Modified polypropylene soft bottle material, as well as preparation method and applications thereof

A polypropylene and soft bottle technology, applied in the field of polypropylene soft bottle materials and its preparation, can solve the problems of harsh production process conditions, low impact strength, secondary pollution, etc., and achieve excellent drop resistance and collision performance, High impact strength, saving processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

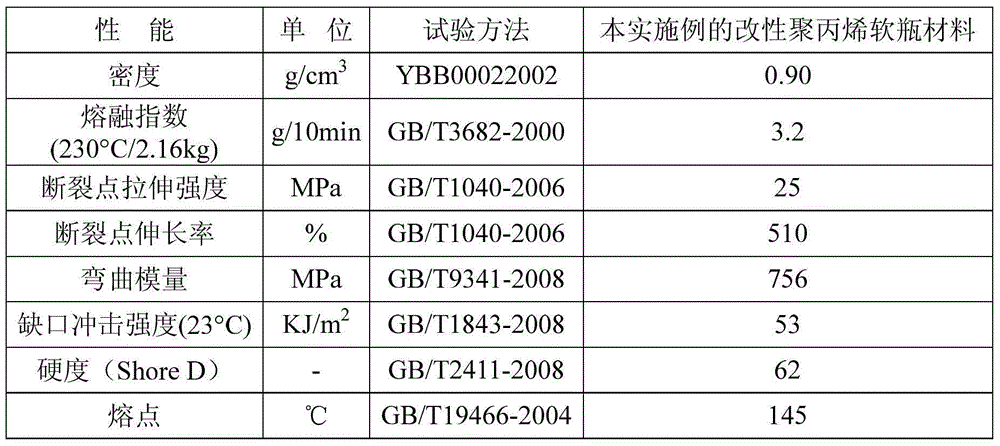

Embodiment 1

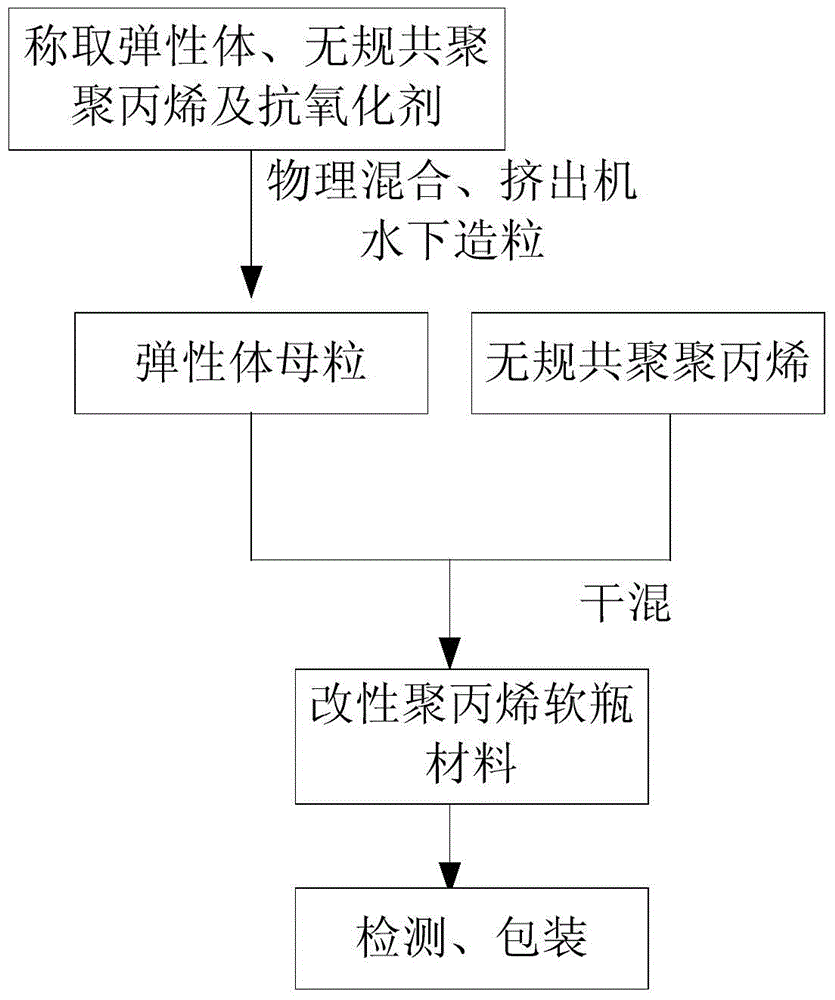

[0031] This embodiment provides a kind of preparation method of modified polypropylene soft bottle material, and this method comprises the following steps, and its flow process is as follows figure 1 Shown:

