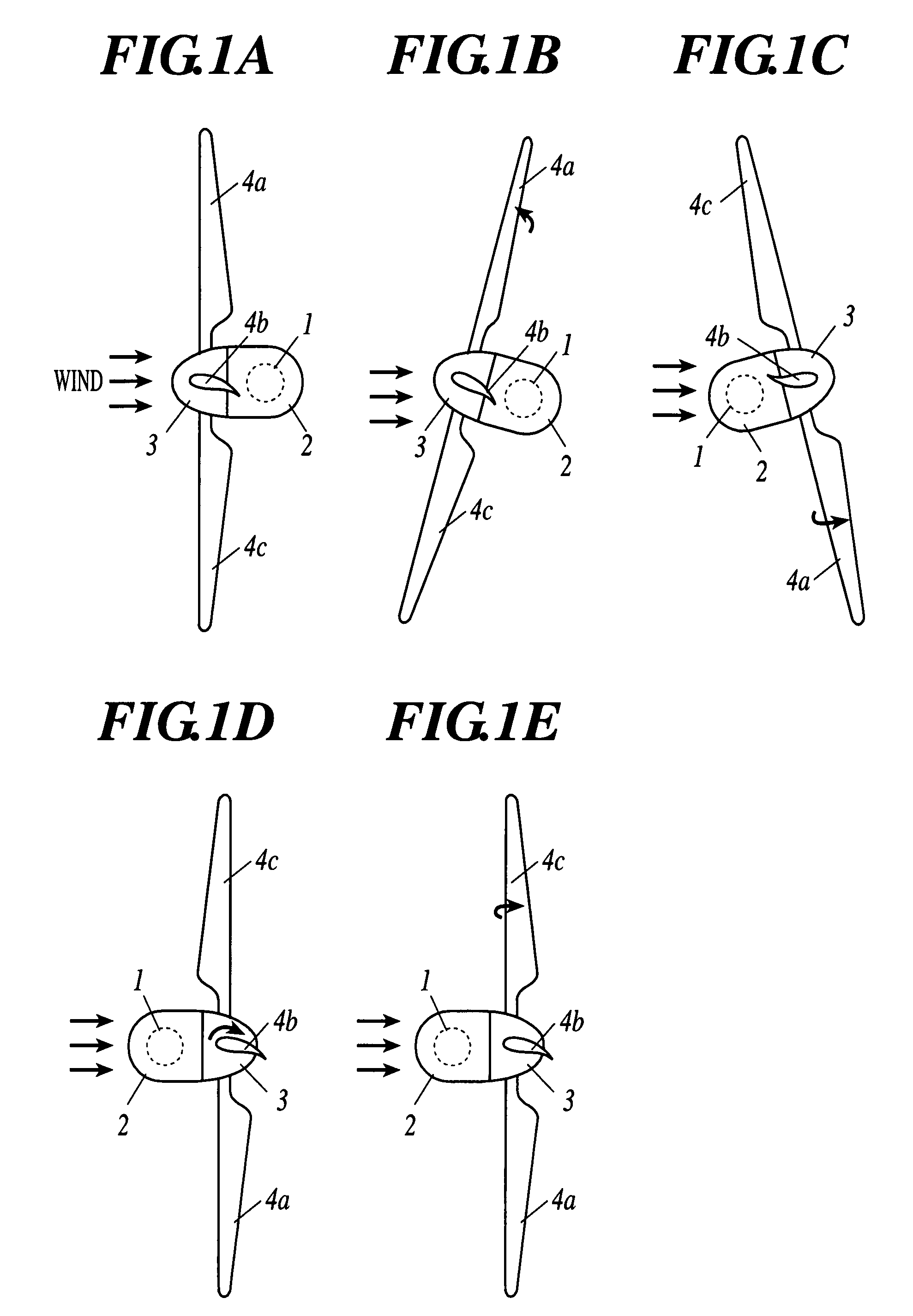

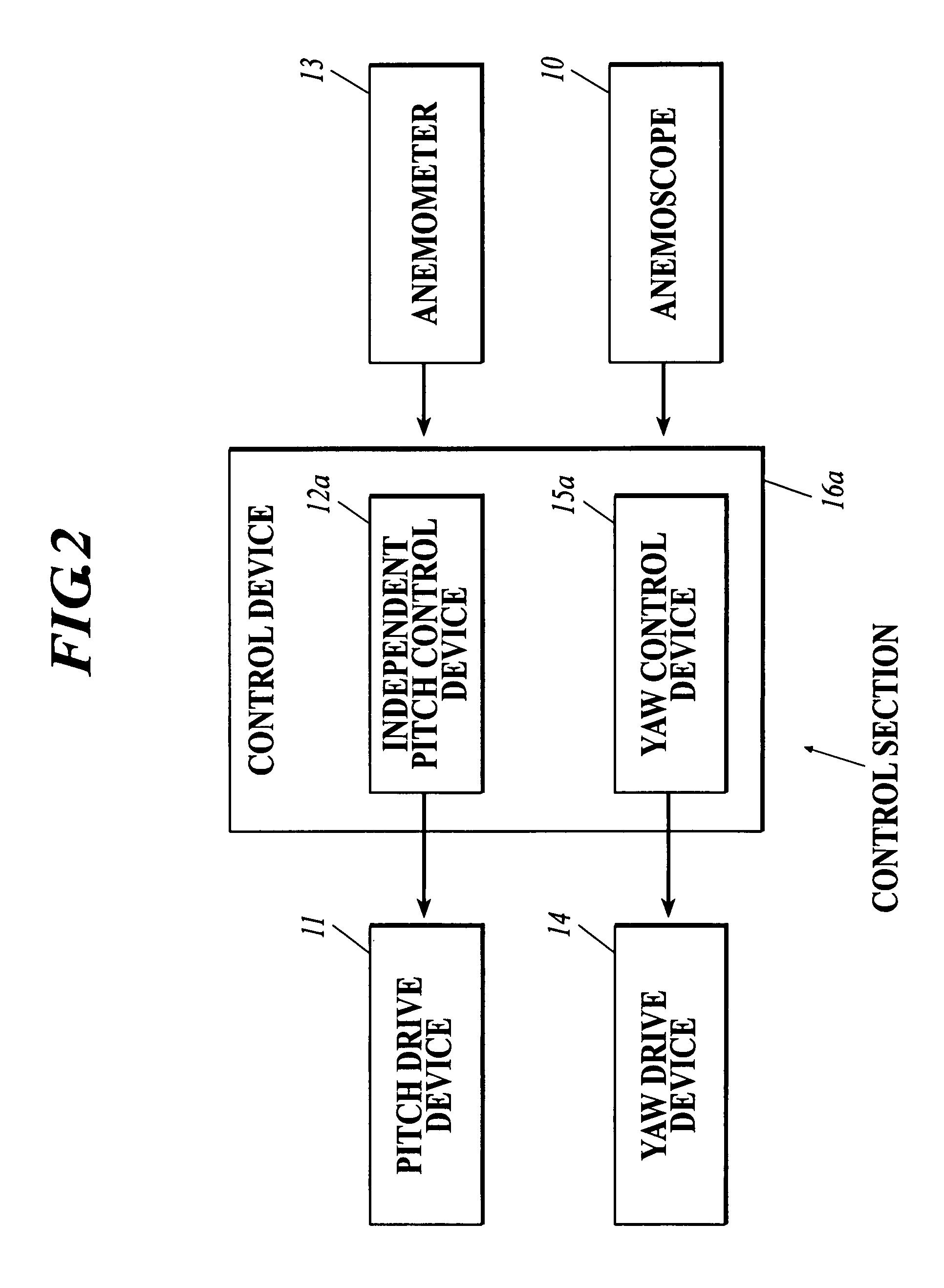

Horizontal axis wind turbine and idling method of the same

A horizontal axis wind turbine includes: a rotor having a hub and at least two or more blades; a nacelle for pivotally supporting the rotor through a rotating shaft connected to the hub; a tower for supporting the nacelle; and an independent pitch control unit capable of independently controlling pitch angles of the blades, respectively, wherein the independent pitch control units control the pitch angles so that all the blades are made in a full feather position in case of a wind speed not less than a predetermined value, and subsequently controls the pitch angles of the respective blades so as to be sequentially reversed one by one, and further subsequently, carries out control so that the wind turbine idles in an all-blade negative feather position where the pitch angles of all the blades are reversed.

Owner:HITACHI LTD

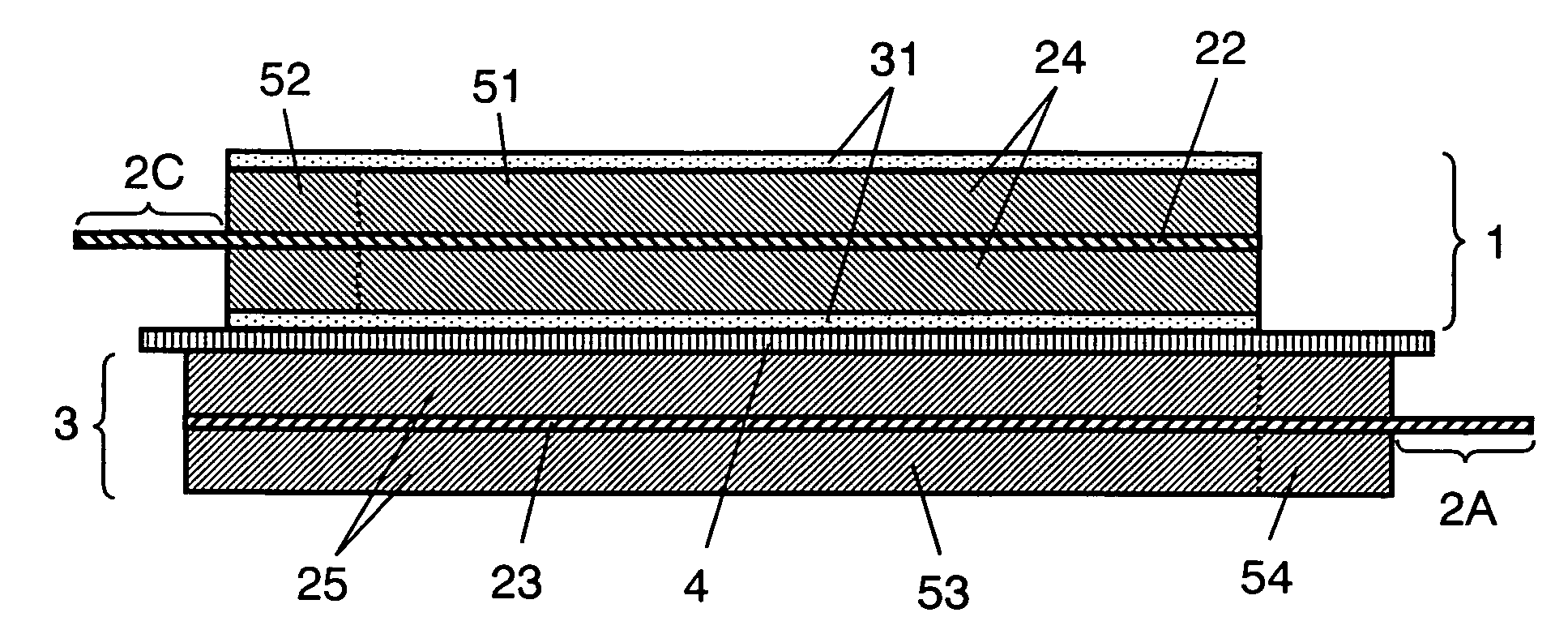

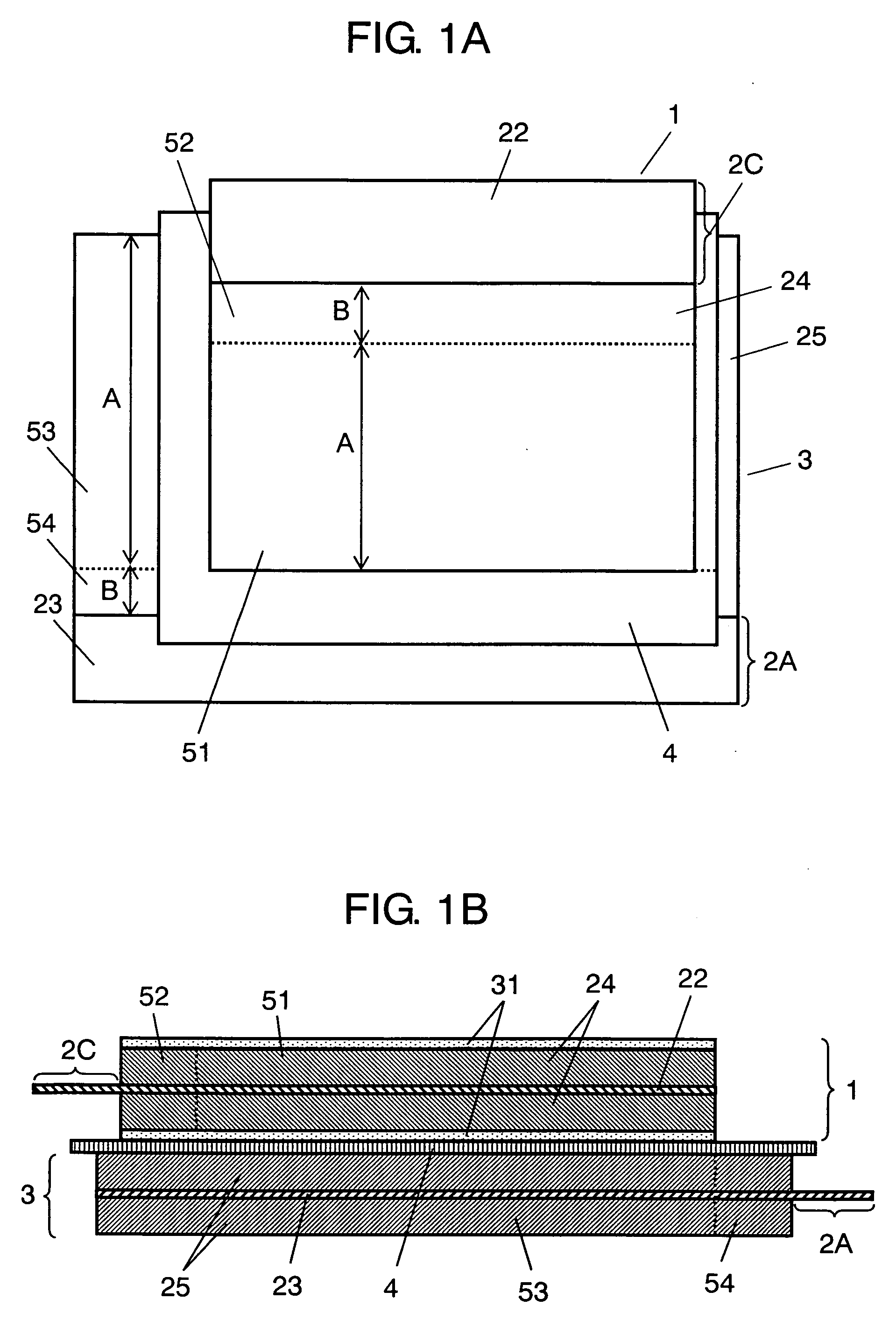

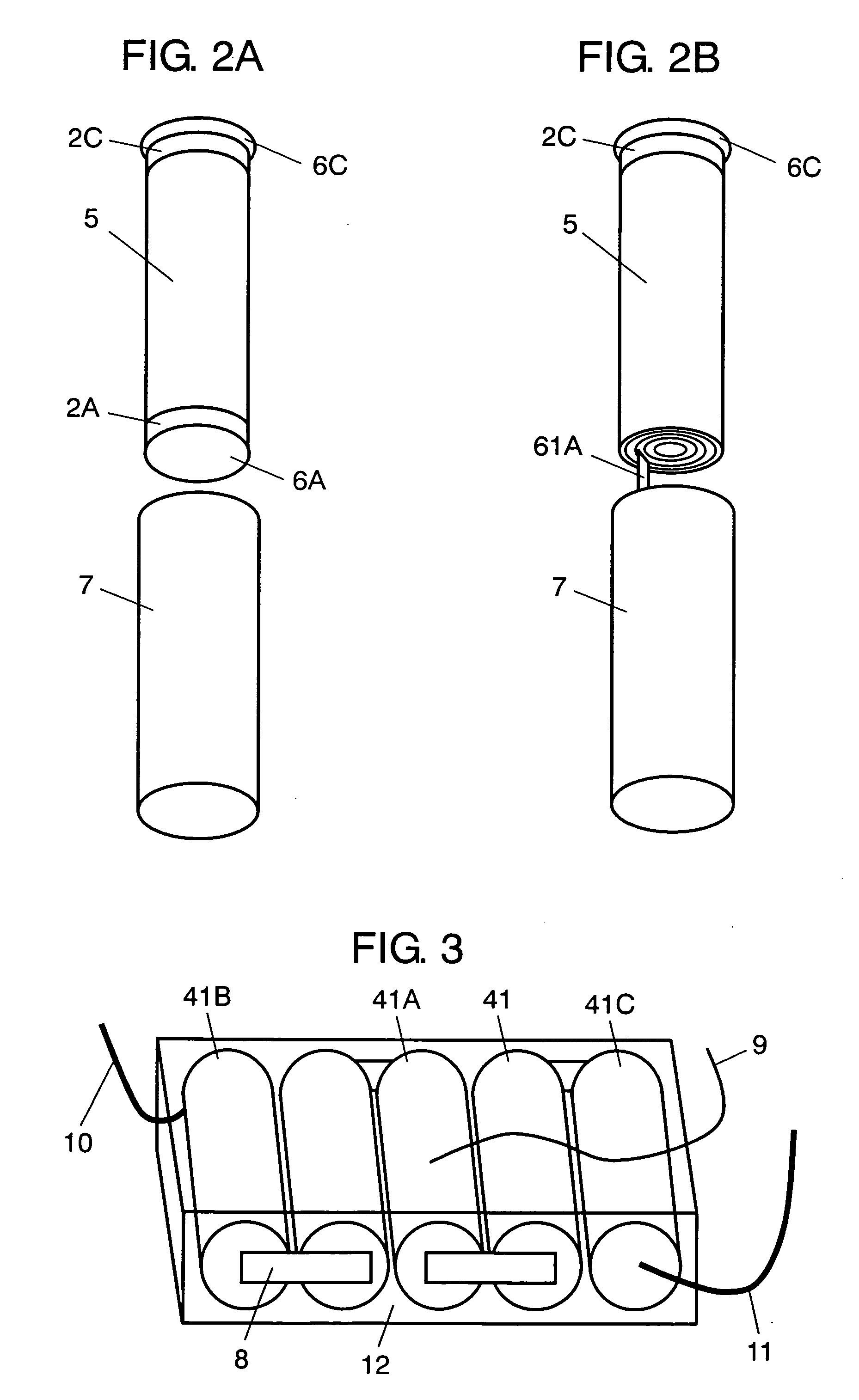

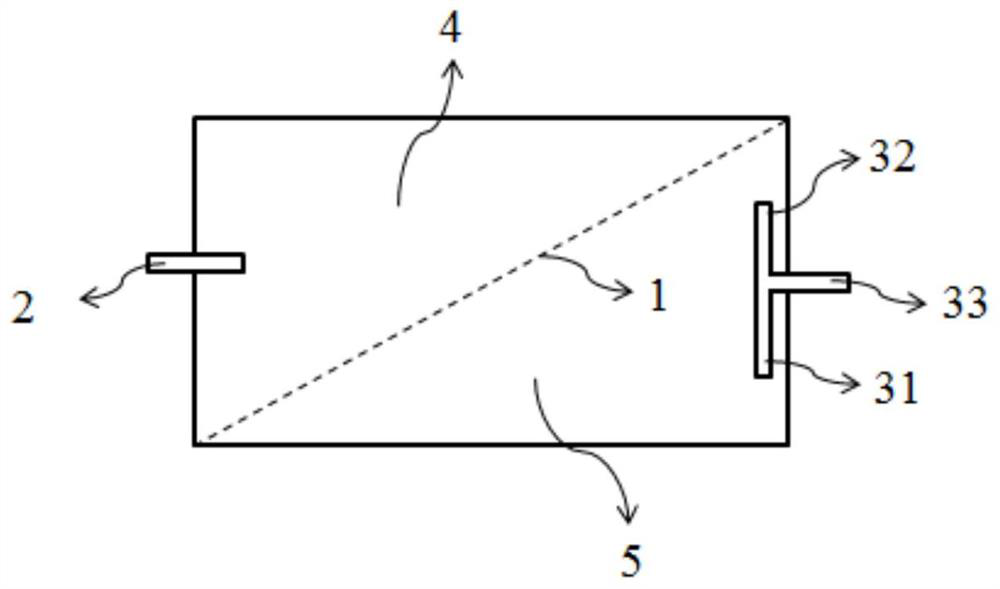

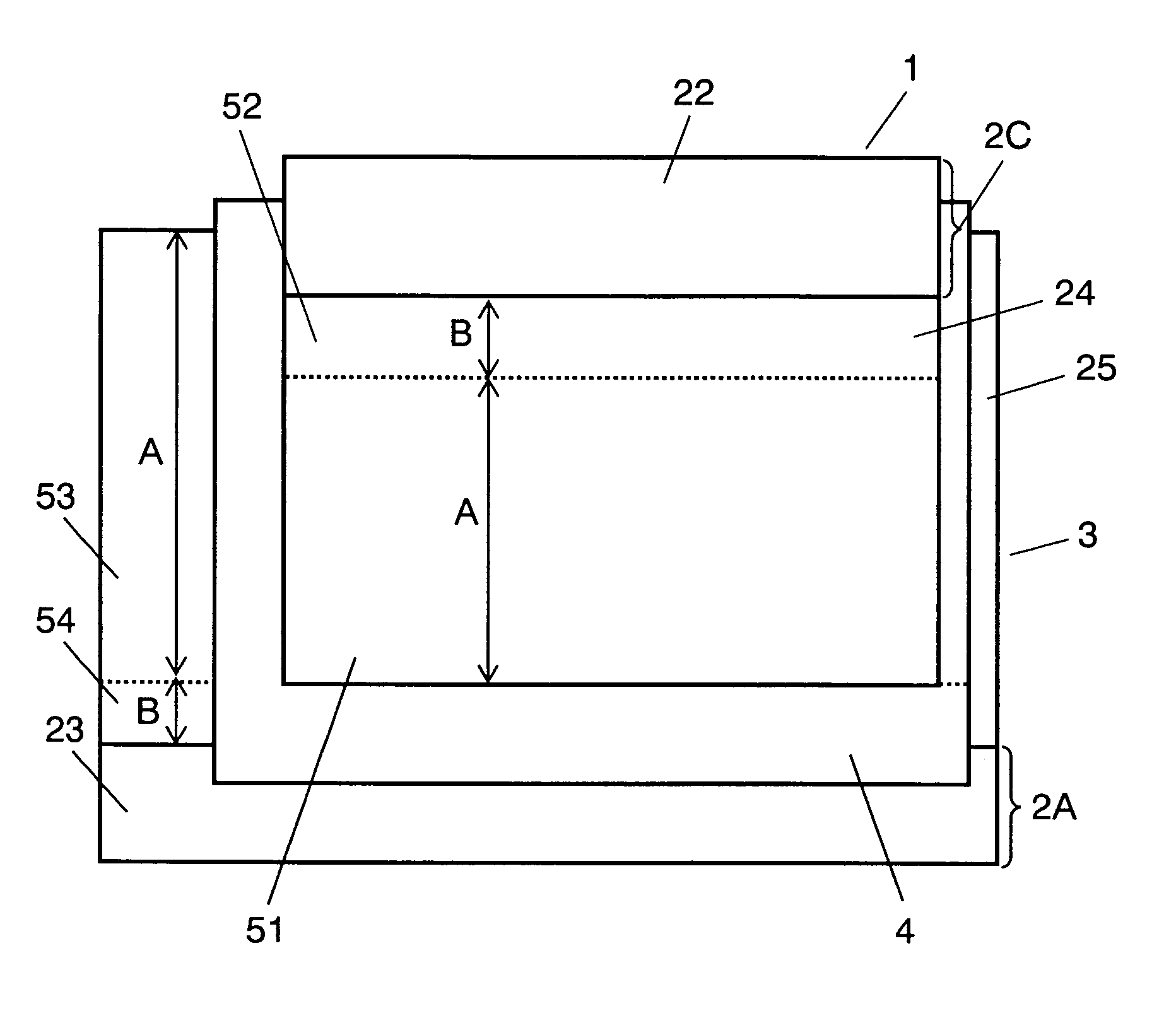

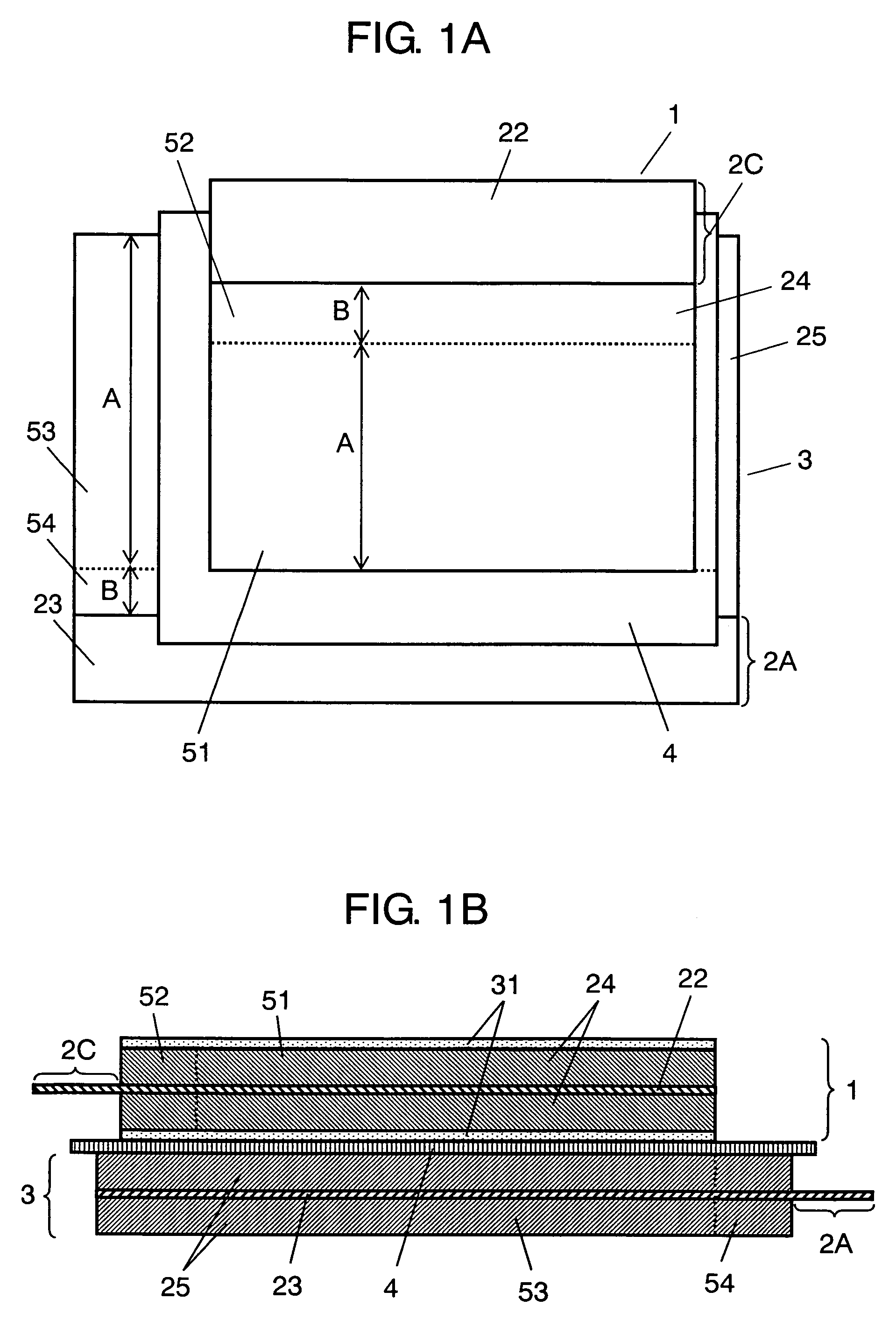

Non-aqueous electrolyte secondary battery and battery pack using the same

InactiveUS20070048615A1Improve discharge characteristicsSolve low usageCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringBattery pack

A non-aqueous electrolyte secondary battery includes an electrode assembly formed by winding positive and negative electrodes, and an insulating layer together. Each of the electrodes has a core sheet and mixture layers formed on both sides of the sheet. The insulating layer electrically insulates the electrodes. At least one of the electrodes includes a core-exposed portion continuous parallel to the winding direction. Each of the mixture layers has an inclined weight region where the amount of mixture per unit area decreases toward the core-exposed portion, and a constant weight region in which the amount of mixture per unit area is constant. The inclined weight region has a width of not more than 0.2 of the width of the mixture layers and has an average mixture density of not less than 40% and not more than 99% of the mixture density of the constant weight region.

