Suspension support for improving collision performance, power assembly structure and automobile

A powertrain and suspension bracket technology, which is applied in the suspension bracket, powertrain structure and automotive fields, can solve the problems of powertrain squeezed passenger cabin deformation, occupant collision damage in the car, etc., to improve collision performance, The effect of reducing the degree of injury and reducing the pressure of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

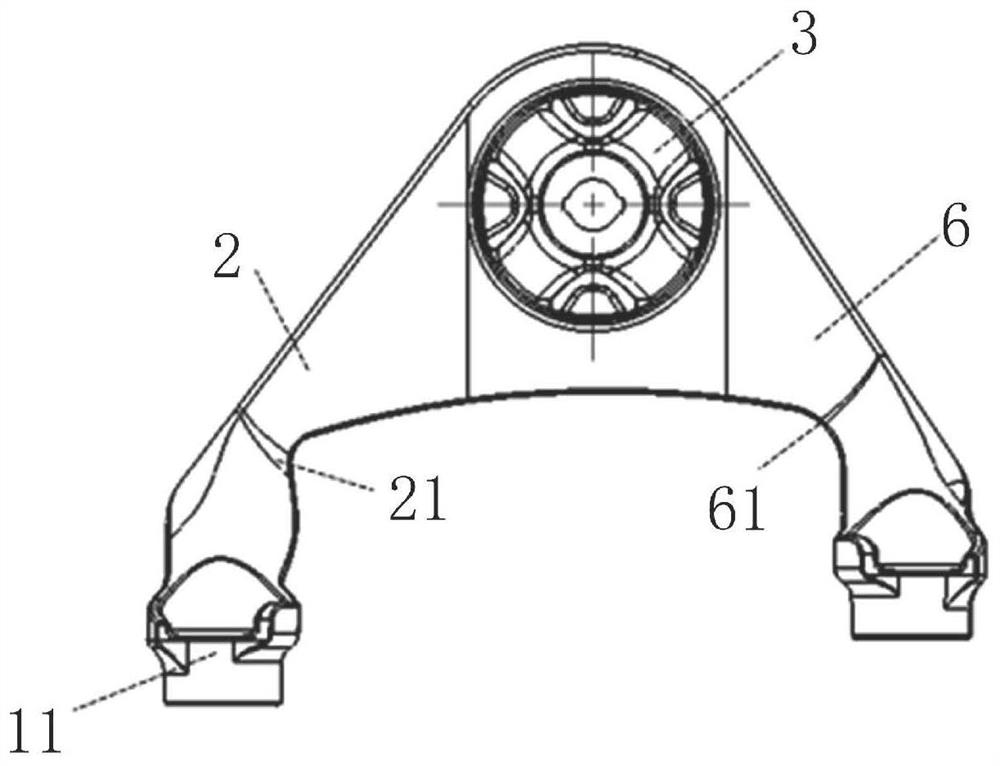

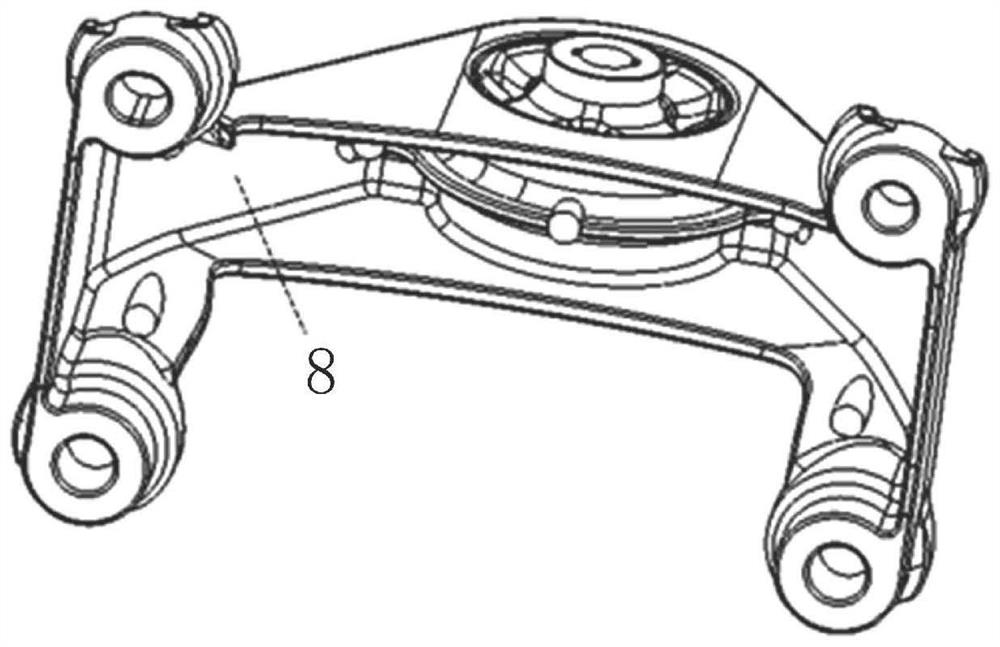

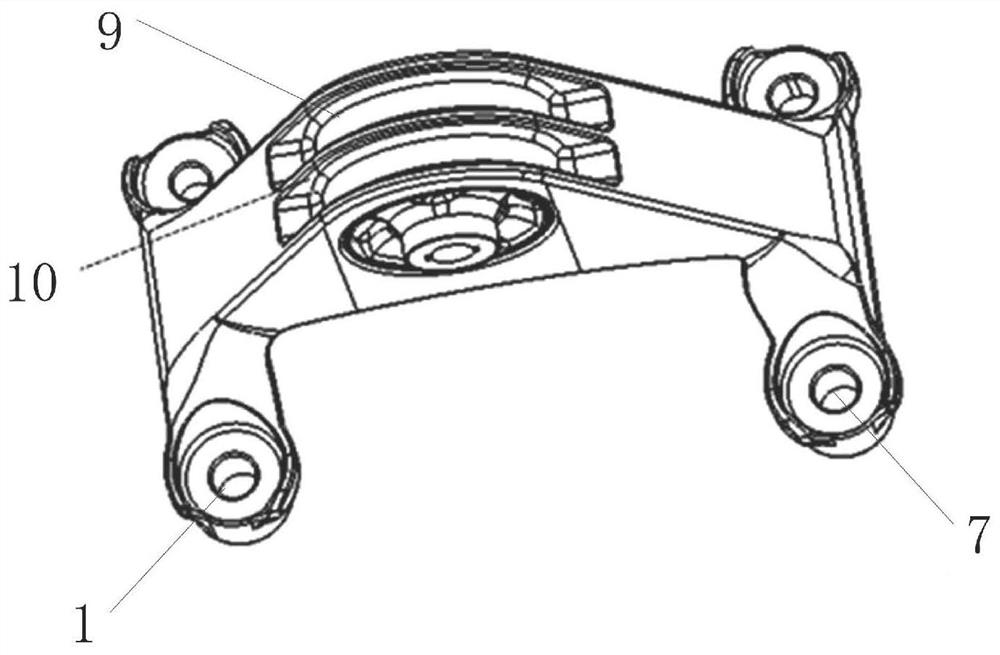

[0035] like Figure 1-5 As shown, a suspension bracket for improving crash performance includes: a first sub-frame mounting portion 1, a suspension front arm 2 and a powertrain mounting portion 3, the suspension forearm 2 is fixedly connected to the first sub-frame Between the mounting portion 1 and the powertrain mounting portion 3, the first subframe mounting portion 1 is used to be fixedly connected to the subframe 4 of the automobile, and the powertrain mounting portion 3 is used to be fixed with the powertrain 5 of the automobile Connected, the suspension bracket is arranged to break at the suspension front arm 2 when the powertrain 5 of the car is squeezed on the suspension front arm 2 . Generally, when a car collides, the power assembly 5 is squeezed on the suspension front arm 2 due to the transmission of the force generated by the collision to the power assembly 5 in the car.

[0036]It should be noted that, in the structure of the automobile in the prior art, the su...

Embodiment 2