[0032] (1) 50% by weight of ethylene-propylene-based propylene-based thermoplastic elastomer (in this ethylene-propylene-based propylene-based thermoplastic elastomer, the weight percentage of ethylene is 5%, the weight percentage of propylene is 95%, and the density is 0.878 g / cm 3; Under the test conditions of 230°C and 2.16kg, the melt flow rate is 10g / 10min; the glass transition temperature is -25°C) and 50% by weight of random copolymerized polypropylene (the random copolymerized polypropylene is Copolymerization product of 7wt% ethylene and 93wt% propylene; under the test conditions of 230°C and 2.16kg, its melt flow rate is 3.0g / 10min; melting point is 140°C; notched impact strength is 10KJ / m 2 ) and 0.08% phenolic antioxidant (2,6-tert-butyl-4-methylphenol) and ...

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of modified polypropylene soft bottle material, and this method comprises the following steps:

[0039] (1) The weight percentage is 65% styrene-based thermoplastic elastomer (the styrene-based thermoplastic elastomer is a styrene-ethylene / butylene-styrene block copolymer, and the weight percentage of styrene≤40%; At 25°C, its viscosity in 20% toluene solution is 500-2000MPa·s) and 35% by weight of random copolymerized polypropylene (the random copolymerized polypropylene is 7wt% of ethylene and 93wt% of propylene) Copolymerization product; under the test conditions of 230°C and 2.16kg, its melt flow rate is 3.0g / 10min; melting point is 140°C; notched impact strength is 10KJ / m 2 ) and 0.08% phenolic antioxidant (bis(3,5-tert-butyl-4-hydroxyphenyl) sulfide) and 0.05% phosphite antioxidant (bis (2,4-di-tert-butylphenyl) pentaerythritol diphosphite) is physically mixed in a high-speed mixer, and then pelletized ...

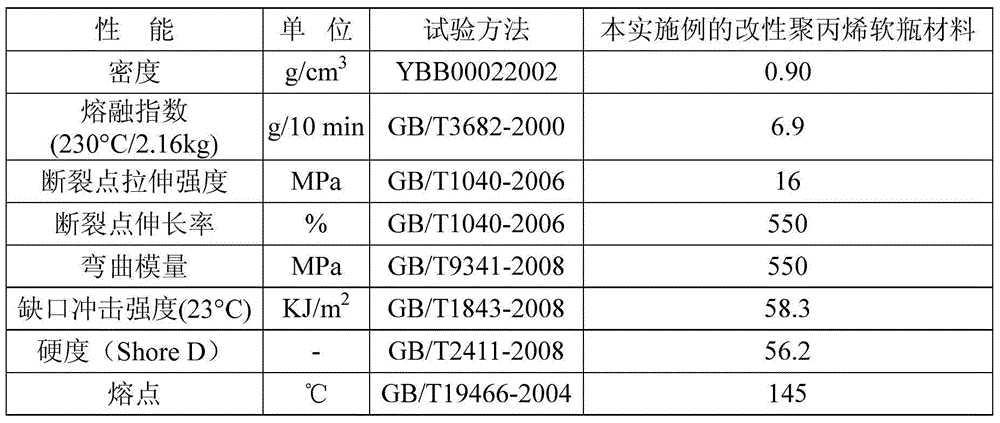

Embodiment 3

[0046] The present embodiment provides a kind of preparation method of modified polypropylene soft bottle material, and this method comprises the following steps:

[0047] (1) 80% styrene-based thermoplastic elastomer (the styrene-based thermoplastic elastomer is a styrene-ethylene / butylene-styrene block copolymer with a weight percentage of styrene≤40%; At 25°C, its viscosity in 20% toluene solution is 500-2000MPa·s) and 20% by weight of random copolymerized polypropylene (the random copolymerized polypropylene is 5wt% of ethylene and 95wt% of propylene) Copolymerization product; under the test conditions of 230°C and 2.16kg, its melt flow rate is 8.0g / 10min; melting point is 148°C; notched impact strength is 7KJ / m 2 ) and 0.08% phenolic antioxidant (tetrakis (β-(3,5-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester) and 0.05% phosphorous acid The ester antioxidant (tris(2,4-di-tert-butylphenyl) phosphite) is physically mixed in a high-speed mixer, and then pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com