Automobile frame

An automobile frame and longitudinal beam technology, applied in the field of vehicles, can solve the problems of frame and cockpit deformation, reduce vehicle safety, damage to parts, etc., achieve high structural rigidity, improve bending resistance, and improve crash performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0059] The present invention will be described in detail below with reference to the accompanying drawings and examples.

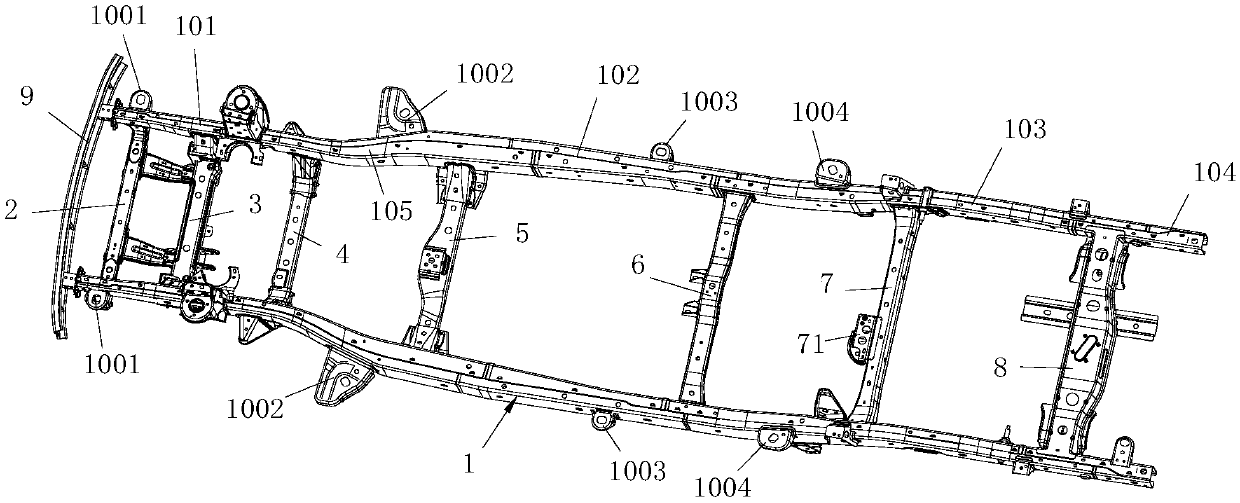

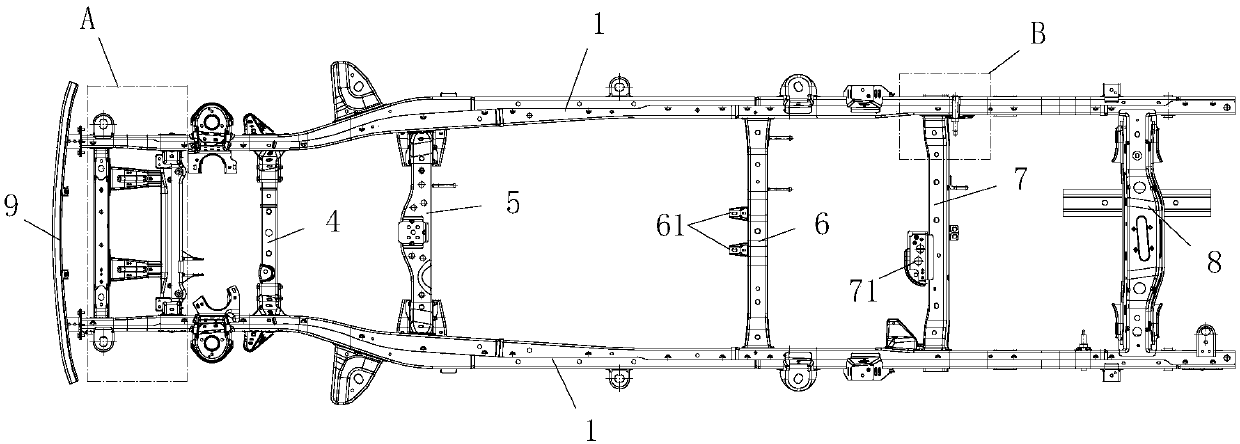

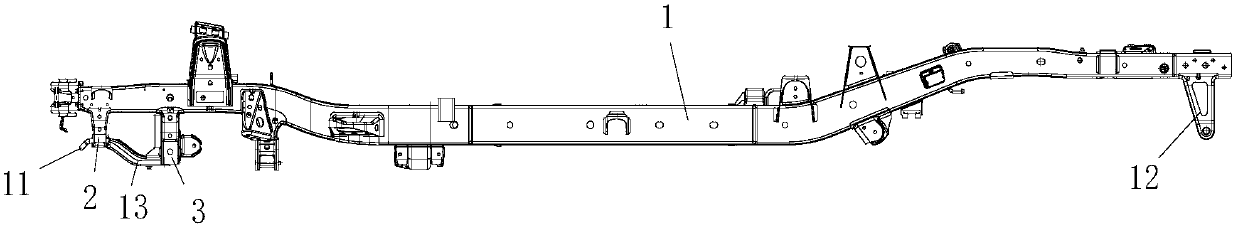

[0060] This embodiment relates to an automobile frame, the overall structure of the automobile frame includes two longitudinal beams, a plurality of cross beams connected between the two longitudinal beams, and spaced sequentially along the direction from the front end to the rear end of the longitudinal beams, and The front anti-collision beam connected between the front ends of the two longitudinal beams, and the spare tire beam connected between the longitudinal beams on both sides close to the tail end of the longitudinal beams, also includes the front transition section arranged in each longitudinal beam, And it is a front transition section reinforcing plate extending along the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com