[0047] like Figure 4-5 As shown, a powertrain structure includes a powertrain 5, a subframe 4 and a suspension bracket for improving crash performance in Embodiment 1. The suspension bracket is fixedly installed on the subframe 4, and the powertrain The component 5 is fixedly connected to the suspension bracket through the powertrain mounting part 3 . The suspension bracket in Embodiment 1 is used in the powertrain structure, so that the suspension bracket of the powertrain structure is broken when the front part of the vehicle collides, and the Z-direction collision and sinking of the powertrain 5 are induced, which effectively solves the problem. The common problem of excessive deformation of the front wall structure of the body due to the impact of the powertrain 5 reduces the degree of injury to the occupants.

Embodiment 3

[0049] An automobile, including the powertrain structure in Embodiment 2, effectively improves the crash performance of the automobile in a frontal collision, increases the living space in the passenger compartment, and provides a very effective frontal collision for many models developed in the later stage. development strategy.

[0050] As mentioned above, the present invention has the following beneficial effects:

[0051] 1) By designing the suspension bracket into a collision fracture structure, the suspension bracket is broken when the car collides, which improves the collision performance of the car, reduces the collision of the car's powertrain and squeezes the front wall structure of the body, and ensures the passenger compartment. The living space inside the vehicle solves the problem in the prior art that when the vehicle collides, the powertrain of the vehicle squeezes the occupant compartment and severely deforms, causing serious collision damage to the occupants ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com