Owner:PANASONIC CORP

Horizontal axis wind turbine and idling method of the same

A horizontal axis wind turbine includes: a rotor having a hub and at least two or more blades; a nacelle for pivotally supporting the rotor through a rotating shaft connected to the hub; a tower for supporting the nacelle; and an independent pitch control unit capable of independently controlling pitch angles of the blades, respectively, wherein the independent pitch control units control the pitch angles so that all the blades are made in a full feather position in case of a wind speed not less than a predetermined value, and subsequently controls the pitch angles of the respective blades so as to be sequentially reversed one by one, and further subsequently, carries out control so that the wind turbine idles in an all-blade negative feather position where the pitch angles of all the blades are reversed.

Owner:HITACHI LTD

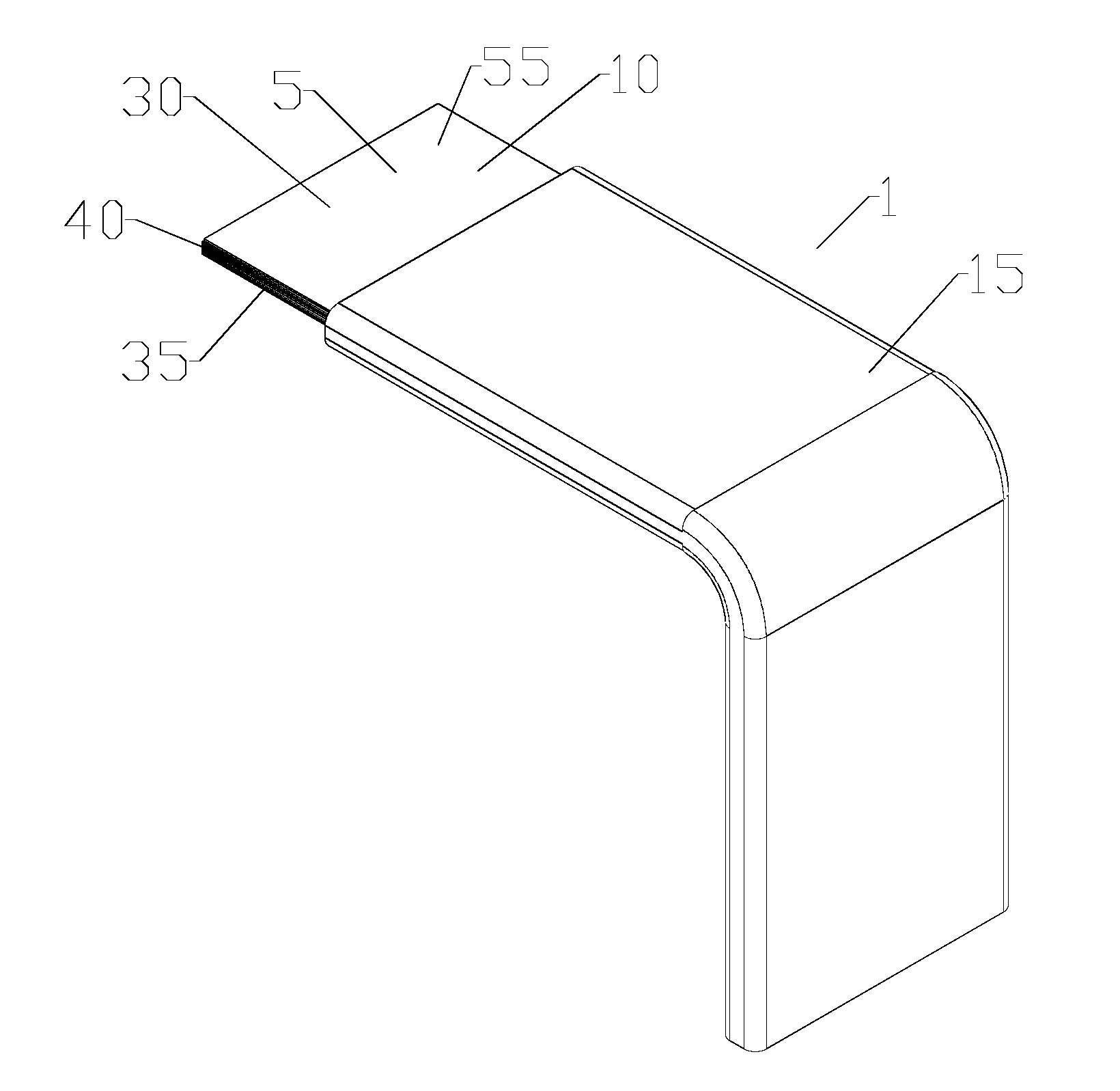

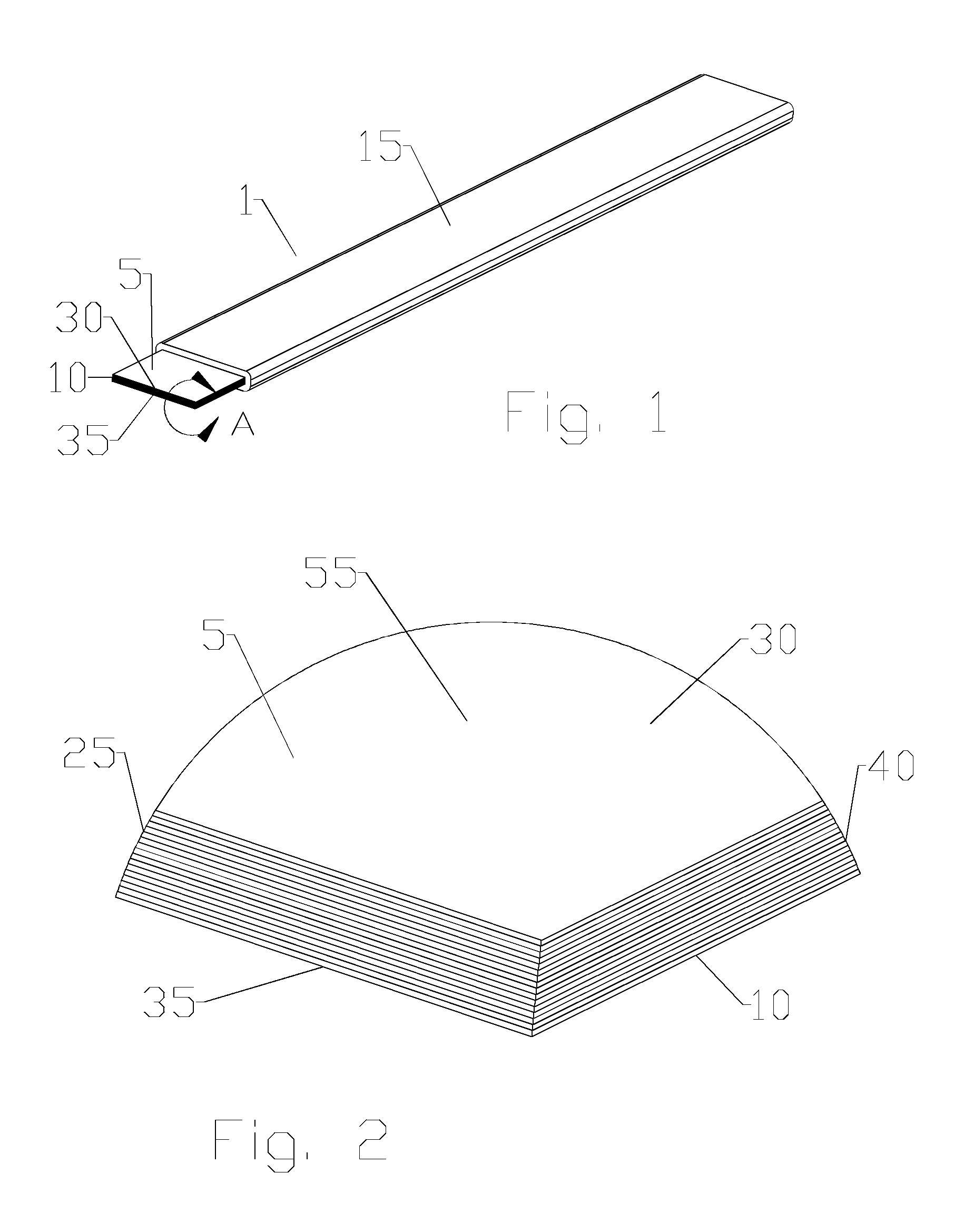

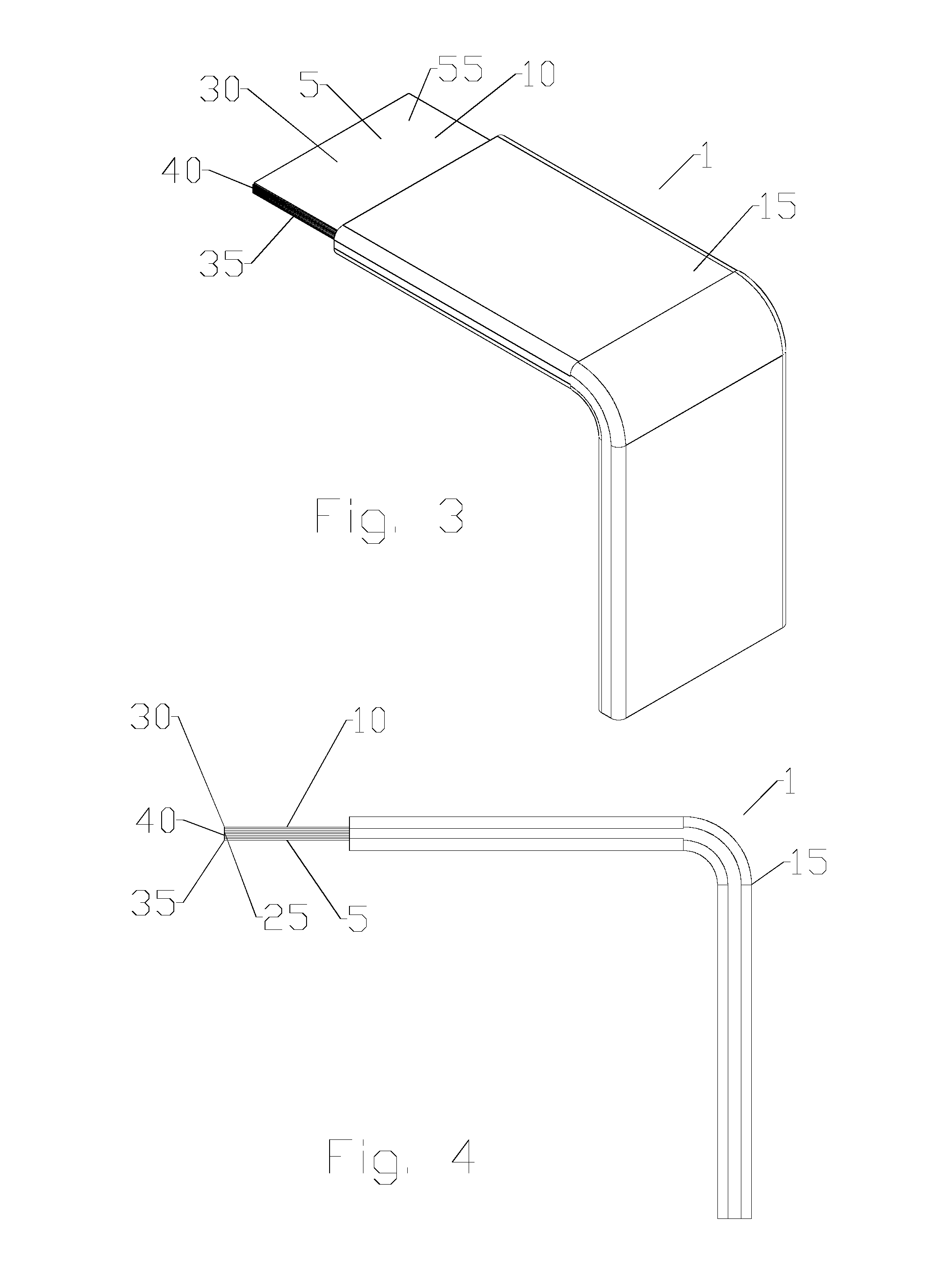

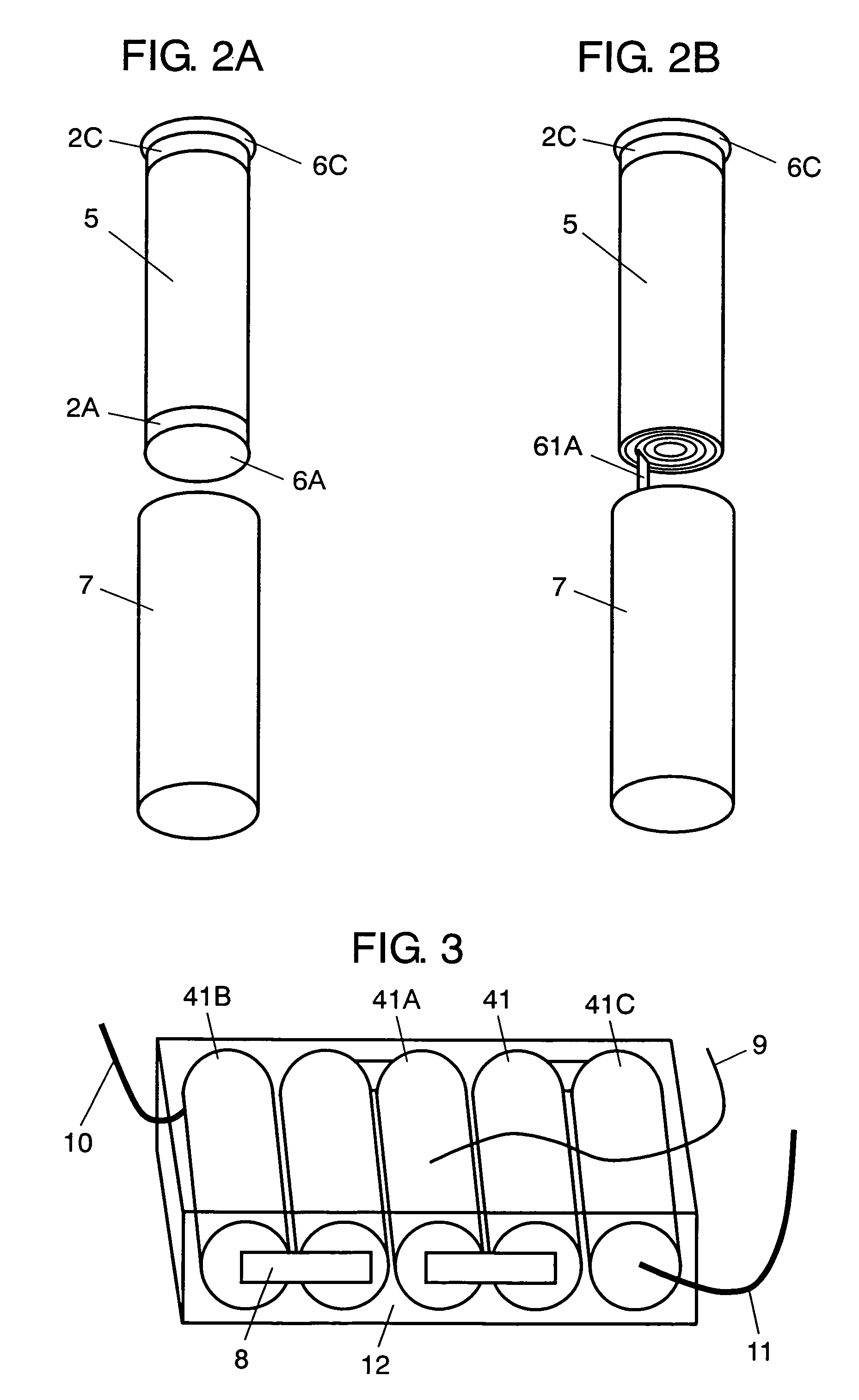

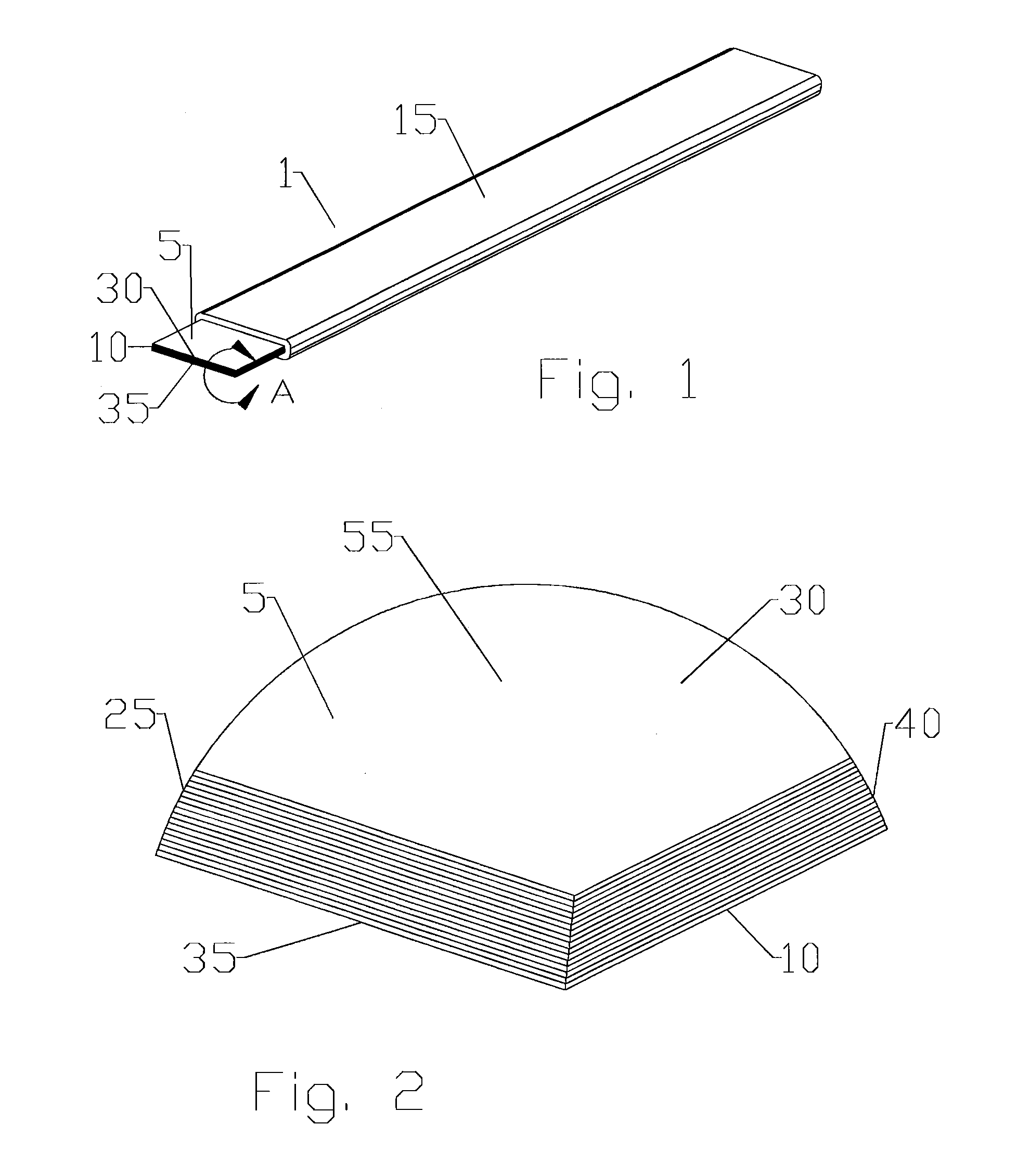

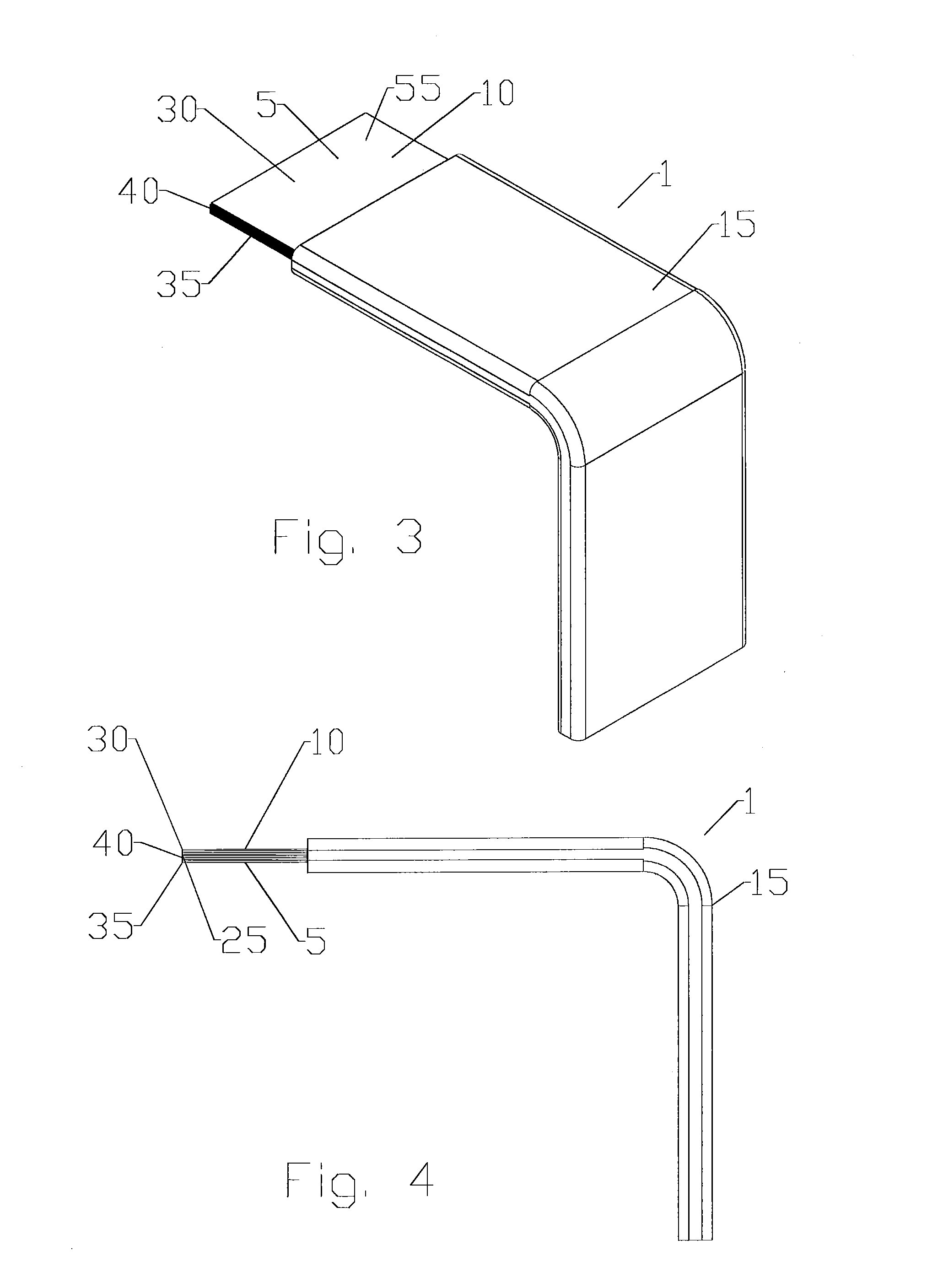

Flexible Electrical Power Cable

InactiveUS20140027153A1Good bending propertiesEasy to installStrip/foil conductorsConductive materialElectrical conductorPower cable

An electrical cable has a plurality of generally rectangular cross-section conductors superposed in a stack, the stack surrounded by a polymer jacket. The stack may be provided with a lubrication layer provided between at least two of the conductors. Conductors of the stack may have a thickness that is greater proximate the middle of the stack than at the top and bottom of the stack and / or a width that is less at the top and the bottom than at the middle. Further stacks may also be provided parallel and coplanar with the first stack, also surrounded by the polymer jacket.

