Design method of flap driving mechanism and flap driving mechanism

A technology of driving mechanism and design method, which is applied in the field of flight control, can solve the problems of low efficiency of driving mechanism, achieve the effect of convenient implementation, practical principle, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

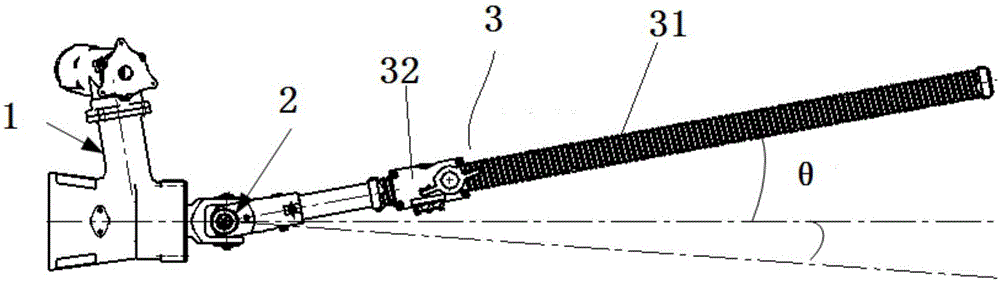

[0025] Such as Figure 1 to Figure 2 Shown, the design method of a kind of flap driving mechanism provided by the present invention is characterized in that, comprises:

[0026] Step 1. When the flap (not shown) is in the non-actuated state, and the drive shaft axis of the universal joint 2 coincides with the axis of the screw 31, define the universal joint 2 and the lead screw 31 here The state under the relative positional relationship is the first initial state.

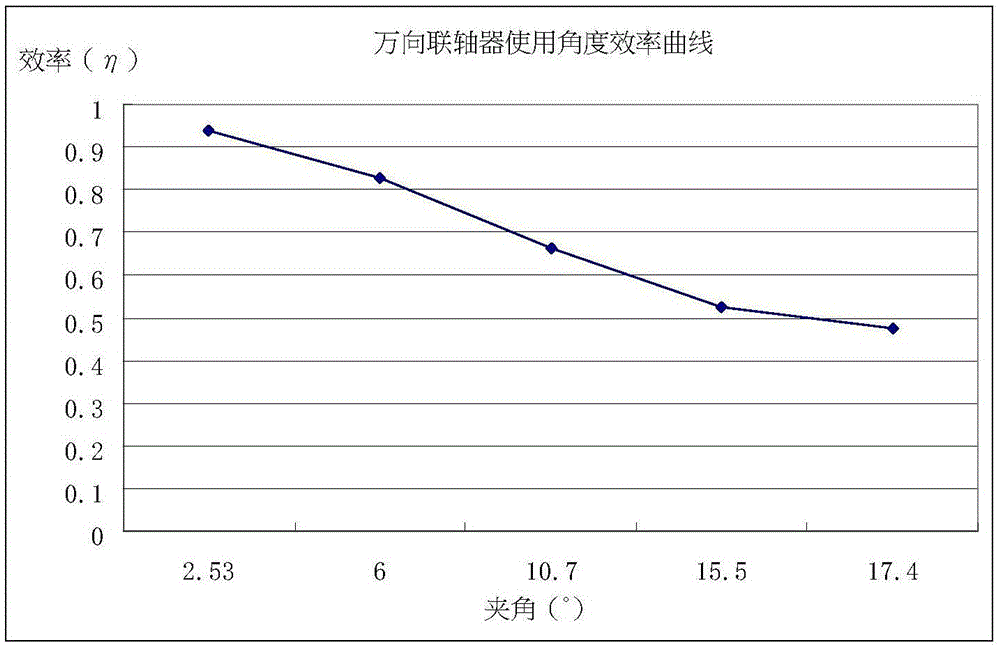

[0027] Step 2, the flap rotates to a maximum set angle (usually prescribed), the lead screw 31 drives the driven shaft of the universal joint 2 to follow the flap to rotate the above maximum set angle, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com