Double-layer horizontal sedimentation tank for drinking water purification of surface water

An advection and surface water technology, applied in the direction of settlement tanks, etc., can solve the problems of poor mud discharge, large floor area, large floor area of advection sedimentation tanks, etc., and achieves easy construction, small floor space, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

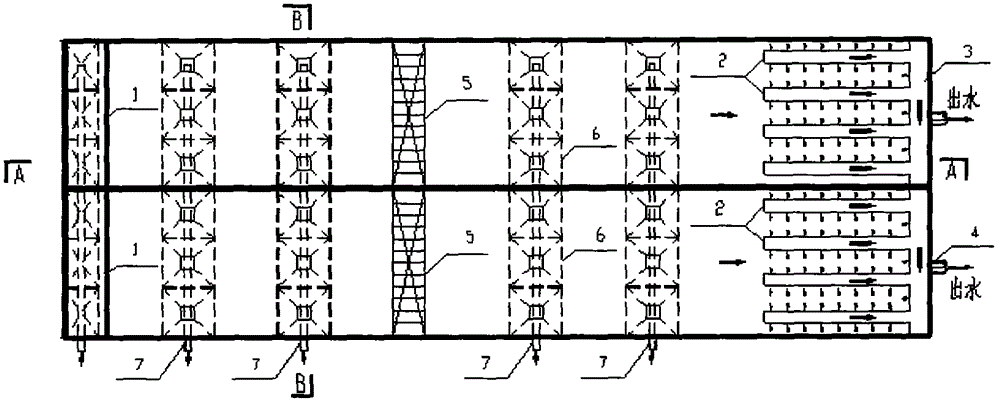

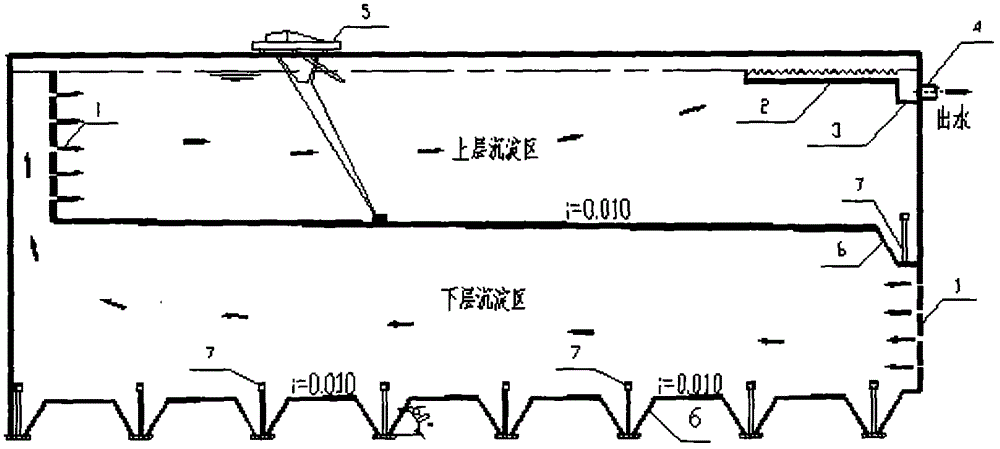

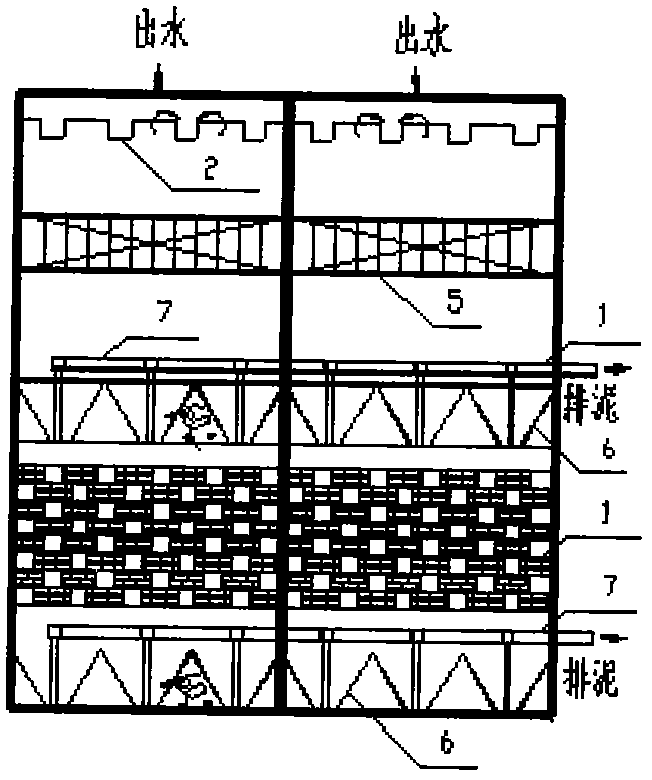

[0019] A structure of surface water drinking water purification double-deck advection sedimentation tank, such as Figure 1-3 As shown, it consists of the lower water intake area, the lower sedimentation area, the upper water intake area, the upper sedimentation area, the water outlet area, the lower mud discharge area and the upper mud discharge area.

[0020] Both the upper water intake area and the lower water intake area use the perforated flower wall 1 for water distribution, which plays the role of uniform water replenishment and energy dissipation. The water inlet perforated flower wall 1 is built with bricks or concrete blocks, and the part outside the holes is plastered with cement mortar; the upper and lower water inlet holes of the flower wall are staggered, and at the same time, the wall from 0.3 to 0.5m above the sedimentation su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com