Owner:COMMSCOPE TECH LLC

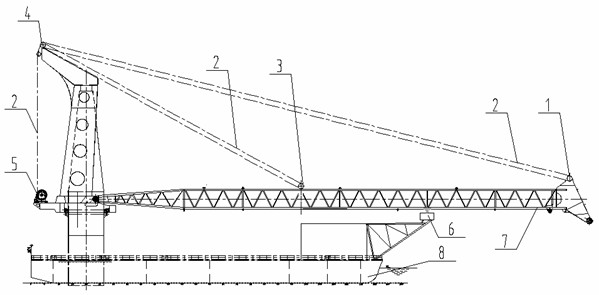

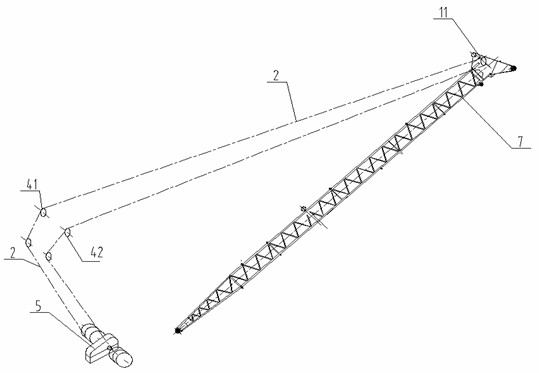

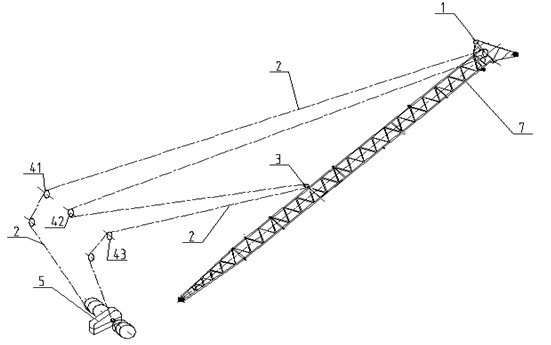

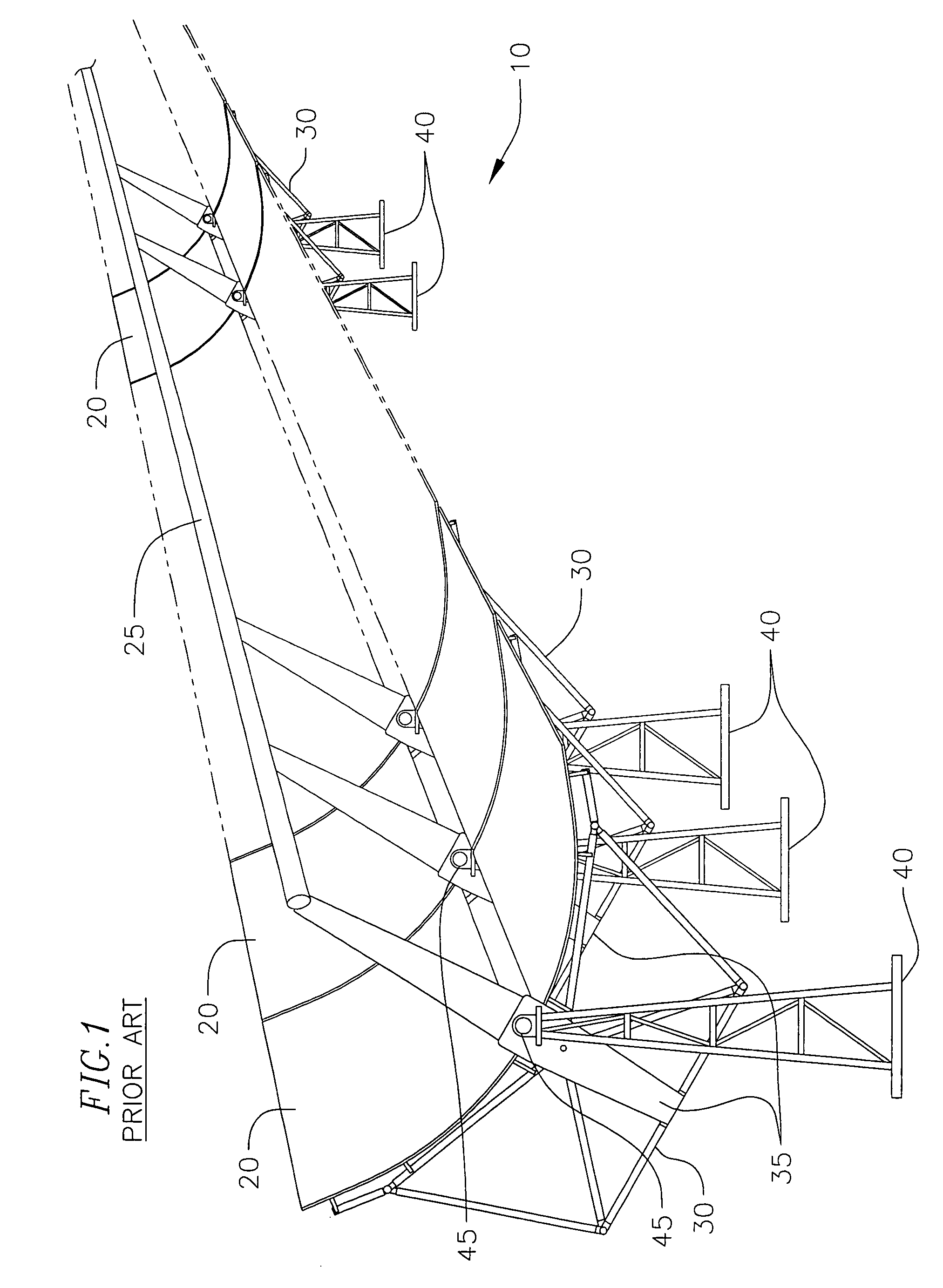

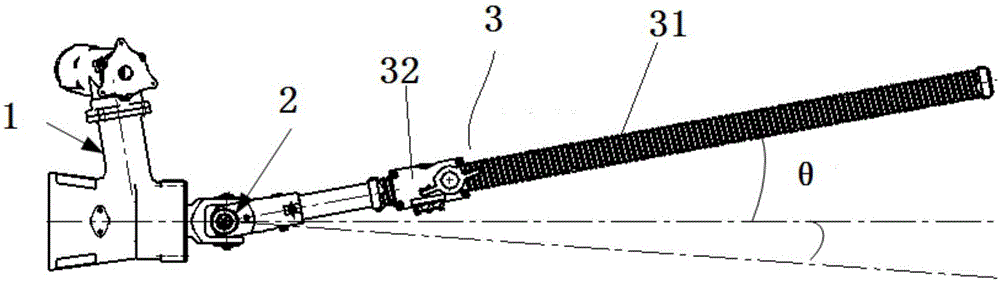

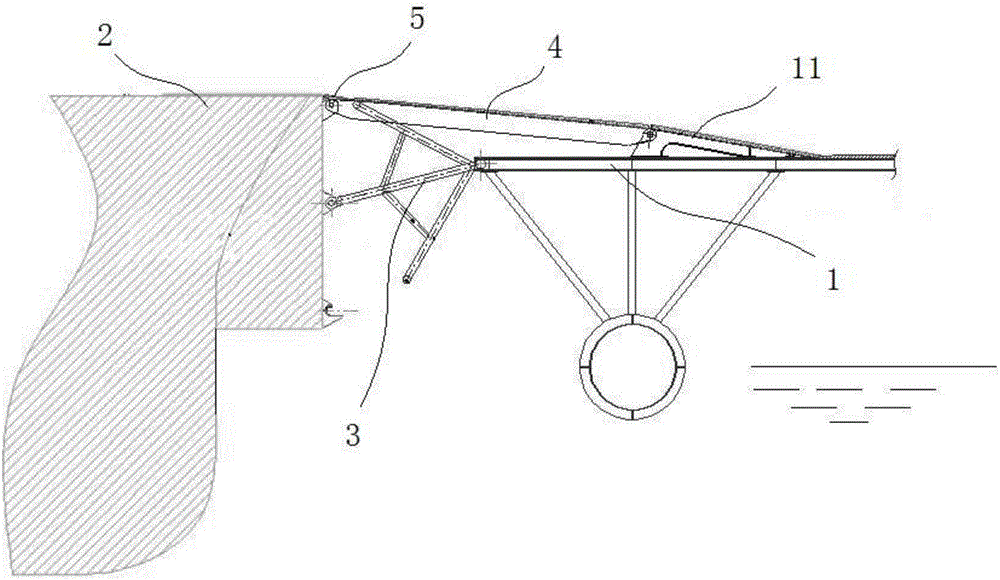

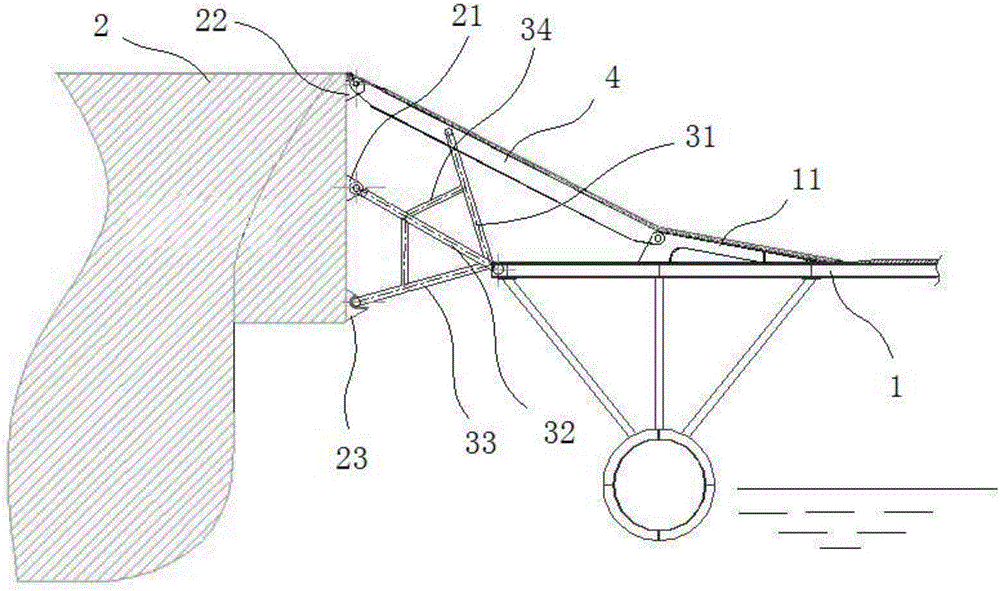

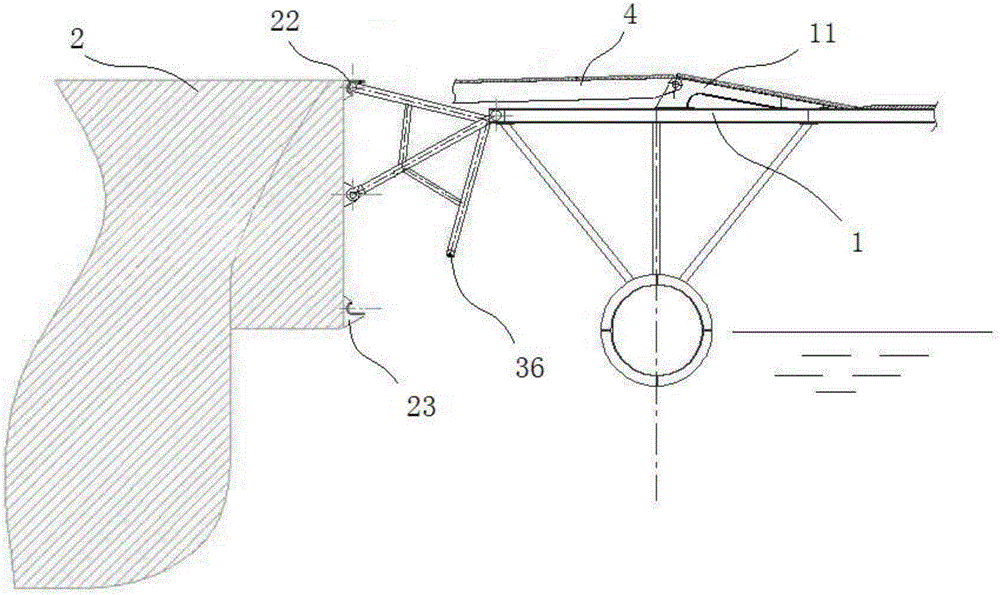

Pretension and lay-off method and device of crane jib for ship

InactiveCN101983894AReduce supportAvoid fatigue damageCargo handling apparatusPassenger handling apparatusEngineeringWinch

The invention relates to a pretension and lay-off method of a crane jib for a ship, belonging to the technical field of a crane. The crane comprises a luffing mechanism composed of a top pulley block, a jib, a winch, a luffing wire rope and a jib head pulley block and a bracket. The method comprises the following steps: A. operating the winch in the forward direction, loosening the jib and layingoff the jib onto the bracket; and B, operating the winch in the reverse direction, pulling the jib upwards to enable the pressure of the jib on the bracket to be less than the pressure on the bracketbefore being subjected to the upward pull, and stopping and shutting off the winch. The invention also relates to a pretension and lay-off device of a crane jib for a ship. The luffing mechanism alsocomprises a middle pulley arranged at the middle of the jib, and the luffing wire rope is connected with the jib head pulley block and the middle pulley through the top pulley block. The pretension and lay-off method and device of a crane jib for a ship can produce a pretension force on the jib by means of the luffing wire rope, thereby reducing the self-weight load of the jib as well as the influence and the destruction on the jib structure as a result of the shock load and the changing load of the bracket on the jib. Besides, the invention has the advantages of simple method and structure, convenient operation and low cost.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

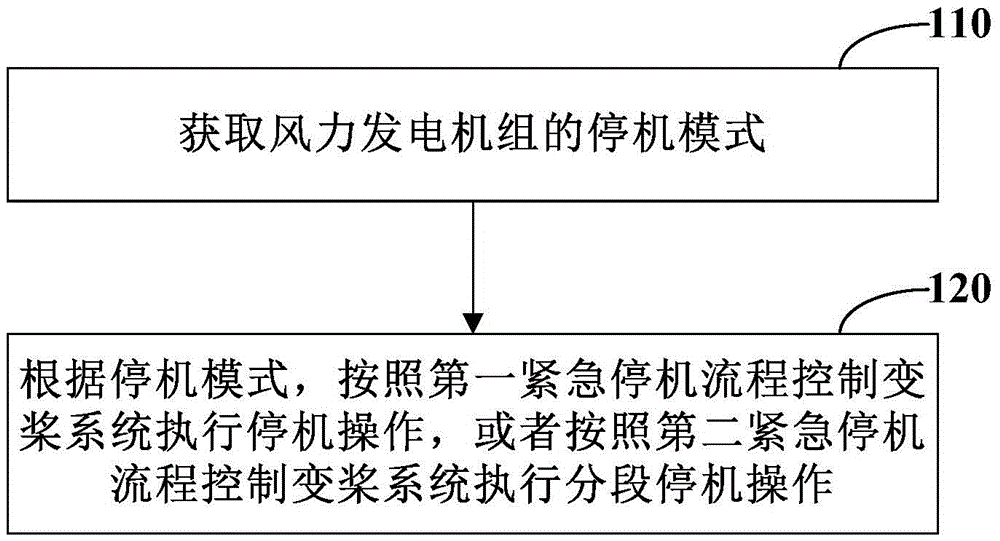

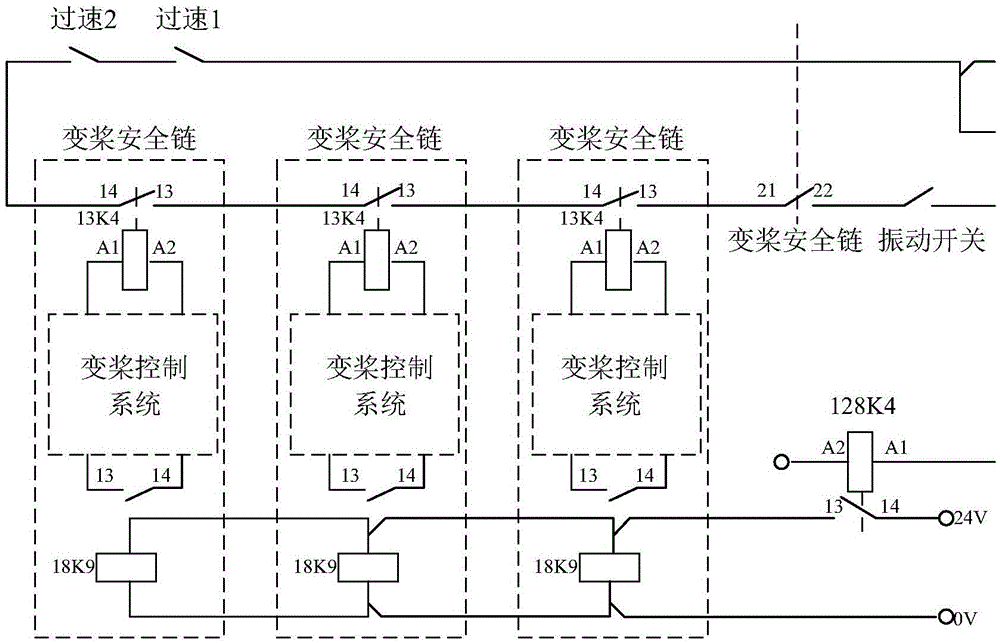

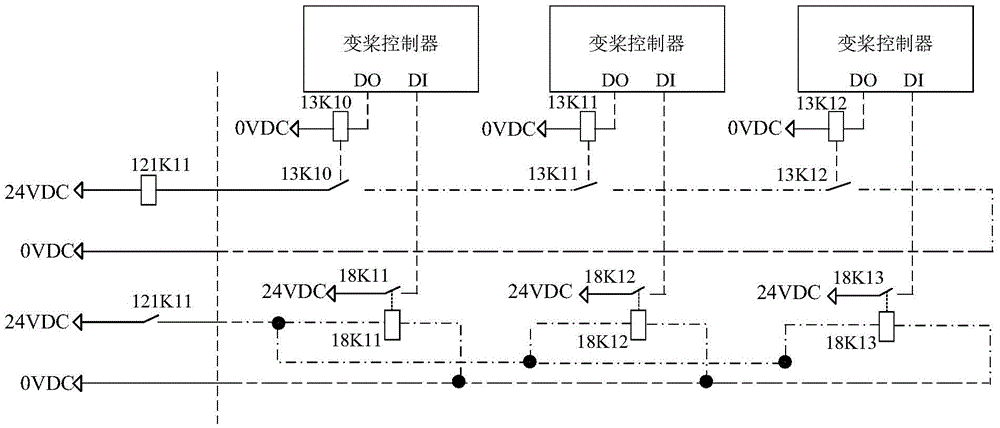

Control method and device for variable pitch system of wind turbine generator set

ActiveCN105484937AImprove securityImprove reliabilityWind motor controlMachines/enginesEngineeringDesign load

The embodiment of the invention provides a control method and a control device for a variable pitch system of a wind turbine generator set. The control method for the variable pitch system of the wind turbine generator set comprises the following steps: obtaining a shutdown mode of the wind turbine generator set; and according to the shutdown mode, controlling the variable pitch system to implement shutdown operation according to a first emergency shutdown process, or controlling the variable pitch system to implement sectional shutdown operation according to a second emergency shutdown process. According to the control method and the control device for the variable pitch system of the wind turbine generator set provided by the invention, corresponding shutdown operation processes are adopted based on different shutdown modes, so that the safety of the shutdown operation of the wind turbine generator set is improved, and the unit design load is reduced.

Owner:BEIJING ETECHWIN ELECTRIC

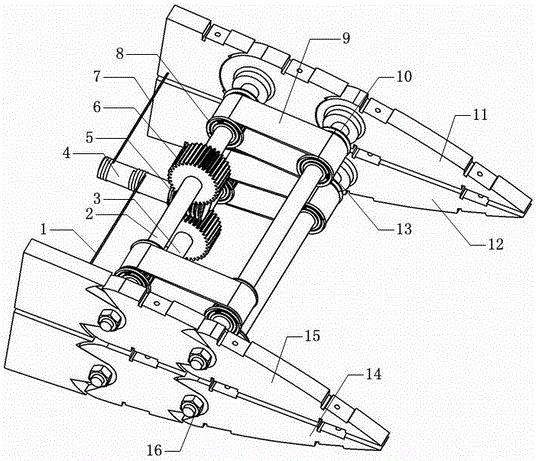

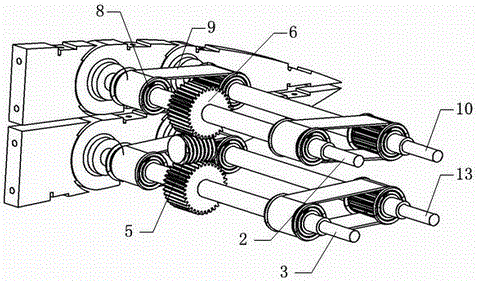

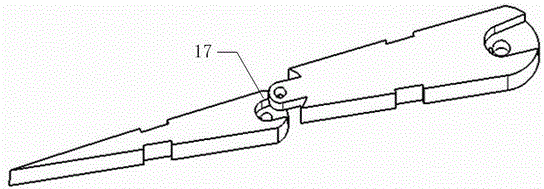

Morphing wing trailing edge driven based on shape memory alloy and deflection method thereof

InactiveCN105836106AImprove reliabilityImprove efficiencyAircraft controlWithout power ampliicationMorphing wingMemory effect

The invention provides a morphing wing trailing edge driven based on shape memory alloy and a deflection method thereof. The trailing edge is partially wound on an insulating rod by utilizing an SMA wire; through heating the SMA wire, the rotation of the insulating rod is realized by utilizing the shape memory effect of the SMA wire; the insulating rod is connected with a worm, so that a traditional motor is replaced for driving; a trailing edge flap is divided into two parts: an upper part and a lower part; according to the deflection method provided by the invention, through the rotation of one worm, two worm wheels are simultaneously driven to rotate, so that upper and lower wing ribs simultaneously deflect from equilibrium positions to limiting positions, and through changing the transmission ratios of the worm wheels and the worm, the deflection of the upper and the lower wing ribs at different angles can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

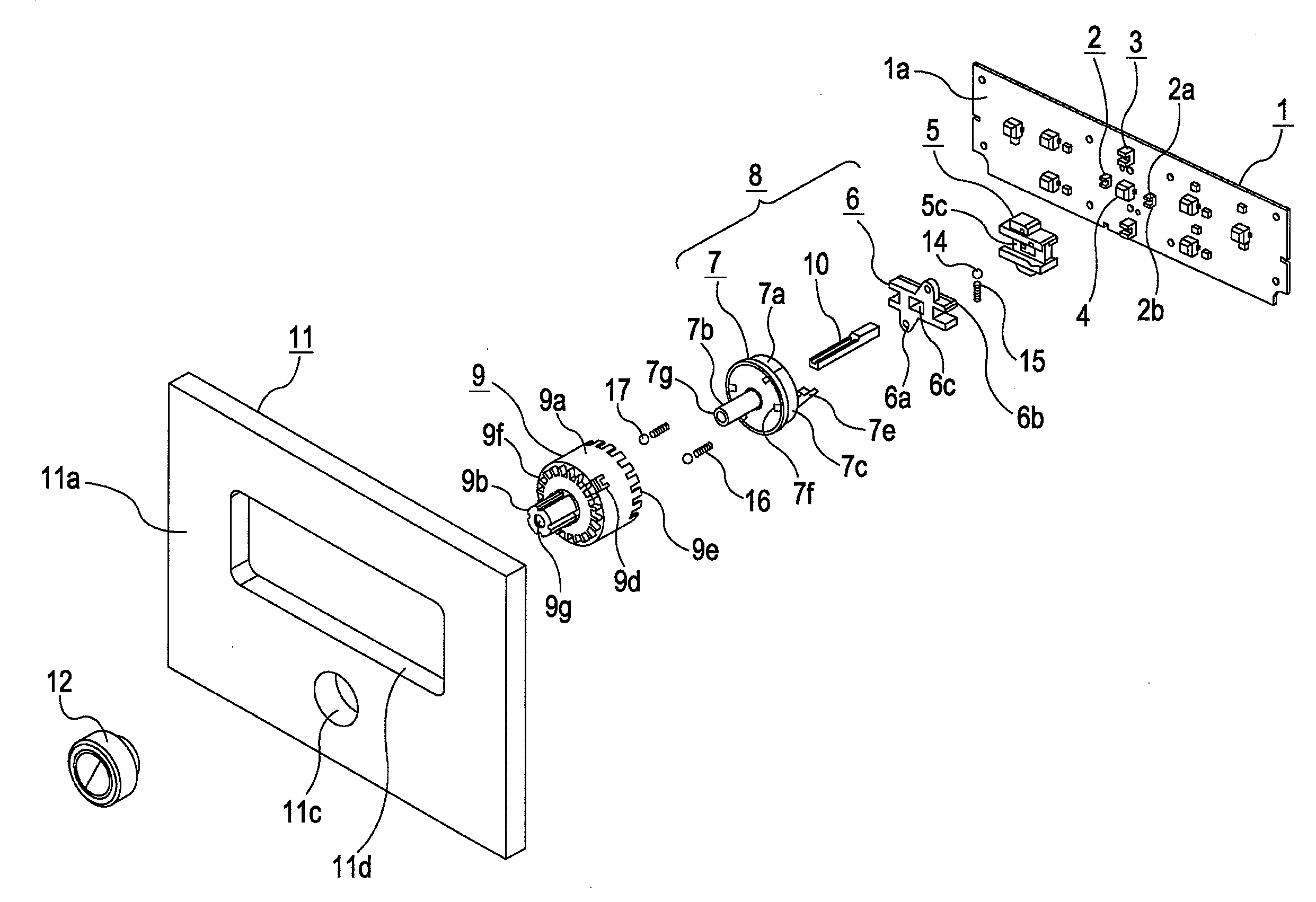

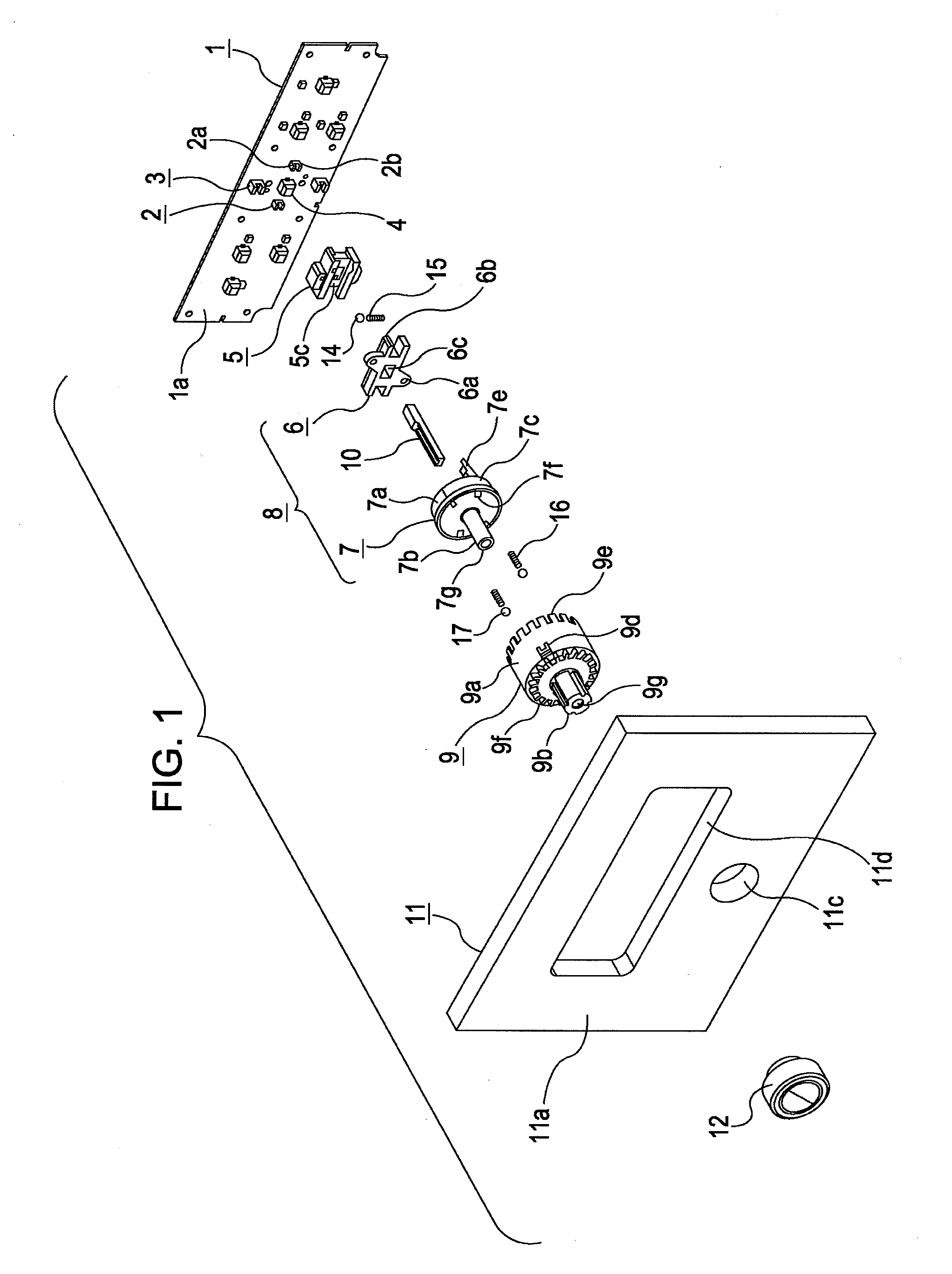

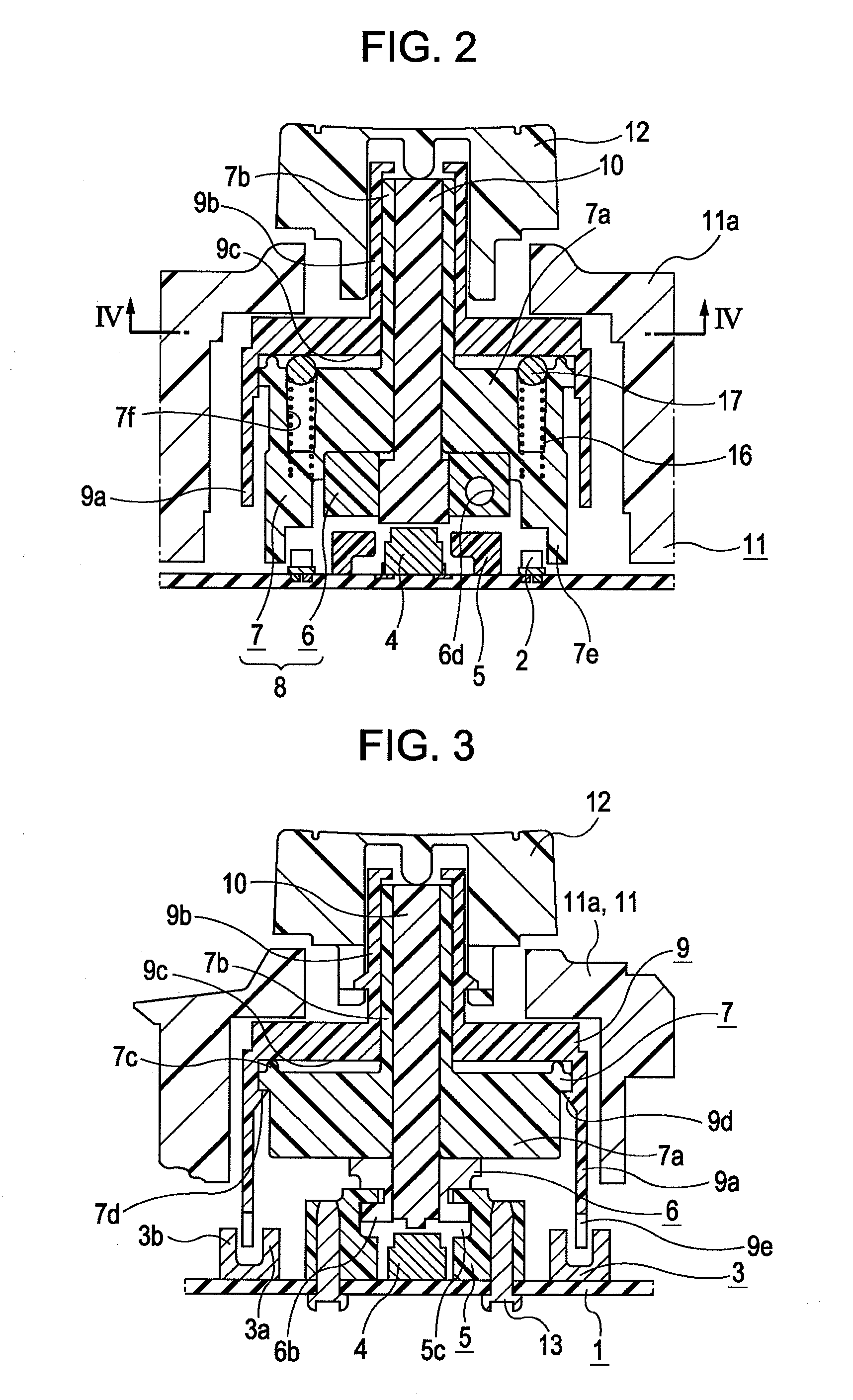

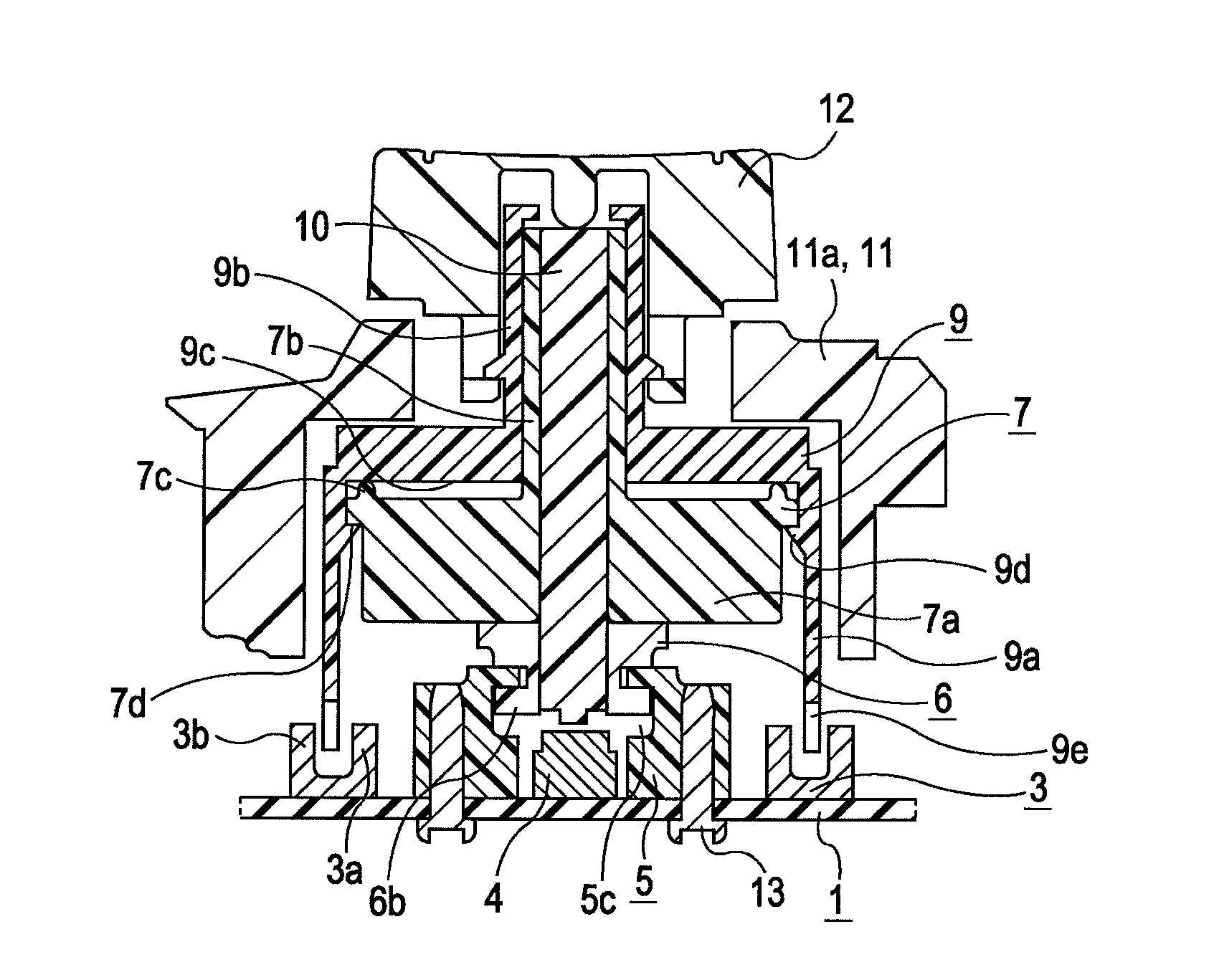

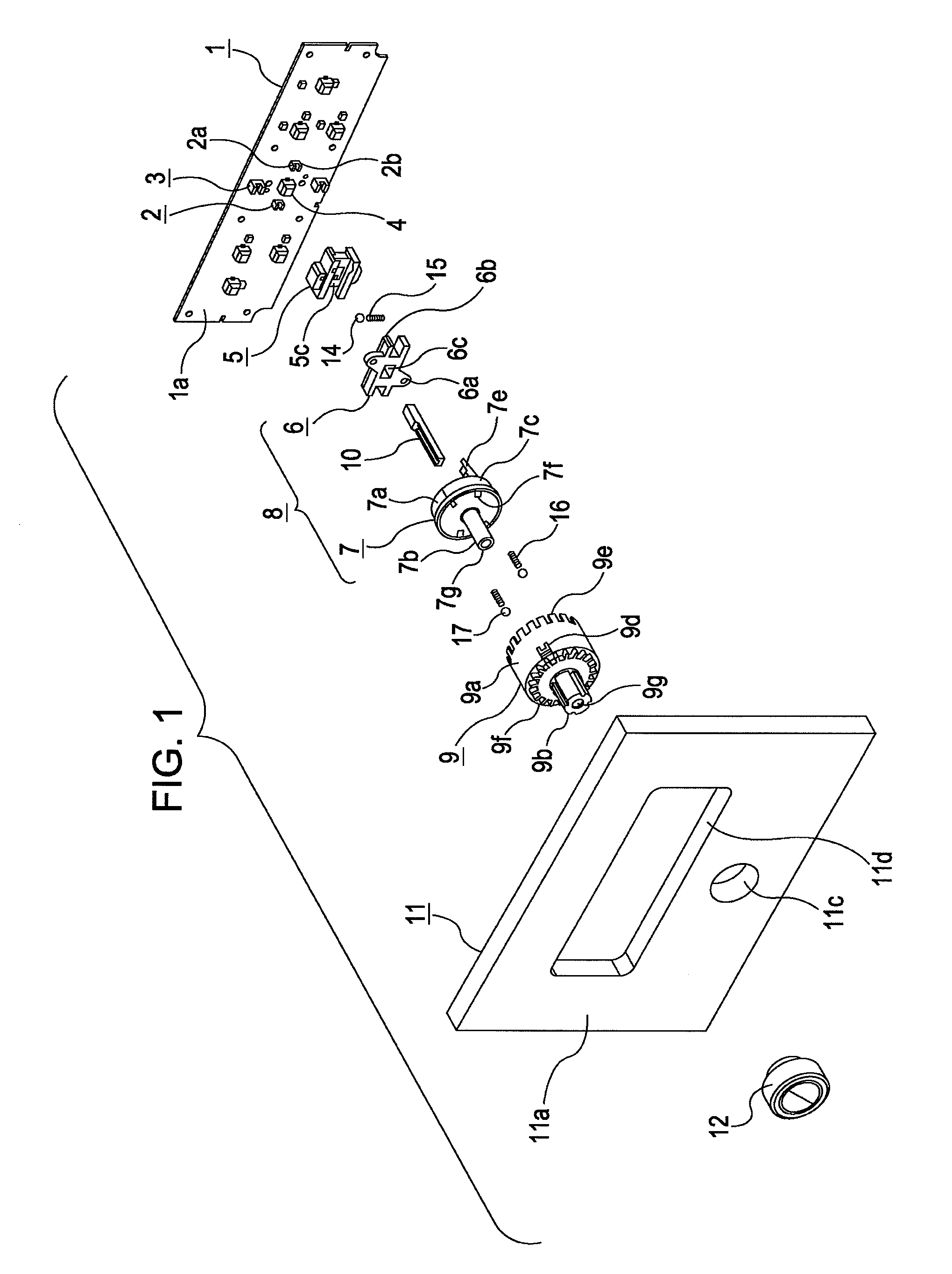

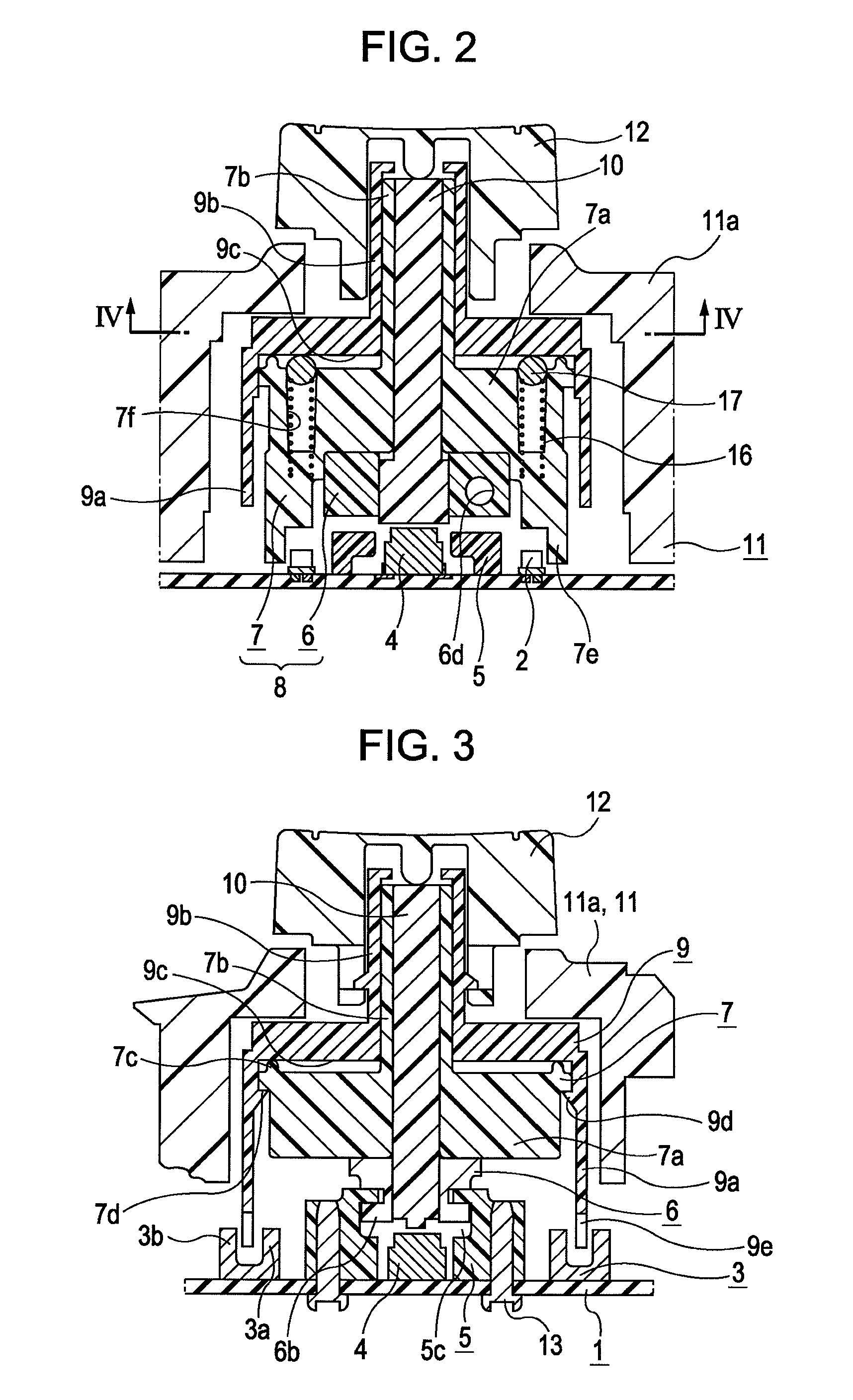

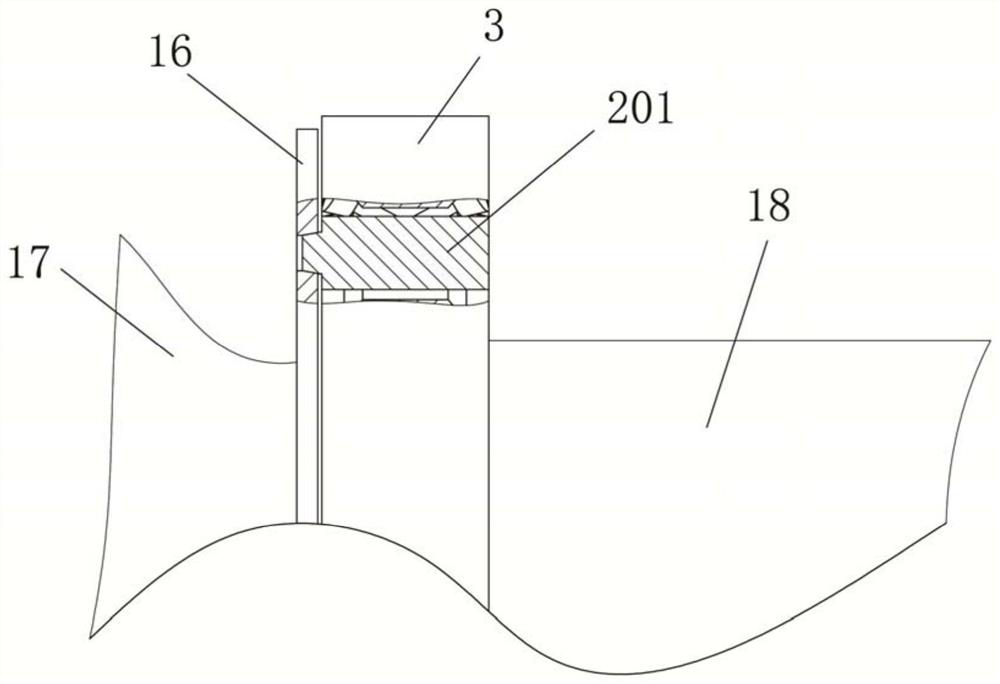

Complex-operation input device

ActiveUS20100321215A1Reduce thicknessCost reductionMaterial analysis by optical meansElectronic switchingEngineeringRotation sensor

A complex-operation input device having an operable knob held in a rotatable and slidable manner includes a rotation sensor that detects rotation of the operable knob on the basis of displacement of a second detected portion, and a slide sensor that detects sliding of the operable knob on the basis of displacement of a first detected portion. The direction in which the second detected portion moves with the sliding of the operable knob is substantially orthogonal to a rotation axis about which the operable knob rotates. The slide sensor is disposed such that, when the operable knob is slid, the slide sensor detects the sliding before the rotation sensor detects the displacement of the second detected portion.

Owner:ALPS ALPINE CO LTD

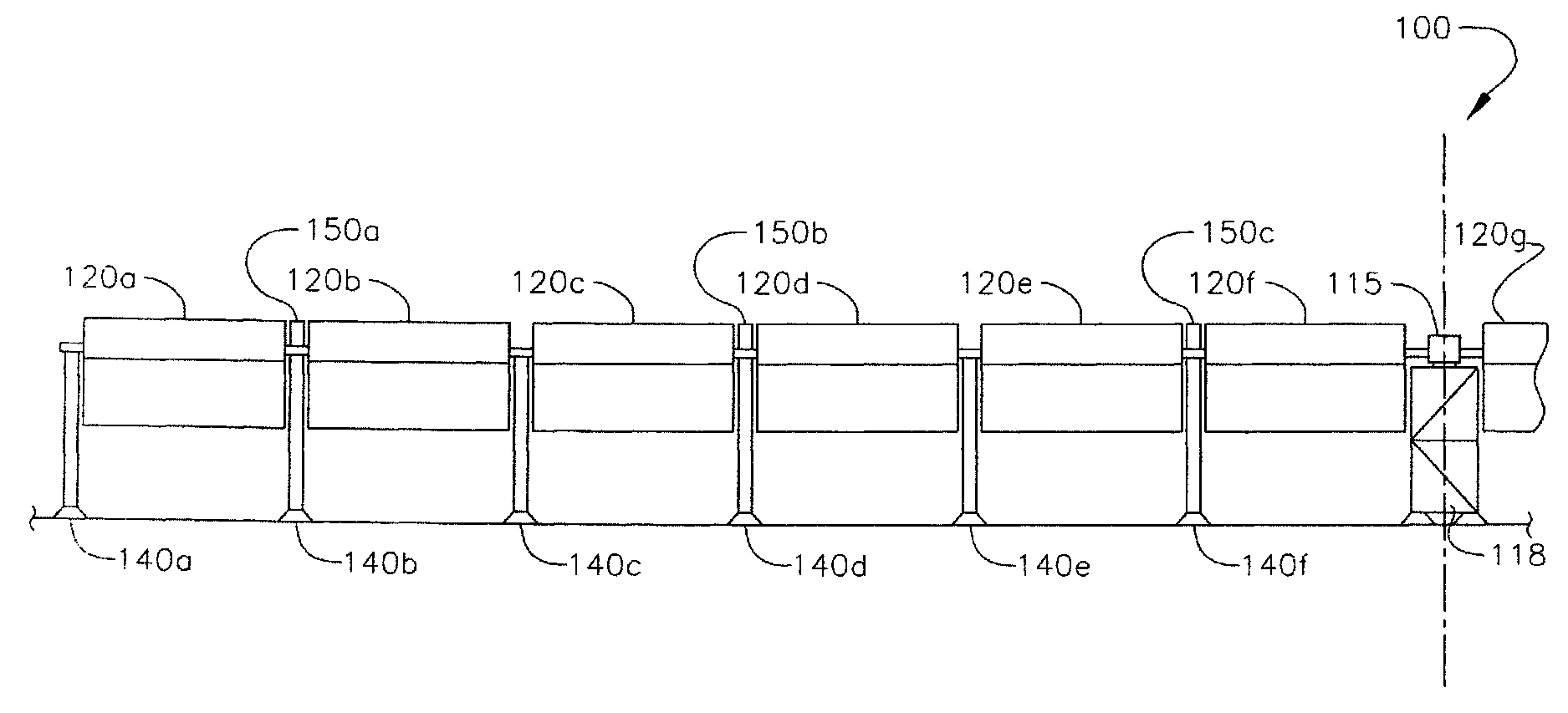

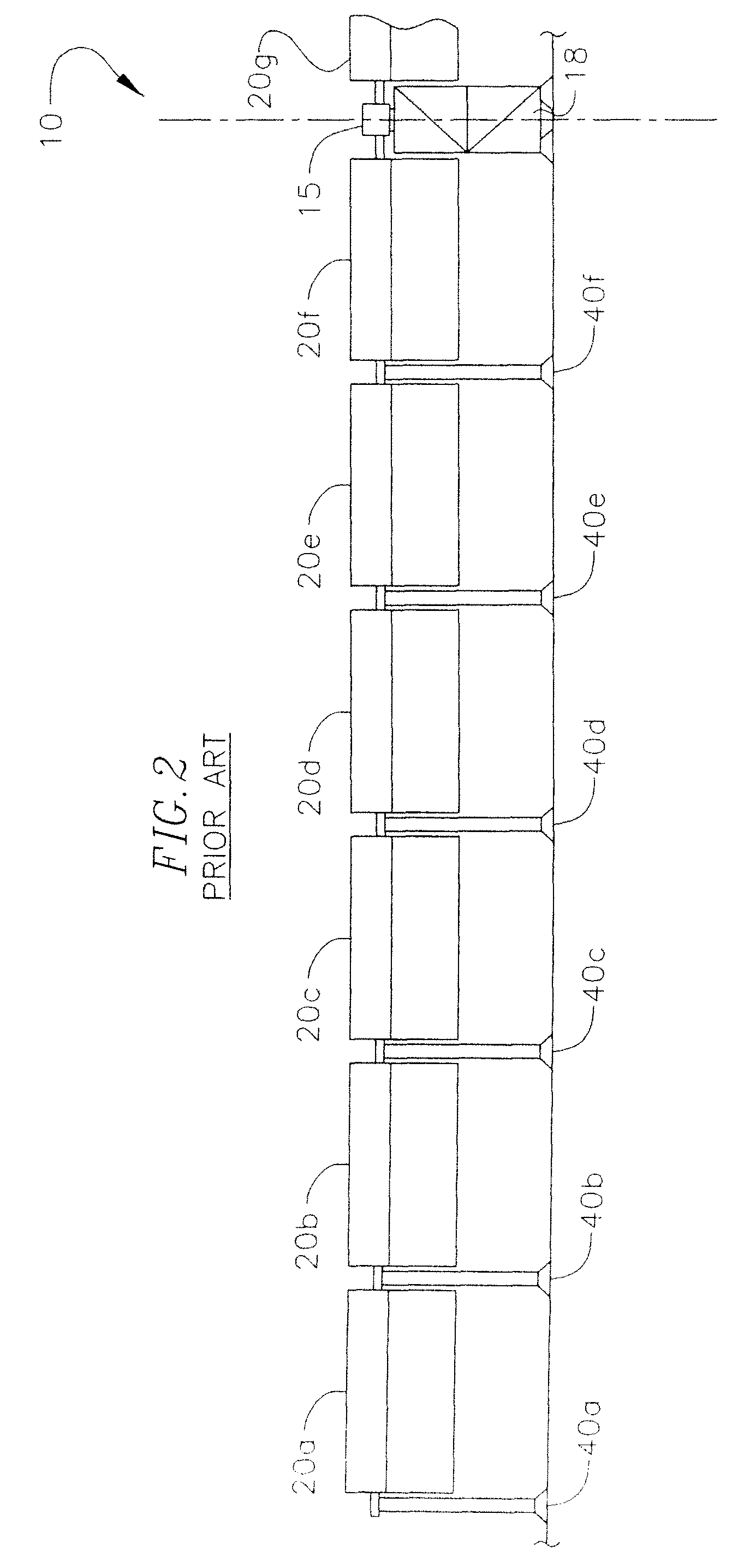

Multiplexed torque brake system for a solar concentrator assembly

InactiveUS8671931B2Design economyReduce design loadSolar heating energySolar heat devicesEngineeringDesign load

A multiplexed torque brake (MTB) system for preventing the accumulation of torsional forces at a center drive and thereby significantly reducing the design load requirements for trough frames of a corresponding solar concentrator assembly (SCA). In one embodiment, an MTB system for an SCA having a plurality of solar reflector frames spaced along a length of the SCA includes a plurality of brake mechanisms arranged at locations spaced apart from each other along the length of the SCA, each of the brake mechanisms coupled to a corresponding one of a plurality of supporting pylons and configured to constrain the solar reflector frames from rotating when subjected to torsional loads, the brake mechanisms adapted to transfer the torsional loads to the corresponding supporting pylons.

Owner:GOSSAMER SPACE FRAMES

Wing-body load alleviation for aircraft

ActiveUS8024079B2Reduce load requirementsReduce design loadDigital data processing detailsActuated automaticallyJet aeroplaneNonlinear filter

A computer implemented method, apparatus, and computer usable program product for symmetric and anti-symmetric control of aircraft flight control surfaces to reduce wing-body loads. Commands are sent to symmetrically deploy outboard control surfaces to shift wing air-loads inboard based on airplane state and speed brake deployment. Surface rate retraction on a wing with peak loads is limited to reduce maximum loads due to wheel checkback accompanied by utilization of opposite wing control surfaces to retain roll characteristics. Airloads are shifted inboard on a swept wing to move the center of pressure forward, thereby reducing the tail load required to perform a positive gravity maneuver. In a negative gravity maneuver, speed brakes are retracted, thereby reducing the positive tail load and reducing the aft body design loads. High gain feedback commands are filtered from wing structural modes above one hertz by a set of linear and non-linear filters.

Owner:THE BOEING CO

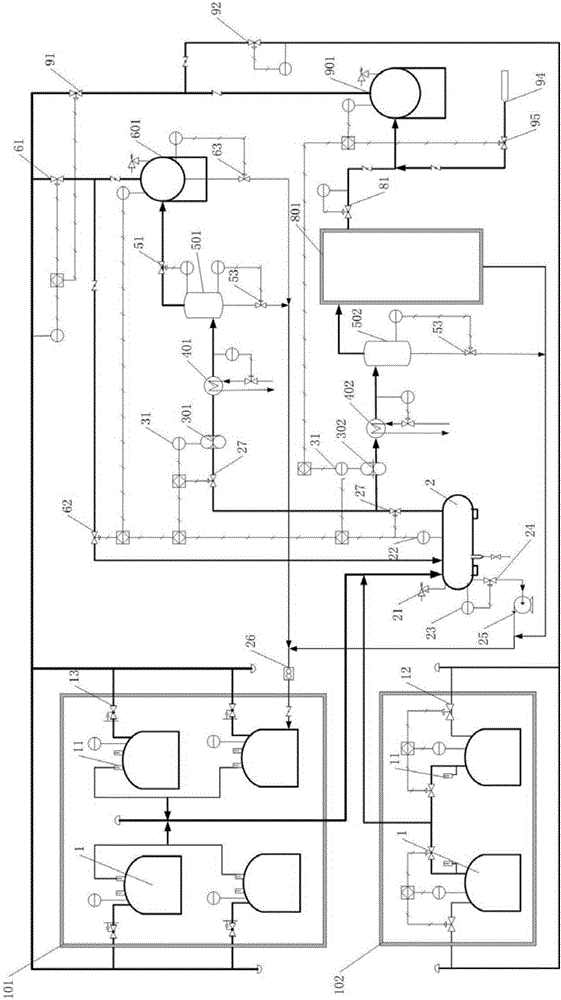

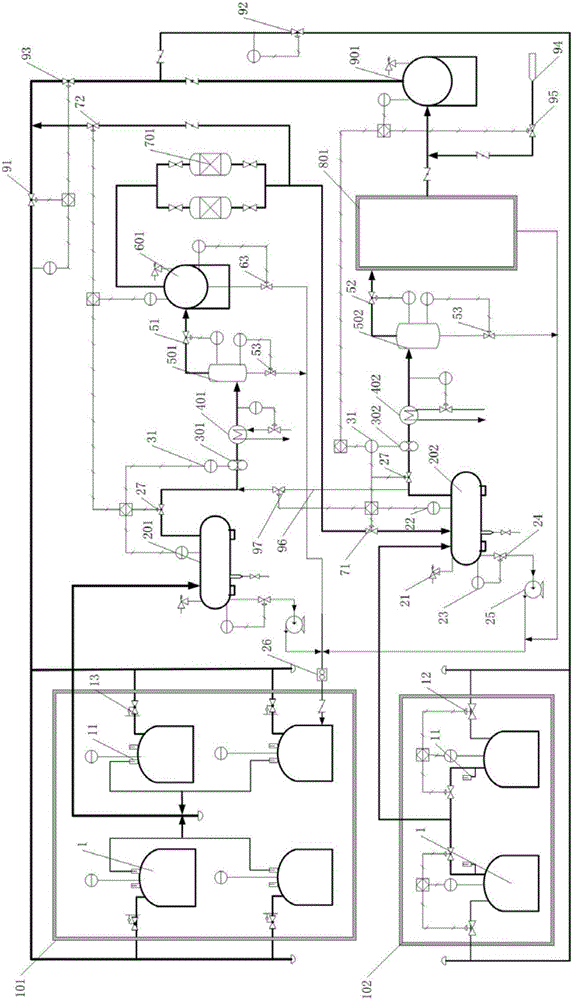

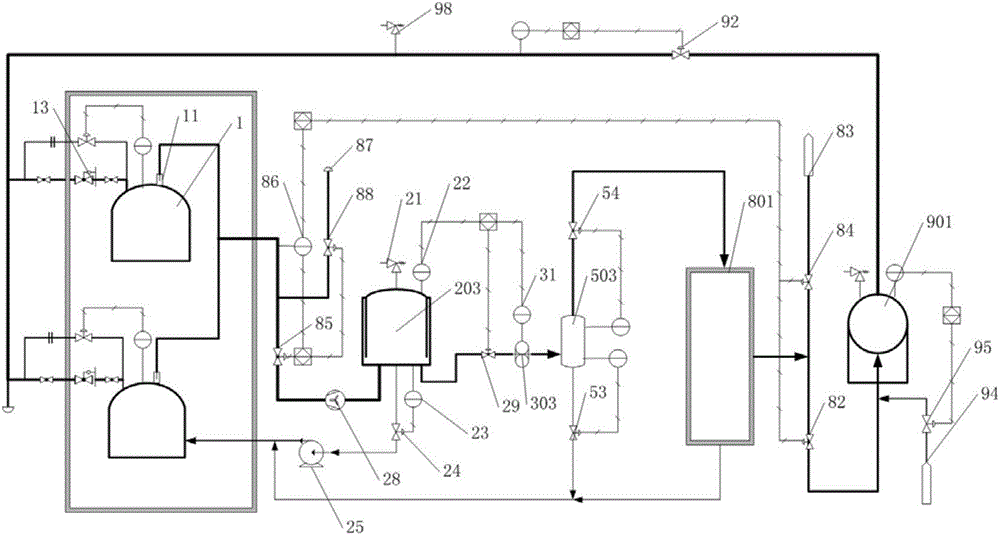

Oil-gas recovering system of storage tank and control method thereof

ActiveCN106742889AGuaranteed uptimeStable operating loadLarge containersDesign loadProcess engineering

The invention relates to the technical field of the oil-gas recovery technology of the storage tank and in particular to an oil-gas recovering system of a storage tank and a control method thereof. The provided oil-gas recovering system of the storage tank comprises the storage tank, a fluid distributing tank, a first compressor, a second compressor, a first separating tank, a second separating tank, a balance tank, an oil-gas recovering device and a buffering tank. The storage tank is successively connected with the fluid distributing tank, the first compressor, the first separating tank and the balance tank. The balance tank is respectively connected with the fluid distributing tank and the storage tank to form an oil-gas balance system. The storage tank is successively connected with the fluid distributing tank, the second compressor, the second separating tank, the oil-gas recovering device, the buffering tank and the storage tank to form the oil-gas recovering system. The oil-gas recovering system of the storage tank is capable of, through the setting of the balance tank, reducing the design load of the oil-gas recovering device, maintaining the stable running of the oil-gas recovering device, avoiding the frequent and great alternating running of the device, reducing the alternating fatigue of the device, and reducing the safety risk. The compared with the current oil-gas recovering device, the design load is reduced by 50%-80%.

Owner:谢玉勋

Horizontal axis wind turbine

InactiveUS8167555B2Reduce loadAvoid it happening againPropellersWind motor controlNacelleHorizontal axis

Owner:HITACHI LTD

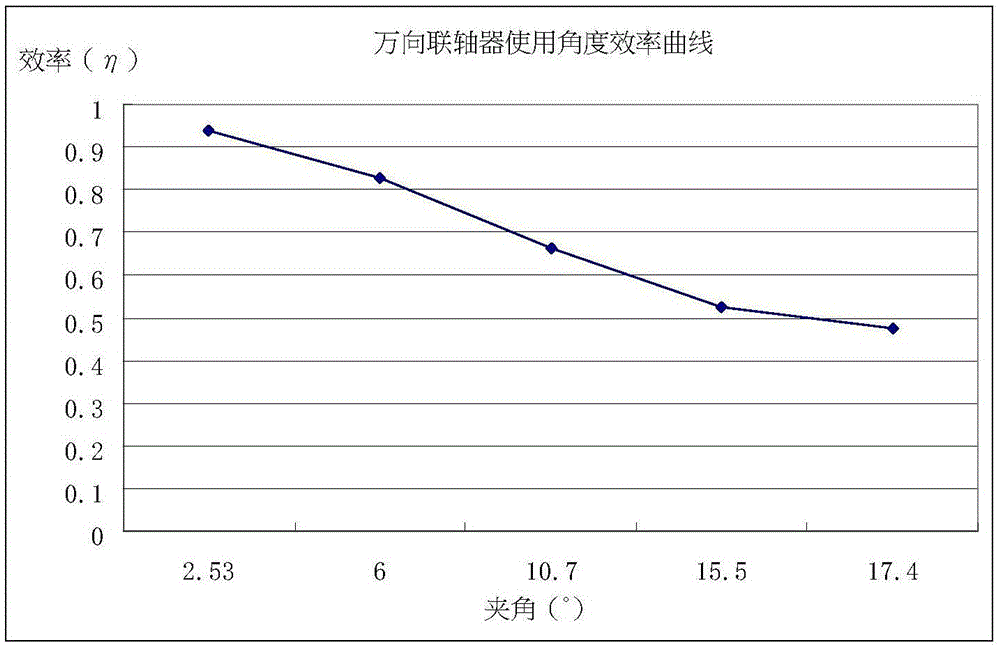

Design method of flap driving mechanism and flap driving mechanism

ActiveCN105035308AReduce design weightImprove reliabilityWithout power ampliicationWeight reductionCouplingDrive shaft

The invention relates to the field of flight control, in particular to a design method of a flap driving mechanism and the flap driving mechanism, and aims to solve the problem that the driving mechanism is low in use efficiency when an aircraft flap is loaded heavily and deflects a large angle. According to the design method of the flap driving mechanism, on the basis that a universal coupling is in an original state, a driven shaft is rotated by a preset angle around a hinge point in the anti-clockwise direction, and the current state of the universal coupling is used as the original state to be designed, so that the efficiency loss of the universal coupling is reduced when the flap is driven to rotate by the same angle, and the efficiency of the driving mechanism is greatly improved; meanwhile, on the premise that the external driving load of by the flap driving mechanism remains unchanged, the design load of the driving mechanism is reduced, the design weight of the driving mechanism is reduced, and the reliability of the driving mechanism is improved; the principle is simple and practical, and easy to implement.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Complex-operation input device

ActiveUS8350731B2Reduce design loadPrevent false detectionMaterial analysis by optical meansElectronic switchingEngineeringRotation sensor

A complex-operation input device having an operable knob held in a rotatable and slidable manner includes a rotation sensor that detects rotation of the operable knob on the basis of displacement of a second detected portion, and a slide sensor that detects sliding of the operable knob on the basis of displacement of a first detected portion. The direction in which the second detected portion moves with the sliding of the operable knob is substantially orthogonal to a rotation axis about which the operable knob rotates. The slide sensor is disposed such that, when the operable knob is slid, the slide sensor detects the sliding before the rotation sensor detects the displacement of the second detected portion.

Owner:ALPS ALPINE CO LTD

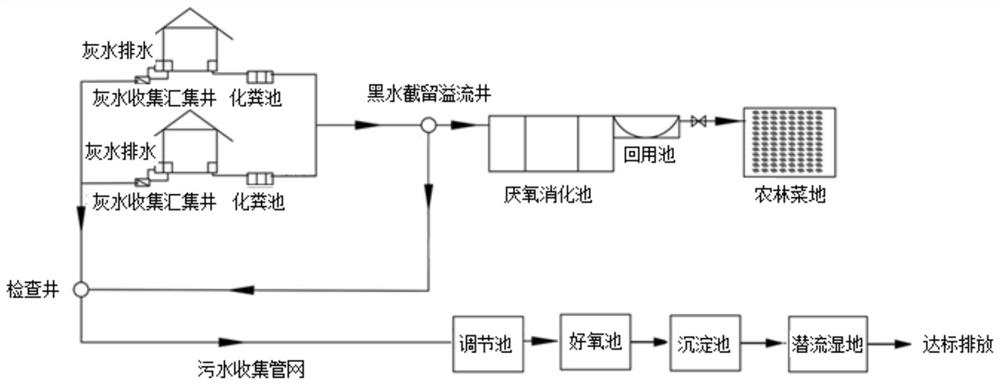

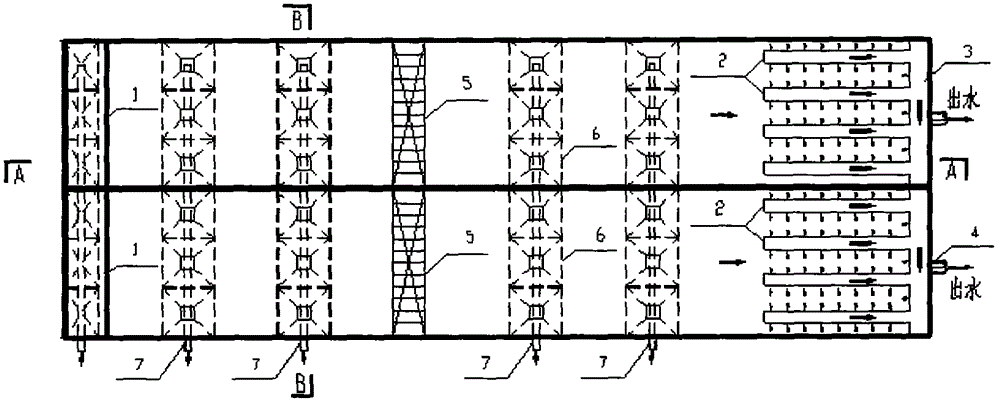

Distributed domestic sewage source separation, collection and treatment system capable of locally recycling resources and reducing pollution load and design method thereof

ActiveCN112125472ALow carbon nitrogen ratioReduce total nitrogenFatty/oily/floating substances removal devicesWater contaminantsWater useGreywater

The invention belongs to the field of village and town sewage treatment and recycling, and relates to a distributed domestic sewage source separation, collection and treatment system capable of locally recycling resources and reducing the pollution load and design method thereof, which includes a quality-divided collection system and a treatment system; The quality-divided collection system comprises a black water intercepting overflow well, a grey water collection and collection well and a sewage collection pipe network; the treatment system comprises more than one set of distributed black water digestion and recycling system and more than one set of miscellaneous water treatment system, and the black water digestion and recycling system comprises an anaerobic digestion tank and a recycling tank. The miscellaneous water treatment system comprises an adjusting tank, an aerobic tank, a sedimentation tank and a subsurface wetland. Domestic sewage is divided into black water and grey water to be collected respectively, cyclic utilization of nitrogen, phosphorus and potassium resources of rural domestic sewage is preferentially achieved on site, the sewage amount and the pollutant concentration in the sewage are reduced, an existing conventional sewage treatment mode of nitrogen and phosphorus removal is thoroughly changed, cyclic utilization of the resources can be truly achieved,and the sewage treatment cost is greatly reduced.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

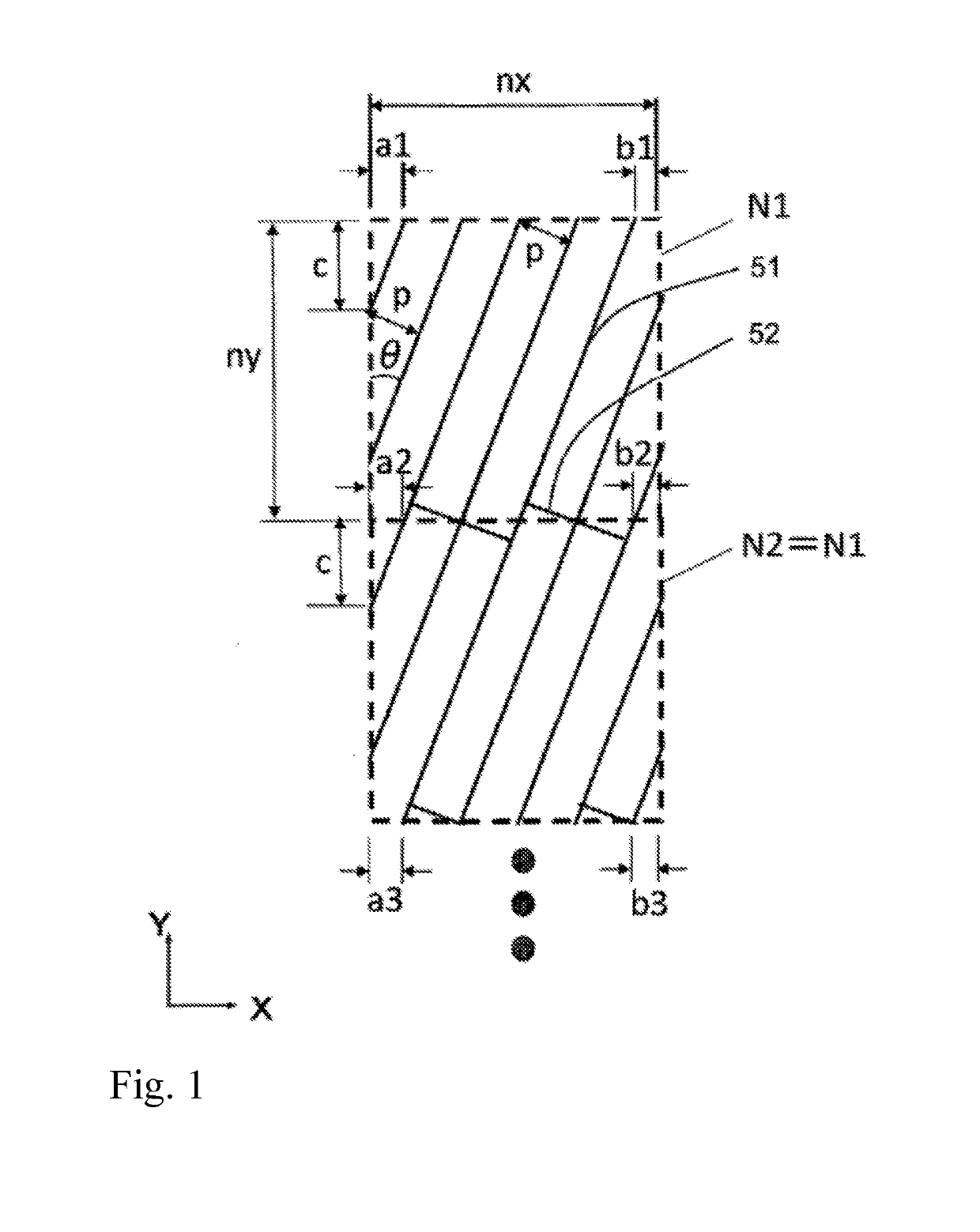

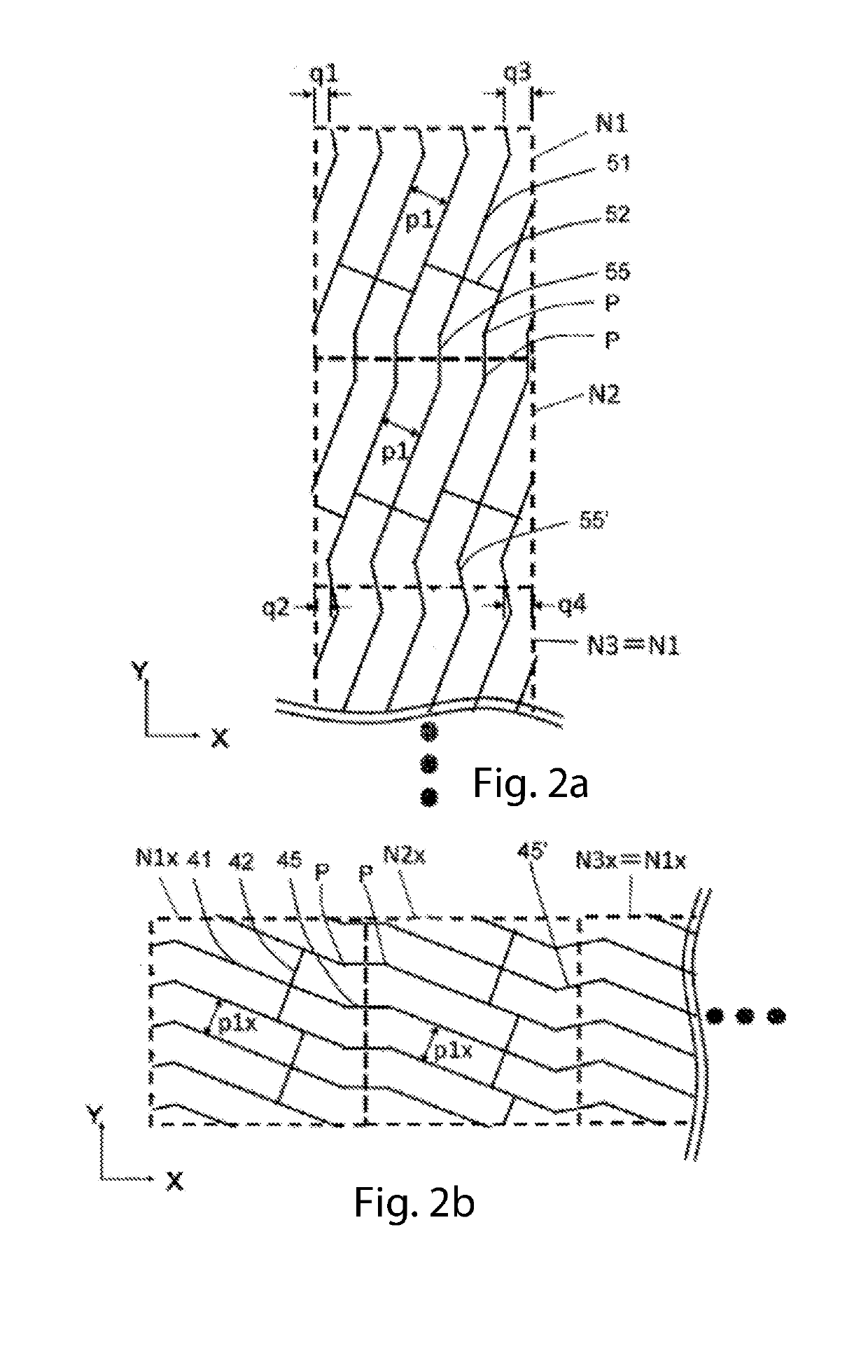

Touch panel and display device comprising same

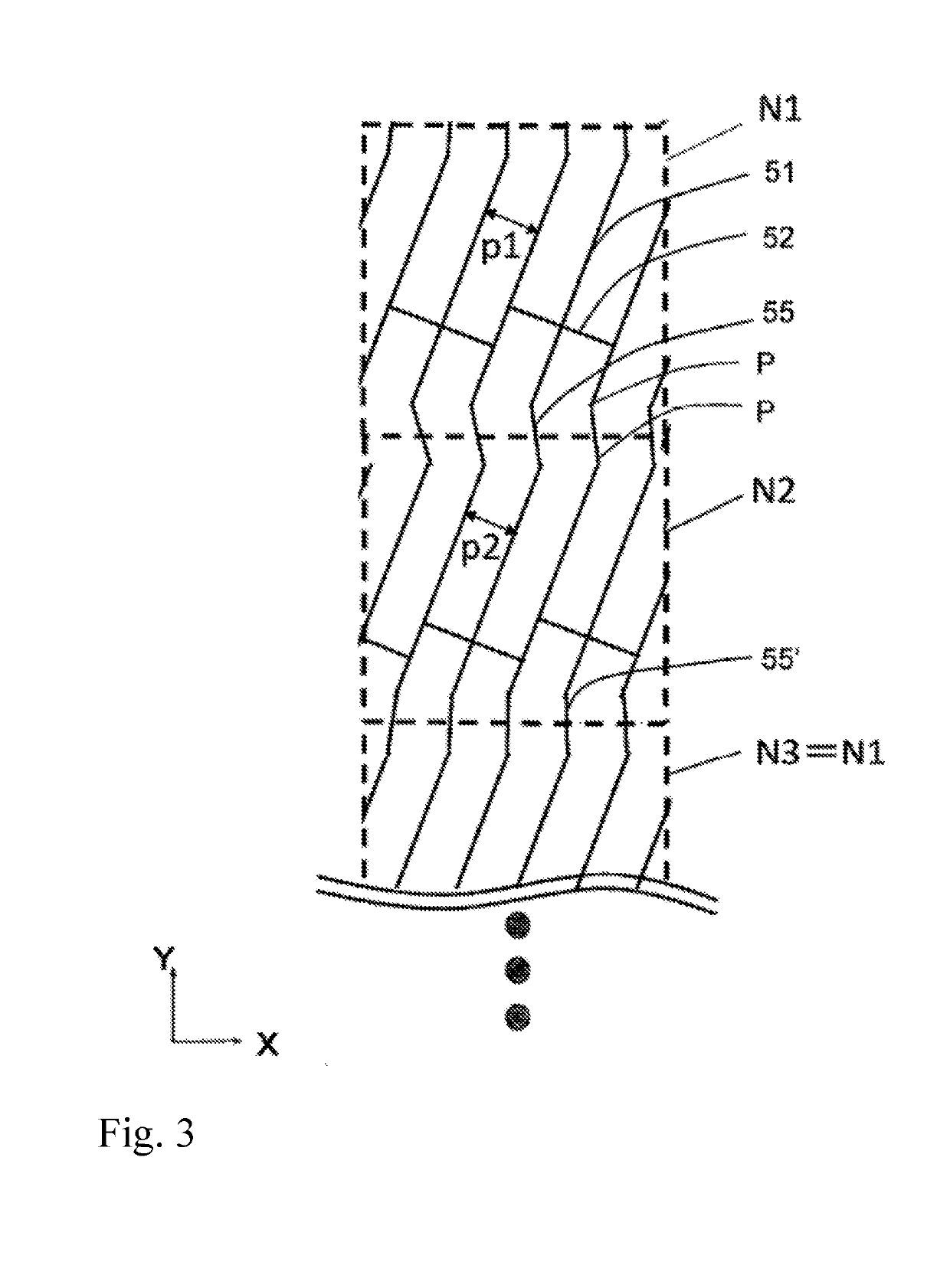

ActiveUS20190129568A1Small design loadHigh degree of freedomInput/output processes for data processingAuxiliary electrodeTouch panel

A touch panel enabling a repeat arrangement with a small design load, and a mesh pattern with a high degree of freedom and does not generate moire, and a display device comprising same. A touch panel in which a drive electrode pattern / sensing electrode pattern include: first main electrode wires / second main electrode wires constituting line segments having a linear shape extending along a first wire direction / second wire direction; and first auxiliary electrode wires / second auxiliary electrode wires constituting line segments having a linear shape extending along the second wire direction / first wire direction and joining the first main electrode wires / second main electrode wires, and respective end points of the first main electrode wires / second main electrode wires are connected to end points of the closest first main electrode wire / second main electrode wire in adjacent nodes, by connecting wires having a different angle of inclination from the first main electrode wires / second main electrode wires.

Owner:VTS TOUCHSENSOR CO LTD

Non-aqueous electrolyte secondary battery and battery pack using the same

InactiveUS7767348B2Improve discharge characteristicsSolve low usageCell seperators/membranes/diaphragms/spacersFinal product manufactureBattery packNon aqueous electrolytes

A non-aqueous electrolyte secondary battery includes an electrode assembly formed by winding positive and negative electrodes, and an insulating layer together. Each of the electrodes has a core sheet and mixture layers formed on both sides of the sheet. The insulating layer electrically insulates the electrodes. At least one of the electrodes includes a core-exposed portion continuous parallel to the winding direction. Each of the mixture layers has an inclined weight region where the amount of mixture per unit area decreases toward the core-exposed portion, and a constant weight region in which the amount of mixture per unit area is constant. The inclined weight region has a width of not more than 0.2 of the width of the mixture layers and has an average mixture density of not less than 40% and not more than 99% of the mixture density of the constant weight region.

Owner:PANASONIC CORP

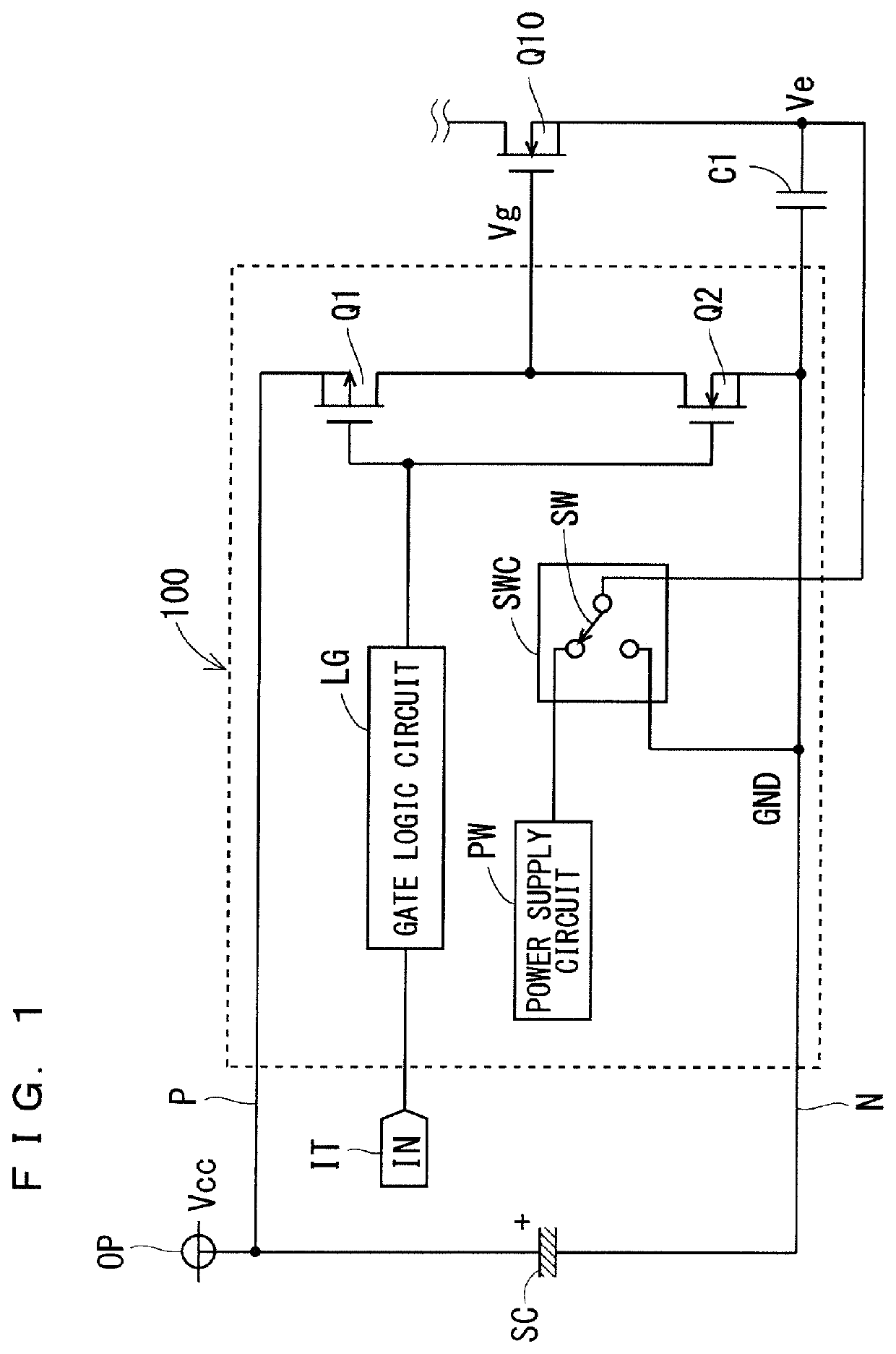

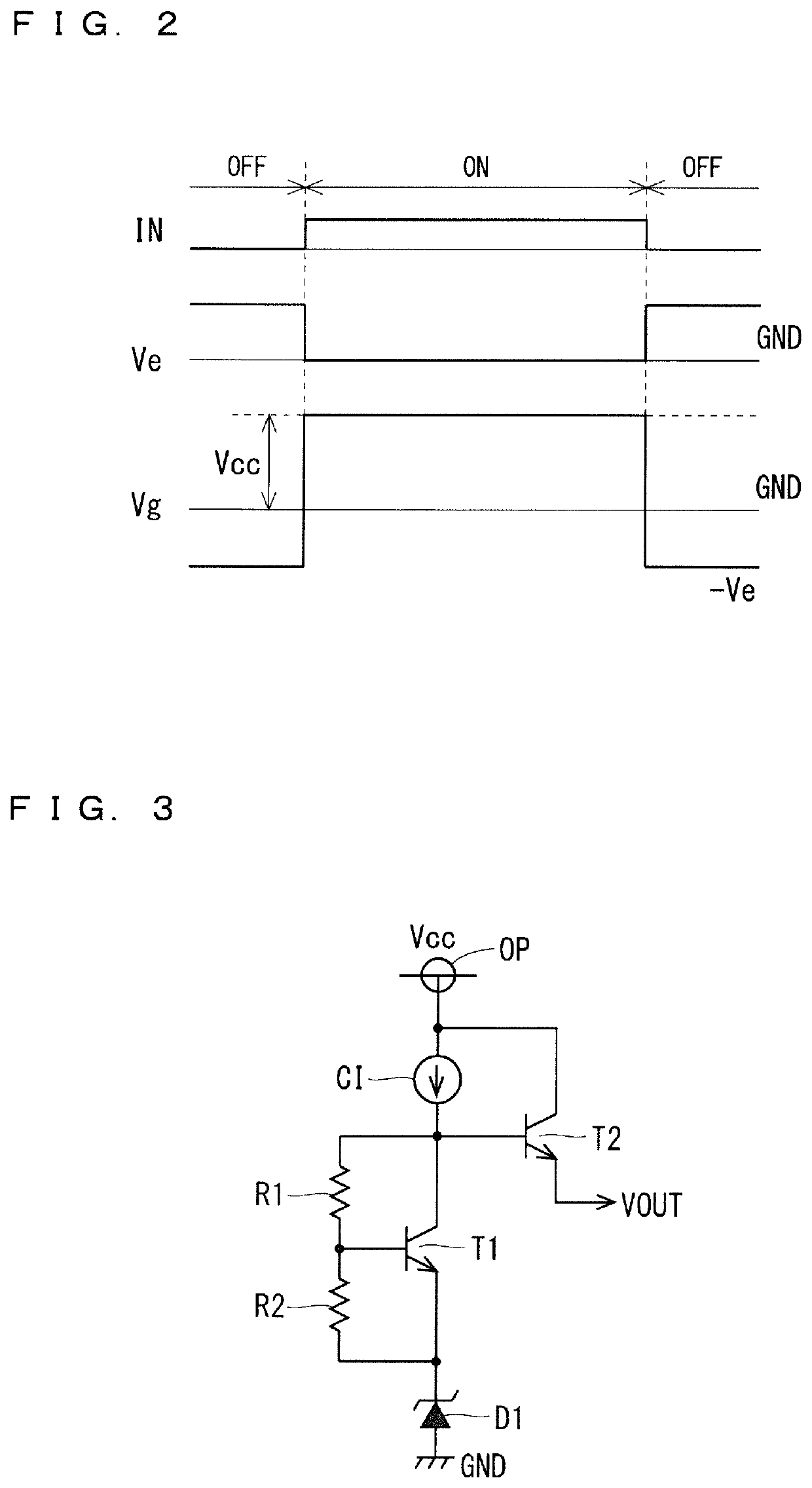

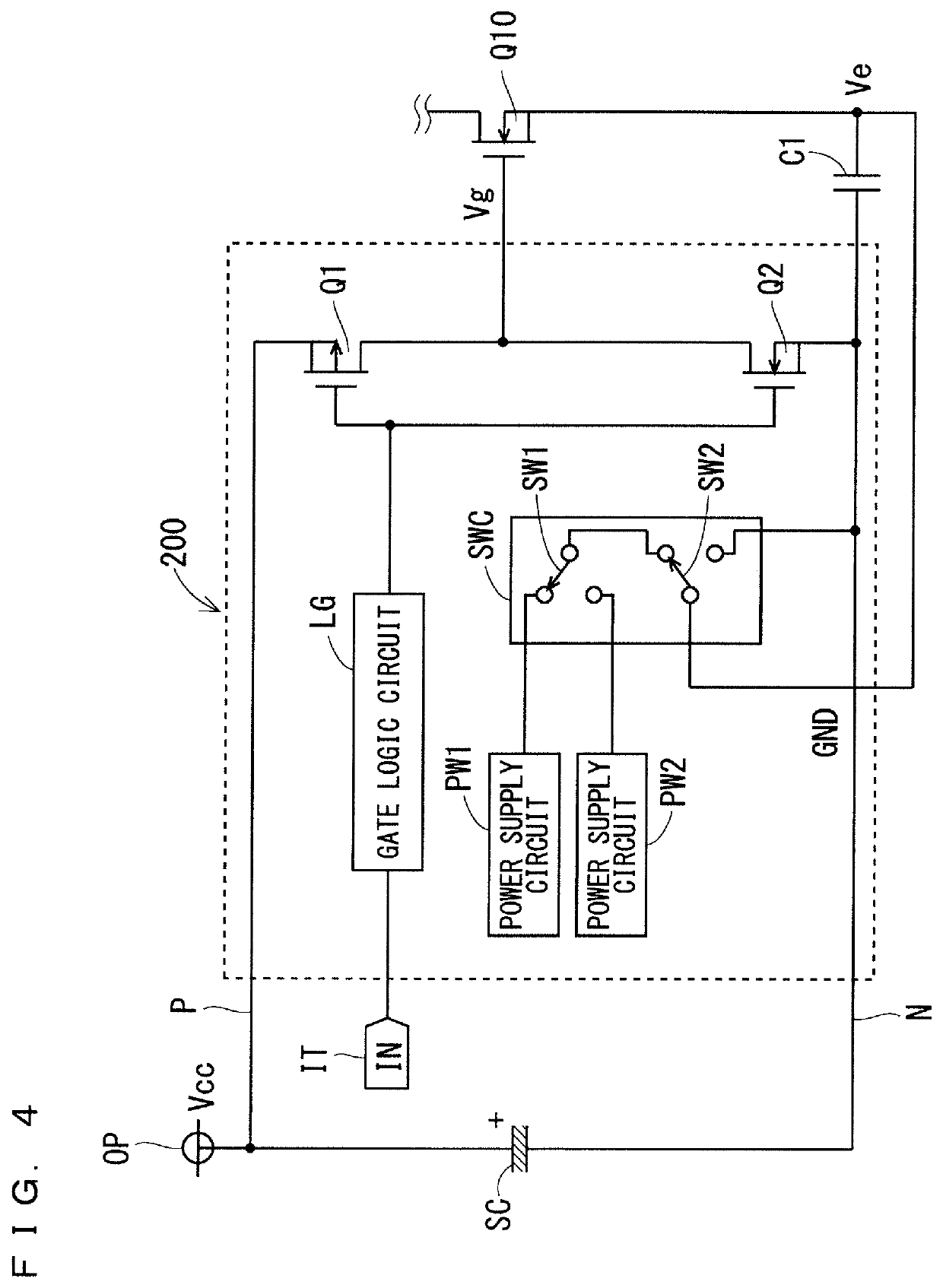

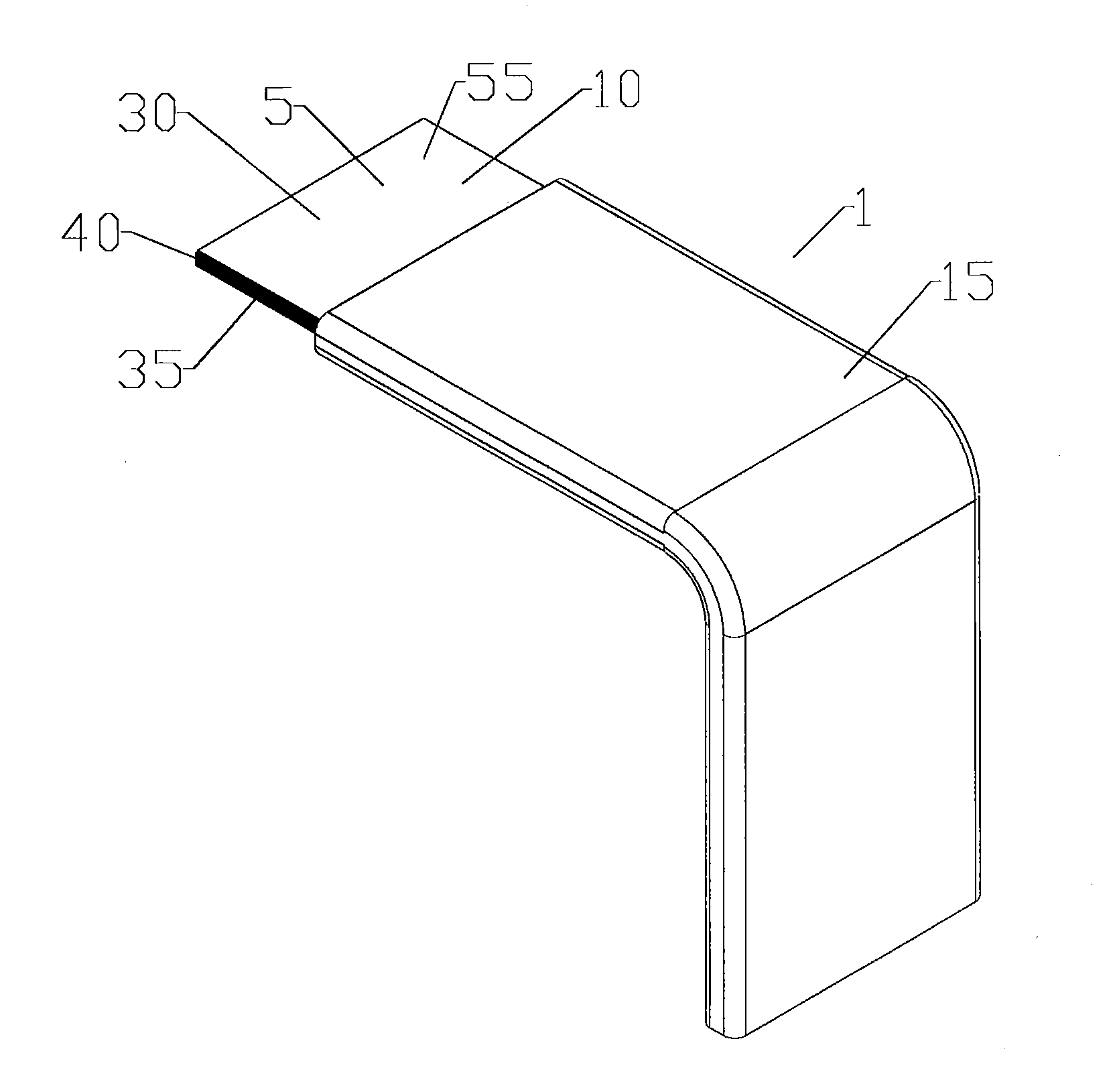

Gate driver and semiconductor module

ActiveUS10784860B1Reduce design loadElectronic switchingPower conversion systemsSoftware engineeringHemt circuits

A gate driver includes a first transistor and a second transistor connected in series between a first and a second power supply line, connection nodes thereof are output nodes of the gate driver, the first and second transistors being configured to operate in a complementary manner, a power supply circuit for applying an offset voltage to a source of the transistor, and a switching circuit for performing switching control to apply the offset voltage output from the power supply circuit to the source of the transistor or to apply the second potential to the source of the transistor. The switching circuit is configured to switch so as to apply the offset voltage to the source of the transistor in accordance with a timing of turning off the gate of the transistor and to apply the second potential to the source in accordance with a timing of turning on the gate.

Owner:MITSUBISHI ELECTRIC CORP

Flexible electrical power cable

ActiveUS20160217884A1Good bending propertiesEasy to installStrip/foil conductorsPlastic/resin/waxes insulatorsElectrical conductorPower cable

An electrical cable has a plurality of generally rectangular cross-section conductors superposed in a stack, the stack surrounded by a polymer jacket. The stack may be provided with a lubrication layer provided between at least two of the conductors. Conductors of the stack may have a thickness that is greater proximate the middle of the stack than at the top and bottom of the stack and / or a width that is less at the top and the bottom than at the middle. Further stacks may also be provided parallel and coplanar with the first stack, also surrounded by the polymer jacket.

Owner:COMMSCOPE TECH LLC

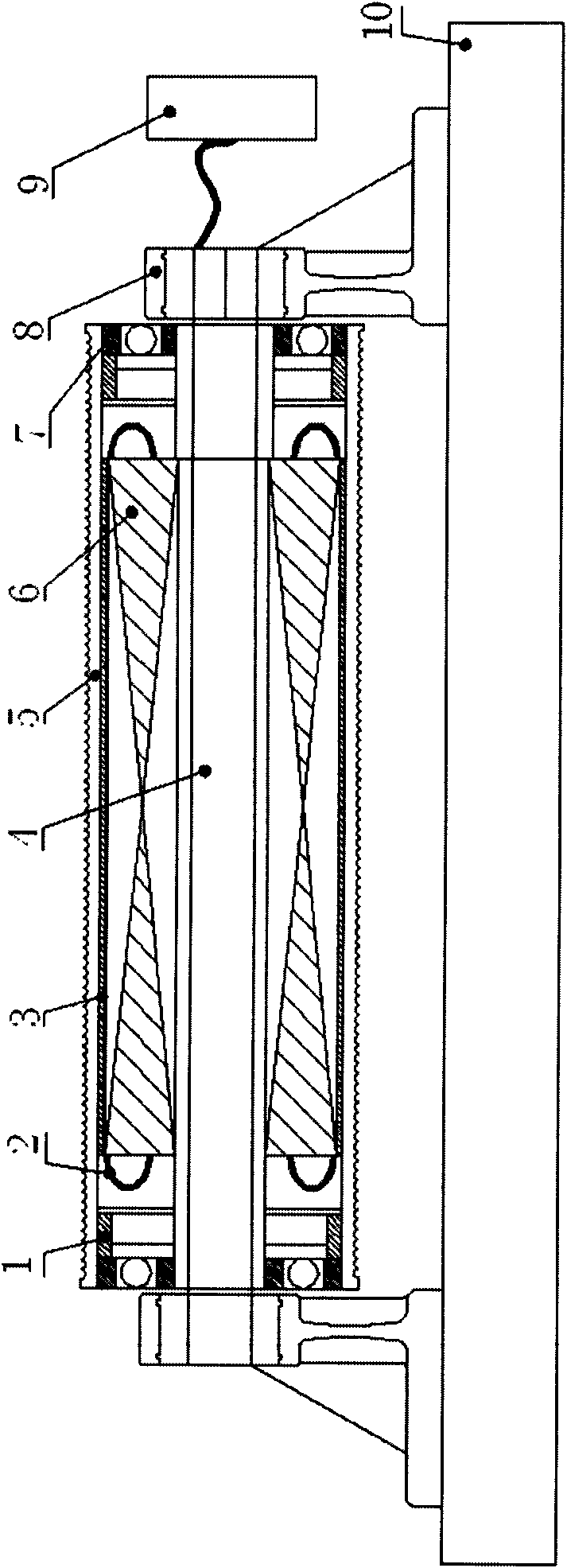

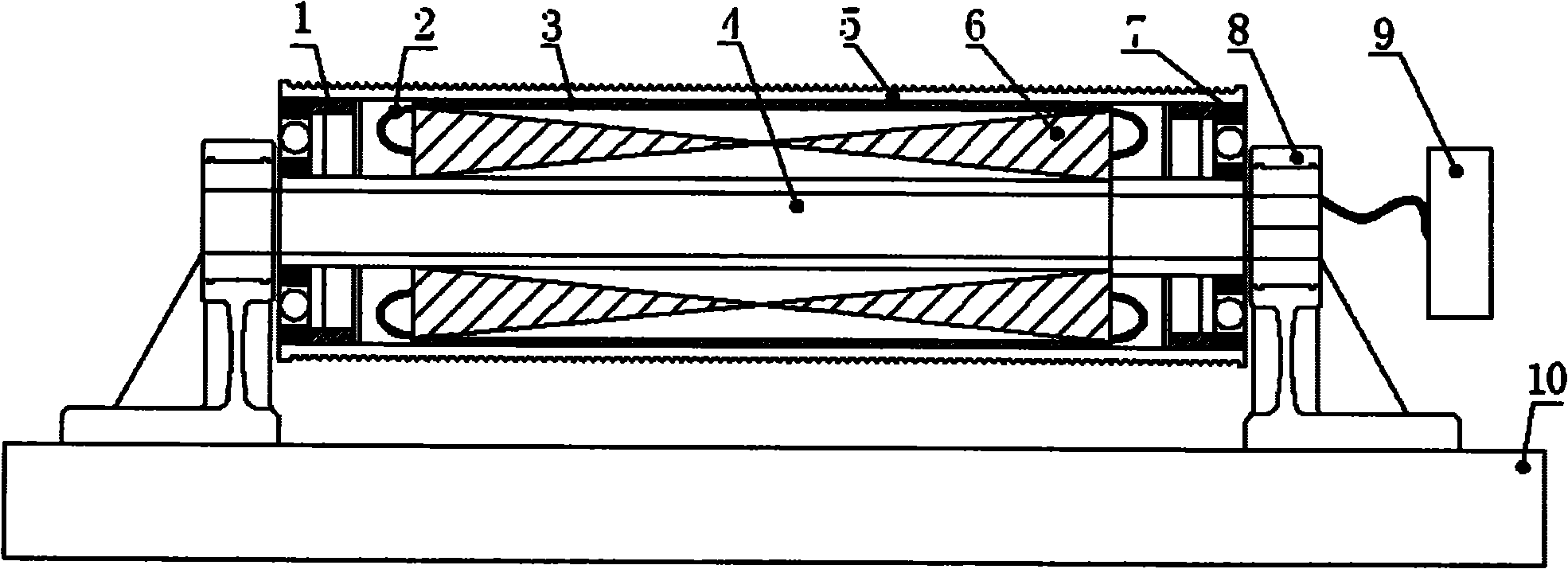

Low-speed outer rotor permanent magnet drive device with rotating speed of outer cylinder being 0.001-30r/min

ActiveCN102185414ASimple structureSimplified weightMechanical energy handlingLow noiseFrequency changer

The invention relates to the field of hoisting machinery, in particular to a low-speed outer rotor permanent magnet drive device with a rotating speed of an outer cylinder of 0.001-30r / min. The device comprises brakes, a winding, a permanent magnet, a central shaft, the outer cylinder, an iron core, a bearing, fixed seats and a frequency converter, wherein the brakes are arranged at both ends in the outer cylinder and fixed to the central shaft; the permanent magnet is installed on the inner wall of the outer cylinder; the outer cylinder is fixed to the central shaft by the bearing; the winding is embedded into the iron core; the iron core is installed on the central shaft to be connected into a whole; the central shaft is fixed in the fixed seats at both ends; and the frequency converteris connected with the winding by an output line. The invention has the two characteristics of simple structure and realization of large-torque output under the low speed condition, and also has the advantages of light weight, high reliability, stable running, microseism, low noise, safety, energy saving and long service life.

Owner:江西起重机械总厂有限公司

Gangway structure for connecting floating bridge with floating platform

The invention provides a gangway structure for connecting a floating bridge with a floating platform and belongs to the technical field of floating bridge connection. The gangway structure for connecting the floating bridge with the floating platform comprises the floating bridge, the floating platform, footplates, a gangway and supporting limiting frames, wherein the footplates are arranged on the floating bridge and the floating platform; the gangway is hinged between the footplates of the floating platform and the floating bridge; and the supporting limiting frames are hinged on the floating bridge and the floating platform. According to the gangway structure for connecting the floating bridge with the floating platform, as a platform footplate is hinged on a floating bridge platform and the platform footplate is matched with a truss type gangway, the adapted draft difference is great and the adaptation is high; as the supporting limiting frames are arranged and a main support is arranged in the form of a double A-shaped truss, the position of the gangway structure between the floating platform and the floating bridge is effectively limited at a maximum draft difference and at a minimum draft difference so as to ensure that vehicles can safely pass; damage of the bridge body caused by collision between the floating bridge and the floating platform can be avoided; and moreover, the design load of the truss type gangway is reduced, the weight of the structure is reduced and the safety is enhanced.

Owner:708TH RES INST OF CSSC

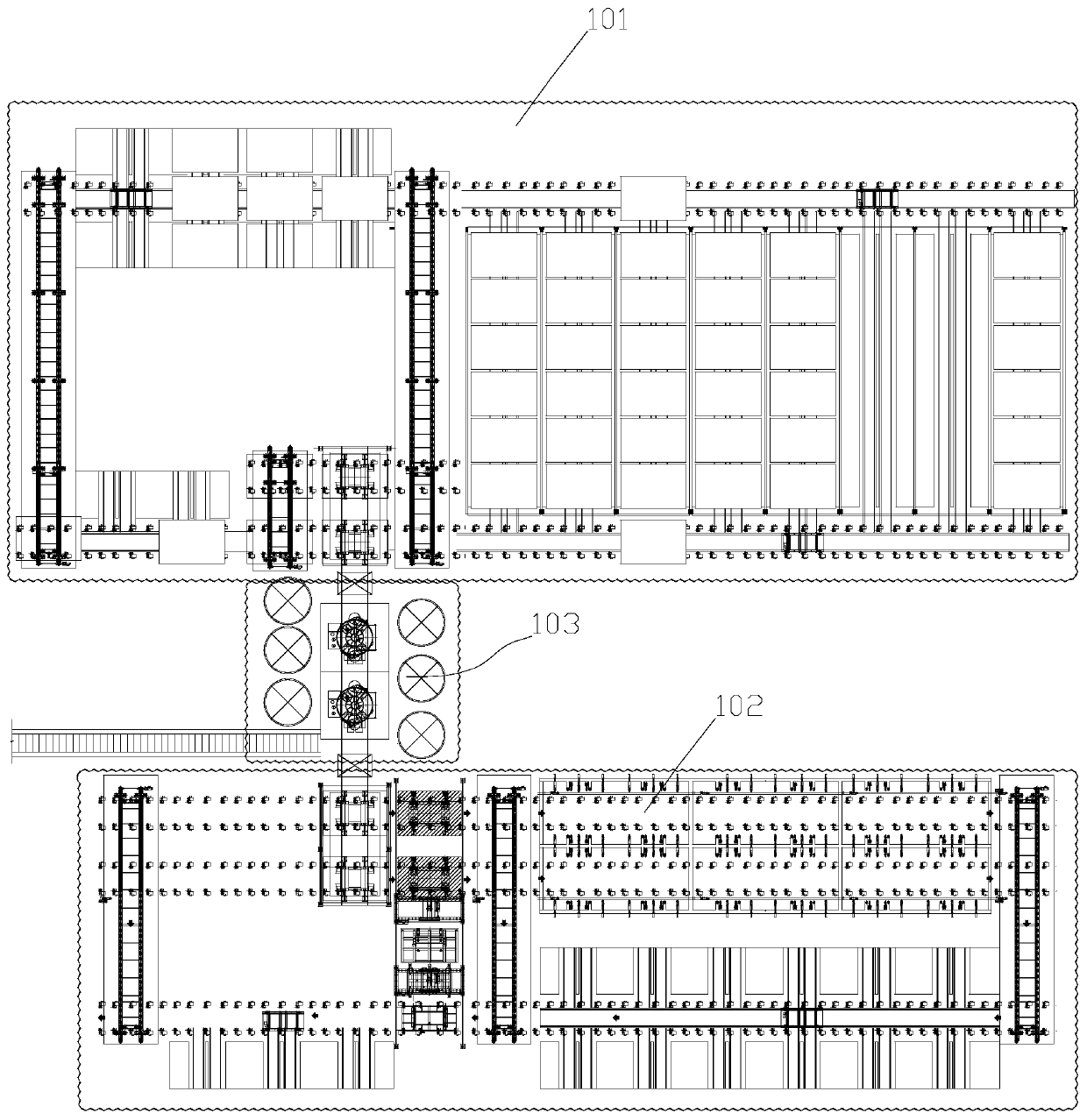

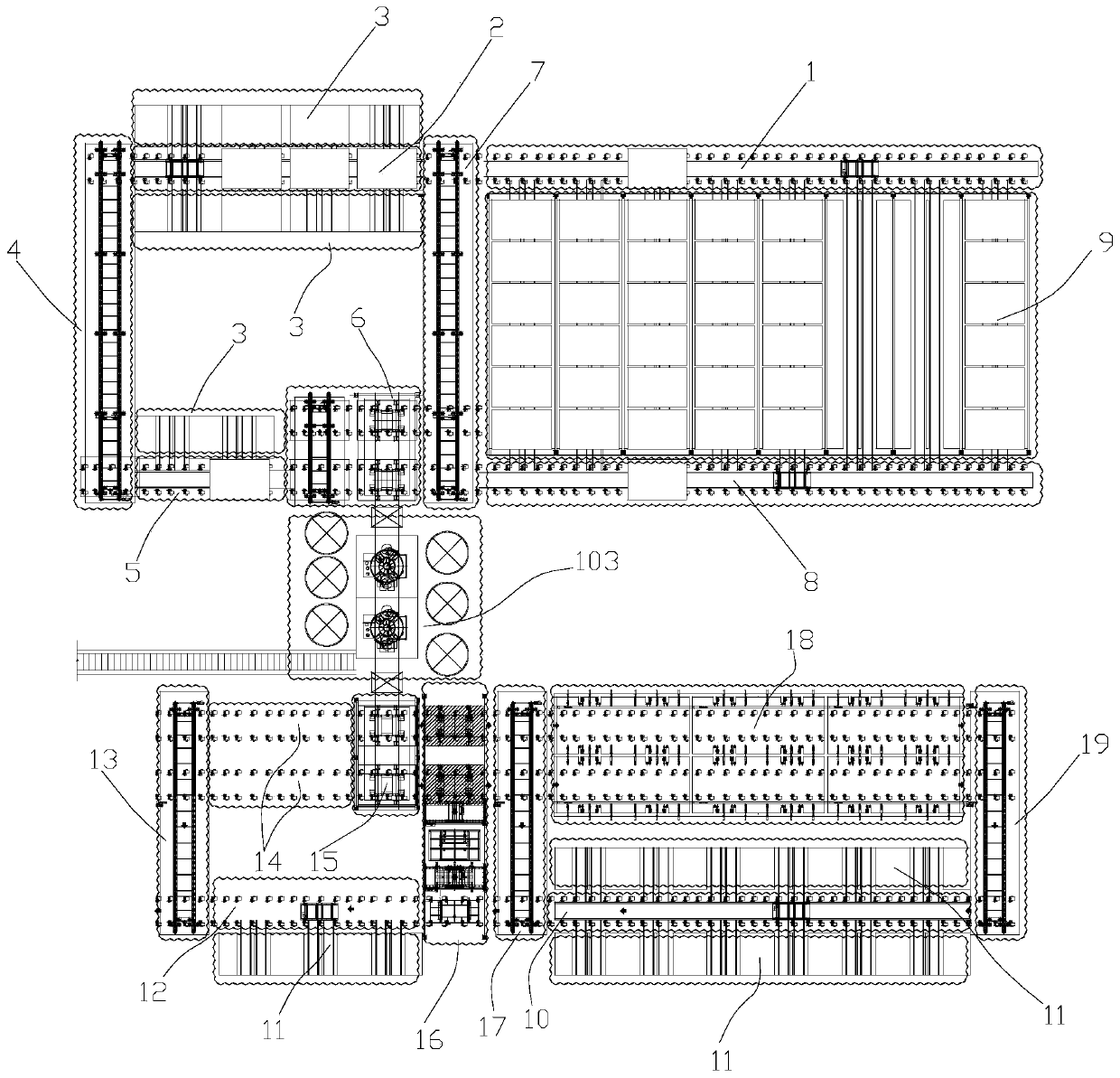

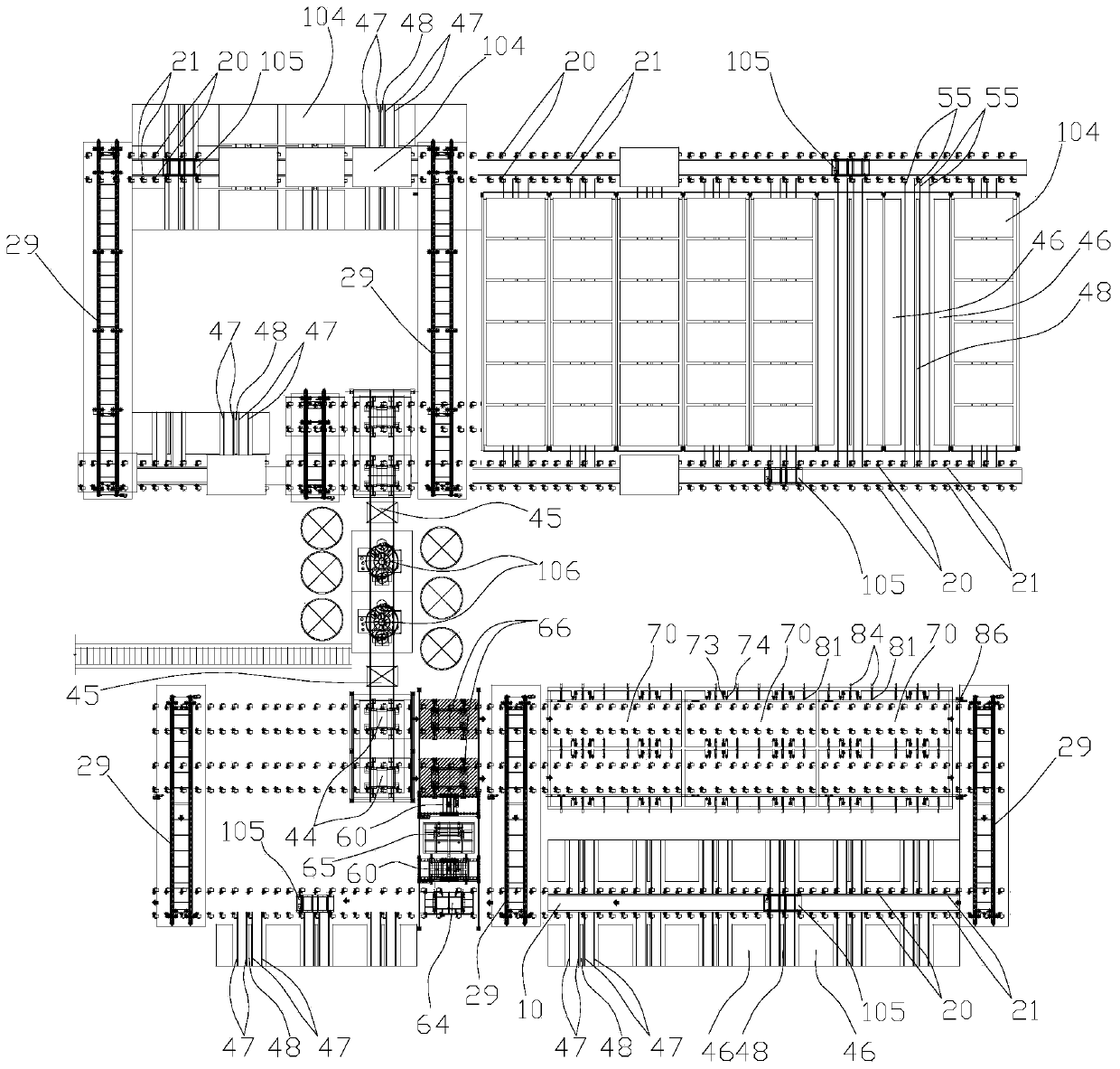

Multipurpose precast concrete component production line and application method thereof

ActiveCN110900815ALow maintenance energy consumptionLight weightCeramic shaping plantsArchitectural engineeringChain link

The invention discloses a multipurpose precast concrete component production line. The production line comprises a special-shaped component operation area, a plate component operation area and a concrete stirring operation area and further comprises a plurality of concrete mixing main machines, a plurality of online empty mold operation mold conveying channels, a plurality of off-line empty mold operation stations, a plurality of mold transverse moving devices using circulating chains, a plurality of combined primary and secondary mold carriers, a plurality of secondary overlapping devices, aplurality of pouring points, a concrete conveying elevated track arranged from a concrete stirring operation area to the pouring points, and a plurality of self-propelled concrete conveying elevated hoppers. The invention further discloses a using method of the multipurpose precast concrete component production line. The production line is advantaged in that the production line is reasonable and ingenious in structural design, suitable for simultaneous online production of precast concrete components needing different curing systems, and suitable for simultaneous online production of the precast concrete components needing different empty mold operation time.

Owner:东莞市中机建科实业有限公司

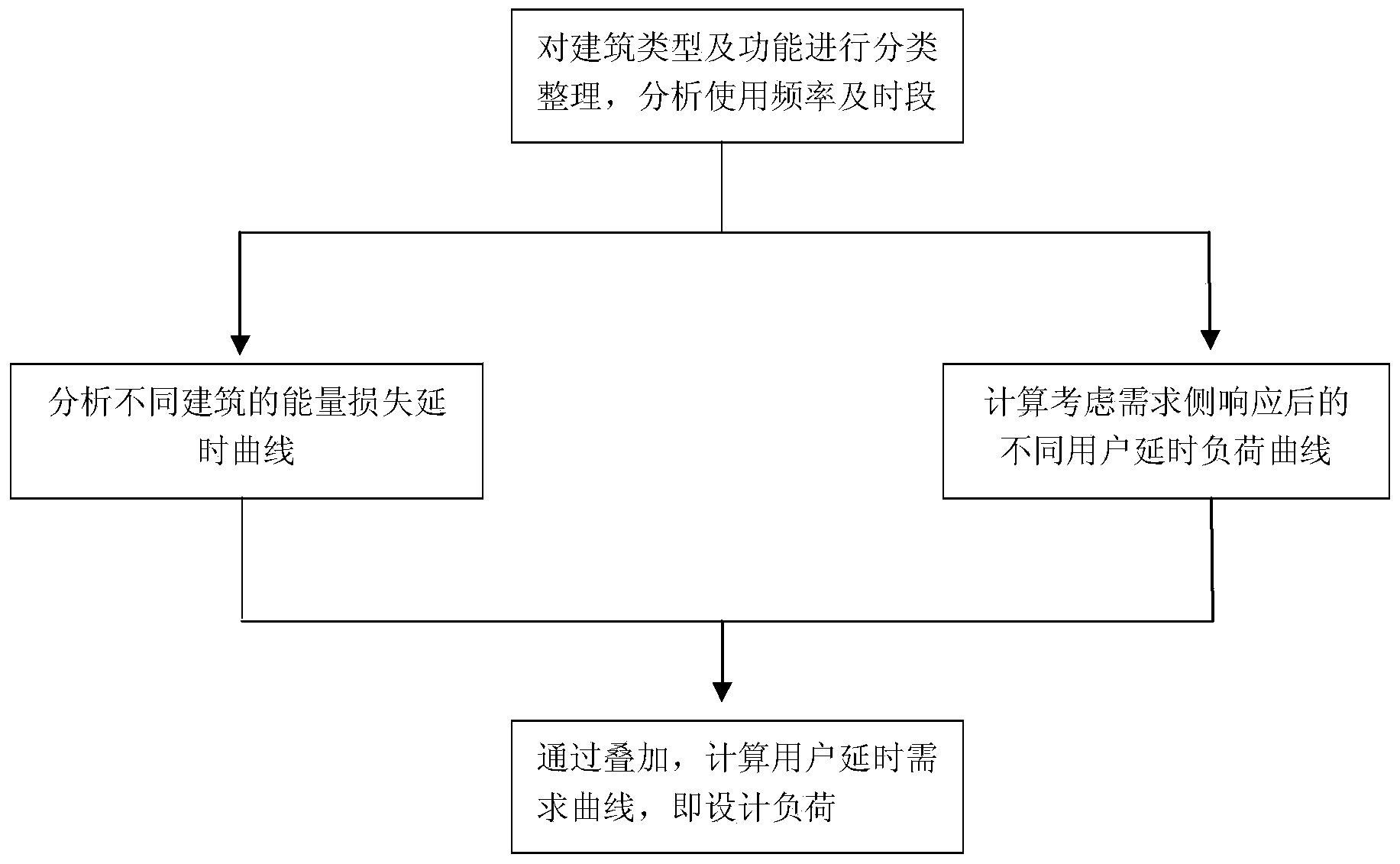

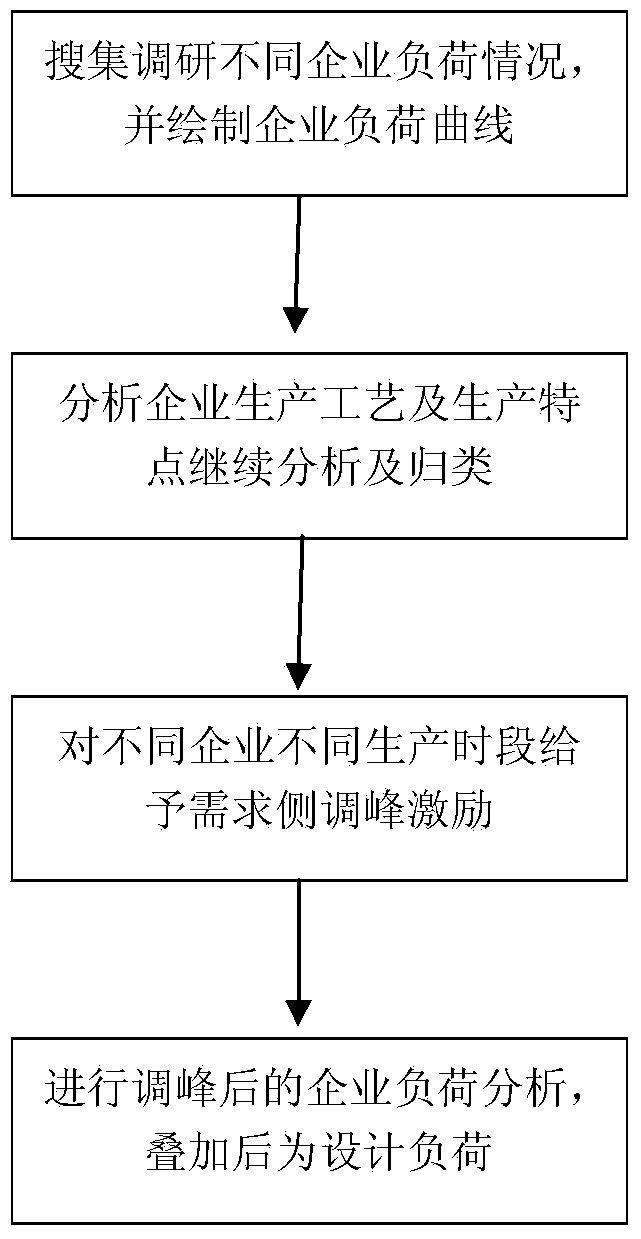

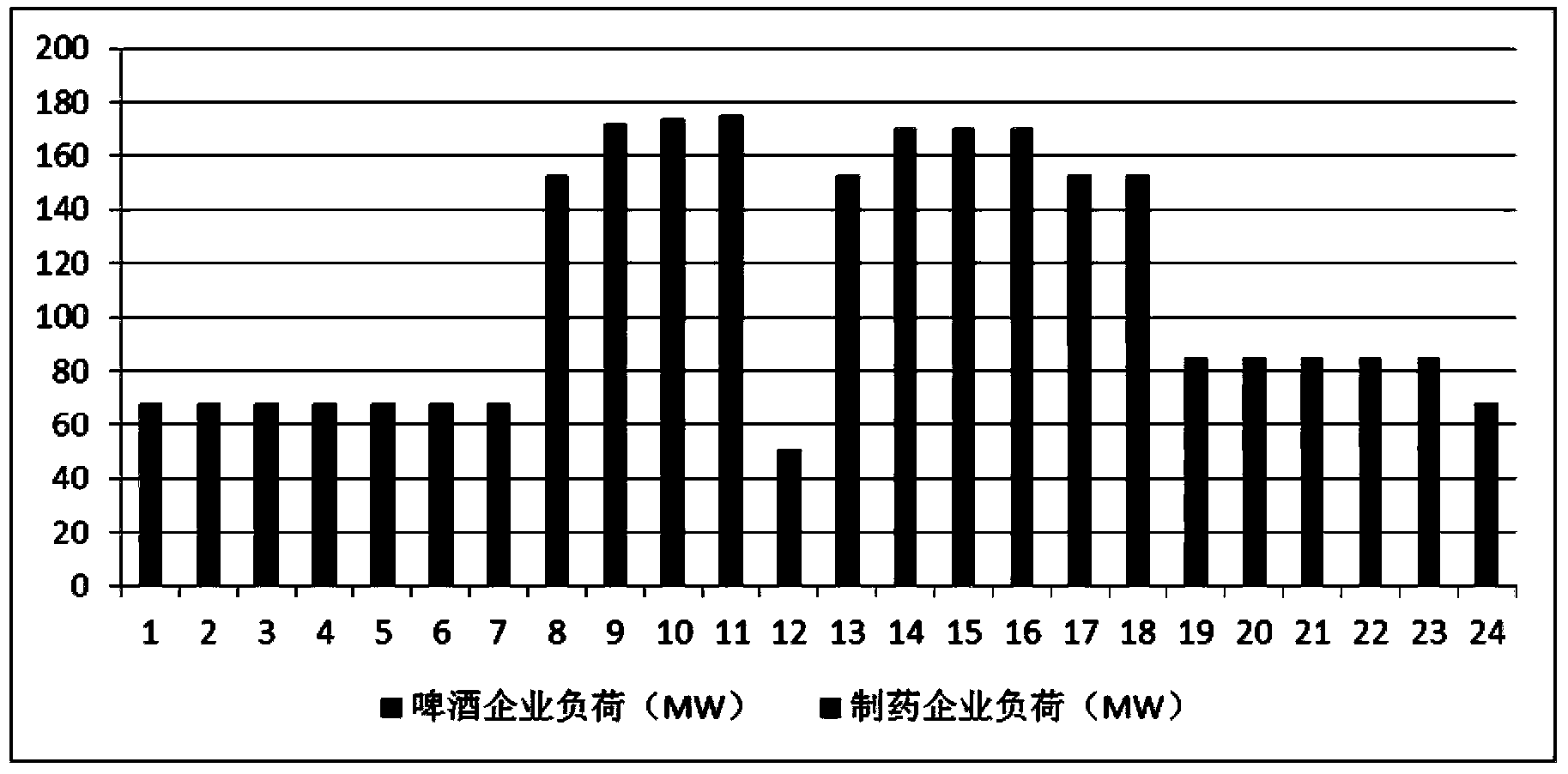

Calculating method for design load of a natural gas distributed energy resource

ActiveCN104166799AReduce project costImprove operational efficiencySpecial data processing applicationsSupply energyDesign load

The invention relates to a calculating method for design load of a natural gas distributed energy resource. The calculating method is characterized by comprising the following steps: obtaining energy consumption unit properties of different types of buildings and enterprises and users with different functions in an area, building or industrial park; calculating yearly energy loss curves of different energy consumption units; calculating user load delay curves by means of the demand side response principle with the combination of user requirements; adding the user load delay curves and the yearly energy loss curves together to obtain the yearly load distribution situations of the users, and making peak load serve as the design load of installation of a distributed energy resource station. By means of the calculating method for design load of the natural gas distributed energy resource, the conflict between energy supply and energy consumption and the conflict between energy supplying and energy saving can be effectively settled, and the problem that an installation scheme is not matched with the load due to large load is solved. By means of a distributed energy supplying system designed through the method, the optimal economical efficiency can be achieved whether from the view point of energy supply or from the view point of energy consumption.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

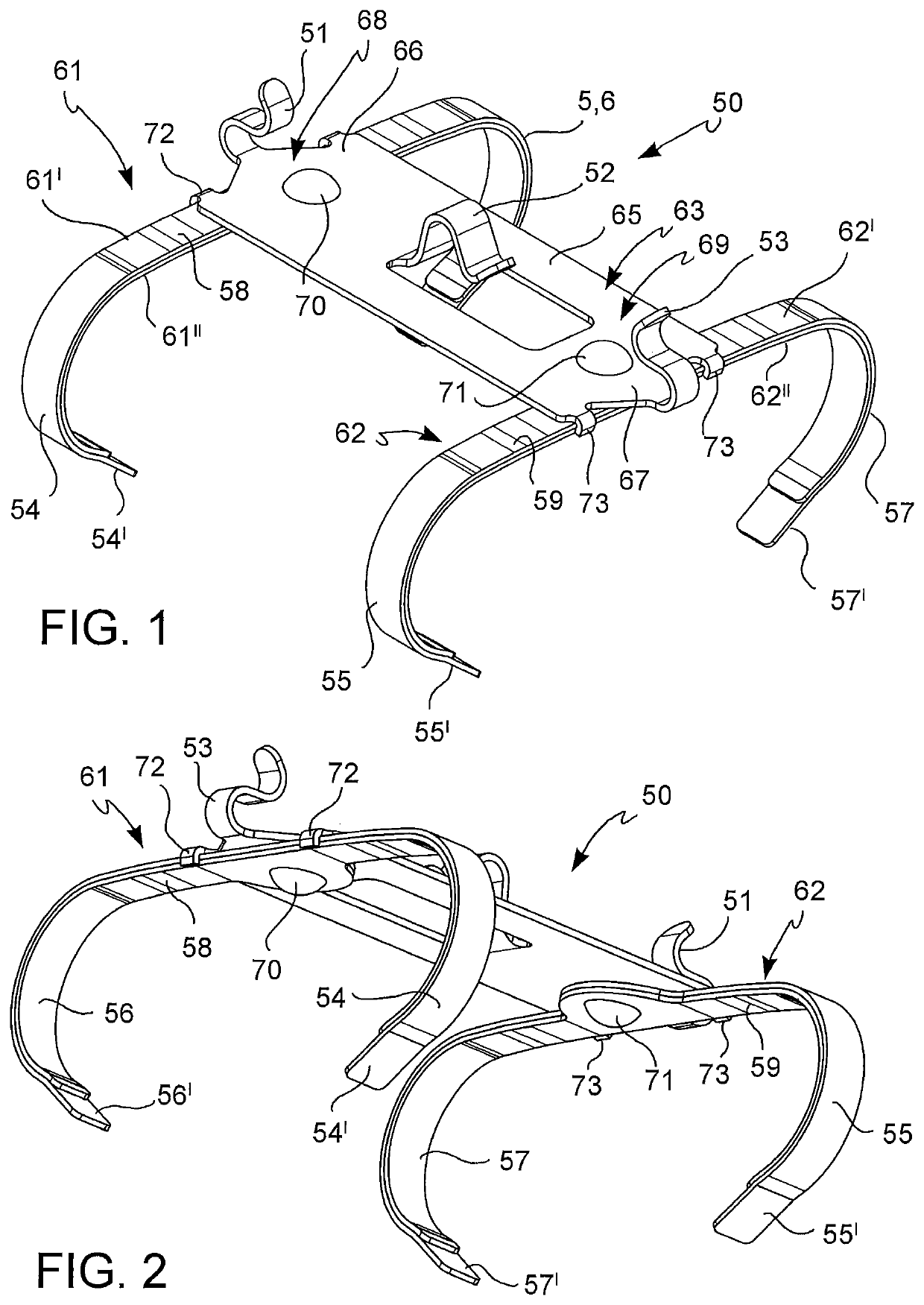

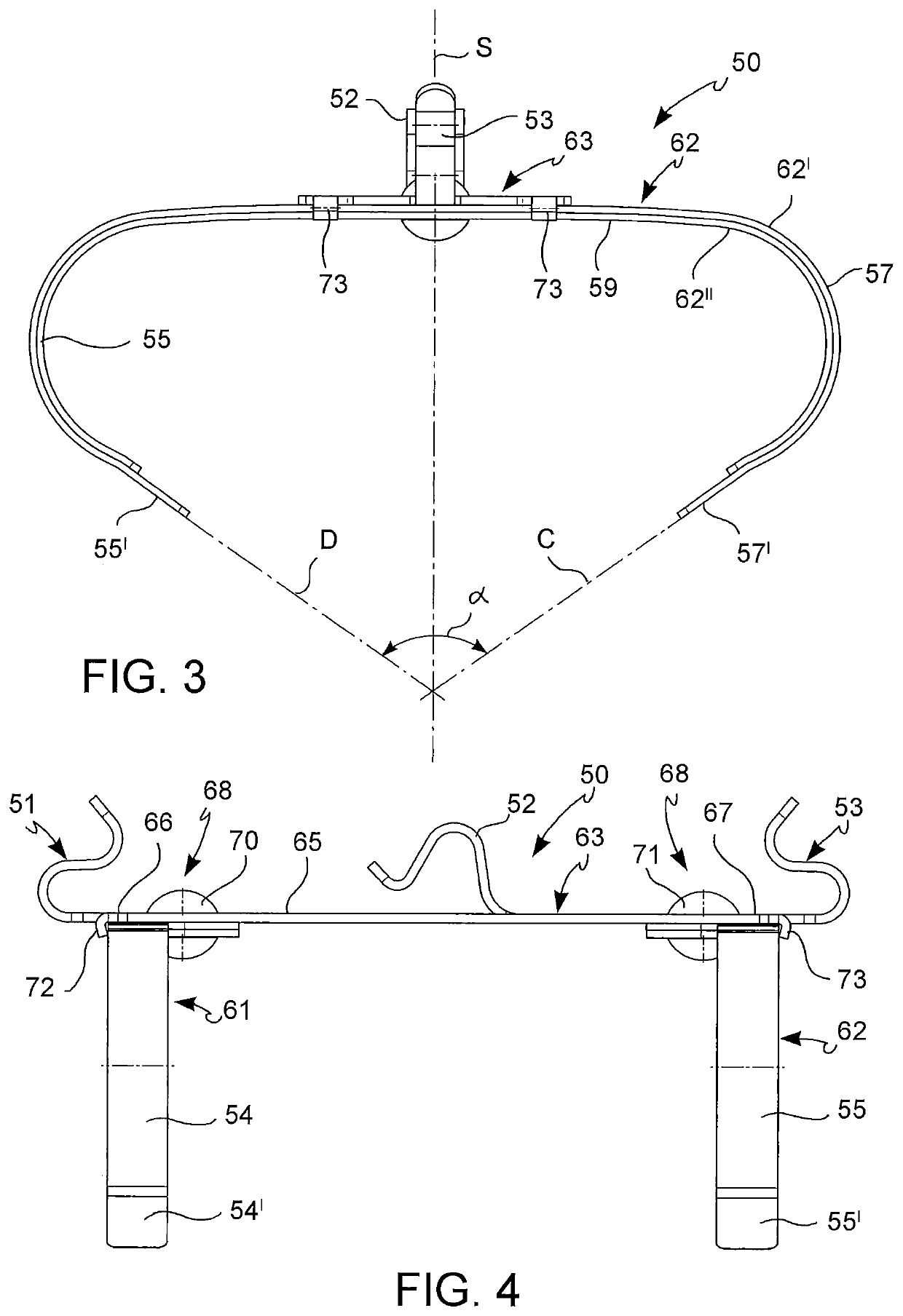

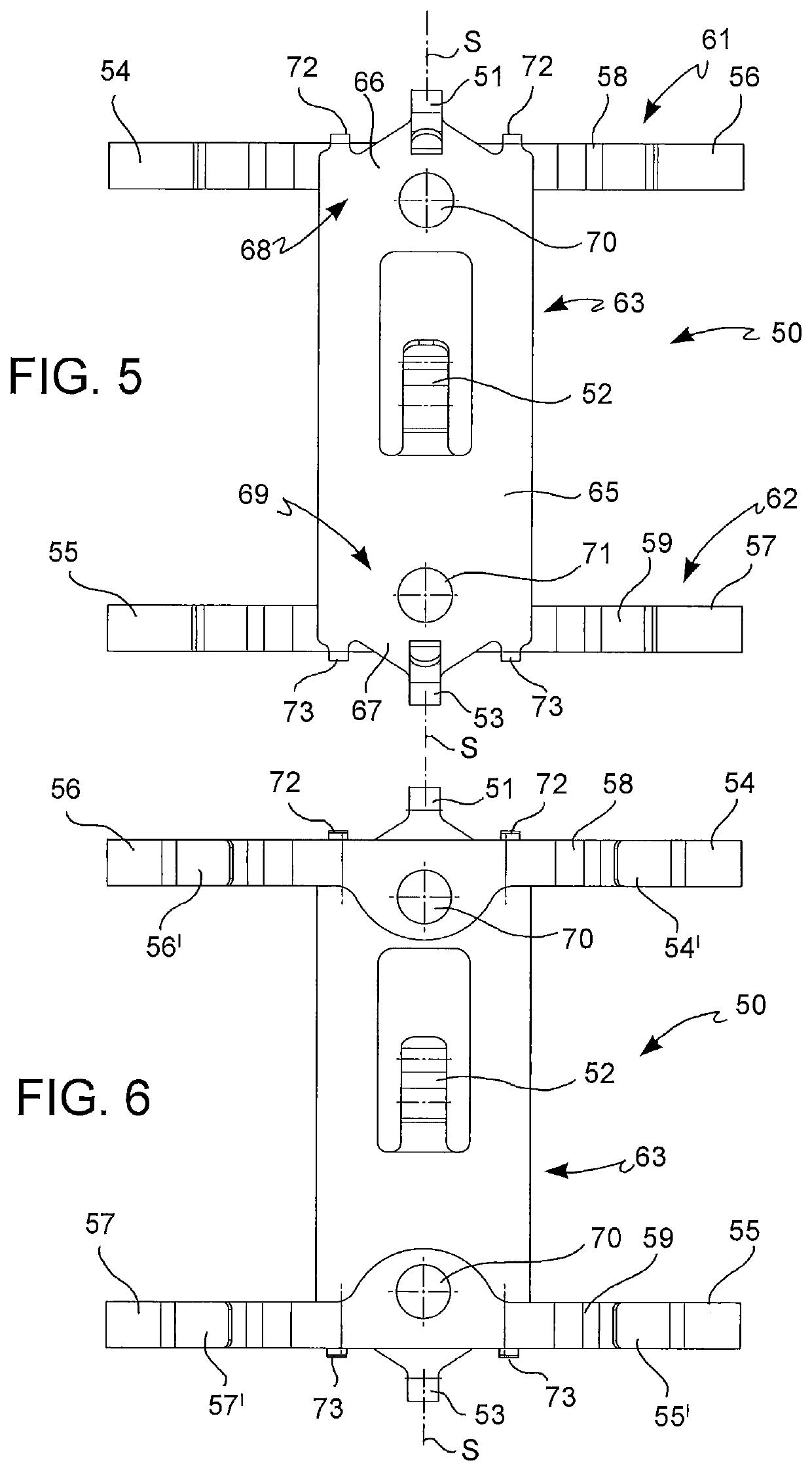

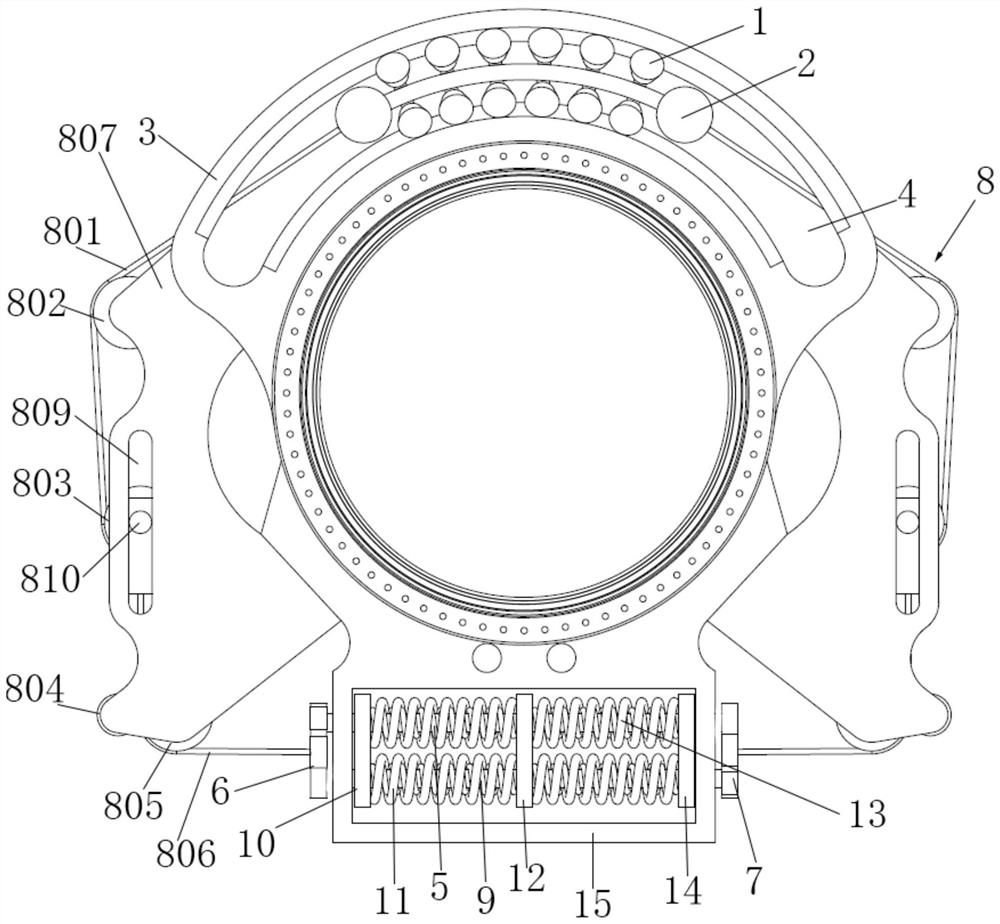

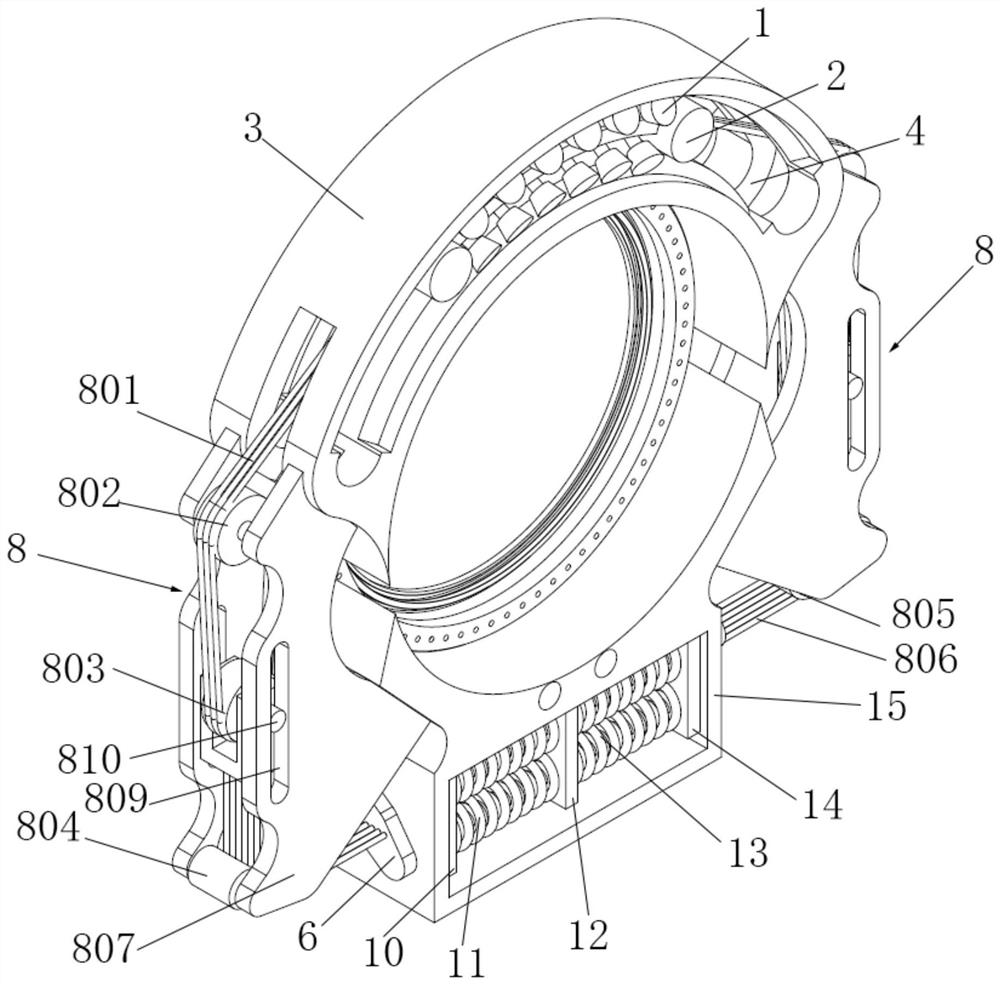

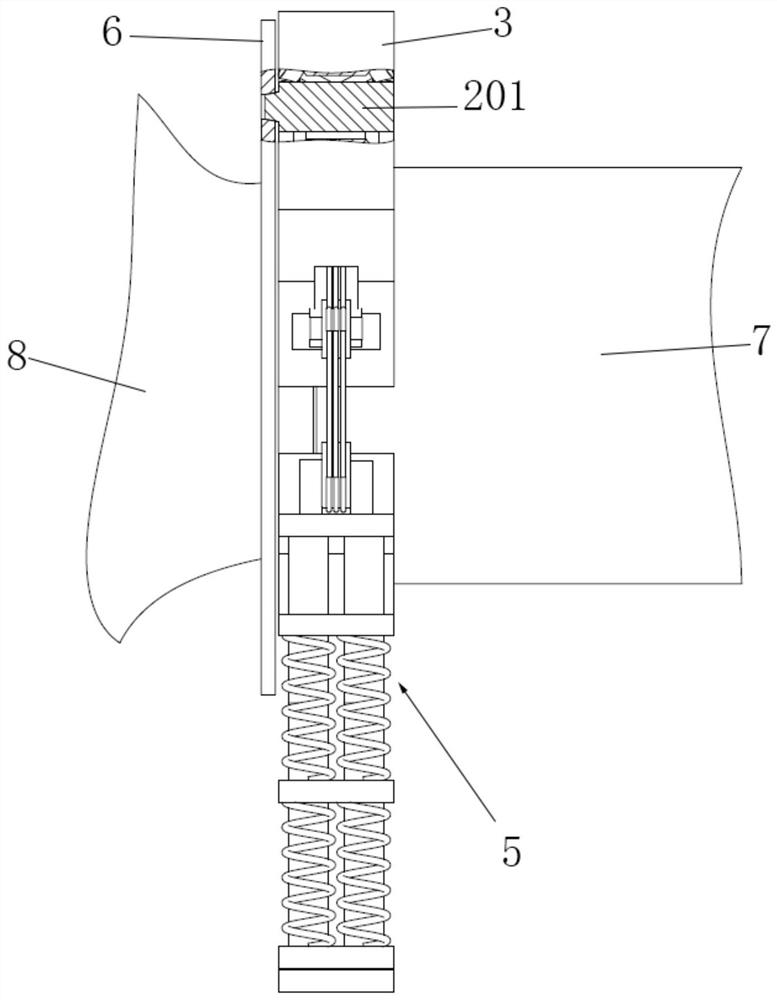

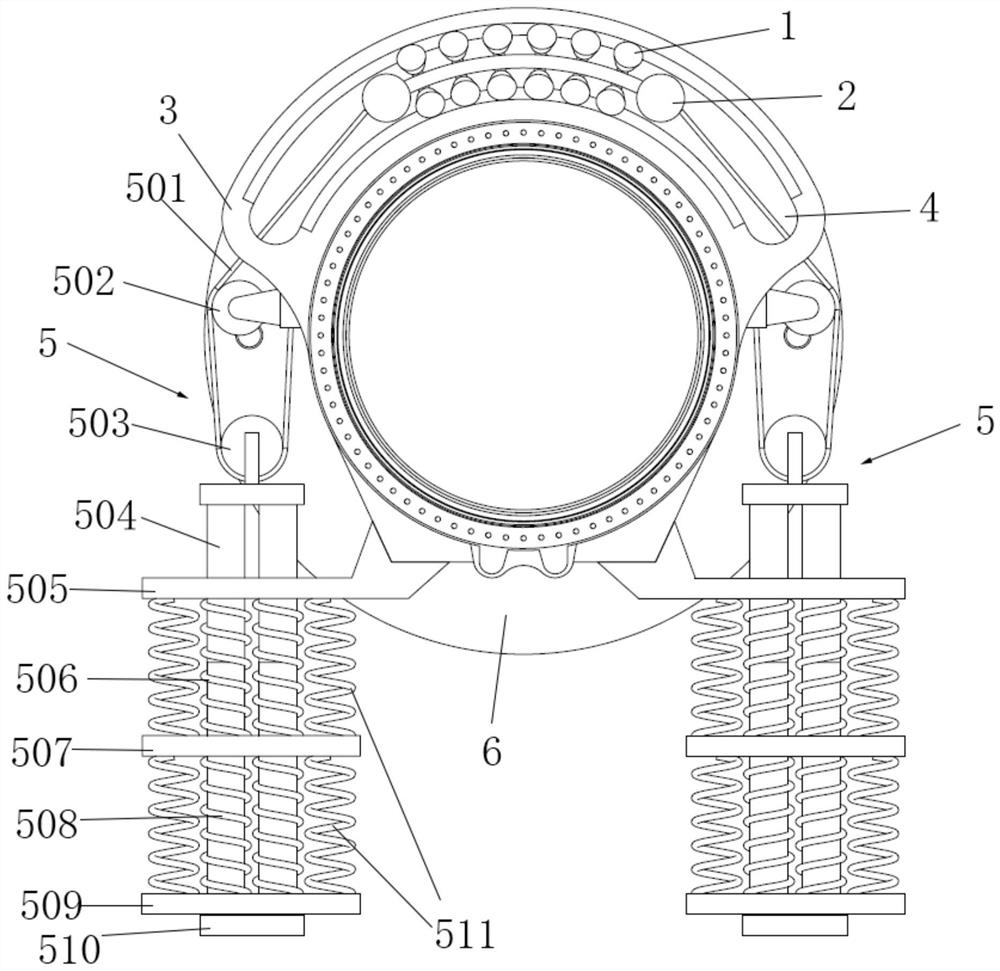

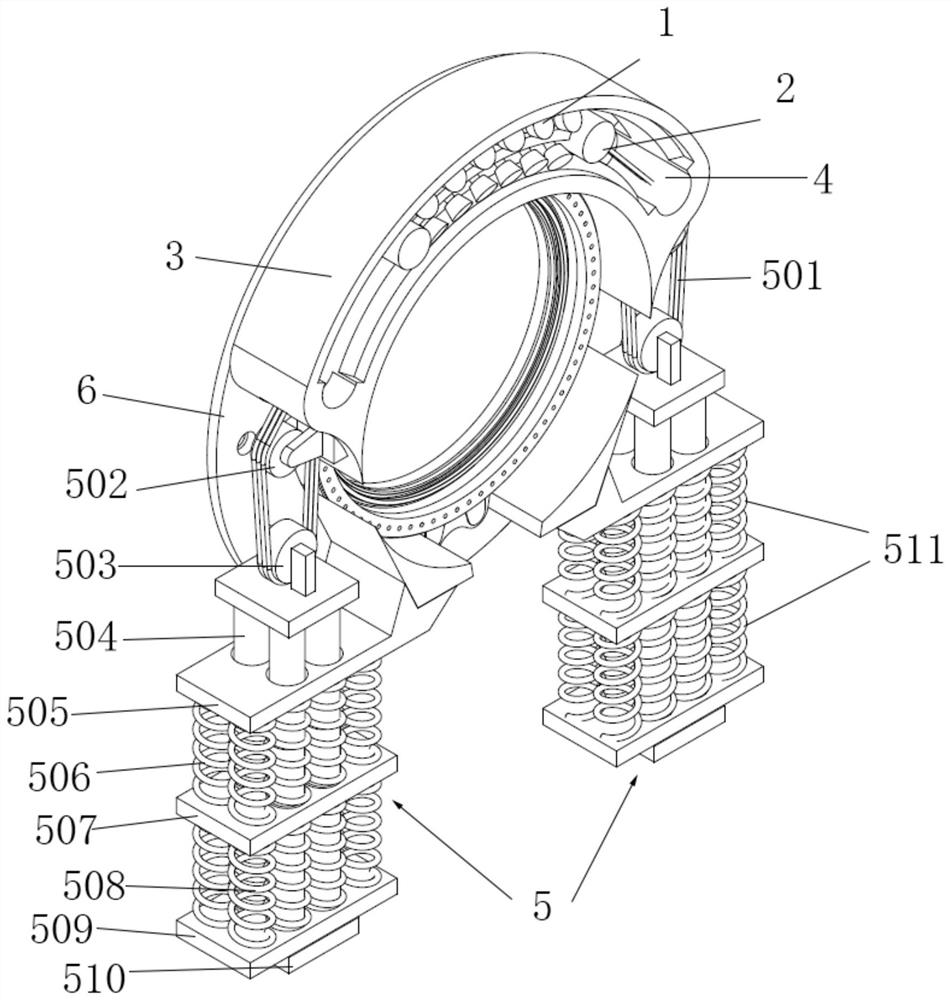

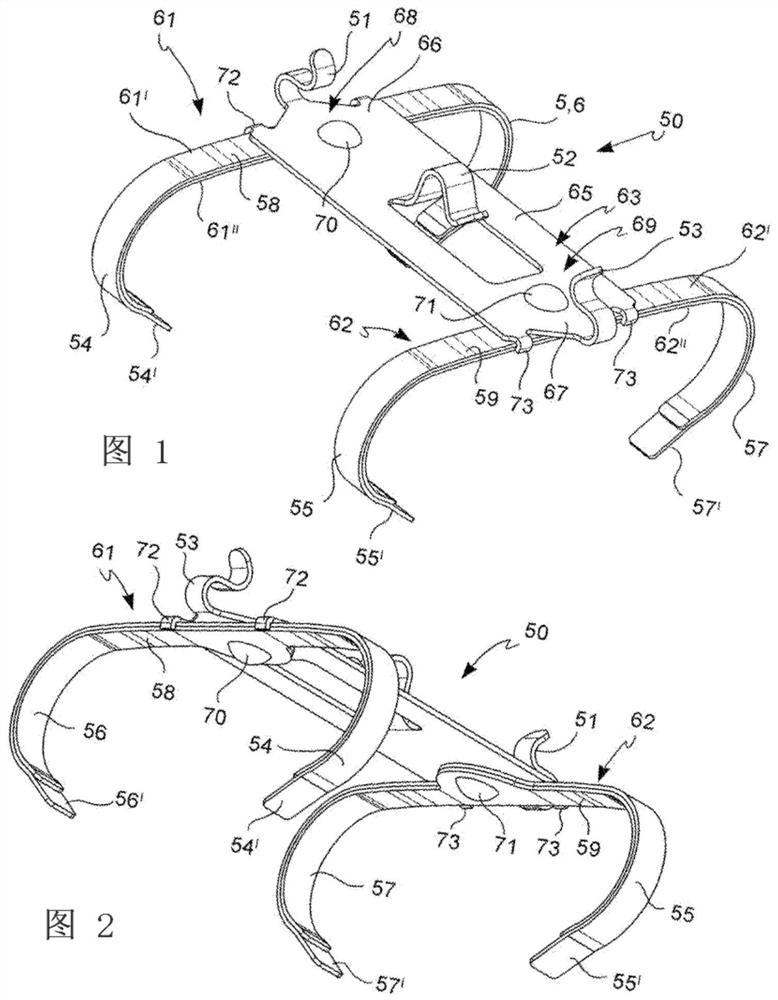

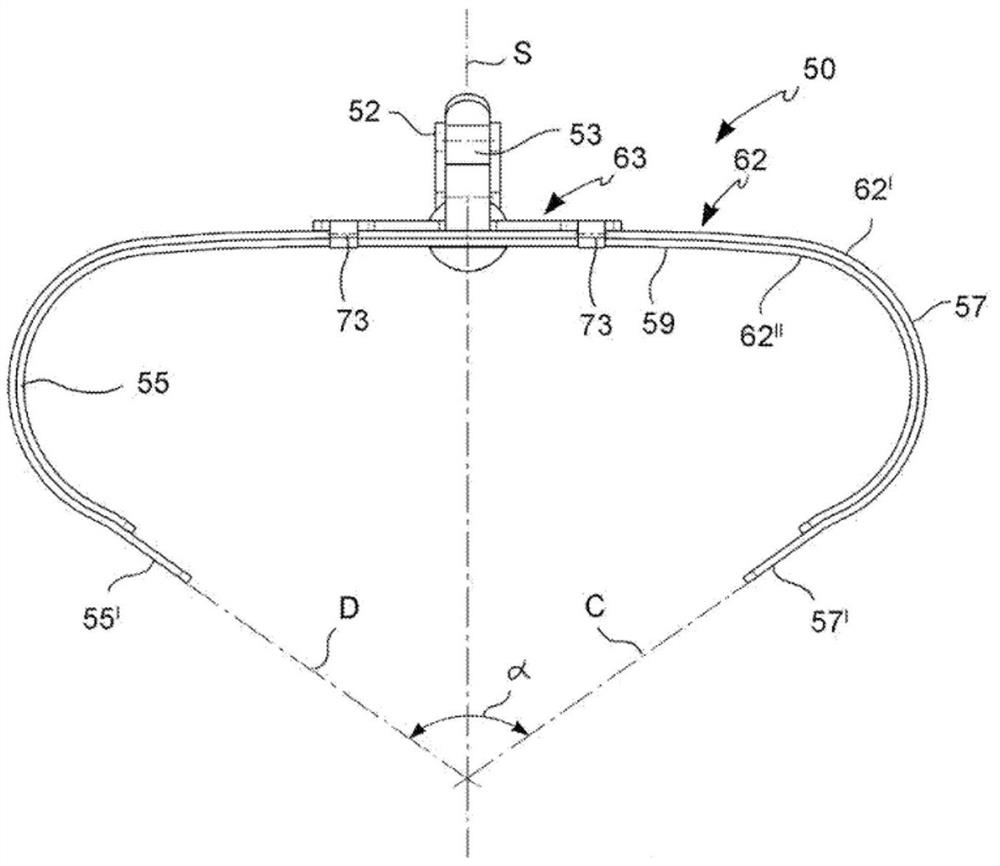

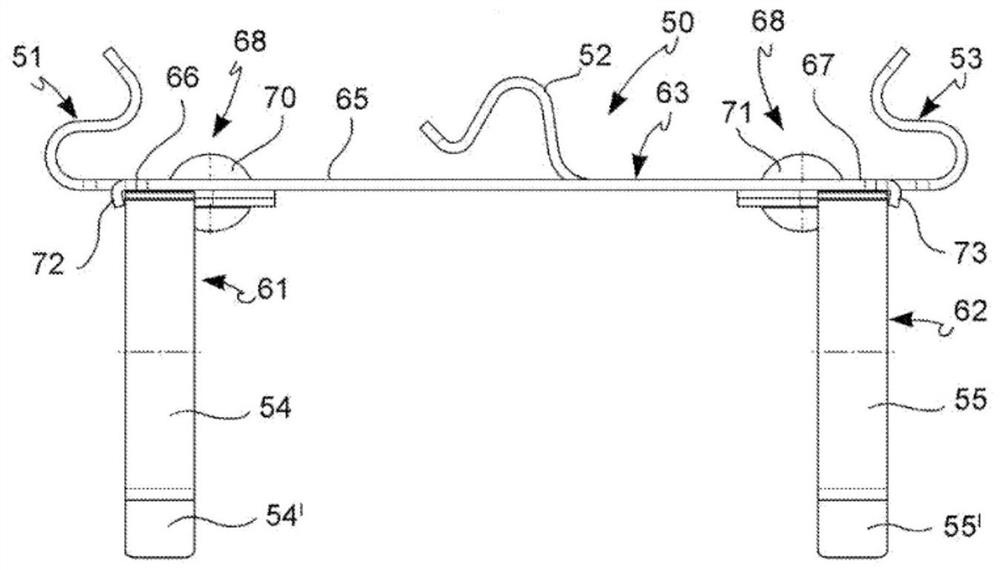

Pad return spring for a disc brake caliper body

ActiveUS20220056969A1Lower the volumeReduce design loadAxially engaging brakesBraking elementsEngineeringMechanical engineering

Owner:FRENI BREMBO SPA

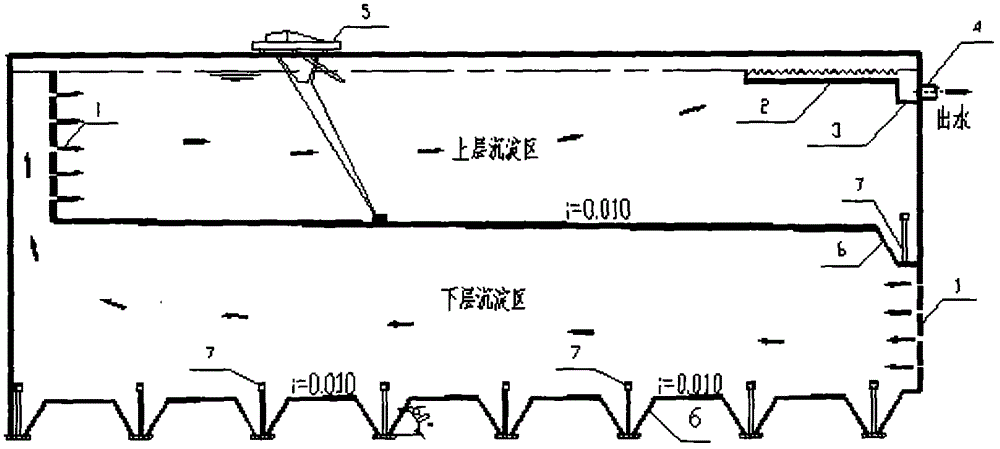

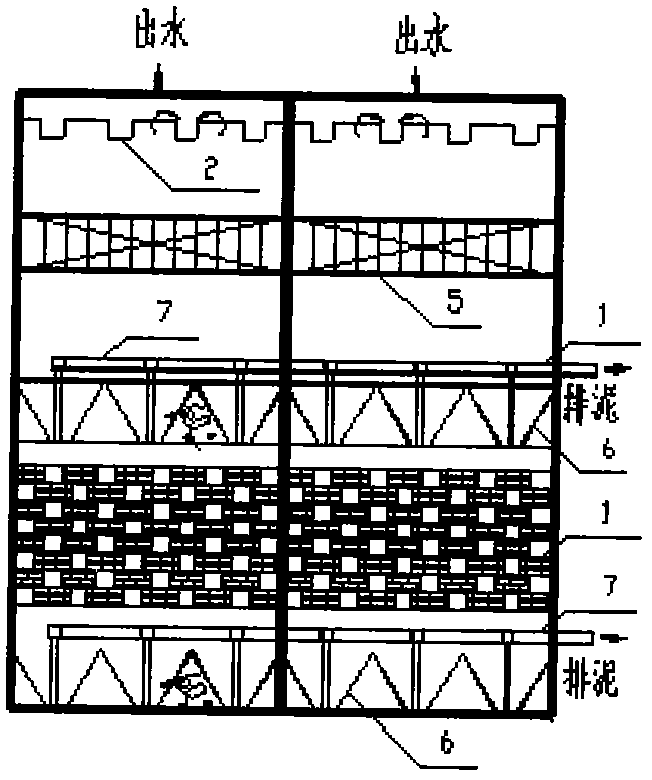

Double-layer horizontal sedimentation tank for drinking water purification of surface water

InactiveCN104784983ASimple structureEasy to installSedimentation settling tanksSludgeHydrostatic pressure

The invention discloses a double-layer horizontal sedimentation tank for drinking water purification of surface water. The double-layer horizontal sedimentation tank comprises an upper layer tank body and a lower layer tank body; a water inlet perforated wall is arranged at the position of a water inlet on the right of the lower layer tank body; the lower layer tank body is communicated with the upper layer tank body through a water inlet perforated wall arranged on the inner left side of the upper layer tank body; a plurality of rows of sludge hoppers are arranged in the lower layer tank body; sludge discharge pipes are arranged at the bottoms among each row of the sludge hoppers, and the upper ends of the sludge discharge pipes are communicated with a sludge discharge main pipe; the tank bottom slope of a sludge discharge area in the upper layer tank body is equal to or larger than 0.01; a single row of sludge hoppers are arranged at the slope bottom on the right side of the sludge discharge area in the upper layer tank body; a sludge scrapping traveler is arranged on the upper layer tank body, and used for scrapping sludge from the bottom of the upper layer tank body; finger-type effluent weirs are arranged on the upper right part of the upper layer tank body; a water collection main pipe is arranged at the tail ends of the finger-type effluent weirs. Through the adoption of the double-layer horizontal sedimentation tank, the problems of unsmooth sludge discharge due to a hydrostatic pressure manner adopted by the conventional horizontal sedimentation tank, a relatively large occupied area of the conventional horizontal sedimentation tank and the like are solved.

Owner:SHIHEZI UNIVERSITY

Flexible wind wheel locking device for braking system of anti-typhoon wind generating set

PendingCN111608871AReduce machine loadReduce loadMachines/enginesWind energy generationEngineeringMachine

The invention discloses a flexible wind wheel locking device for a braking system of an anti-typhoon wind generating set. With the adoption of a flexible wind wheel locking design scheme, the flexiblewind wheel locking device comprises two rope retracting devices which are symmetrically distributed on the left side and right side of a front flange of a gearbox and connected with the left end andthe right end of a swinging trolley; and the swinging trolley is integrated with a housing of a wind wheel locking pin assembly of the braking system, and can move in an arc guide slot hole of the front flange of the gearbox to drive the rope retracting device on the left side or the right side to be tightened, and at the same time to drive one of guide posts in the center of the bottom of the front flange of the gearbox to be pulled out, so that a spring sleeving the guide post is compressed to provide restoring force to a wind wheel. According to the invention, the wind wheel is allowed to swing within a certain angle, and the greater the angle deviation from the positive Y position is, the greater the restoring force is, so that the load of the wind wheel and the whole machine is greatly reduced, and the overall design difficulty of the wind generating set is greatly reduced.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Flexible wind wheel locking device for braking system of anti-typhoon wind generating set

The invention discloses a flexible wind wheel locking device for a braking system of an anti-typhoon wind generating set. The flexible wind wheel locking device adopts a flexible wind wheel locking design scheme. The flexible wind wheel locking device comprises a swinging trolley and two flexible wind wheel locking units; the two flexible wind wheel locking units are symmetrically distributed on the left side and right side of a front flange of a gearbox and connected with the left end and the right end of the swinging trolley; and the swinging trolley is integrated with a housing of a wind wheel locking pin assembly of the braking system, and can move in an arc guide slot hole of the front flange of the gearbox to drive a wire rope group on the left side or the right side to be tightened,and at the same time to drive a guide post of the flexible wind wheel locking unit on one side to be pulled out, so that a spring sleeving the guide post is compressed to provide restoring force to awind wheel. According to the invention, the wind wheel is allowed to swing within a certain angle, and the greater the angle deviation from the positive Y position is, the greater the restoring forceis, so that the load of the wind wheel and the whole machine is greatly reduced, and the overall design difficulty of the wind generating set is greatly reduced.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

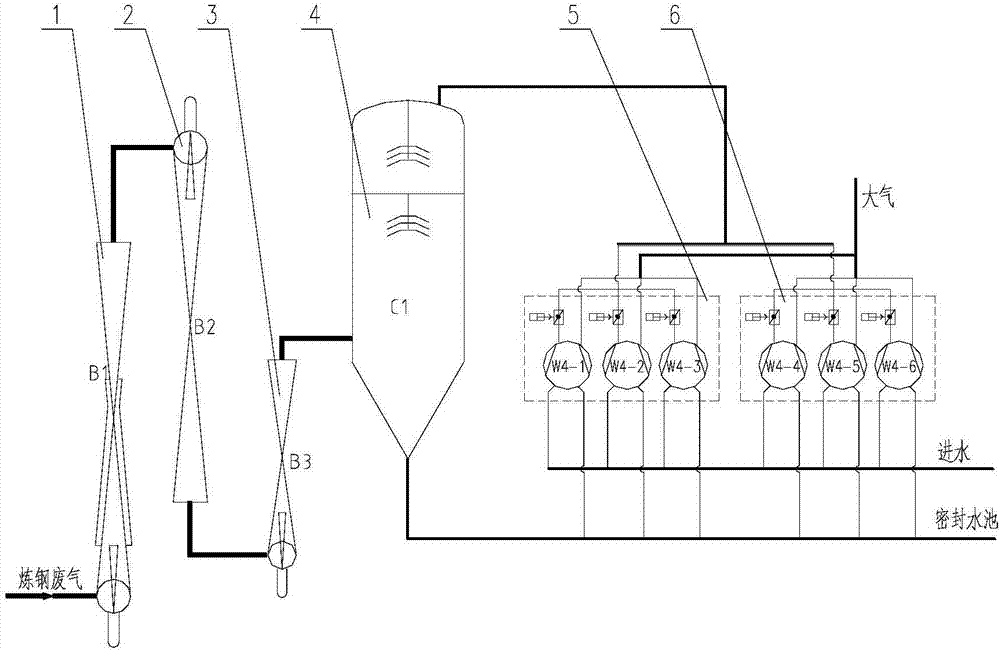

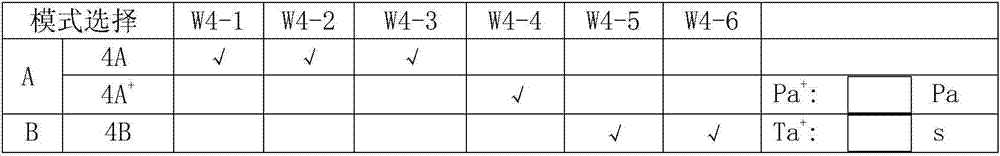

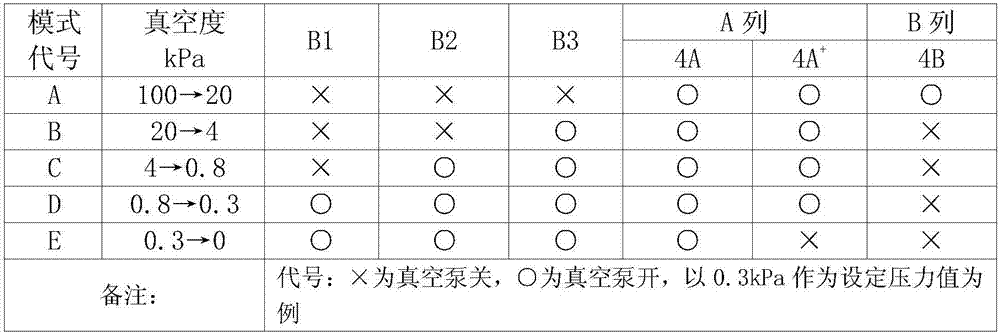

Vacuum pump system combining three stages of booster pumps and water ring pumps

PendingCN107541586AReduce consumptionLow costPump installationsPositive-displacement liquid enginesThermodynamicsVacuum pressure

The invention discloses a vacuum pump system combining three stages of booster pumps and water ring pumps. The vacuum pump system comprises a booster pump B1 communicating to a waste gas generating position, and an output end of the booster pump B1 is sequentially connected with a booster pump B2, a booster pump C3, a condenser C1 and water ring pump units; exhaust ports of the water ring pumps ofwater ring pump units are connected with waste gas outlets, and the water ring pump units are W4 water ring pump units; after working modes of the water ring pumps are selected and confirmed, a vacuum system is started; and all stages of vacuum pumps are started and stopped according to preset vacuum pressure values until a vacuum degree required by a process is met. The vacuum pump system has the characteristics of meeting requirements of the refining process and high efficiency and energy conservation.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Pad return spring for a disc brake caliper body

ActiveCN113195922AReduce widthTotal thickness unchangedAxially engaging brakesBraking elementsControl theoryMechanical engineering

A pad return spring (50) for a disc brake caliper body adapted to straddle a brake disc, said brake disc comprising a first braking surface of brake disc and an opposite second braking surface of brake disc, said caliper body comprising: a first elongated wheel-side element comprising an outer caliper side of first elongated element and an inner caliper side of first elongated element, wherein said outer caliper side of first elongated element is adapted to face a vehicle wheel and wherein at least one portion of the inner caliper side of first elongated element is adapted to face said first braking surface of brake disc by means of a first pad); a second elongated opposite wheel-side element comprising an outer caliper side of second elongated element and an inner caliper side of second elongated element, wherein at least one portion of the inner caliper side of second elongated element is adapted to face said second braking surface of brake disc by means of a second opposite pad; - said first elongated wheel-side element comprises at least one thrust means seat adapted to receive thrust means which are suitable for influencing the first pad against said first braking surface of brake disc; at least said second elongated opposite wheel-side element comprises at least two portions each defining a connecting seat adapted to connect the caliper body to a support element for supporting the caliper on the vehicle; said caliper body comprises at least one elongated element connecting bridge adapted to connect said first elongated wheel-side element to said second elongated opposite wheel-side element so as to be suitable for straddling said brake disc; said at least one elongated element connecting bridge comprises a middle connecting bridge which extends according to the axial direction and defines an outer middle bridge side externally facing the caliper body, an inner middle bridge side internally facing the caliper body, opposite to the outer middle bridge side, a middle bridge disc inlet side, a middle bridge disc outlet side, opposite to the middle bridge disc inlet side; said pad return spring (50) comprising a first pad retraction element (61) and a second pad retraction element (62), each of said first pad retraction element (61) and second pad retraction element (62) defining a middle stretch (58 59), a first side stretch (54, 55) adapted to influence said first pad, and an opposite second side stretch (56, 57) adapted to influence said second pad to move said first pad and said second opposite pad away from said first braking surface of brake disc and from said opposite second braking surface of brake disc at the end of a braking action; wherein said first pad retraction element (61) and said second pad retraction element (62) are shaped as a folded band and consist of a plurality of overlapping sandwiched sheet layers (61' 62'); said spring comprising an elongated connecting element (63) which connects the first pad retraction element (61) and the second pad retraction element (62) to each other at said middle stretch (58, 59); said spring comprising anchoring means (51, 52, 53) adapted to removably restrain said pad return spring (50) to said middle connecting bridge (18).

Owner:FRENI BREMBO SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com